Patents

Literature

91results about How to "Increase delivery pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

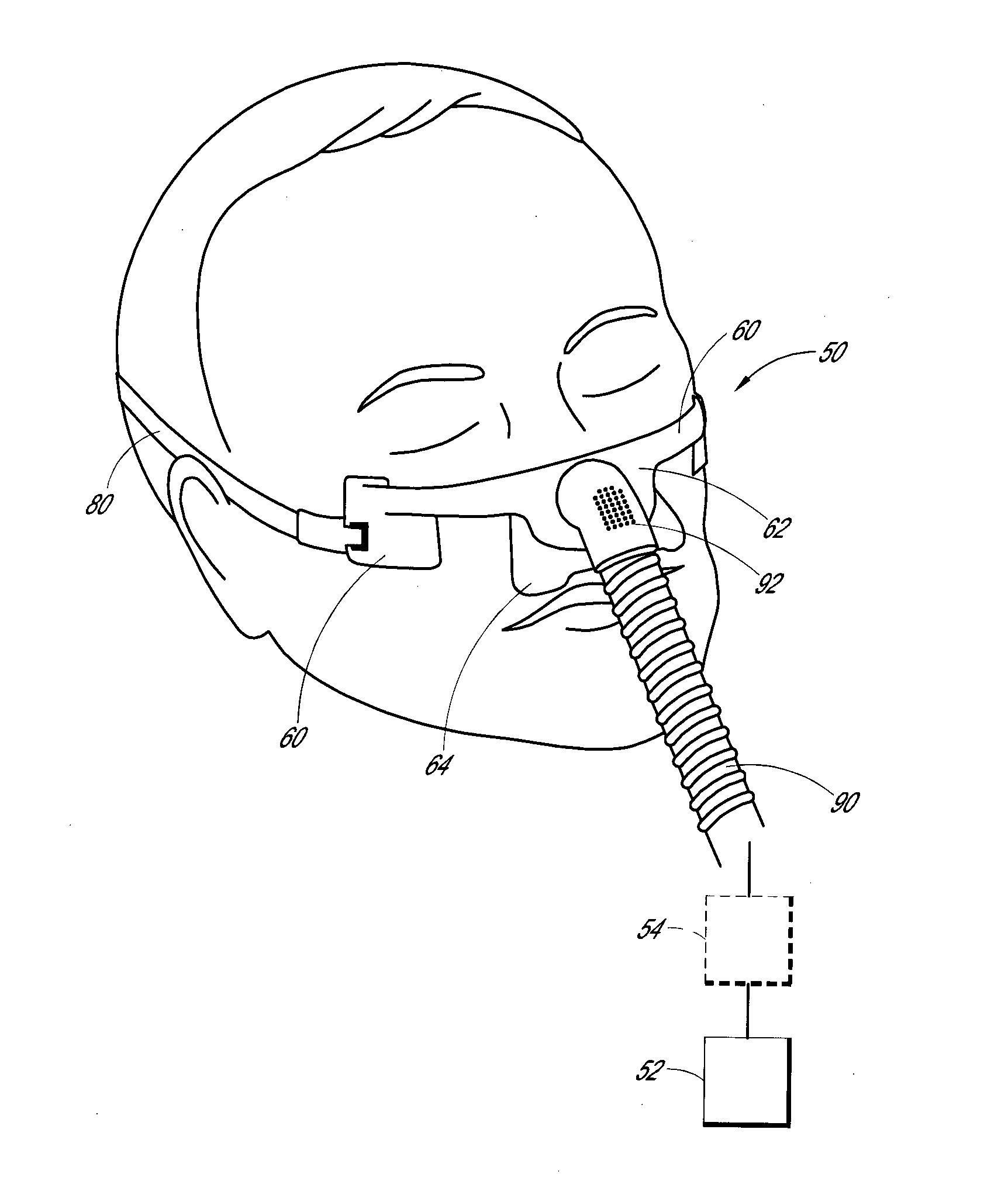

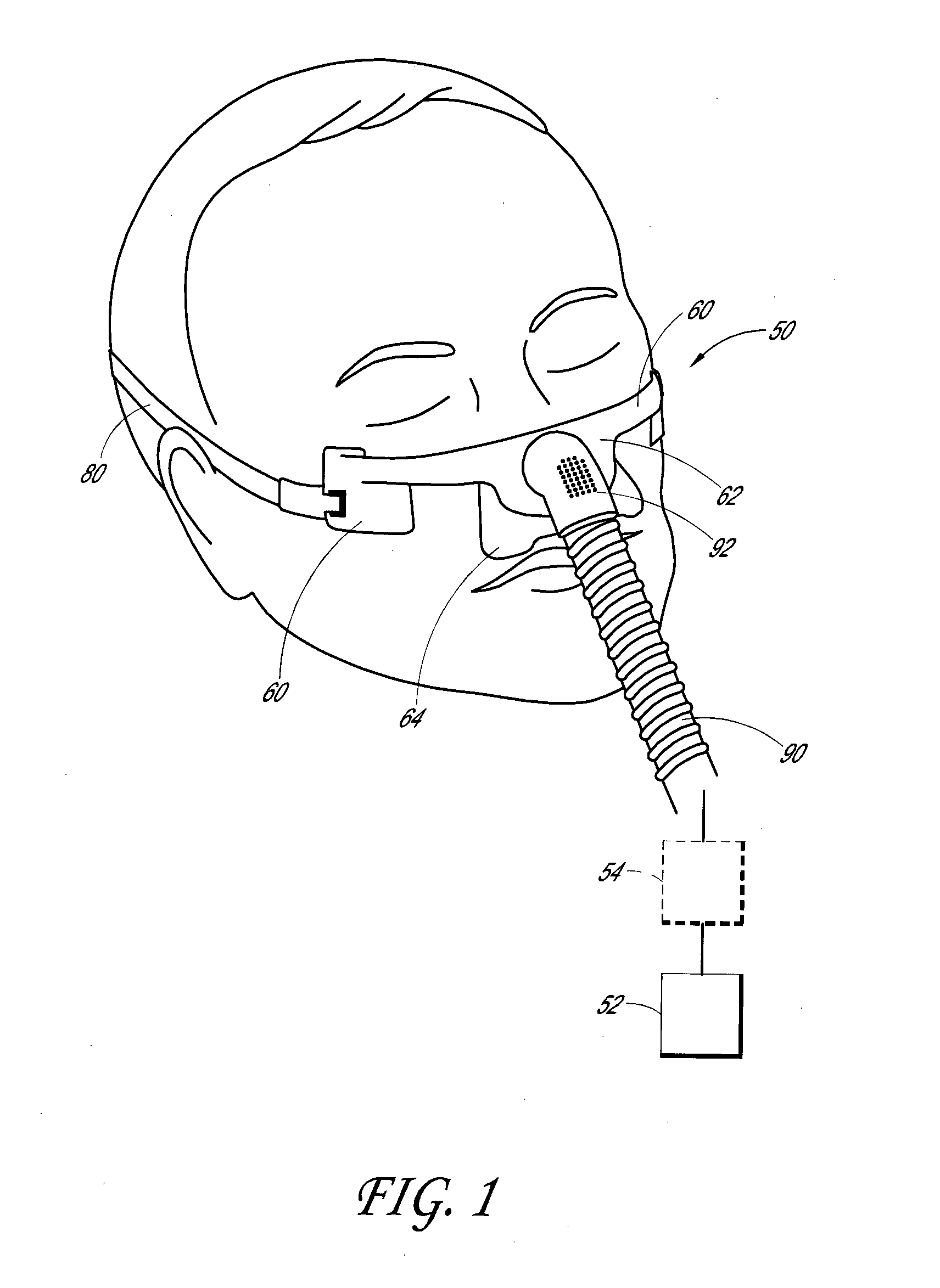

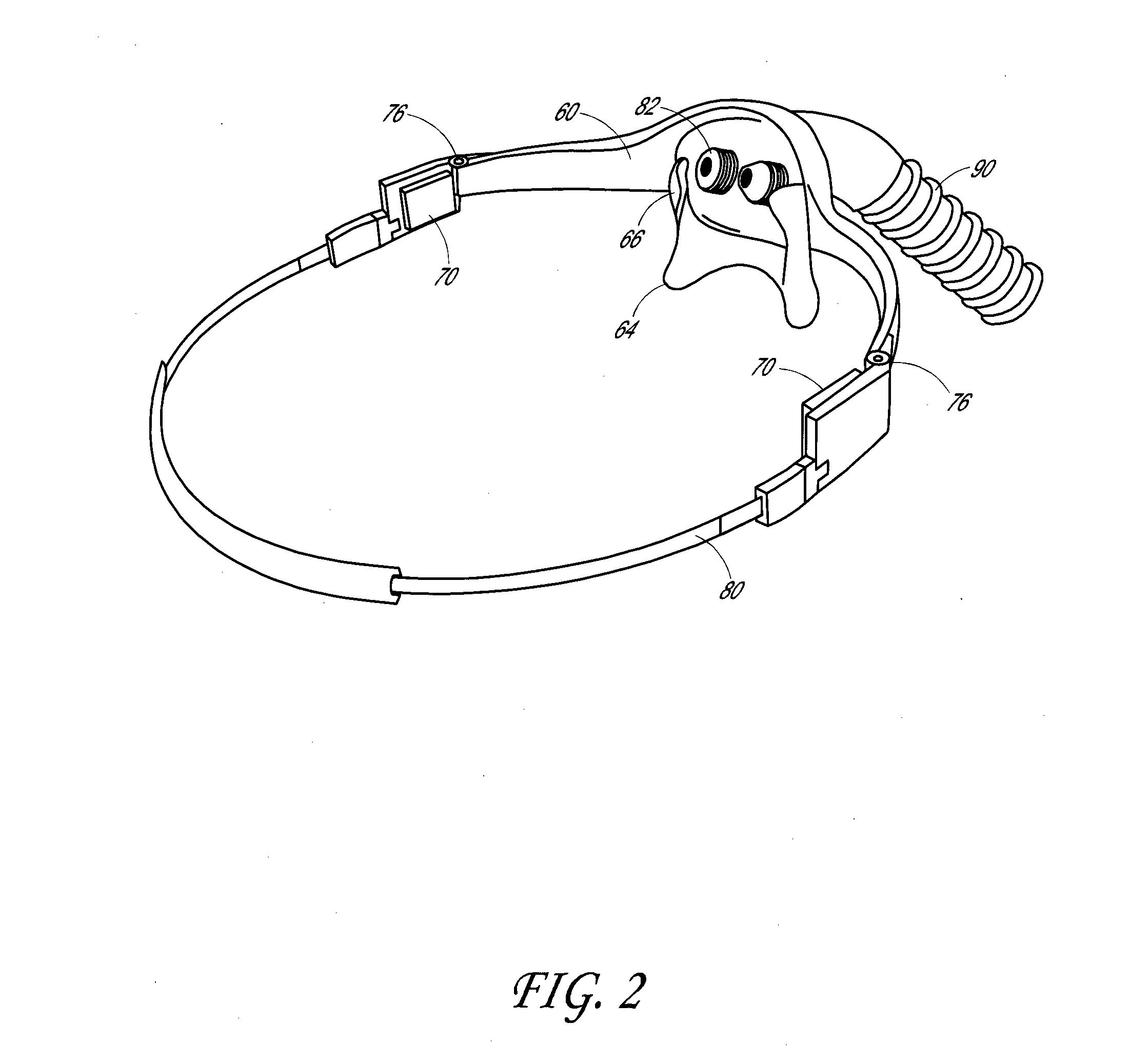

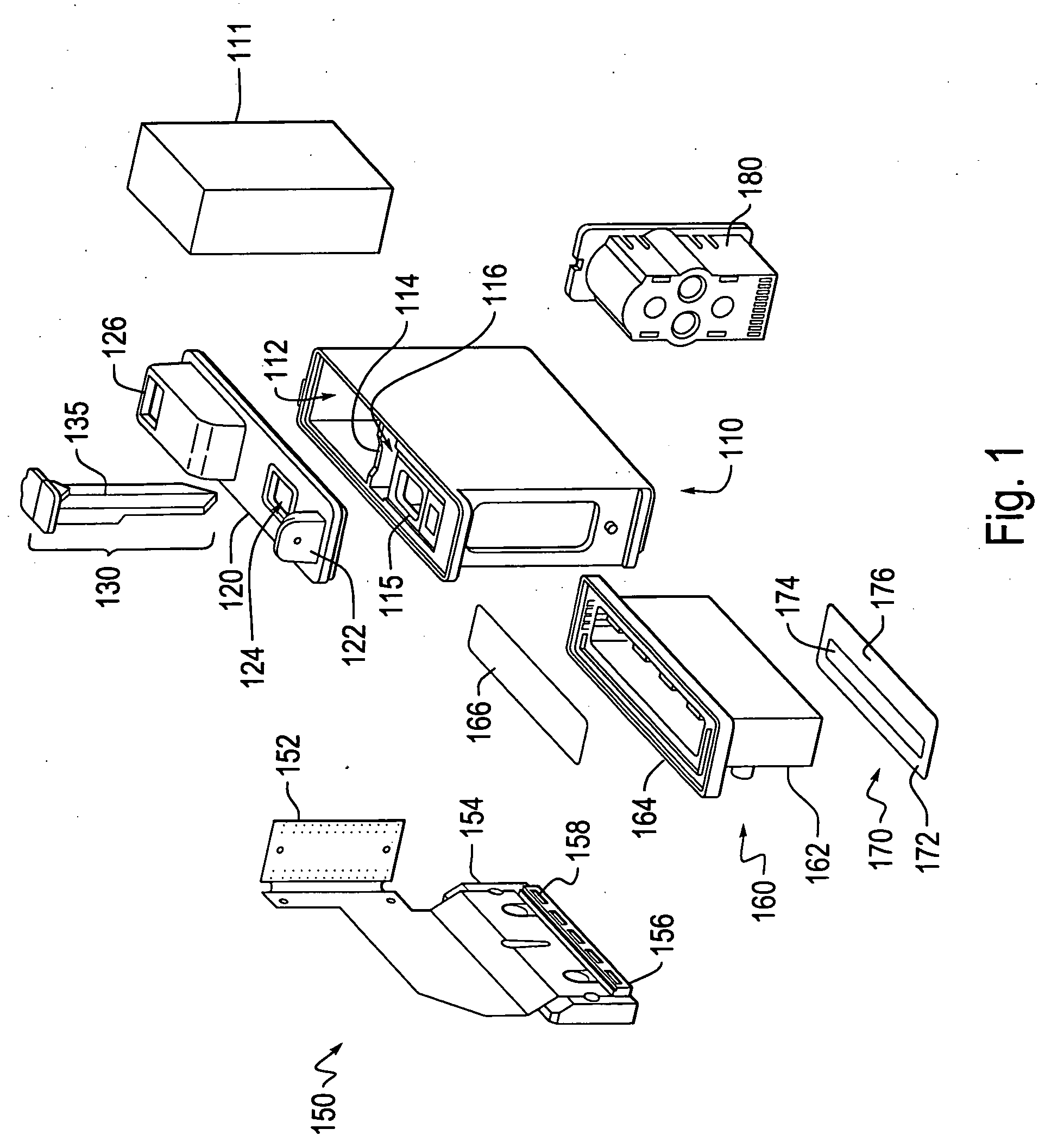

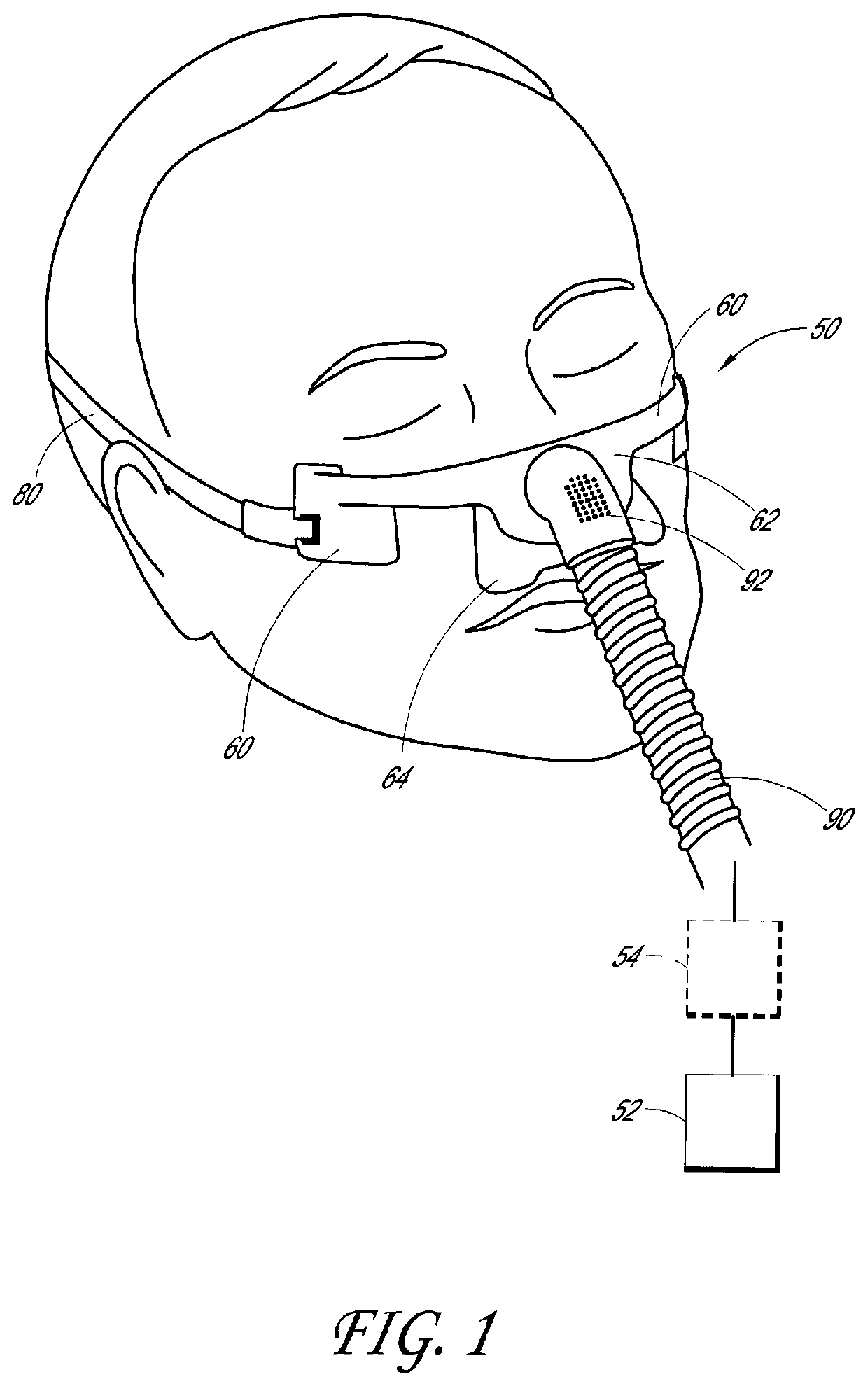

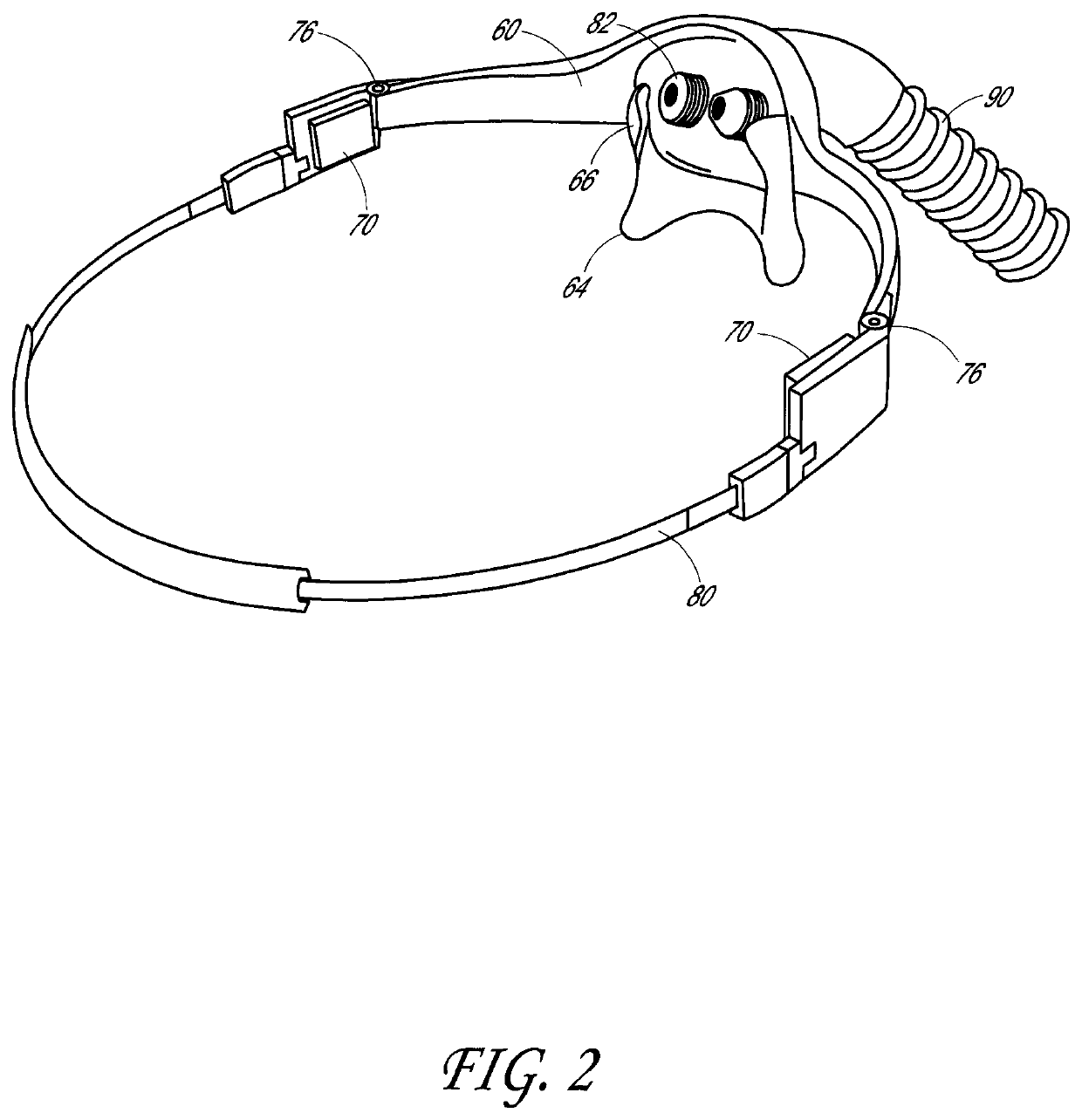

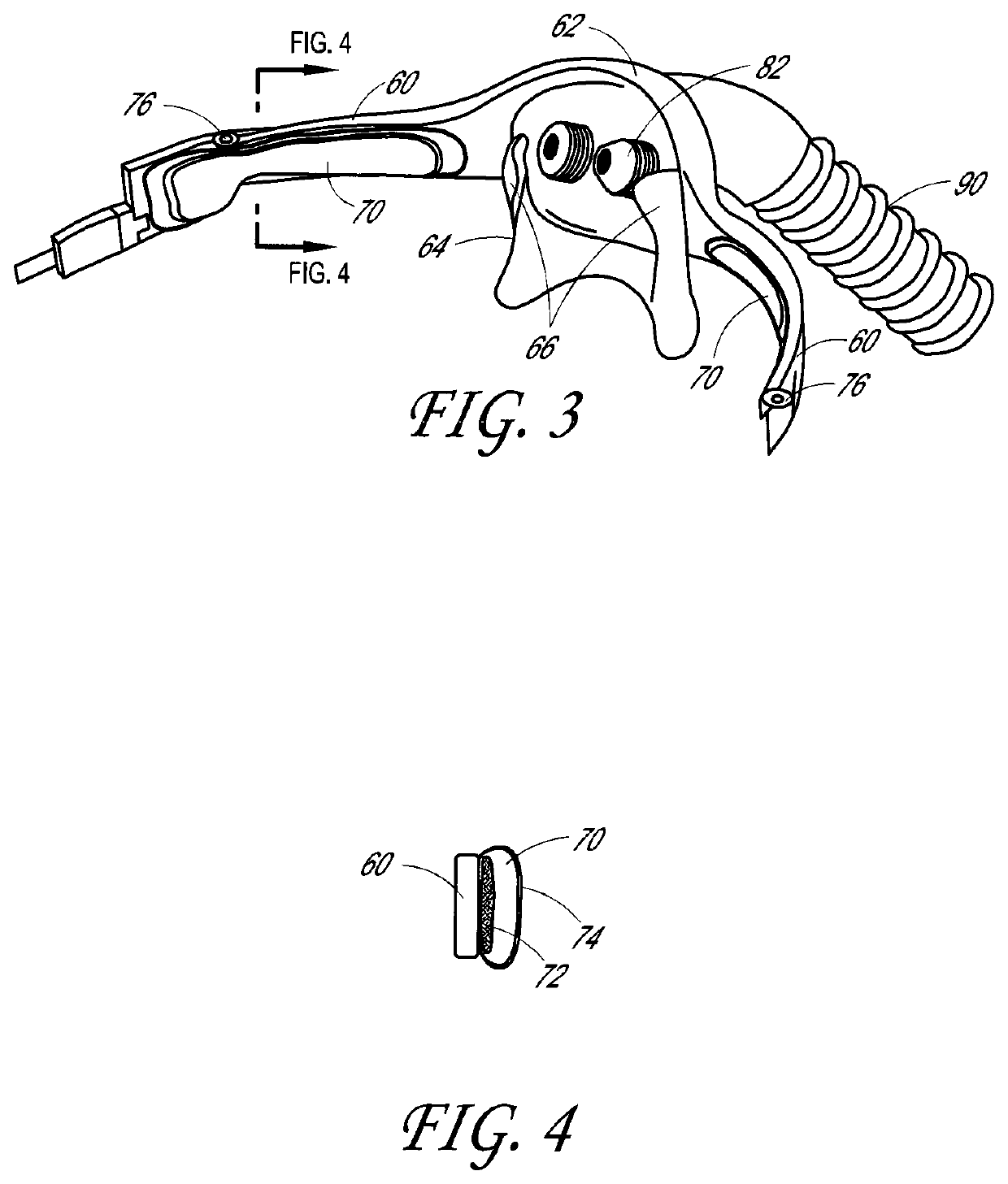

Nasal interfaces for respiratory therapy

ActiveUS20150209541A1Reduce draftReduce noiseRespiratory masksBreathing masksNasal cavityNasal prongs

Patient interfaces for respiratory therapy in the form of nasal interfaces or nasal masks include features that enhance or provide lateral stability of the interface. At least some of the embodiments provide multiple facial contact points or areas located in the general areas of the user's cheeks and / or upper lip. Some embodiments of the nasal interfaces provide advantageous sealing characteristics. The nasal interfaces may provide a controlled expiratory flow to reduce noise. Some embodiments include nasal pillows instead of or in addition to nasal prongs. The nasal pillows can have exhaust vents or can change in length in response to a pressure level within the nasal pillow.

