Patents

Literature

175results about How to "Reduce delivery volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

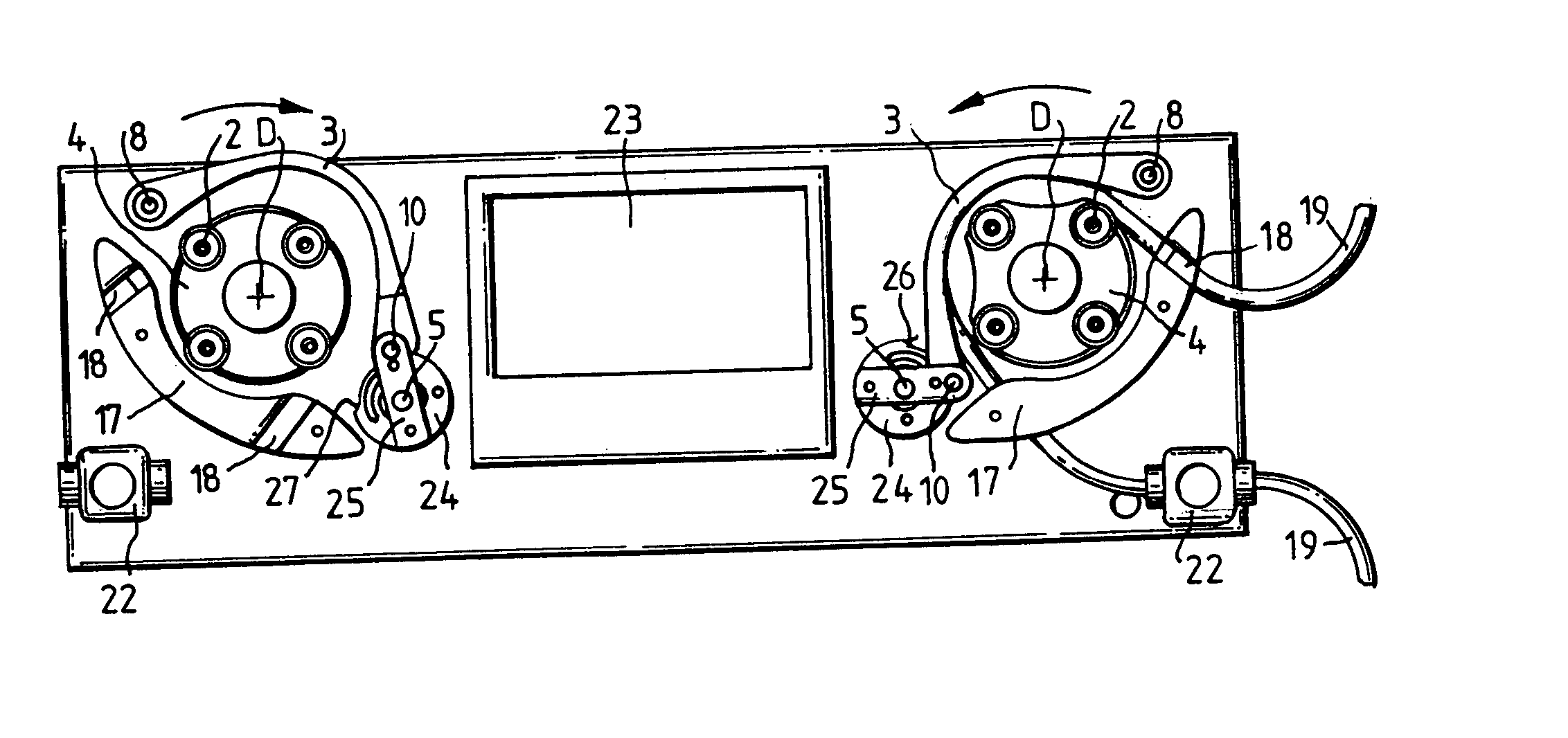

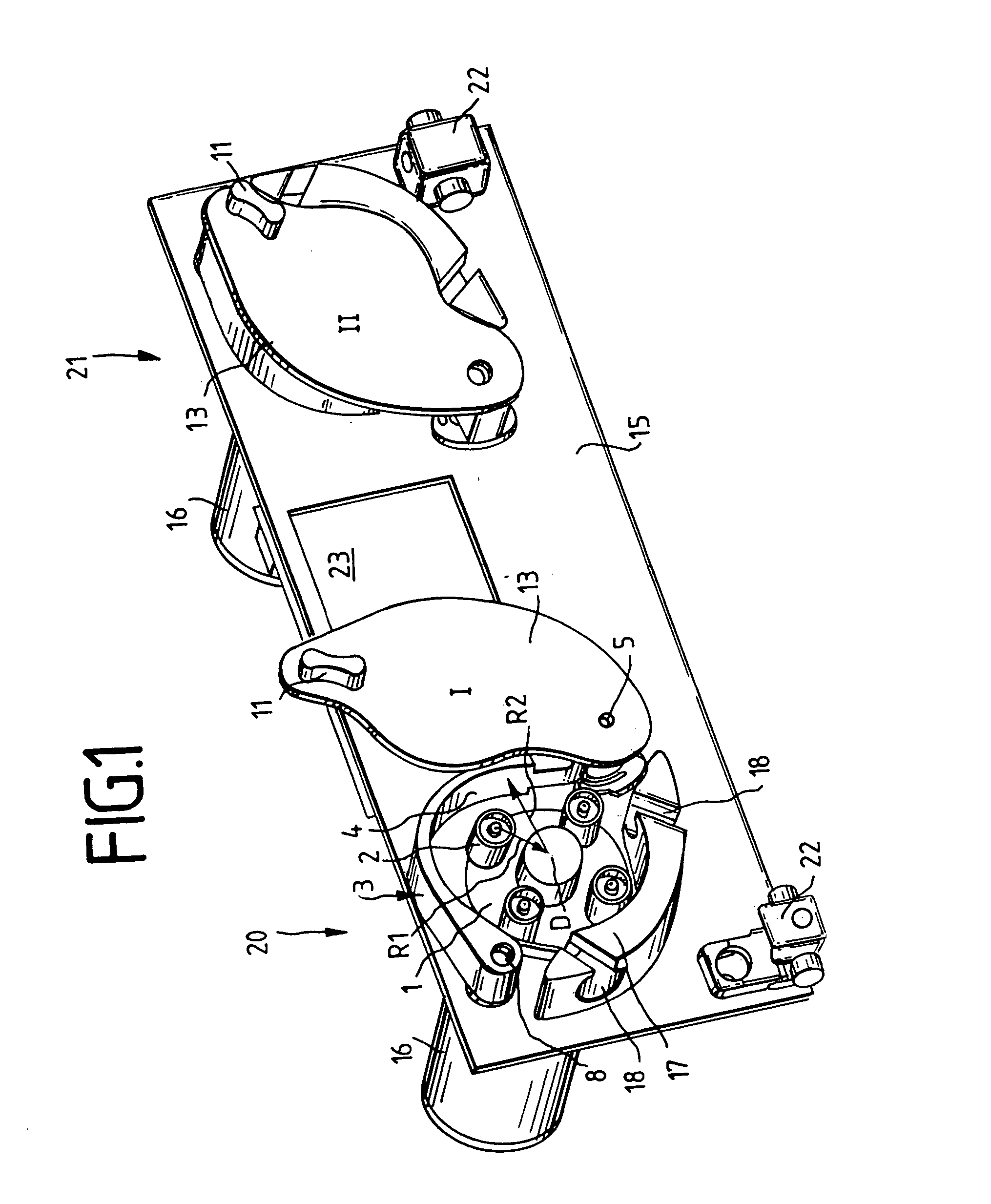

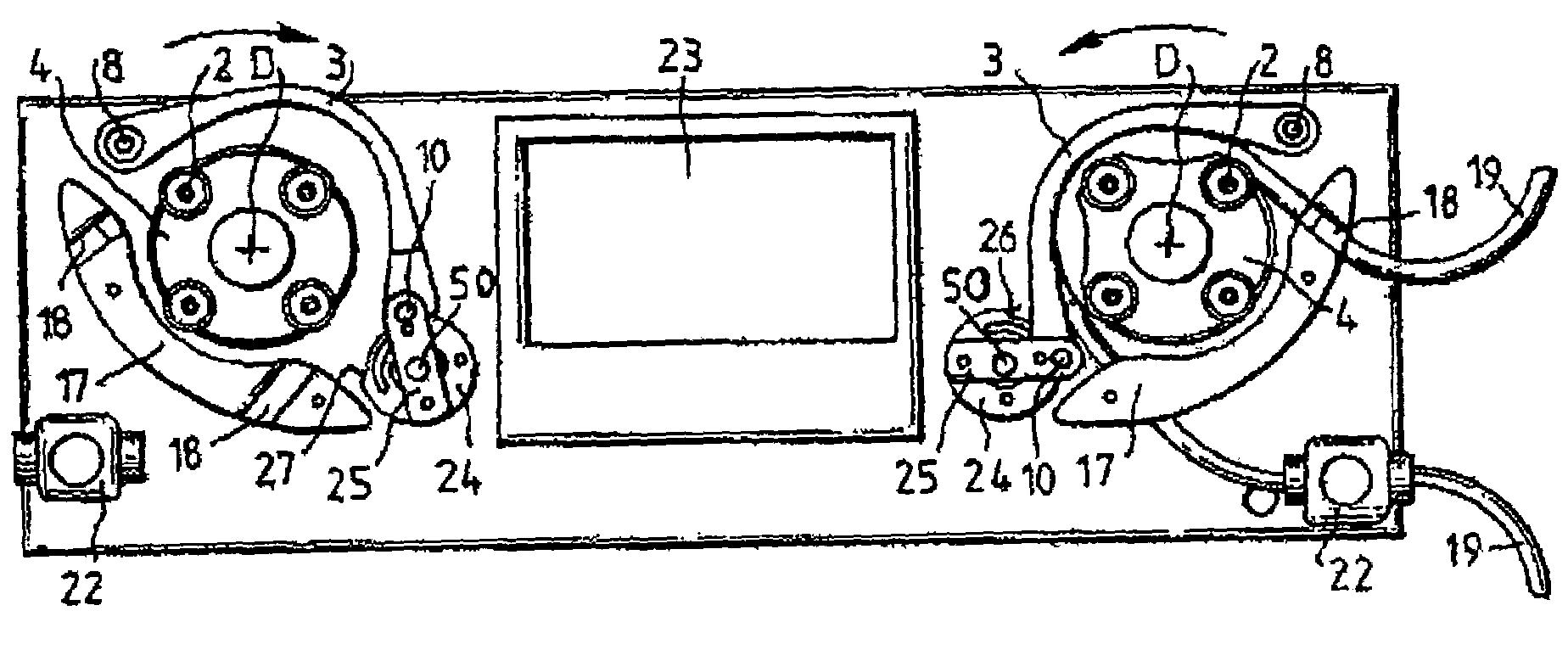

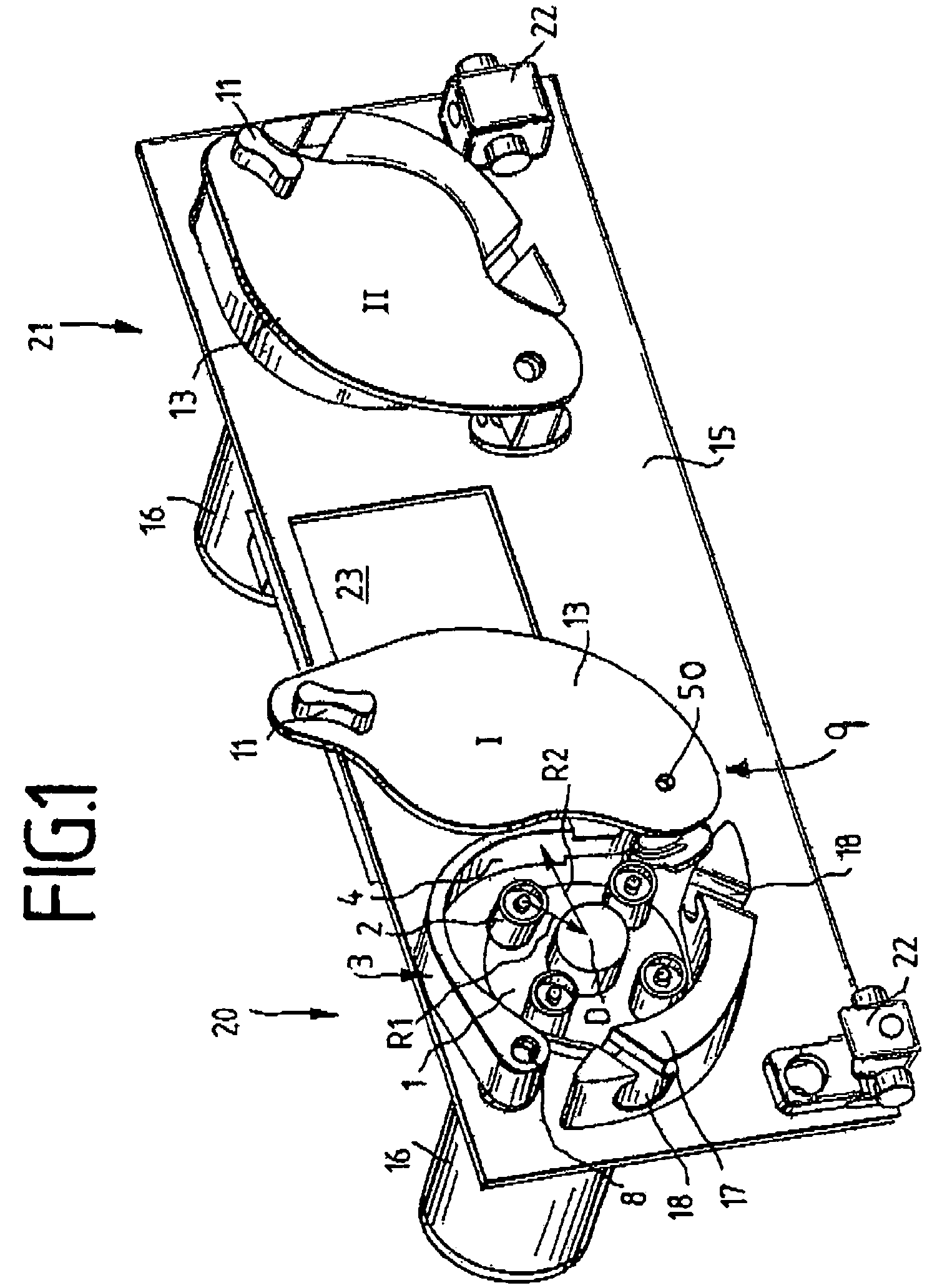

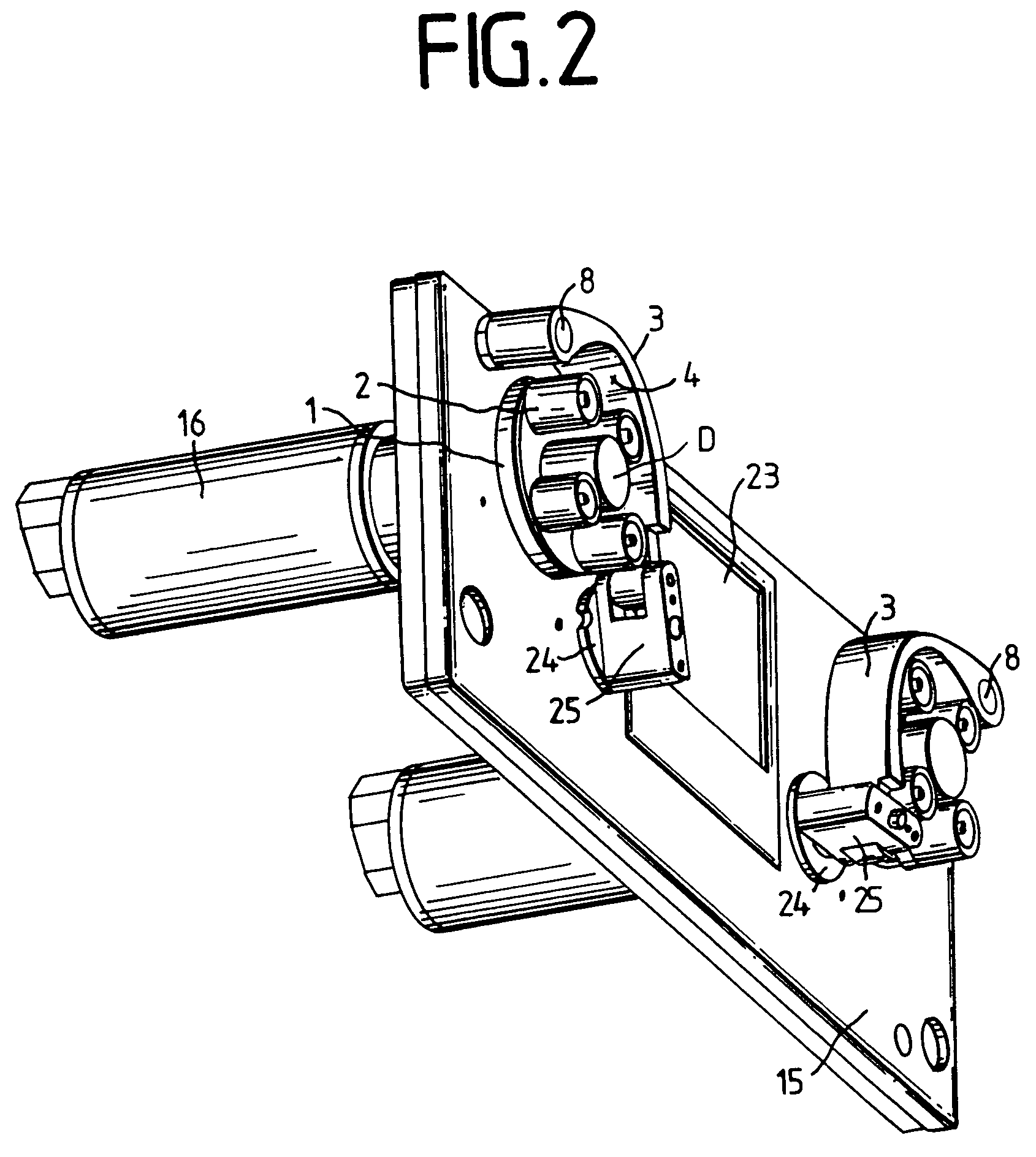

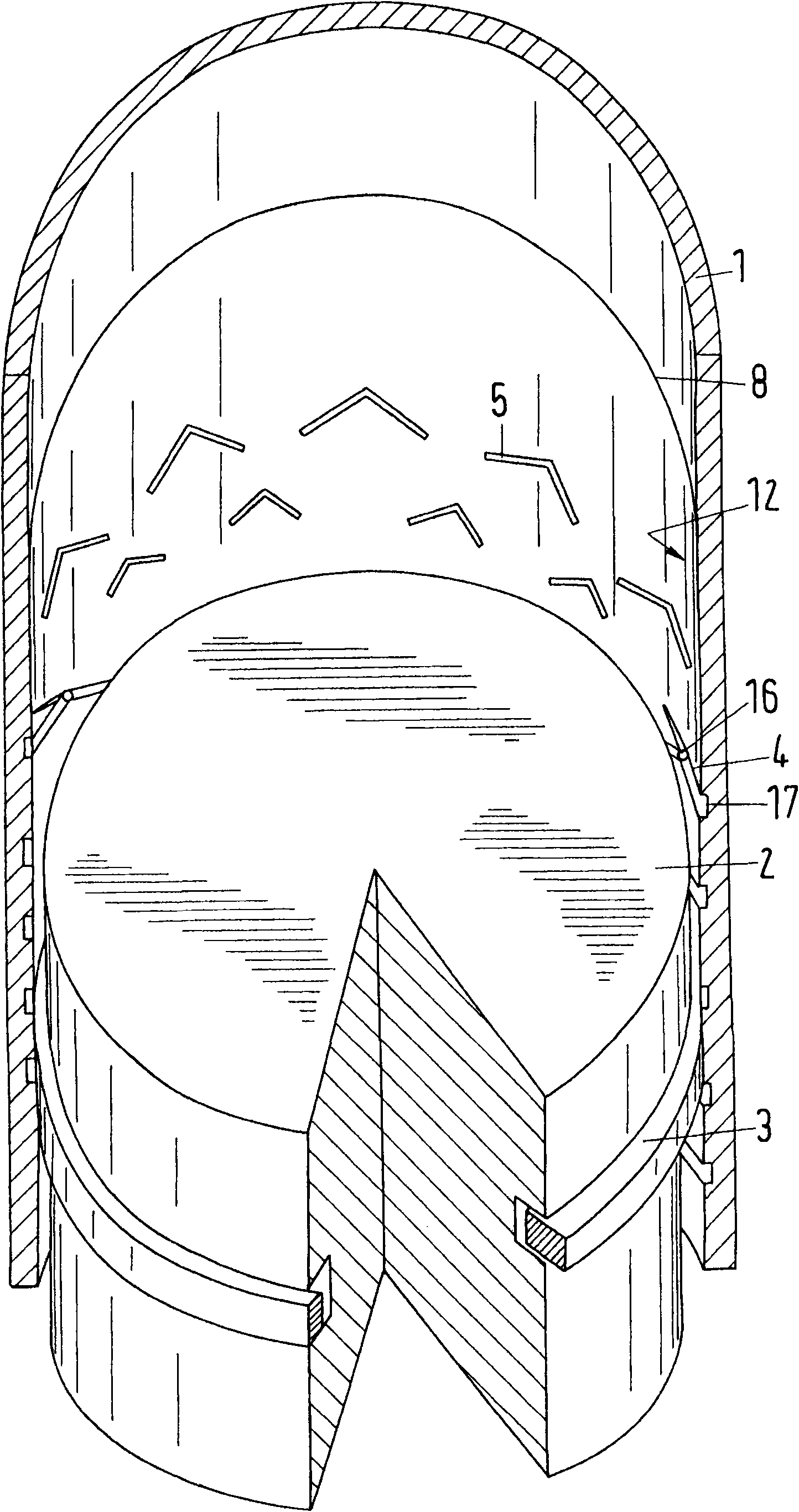

Peristaltic hose pump

InactiveUS20040037724A1Increase delivery pressureIncrease delivery rateFlexible member pumpsEngine componentsSynthetic materialsEngineering

The invention relates to a peristaltic hose pump comprising a roller wheel (1), which can rotate about a roller wheel axis D and which has rollers (2) that are mounted on the roller wheel (1). The rollers (2) roll away on a circular path having a radius R1 with regard to the roller wheel rotation axis D. The peristaltic hose pump also comprises a pressure arched element (3) with a supporting surface (4), whereby the supporting surface (4) extends along a circular path having a radius R2 around the rotation axis D of the roller wheel (1). In addition, a flexible hose (19) can be placed between the supporting surface (4) and the rollers (2) of the roller wheel (1). According to the invention, the supporting surface (4) is formed out of an elastically deformable synthetic material, and the pressure arched element (3) is pre-shaped with the provision that the extension of the supporting surface (4), when the pressure arched element (3) is not under tension, essentially corresponds to the extension of the supporting surface (4) when under tension.

Owner:W O M WORLD OF MEDICINE GMBH

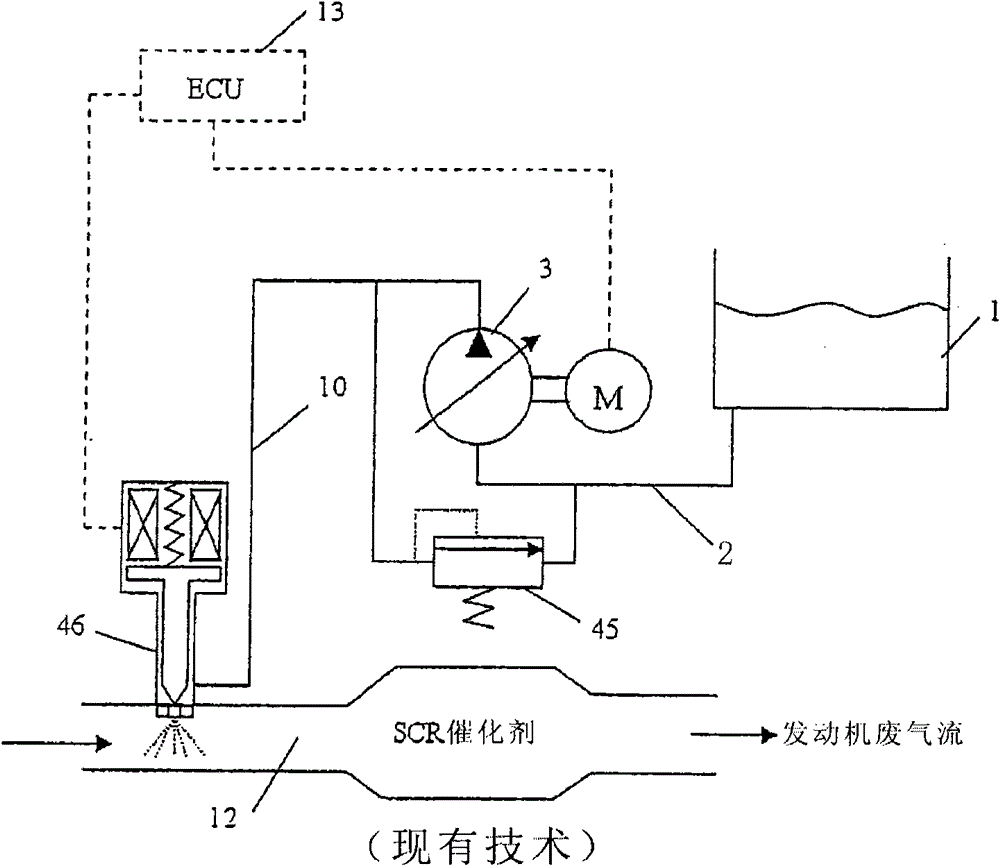

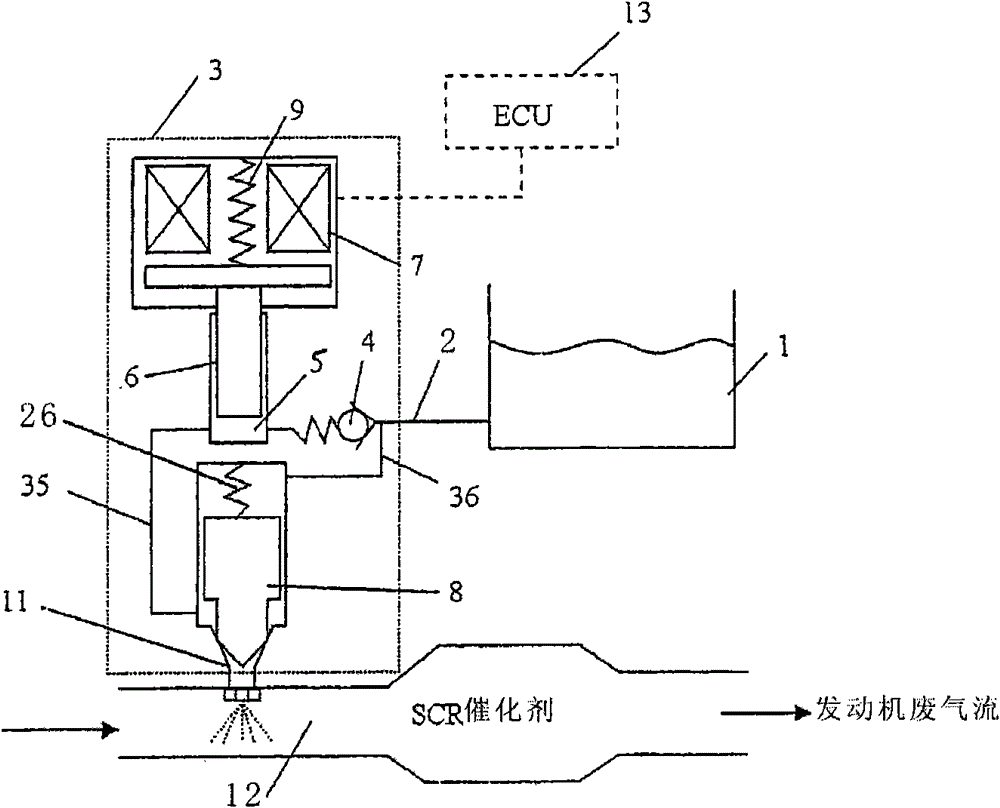

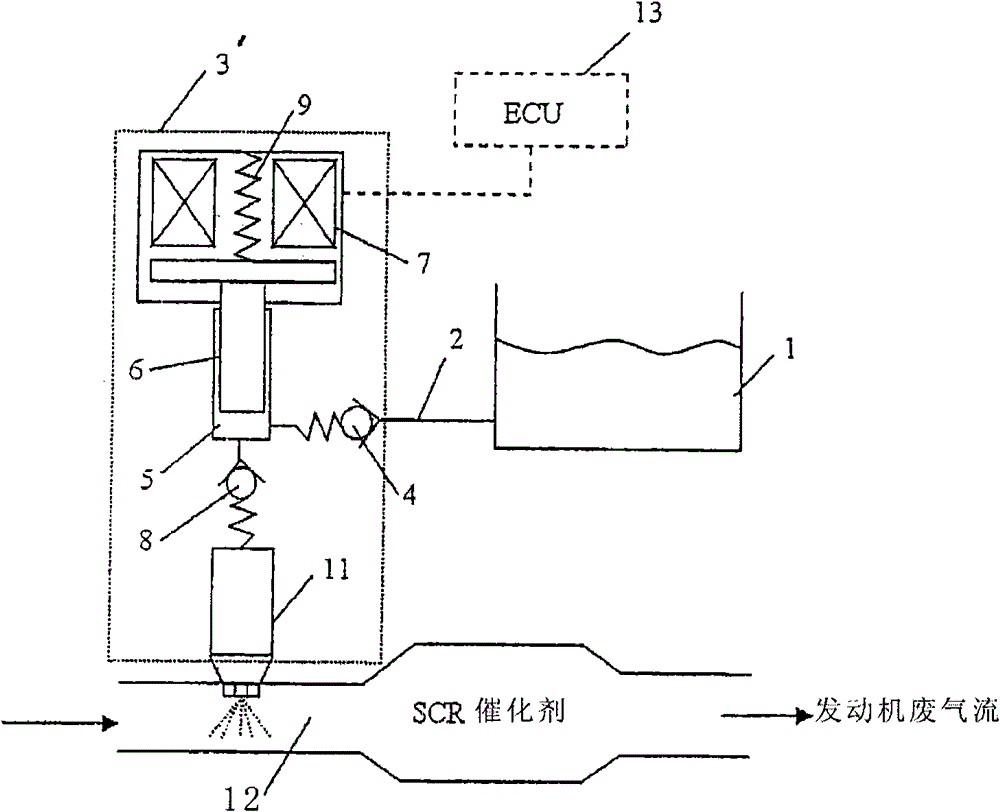

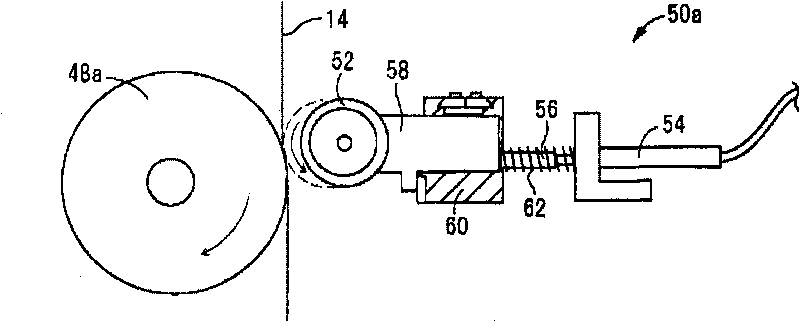

Integrated pump and injector for exhaust after treatment

InactiveCN102803671AReduce power consumptionMinimize power consumptionInternal combustion piston enginesExhaust apparatusAfter treatmentExhaust fumes

A urea solution injection system and an injector with which urea solution or other exhaust treatment liquid from a source tank can be injected as an atomized spray into an exhaust pipe. A metering pump with integrated injection nozzle are contained in a common housing mounted directly to the exhaust pipe, thereby eliminating the separate electric motor driven pump, line between pump, and injector in conventional systems.

