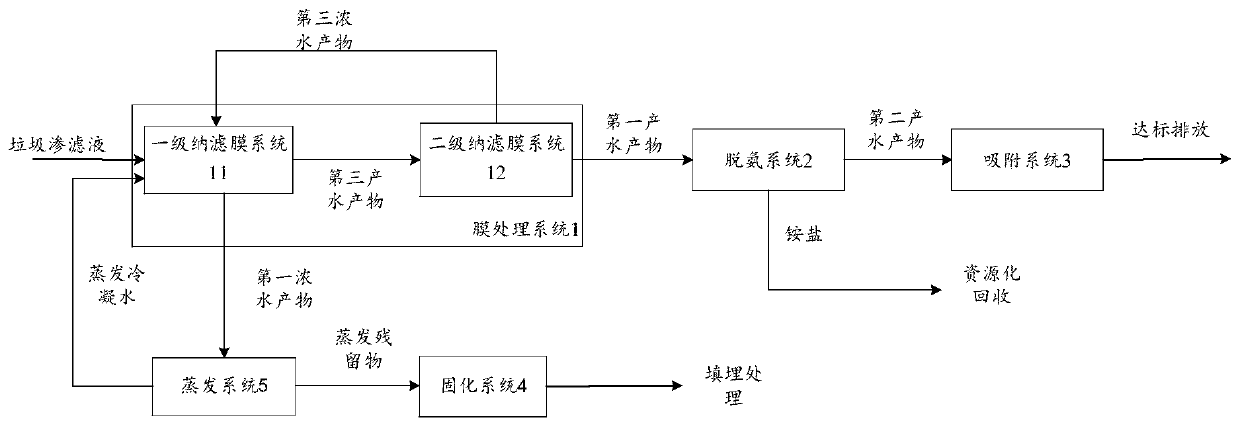

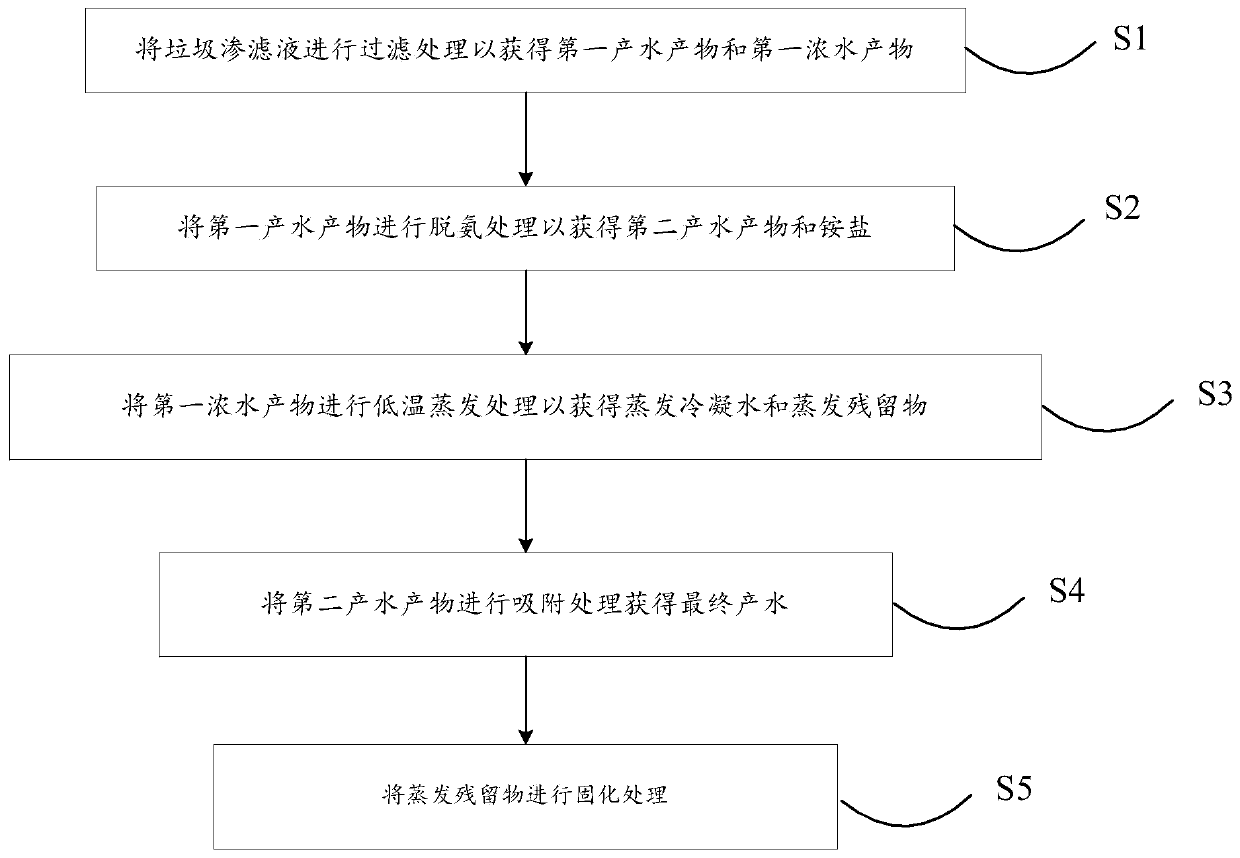

Landfill leachate zero-emission treatment device and method

A landfill leachate and treatment device technology, applied in the direction of contaminated groundwater/leachate treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as inability to achieve zero discharge, difficulty in recycling, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The landfill leachate was taken for the above test. The ammonia nitrogen content of the leachate stock solution was 2881mg / L, the COD content was 11500mg / L, and the total hardness was 1312mg / L. Among them, the first-level nanofiltration membrane system chooses the disc-tube nanofiltration membrane module (the first-level DTNF membrane system), and the second-level nanofiltration membrane system chooses the disc-type nanofiltration membrane module (the second-level DTNF membrane system). The ammonia nitrogen content of the third water product produced after the first-stage DTNF membrane system treatment is 2500mg / L, the COD content is 1100mg / L, and the total hardness is 260mg / L. It can be seen that the ammonia nitrogen content in the third product water product treated by the first-stage DTNF membrane system did not decrease too much, but the COD content and total hardness decreased significantly, the COD content decreased by 90%, and the total hardness decreased by 80%. ...

Embodiment 2

[0063] The landfill leachate was taken for the above test. The ammonia nitrogen content of the leachate stock solution was 2881mg / L, the COD content was 11500mg / L, and the total hardness was 1312mg / L. Among them, the first-level nanofiltration membrane system chooses the disc-tubular nanofiltration membrane module (DTNF membrane system), and the second-level nanofiltration membrane system chooses the micro-tubular nanofiltration membrane module (MTNF membrane system). After being treated by DTNF membrane system, the ammonia nitrogen content of the third produced water product is 2500mg / L, the COD content is 1100mg / L, and the total hardness is 260mg / L. It can be seen that the ammonia nitrogen content in the third water product treated by the DTNF membrane system did not decrease too much, but the COD content and total hardness decreased significantly, the COD content decreased by 90%, and the total hardness decreased by 80%. The ammonia nitrogen content of the first water produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com