Owner:FISHER & PAYKEL HEALTHCARE LTD

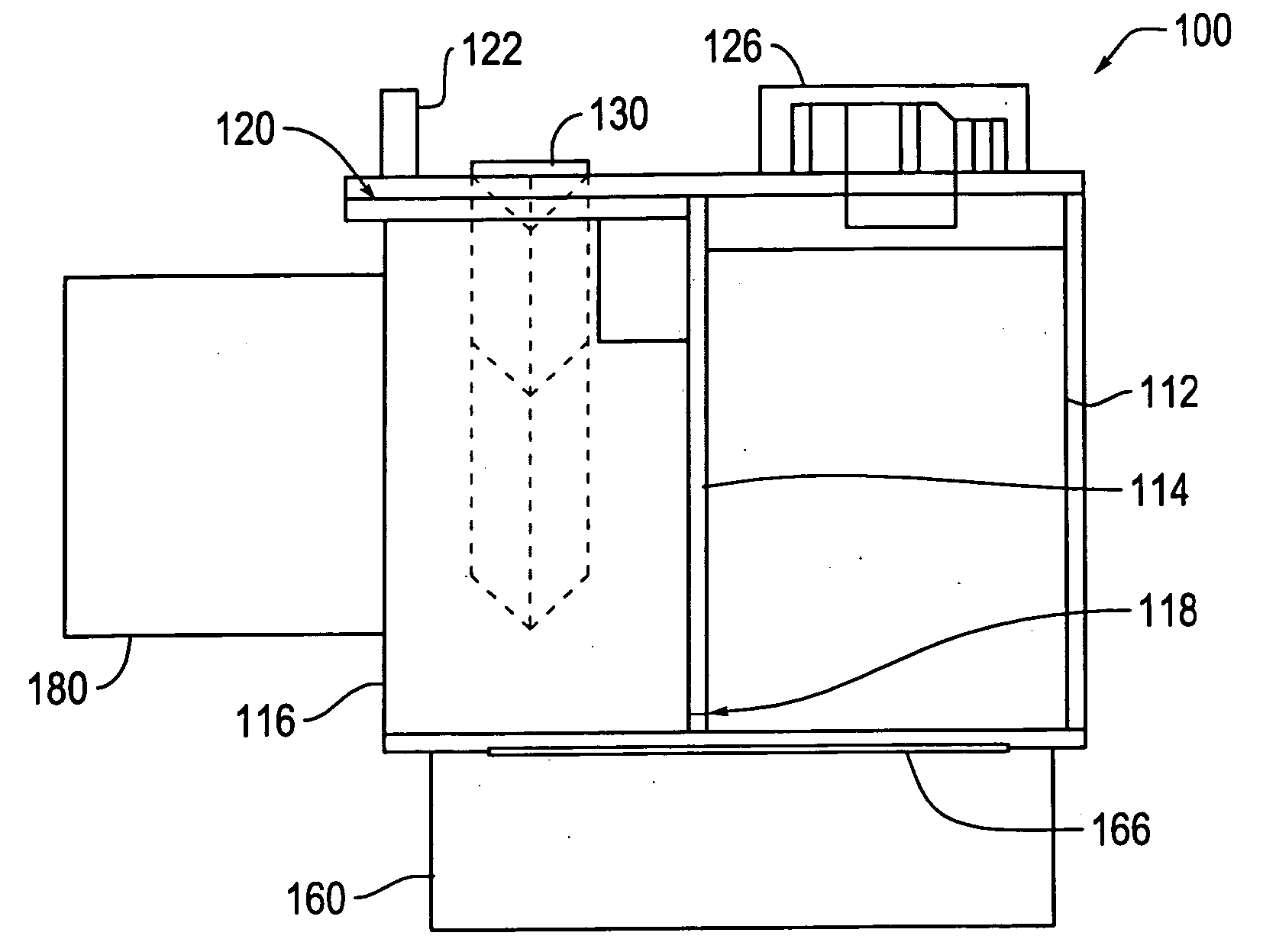

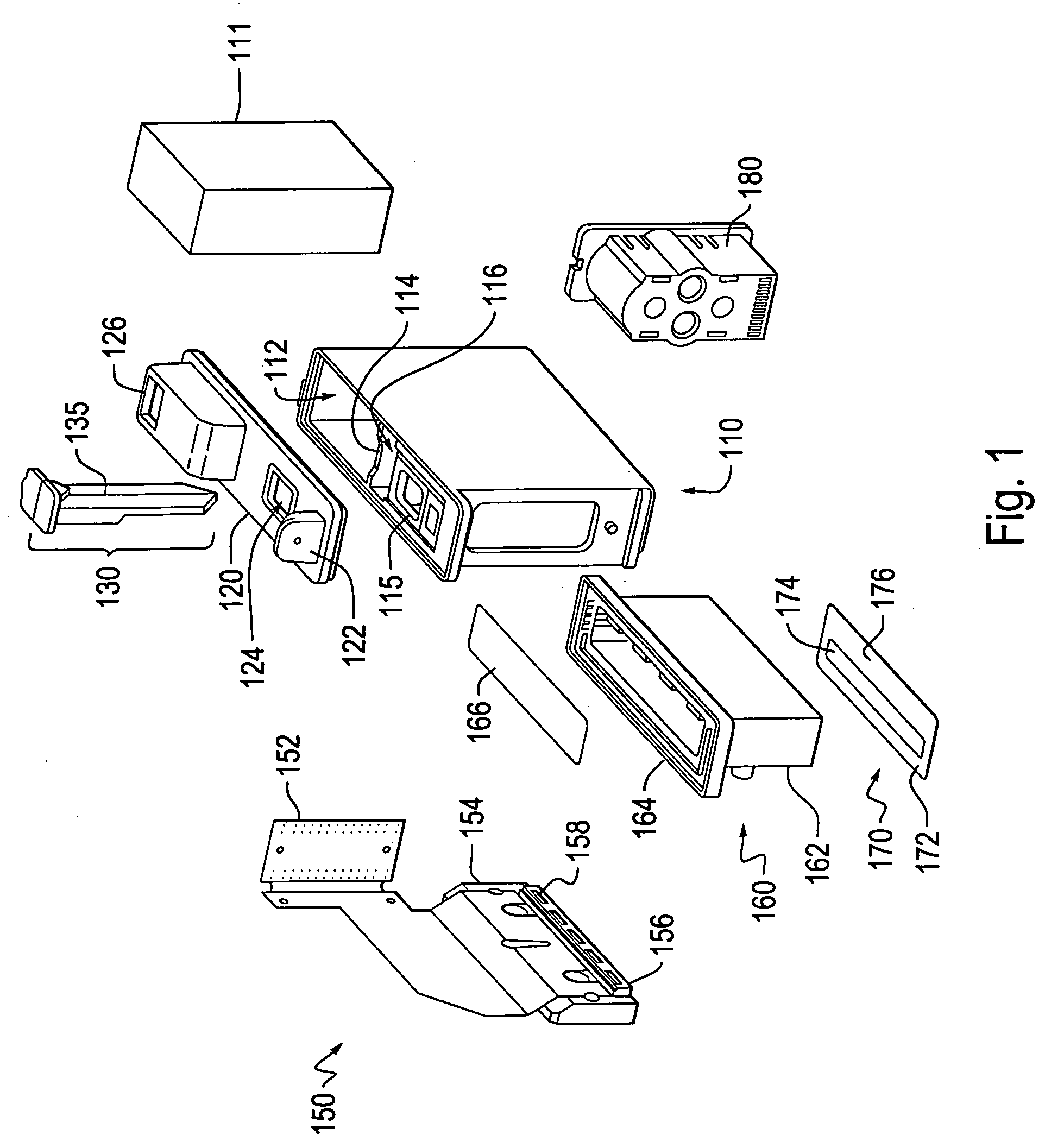

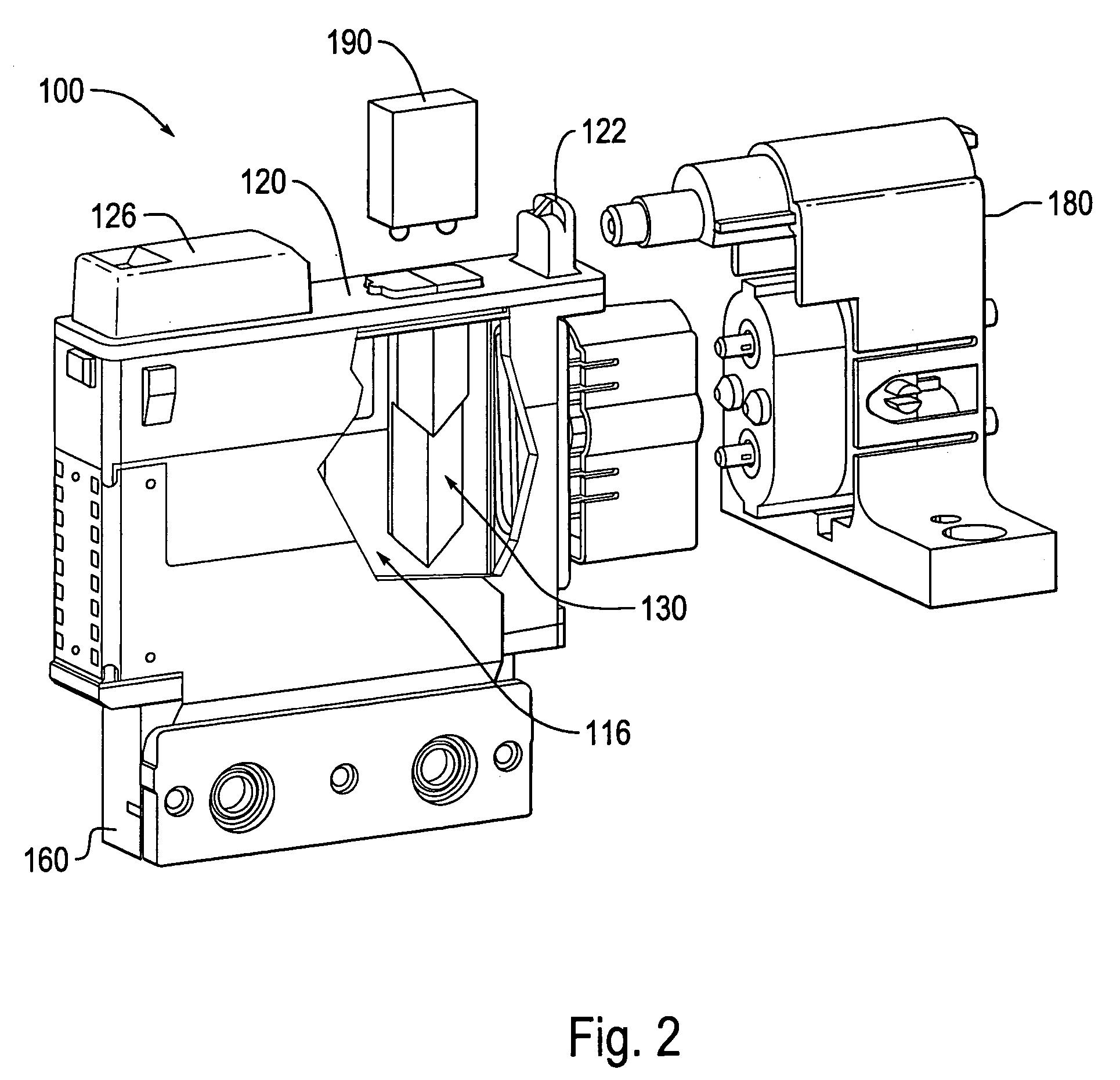

Pressure control architecture for fluid tanks having fluid level sensing

InactiveUS20050140759A1Reduce fluid leakageImprove efficiencyLiquid surface applicatorsCoatingsFluid levelEngineering

A refillable fluid container system having a pressure control architecture in which persistent air bubbles are released from a capillary or foam fluid reservoir and are directed from an optical level sensing system in a liquid fluid reservoir.

Owner:FUJIFILM BUSINESS INNOVATION CORP

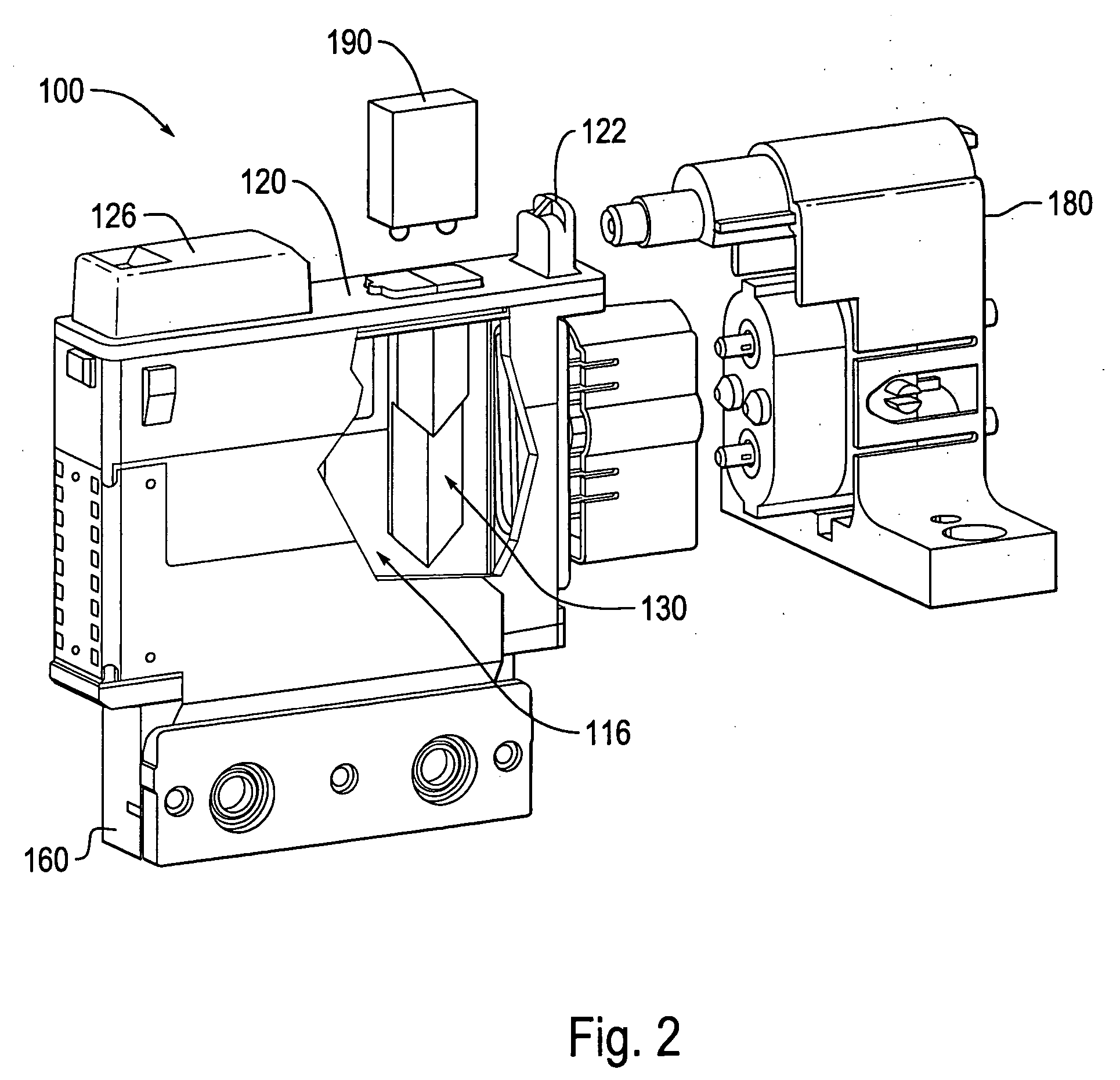

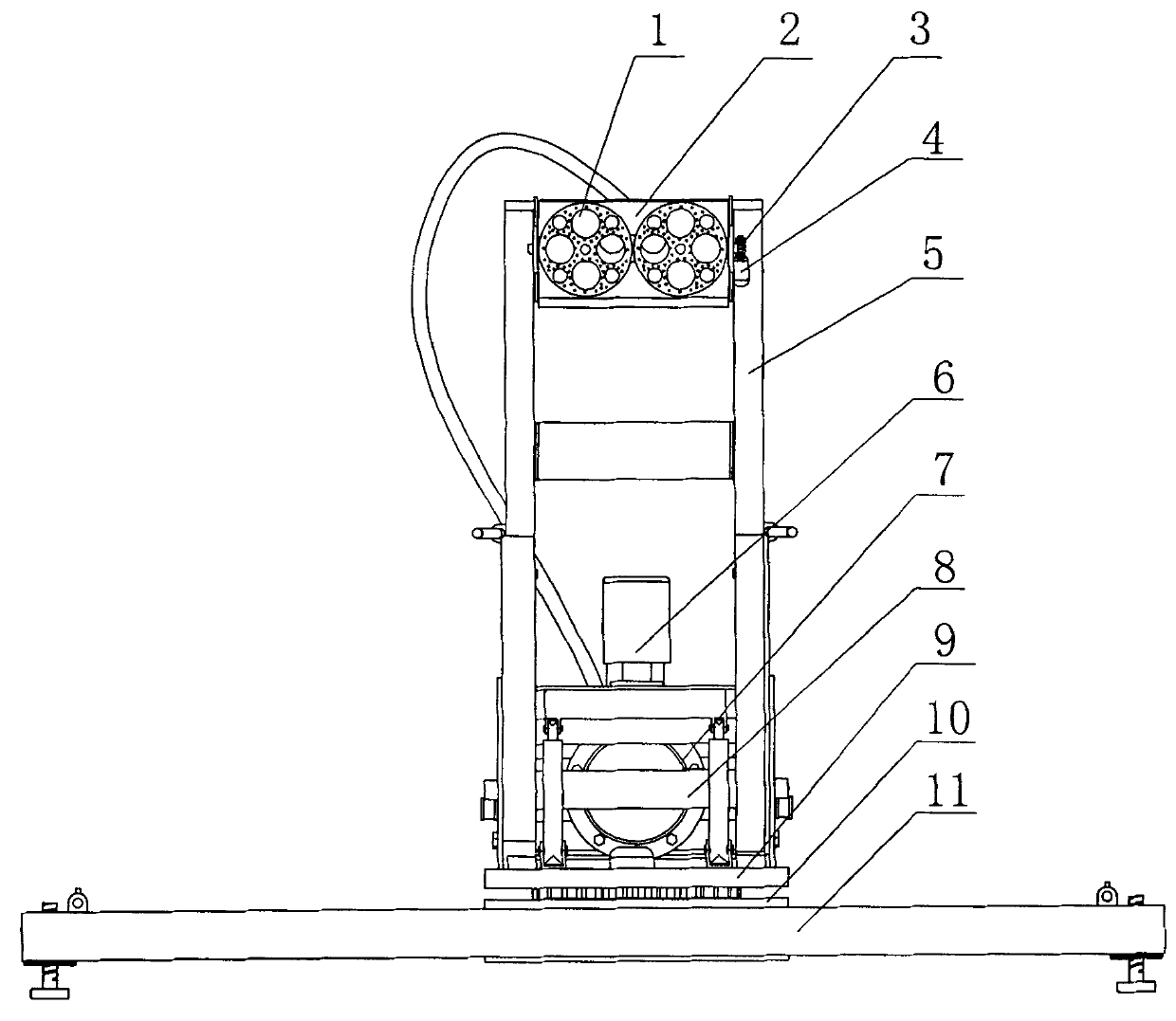

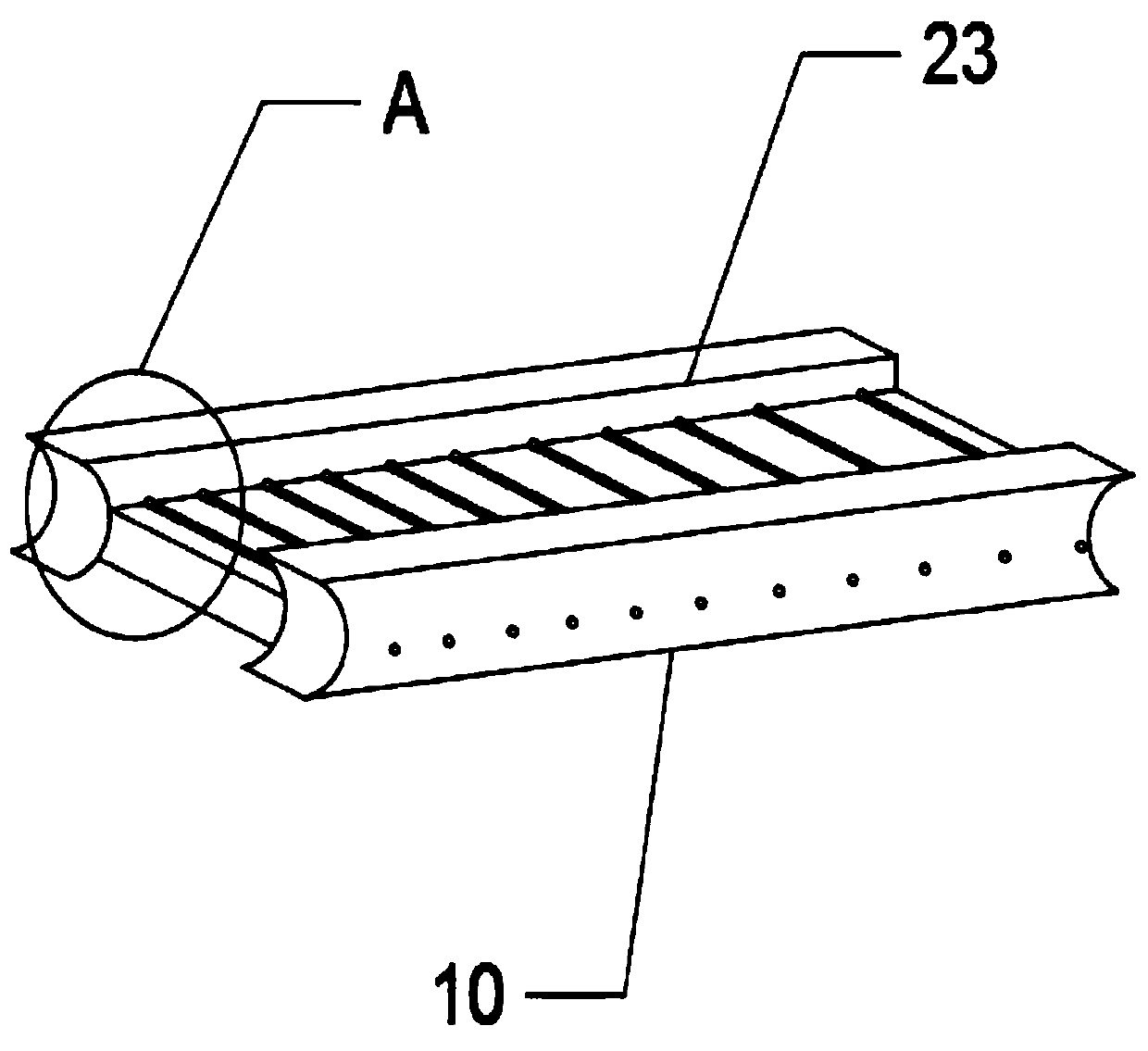

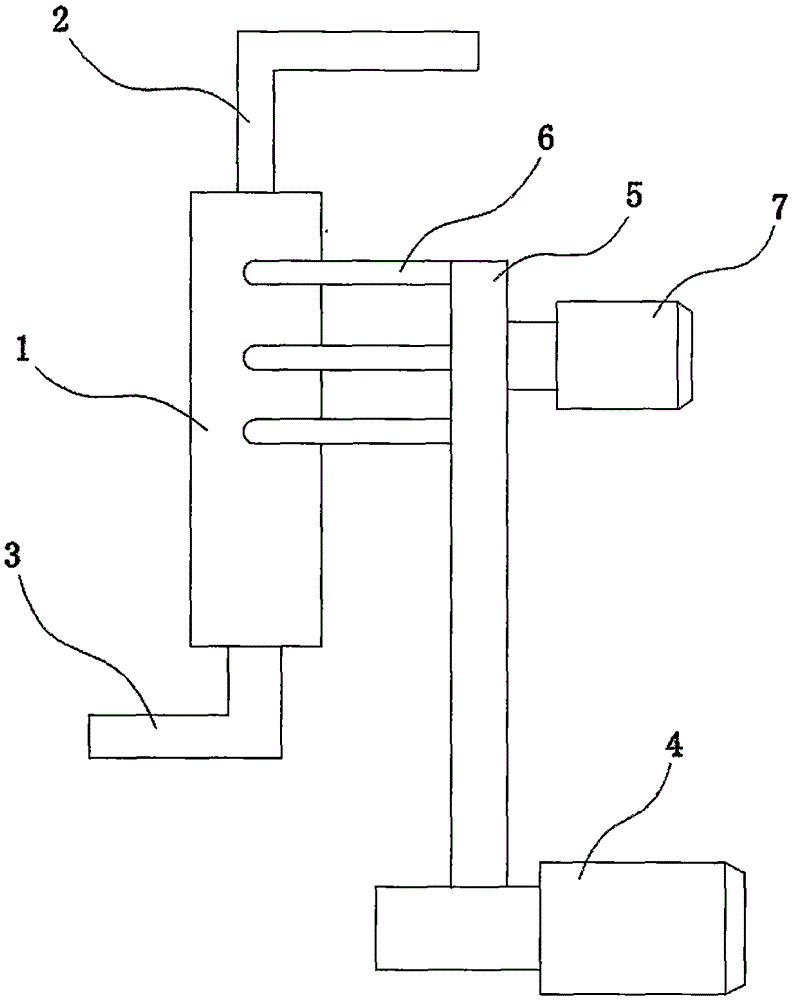

Powder conveying device

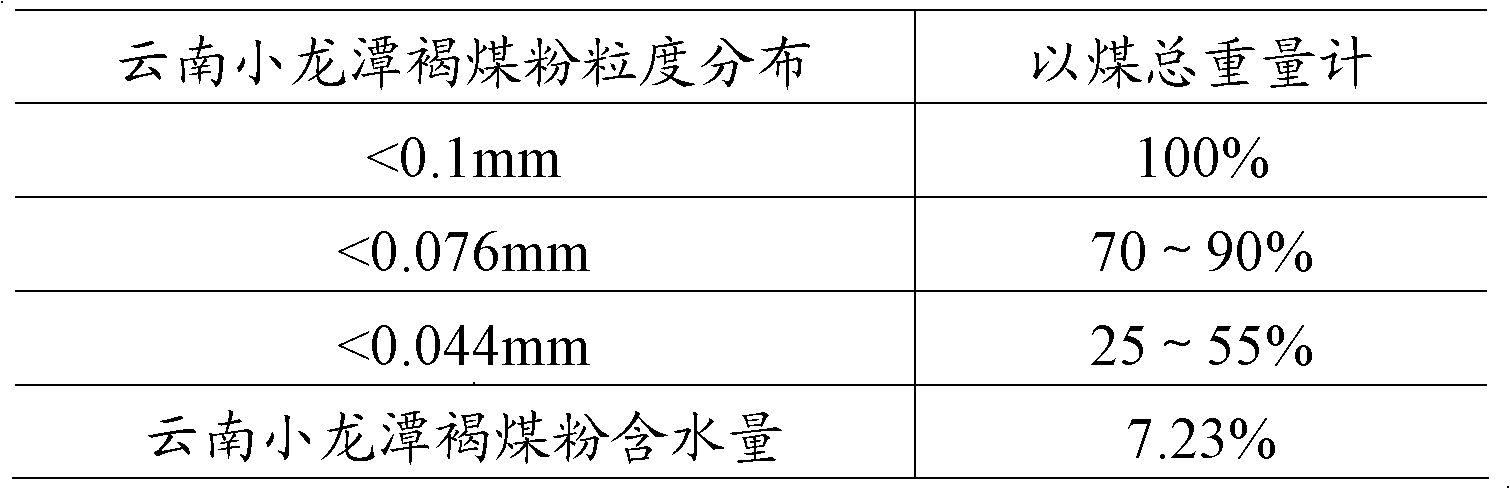

The invention relates to a powder conveying device. The device is composed of a powder storage system A, a powder pressing and conveying system B, a powder flow monitoring and adjusting system C, a powder weighing system D and a powder recycling system E; the power firstly enters the powder storage system A, and then enters the powder pressing and conveying system B under the effect of gravity and negative pressure of a pressurizer; after the powder flow monitoring and adjusting system C performs flow control, the powder is discharged in a continuous manner; when a constant-flow state is established or a verification coefficient of a measurement instrument is obtained before driving, the pressurized powder discharged from the powder flow monitoring and adjusting system C enters the powderweighing system D through valve switch, and the powder weighing system D weighs and computes the verification coefficient of the powder flow measurement instrument; and then the powder is depressurized by the powder recycling system E and returns to the powder storage system to be recycled. The device has a simple structure and a large flow adjusting range, requires small investment, is continuous and stable in operation, saves energy and is environmentally-friendly. Therefore, the powder conveying device provided by the invention has strong adaptability and a remarkably wide application prospect.