Owner:斯塔纳迪恩公司

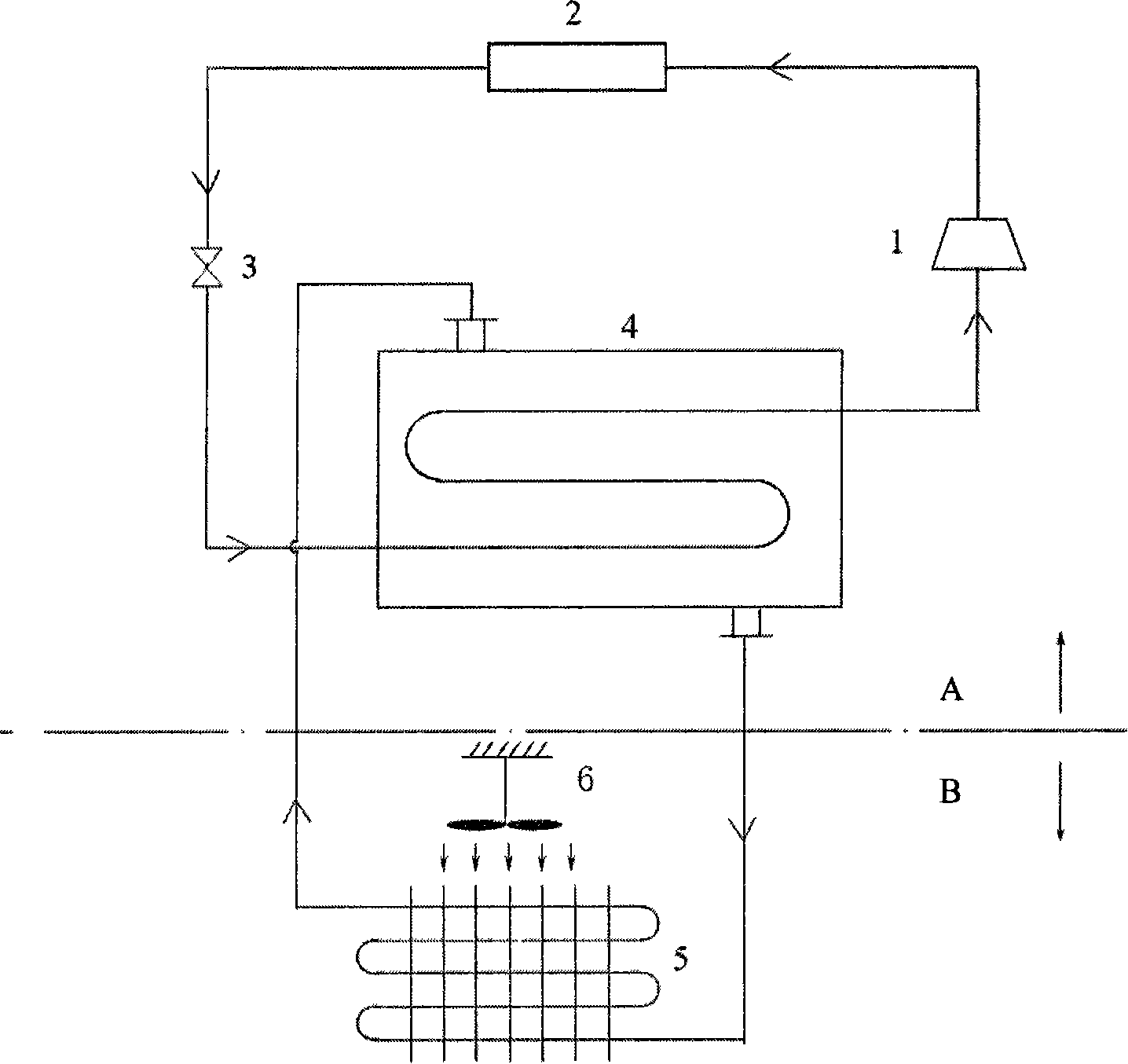

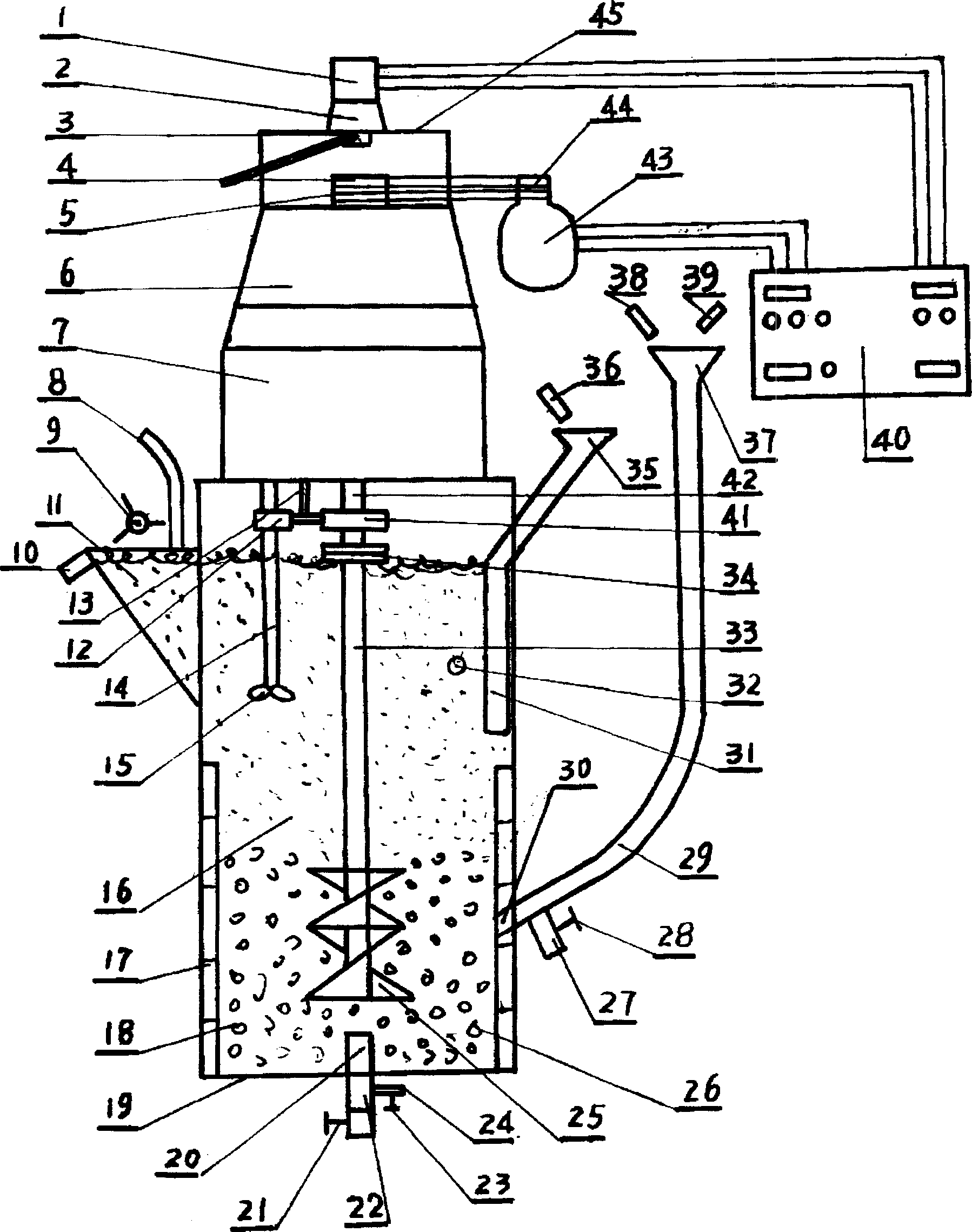

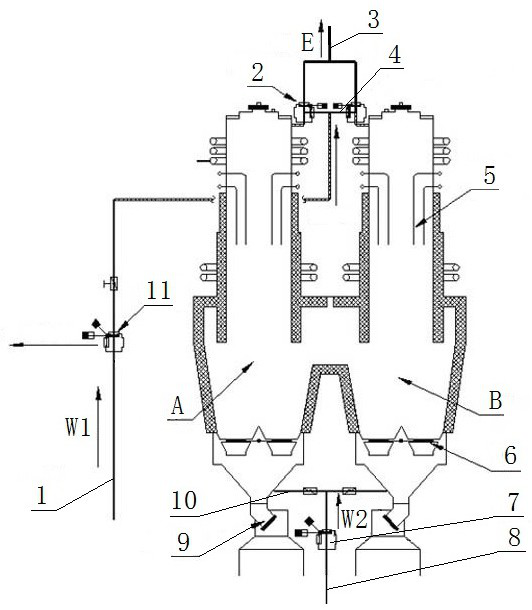

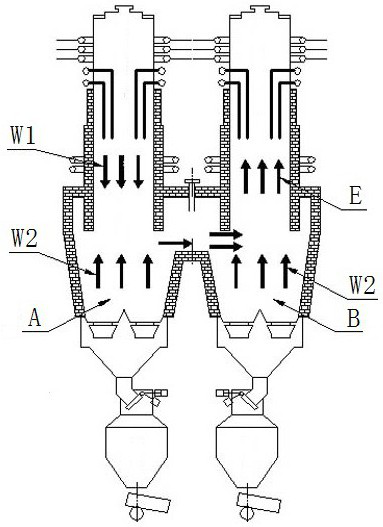

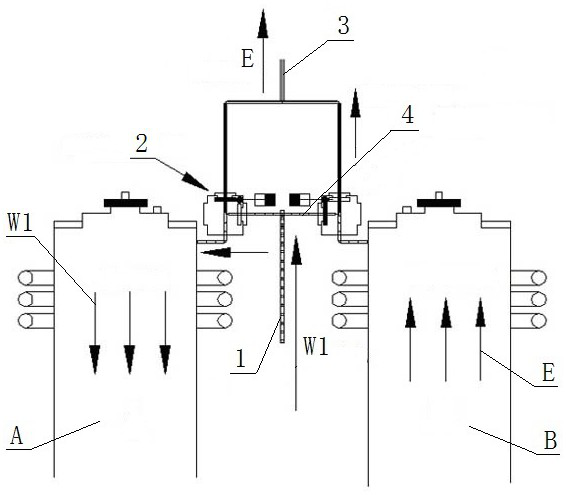

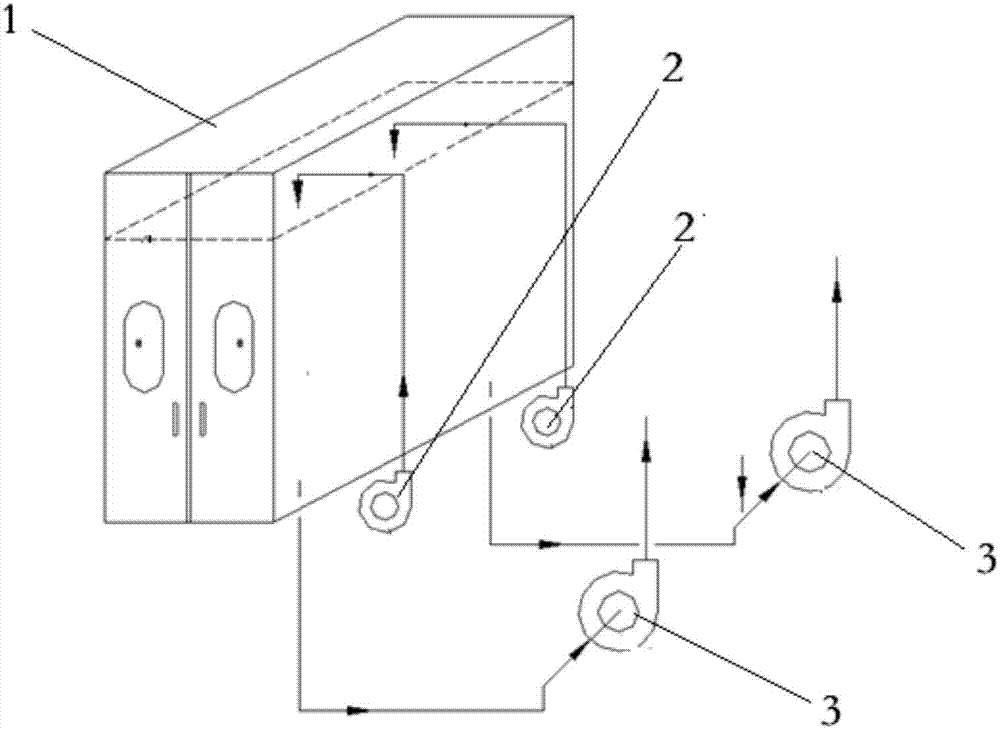

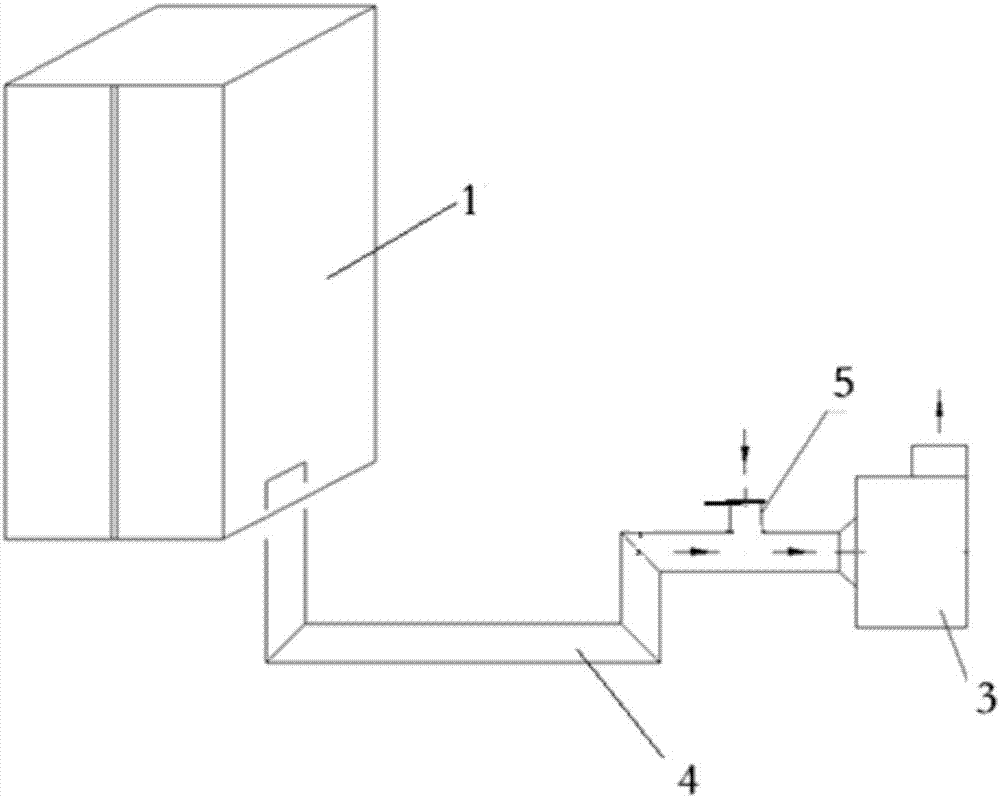

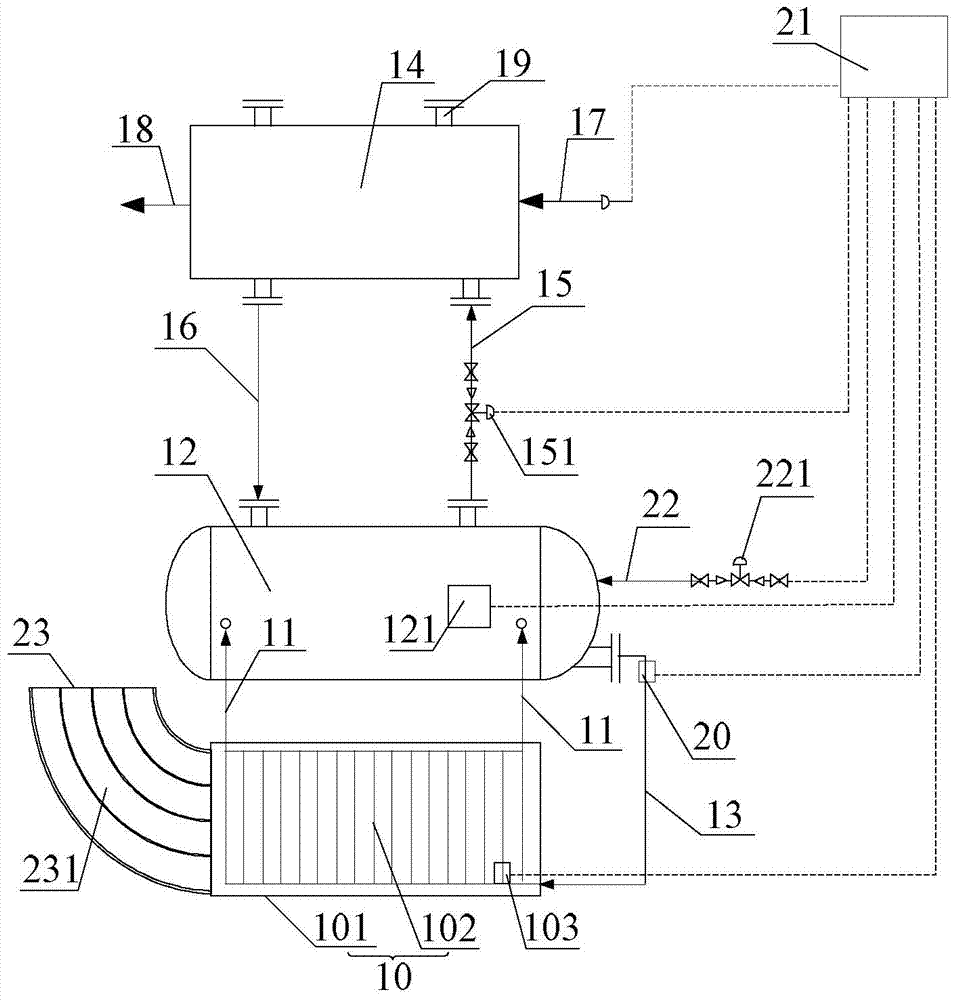

Temp lowering device for deep mine

InactiveCN101089366AEasy maintenance and managementReduce delivery volumeLighting and heating apparatusTunnel/mines ventillationEngineeringCirculating pump

The present invention discloses a deep exploitation wall temperature-dropping equipment. It includes ground machine unit A and underground machine unit B, and is characterized by that the ground machine unit A includes compressor, condenser, expansion valve and evaporative condenser, in which the inlet of compressor is connected with outlet of evaporative condenser, the outlet of compressor is connected with inlet of condenser, and the outlet of said condenser is connected with inlet of evaporative condenser by means of expansion valve. The underground machine unit B includes underground heat exchanger and air feeder, in which the bottom heat-exchanging working medium outlet of said evaporative condenser is connected with inlet of underground heat exchanger, and the outlet of underground heat exchanger is connected with top heat-exchanging working medium inlet of the evaporative condenser.

Owner:NANJING UNIV

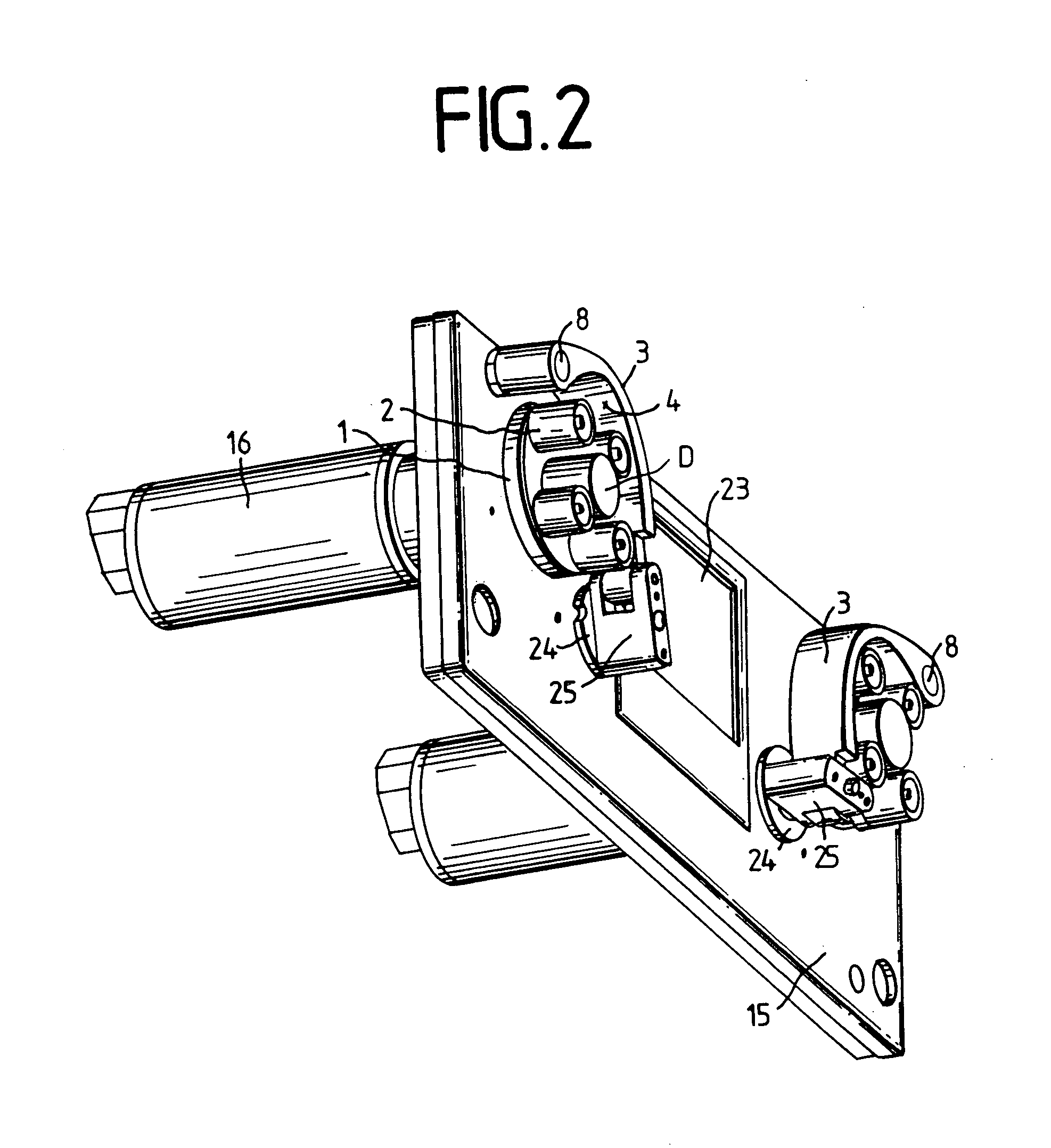

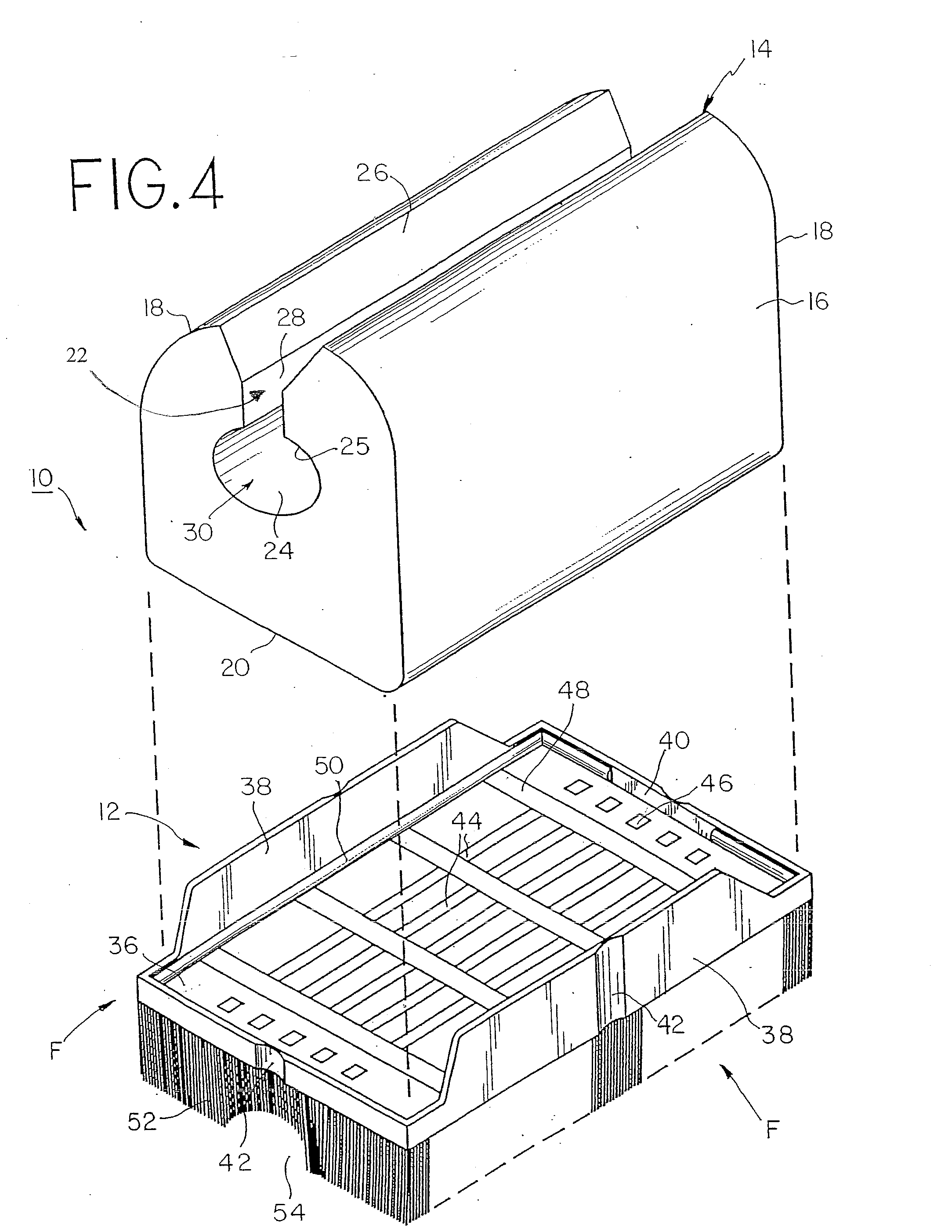

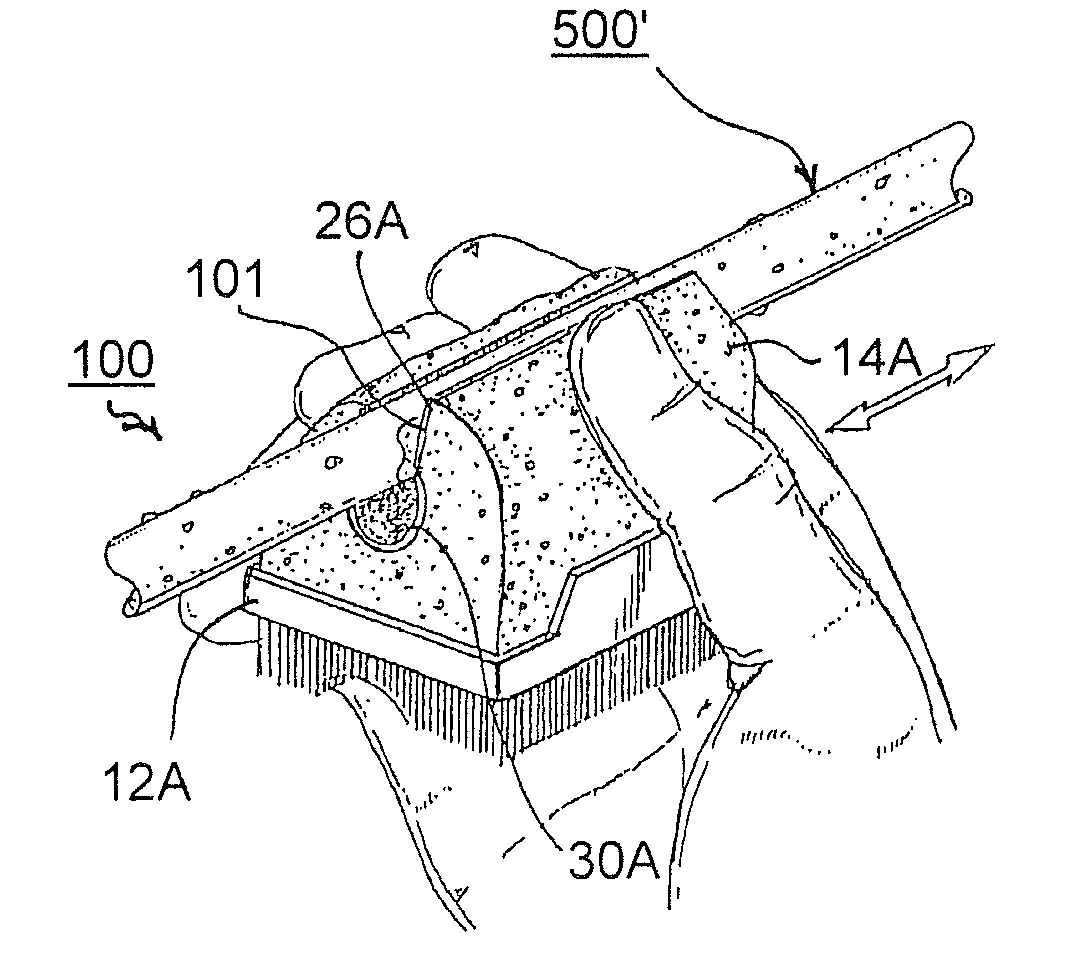

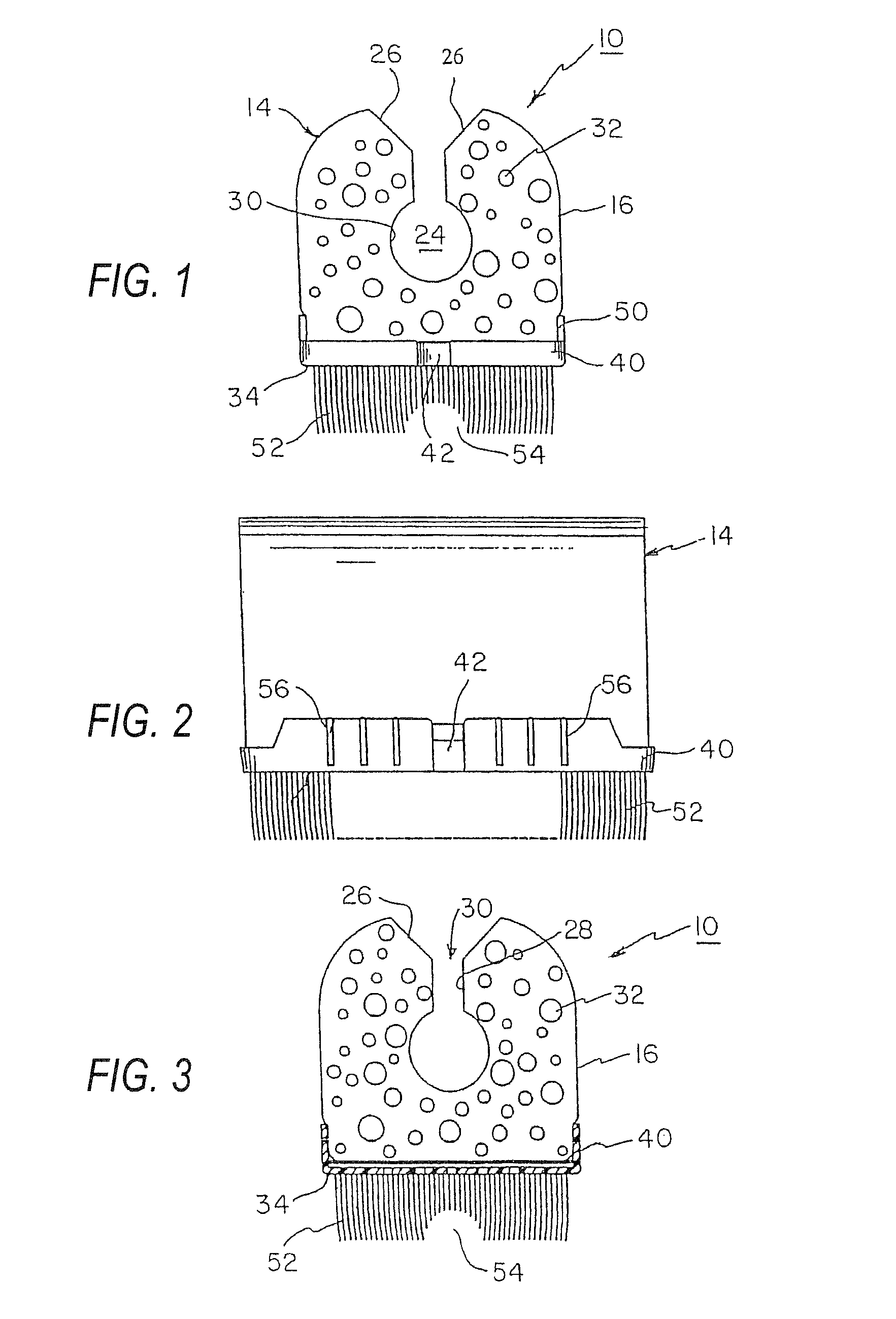

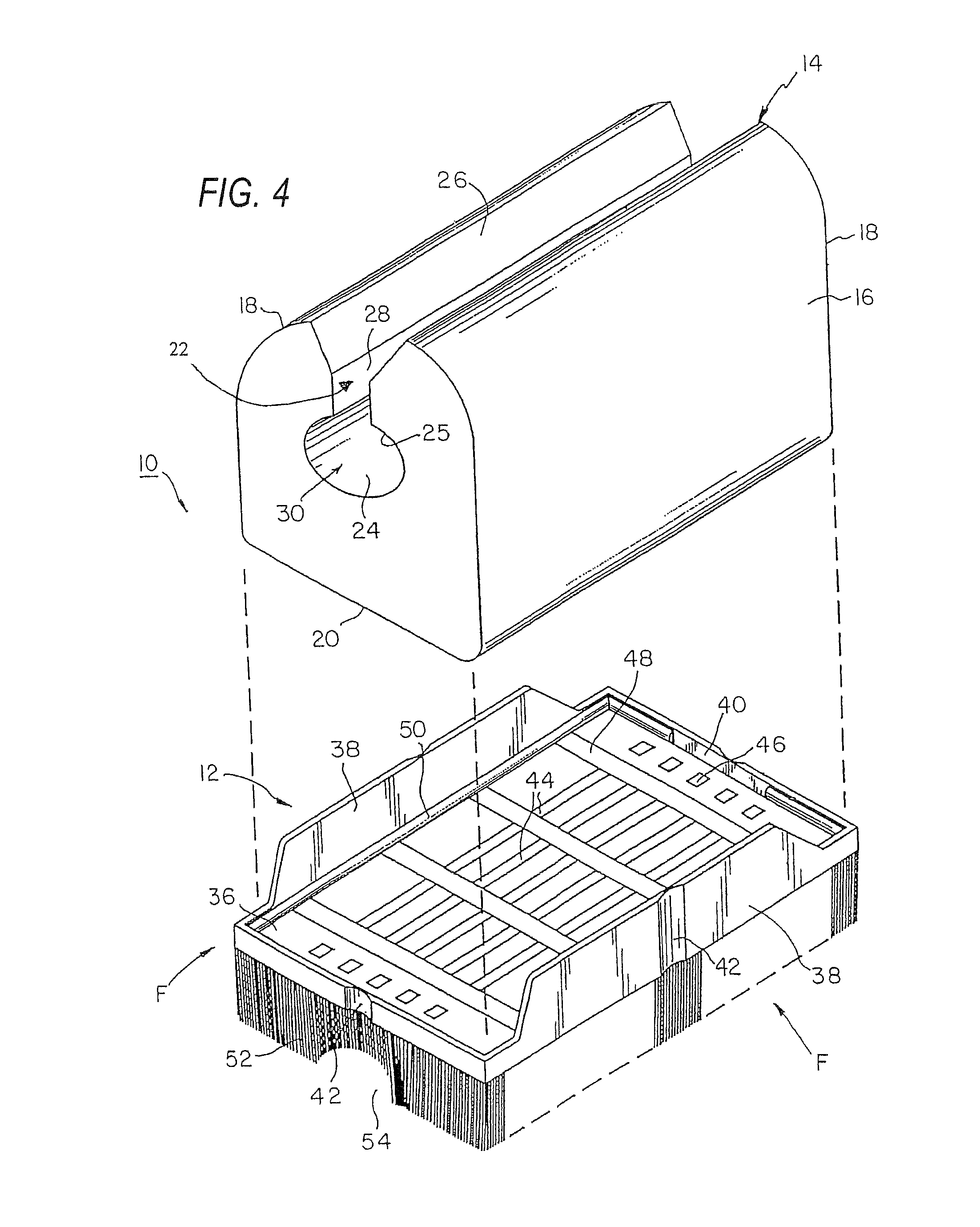

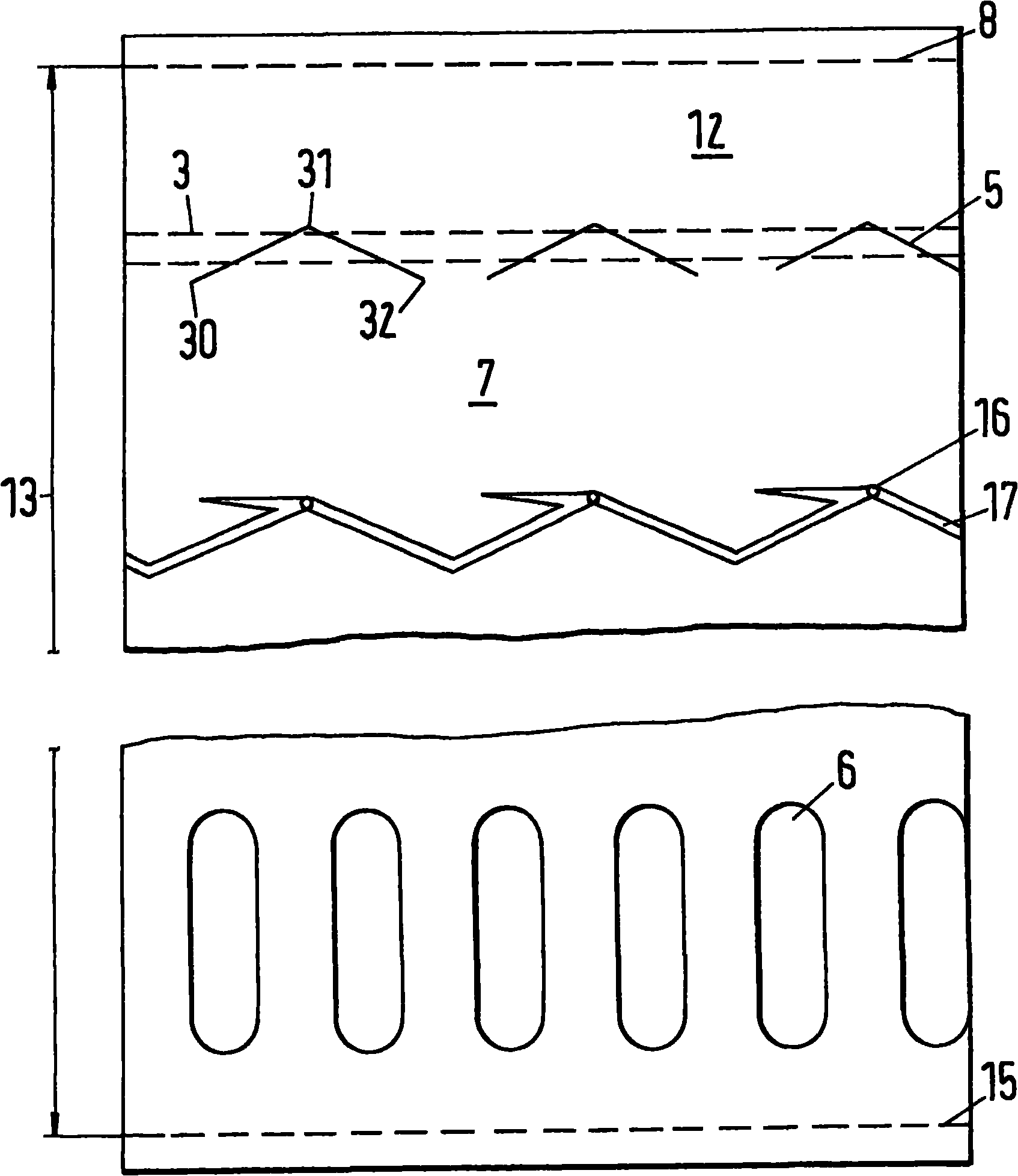

Peristalic pump having hinged backing plate

InactiveUS7287968B2Increase pressureDelivery rate is relatively smallFlexible member pumpsEngine componentsMechanical engineeringEngineering

A peristaltic hose pump comprising a roller wheel, which can rotate about a roller wheel axis and which has rollers that are mounted on the roller wheel. The rollers roll along a circular path having a certain radius with respect to the roller wheel axis. The peristaltic hose pump also comprises a pressure arched element with a supporting surface, whereby the supporting surface extends along a circular path having a certain radius around the rotation axis of the roller wheel. In addition, a flexible hose can be inserted between the supporting surface and the rollers of the roller wheel.

Owner:W O M WORLD OF MEDICINE GMBH

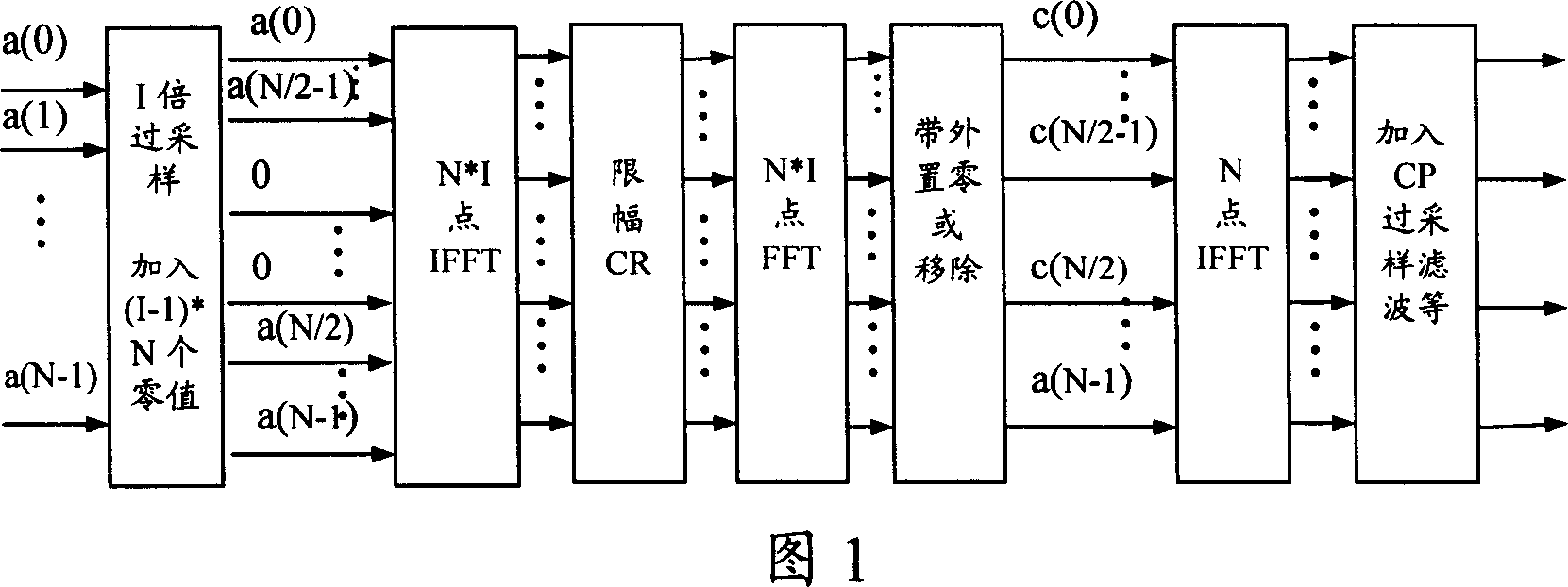

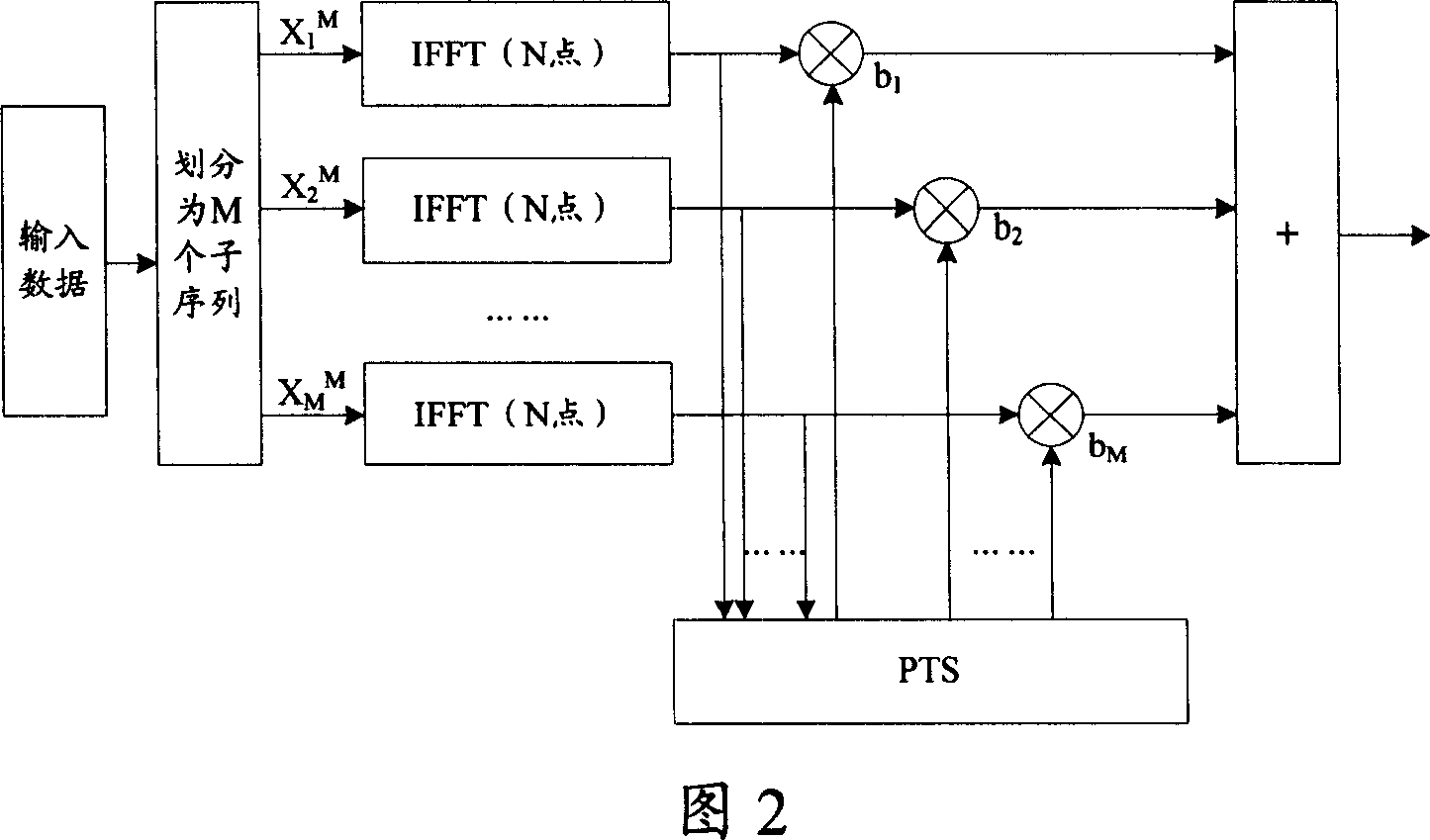

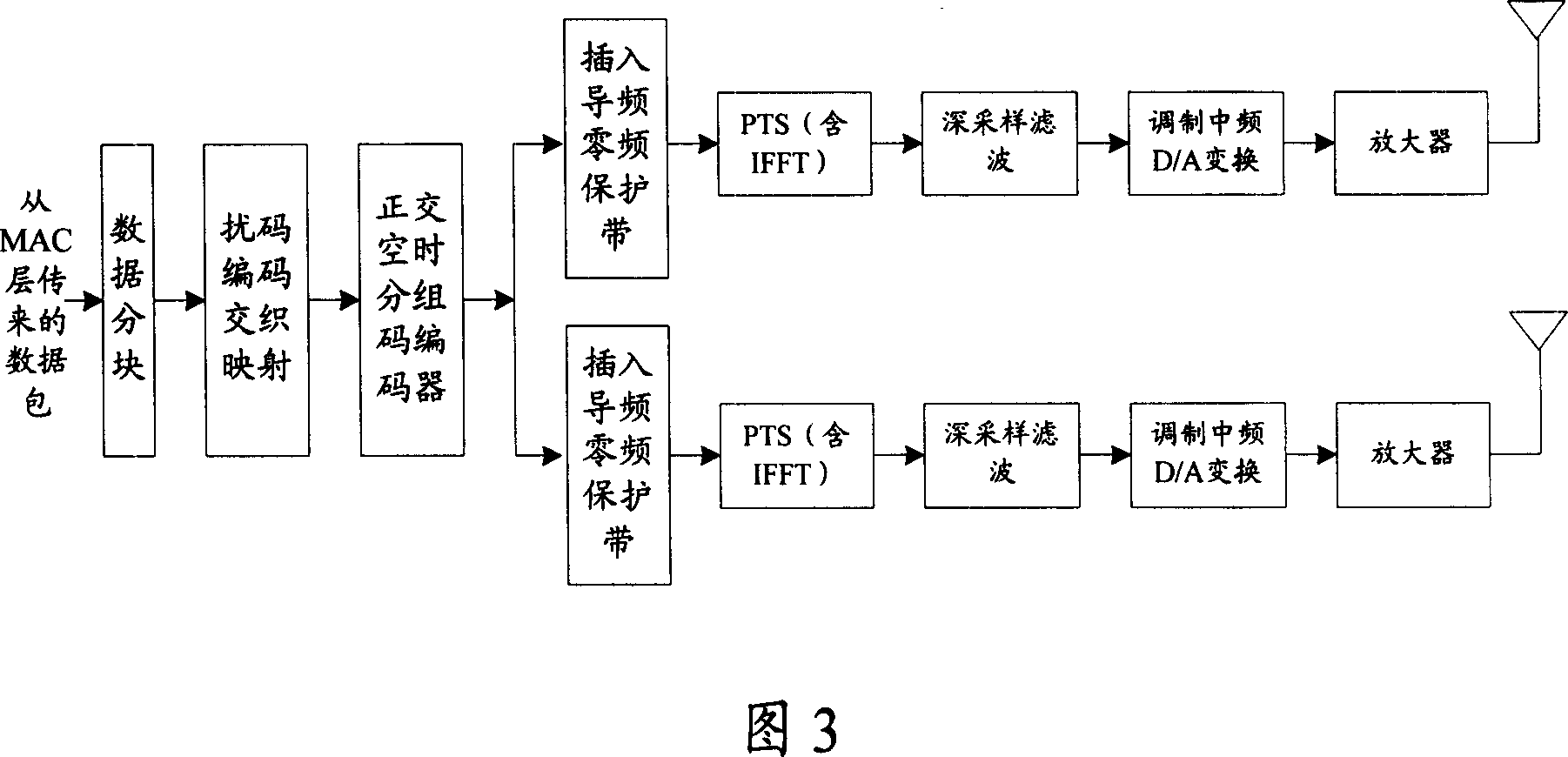

Peak average power rate control method, receiving end and transmitting end

InactiveCN1929469AKeep lowering effectReduce computationMulti-frequency code systemsData streamInformation transmission

This invention relates to data transmission technique to one peak even power control method of one MIMO-OFDM system, receive end and emission end, which solves current linear PAPR applied in the system and computes large problem to improve MIMO-OFDM system data low effect problem. The invention adopts OSTBC technique for coding two paths of data flow even and odd characters relationship on weight vector.

Owner:ZHEJIANG UNIV +1

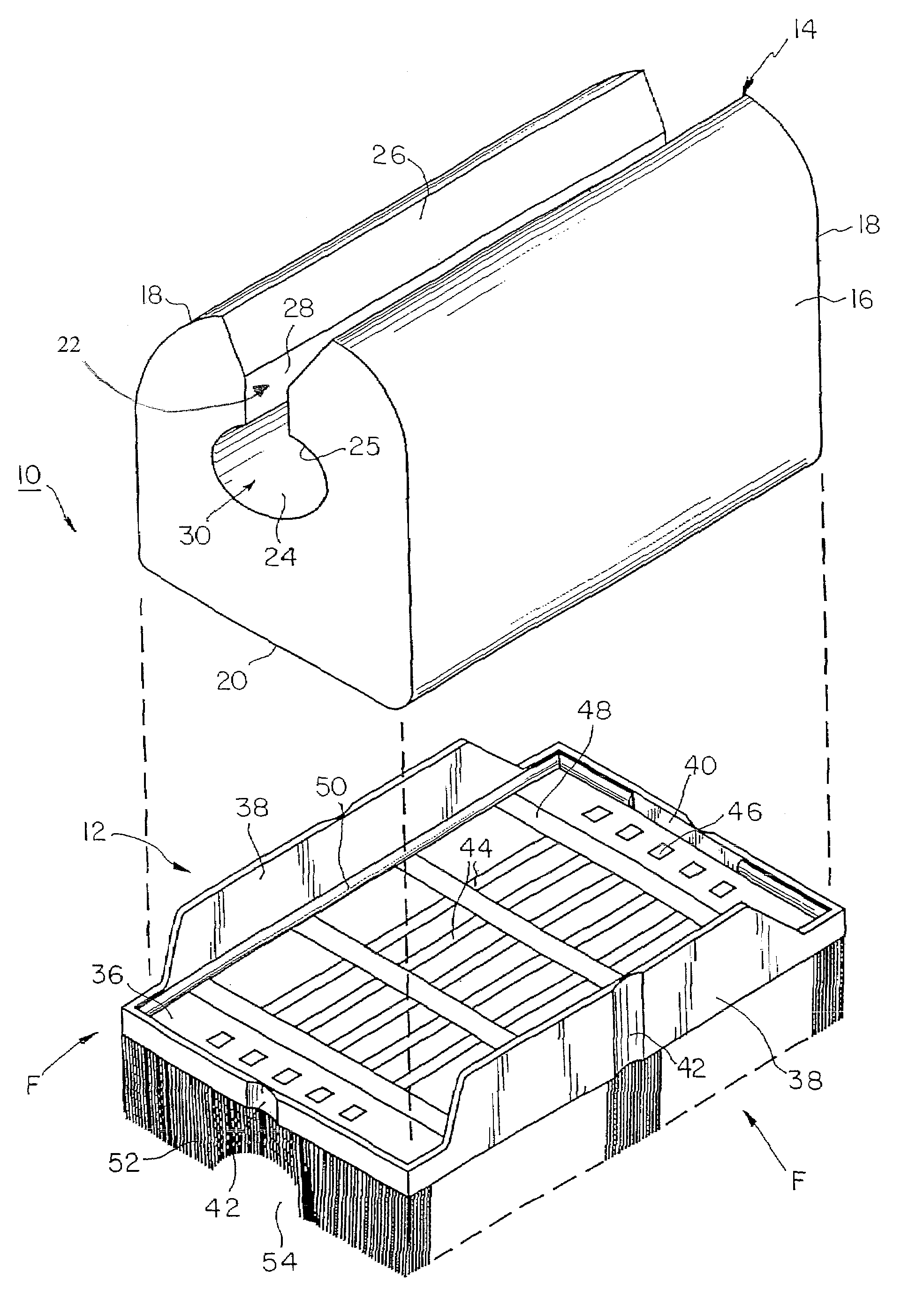

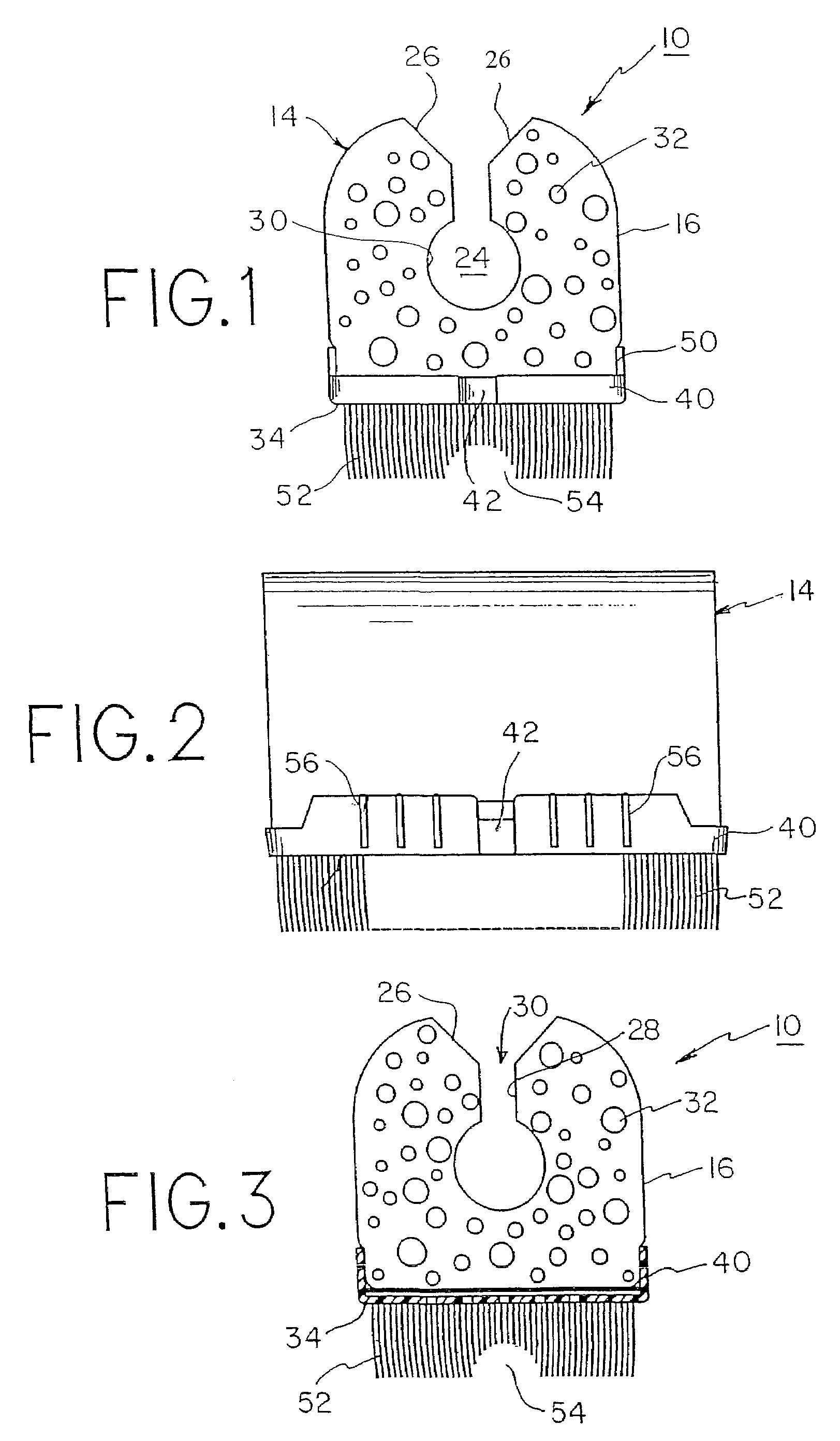

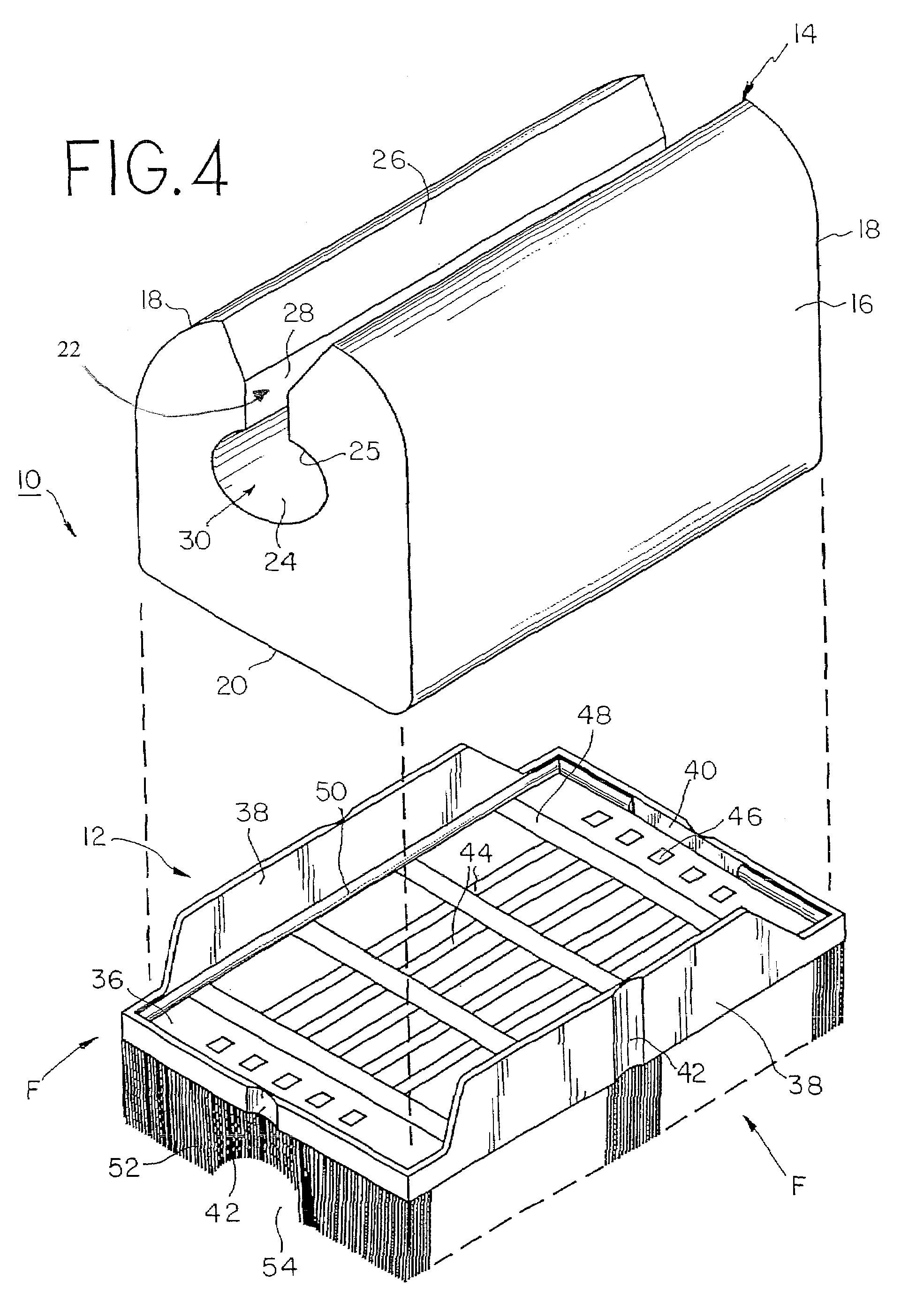

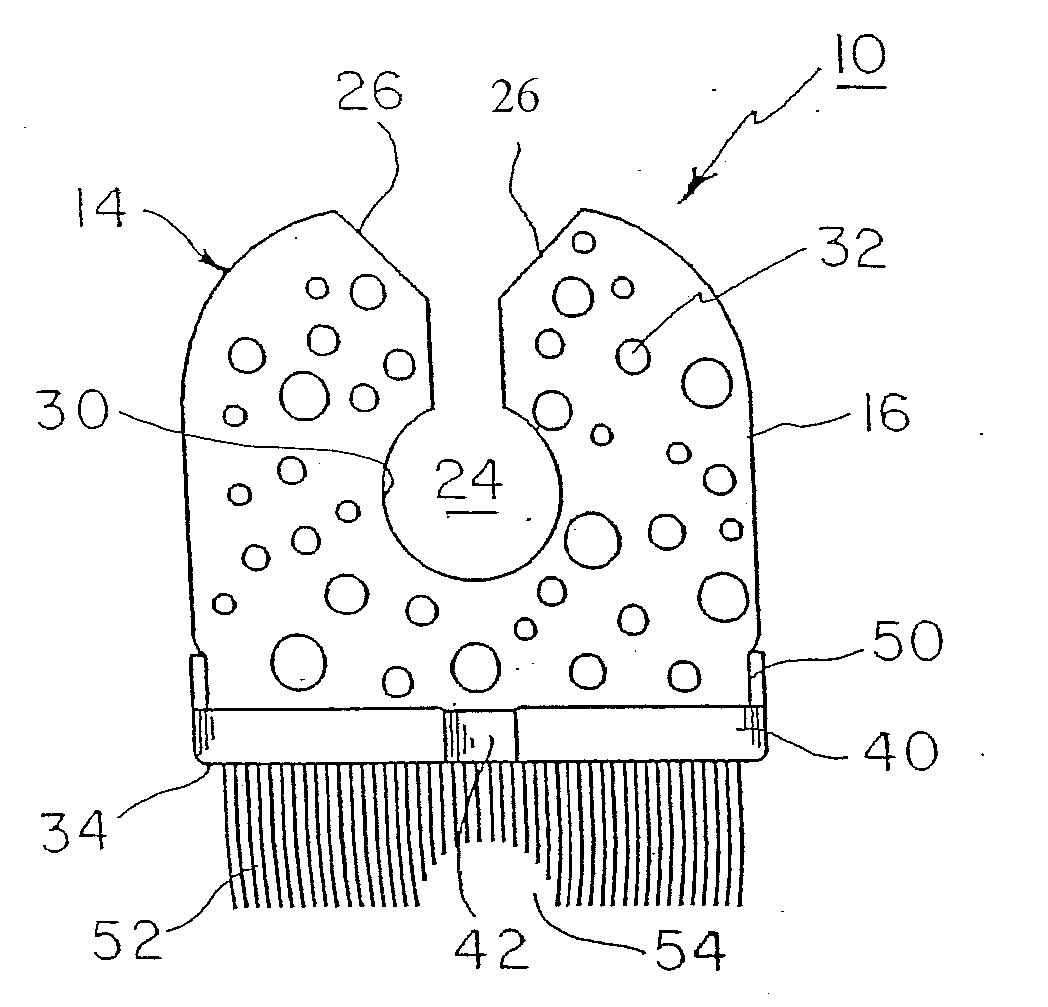

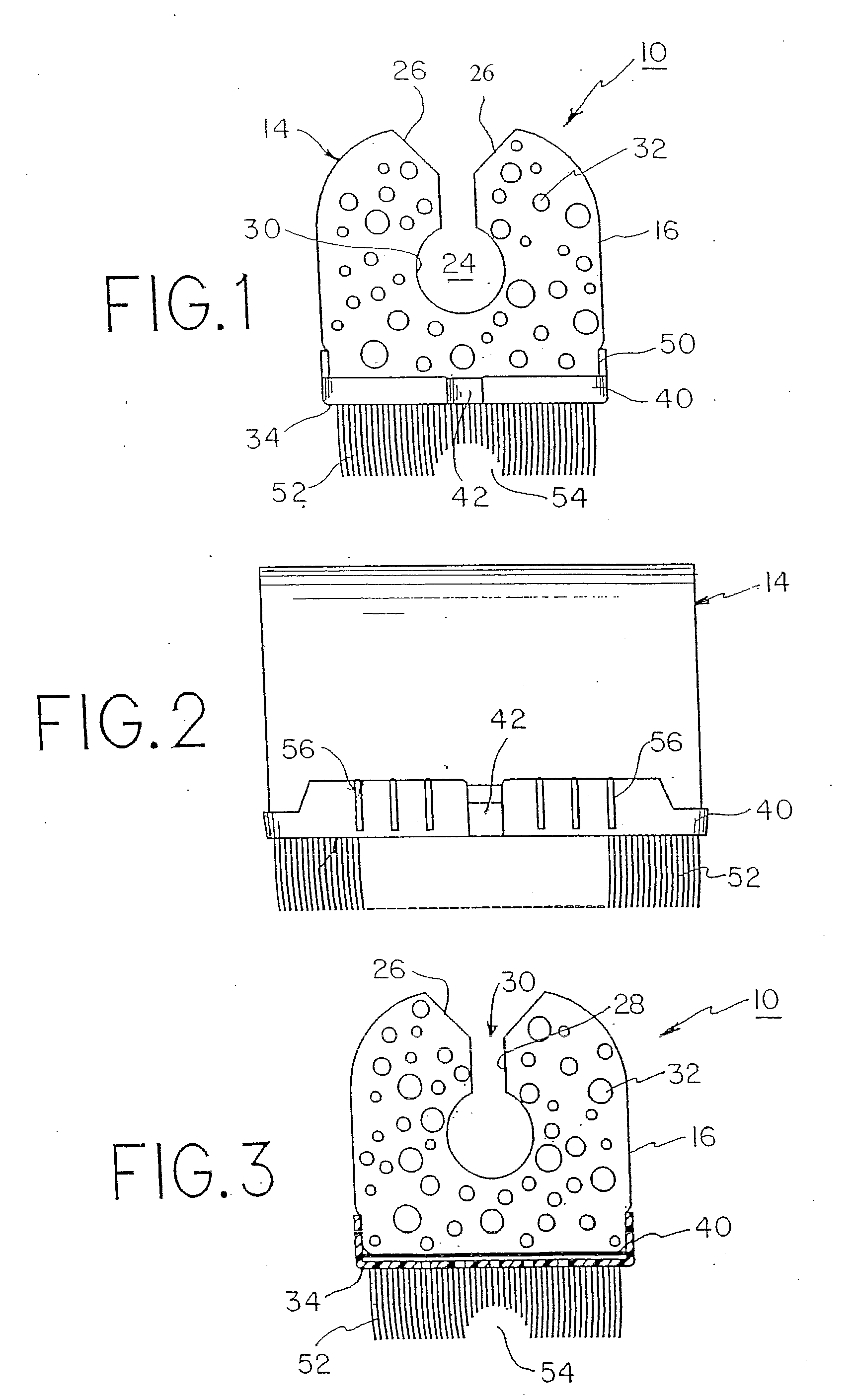

Surgical scrub brush and cleaner apparatus

ActiveUS7260863B2Time-effective and efficientEasy to cleanDiagnosticsSurgeryEngineeringBending force

A scrub brush-sponge includes a base provided with a recessed peripheral lip, which has a plurality of attenuated regions configured to minimize the resistance of the base to external bending forces, and a sponge coupled to the base and made from polymeric material, which may have as low a PPI as 10. The sponge is configured so that it can effectively surround at least a substantial peripheral portion of instruments or portions to be treated with fluid, which is contained within the sponge, without applying substantial external forces to the base.