Owner:陕西省煤化工工程技术研究中心 +1

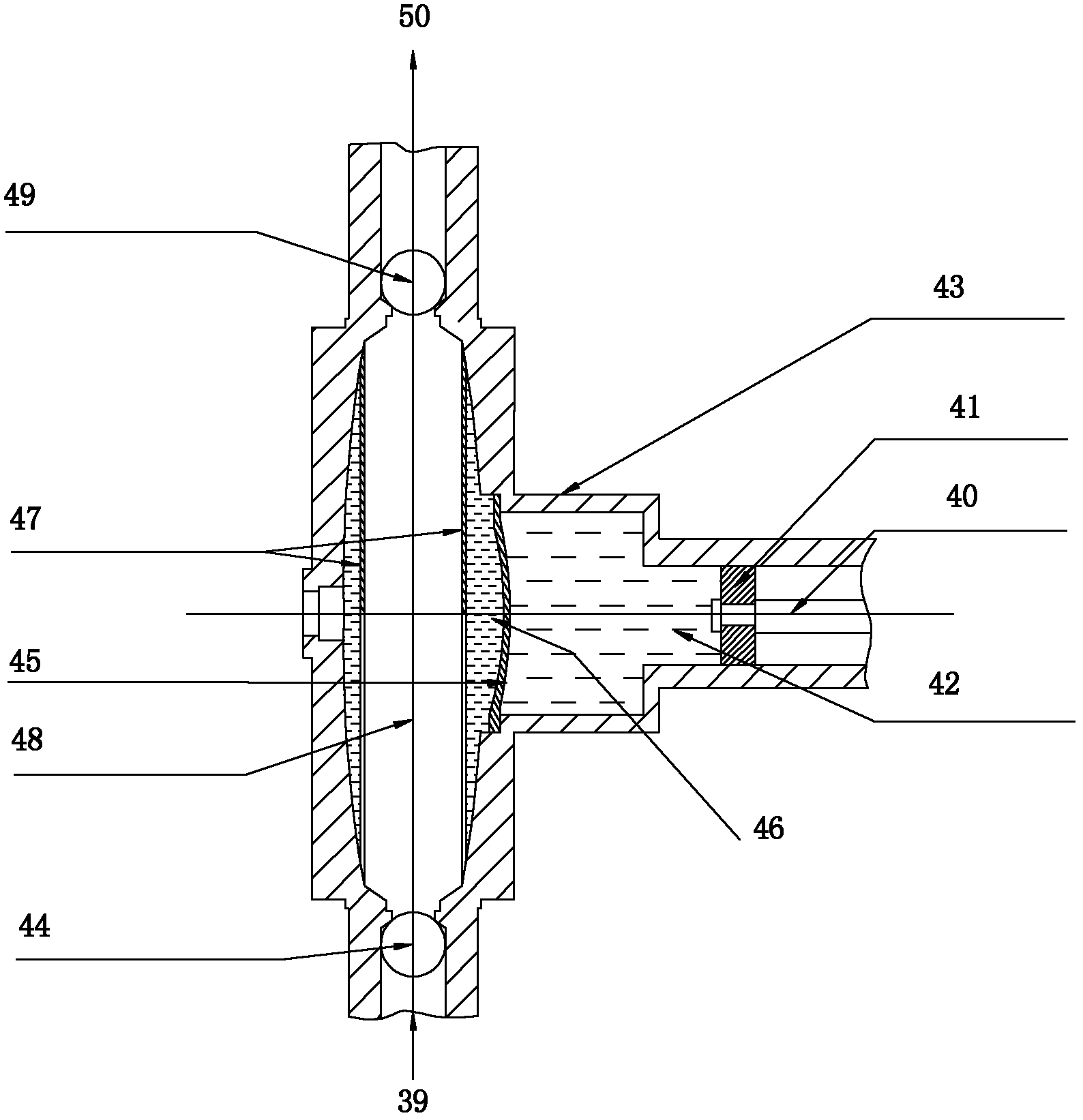

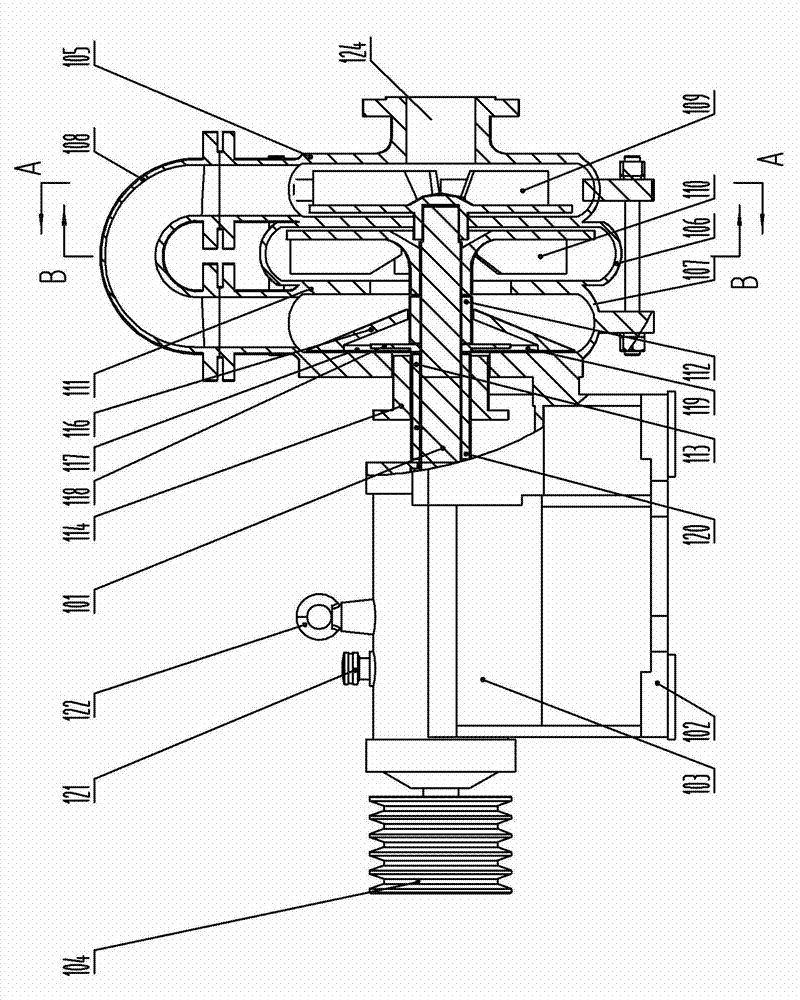

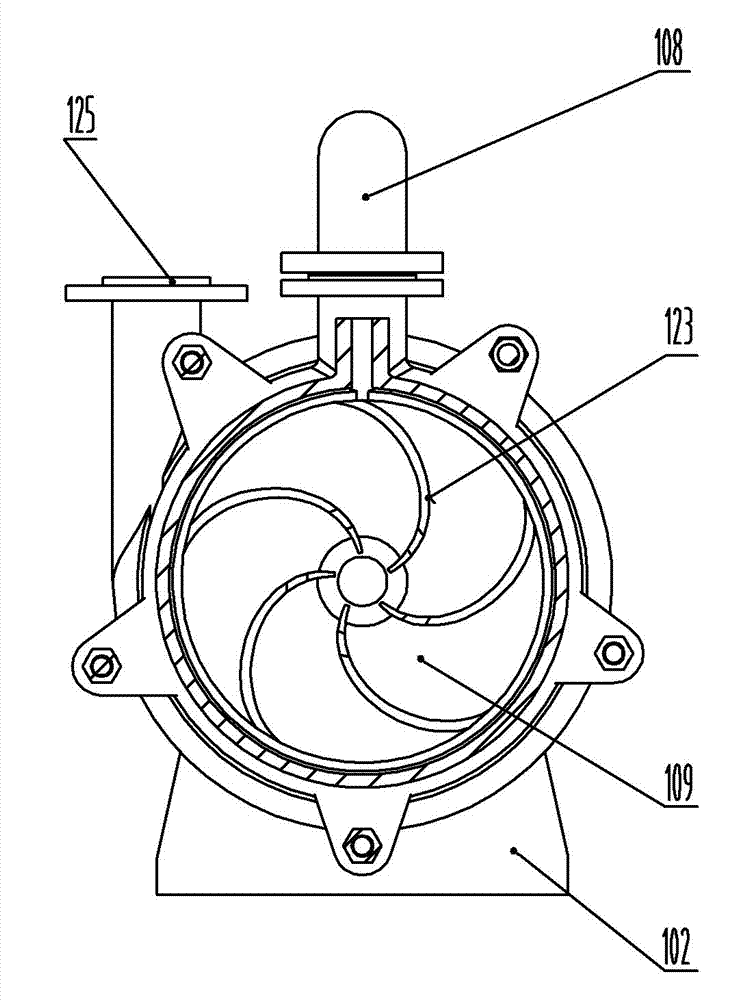

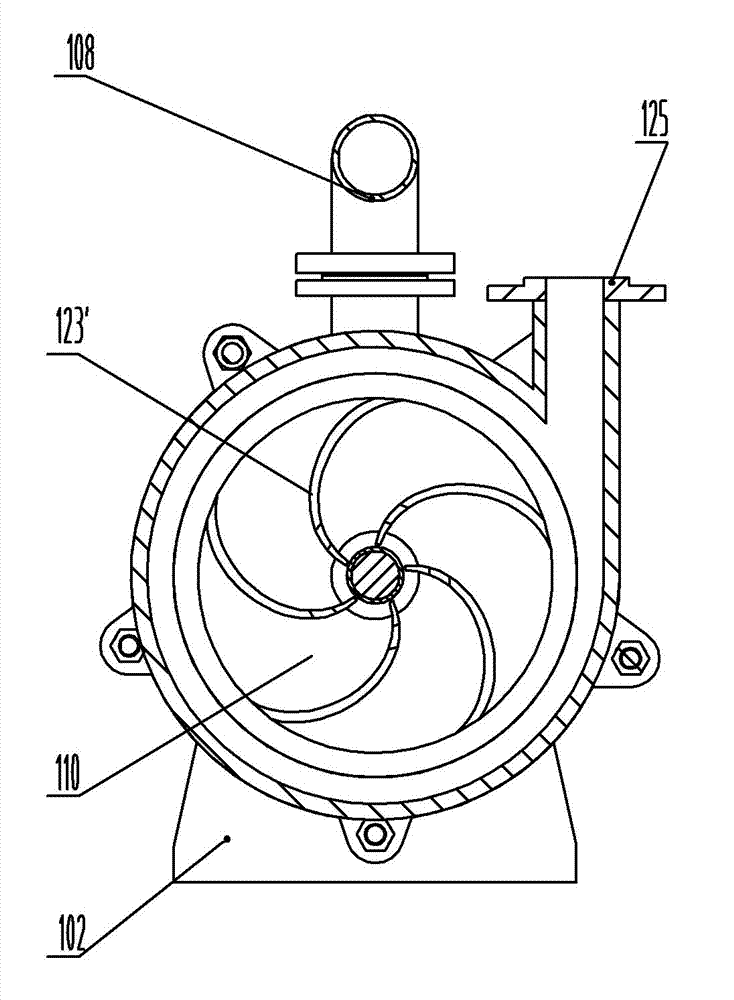

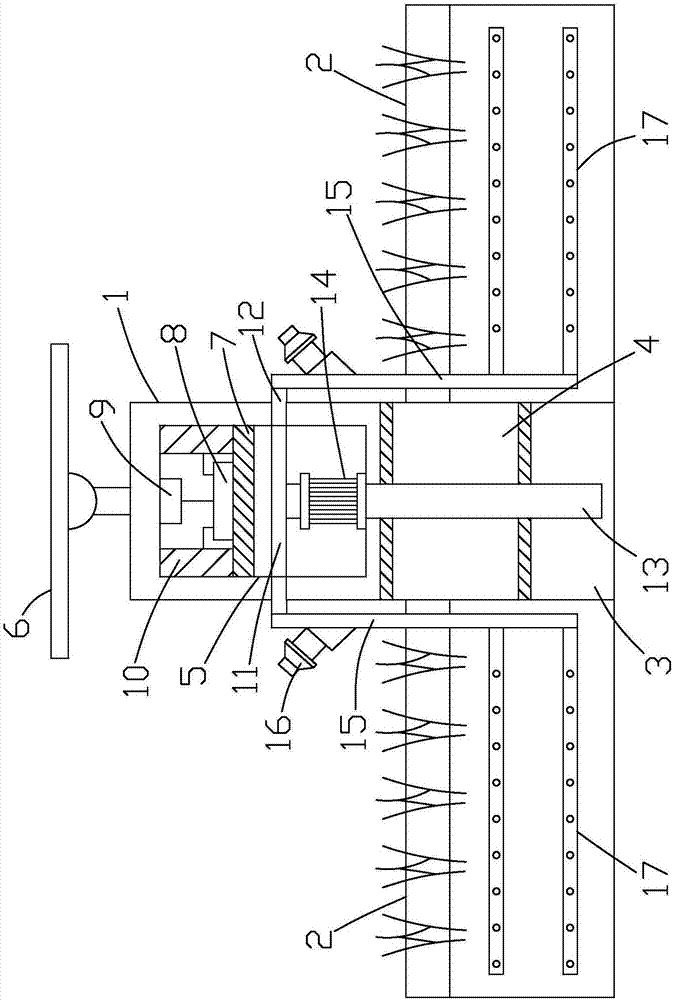

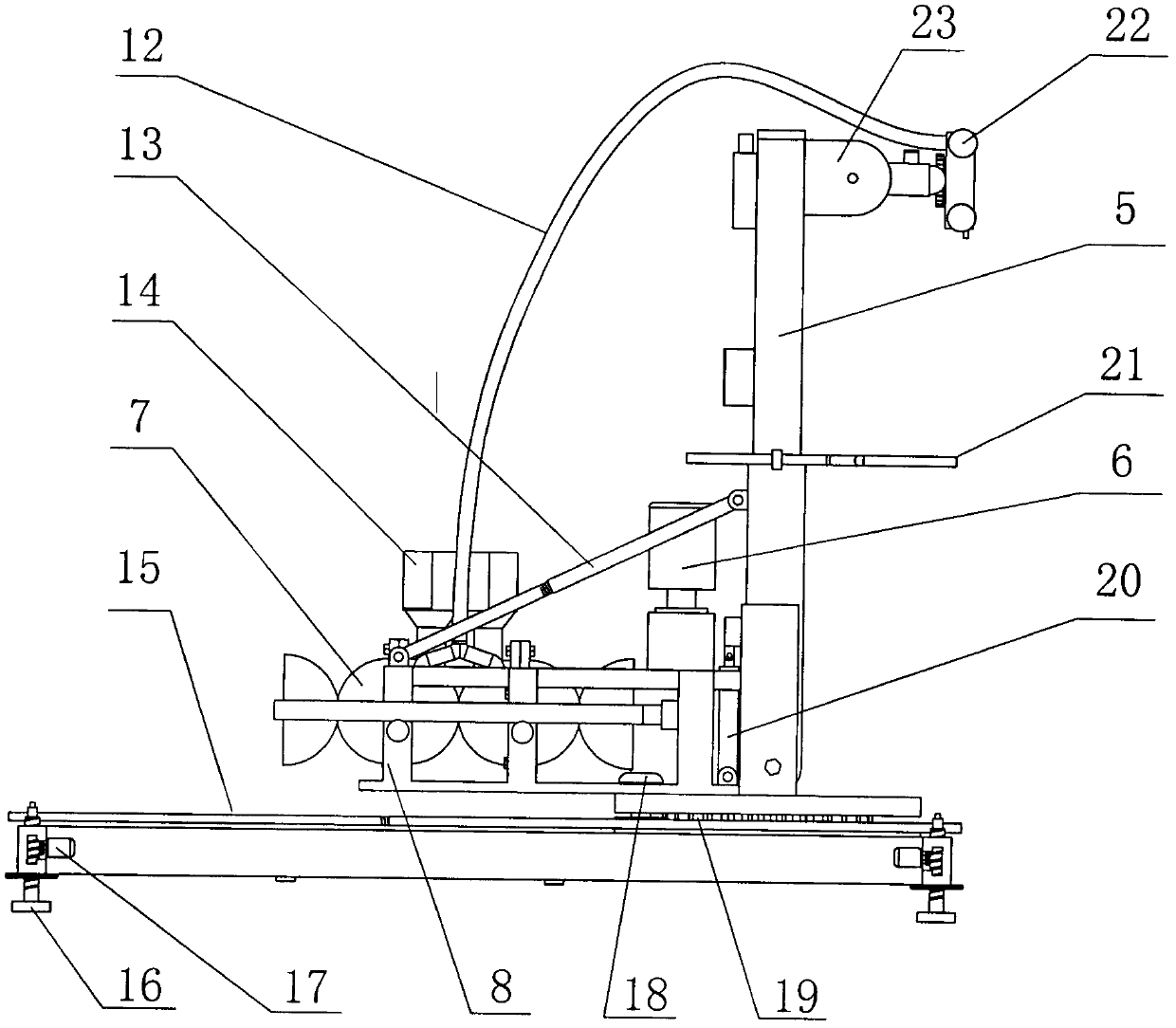

External soil spraying machine and special two-stage energy-saving high-lift underflow pump for external soil spraying machine

ActiveCN103026838AHigh liftStable deliveryBroadcast seedersFertiliser and seeding apparatusImpellerHelical blade

The invention belongs to the technical field of spraying machinery, and particularly relates to an external soil spraying machine and a special two-stage energy-saving high-lift underflow pump for the external soil spraying machine. The underflow pump comprises a transmission shaft, a pump body, a bearing chamber and a coupling, wherein the pump body comprises a one-stage pump body, a two-stage pump body and a two-stage feed pump body; a one-stage impeller is fixedly mounted at the right end of the transmission shaft in a sleeving manner; an elbow is communicated between the one-stage pump body and the two-stage feed pump body; a guard plate is arranged between the two-stage feed pump body and the two-stage pump body; a locating sleeve is mounted on the transmission shaft between the two-stage feed pump body and the two-stage pump body in a sleeving manner; a two-stage impeller is mounted on the locating sleeve in a sleeving manner, and mounted between a radial flange at one end of the locating sleeve and the guard plate; a feed channel is formed between the guard plate and the locating sleeve; the one-stage impeller and the two-stage impeller are mounted back to back; the bending direction of a helical blade of the one-stage impeller is counterclockwise; the bending direction of a helical blade of the two-stage impeller is clockwise; a horizontal feed port is formed in the right end face of the one-stage pump body; and a discharge port is formed vertically in a tangential direction of the pump body on the front side of the two-stage pump body. The underflow pump is higher in lift, and is suitable for conveying viscous slurry; the structure of the spraying machine is simplified; the manufacturing cost and engineering use cost of the spraying machine are lowered; breakdown maintenance points of the spraying machine are decreased; and the power loss of equipment is reduced.

Owner:河南恒睿机械制造有限公司

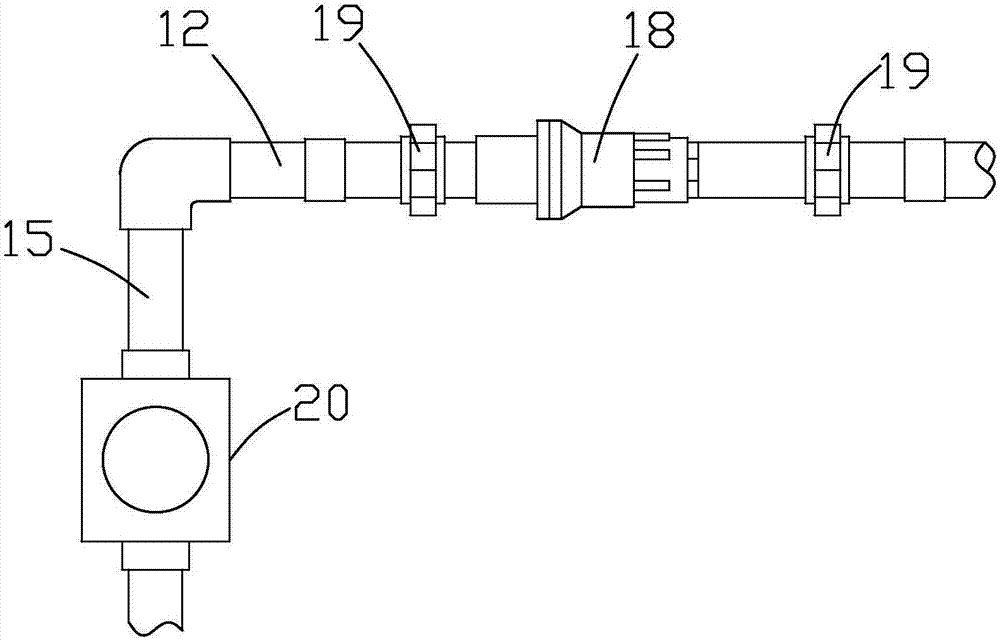

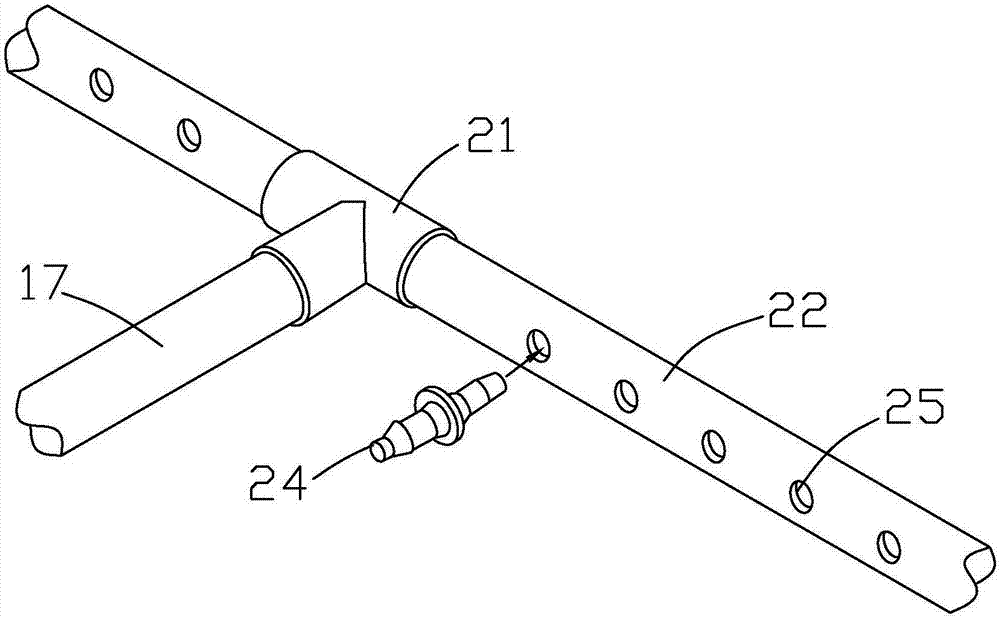

Automatic irrigation system and method used for wild rice stem planting

InactiveCN107079786AStable and reliable delivery of waterEasy to controlWatering devicesRenewable energy machinesAutomatic controlControl system

The invention discloses an automatic irrigation system and method used for wild rice stem planting. The system comprises a box body, a solar power generation device, an irrigation mechanism and pesticide spraying mechanisms. A control box is arranged in the box body, a waterproof plate is arranged in the control box, a control system is arranged above the waterproof plate, and a water diversion mechanism is arranged below the waterproof plate and comprises a water divider and a water intake pipe. Irrigation devices are arranged on the two sides of the box body, the pesticide spraying mechanisms are also arranged on the two sides of the box body, the irrigation devices comprise water diversion pipes, water conveying pipes and water penetration pipes, a horizontal guide pipe is arranged between the two water conveying pipes on the same side of the box, and the pesticide spraying mechanisms are arranged on the horizontal guide pipes. The automatic irrigation method comprises the steps of ridge reinforcing construction, construction of the box body and the generation device, construction of the irrigation mechanism, installation of the pesticide spraying mechanisms, trial operation of the automatic irrigation system and equipment maintenance. By means of the irrigation method, water is convenient and efficient to take, the irrigation cost is reduced, use and maintenance are convenient, meanwhile, automatic control can be achieved, and the labor intensity of manual operation is reduced.

Owner:湖州桑农生态农业有限公司

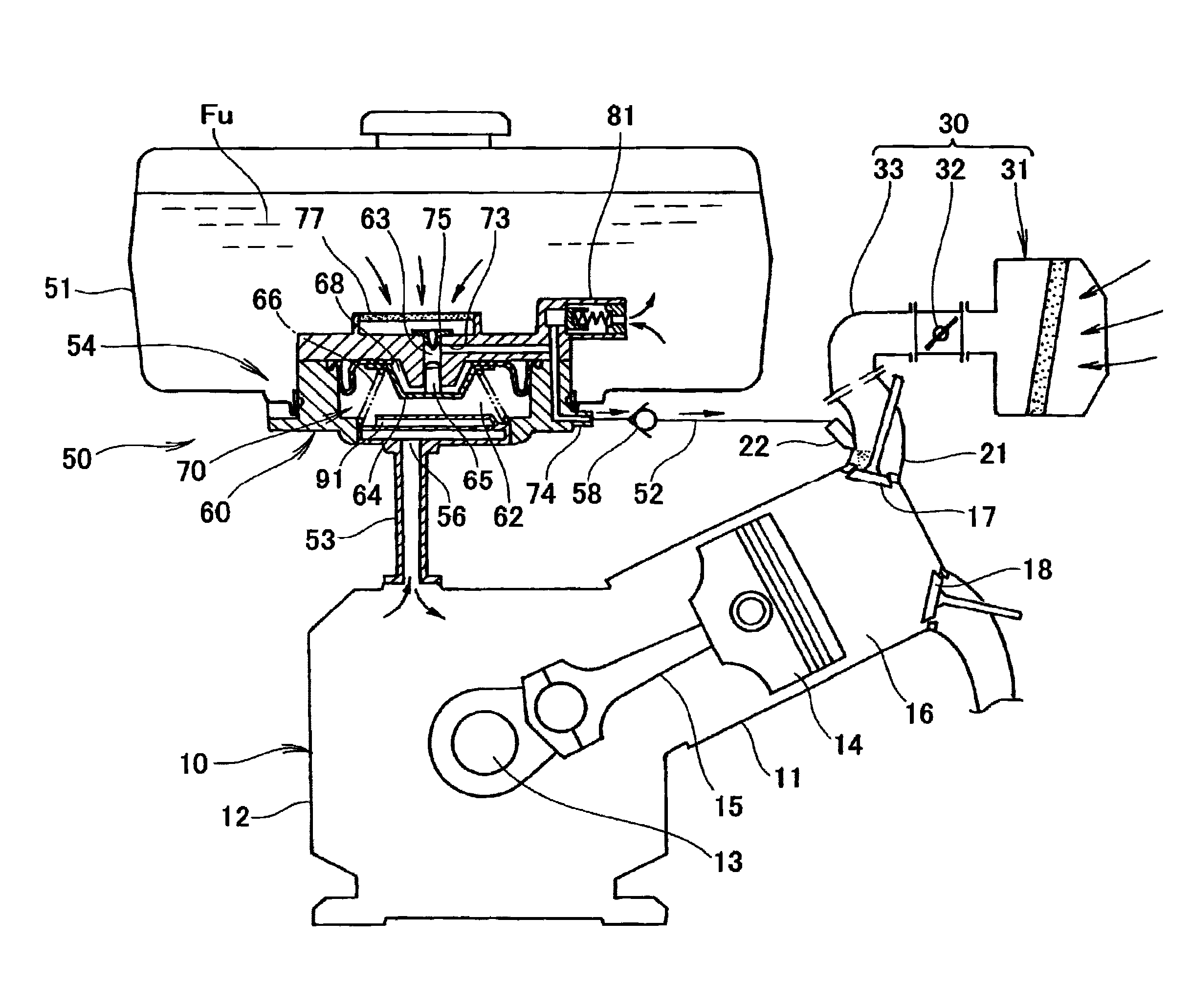

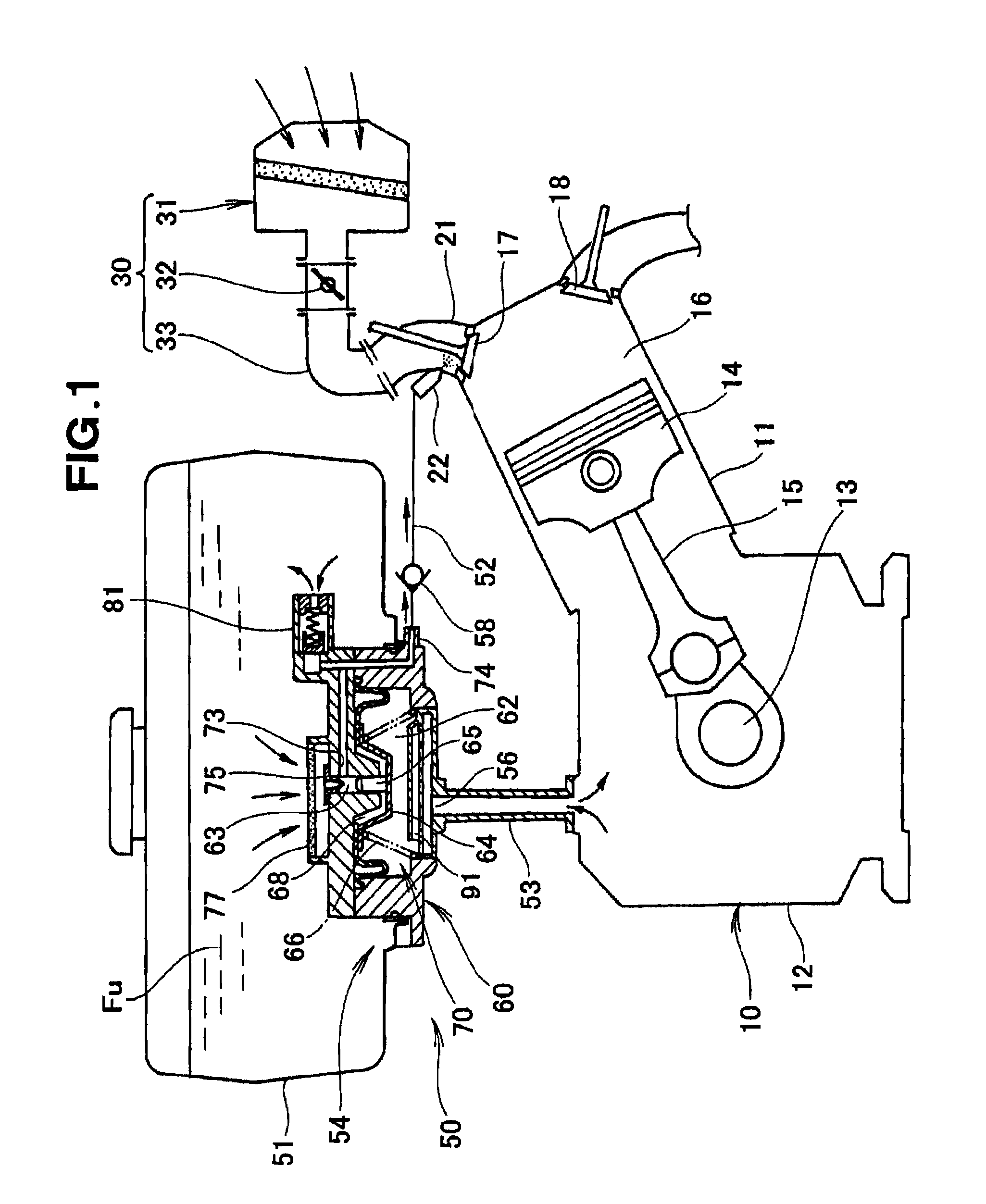

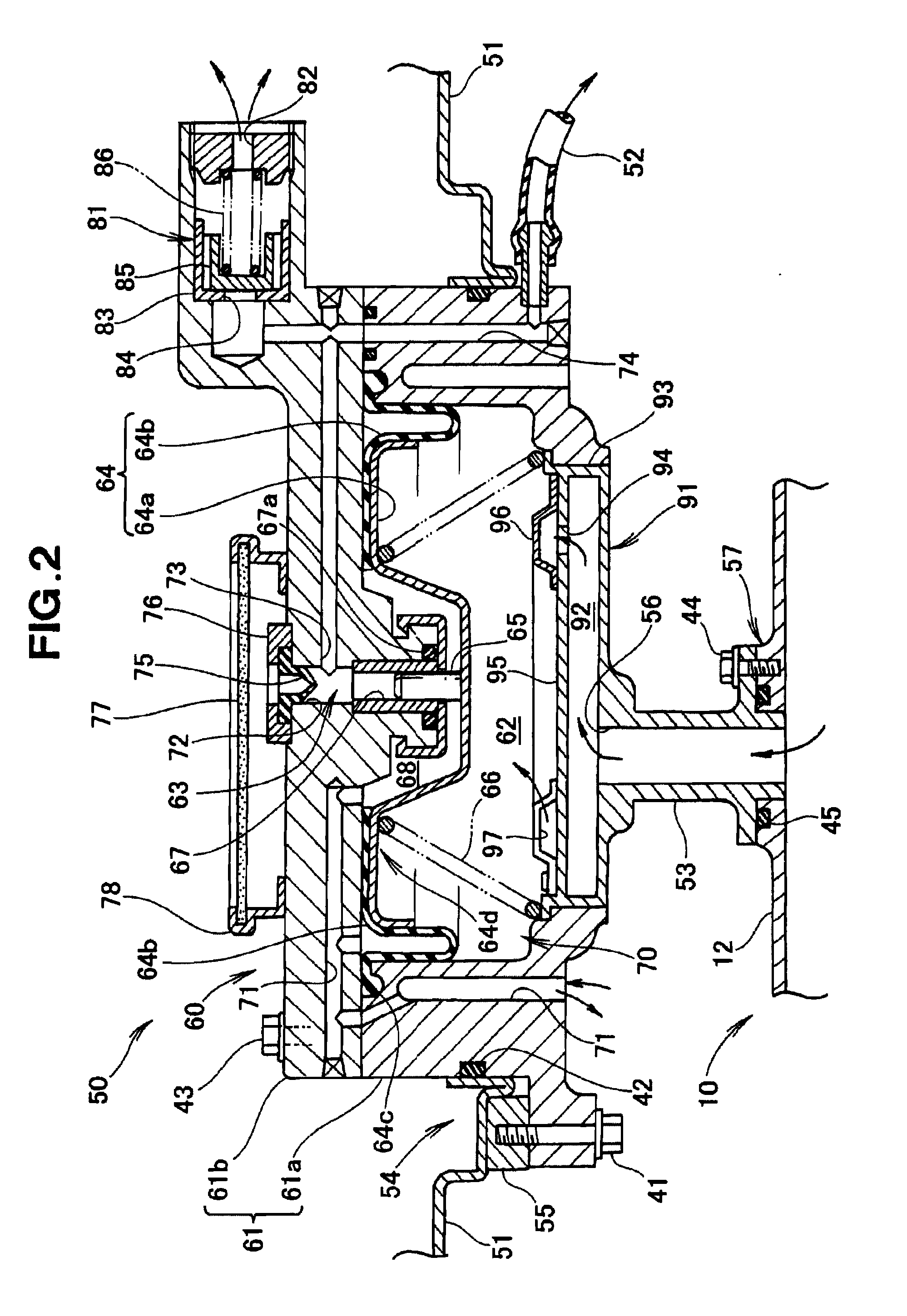

Fuel supply device for internal combustion engine

InactiveUS20140026857A1Effectively preventing oil mist from enteringIncrease delivery pressureLow-pressure fuel injectionMachines/enginesDiaphragm pumpPump chamber

A fuel supply device supplies fuel from a fuel tank to an injector by driving a diaphragm pump by use of pressure variation within a crankcase. The diaphragm pump includes: a pump casing; a diaphragm partitioning the interior of the pump casing into a negative pressure chamber and a pump chamber; and a plunger connected to the diaphragm and reciprocatively movable to and from the pump chamber. A pressure receiving area over which the plunger receives, at its end surface in a plunger advancing / retracting direction, pressure from the pump chamber is set smaller than a pressure receiving area over which the diaphragm receives pressure from the negative pressure chamber in the advancing / retracting direction.

Owner:HONDA MOTOR CO LTD

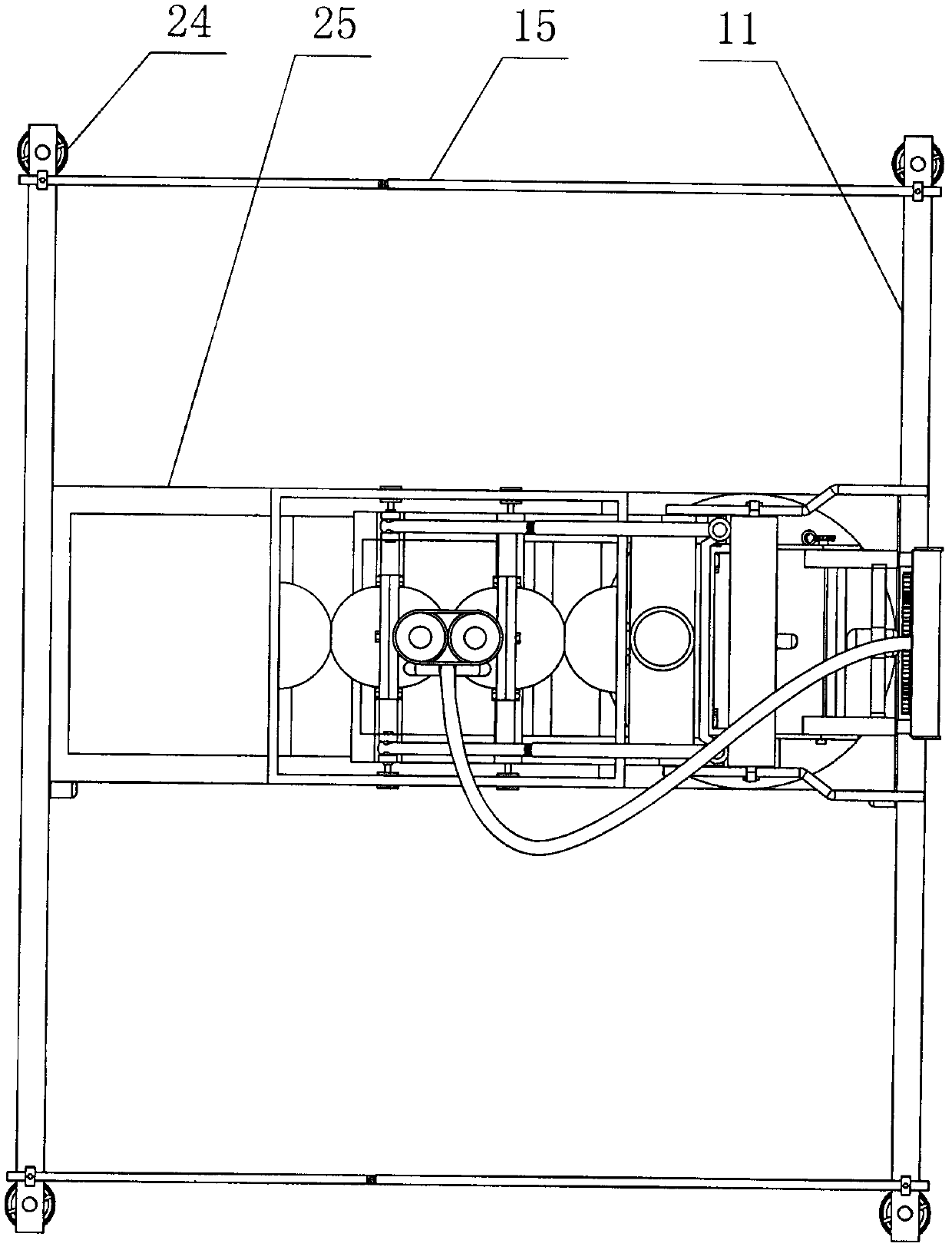

Multifunctional remote control automatic plastering machine

InactiveCN102677875AAdjust the quick installationQuick installationBuilding constructionsGear wheelRemote control

The invention relates to a multifunctional remote control automatic plastering machine, comprising a hydraulic conveyor, a plastering device, a flexible lifting track, a rotating chassis, a rack, a travelling track and a remote controller. The multifunctional remote control automatic plastering machine is characterized in that the rack and the flexible lifting track are arranged on the rotating chassis, a big gear wheel and a sliding base plate are arranged below the rotating chassis, the sliding base plate is placed into a lateral track, the lateral track is placed into a longitudinal track, the rack is provided with the hydraulic conveyor, a fixed plate of the plastering device is provided with a steering motor, a turbine worm and a telescopic arm, the telescopic arm is connected with a plastering head, the plastering head is provided with two rotating millstones, and the plastering device is placed into the flexible lifting track. Compared with the prior art, the multifunctional remote control automatic plastering machine disclosed by the invention has the advantages of compact structure, fast mounting adjustment, flexibility in operation, good quality and high working efficiency.

Owner:黎光

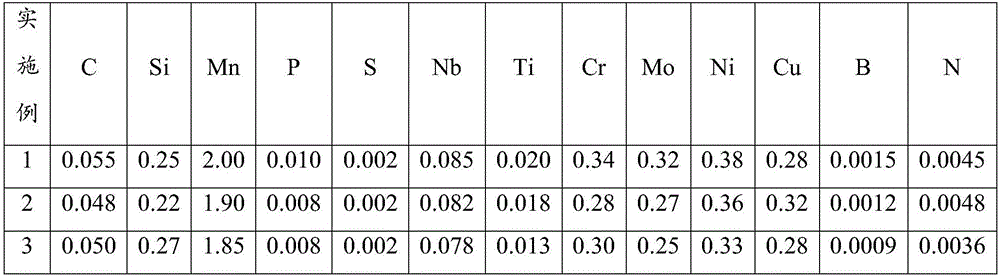

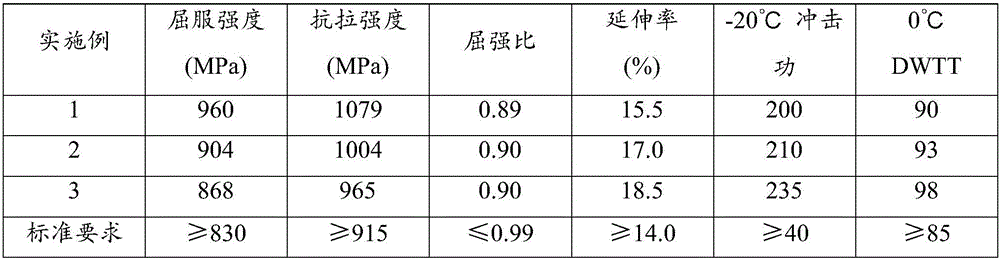

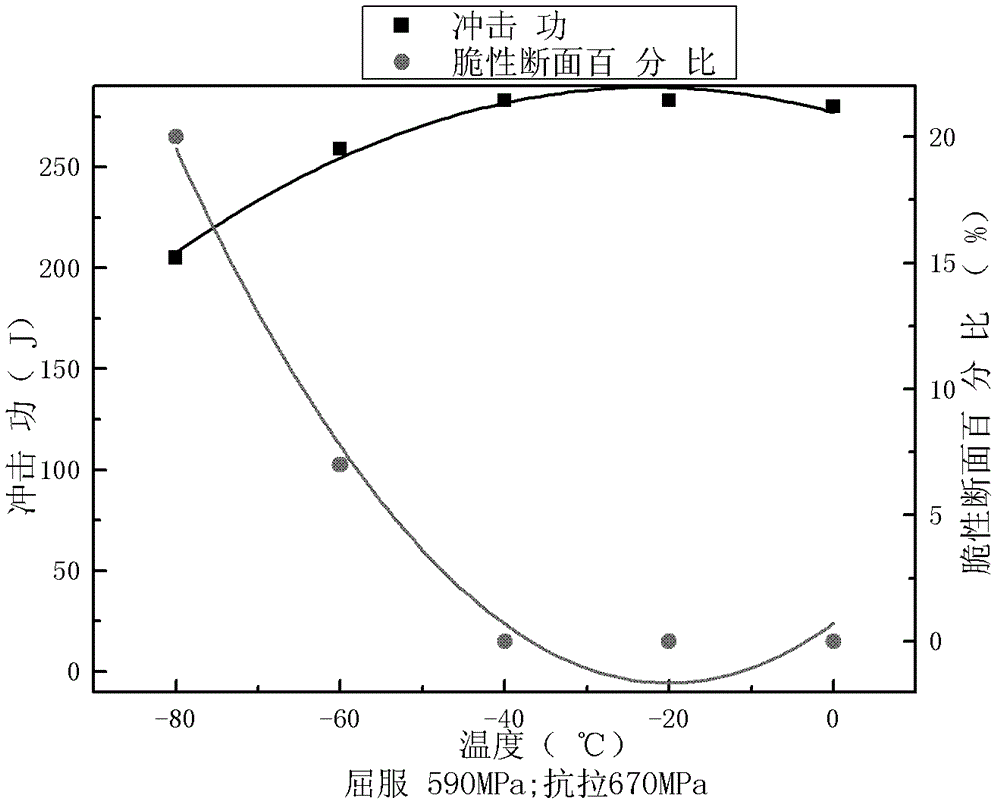

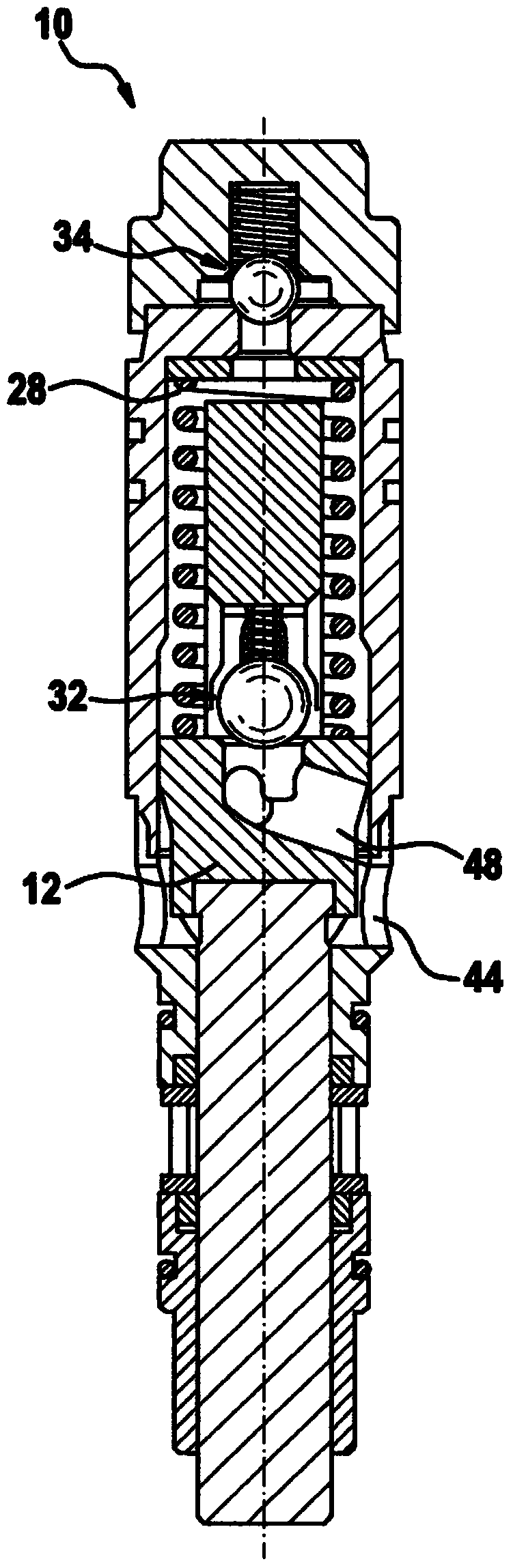

X120 high grade pipeline steel and preparation method thereof

The invention discloses an X120 high grade pipeline steel. The X120 high grade pipeline steel comprises the following components in percentages by weight: 0.04-0.06% of C, 0.20-0.30% of Si, 1.80-2.00% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.075-0.090% of Nb, less than or equal to 0.030% of V, 0.010-0.020% of Ti, less than or equal to 0.050% of Al, 0.25-0.35% of Cr, 0.25-0.35% of Mo, 0.30-0.40% of Ni, 0.25-0.35% of Cu, 0.0008-0.015% of B, less than or equal to 80 ppm of N, 0.15-0.25% of Pcm and the balance of Fe and impurities. The invention further discloses a preparation method of the X120 high grade pipeline steel. A steel plate produced from the X120 high grade pipeline steel has the advantages of high strength, high toughness and low yield ratio.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

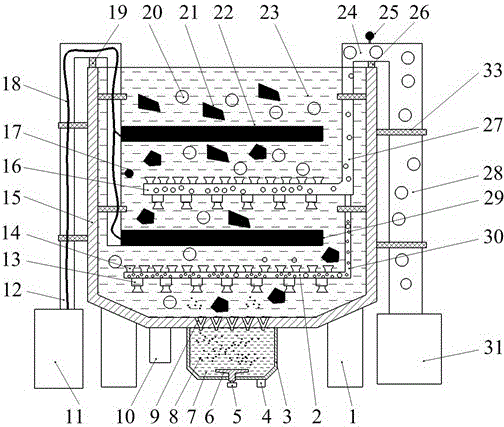

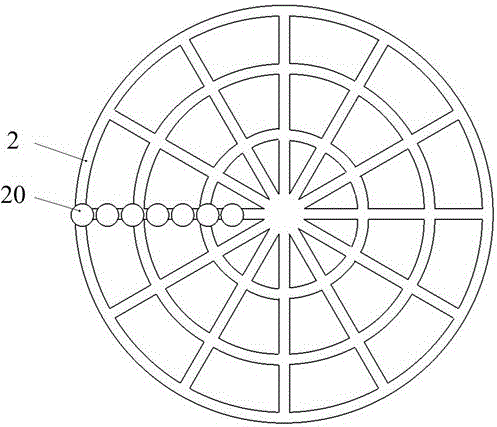

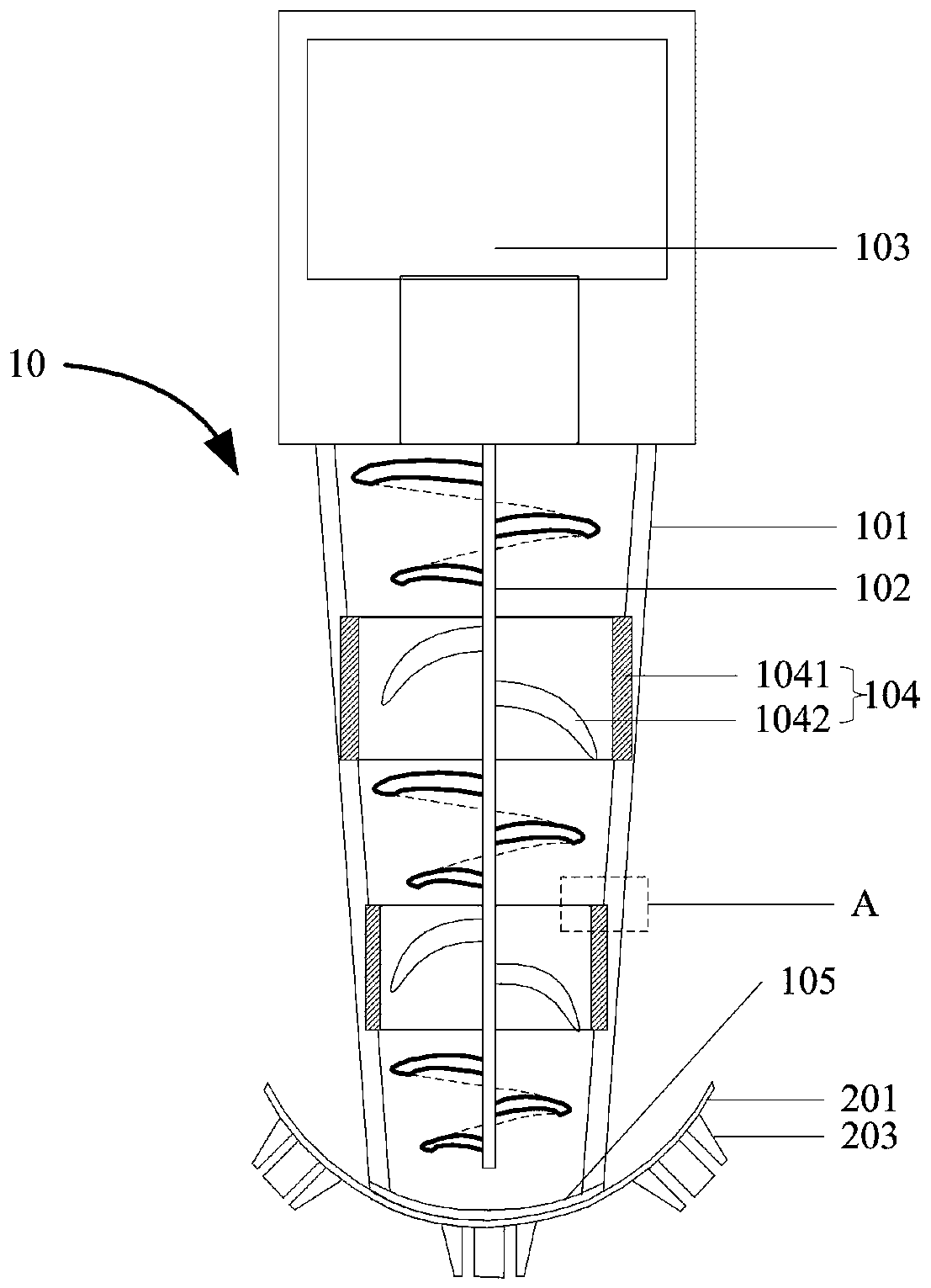

Pulping equipment based on air blasting energy and with secondary repulping function

ActiveCN106592306AImprove blasting slurry efficiencyPrevent blastingPaper recyclingRaw material divisionPulp and paper industryAir bubble

The invention provides pulping equipment based on air blasting energy and with a secondary repulping function. The pulping equipment mainly comprises a coarse pulp generating device, a bubble generating device, a bubble heating device and a fine pulp generating device. The pulping equipment is characterized in that air blasting energy is used for repulping and secondary fine repulping. Repulping through the air blasting energy is achieved through the bubble generating device and the bubble heating device; multi-area blasting repulping is achieved through upper and lower exhaust rings; scallop tubes are used for guiding bubble diversion, so that the upper and lower exhaust rings are protected; Y-shaped filters are used for screening and filtering crushed materials; the coarse pulp generating device is used for generating coarse pulp; and the fine pulp generating device is used for achieving fine repulping.

Owner:UNIV OF JINAN

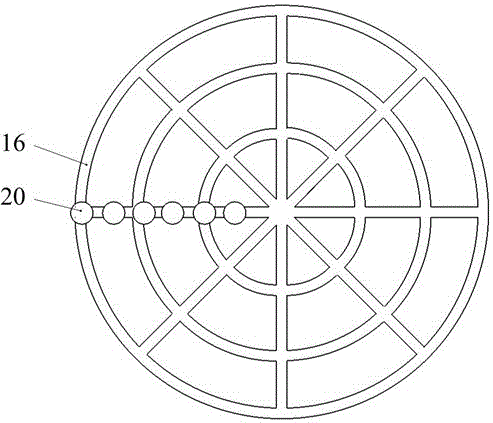

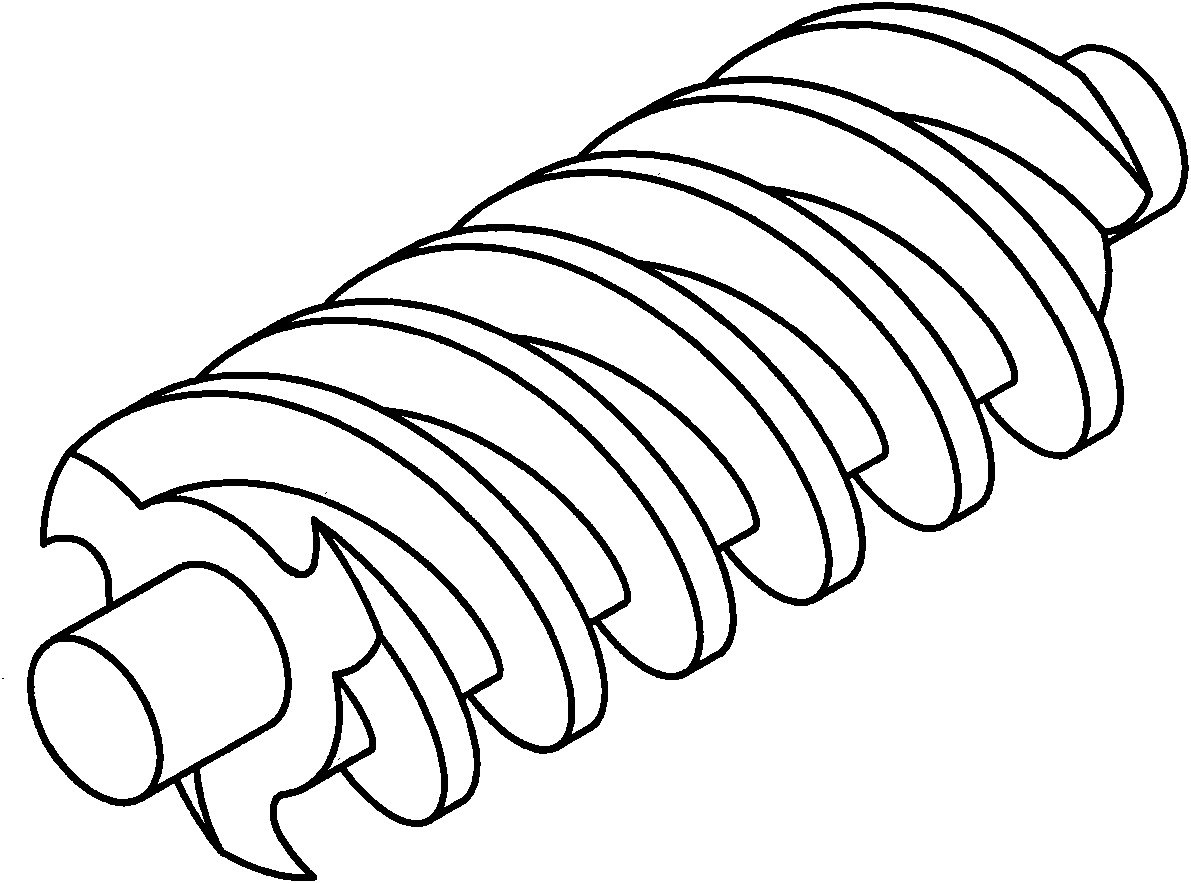

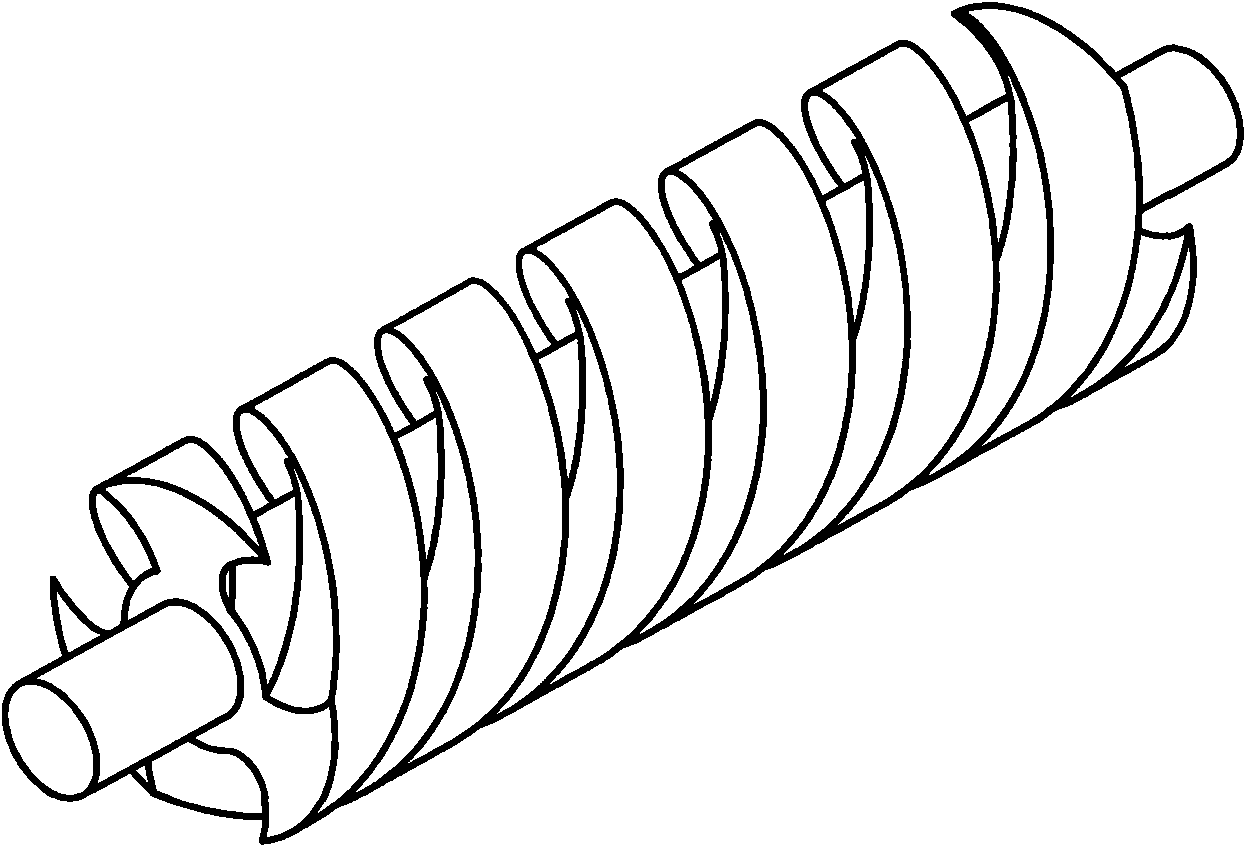

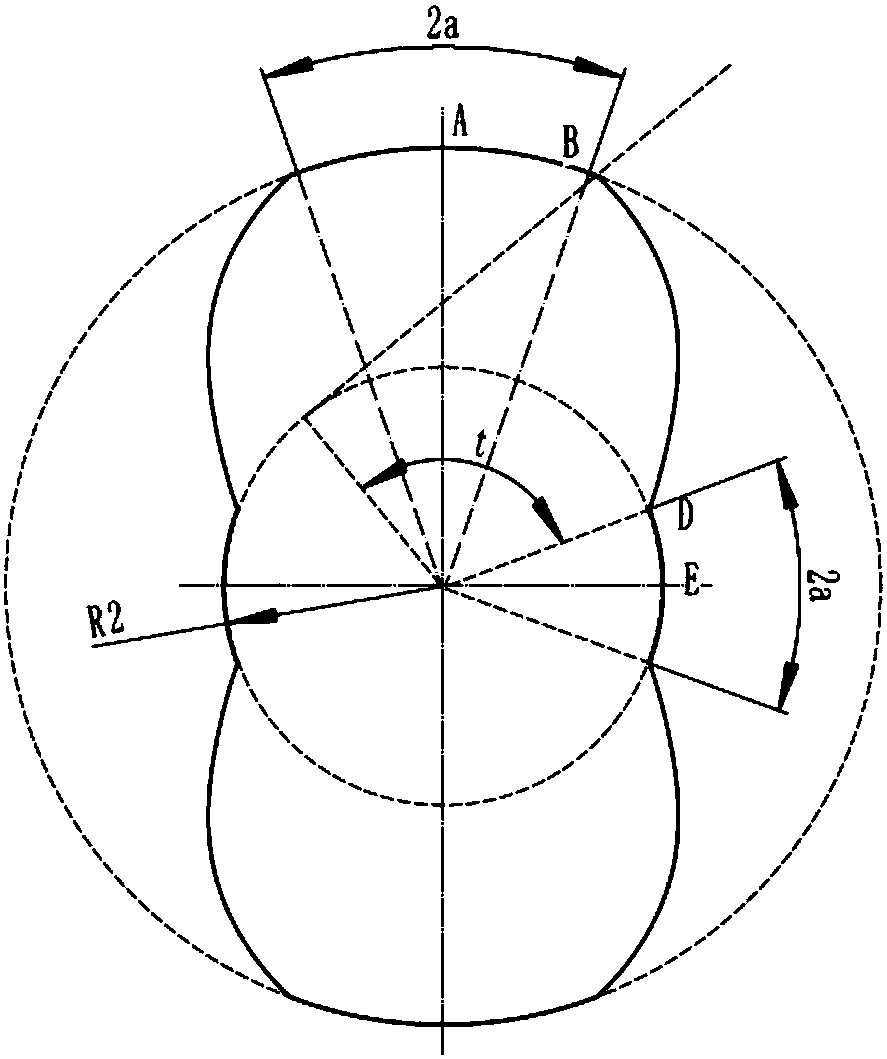

Double-screw mixing transmission pump tooth type

InactiveCN101603532AEasy to processImprove efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringContact line

The invention discloses a double-screw mixing transmission pump tooth type. The shaped line of the double-screw mixing transmission pump tooth type is composed of two triple-head screw shaped lines, wherein, one screw shaped line is a convex screw shaped line, and the other screw shaped line is a concave screw shaped line. The convex screw shaped line is defined by an equation, the tooth shape of each screw is the same, and is distributed evenly along circumference; the tooth shape of each screw is composed of an arc-arc envelope curve and a point meshing cycloid; a main meshing zone adopts the point meshing cycloid and a long limb epicycloid ; other zones adopt the arc-arc envelope curves; the concave screw shaped line is totally obtained with the method that the convex screw adopts the meshing principle for conjugation calculation. The double-screw mixing transmission pump tooth type line of the invention totally conforms to the meshing principle, two rotor shaped lines are mutually conjugated, meshing lines formed by the shaped lines are closed, and contact lines formed by the rotors are continuous, so that the double-screw mixing transmission pump in the invention can be suitable for multiphase medium transmission places with higher transmission pressure and high air voids. Meanwhile, the screw adopting the double-screw mixing transmission pump tooth type of the invention has convenient manufacturing and high efficiency.