Owner:BIOMED PACKAGING SYST

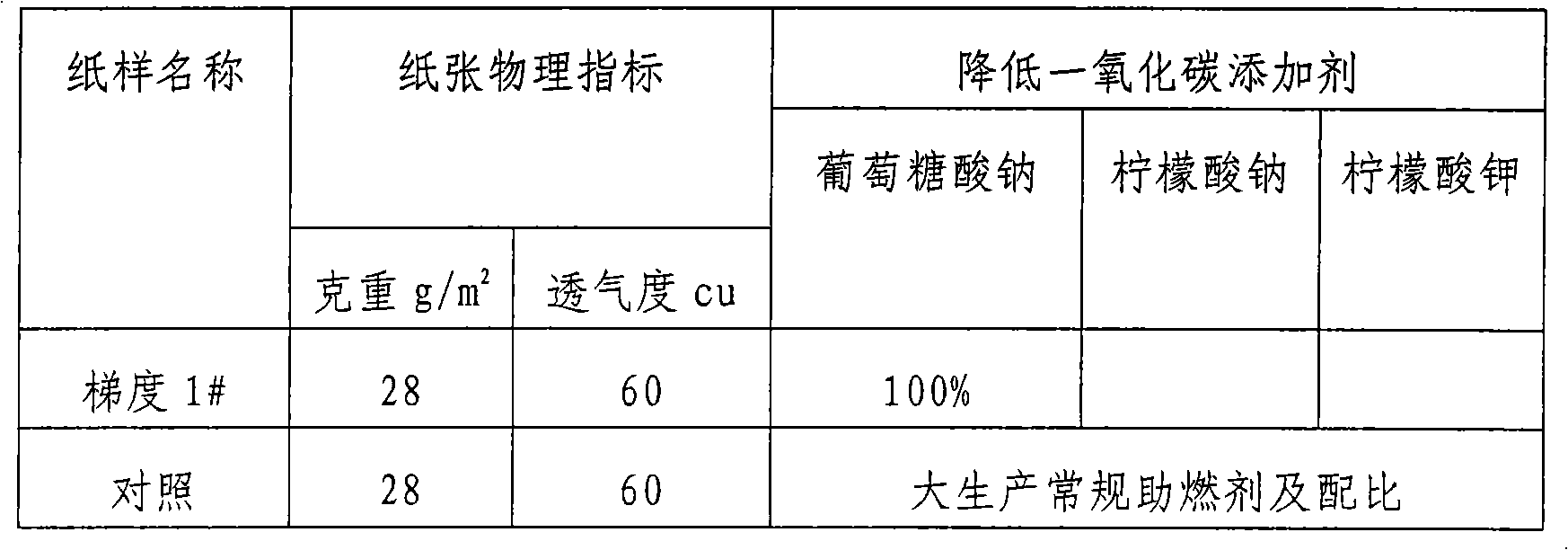

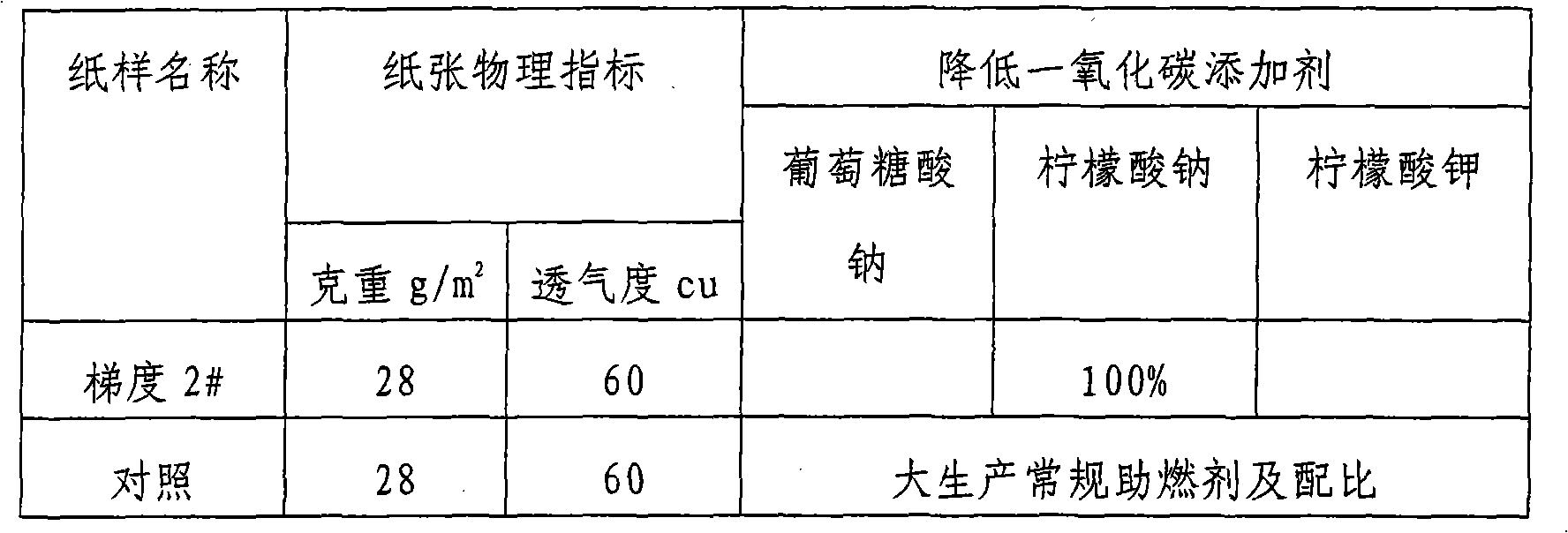

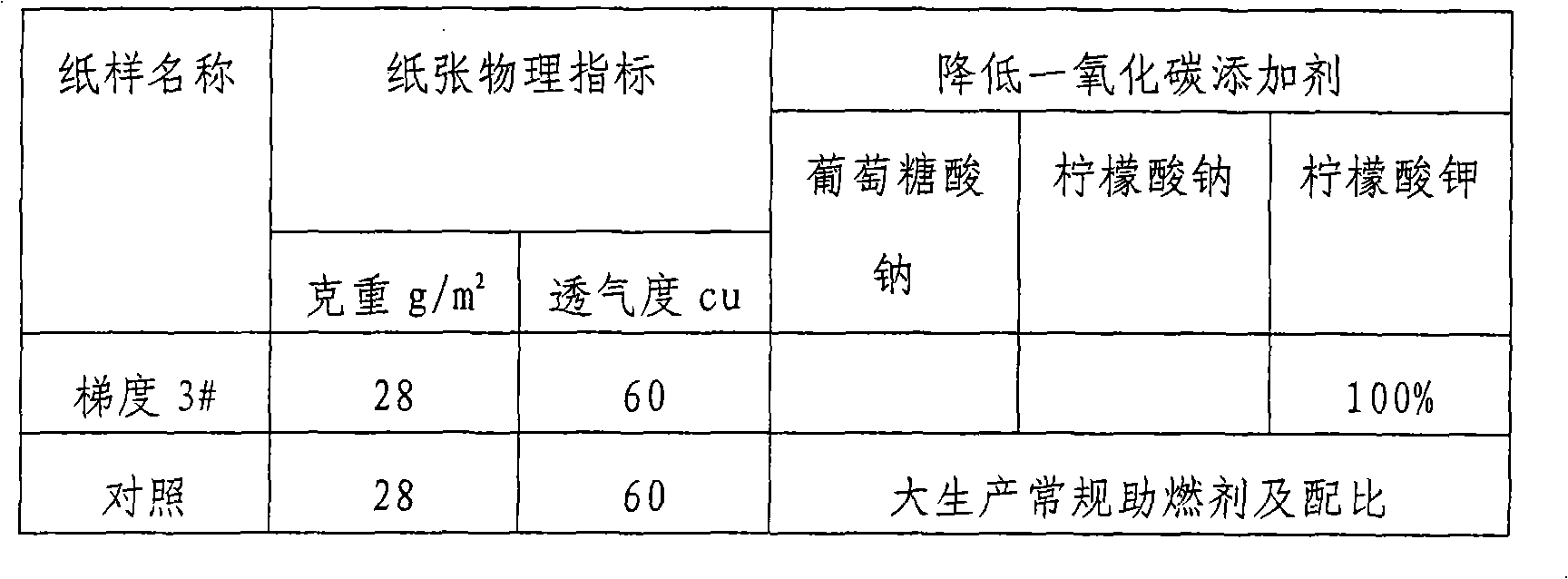

Additive capable of effectively reducing cigarette CO delivering amount and application thereof

InactiveCN101319477AImprove cigarette qualityImprove sensory comfortNon-fibrous pulp additionCigar manufactureChemistryFructose

The invention discloses an additive capable of effectively lowering CO delivering amount of a cigarette and an application thereof. The additive is prepared by evenly mixing 99 percent of lowering CO additive and 1 percent of odor absorption improvement auxiliary agent, wherein the lowering CO additive comprises one of potassium gluconate, sodium gluconate, potassium citrate, sodium citrate, potassium bicarbonate and sodium bicarbonate or is mixture of the potassium gluconate, the sodium gluconate, the potassium citrate, the sodium citrate, the potassium bicarbonate and the sodium bicarbonate. The odor absorption improvement auxiliary agent comprises one of oligomeric maltose and oligomeric fructose or mixture of the oligomeric maltose and the oligomeric fructose. The additive is prepared into eluate for cigarette paper, the eluate is used in the cigarette paper by the spraying process, and the obtained finished products of cigarette paper are used for cigarette production, thereby effectively lowering the CO delivering amount of the cigarette and simultaneously improving the quality of the low CO cigarette. The additive has the advantages of simple method, low cost and obvious industrial application value.

Owner:YUNNAN RES INST OF TOBACCO SCI

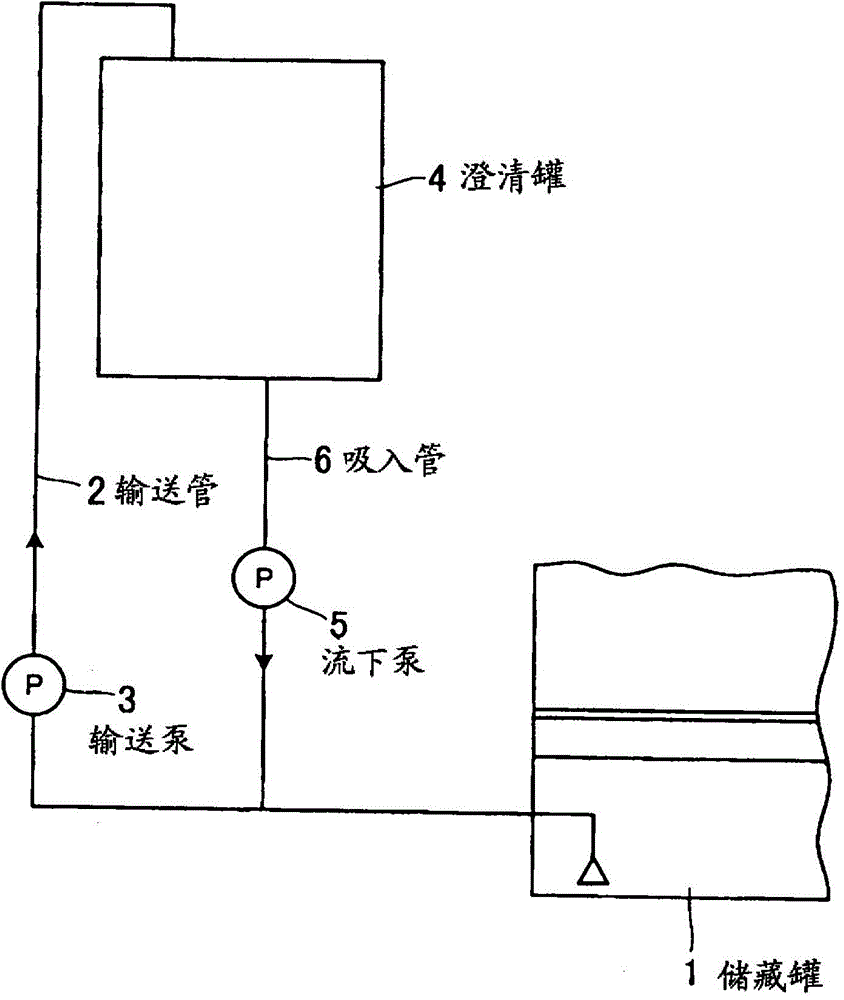

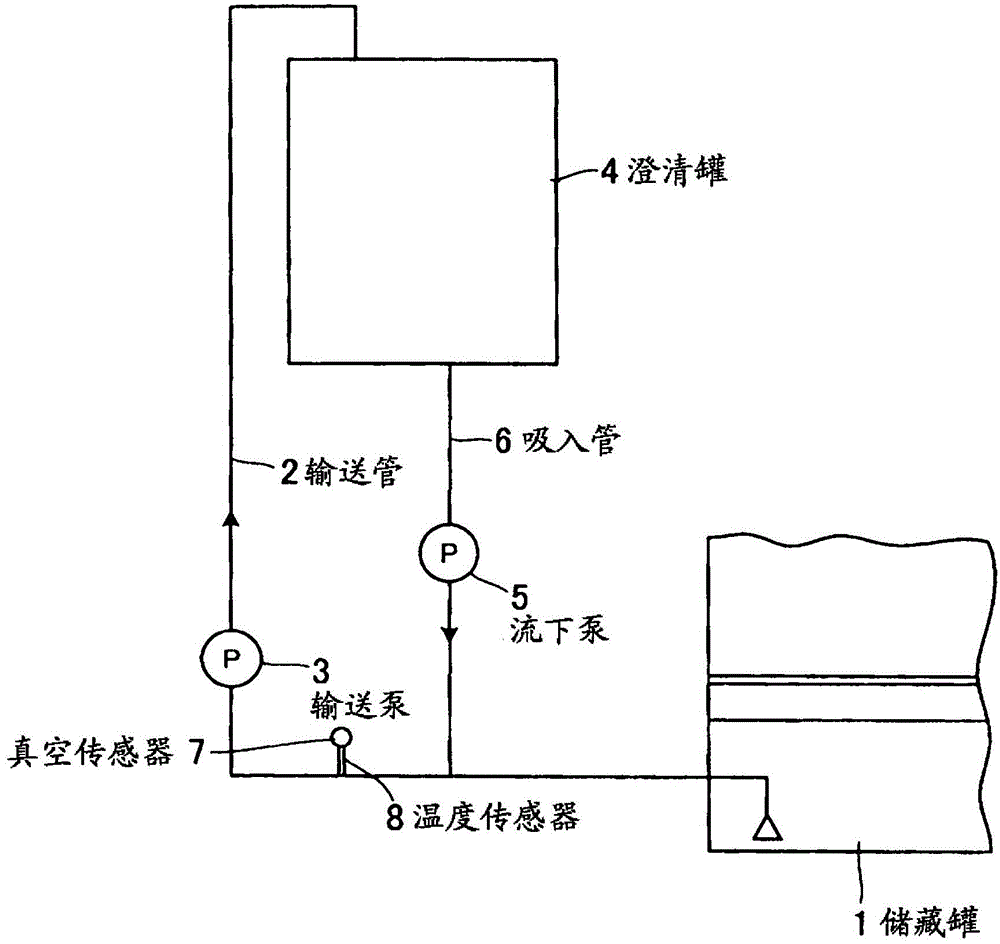

Heating method of fuel oil

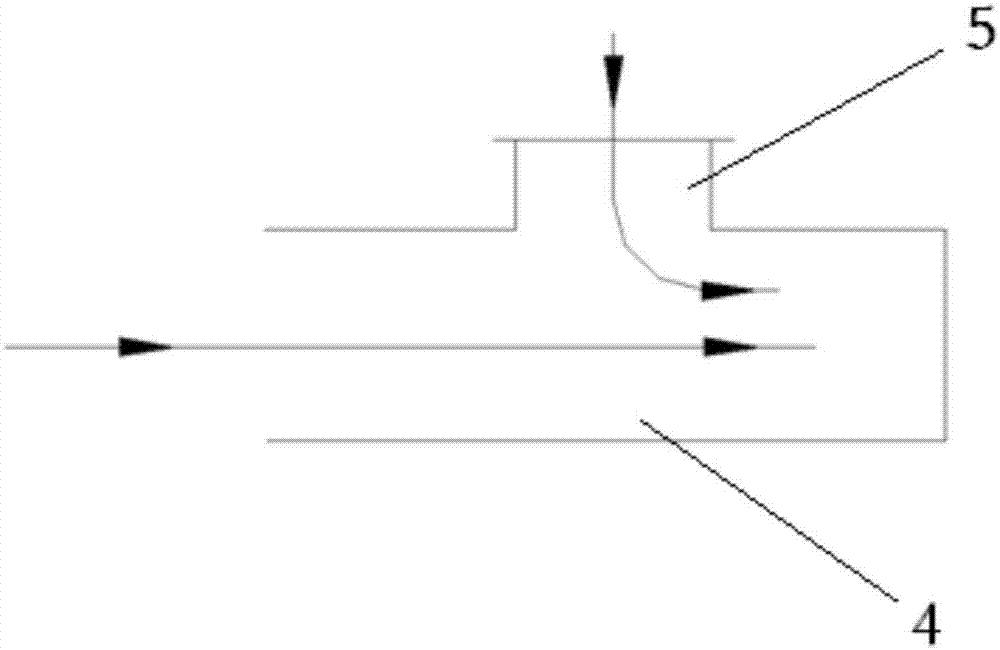

ActiveCN104443339AImprove power loadReduce conveying speedPropulsion power plantsMachines/enginesEngineeringFuel oil

The present invention aims for improving power load of a delivery pump and reducing absorbing resistance of a delivery pipe. When the delivery pump (3) of the fuel oil is used for delivering, a downflow pump (5) is kept to operate continuously, so that the high temperature oil form the downflow pump (5) is mixed and delivered to the fuel oil form a storage tank (1) and absorbed by the delivery pump (3) so that the viscosity of the fuel oil is reduced, and therefore the power load of the delivery pump (3) is improved, the delivery amount of the fuel oil form the storage tank (1) is reduced as much as the amount of the downflow oil, the delivery speed of the storage tank is reduced and the absorbing resistance is reduced.

Owner:HOKUSHIN ENG

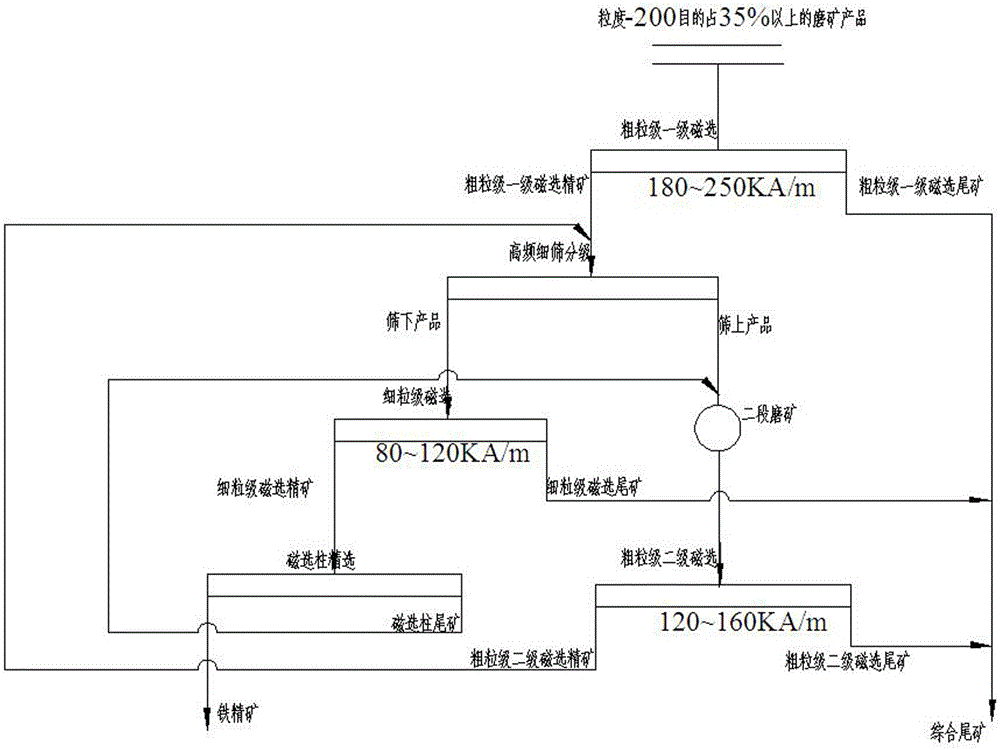

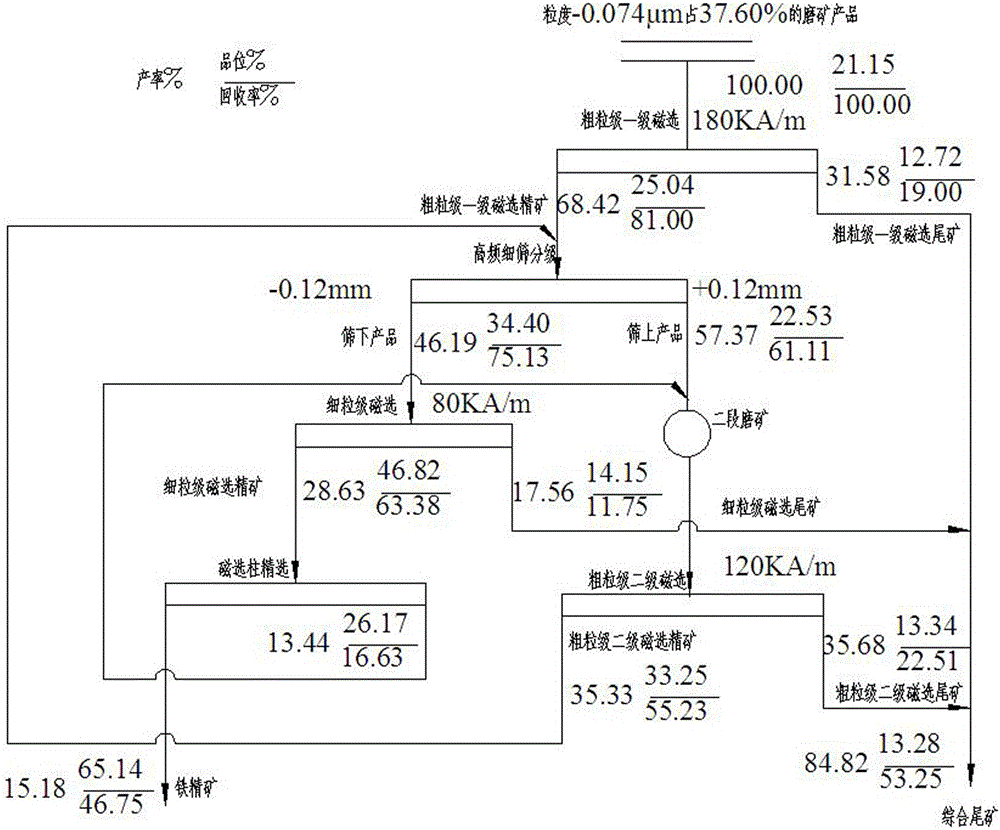

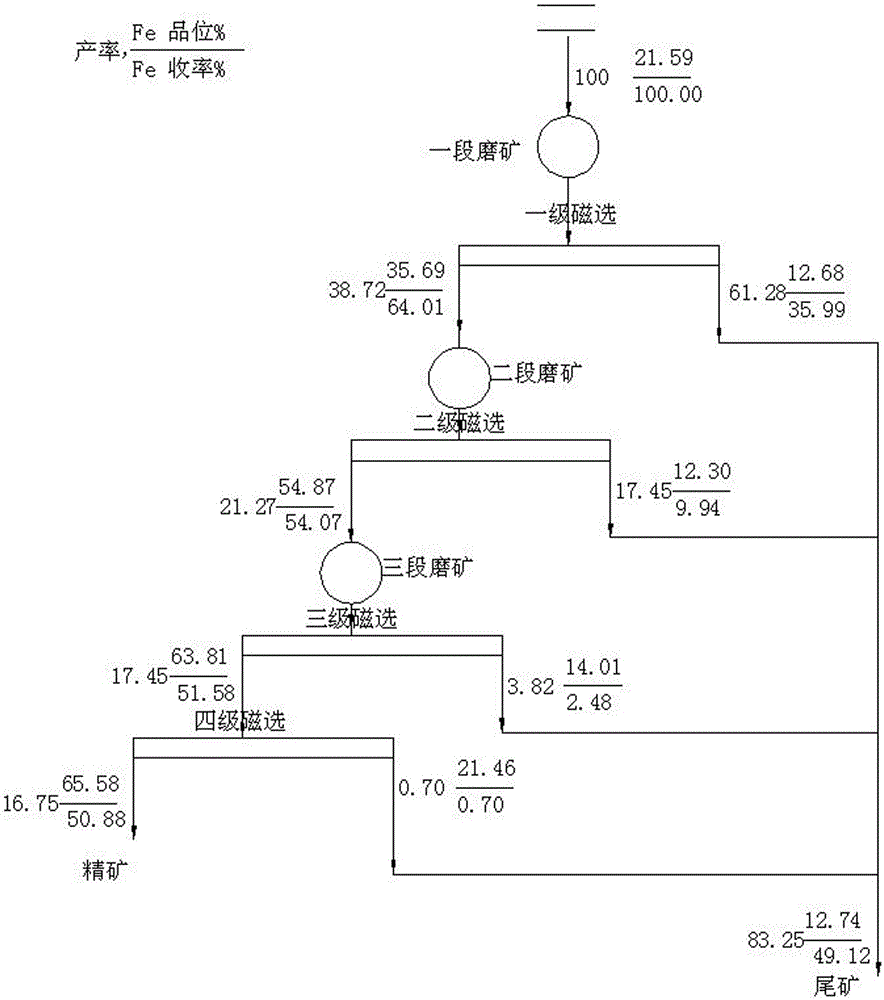

Lean magnetite beneficiation method capable of reducing fineness of grinding ore

ActiveCN104959228AWidely applicable to magnetic separation processStrong process adaptabilityMagnetic separationIronstoneMagnetite

The invention relates to a lean magnetite beneficiation method capable of reducing fineness of grinding ore, which comprises the following process steps: (1) finely grinding crushed lean magnetite ore and then carrying out primary coarse particle magnetic separation; (2) classifying primary coarse particle magnetic separation magnetic concentration by adopting a high frequency fine screen; (3) carrying out secondary ore grinding on oversize products and then carrying out secondary coarse particle magnetic separation; (4) returning secondary coarse particle magnetic separation magnetic concentration to the high frequency fine screen in step (2) to be reclassified, and repeating the operations of steps (2) to (6); (5) carrying out fine magnetic separation on high frequency undersize products; (6) carrying out fine separation on fine magnetic separation magnetic concentration by adopting a magnetic separation column so as to obtain iron ore concentration, returning magnetic separation column tailings to the secondary ore grinding procedure in step (3) and repeating the operations of steps (3) and (4). The granularity of -0.074 micrometers of iron ore concentration separated by the method disclosed by the invention accounts for 35-88%, which is reduced by more than 10% compared with iron ore concentration obtained by a conventional dressing production procedure, iron grade is 65-69%, and iron recovery rate is 45-97%.