Owner:XI AN JIAOTONG UNIV

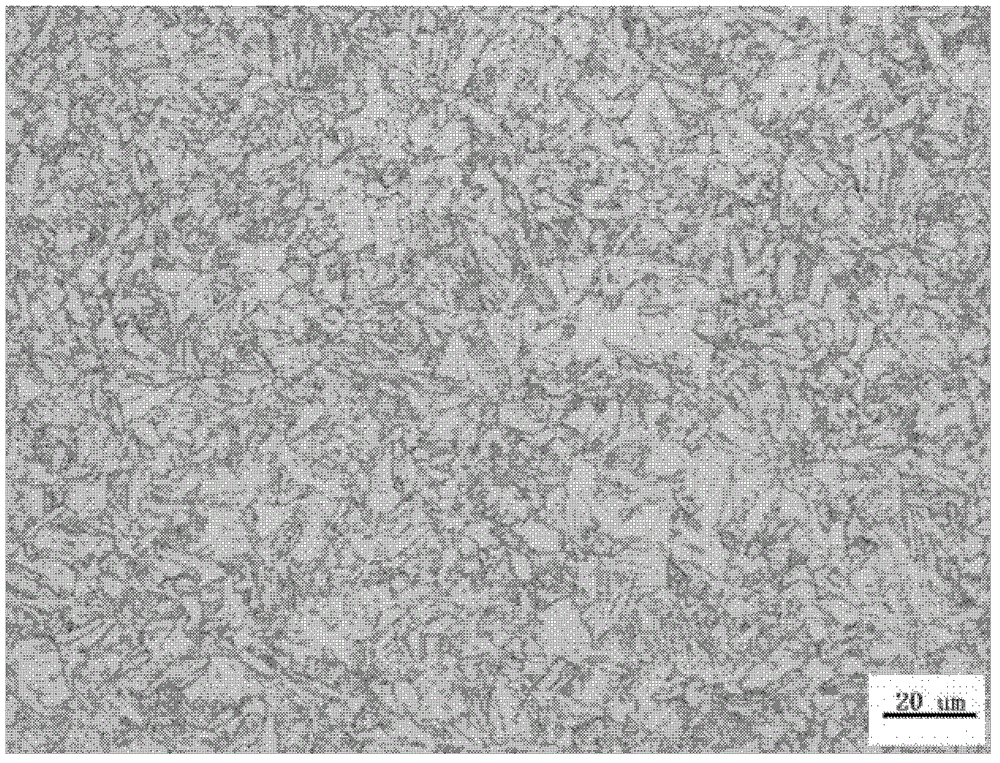

X80 steel grade anti-corrosion low-temperature seamless line pipe

The invention provides an X80 steel grade anti-corrosion low-temperature seamless line pipe which comprises the following components in percentage by weight: 0.08 to 0.14 percent of C, 0.20 to 0.35 percent of Si, 1.10 to 1.40 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.20 percent of Mo, 0.020 to 0.060 percent of Al, 0.02 to 0.05 percent of Nb, 0.05 to 0.10 percent of V, 0.10 to 0.20 percent of Cu, 0.10 to 0.20 percent of Ni, less than or equal to 0.015 percent of Ti, less than or equal to 0.15 percent of Cr, 0.0015 to 0.0060 percent of Ca, less than or equal to 0.0005 percent of B, less than or equal to 0.012 percent of N, less than or equal to 0.43 percent of CEV, less than or equal to 0.23 percent of Pcm and trace amount of ferrum and impurity elements. The line pipe has the rigidity of less than or equal to 250 HV10 and grain size of more than or equal to 8 levels, and passes tests of hydrogen induced cracking (HIC) and sulfide stress corrosion (SSC) corrosion tests at the ductile-brittle transition temperature of below -60 DEG C. The line pipe has the advantages that the integral tissue of a pipe body is uniform,the equivalent carbon content is less than the that of the requirement of the American petroleum institute (API) 5L standard, the welding performance is high, the low-temperature toughness and anti-corrosion performance are excellent, the cost is low, and the requirement of users on the X80 steel grade seamless line pipe can be met completely.

Owner:TIANJIN STEEL PIPE MFG CO LTD

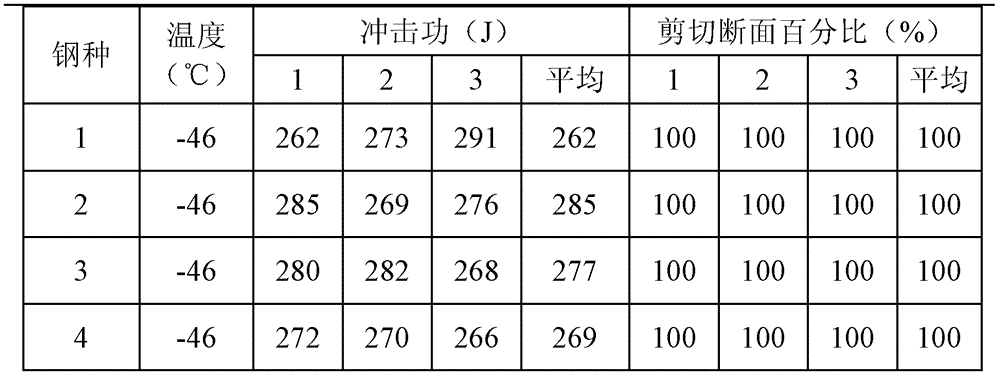

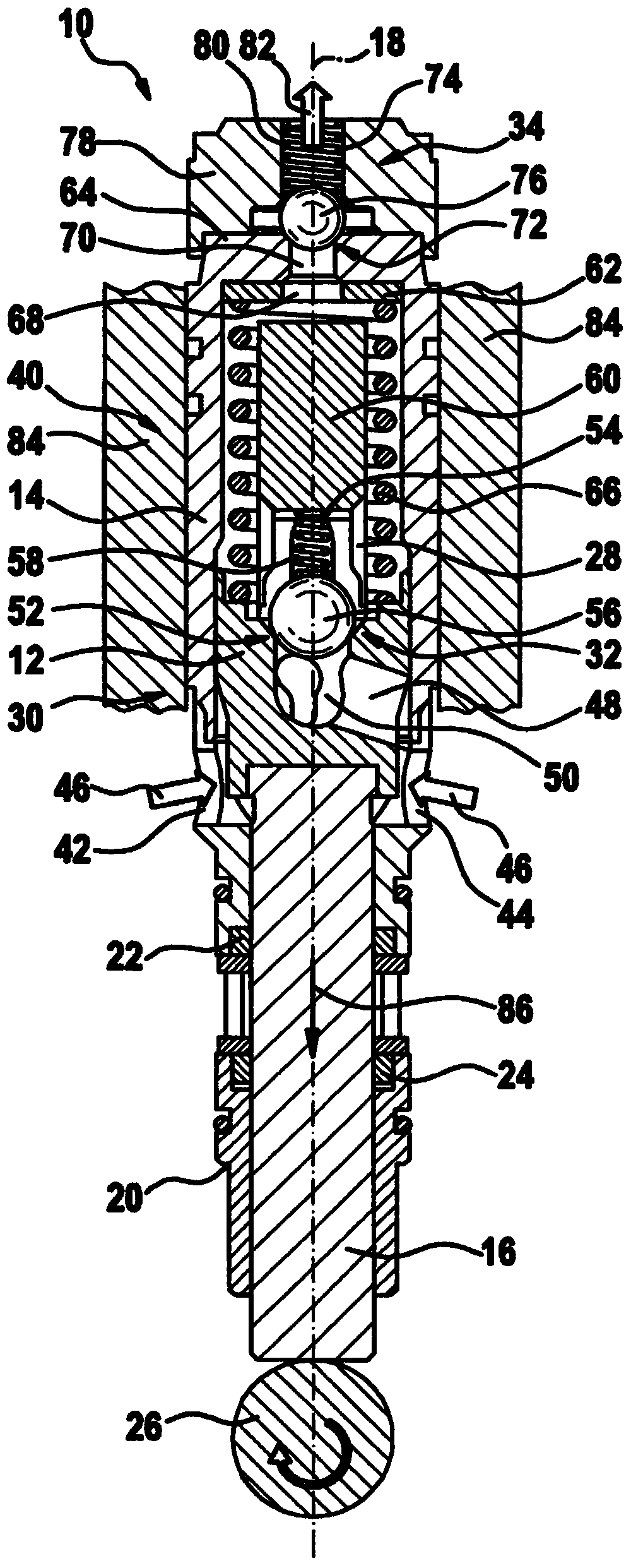

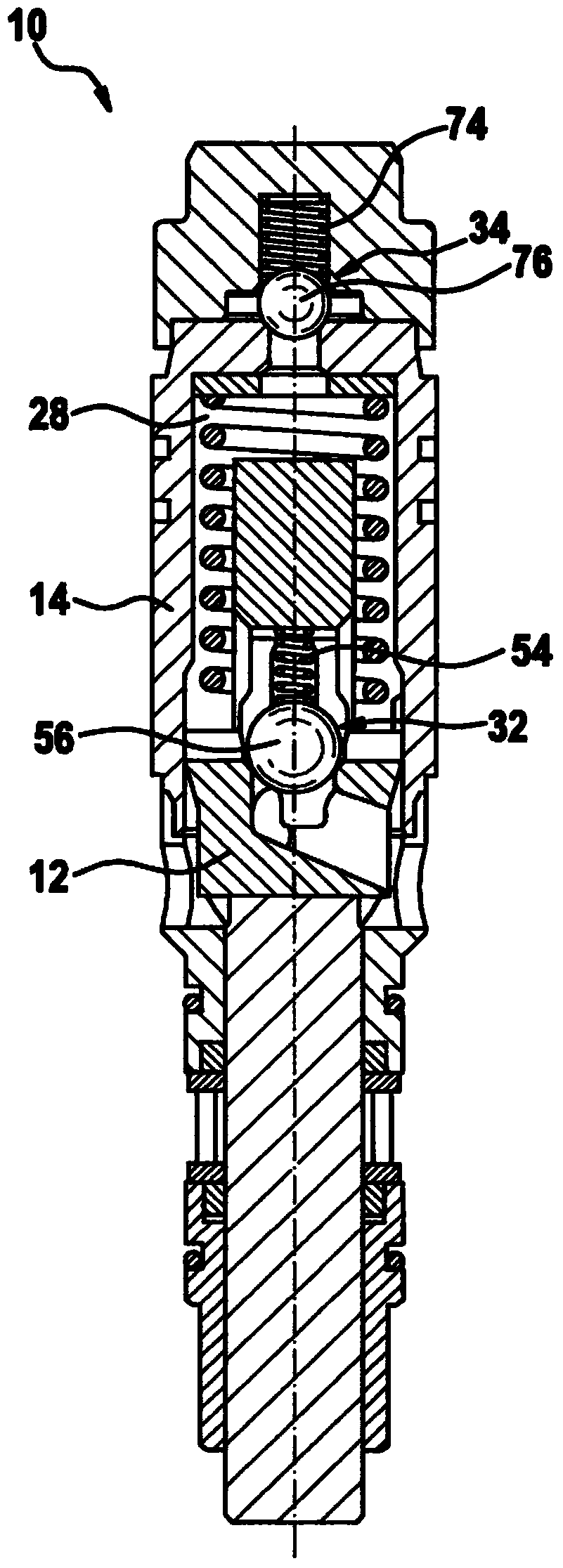

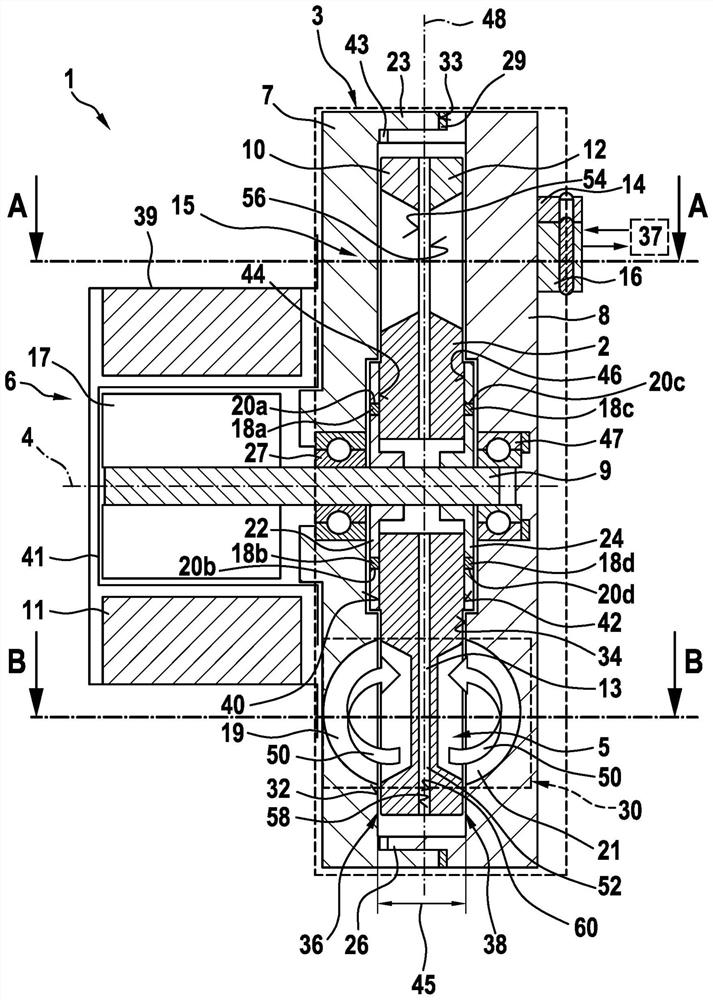

Piston pump

InactiveCN103790819AHigh-volume manufacturingImprove reliabilityPositive displacement pump componentsCleaning using liquidsEngineeringHigh pressure

The present invention relates to a piston pump (10) form high-pressure transmission of a fluid to be transmitted. The piston pump (10) comprises a pressure generating unit (30) and a control unit (40) which are arranged together in an individual housing (84) and aligned to each other along a common longitudinal axis (18).

Owner:ROBERT BOSCH GMBH

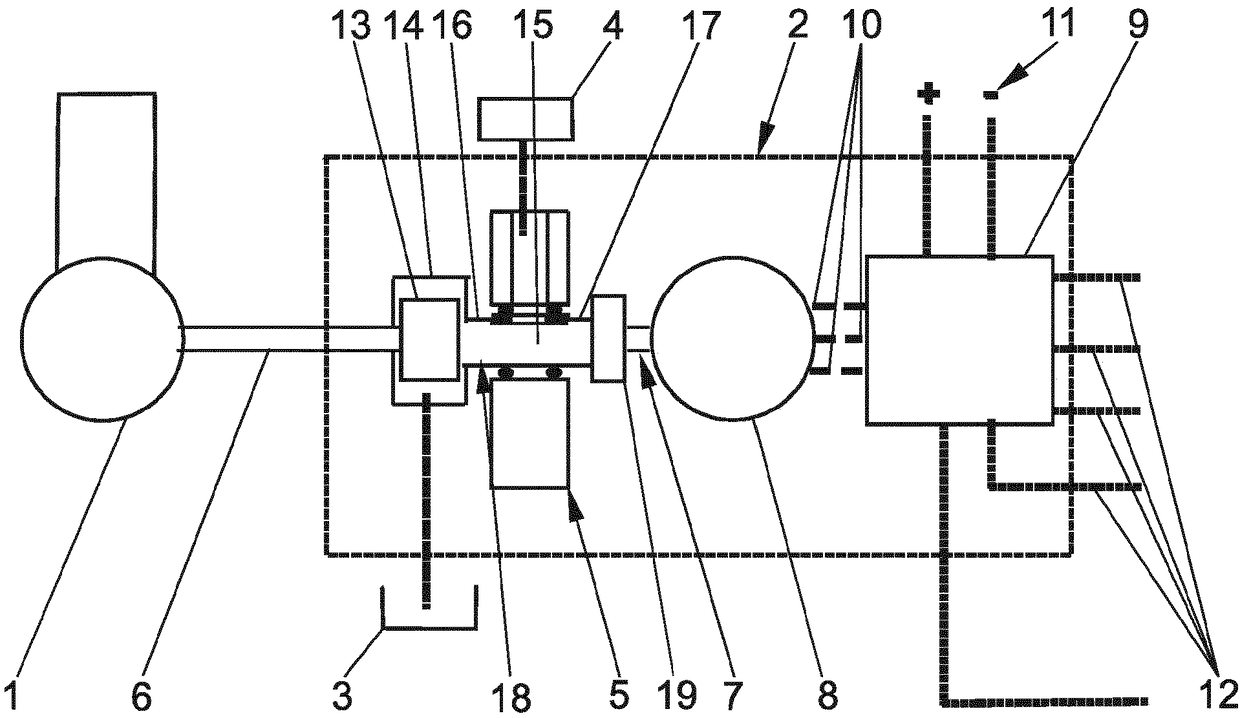

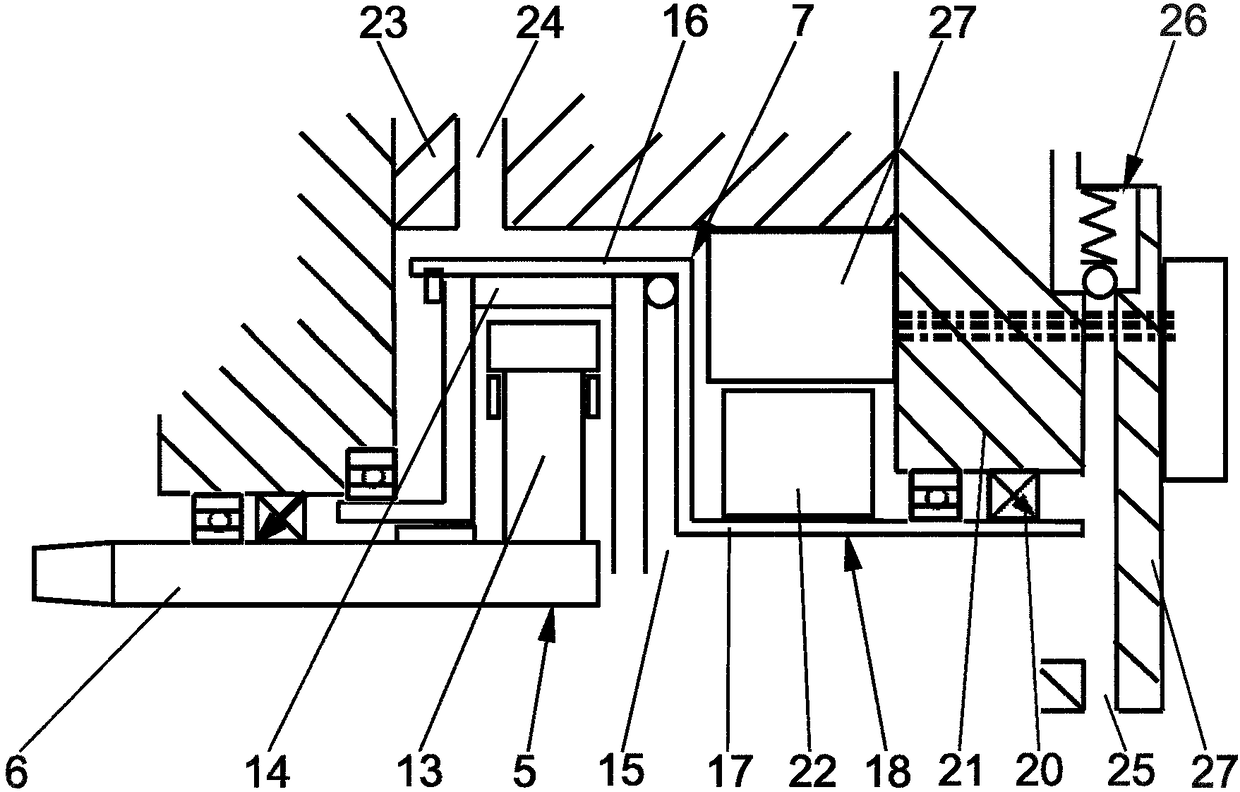

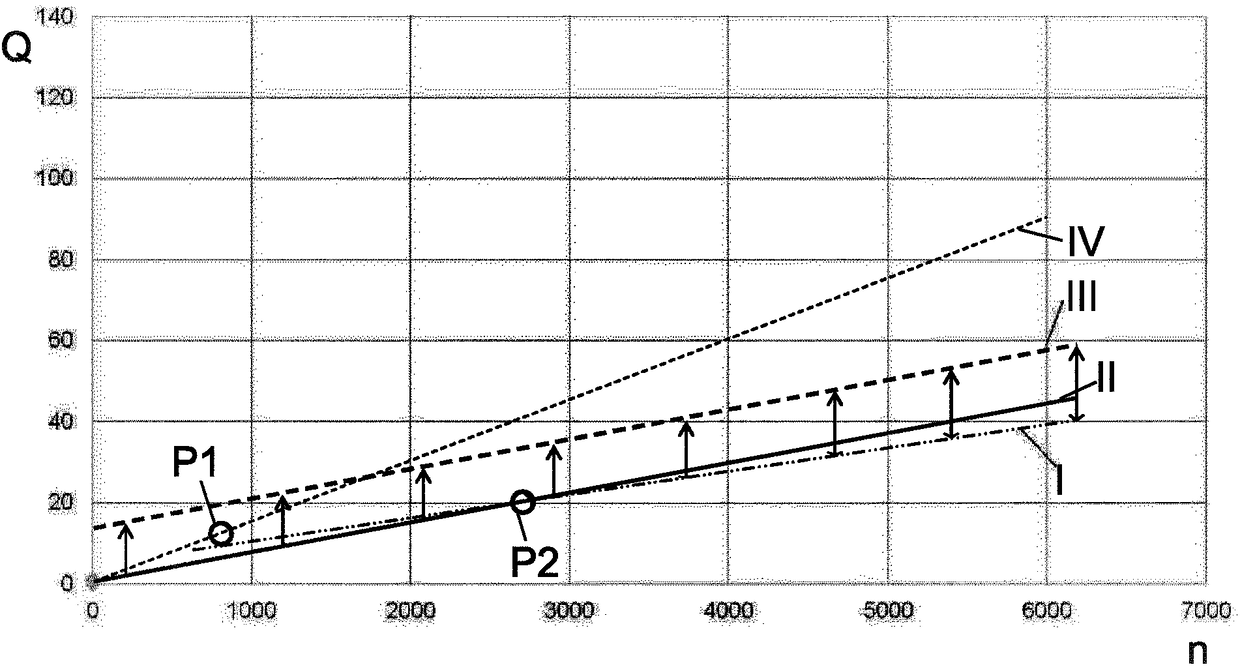

Delivery device for motor vehicle

ActiveCN108138612AReduce delivery powerMeet increased demandGear lubrication/coolingRotary piston pumpsElectricityExternal combustion engine

The invention relates to a delivery device (2) for a motor vehicle for delivering oil from an oil sump (3) to a lubricating oil circuit of an internal combustion engine (1), which delivery device hasas an oil pump (5) a double-stroke vane cell pump (28) having positive guidance of vanes (32). A direct drive (6) of the vane cell pump (28) via the internal combustion engine (1) is designed for a working point P2. An increased or reduced oil demand is compensated for by an electric drive (7) that can be connected. In this way, a compact and very small-dimensioned oil pump (5) can be employed.

Owner:VTESCO TECH GMBH

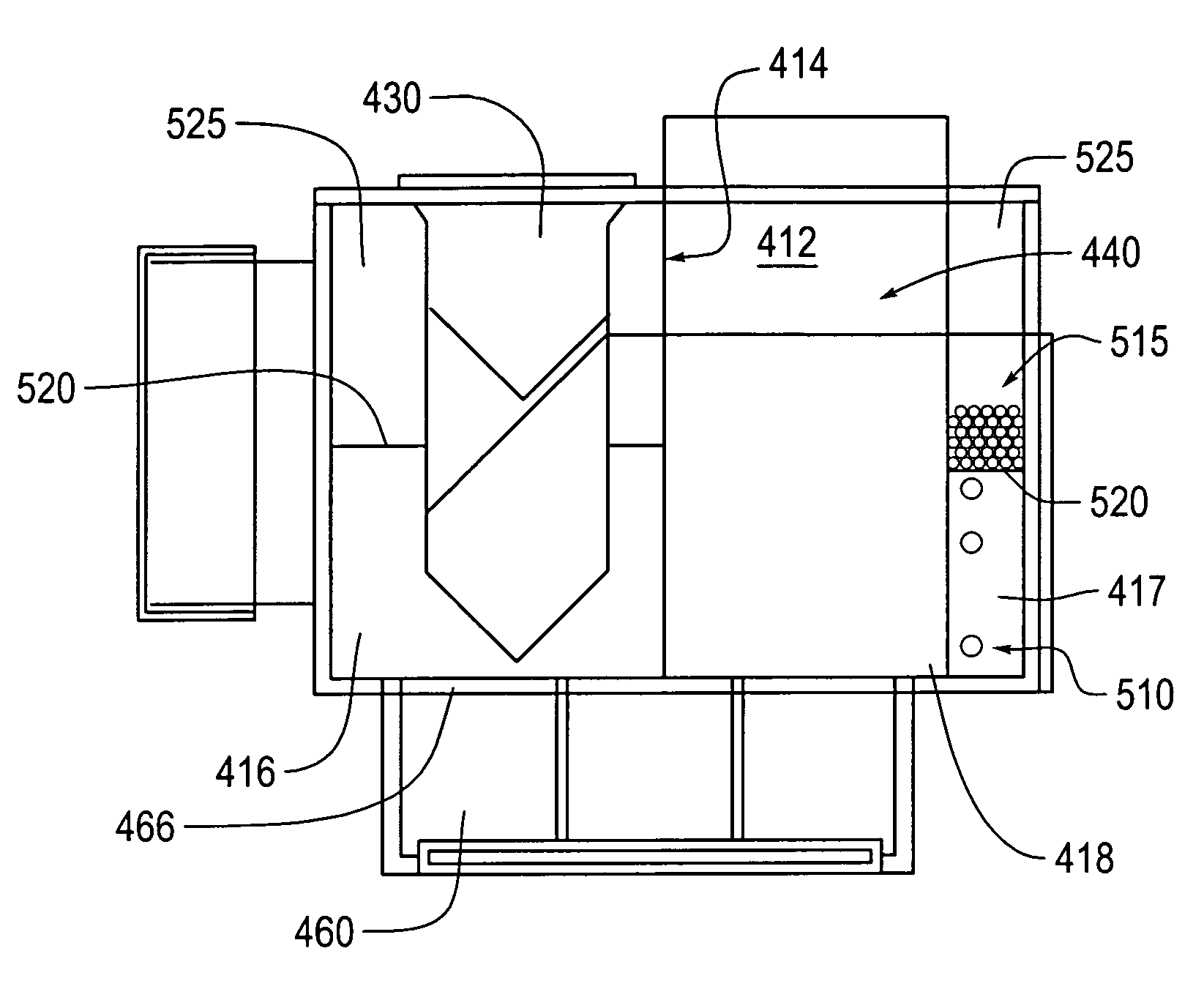

Pressure control architecture for fluid tanks having fluid level sensing

InactiveUS7048365B2Reduce liquid leakageImprove efficiencyLiquid surface applicatorsCoatingsEngineeringFluid level

A refillable fluid container system having a pressure control architecture in which persistent air bubbles are released from a capillary or foam fluid reservoir and are directed from an optical level sensing system in a liquid fluid reservoir.

Owner:FUJIFILM BUSINESS INNOVATION CORP

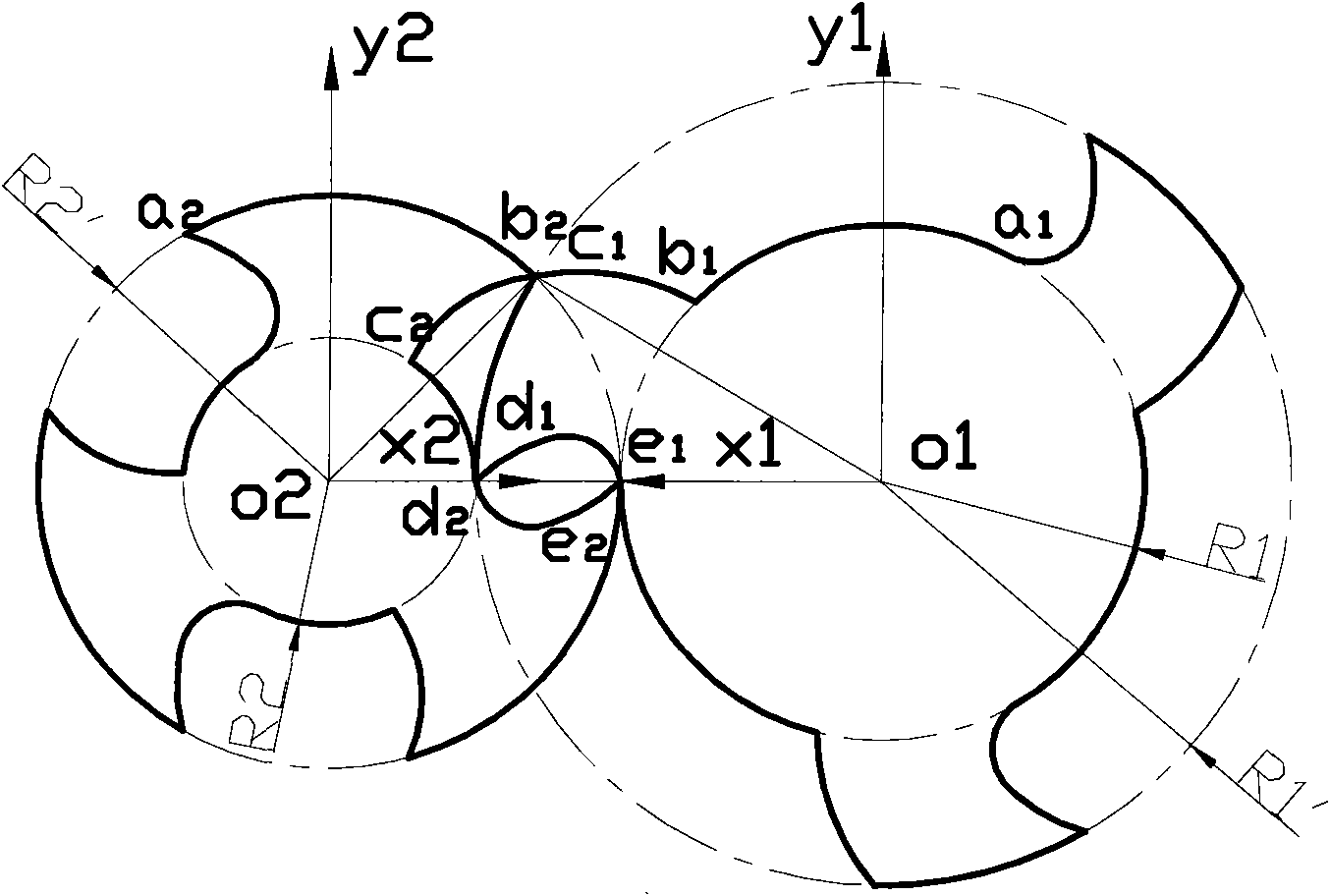

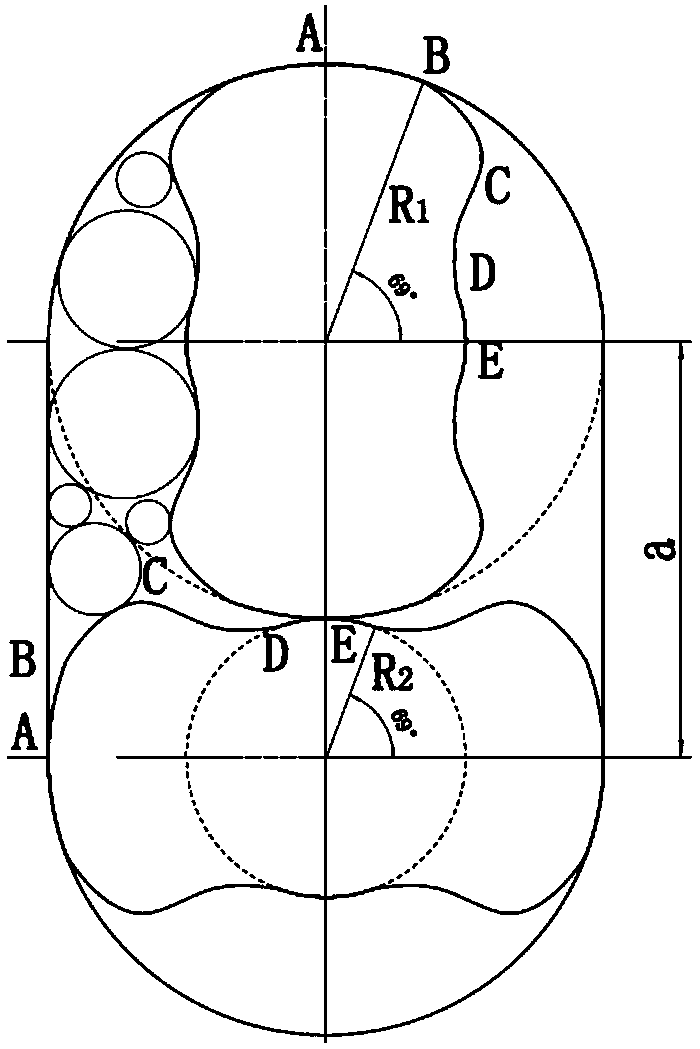

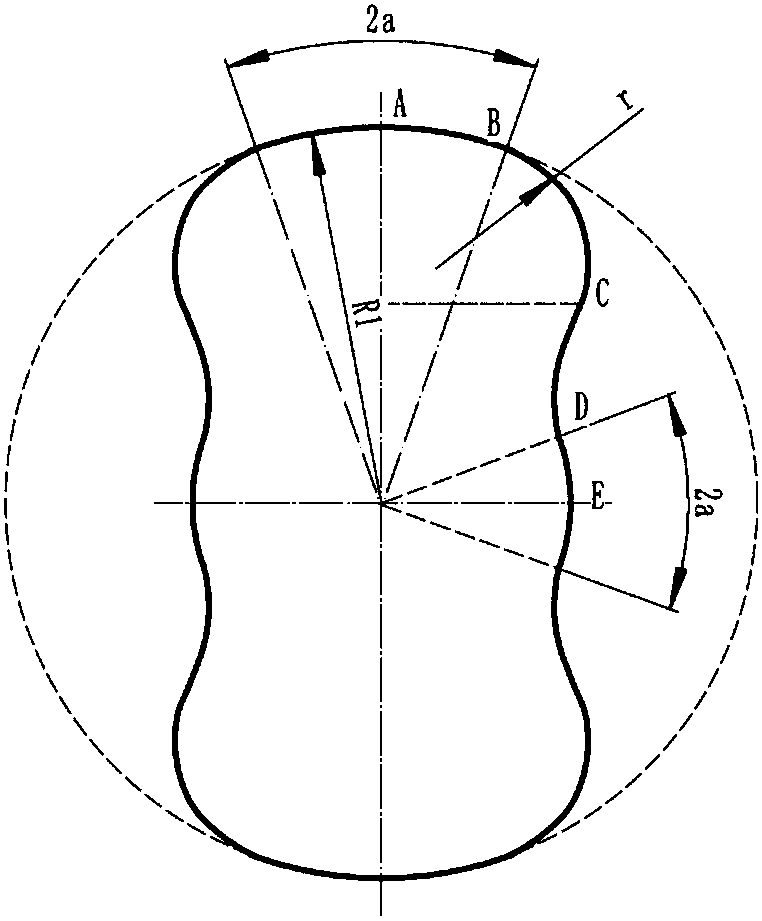

Wide head rotor of high vacuum displacement pump

ActiveCN107061271AWide working pressure rangeIncrease the shaft diameterPump componentsRotary piston pumpsMetal frameworkEngineering

The invention discloses a wide head rotor of a high vacuum displacement pump. In an existing cam pump technology, seal between a pump body and a rotor is linear pump, and therefore, vacuum capacity is easily caused to drop after the rotor and the pump body are worn. The end surface of the wide head rotor of the high vacuum displacement pump is of an axisymmetric structure, and a 1 / 4 molded line of the end surface consists of three parts: a top end wide head circular arc AB, a transition curve BD and an intermediate circular arc DE, and the rotor is formed by wrapping a metal framework and rubber; and the top end wide head circular arc AB and the intermediate circular arc DE of the wide head rotor are two conjugate curves. The wide head rotor effectively increases a working pressure range of the high vacuum displacement pump, ensures lasting stability of conveying pressure, reduces pulsation and improves working efficiency.