Owner:抚顺罕王傲牛矿业股份有限公司

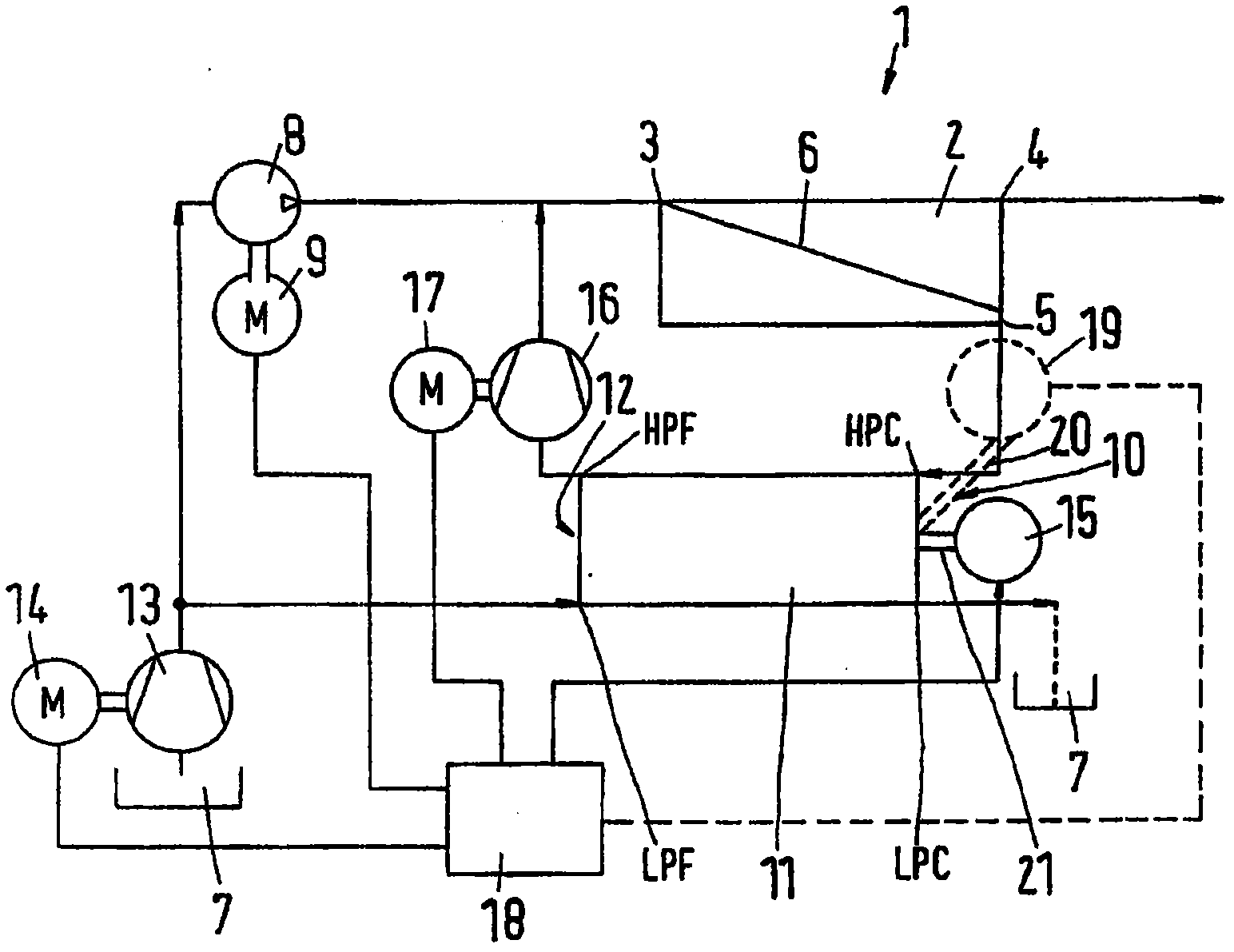

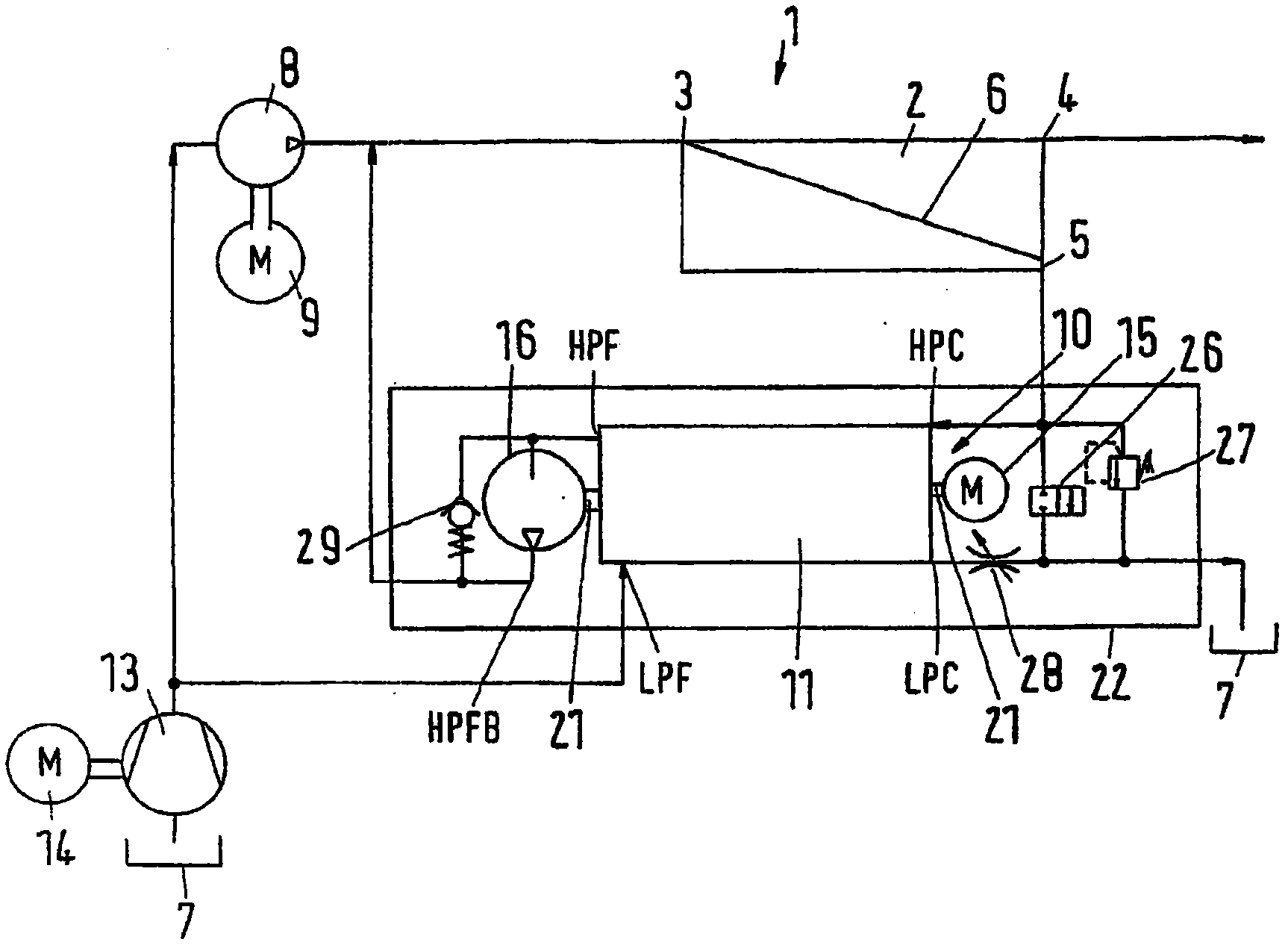

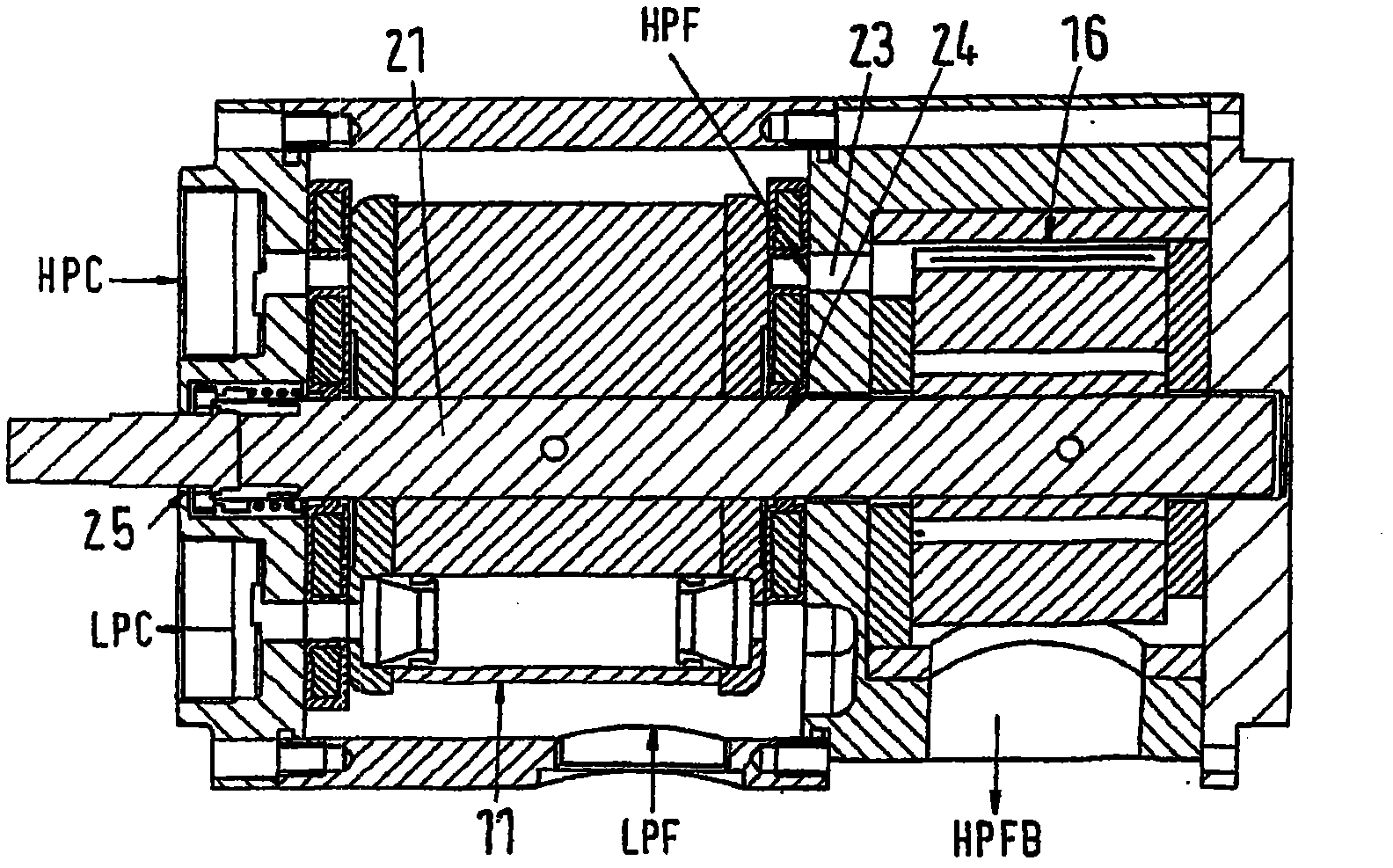

Reverse-osmosis apparatus

ActiveCN102138007AControl speedReduce delivery volumeMembranesGeneral water supply conservationReverse osmosisPressure exchanger

The present invention relates to a reverse-osmosis apparatus (1) having a diaphragm unit (2) which has an inlet (3), a permeate outlet (4) and a concentrate outlet (5), a high-pressure pump (8) which is connected to the inlet (3), a pressure exchanger (11), of which the concentrate side (10) is connected to the concentrate outlet (5), and a boosting pump between the pressure exchanger (11) and the inlet (3). The aim is to consume as little energy as possible. To this end, provision is made for the booster pump to be in the form of a positive-displacement pump (16).

Owner:DANFOSS AS

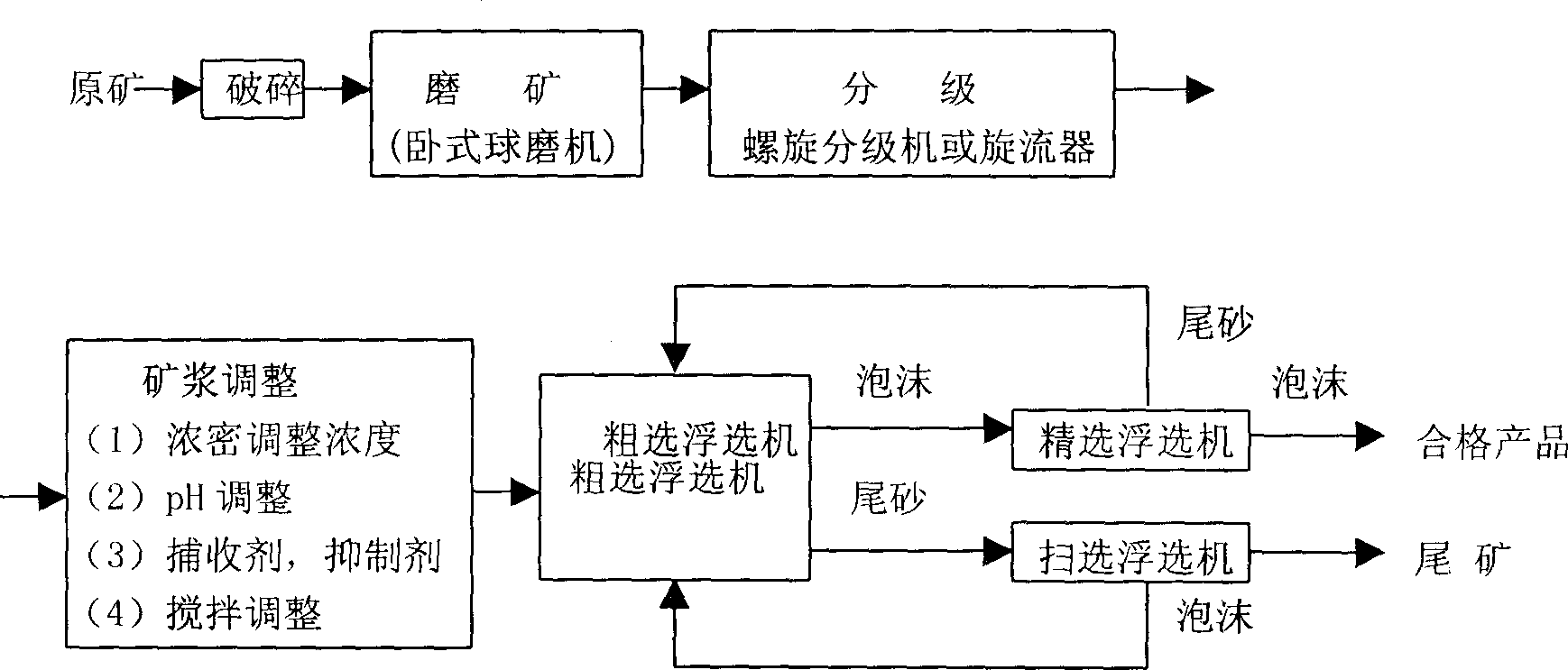

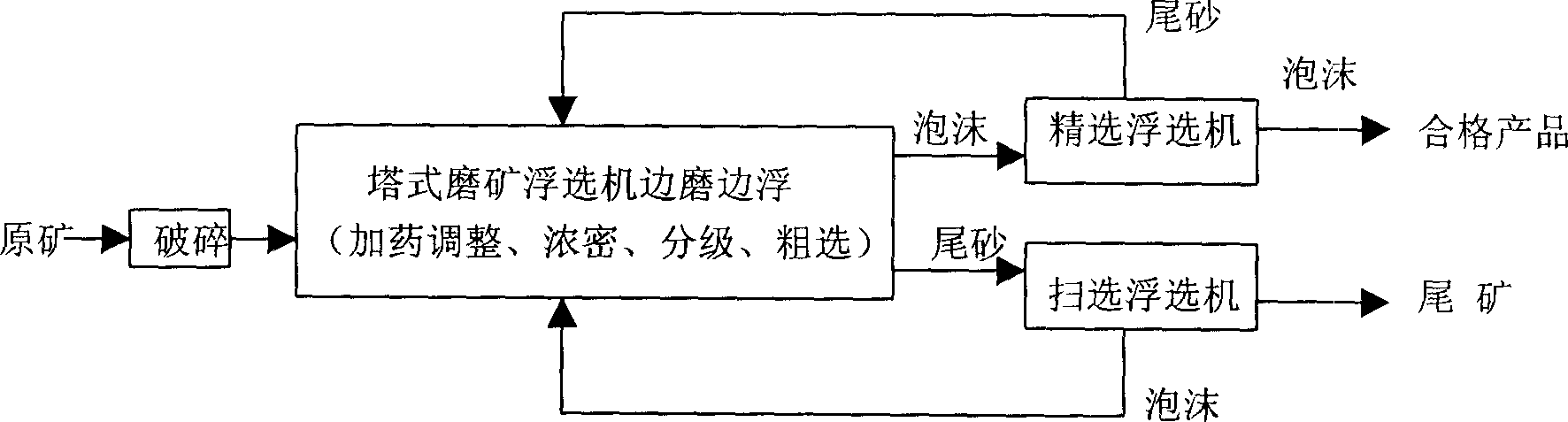

Grinding while floatation process for carrying out floatation separation in grinding

InactiveCN1401433APrevent secondary muddying and other phenomenaReduce wearFlotationEngineeringTower

A process for grinding and hydrosizing ore at same time includes crushing raw ore, feeding it into tower-type grinding floatation machine while adding pH regulator, supprssor and collector, grinding while hydrosizing, collecting froth, refining in fine floatation machine, returning tail sand back to grinding floatation machine, collecting the tail sand of grinding floatation machine, scavenging in the scavenging floatation machine, and returning the scavenged froth back to the grinding floatation machine. Its advantages are short process flow and high recovery yield.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

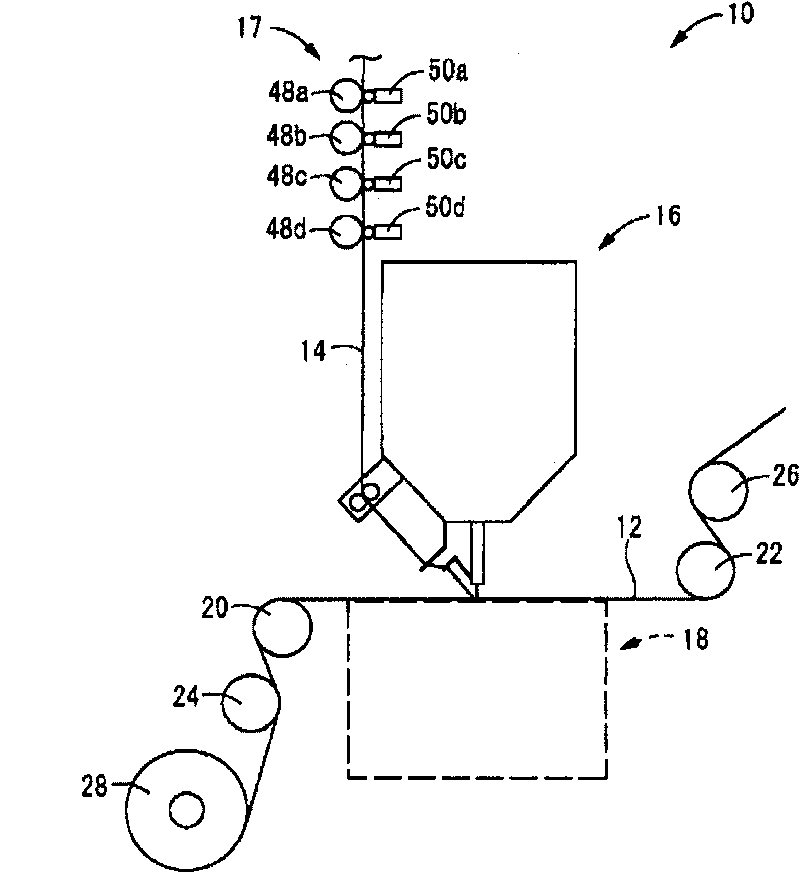

Surgical scrub brush and cleaner apparatus

ActiveUS20080010766A1Easy to cleanTime-effective and efficientKitchenware cleanersDiagnosticsFiberEngineering

A scrub brush-sponge includes a base provided with a recessed peripheral lip, which has a plurality of attenuated regions configured to minimize the resistance of the base to external bending forces, and a sponge coupled to the base and made from polymeric material, which may have as low a PPI as 10. The sponge is configured so that it can effectively surround at least a substantial peripheral portion of instruments or portions to be treated with fluid, which is contained within the sponge, without applying substantial external forces to the base. A flexible layer made of woven or non-woven bonded polymeric fibers is on a scrubbing surface of the sponge and provides an enhanced scrubbing feature. An abrasive may be included on the flexible layer to further enhance the scrubbing feature.

Owner:BIOMED PACKAGING SYST

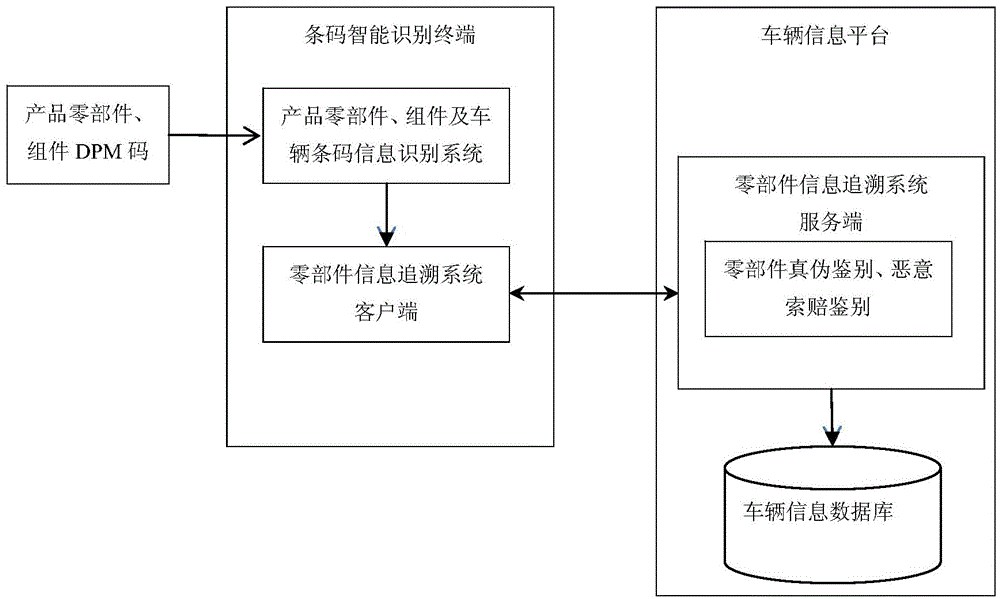

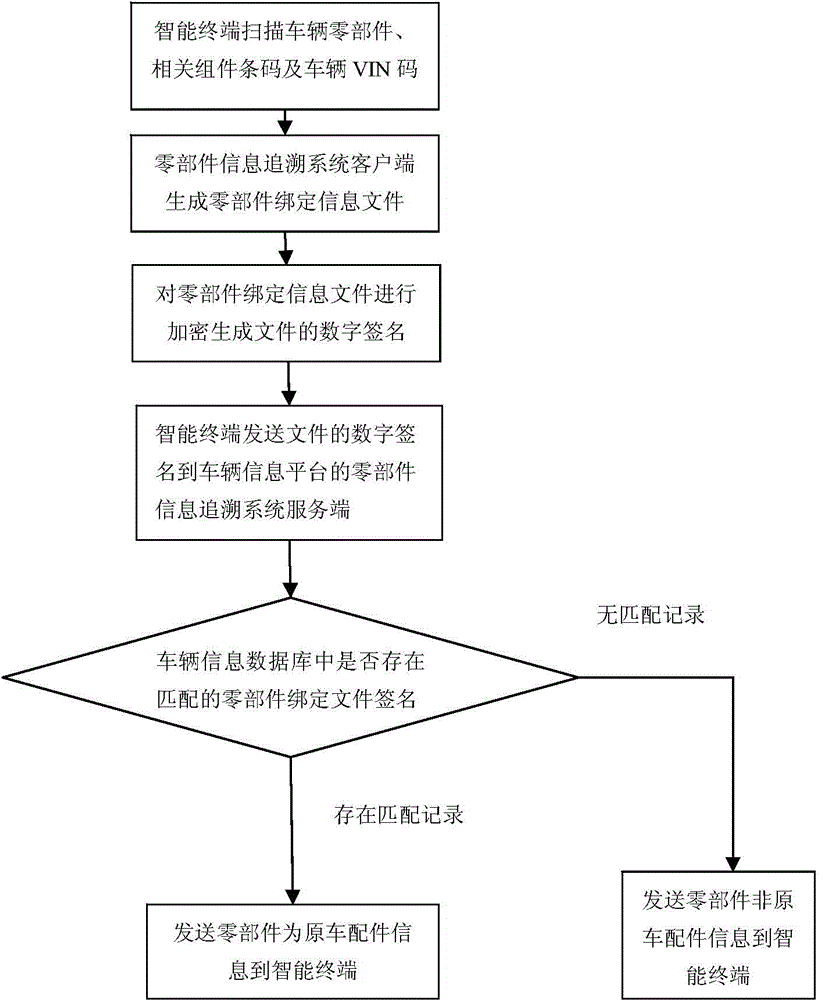

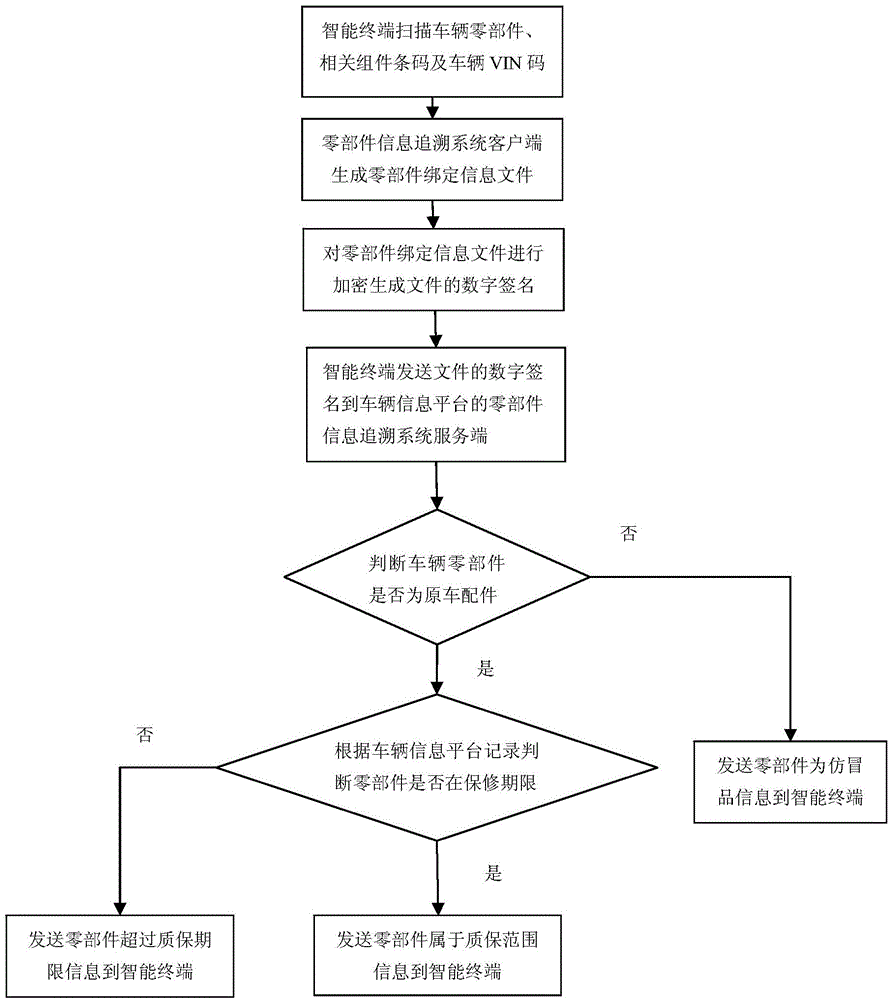

Tracing and discriminating method for anti-counterfeiting information of vehicle component

ActiveCN104424570AEasy to parseConvenient queryCommerceSensing by electromagnetic radiationDigital signatureBarcode

The invention relates to a tracing and discriminating method for anti-counterfeiting information of a vehicle component. The method comprises the following steps that: a barcode intelligent terminal scans or inputs component barcode identifier information; the barcode intelligent terminal generates an XML-format file from the collected component barcode identifier information according to level binding relation, carries out encryption on the file to obtain a digital signature, and sends the digital signature to a vehicle information platform; the vehicle information platform queries whether the digital signature exists in the database of the vehicle information platform; if so, the component belongs to the original vehicle fittings; if not, the component does not belong to the original vehicle fittings; and the query result is fed back to the barcode intelligent terminal. According to the invention, authenticity identification and information query of the vehicle as well as the main components and parts of the vehicle for the consumers can be realized and thus the vehicle components can be prevented from being replaced; and a discriminating method for malicious claims beyond the warranty and the fraud of the vehicle with warranty can be provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

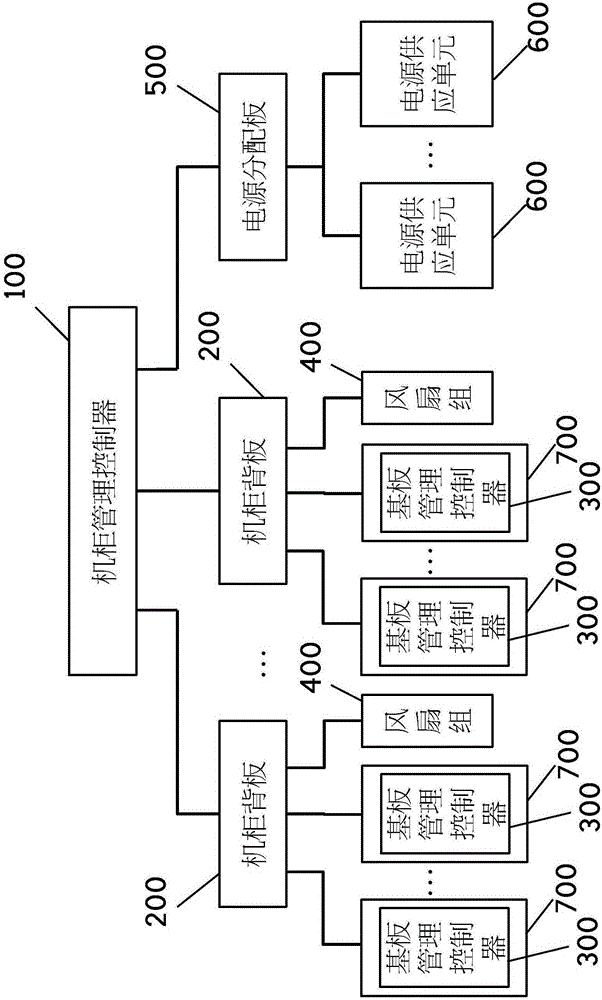

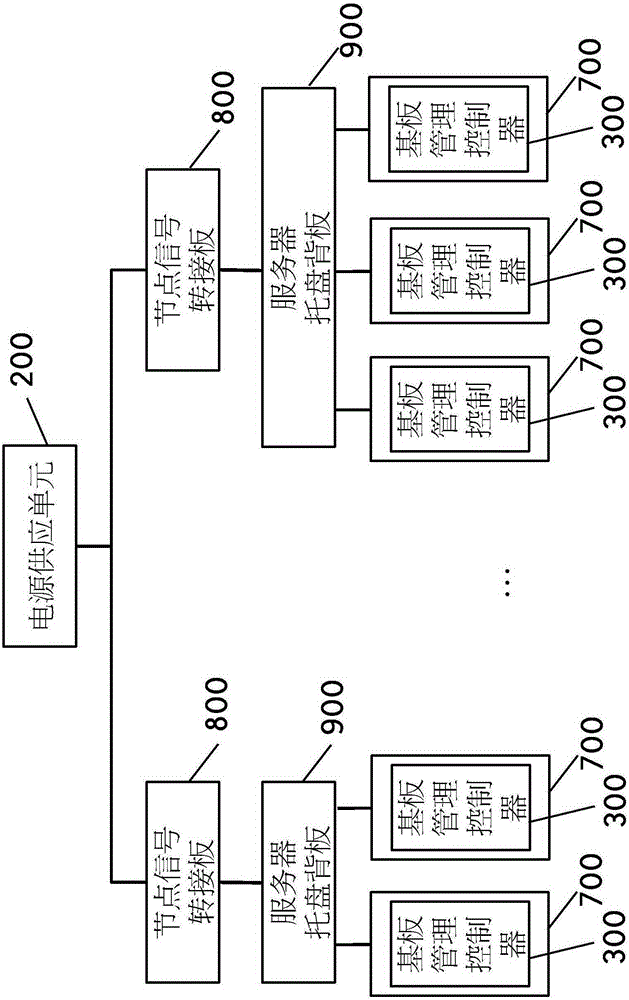

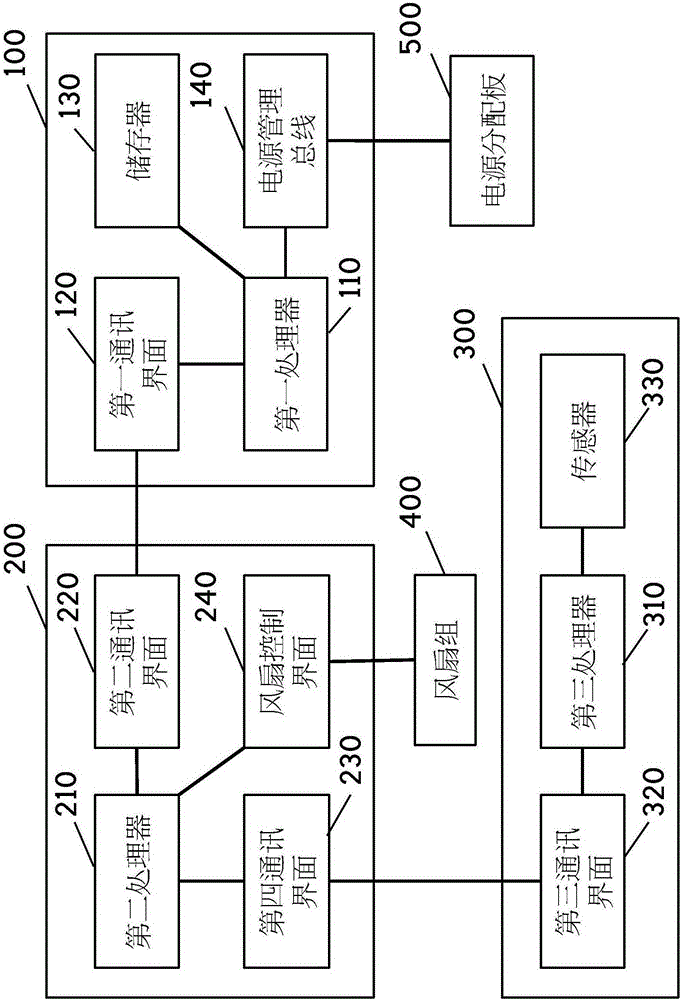

Monitoring method for server cabinet

InactiveCN106557405AReduce computing burdenImprove transmission efficiencyHardware monitoringState parameterEngineering

The invention provides a monitoring method for a server cabinet. The monitoring method comprises the following steps of: a cabinet management controller, cabinet backplanes and substrate management controllers are initialized; after initialization is finished, the cabinet management controller sends a starting message to the connected cabinet backplane; after the initialization is finished, the cabinet backplane sends another starting message to the connected substrate management controller; each cabinet management controller uninterruptedly transmits the real-time monitoring parameter of the server of each substrate management controller to the connected cabinet backplane in fixed time from a moment when each substrate management controller receives the starting message; and the cabinet backplane uninterruptedly transmits the real-time monitoring parameter to the cabinet management controller in fixed time from the moment when the cabinet backplane receives the starting message sent from the cabinet management controller. Therefore, for state parameters which are frequently sent, a polling way is not adopted, and instead, a one-way transmission way is adopted to save time for collecting data so as to be favorable for carrying out reaction according to data in real time.

Owner:MITAC COMP (SHUN DE) LTD +1

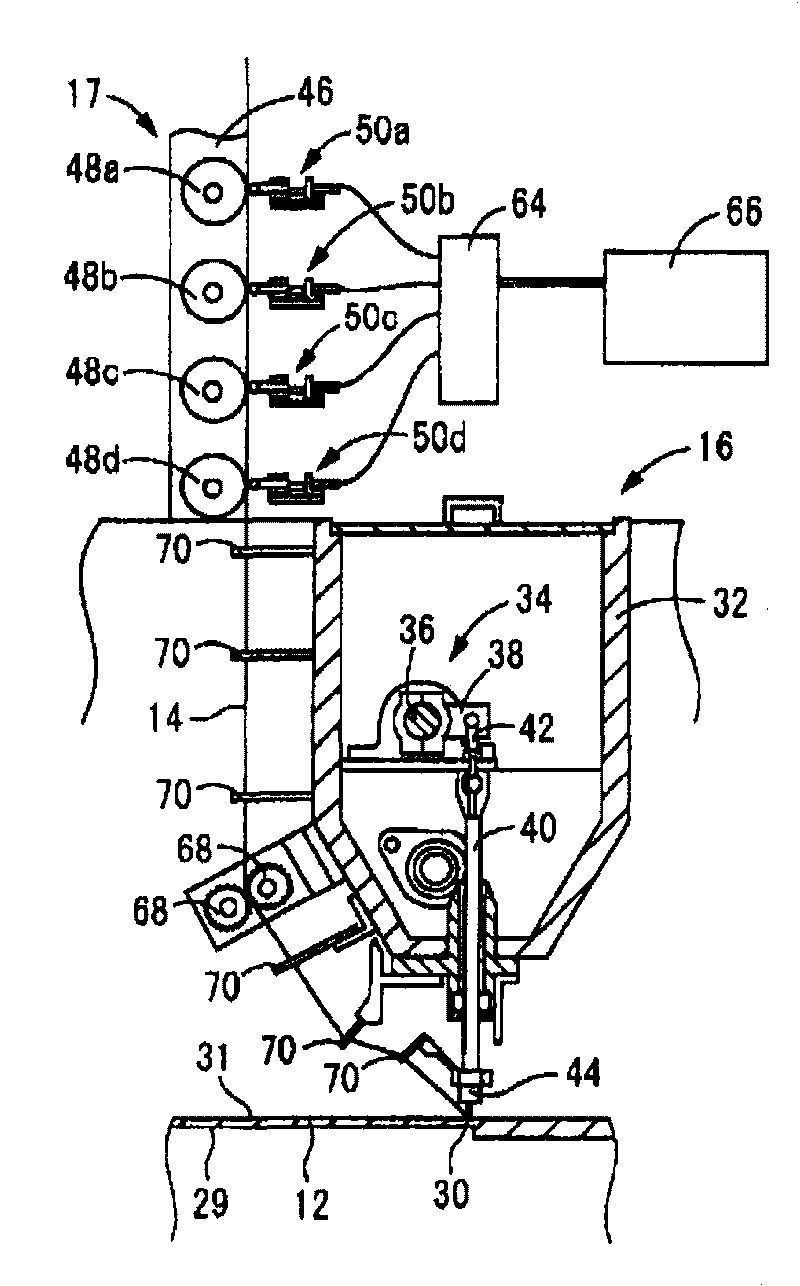

Surgical scrub brush and cleaner apparatus

InactiveUS8001645B2Time-effective and efficientEasy to cleanKitchenware cleanersDiagnosticsFiberEngineering

A scrub brush-sponge includes a base provided with a recessed peripheral lip, which has a plurality of attenuated regions configured to minimize the resistance of the base to external bending forces, and a sponge coupled to the base and made from polymeric material, which may have as low a PPI as 10. The sponge is configured so that it can effectively surround at least a substantial peripheral portion of instruments or portions to be treated with fluid, which is contained within the sponge, without applying substantial external forces to the base. A flexible layer made of woven or non-woven bonded polymeric fibers is on a scrubbing surface of the sponge and provides an enhanced scrubbing feature. An abrasive may be included on the flexible layer to further enhance the scrubbing feature.

Owner:BIOMED PACKAGING SYST

Tufting machine

Owner:NAKAGAWA SEISAKUSHO

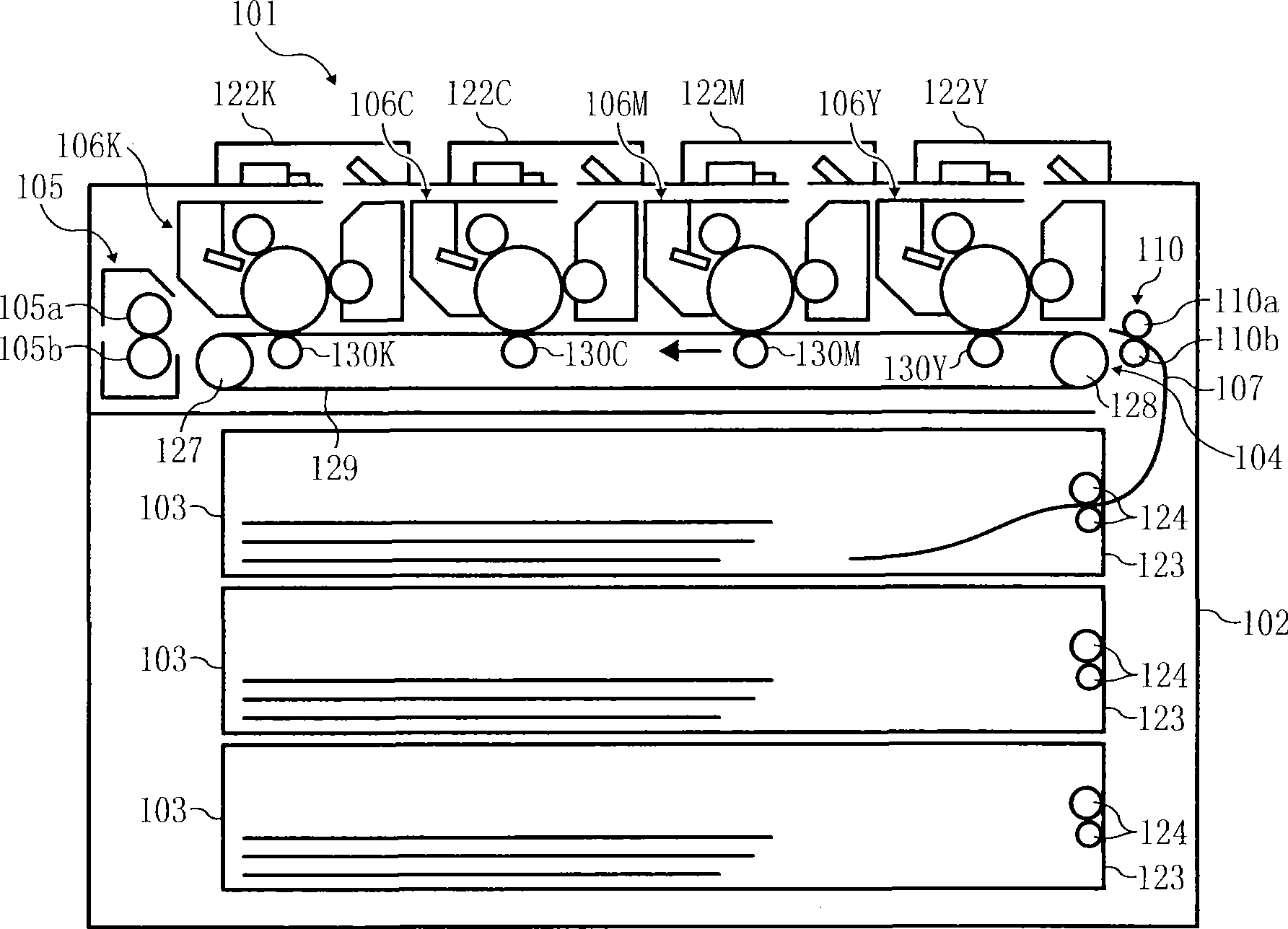

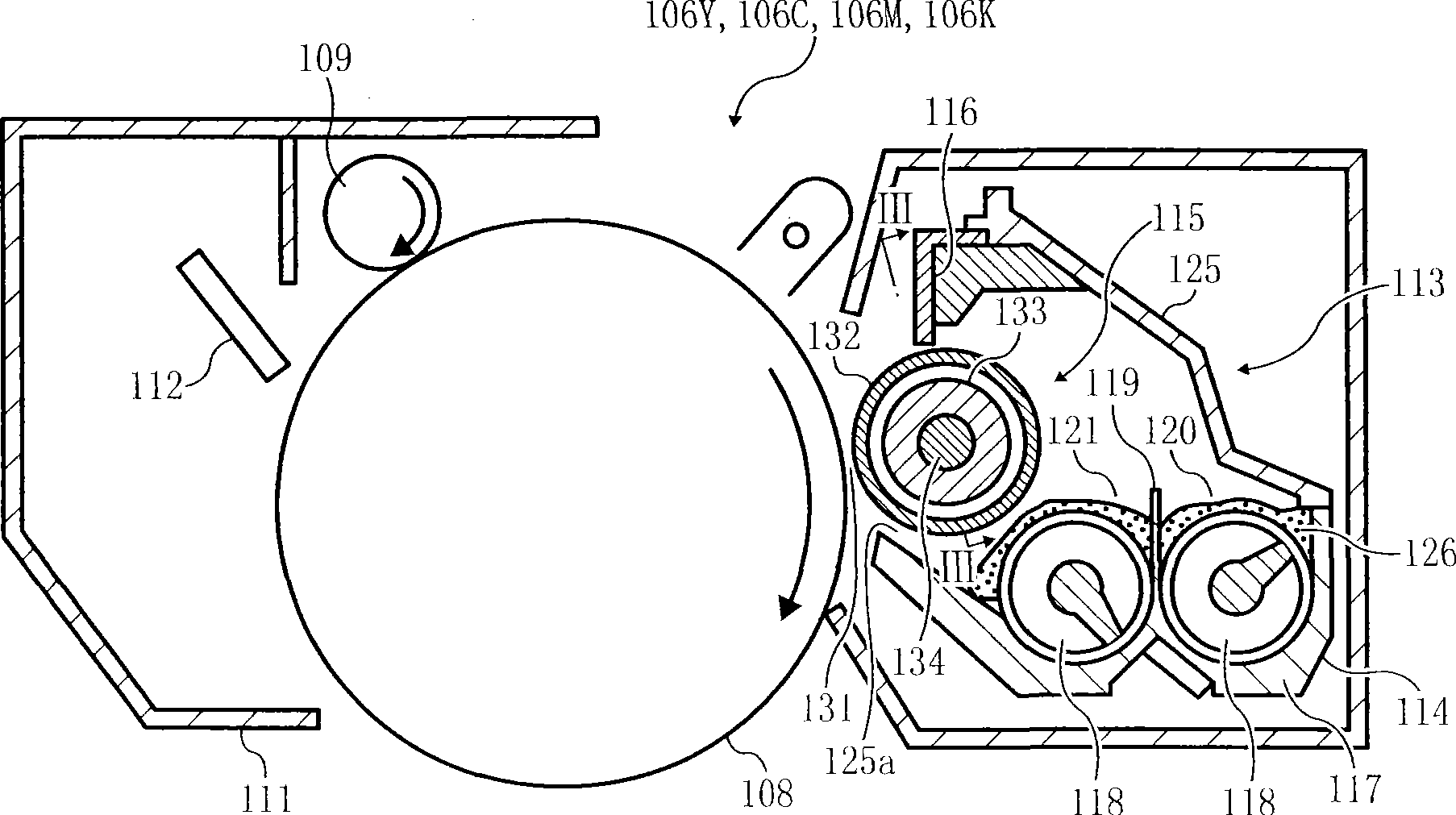

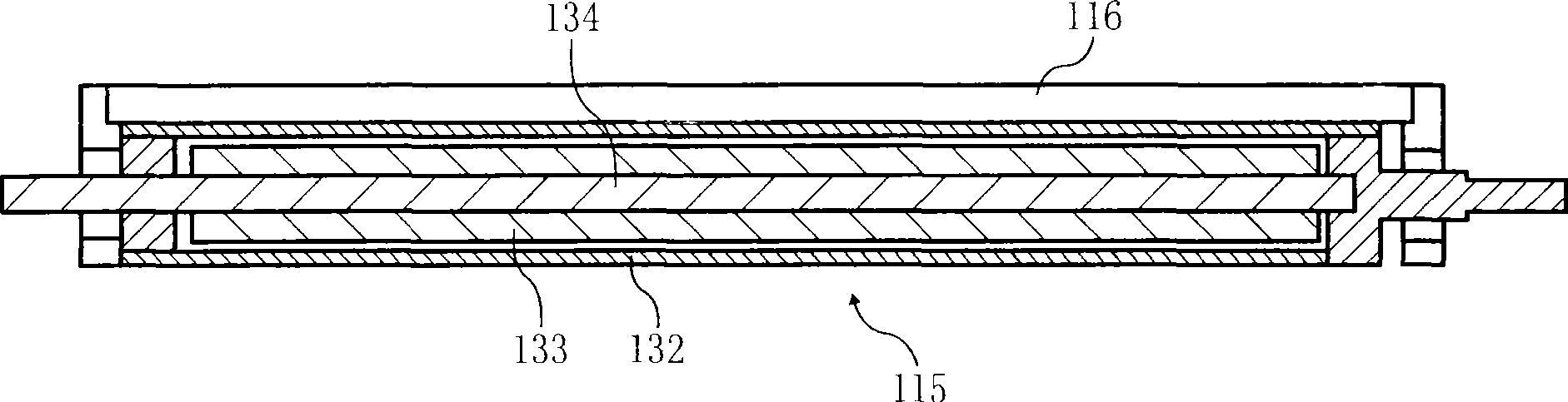

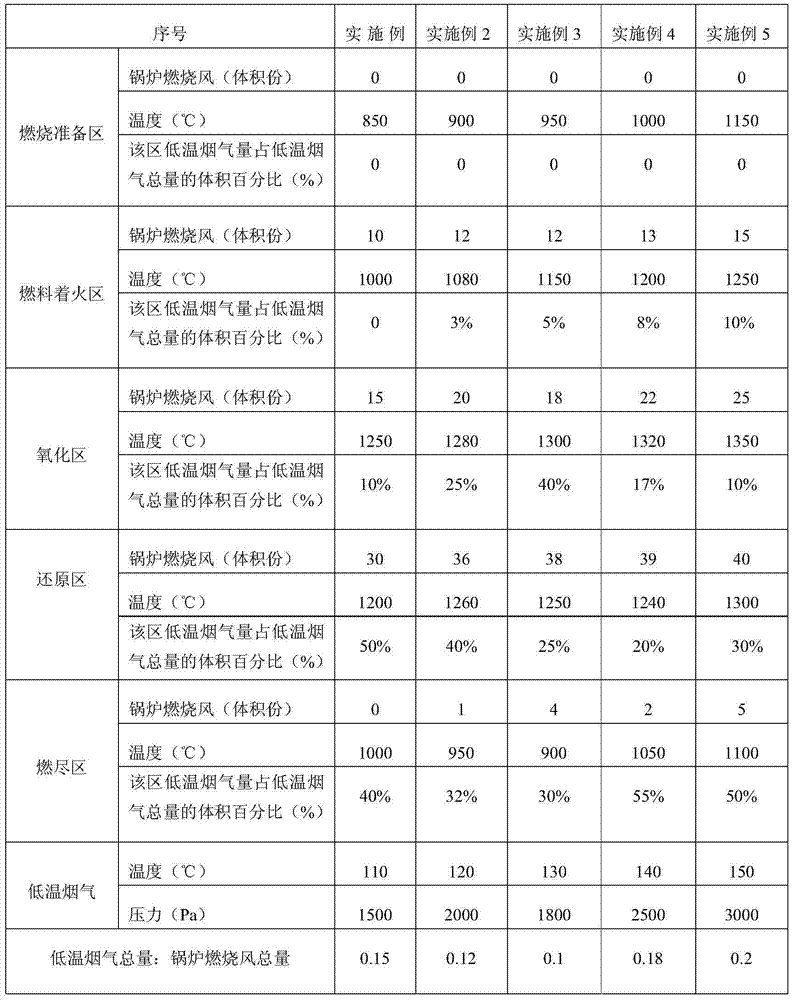

Developing roller, developing device, process cartridge, and image forming apparatus

InactiveCN101382761APreventing uneven image densityIncrease intakeElectrographic process apparatusMagnetEngineering

The present invention provides a developing roller, a developing device, a process cartridge and an image forming device, which may inhibit the reduction of transmitting amount due to the aging variation, thus avoiding unevenness of image intensity. Specifically, the process cartridge of the image forming device comprises a developing roller with a fixed magnet roller and a developing sleeve (132). The outer surface of the developing sleeve has a plurality of recesses (139) of elliptic shape in plan view regularly or irregularly arranged therein so as not to overlap, and the long axis of the recess is in parallel with the length direction of the developing sleeve (132).

Owner:RICOH KK

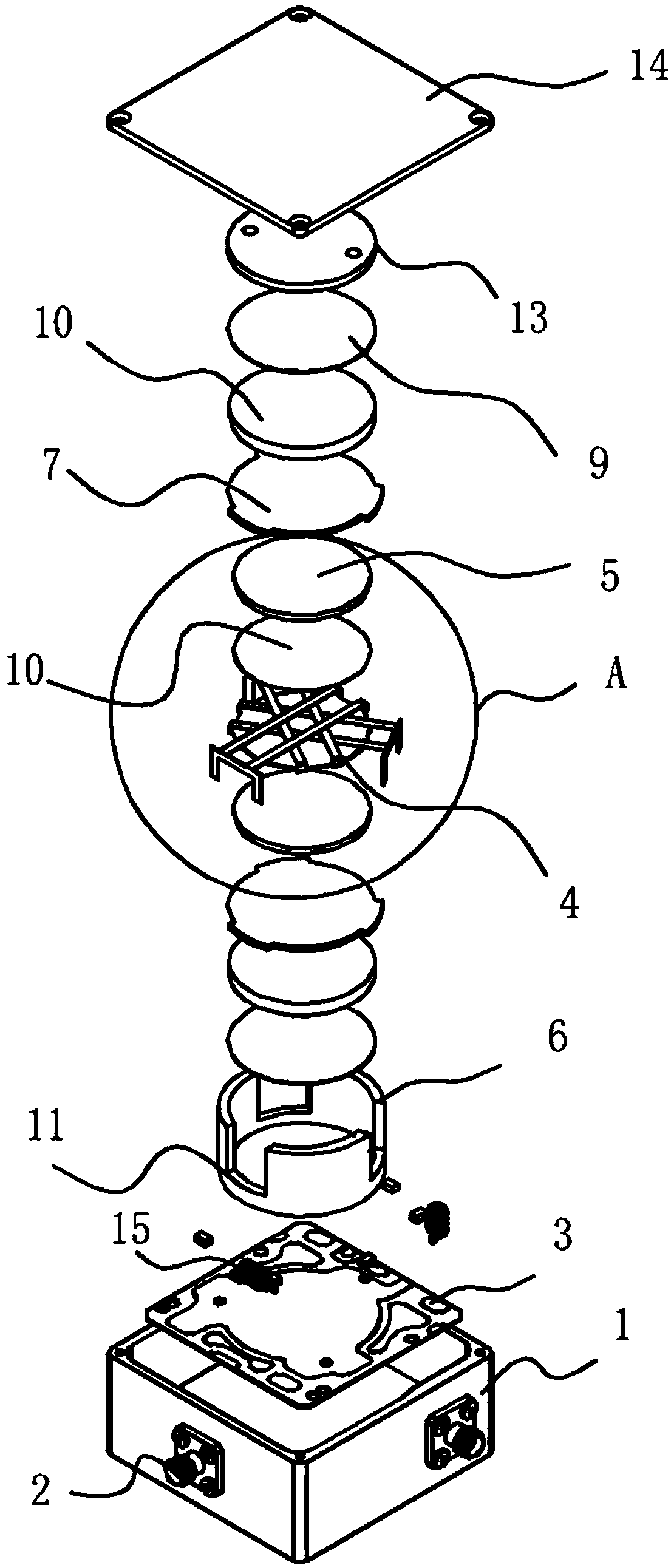

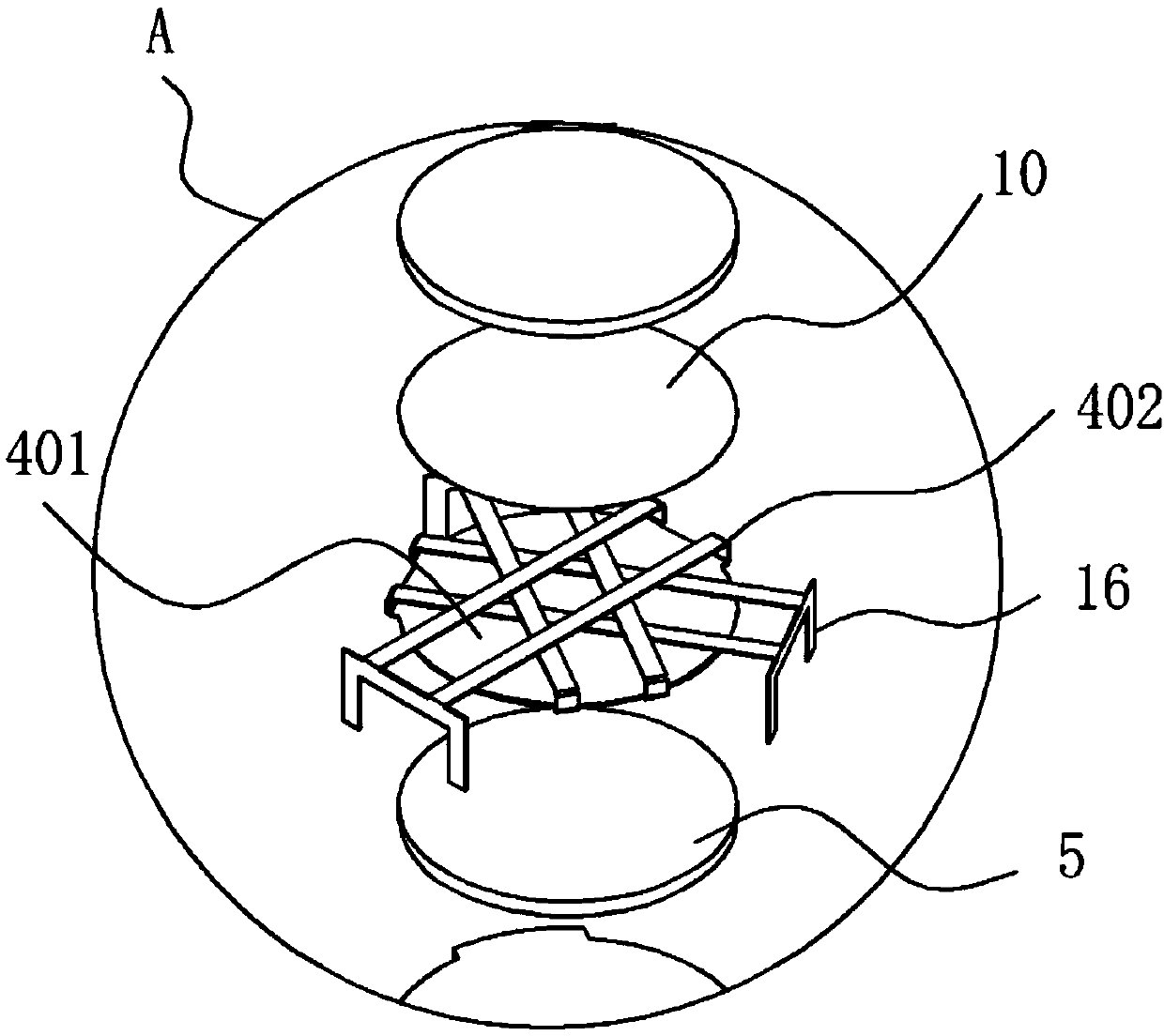

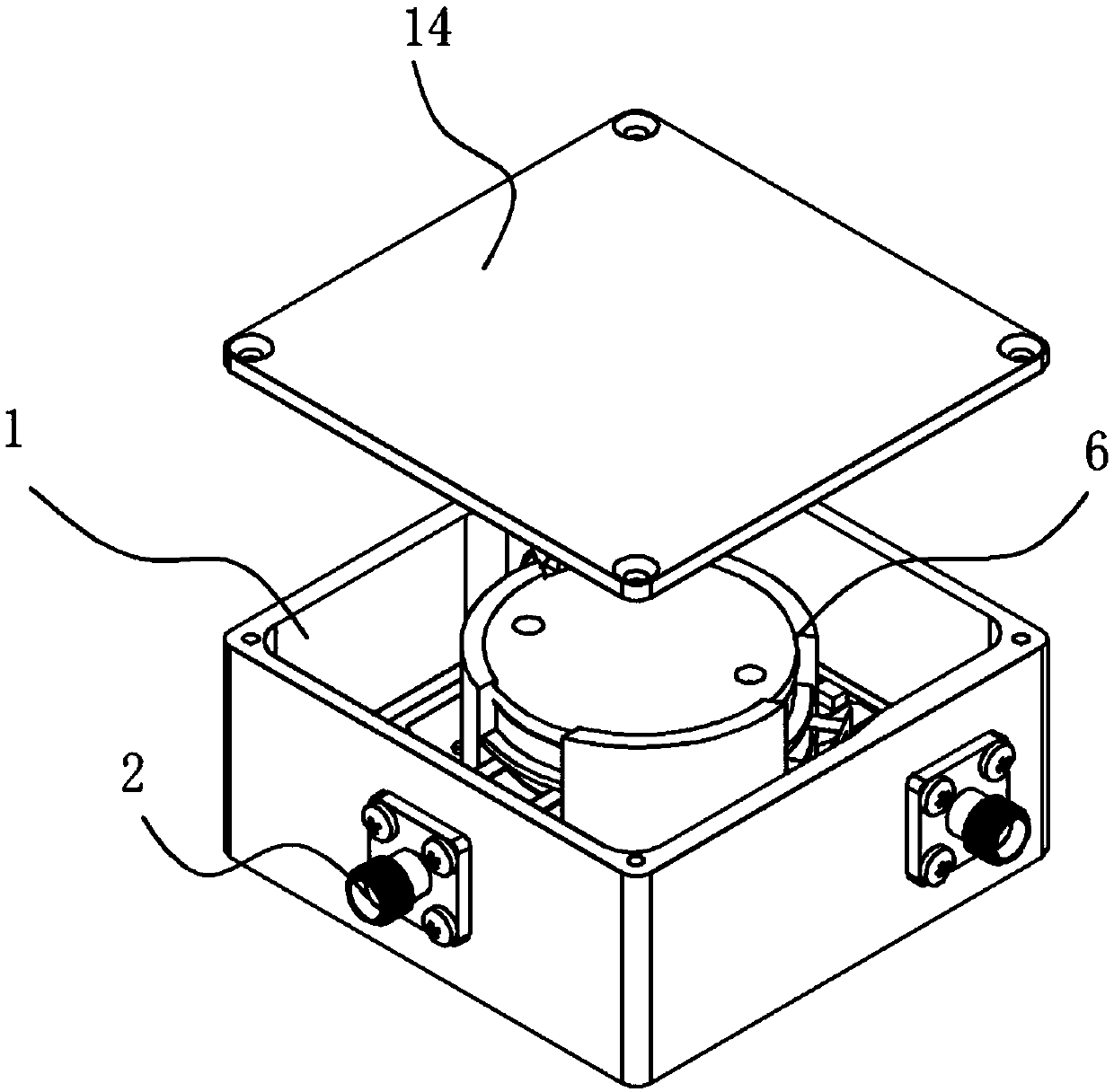

Radio frequency communication circulator and isolator

ActiveCN108682928ASimple structureImprove space utilizationWaveguide type devicesElectrical conductorMicrowave

The invention belongs to a radio frequency transmission device and discloses a radio frequency communication circulator and an isolator. The radio frequency communication circulator comprises a casingand an electromagnetic limiting device arranged in the casing. The casing is provided with three connectors, and the signal one-way annular transmission among the connectors is restricted by the electromagnetic limiting device. The electromagnetic limiting device comprises a circuit board and a gyromagnetic body, the gyromagnetic body comprises a center conductor of a Y-shaped structure and ferrites arranged on two sides of the center conductor to sandwich the center conductor, and an additional magnetic field is arranged at the outer side of the ferrites such that the ferrites form magnets whose gyromagnetic characteristics to restrict an incoming microwave radio frequency signal from one-way annular transmission. Through optimizing an internal structure, the volume is reduced, and the degree of integration is raised.

Owner:优译有限公司

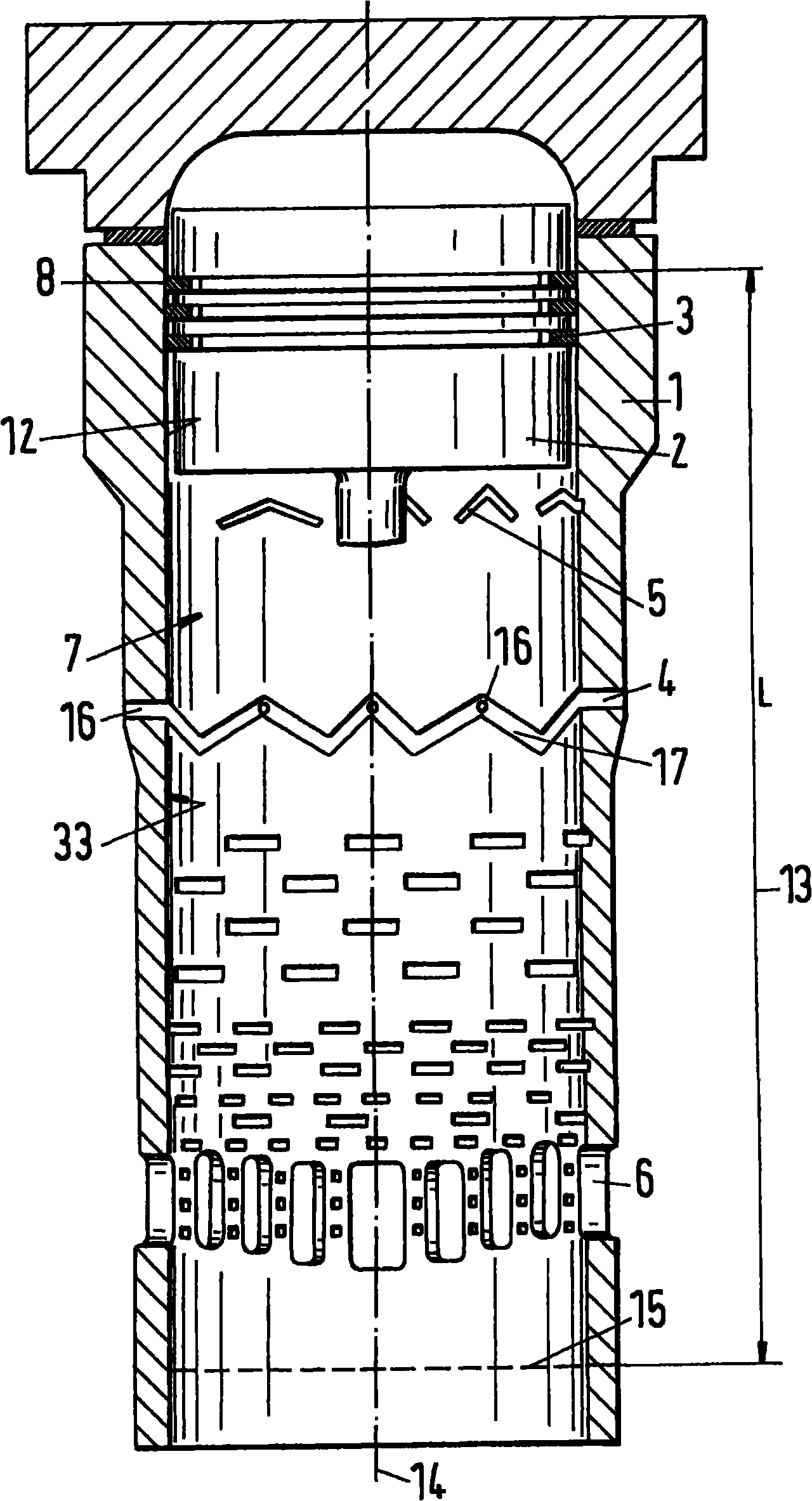

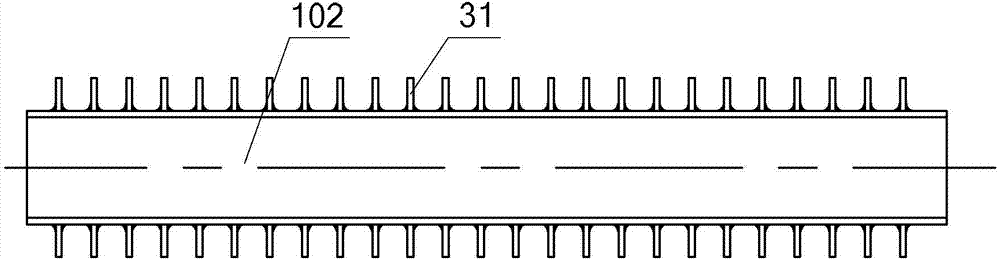

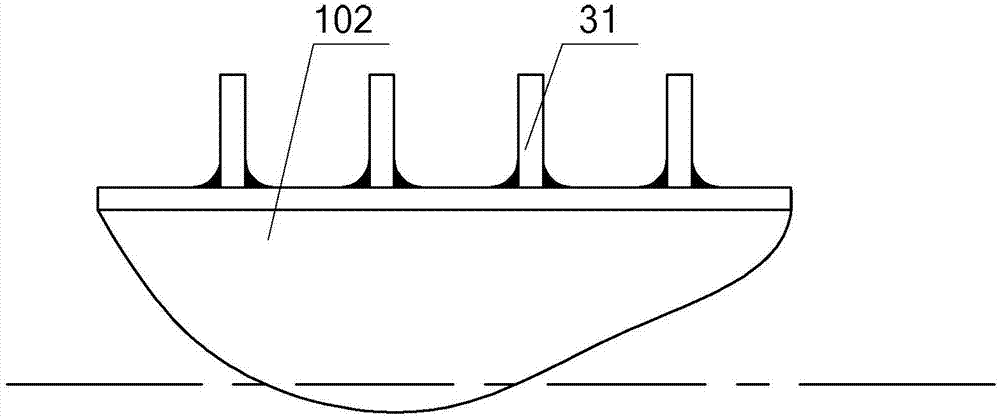

Cylinder with devices for distributing lubricants

ActiveCN101846010AReduce consumptionReduce delivery volumeCylinder headsCylindersInterior spaceEngineering

The invention relates to a cylinder with devices for distributing lubricants, in particular, to a cylinder for a reciprocating piston engine holding a piston prepared with at least a piston ring. The cylinder has a slit for holding and distributing lubricants. The slit is arranged at a sliding surface. The slit includes a first part and a second part, wherein the first part includes a first end and a second end. The first end has a first orifice and the second end has a second orifice. The second part includes a second end and a third end. The third end includes a third orifice. First and third orifices are arranged under the piston ring via the slit and the second orifice is arranged above the pistion ring via the slit, thereby the pistion ring could form a channel for lubricants between an inner space of the cylinder above the piston ring and the inner space of the cylinder under the piston ring when it is located between one of first and third orifices and the second orifice.