Owner:HANGZHOU DIANZI UNIV

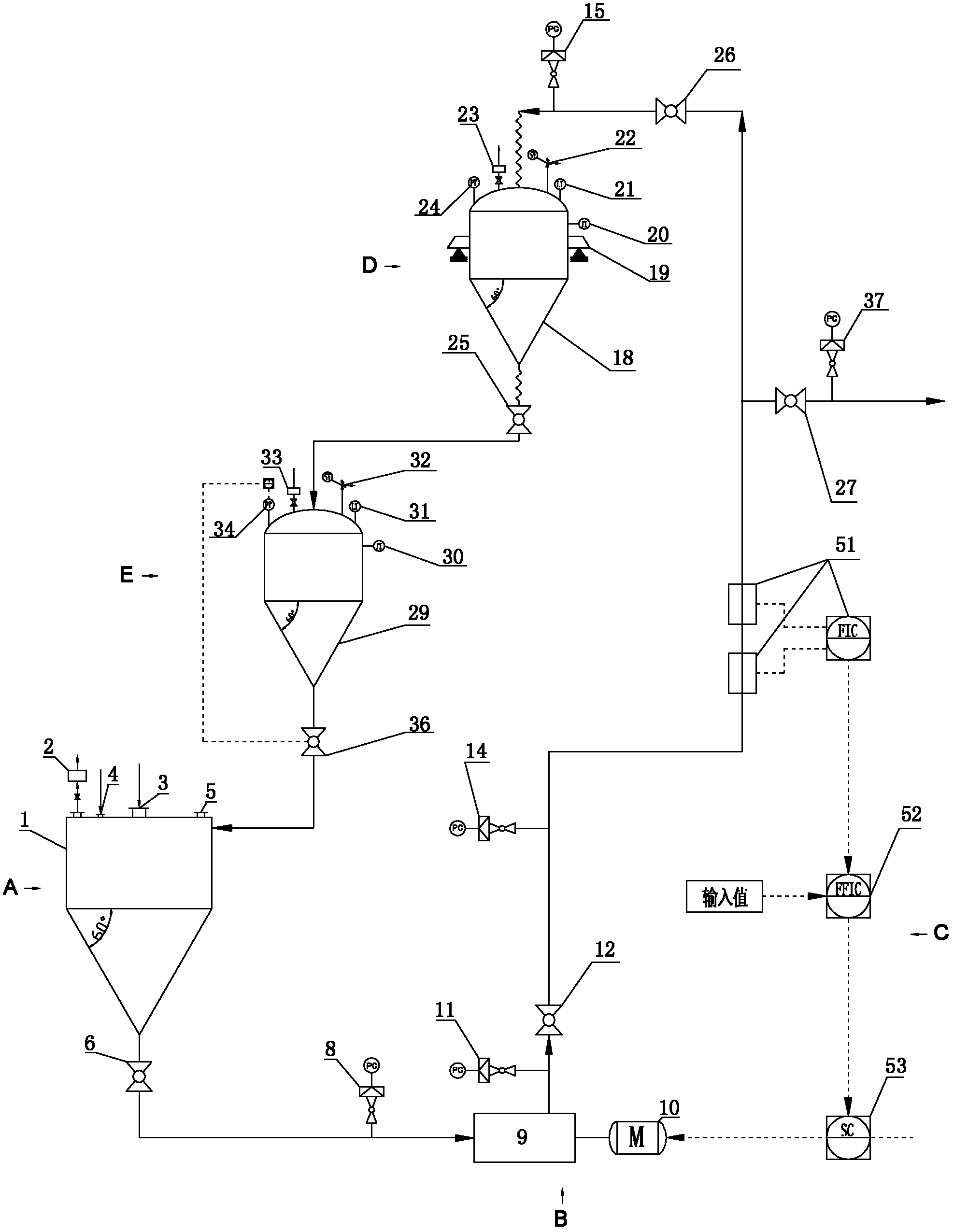

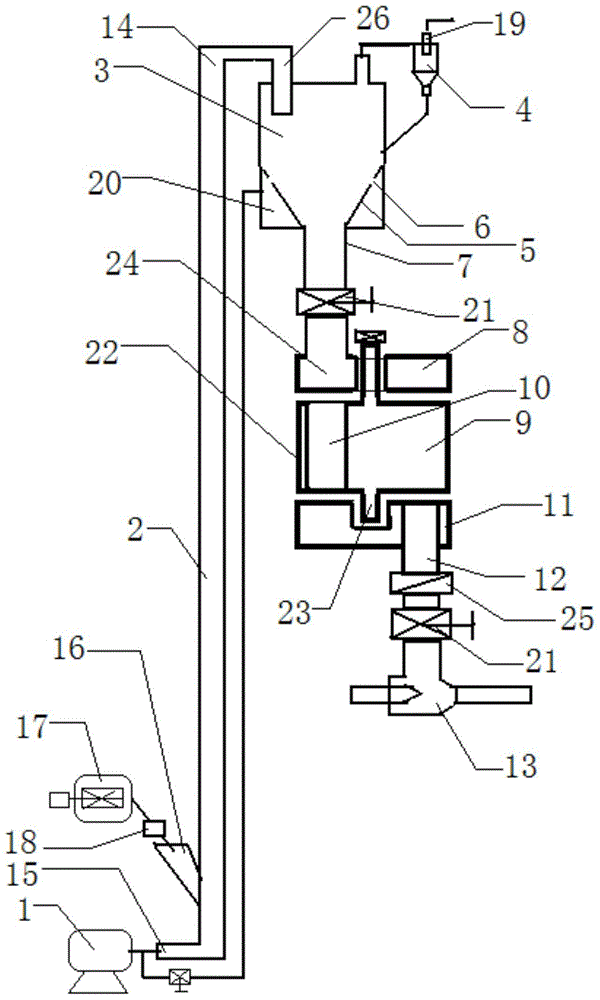

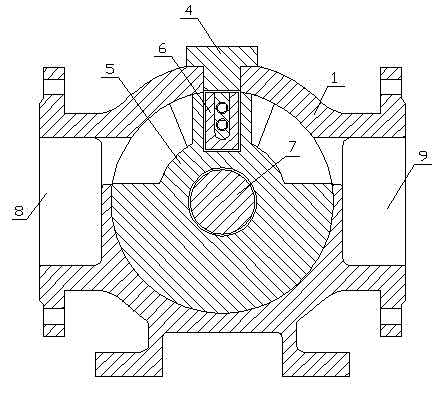

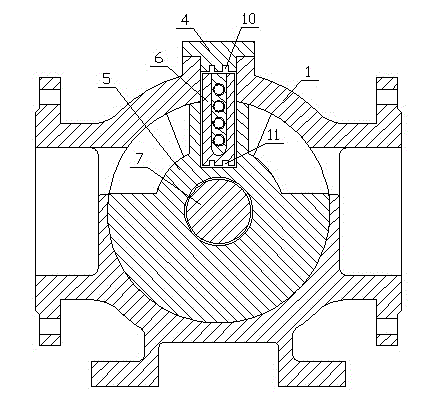

Low-energy-consumption high-pressure powder conveying device

ActiveCN104444374AIncrease delivery pressureReduce energy consumptionBulk conveyorsProduct gasGas chamber

The invention provides a low-energy-consumption high-pressure powder conveying device. A low-pressure conveying air inlet is formed in the bottom of a lifting pipe. A powder inlet is formed in the lower portion of the lifting pipe. The top of the lifting pipe is connected with a feeding bin through a quick separator. The low-pressure conveying air inlet in the bottom of the lifting pipe is connected with a fan. The powder inlet in the lower portion of the lifting pipe is connected with a crusher through a feeder. A gas outlet in the top of the feeding bin is provided with a gas-solid separator. A feed leg of the gas-solid separator is returned back to the lower middle portion of the feeding bin. One to twelve conical hoppers are arranged at the bottom of the feeding bin. Air inlets are formed in the side walls of the upper portions of the conical hoppers. A fluidization gas chamber is arranged from the middles of the conical hoppers to the bottom of the feeding bin and connected with the fan through a bypass. The feed leg of each conical hopper is connected with an irregularly-shaped hole in an upper fixing valve plate of a powder conveying pump through a valve. A lower stock bin connected with an irregularly-shaped hole in a lower fixing valve plate of the powder conveying pump passes through a check valve and the valve in sequence to be connected with a high-pressure injection pump.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-viscosity polyamide-6 preparation method

The invention discloses a high-viscosity polyamide-6 preparation method. According to the present invention, the polyamide-6 is tackified by using the following methods that the tri-amino end-cappingagent is added to increase the amino terminal content, the conveying pressure between the front polymerization pipe and the rear polymerization pipe is increased, the flat wet slices are obtained through slicing, the solid phase condensation polymerization efficiency in the second-stage drying is improved, and the energy loss is reduced.

Owner:JIANGSU RUIMEIFU IND

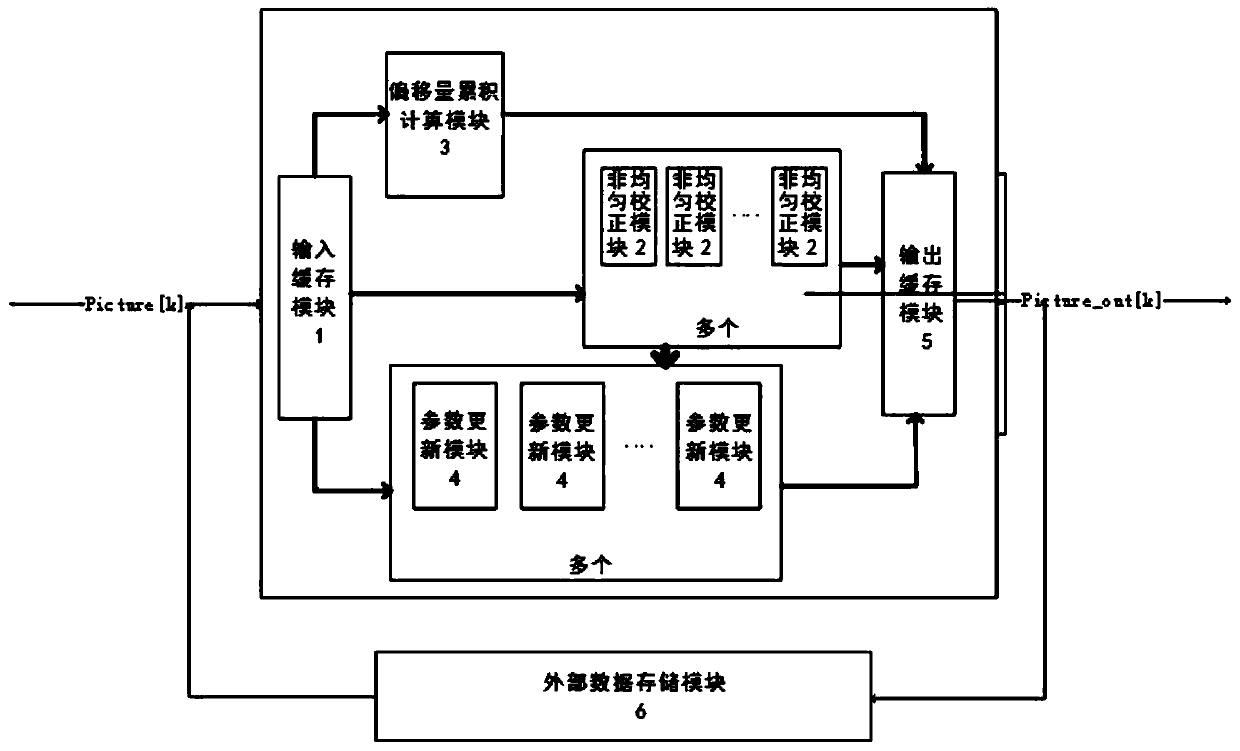

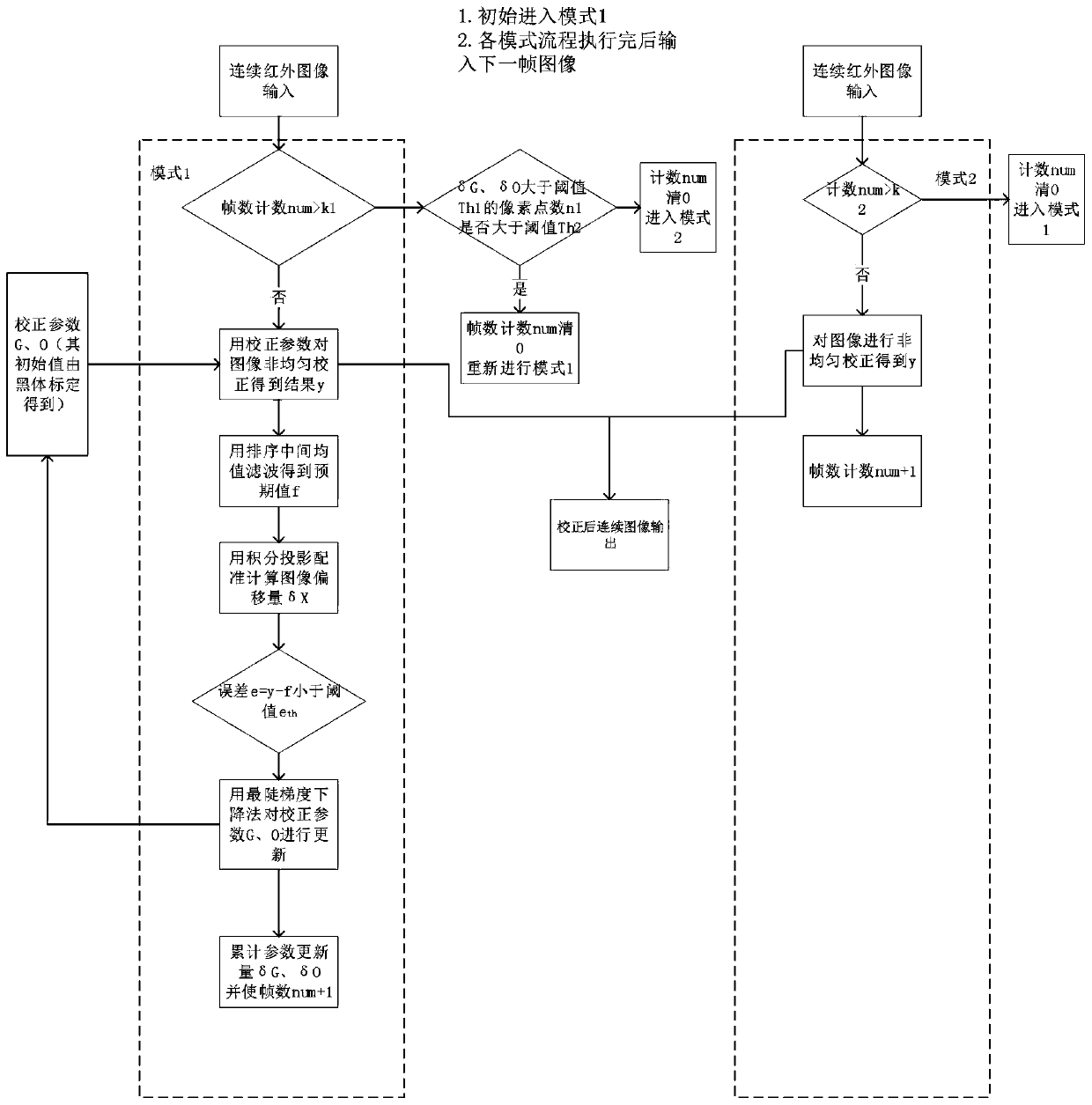

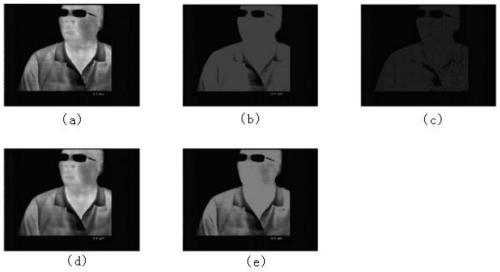

Non-uniformity correction method based on scene adaptation and hardware implementation device thereof

ActiveCN111145115AImprove the correction effectReduce edge blurringImage enhancementEnergy efficient computingExternal dataEngineering

The invention provides a non-uniformity correction method based on scene adaptation and a hardware implementation device thereof, and the method comprises the steps: collecting an original infrared image, obtaining pixel data, and carrying out the statistics of the number of frames; initializing correction parameters of the original infrared image to obtain an initial gain correction coefficient and an initial offset correction coefficient; entering an initial correction mode, and determining a current correction mode, carrying out non-uniform correction frame by frame according to the frame number, judging whether an initial gain correction coefficient and an initial offset correction coefficient are updated or not; when it is judged that updating is not carried out, obtaining corrected pixel data, and when it is judged that updating is carried out, obtaining updated correction parameters and corrected pixel data, wherein the corrected pixel data are corrected infrared images; cachingthe corrected infrared image and the updated correction parameters, and storing the infrared image and the updated correction parameters in an external data storage module. The device comprises an input cache module, a non-uniformity correction module, an offset accumulation calculation module, a parameter updating module, an output cache module and an external data storage module.

Owner:FUDAN UNIV

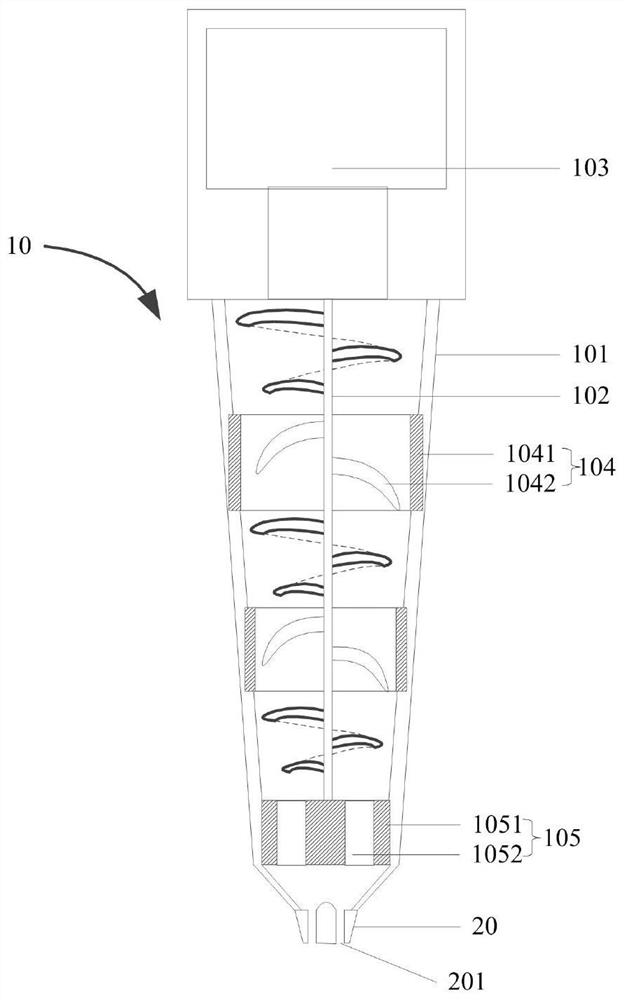

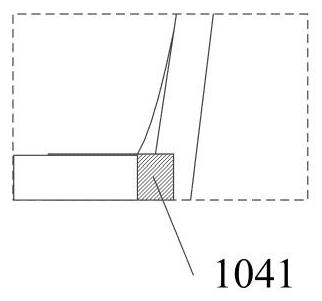

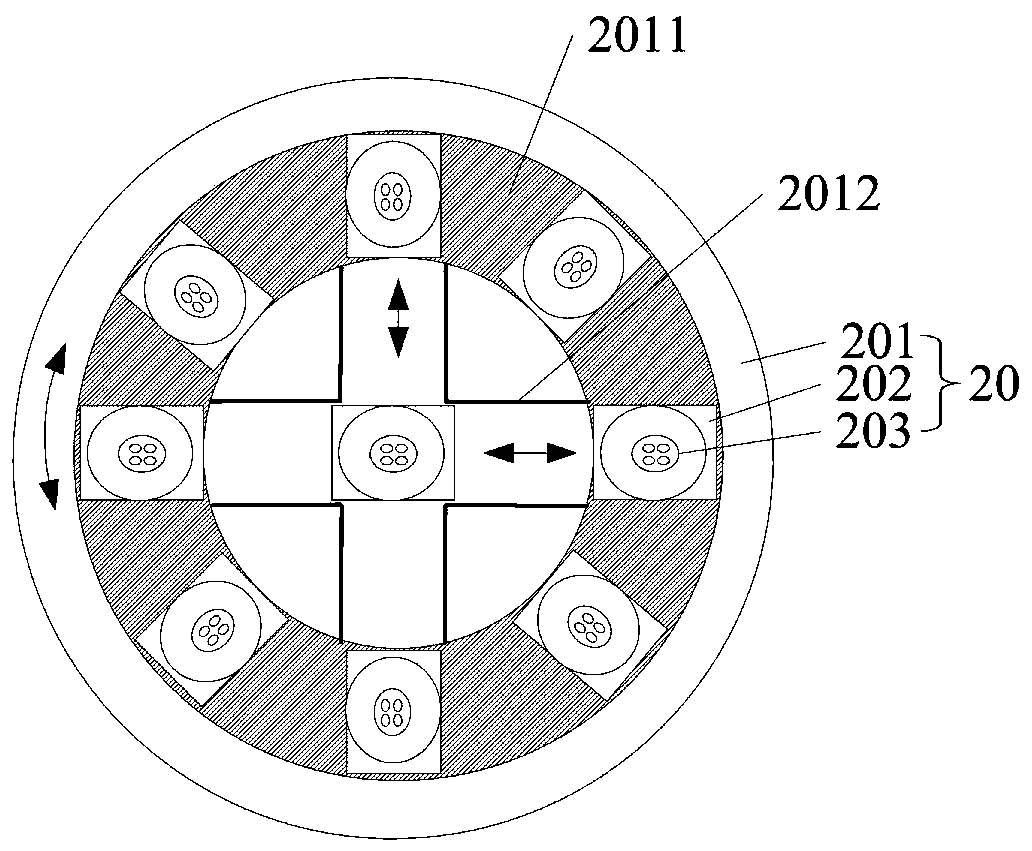

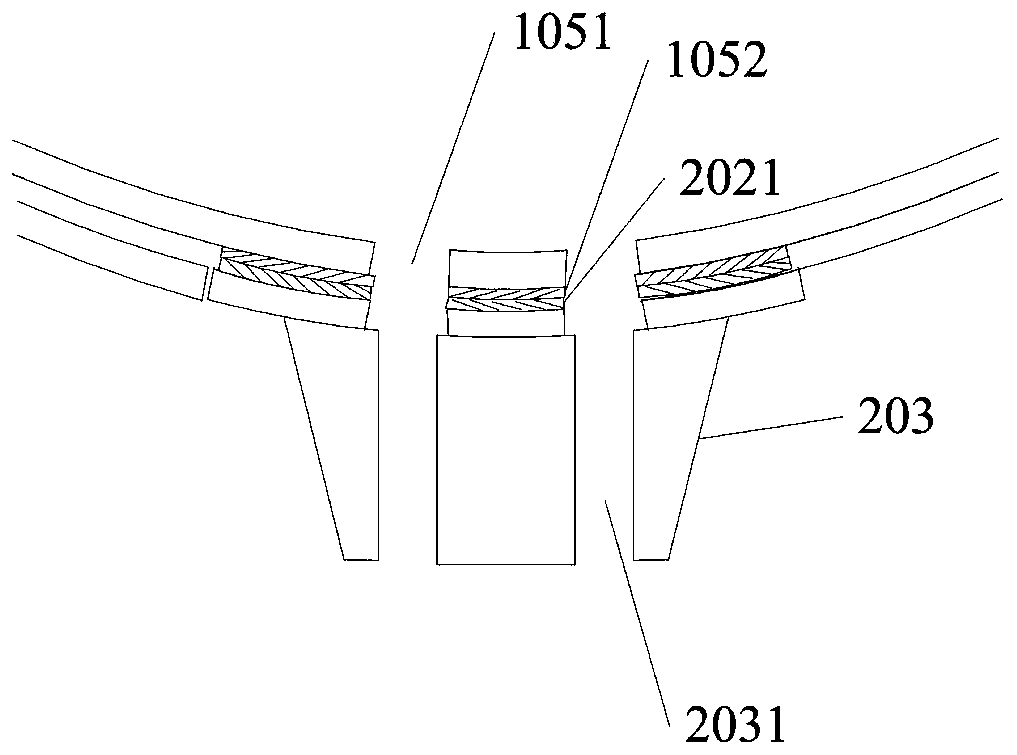

Bio 3d printing nozzle

ActiveCN111331845BEvenly distributedKeep homogeneous3D object support structuresDomestic articlesHigh densityEngineering

The invention discloses a biological 3D printing nozzle. The biological 3D printing nozzle comprises a conveying pipe arranged over a 3D printing table, and further comprises a cylinder, a shaft, a motor for driving the shaft to rotate, at least two first pressurized conveying sections, a pair of pressurized conveying stirring blades, a second pressurized conveying section, two piezoelectric ceramic tubes II, and a nozzle body detachably arranged on the lower end of the conveying pipe; and two spray holes are formed in the axial direction of the nozzle body in a penetrating mode, and the spraying ranges of the two spray holes for spraying biological mucus do not overlap. The biological 3D printing nozzle can evenly and smoothly spray biological tissue fluid with high viscosity and high density, and the printing requirements of biomedical products are met.