Owner:WAERTSILAE SCHWEIZ AG

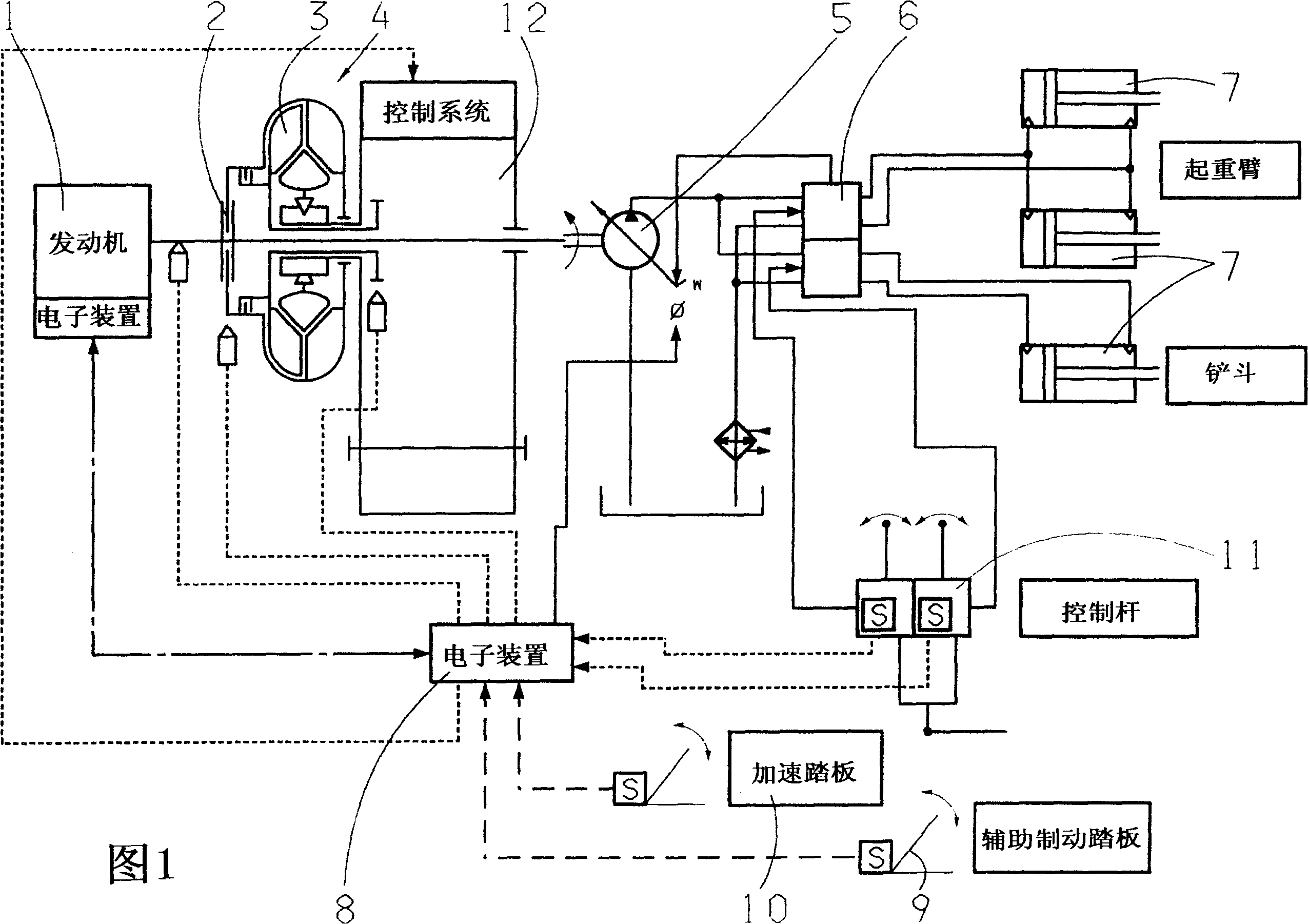

Engine assembly for driving a motor vehicle

InactiveCN1768219AReduce capacityReduce speedGearing controlSoil-shifting machines/dredgersMobile vehicleHydraulic pump

In order to reduce the structural volume of the engine (1) used to drive the mobile vehicle, especially the transmission line of such a working machine as a wheel loader, the hydraulic pump (5) of the engine (1) and the working hydraulic system An infinitely adjustable gearbox is arranged between them, which can be adjusted depending on the load state of the engine (1).

Owner:ZF FRIEDRICHSHAFEN AG

Method for preventing air release valves of double-hearth kiln from spraying ash

ActiveCN112146447AReduce operating pressureImprove furnace conditionHuman health protectionMaintainance of heating chambersCombustionDust control

The invention discloses a method for preventing air release valves of a double-hearth kiln from spraying ash. The method comprises the following steps as follows: A, when a system cuts off conveying coal gas to the kiln, an electric control valve is opened to convey the gas in the kiln to a dust remover, and the pressure in the kiln is reduced to 10kpa or lower before entering a reversing period;B, blowing is conducted on a dust removal cloth bag once per hour; C, during reversing, a combustion-supporting air release valve is opened for 3 seconds, and then a cooling air release valve is opened; D, raw material granularity control is conducted; and E, the opening and closing action time of each valve is adjusted to be 4-5 seconds by adopting a mode of feeding during combustion. Compared with the prior art, during reversing of the kiln, the gas in the kiln is released to the dust remover in advance, dust sprayed out of the combustion-supporting air release valve is recycled, the pressure in the kiln is reduced through technological operation improvement and other means, and the ash spraying phenomenon generated by the combustion-supporting air release valve and the cooling air release valve is prevented.

Owner:LIUZHOU IRON & STEEL CO LTD

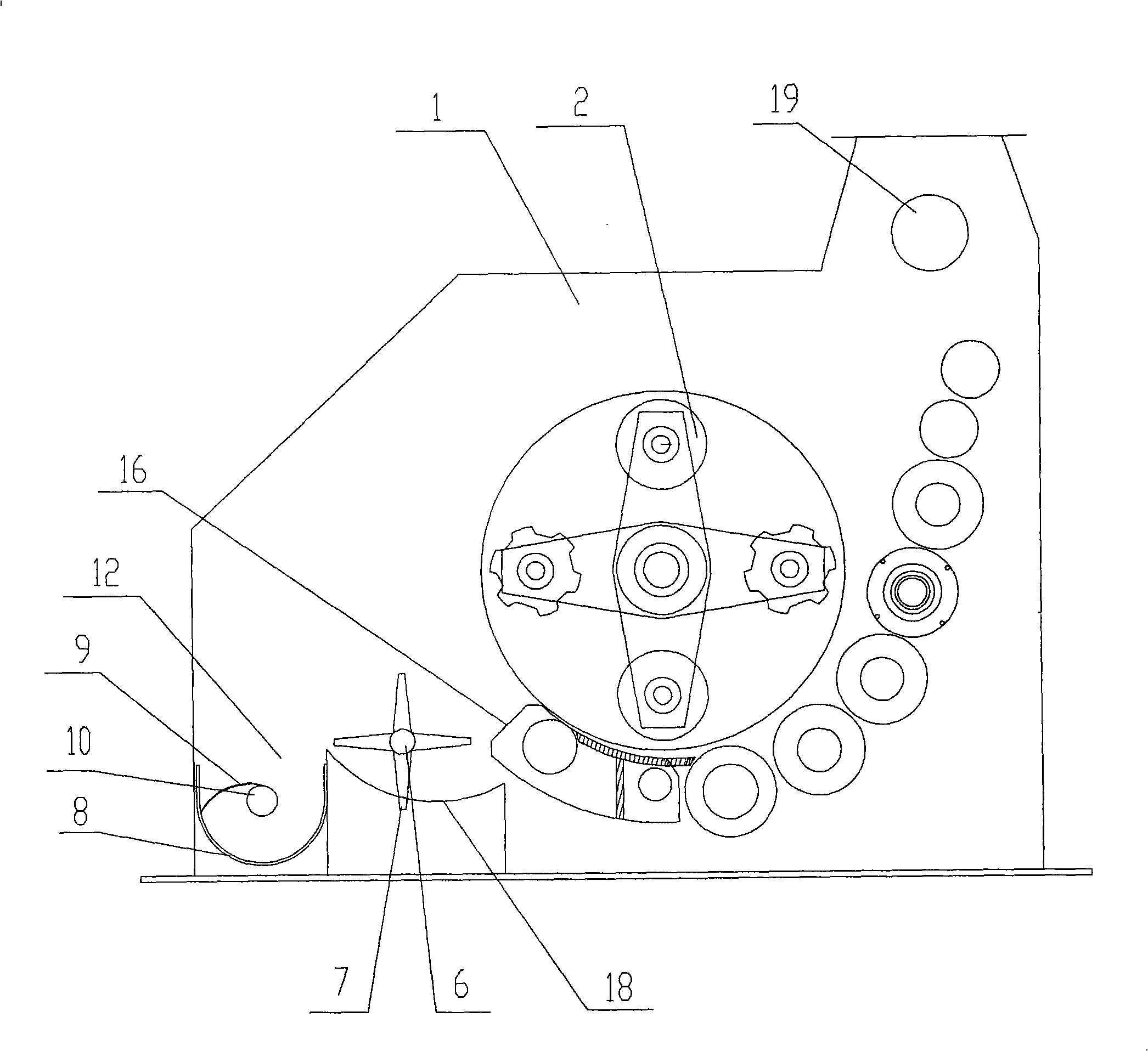

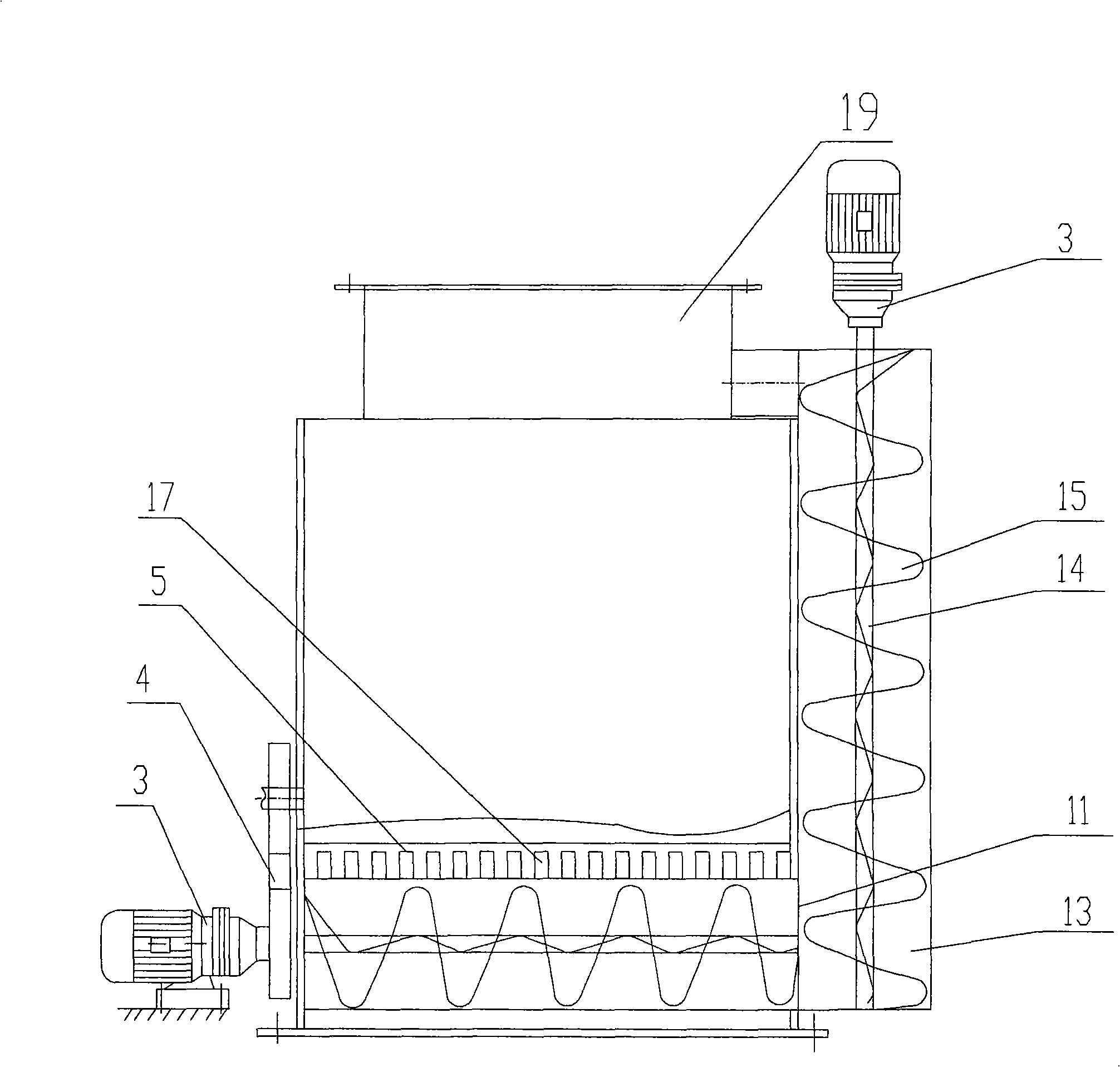

Automatic cycle crusher

The invention discloses an automatic cycle crusher, comprising a frame, wherein, a feeding port, a crushing cavity and a discharge port are arranged on the frame, the discharge port is provided with a screening device for firstly screening crushed materials, the materials-screening part of the screening device is provided with a horizontal screening conveying device for horizontally conveying the materials and secondly screening the materials, the outlet of the horizontal screening conveying device is provided with a lift conveying device for lifting and conveying the materials into the feeding port so that the materials enter into the crushing cavity for recycling crushing, and the screening device, the horizontal screening conveying device and the lift conveying device are all driven by a drive mechanism. The invention has the advantages that the crushed materials are firstly and secondly screened during horizontal conveying, and conveyed to the feeding port in a lifting way and recrushed by the crusher.

Owner:张世洪 +1

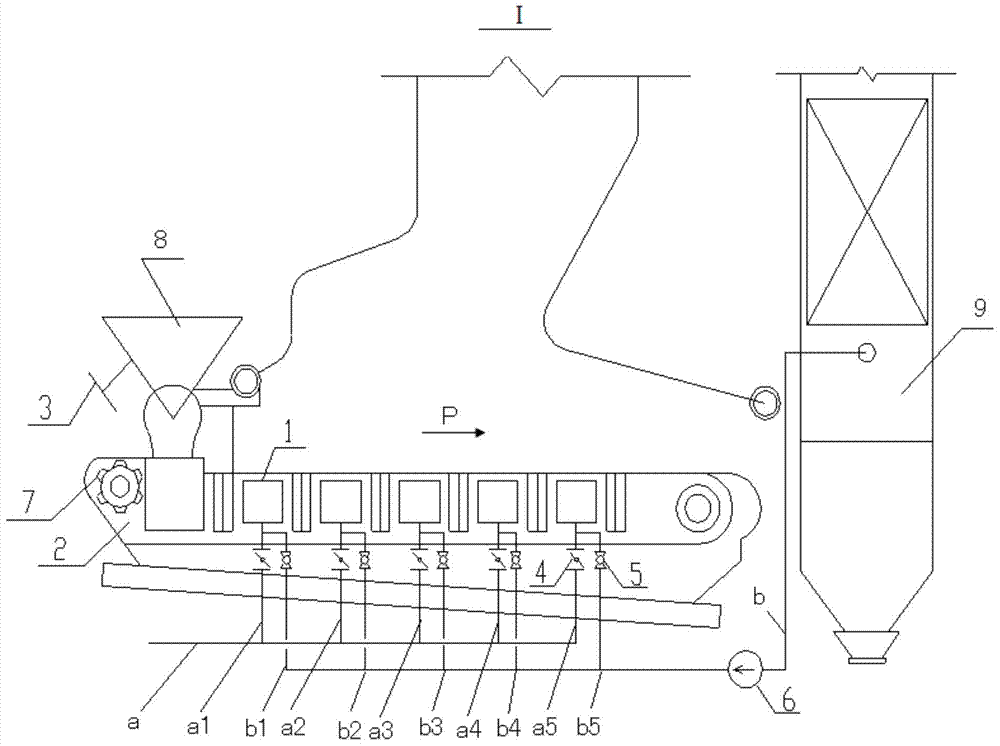

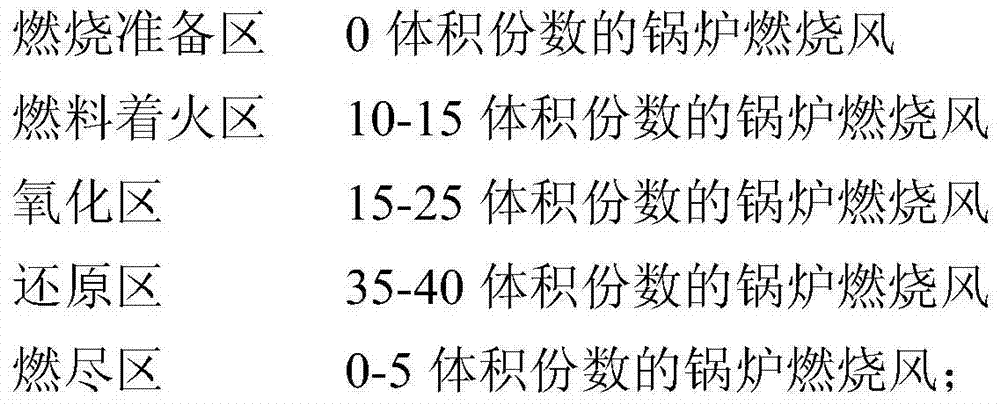

Compound recycling low-nitrogen combustion method for chain boiler

InactiveCN104728830AOptimize combustion structureBurn fullyAir supply regulationSolid fuel combustionCombustion chamberLow nitrogen

The invention discloses a compound recycling low-nitrogen combustion method for a chain boiler. The method comprises the steps that boiler combustion wind is supplied into a combustion preparation zone, a fuel combustion zone, an oxidation zone, a reducing zone and a burn-out zone of the boiler according to the proportion, 0% of the boiler combustion wind is supplied to the combustion preparation zone, 10-15% of the boiler combustion wind is supplied to the fuel combustion zone, 15-25% of the boiler combustion wind is supplied to the oxidation zone, 35-40% of the boiler combustion wind is supplied to the reducing zone, and 0-5% of the boiler combustion wind is supplied to the burn-out zone; low-temperature smoke after combustion in the boiler is extracted, supplied to the combustion preparation zone, the fuel combustion zone, the oxidation zone, the reducing zone and the burn-out zone after boosting is carried out, and mixed with the boiler combustion wind so as to be supplied to the chain boiler to be combusted. According to the compound recycling low-nitrogen combustion method for the chain boiler, generation of fuel type NOx and heating power type NOx can be effectively controlled, full combustion of the fuel can be promoted, and the optimal combustion effect in a combustion chamber of the boiler is achieved easily.

Owner:上海卫源节能环保科技有限公司

Sorting dustbin

ActiveCN105329588AReduce delivery volumeReduce loadWaste collection and transferRefuse receptaclesLitterProcessing plants

The invention relates to a sorting dustbin which comprises a bin body and a ventilation assembly. The bin body is provided with a first chamber, a second chamber and a third chamber. The first chamber is provided with a first opening, and the third chamber is provided with a second opening. The first chamber and the second chamber are communicated. An ignition device is arranged in the second chamber. The third chamber is isolated from the first chamber and the second chamber. The ventilation assembly is communicated with the second chamber. Garbage is sorted through the first chamber and the third chamber, and incombustible garbage is stored in the third chamber while combustible garbage is conveyed to the second chamber from the first chamber and is incinerated in the second chamber. Garbage can be processed quickly through garbage sorting, the situation that the surroundings are affected after garbage is stacked for too long is avoided by incinerating combustible garbage, the garbage conveying capacity is reduced, and labor is greatly saved. Besides, loads of garbage processing plants are reduced, and the influence on the surroundings of the garbage processing plants is reduced.

Owner:北京鑫存远方网络科技有限公司

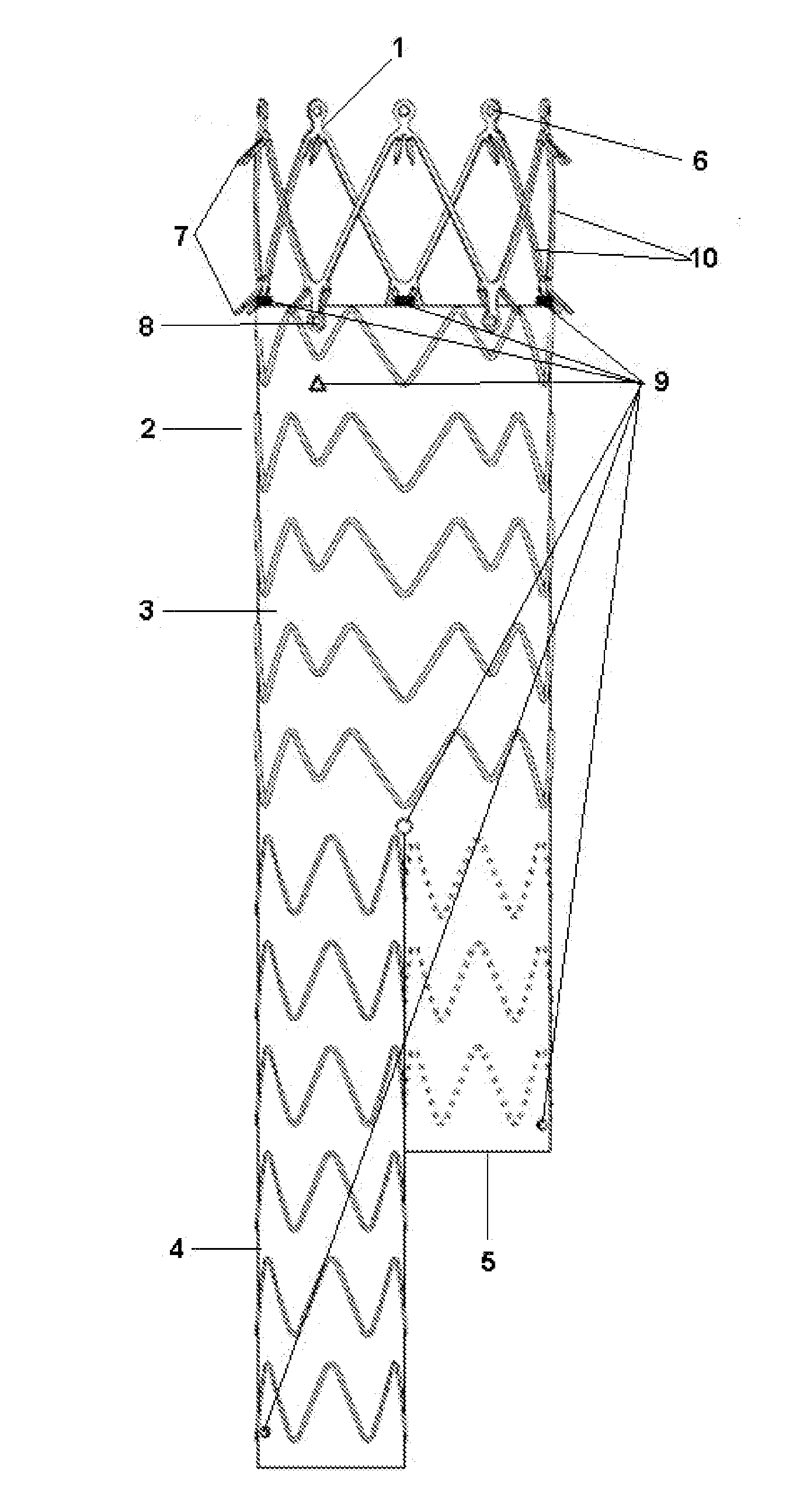

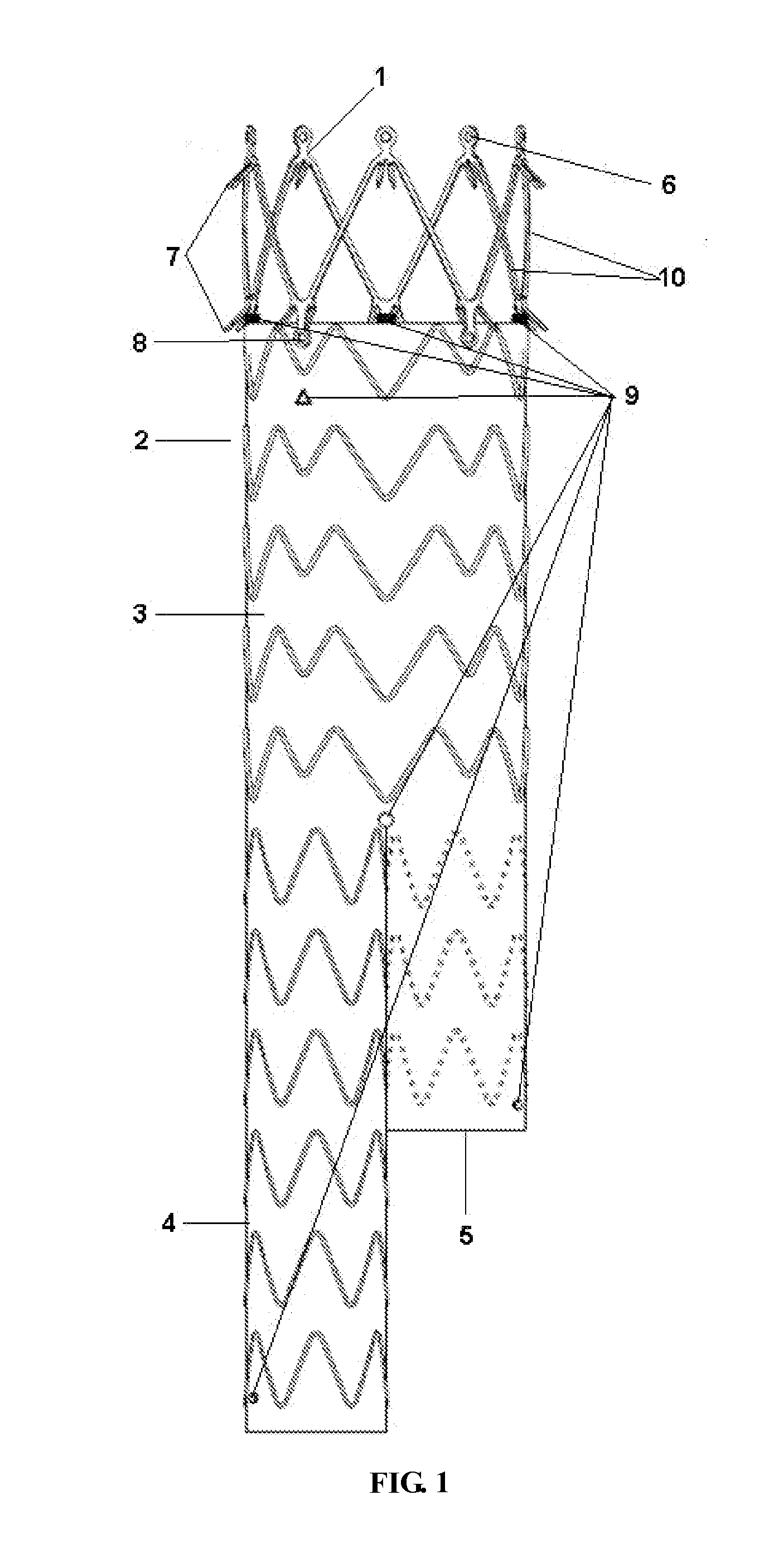

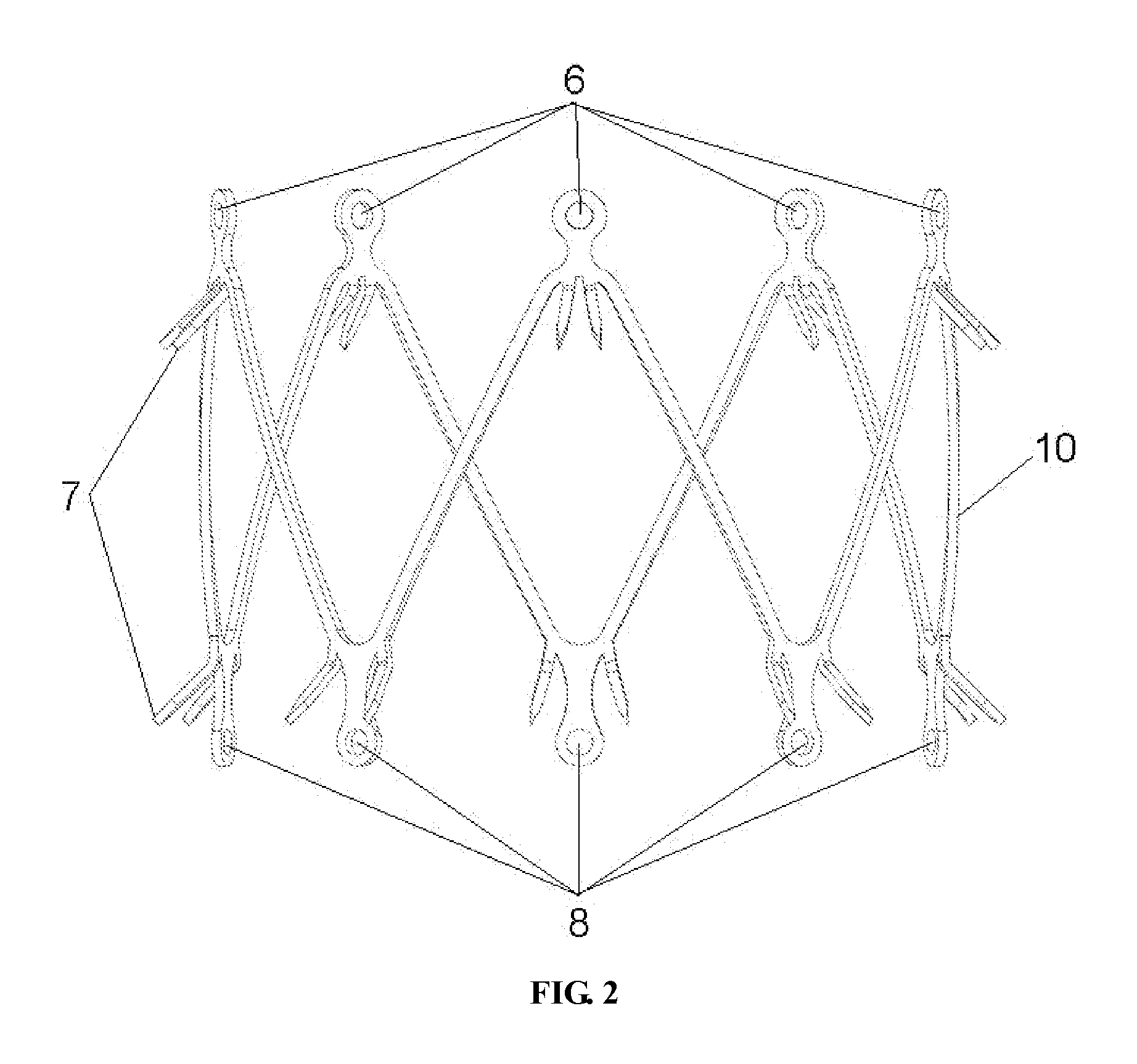

Aortic stent-graft

An aortic stent-graft capable of avoiding migration of location, which includes a covered stent body and a bare stent connected to a proximal end of the covered stent body, with barbs for looseness-proof fixation which are provided at each wave crest and each wave trough of the bare stent and extend towards a distal end of the covered stent body. After the aortic stent-graft is fastened by the looseness-proof fixation structures, because the barbs arranged at each wave crest of the bare stent are not on the same plane with the barbs arranged at each wave trough of the bare stent, simultaneous relative motions of the two sets of barbs which may lead to detachment or loosening of the looseness-proof fixation structures will not happen, so that the aortic stent-graft is able to be fastened onto a blood vessel wall more firmly.