Owner:新沂市中振电器科技有限公司

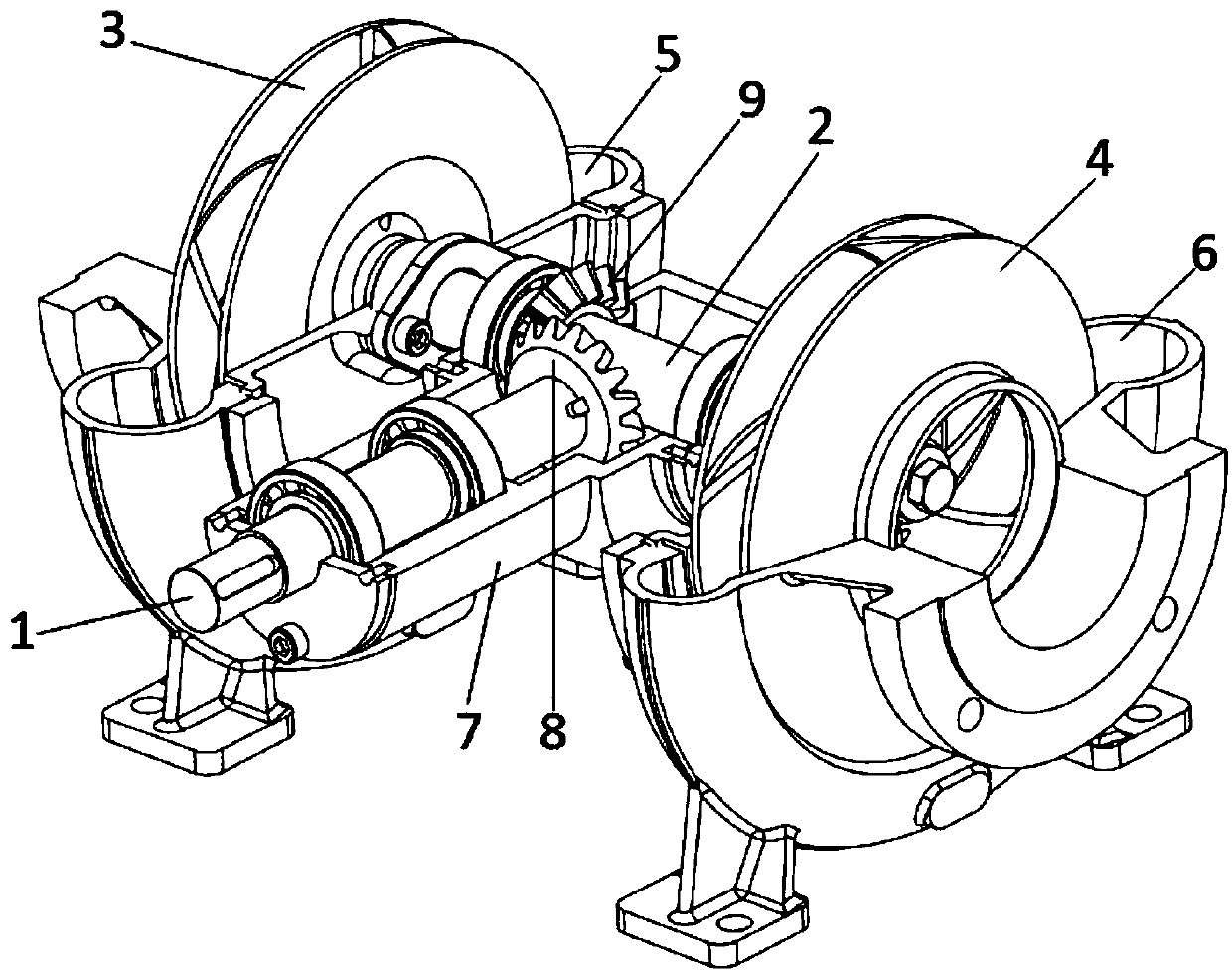

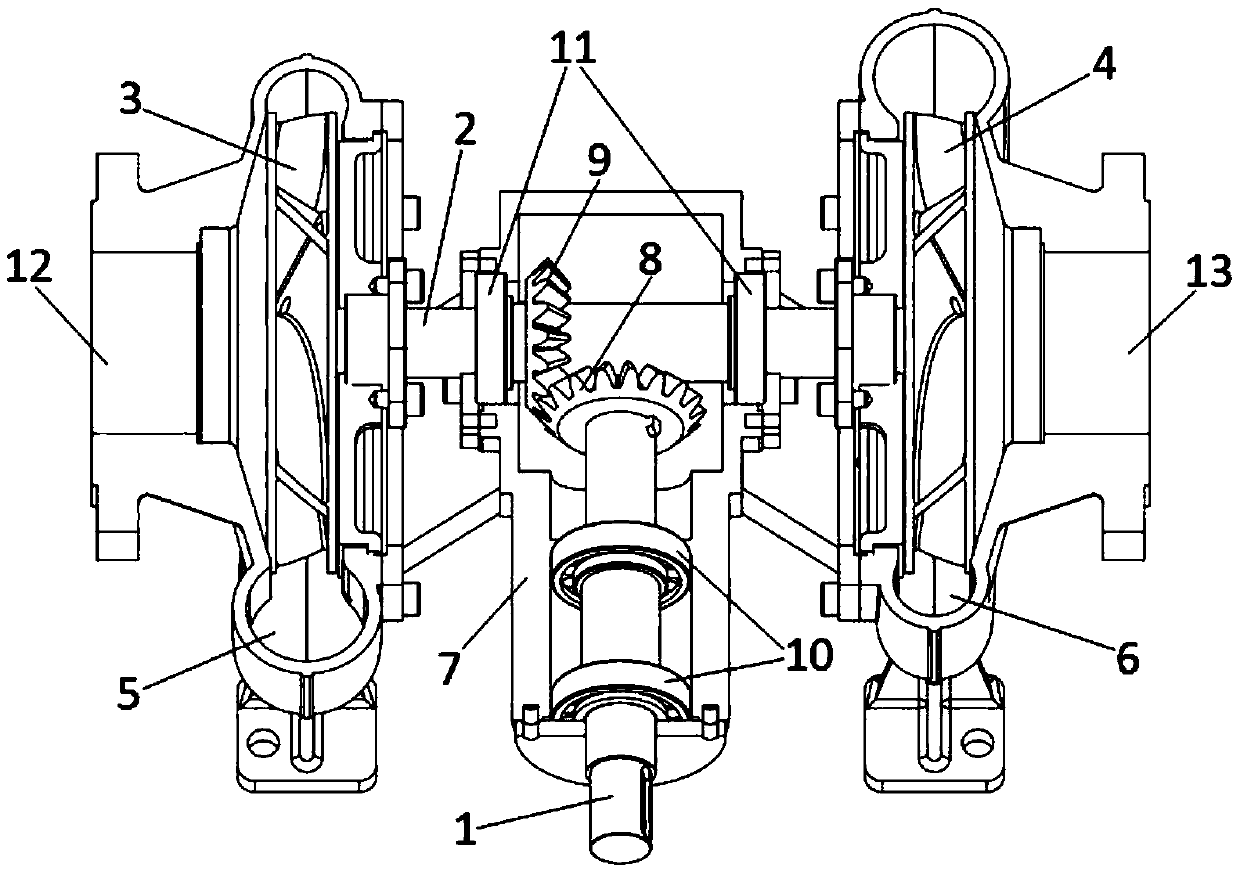

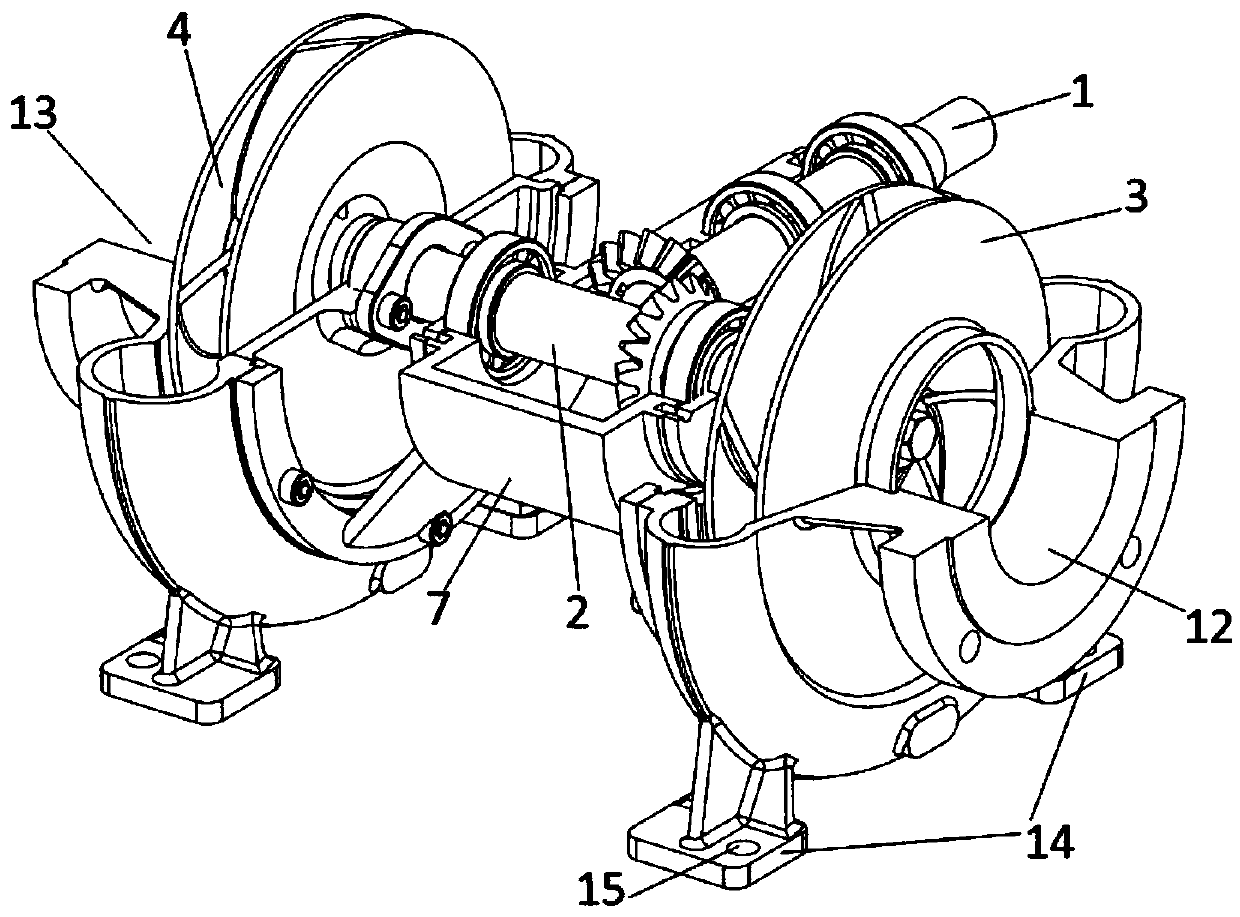

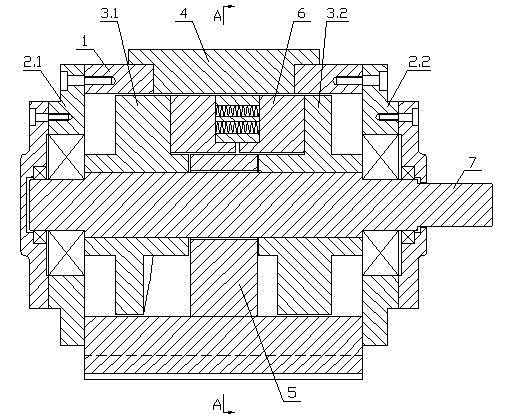

New structure multifunctional composite pumping device

PendingCN107939698AMeet delivery requirementsOvercome installation space limitationsPump componentsPump installationsDrive shaftClassical mechanics

The invention discloses a new structure multifunctional composite pumping device. The new structure multifunctional composite pumping device comprises a transmission device, a conveying device and anauxiliary device. The transmission device is mainly composed of a driving shaft and a driven shaft which are in a pair, the installing direction of the driving shaft is perpendicular to the installingdirection of the driven shaft, and torque is transmitted between the driving shaft and the driven shaft through a pair of bevel gears. The two bevel gears are arranged on the driving shaft and the driven shaft correspondingly. The conveying device is mainly composed of two impellers and two volutes. The two impellers are arranged at the two ends of the driven shaft correspondingly and matched with the two volutes correspondingly. The auxiliary device is mainly composed of a bridge frame, bearings and sealing covers. The driving shaft and the driven shaft are arranged in the bridge frame through the bearings. Due to lubricating oil in the bridge frame, the lubricating function is ensured. Due to the sealing covers at the upper portion and the front portion of the bridge frame, it is ensured that lubricating oil does not leak. The bridge frame and the two volutes are connected into a whole through bolts. The new structure multifunctional composite pumping device is simple in structure,small in size and capable of automatically balancing the axial force of the impellers; the conveying amount is increased; and different media can be conveyed and mixed.

Owner:QUZHOU UNIV

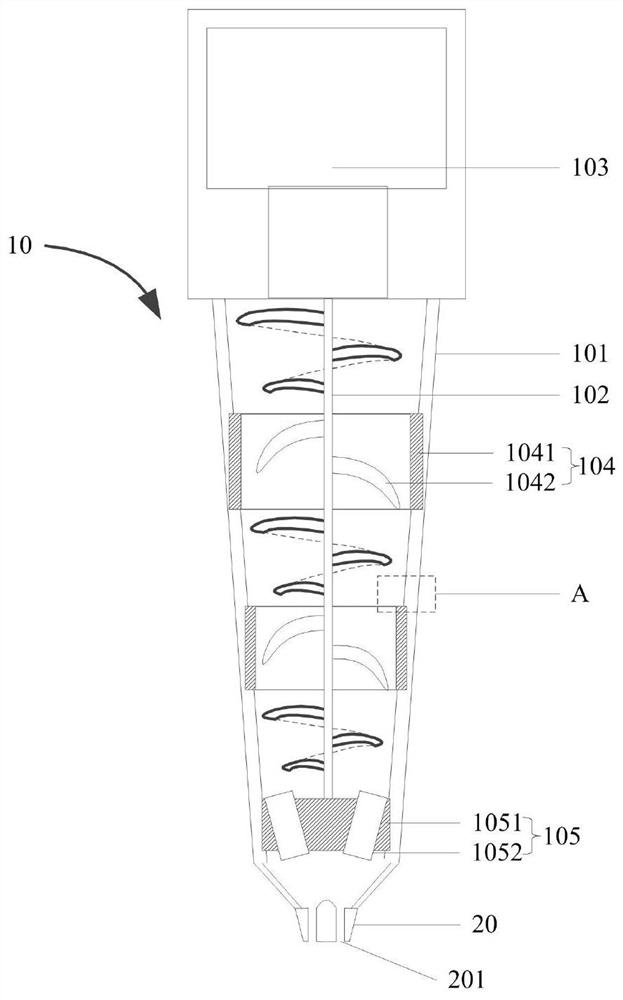

Multi-type spray head replaceable biological 3D printing device

ActiveCN111361153AEasy to replaceSwitch at will3D object support structuresDomestic articlesEngineeringBiomedicine

The invention discloses a multi-type spray head replaceable biological 3D printing device. The multi-type spray head replaceable biological 3D printing device comprises a conveying pipe and a nozzle assembly, wherein the conveying pipe is arranged over a 3D printing platform and comprises a barrel body, a shaft, a motor driving the shaft to rotate, at least two first pressurizing conveying sections, and a pair of pressurizing conveying stirring blades; the nozzle assembly is detachably arranged on the spherical surface of a spherical crown shaped sealing head and comprises a spherical crown shaped supporting shell, an annular slide groove, a pair of arc-shaped slide grooves arranged in a crossed mode, a plurality of arc-shaped plate bodies and a plurality of nozzles. The multi-type spray head replaceable biological 3D printing device can uniformly and smoothly spray biological interstitial fluid high in viscosity and density, and meets the printing requirements of biomedical products.

Owner:HEFEI C&P NONWOVEN PROD

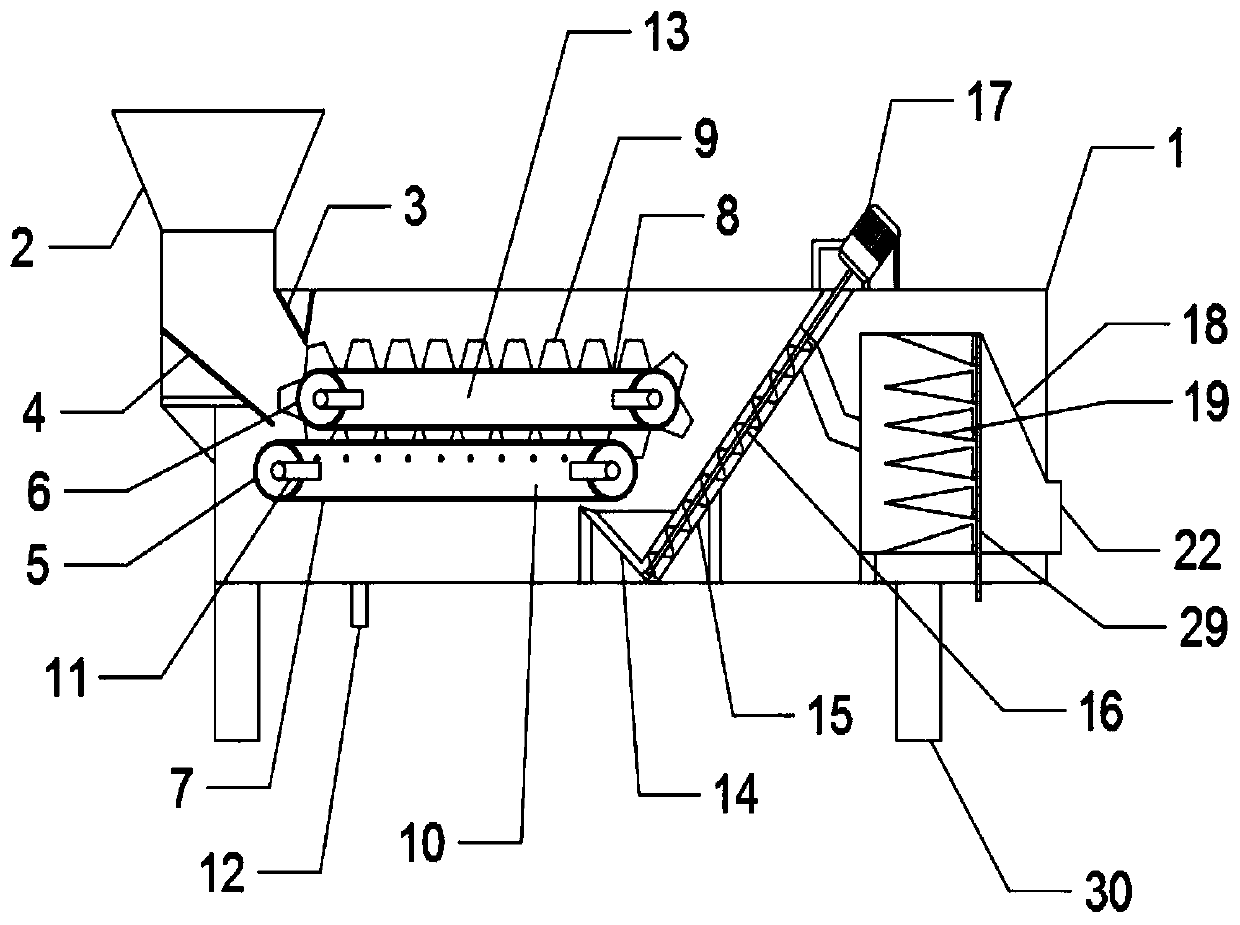

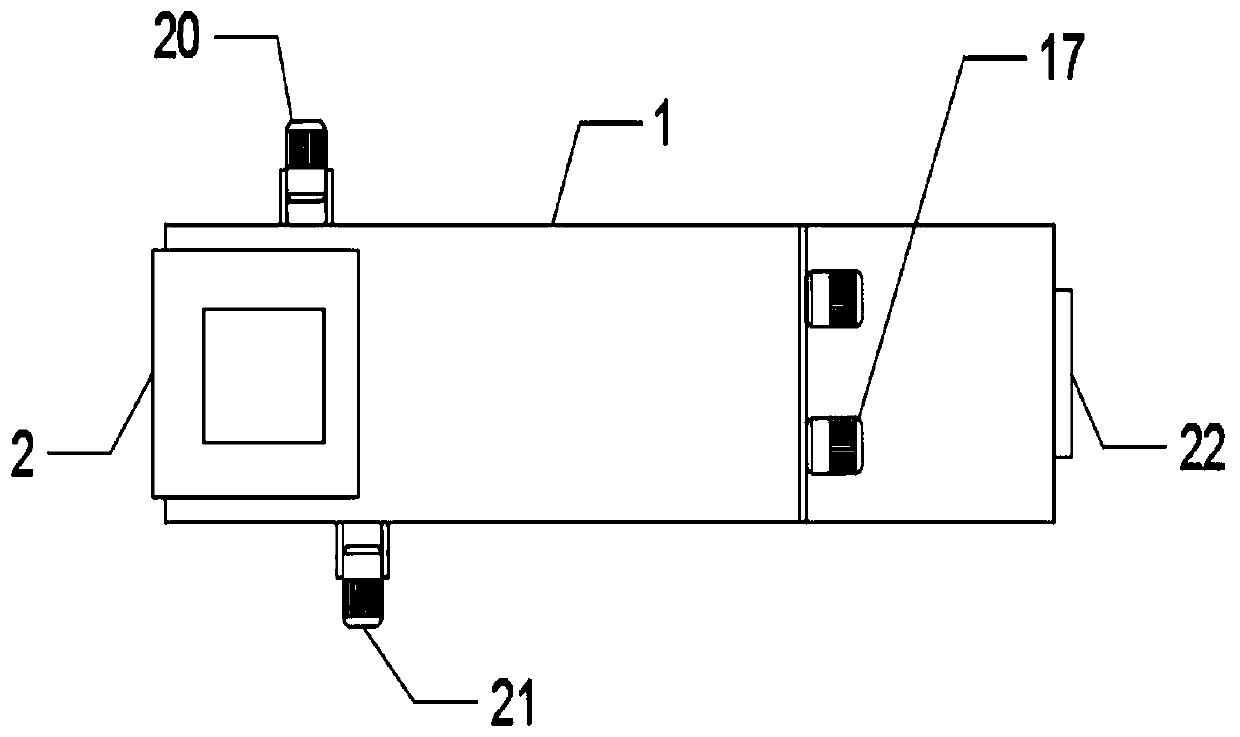

Sludge thickening and dewatering all-in-one machine

The invention discloses a sludge thickening and dewatering all-in-one machine. The invention belongs to the technical field of environmental protection. The sludge thickening and dewatering all-in-onemachine includes a housing, wherein two first transmission rollers are arranged in the shell; two second transmission rollers are arranged above the first transmission roller; a first conveying beltis connected between the two first transmission rollers; a second conveying belt is connected between the two second transmission rollers; a plurality of pressing blocks are arranged on the second conveying belt; a plurality of pressing grooves are formed in the first conveying belt; a plurality of round holes are formed in the pressing groove, the round holes are covered with filter cloth, a sludge collecting groove is formed below the first conveying belt, two sludge pressing pipes are arranged in the sludge collecting groove, sludge pressing screw rods are arranged in the sludge pressing pipes, two sludge pressing motors are arranged at the upper end of the shell, and power output shafts of the sludge pressing motors are fixedly connected with the upper ends of the sludge pressing screwrods. Sludge in the pressing groove is subjected to pressure filtration step by step through the pressing block and then concentrated through the concentration device, and therefore the purposes of integrating sludge treatment and improving the treatment efficiency are achieved.

Owner:安徽恒帆环保科技有限公司

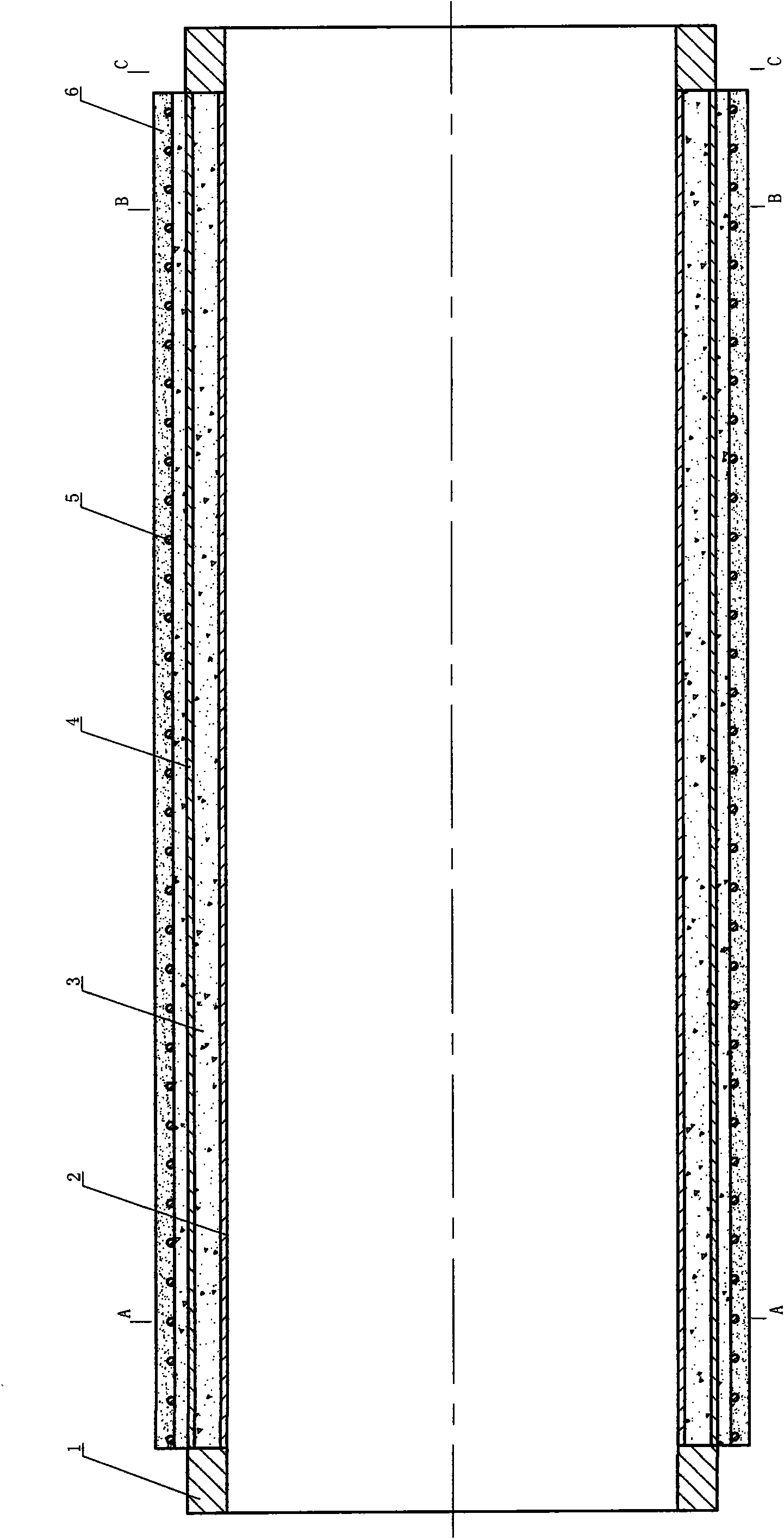

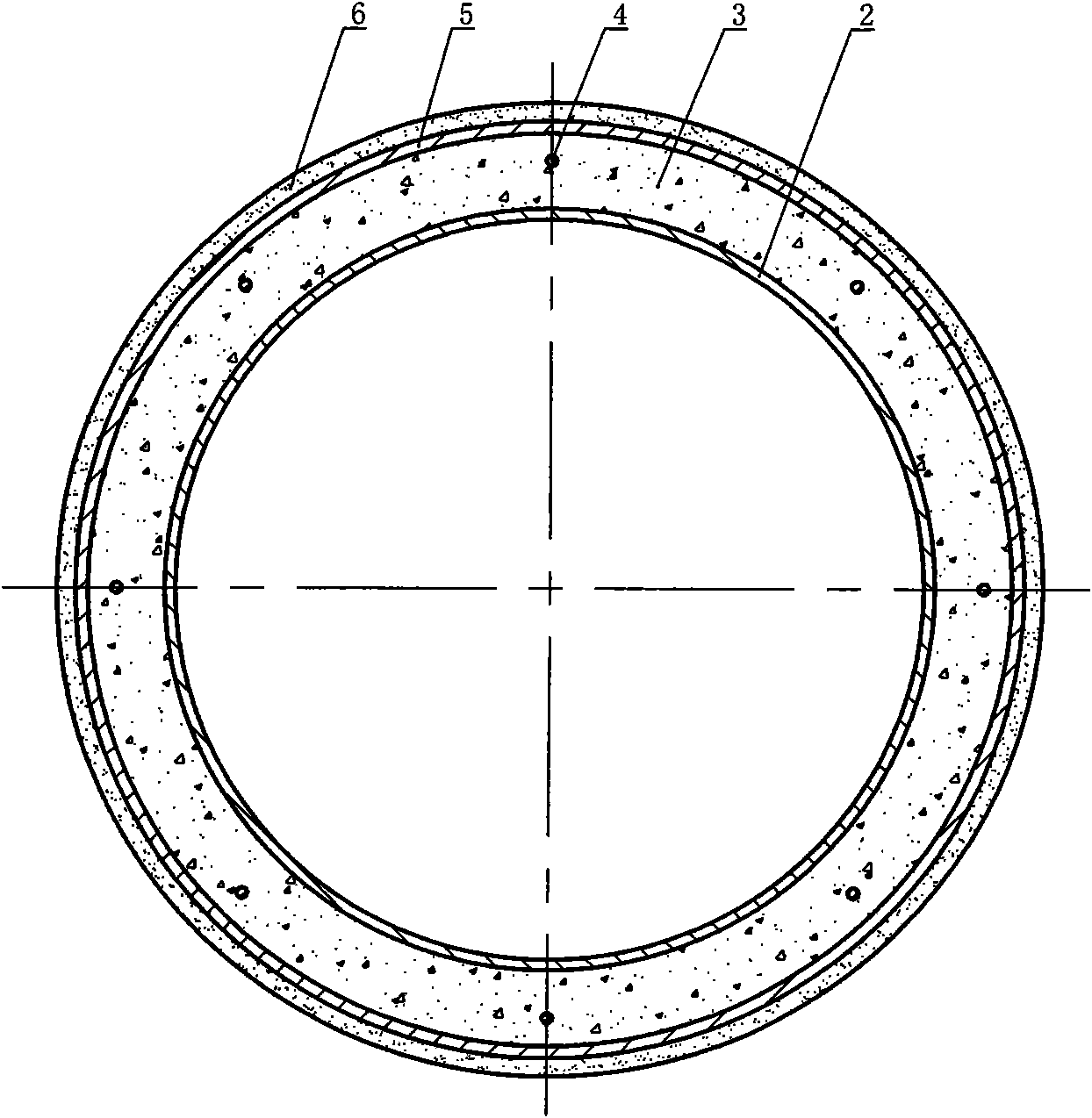

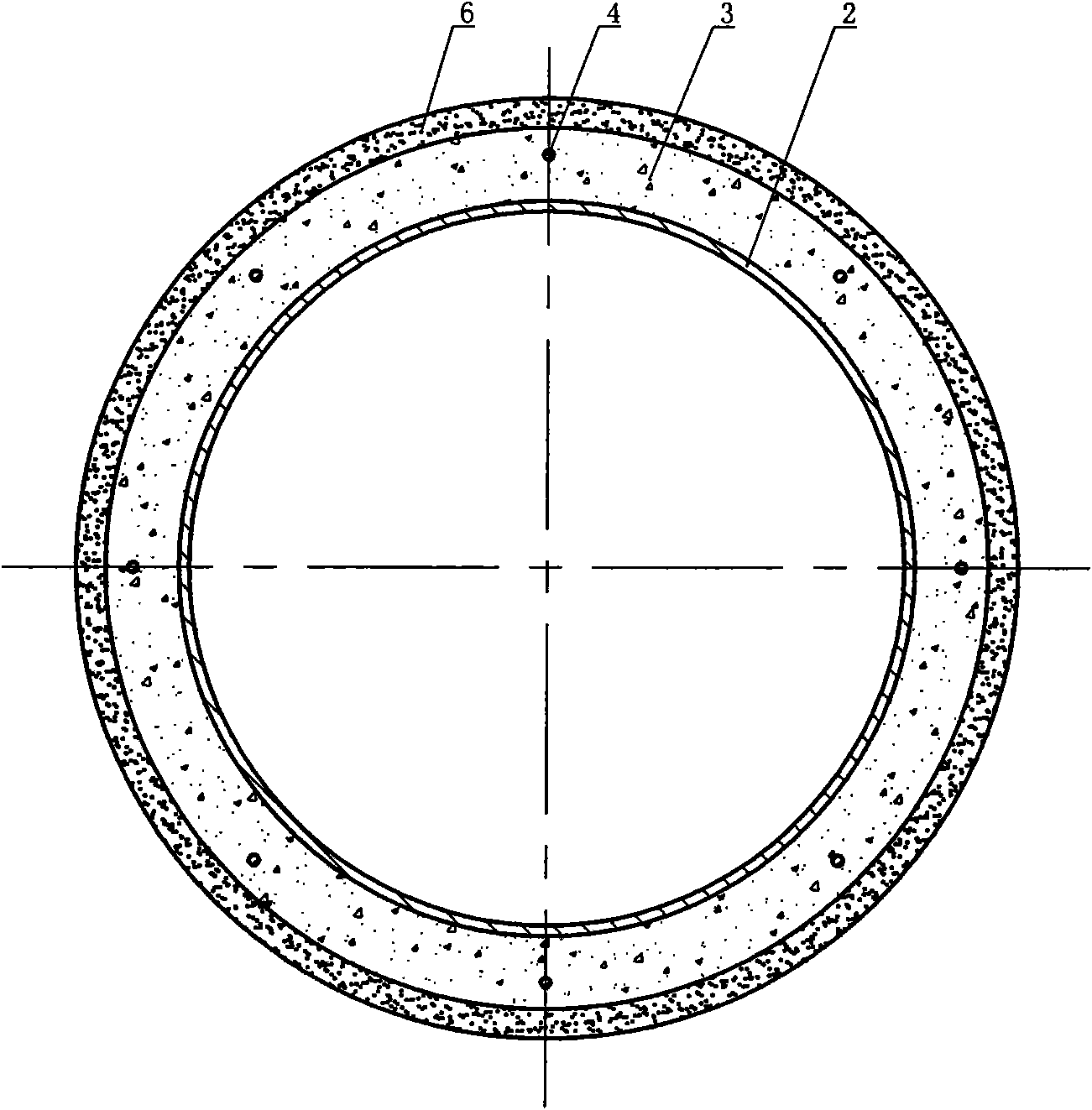

High-pressure resistant oil and gas pipeline

The invention relates to a high-pressure resistant oil and gas pipeline, which comprises a steel pipe. A steel ring is coaxially and fixedly arranged at two ends of the steel pipe respectively, a steel bar framework is coaxially and fixedly arranged between the two steel rings, concrete is coaxially and fixedly arranged on the outer wall of the steel pipe, a prestressed steel wire is wound on the outer wall of the concrete, and protective layers are fixedly arranged on the outer wall of the concrete and the outer wall of the prestressed steel wire. The high-pressure resistant oil and gas pipeline has simple integral structure and scientific and reasonable design, effectively reduces the consumption of steels, reduces the production cost, prolongs the service life, and has simple process and good corrosion resistance.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

Axisymmetric curved surface rotary variable displacement pump

ActiveCN102979725AReduce frictional resistanceReduce useless power consumptionRotary piston pumpsRotary piston liquid enginesReciprocating motionWear resistant

The invention provides an axisymmetric curved surface rotary variable displacement pump. The pump is characterized in that wear-resistant linings with good lubricating properties and low friction coefficients wrap stressed faces on negative pressure area sides of slide dampers and / or a plurality of axial through grooves are arranged on stressed face sides of the slide dampers and sliding chutes of a separation disc. The pump has the beneficial effects that under the condition that single sides of the slide dampers are stressed, the lubricating properties are improved, sliding friction is reduced, not only is the reciprocating motion resistance low, the load low and the invalid axle power consumption low, but also wear of the stressed faces of the slide dampers is reduced and the service lives are prolonged; besides, the conveying pressure of the pump can be also increased and some high pressure rotary variable displacement pumps can be developed; and as the sliding lubricating properties of the slide dampers are increased, basically frictional heating can not be generated and the plastics with good wear resistance can be adopted as damper components.