Owner:BEIJING PERCUTEK THERAPEUTICS CO LTD

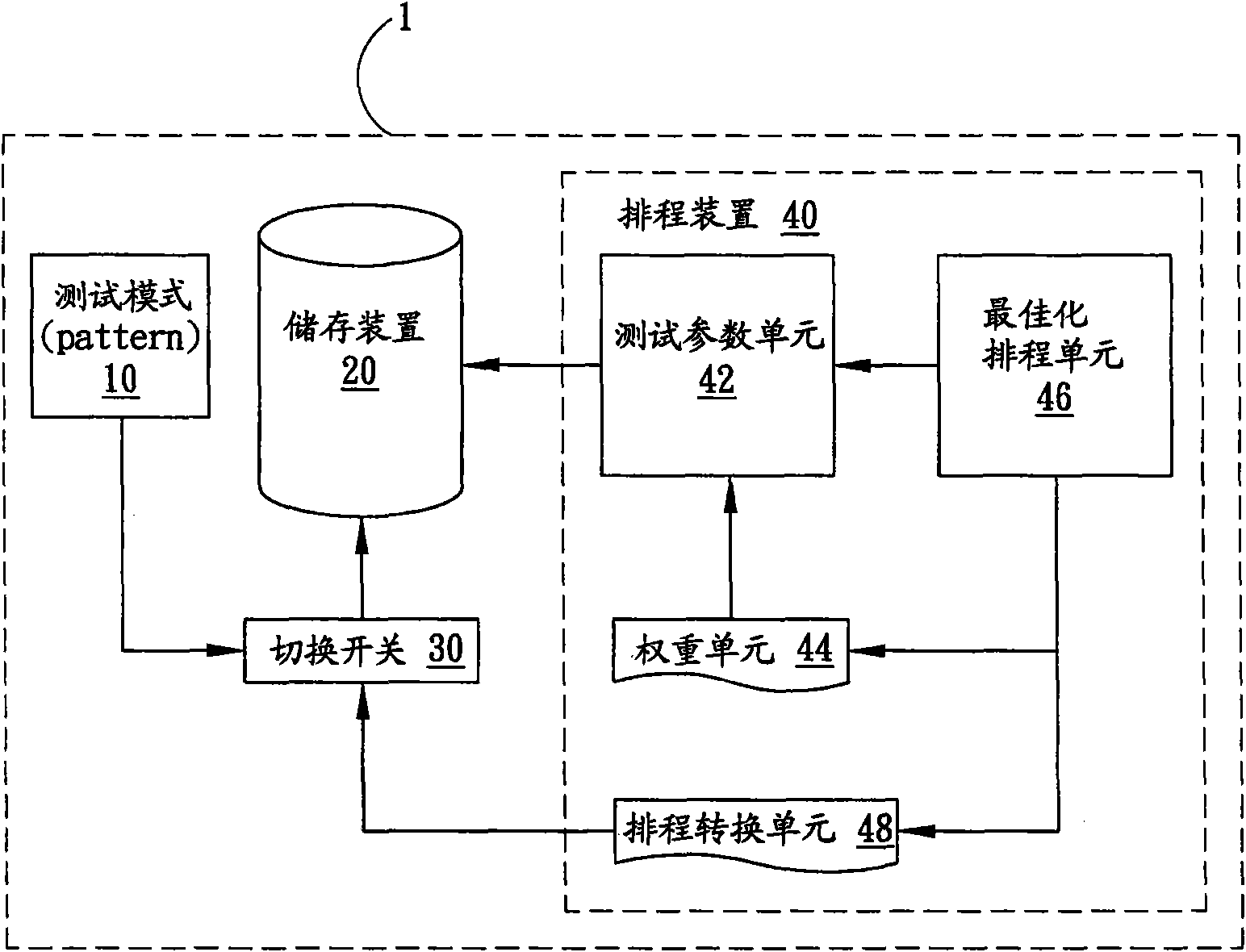

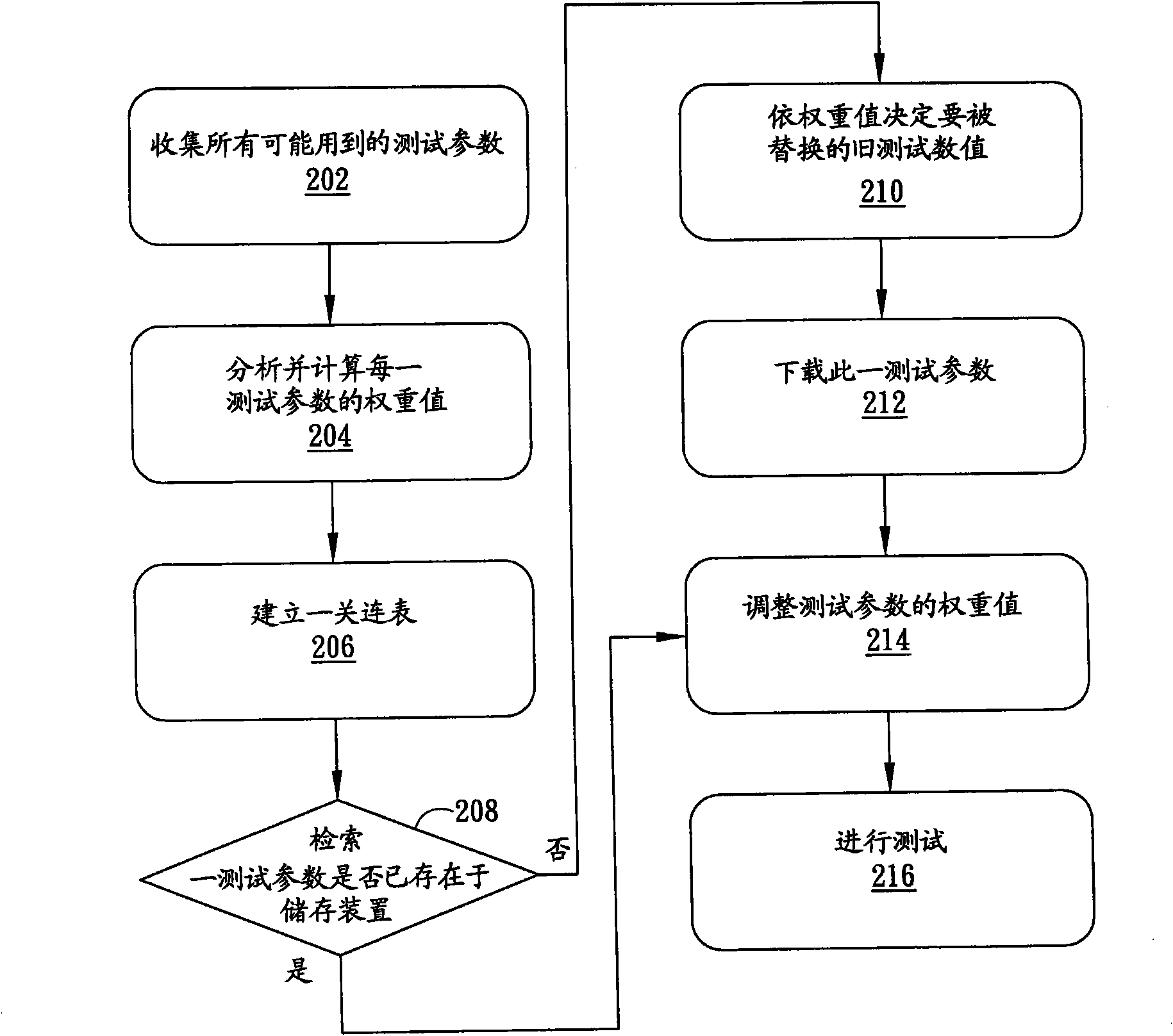

Test scheduling system and test scheduling method

ActiveCN101666853AReduce delivery volumeAutomatically adapts to dynamic adjustmentsIndividual semiconductor device testingTest flowTest scheduling

The invention relates to a test scheduling system and a test scheduling method, in particular to a test scheduling system and a test scheduling method for automatically optimized testing a parameter download process in a testing process. The test scheduling system and the test scheduling method calculate a weight value of each testing parameter through a weight unit, and establish an optimized testing parameter download process by a mode that the priority for downloading the testing parameters is given to larger weight value, so that the required testing parameters can be downloaded in the minimum downloading frequencies and time of the testing parameters to improve the testing efficiency.

Owner:KING YUAN ELECTRONICS

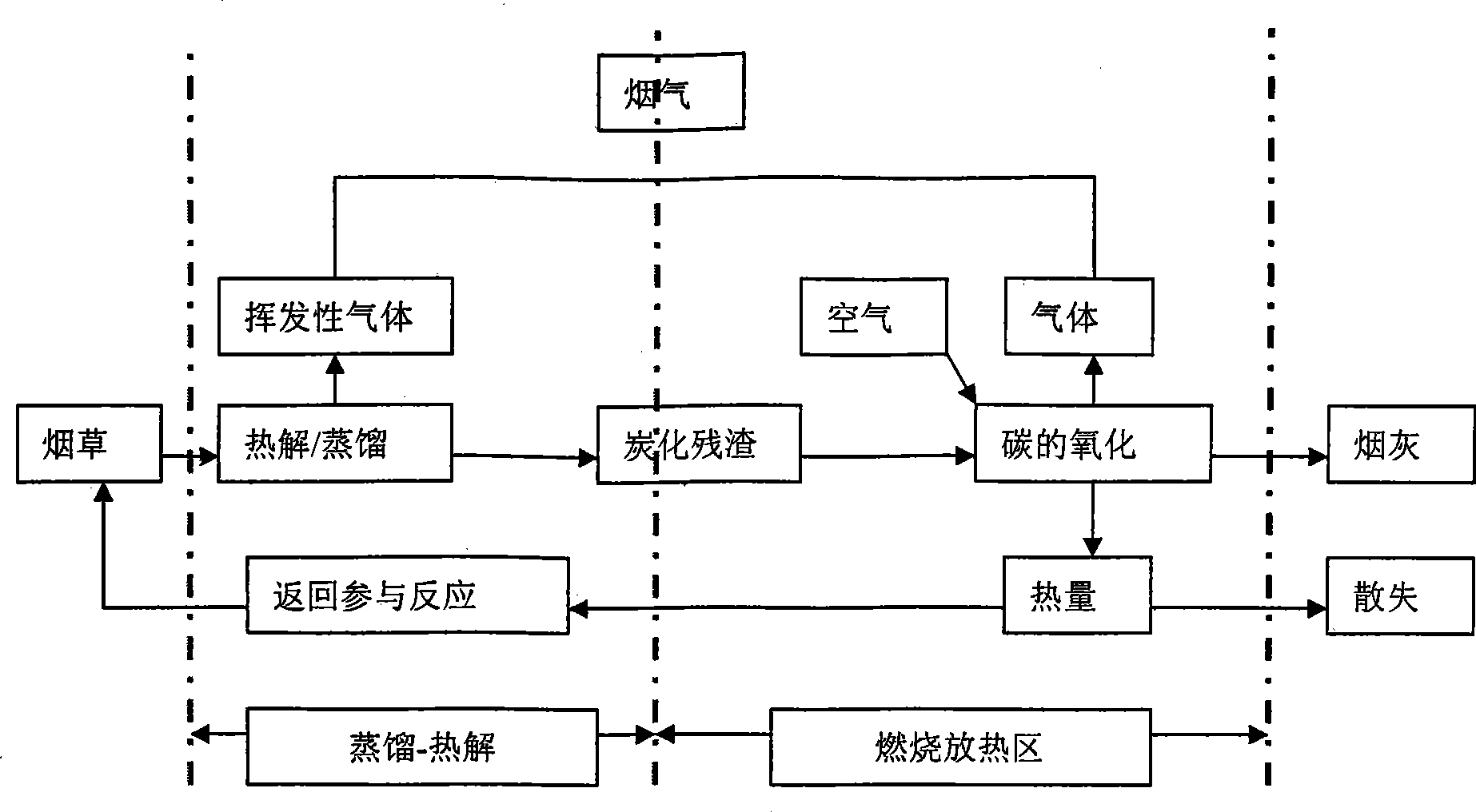

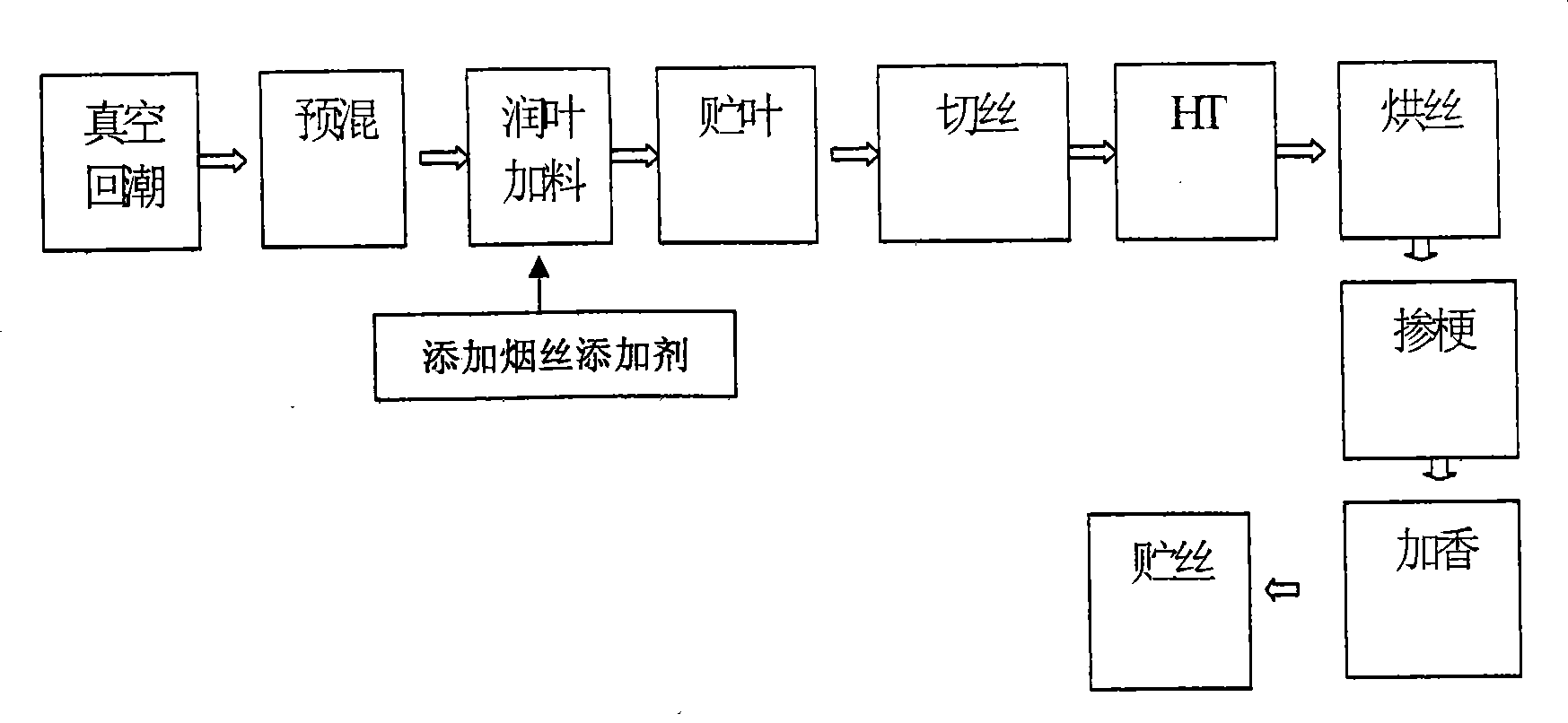

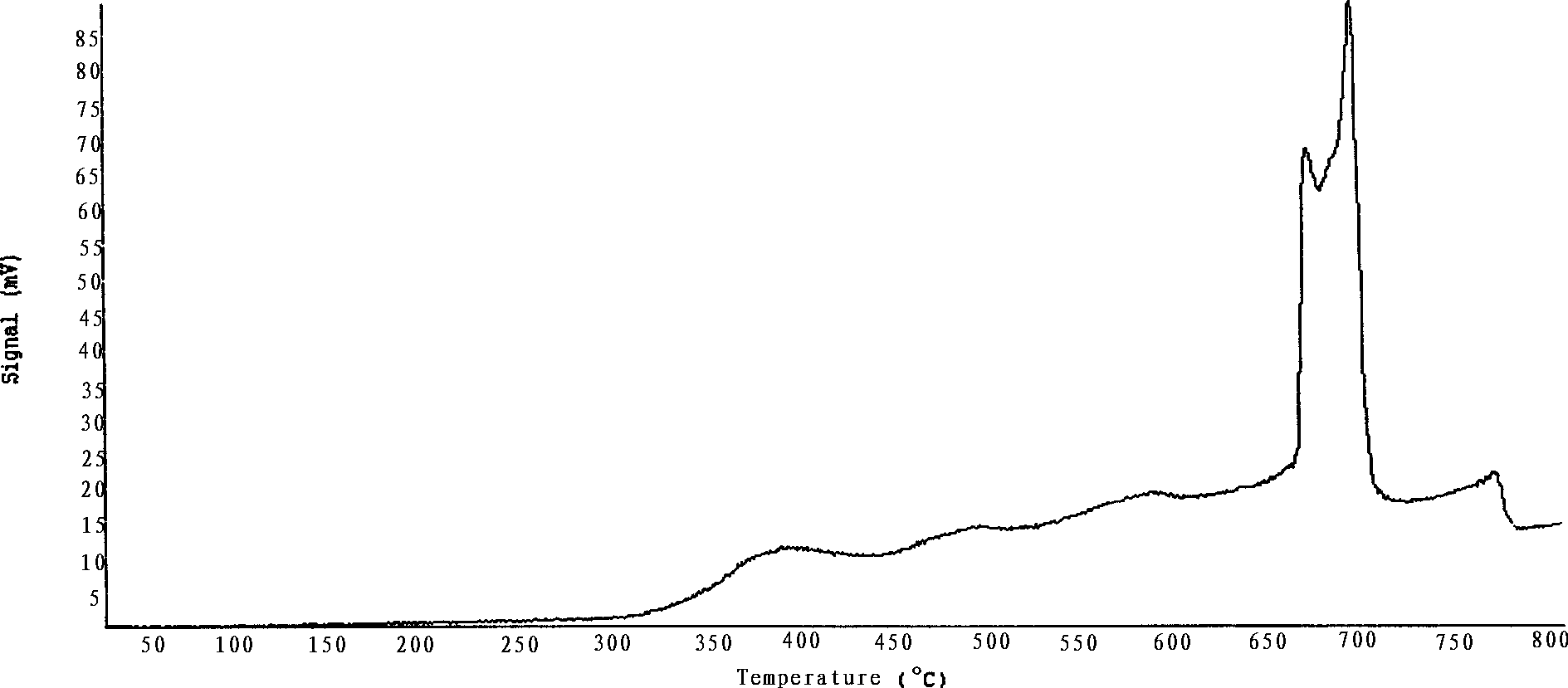

Tobacco shred additive capable of reducing carbon monoxide in cigarette fume

InactiveCN101416779ARaise the combustion temperatureReduce delivery volumeTobacco preparationTobacco treatmentHYDROSOLSodium sulfate

The invention discloses a cut tobacco additive which can reduce the CO in the smoke gas. The additive is colloid water solution and comprises the components with the weight percentage as follows: 90 to 100 percent of organic sodium stannate kalium; 0 to 8.5 percent of cerous hydroxide as well as 0 to 1.5 percent of crystalline hydrate; wherein, the organic sodium stannate kalium is selected from one or two mixtures of sodium glutamate, potassium glutamate, sodium citrate and potassium citrate; the crystalline hydrate is selected from one of aluminum potassium sulfate dodecahydrate or hydrate sodium sulfate. The preparation method is as follows: 5 portions of CeO2 nano-hydrosol is prepared at first; then 60 portions of organic acid salt water solution with a content of 50 percent are added into one portion of the crystalline hydrate with a weight percentage of 30 percent and uniformly mixed and stirred for 30 minutes, thus obtaining the needed product. The product can effectively reduce the feed amount of the CO in a sample cigarette; for different test brands, the range by which CO is reduced is between 8.15 to 11.49 percent.

Owner:YUNNAN RES INST OF TOBACCO SCI

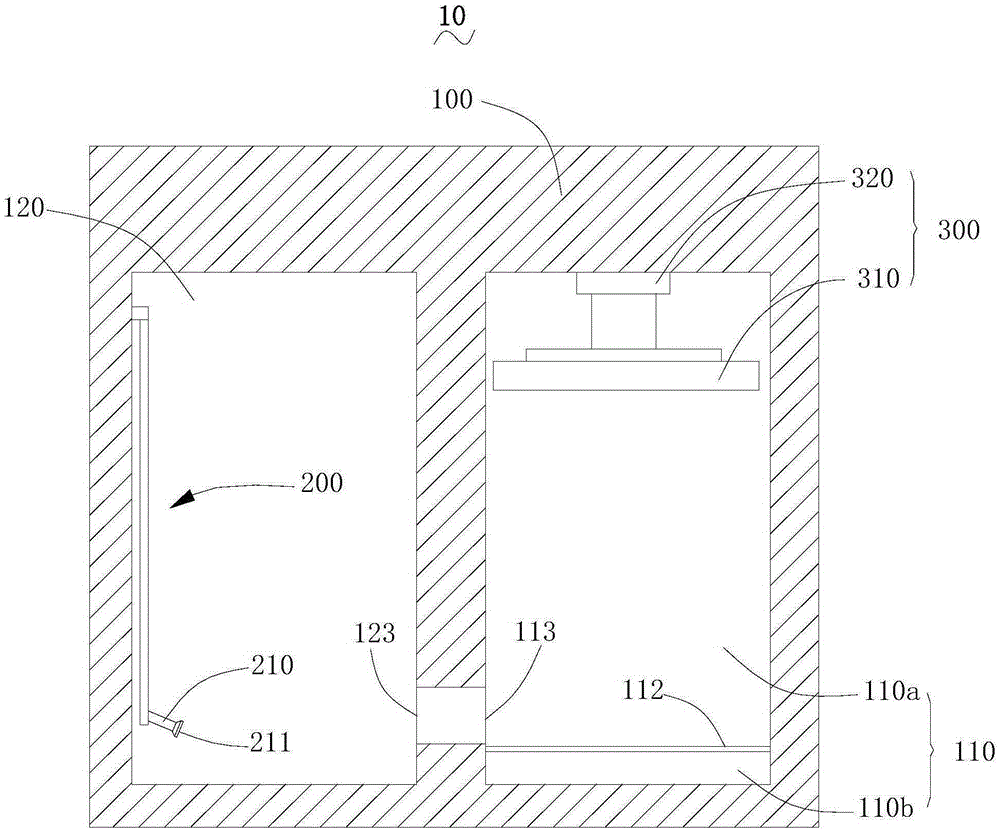

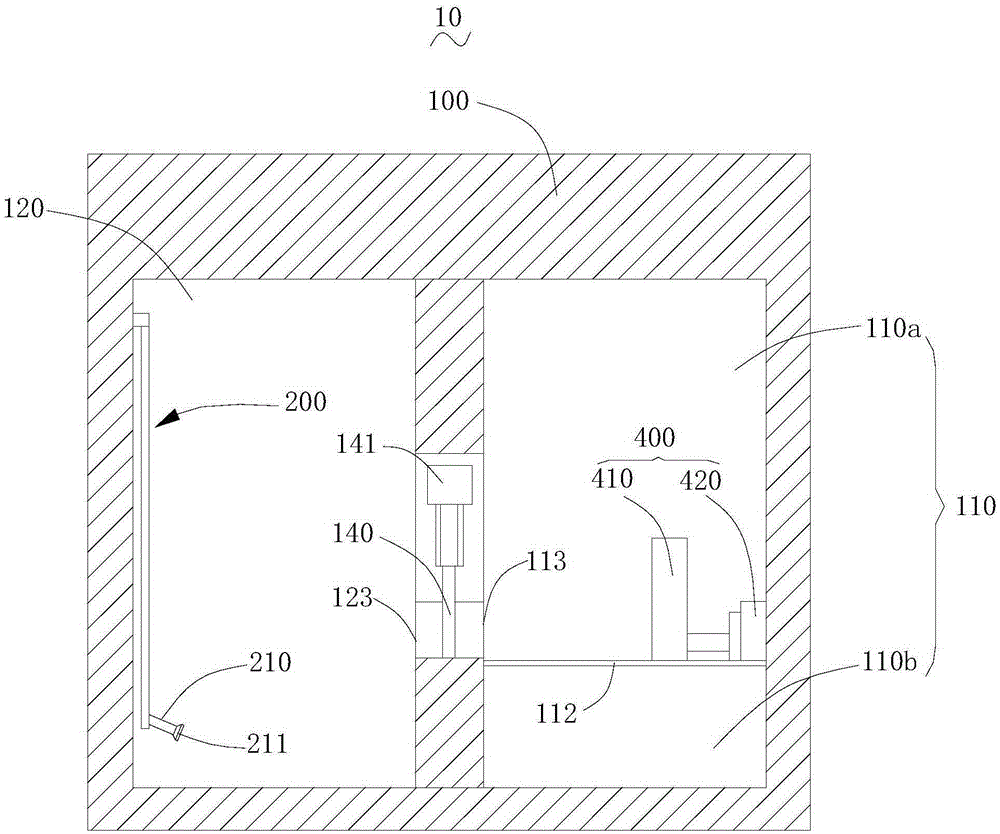

Box chamber space inner air pressure adjusting method

InactiveCN107504620AEliminate the defect that data cannot be adjustedEliminate non-adjustable defectsSpace heating and ventilation safety systemsLighting and heating apparatusAir volumeAtmospheric air

The invention discloses a box chamber space inner air pressure adjusting method. An air inlet system for supplying air into a box chamber space and an air outlet system for exhausting air outwards from the box chamber space are included. The air outlet system comprises an exhaust pipe and an exhaust fan which communicate with the box chamber space, in addition, an air supplementing pipe of a bypass communicates with the exhaust pipe, and a port of the air supplementing pipe is provided with an air volume adjusting structure and communicates with the atmosphere. The air inlet volume of the air supplementing pipe is adjusted through the air volume adjusting structure, and accordingly the air pressure of the box chamber space is adjusted.

Owner:XIAN AIRCRAFT IND GROUP

Dewing-free smoke heat energy carrying and transferring device

InactiveCN103486869AIncrease temperatureReduce delivery volumeIncreasing energy efficiencyHeat exchange apparatusThermal energyAutomatic control

The invention discloses a dewing-free smoke heat energy carrying and transferring device, relates to heat energy recycling technology and solves the problem of dewing and corroding of heat exchangers in the prior art. The dewing-free smoke heat energy carrying and transferring device comprises a cooler and a heat energy exchanger, the cooler comprises a shell and a cooling pipe arranged in the shell, one end of the cooling pipe is communicated with an evaporator through a water outgoing pipe, the evaporator is communicated with the other end of the cooling pipe through a water incoming pipe, the heat energy exchanger is communicated with the evaporator through a steam pipe and a condensation pipe respectively, an input pipeline for feeding of a low-temperature medium and an output pipeline for outputting of a high-temperature medium are arranged on the heat energy exchanger, a first thermodetector is arranged on the water incoming pipe and connected with an automatic control system, according to temperature detected by the first thermodetector, the automatic control system can adjust transferring quantity of the low-temperature medium in the input pipeline to control the temperature of liquid sequentially entering the evaporator and the water incoming pipe from the condensation pipe and finally reaching the cooling pipe to be higher than a dewing point of smoke in the cooler.

Owner:杨君廷 +1

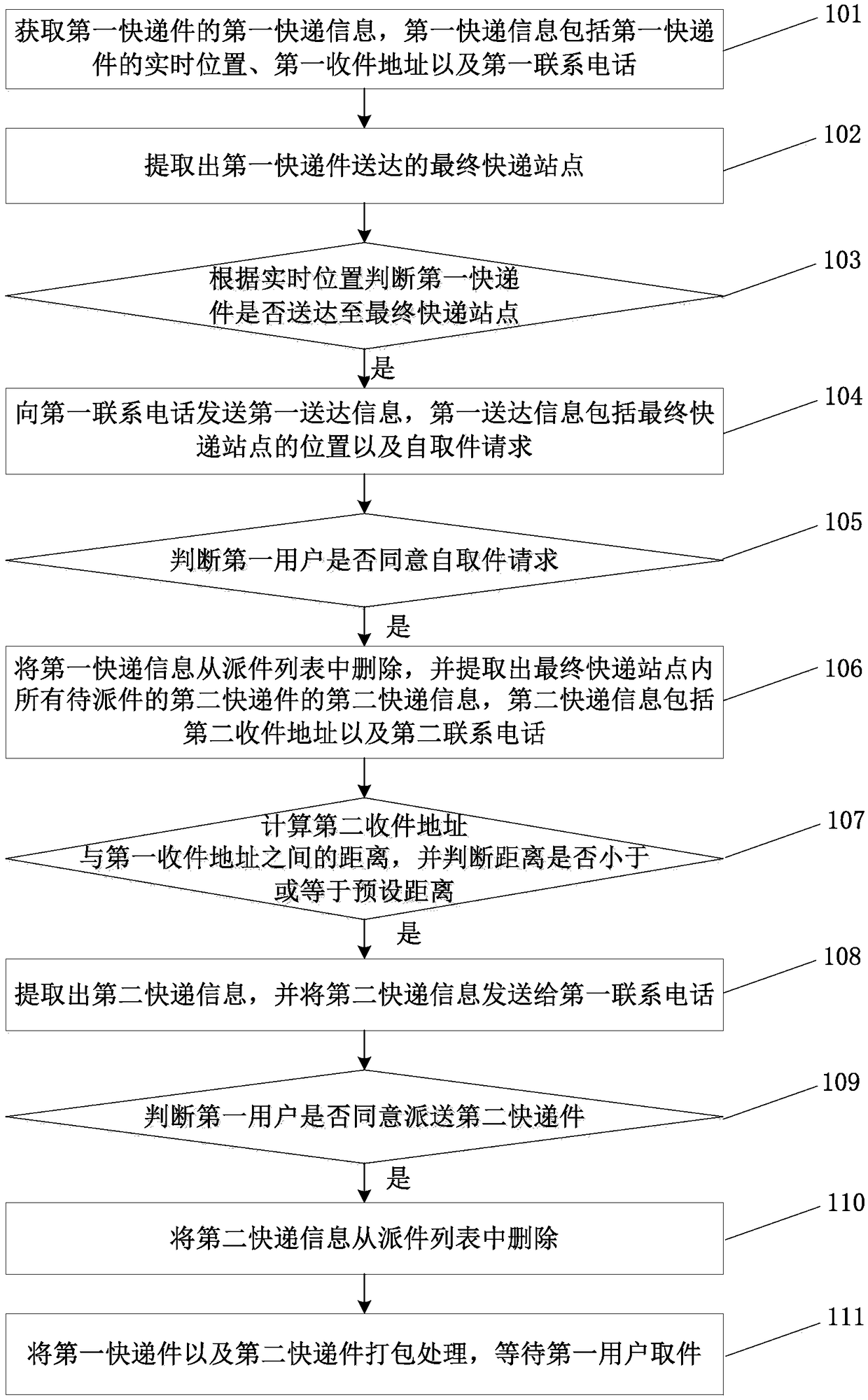

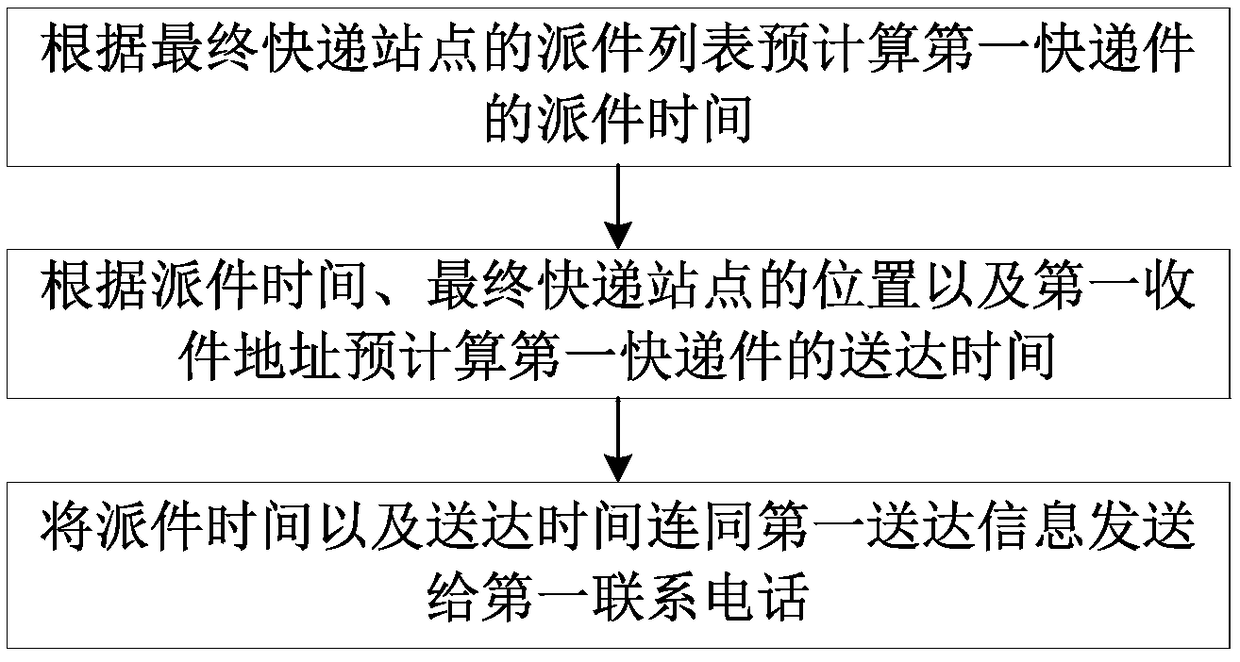

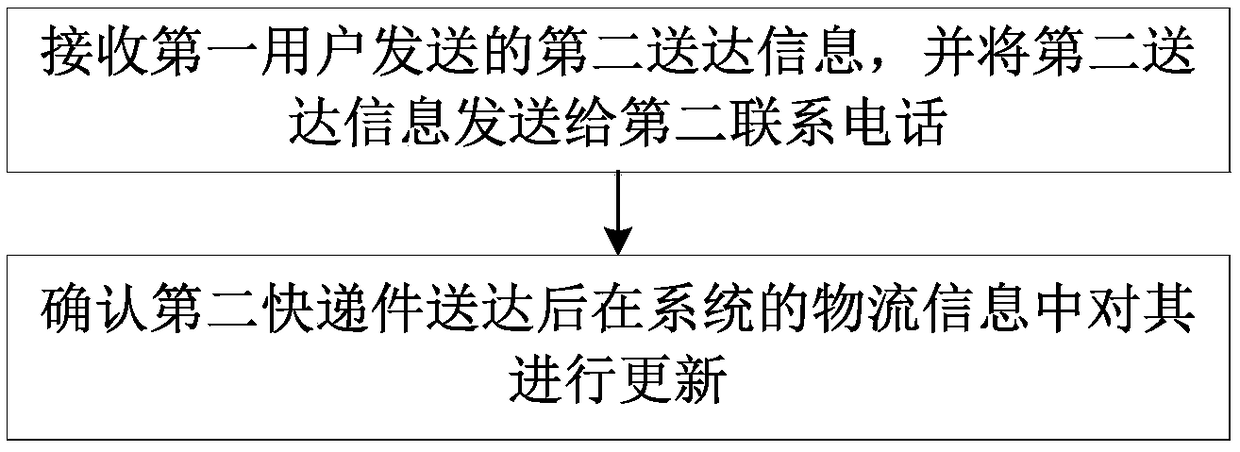

A self-picking method based on information sharing and a system thereof

InactiveCN109389347ADelivery time will not be delayedImprove delivery efficiencyLogisticsInformation sharingComputer science

The invention relates to a self-picking method based on information sharing and a system thereof. The method includes: obtaining first express information of a first express, wherein the first expressinformation comprises a first receiving address of the first express and a first contact telephone number; extracting a final courier station for delivery of the first courier; determining whether the first courier is delivered to the final courier station; If so, sending a first delivery message to the first contact telephone, the first delivery message comprising a self-retrieval request; determining whether the first user agrees to the self-retrieval request; If yes, extracting the second express information of the to-be-delivered item, the second express information includes a second receiving address and a second contact telephone number; calculating a distance between the second receiving address and the first receiving address, and judging whether the distance is less than or equalto a preset distance; If yes, extracting the second express information and sending the second express information to the first contact telephone; determining whether the first user agrees to deliverthe second courier; If so, the first courier and the second courier are packaged.

Owner:苏州亮磊知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com