Owner:宜兴市宙斯泵业有限公司

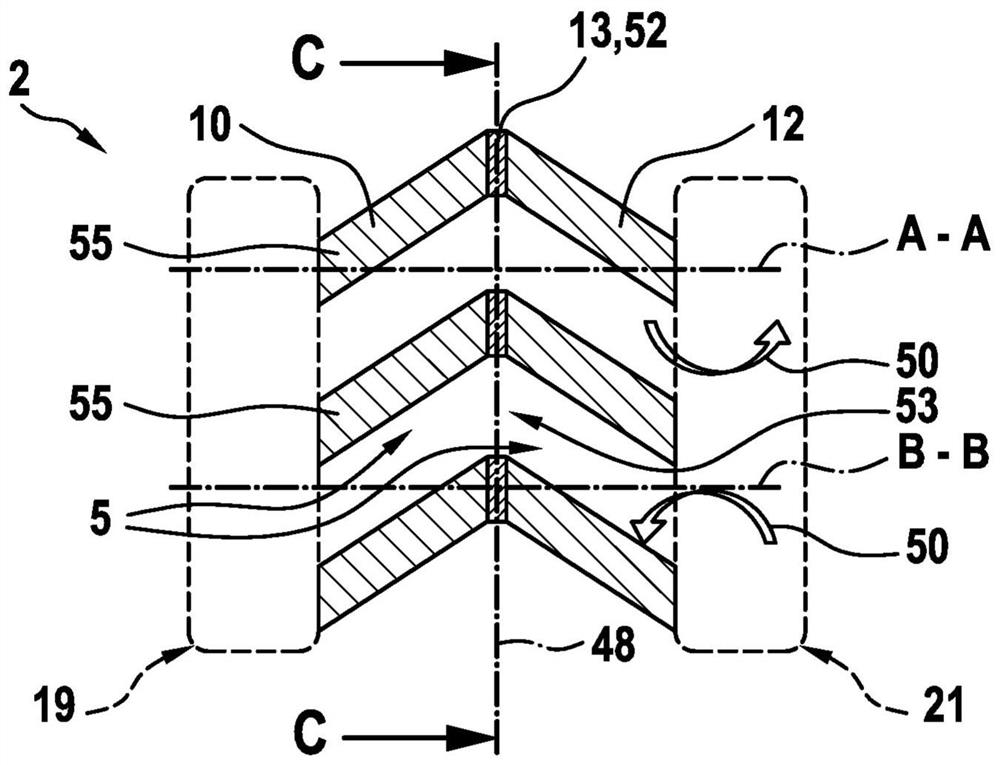

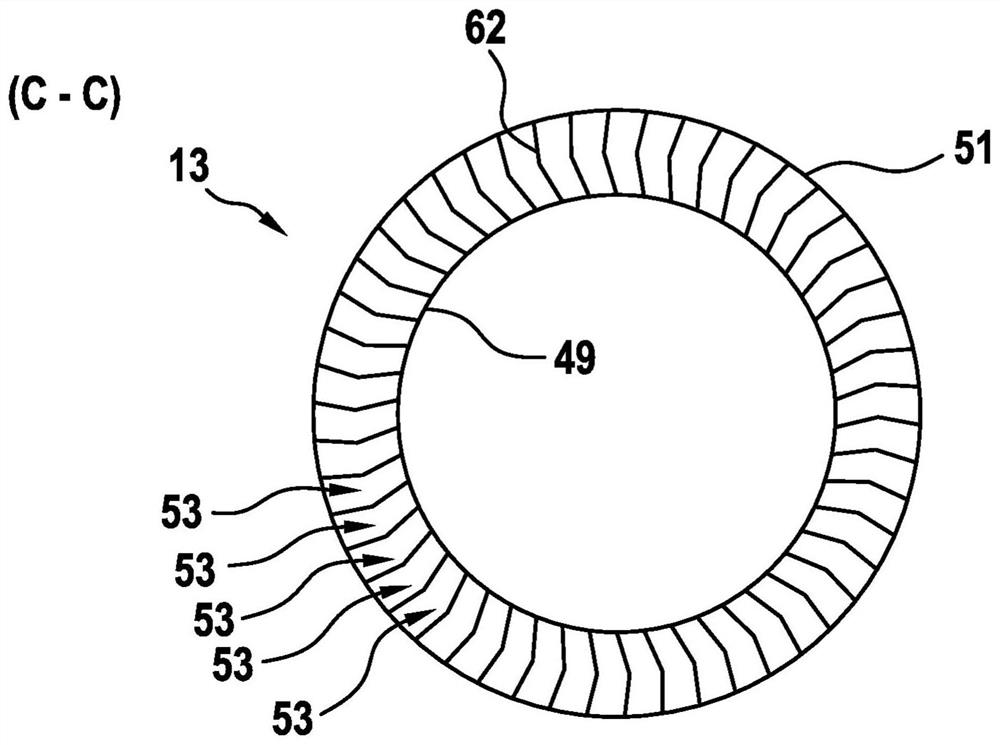

Side-channel compressor for a fuel cell system for conveying and/or compressing a gaseous medium

PendingCN113167284AReduce failure rateReliable encapsulationPump componentsWorking fluid for enginesRotational axisImpeller

Owner:ROBERT BOSCH GMBH

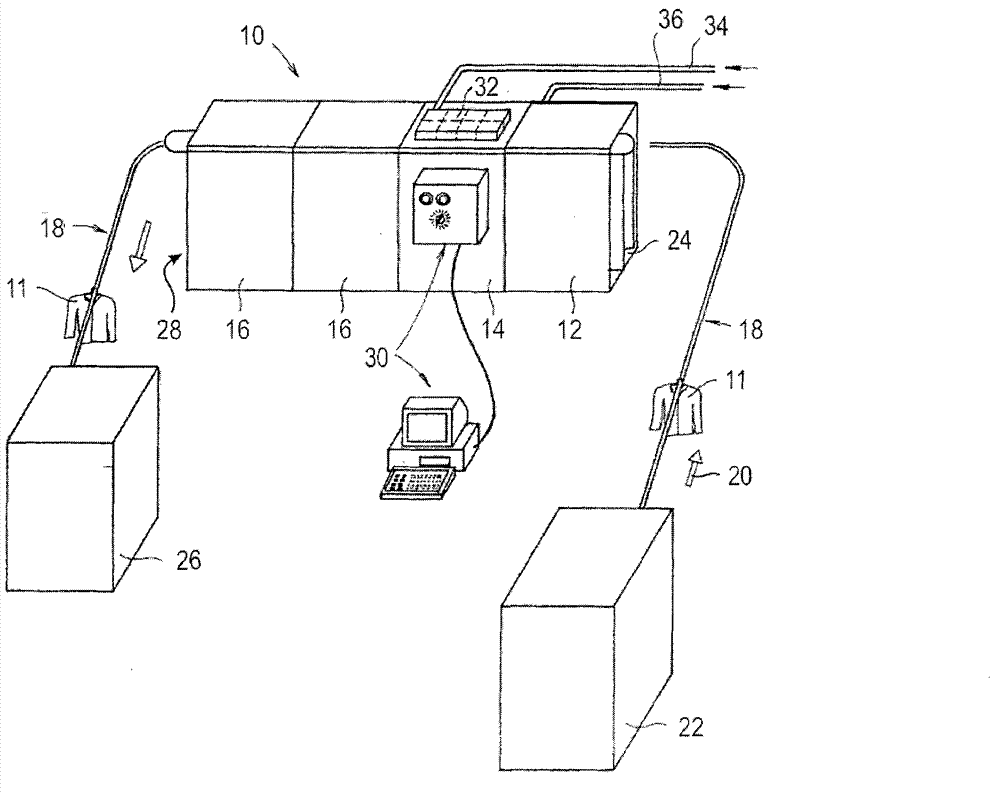

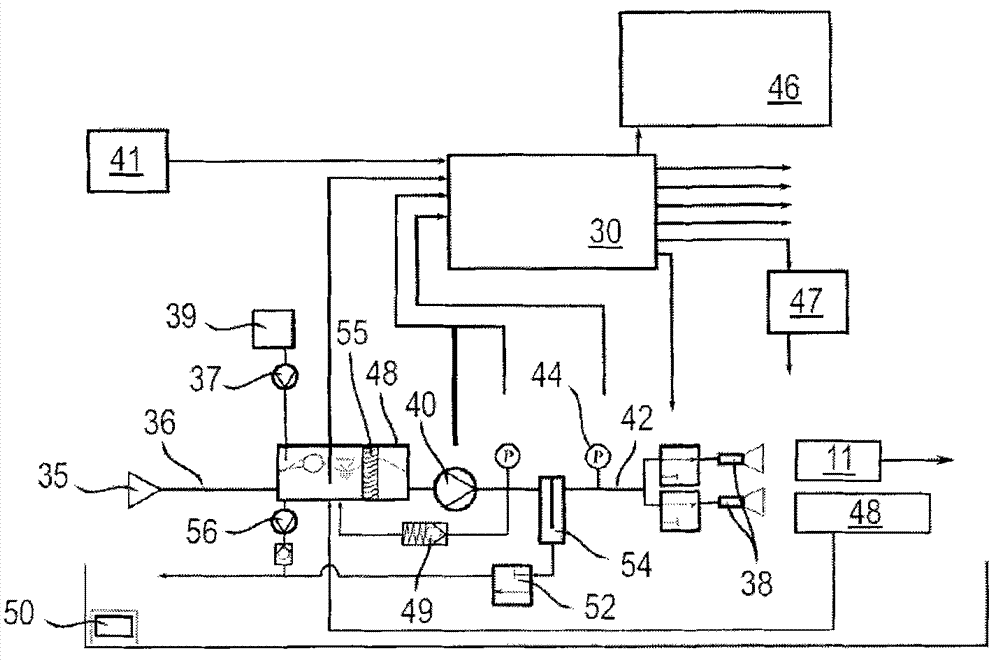

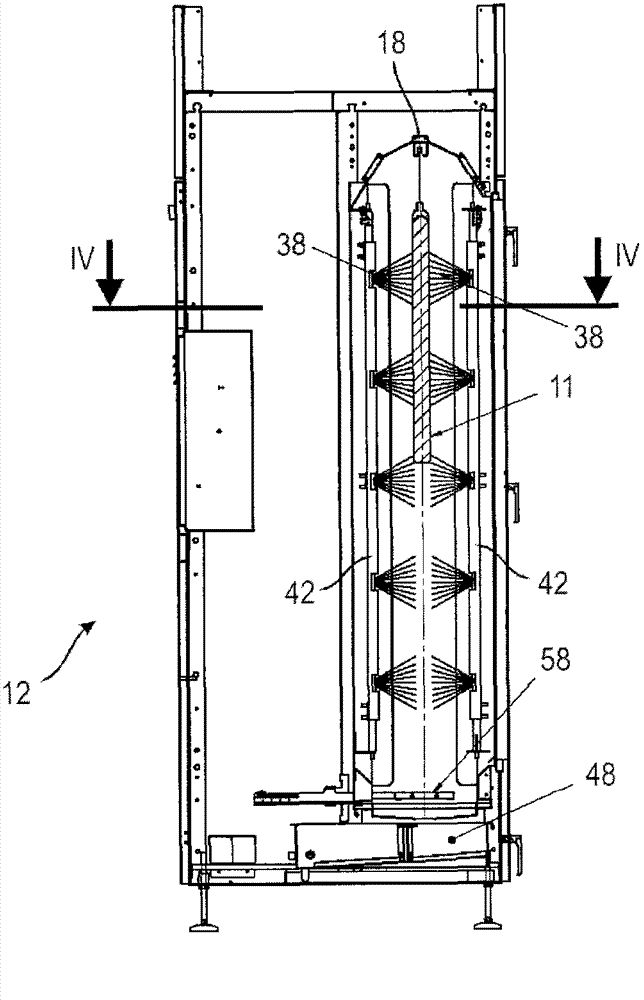

Tunnel type trimmer for processing textiles

InactiveCN102787482AImprove flatnessAdjustable delivery pressureIroning apparatusTextiles and paperLiquid mediumEngineering

The invention relates to a tunnel type trimmer for processing textiles (11), comprising a steam module (14) applying steam on the textiles (11), a pre-wetting module (12) which is connected before the steam module (14) and applies liquid medium to the textiles (11), and a conveying system (18) which enables the textiles (11) to move and pass through modules (12, 14, 16) of a tunnel type trimmer (10). The pre-wetting module (12) has a spraying nozzle (38) which aligns with the textiles (11) passing through the pre-wetting module (12). The pre-wetting module (12) has an independent high pressure pump (40) having an adjustable conveying pressure. The spraying nozzle (38) is connected to the high pressure pump (40) through a conveying pipeline (42).

Owner:VEITH GMBH & CO KG

Cyclone isolating structure of mud-water separation system

InactiveCN106242200AEasy separationImprove separation efficiencySludge treatment by de-watering/drying/thickeningVortex flow apparatusCycloneThree level

The invention relates to a cyclone isolating structure of a mud-water separation system, wherein the cyclone isolating structure includes a swirler, the upper end and the lower end of the swirler are provided with a muddy water discharge pipe and a magnetic powder discharge pipe respectively, and one side of the swirler is provided with a feed pipe; the feed pipe is connected with a feed port at the upper part of the swirler, the lower end of the feed pipe is provided with a feed delivery pump, the feed pipe includes a feed main pipe and feed branched pipes vertically arranged side by side and connected with the feed main pipe in the radial direction, and the feed branched pipes are connected with the swirler; the lower end of the feed main pipe is connected with the feed delivery pump, and the upper end of the feed main pipe is provided with an auxiliary delivery pump; the auxiliary delivery pump is located at a connection part of the feed branched pipes and the feed main pipe. The feed branched pipes vertically arranged side by side form a three-level structure, a material (sludge) is delivered to the swirler in a dispersion manner, separation operation of the swirler is facilitated, and the separation efficiency and effect are improved; with arrangement of the auxiliary delivery pump, the delivery pressure is facilitated to be increased, and the separation efficiency is further improved.

Owner:WUXI LIANGHUI ENVIRONMENTAL PROTECTION MACHINERY CO LTD

Nasal interfaces for respiratory therapy

ActiveUS10576233B2Improve comfortImprove stabilityRespiratory masksBreathing masksNasal prongsNasal congestion

Patient interfaces for respiratory therapy in the form of nasal interfaces or nasal masks include features that enhance or provide lateral stability of the interface. At least some of the embodiments provide multiple facial contact points or areas located in the general areas of the user's cheeks and / or upper lip. Some embodiments of the nasal interfaces provide advantageous sealing characteristics. The nasal interfaces may provide a controlled expiratory flow to reduce noise. Some embodiments include nasal pillows instead of or in addition to nasal prongs. The nasal pillows can have exhaust vents or can change in length in response to a pressure level within the nasal pillow.

Owner:FISHER & PAYKEL HEALTHCARE LTD

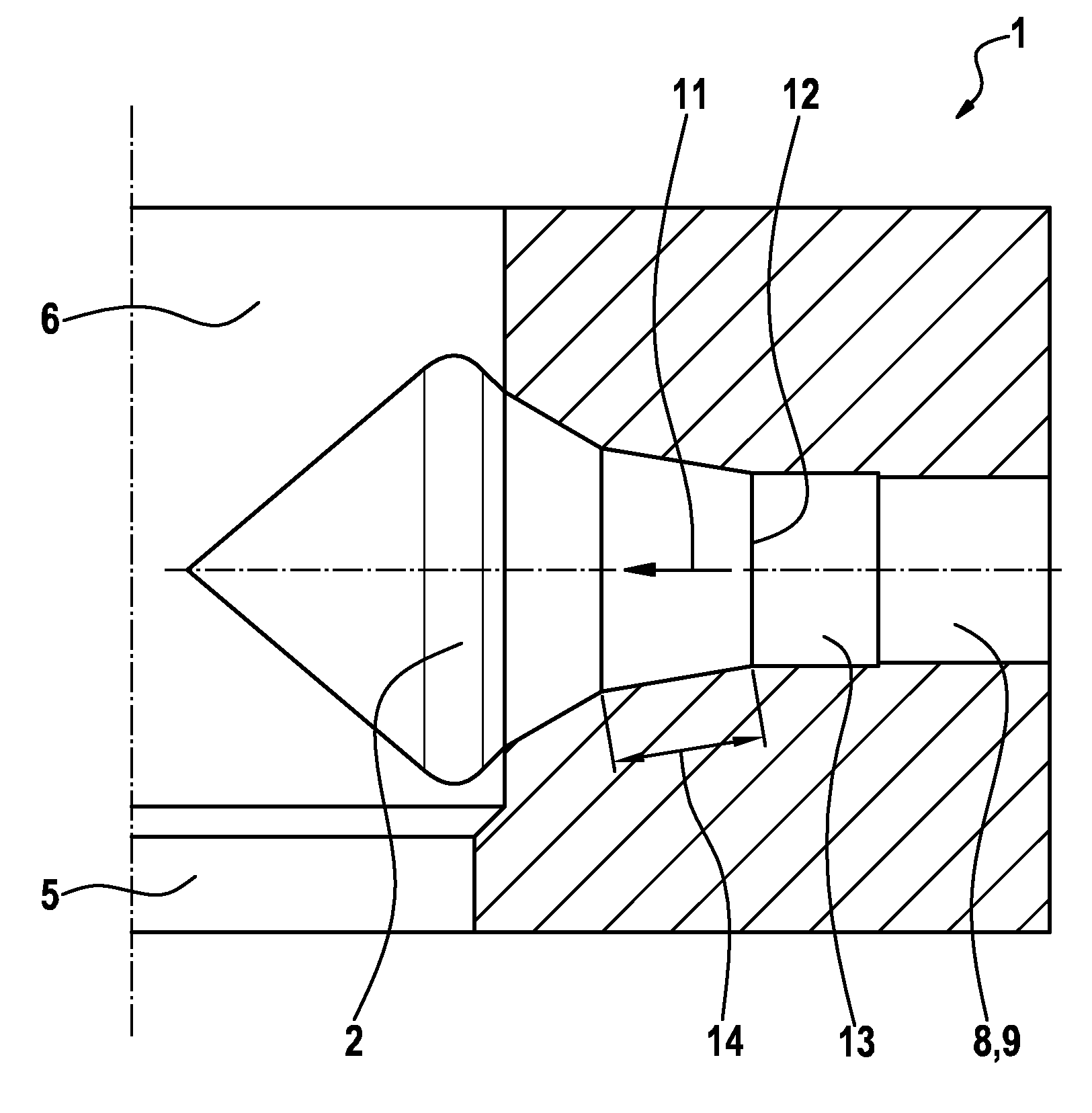

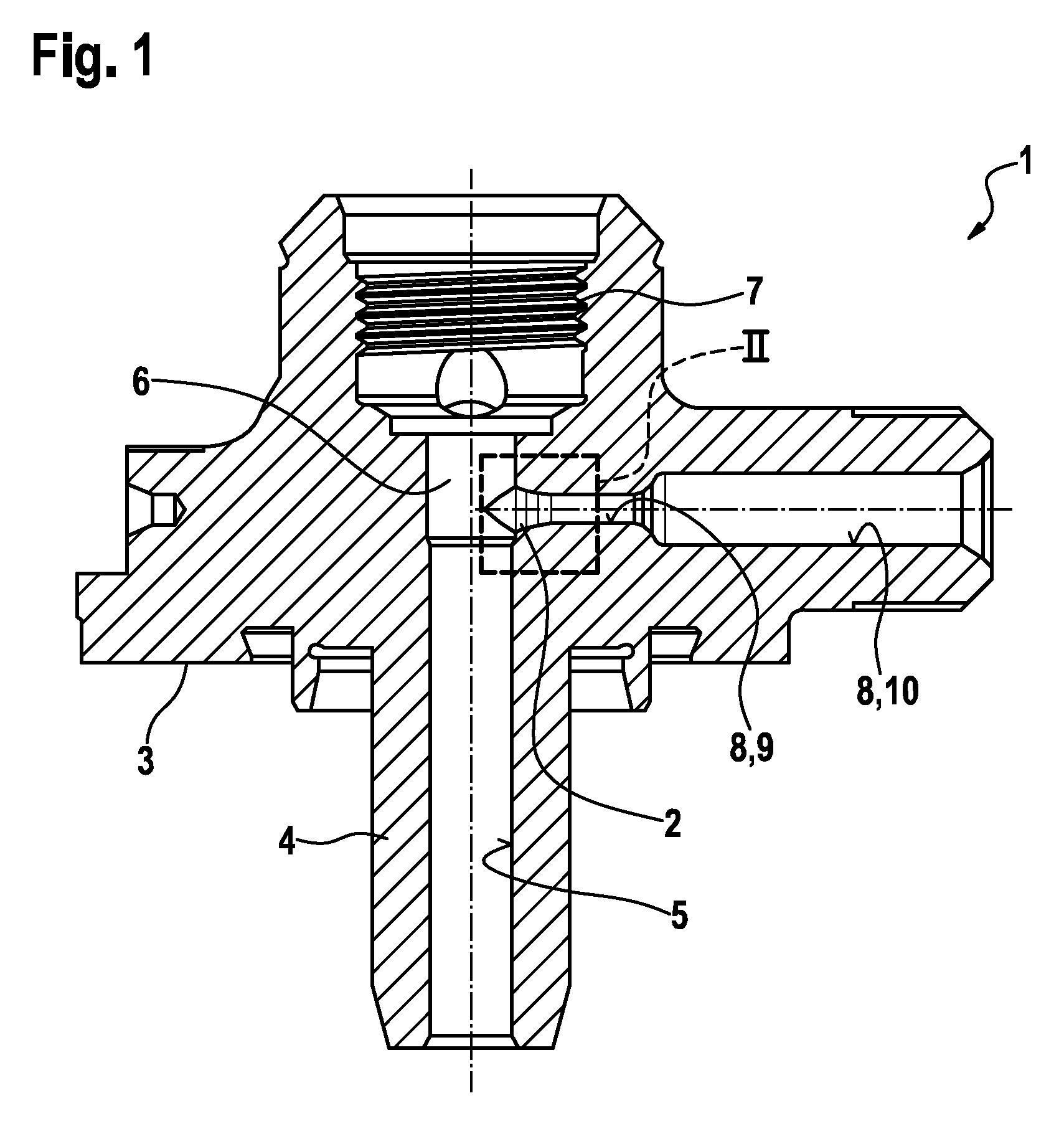

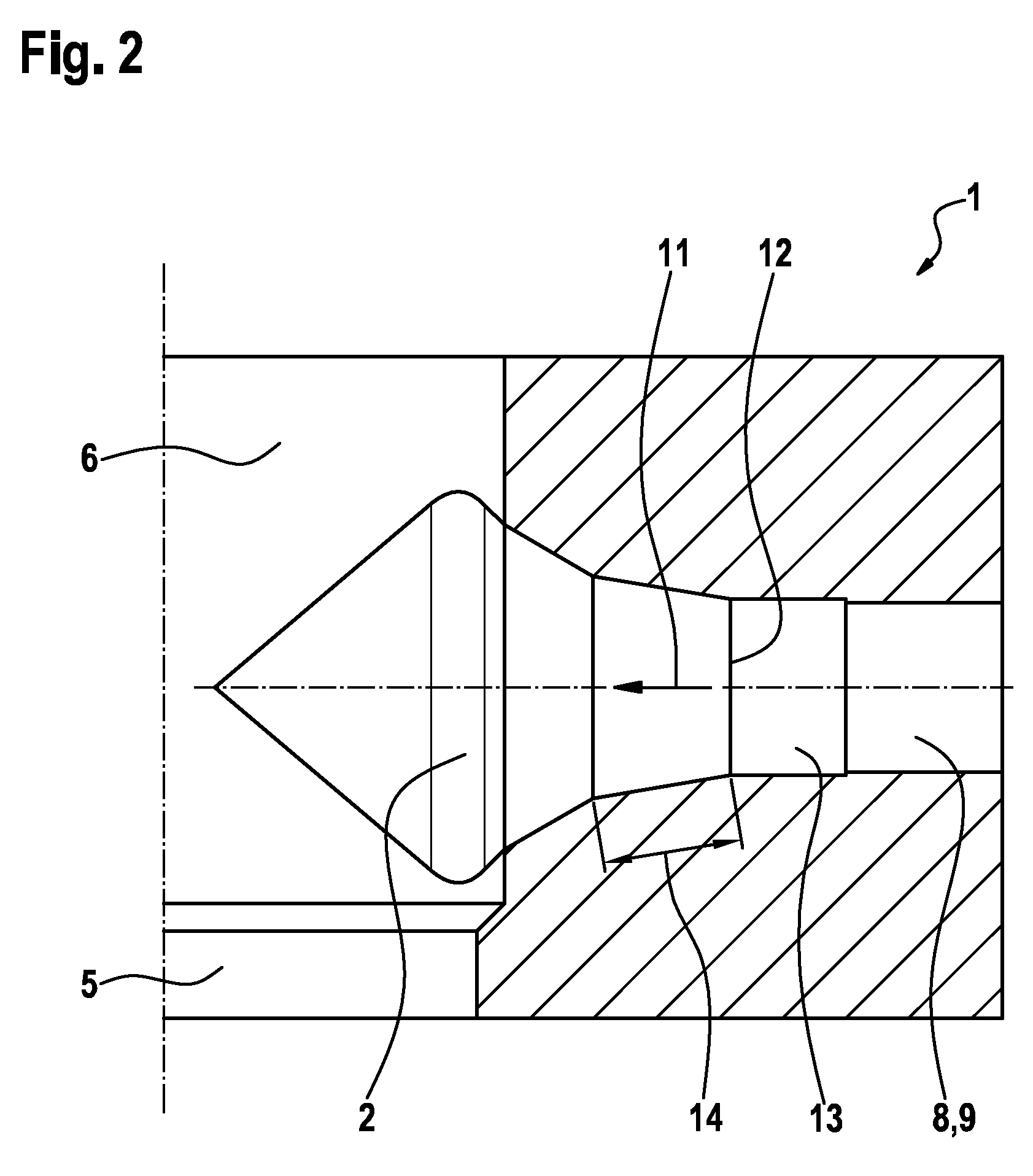

Metallic component for high-pressure applications

ActiveUS9193000B2Improve consistencyIncrease rangeElectrolysis componentsWear reducing fuel injectionCombustionHigh pressure

A metallic component (1) for high-pressure applications, which serves in particular for fuel injection systems of air-compressing, self-igniting internal combustion engines, comprises at least one transition region (2). The transition region (2) is re-worked here after a hardening operation. The re-working is performed by electrochemical removal and mechanical removal, in particular honing.

Owner:ROBERT BOSCH GMBH

Preparation method of oxidized graphene modified polyamide-6

The invention discloses a preparation method of oxidized graphene modified polyamide-6. The preparation method comprises following steps: 1, raw material preparation; 2, pre-polymerization; 3, post-polymerization; 4, slicing; 5, extracting; and 6, drying cooling packaging. According to the preparation method, a composite component containing silicon, calcium ions, and sodium ions is introduced, sothat product flow performance is improved.

Owner:JIANGSU RUIMEIFU IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com