Multifunctional remote control automatic plastering machine

A plastering machine, multi-functional technology, applied in the direction of construction, building construction, etc., can solve the problems of poor plastering quality, insufficient pressure, insufficient grinding precision, etc., to ensure plastering quality, high conveying pressure, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

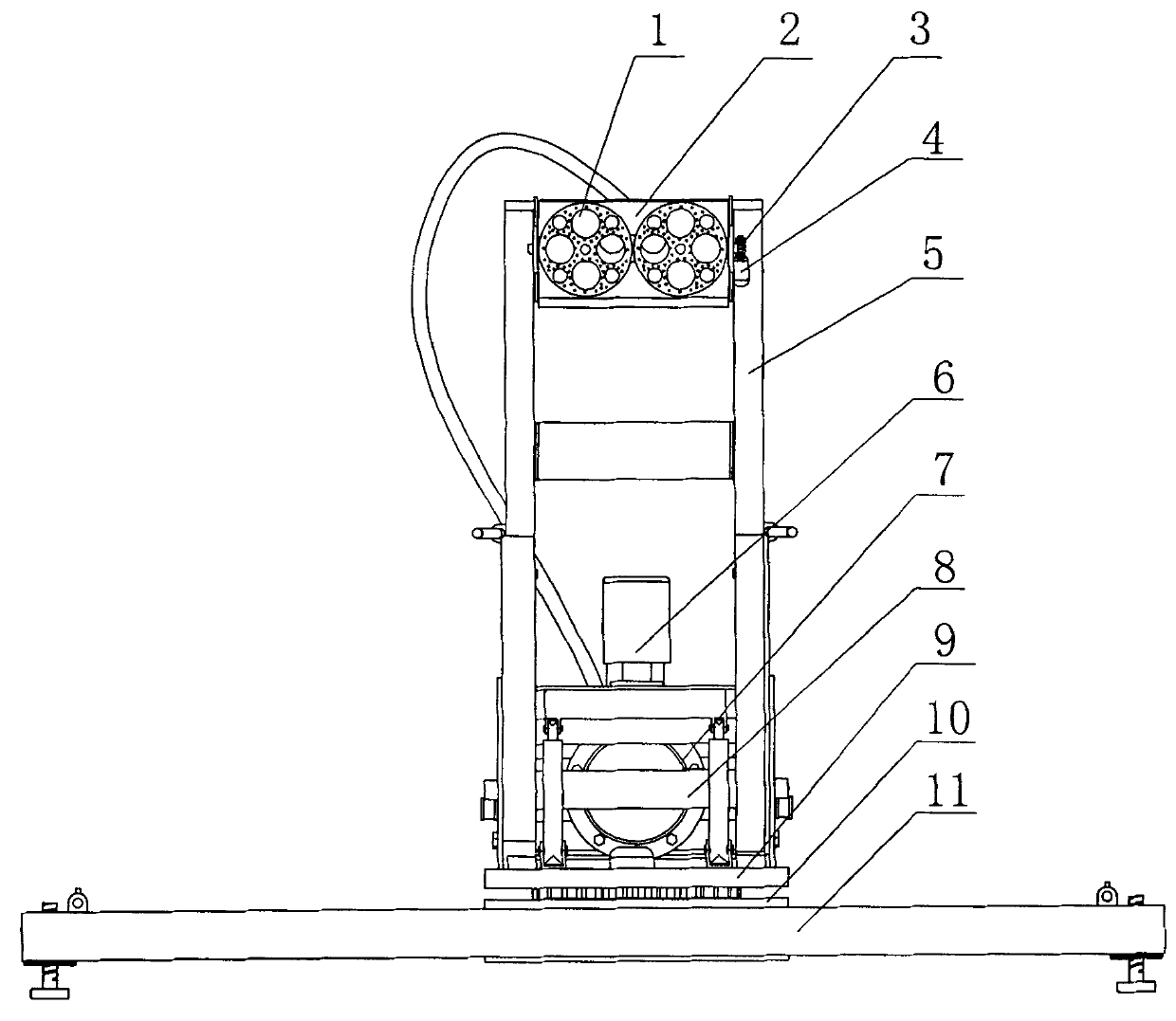

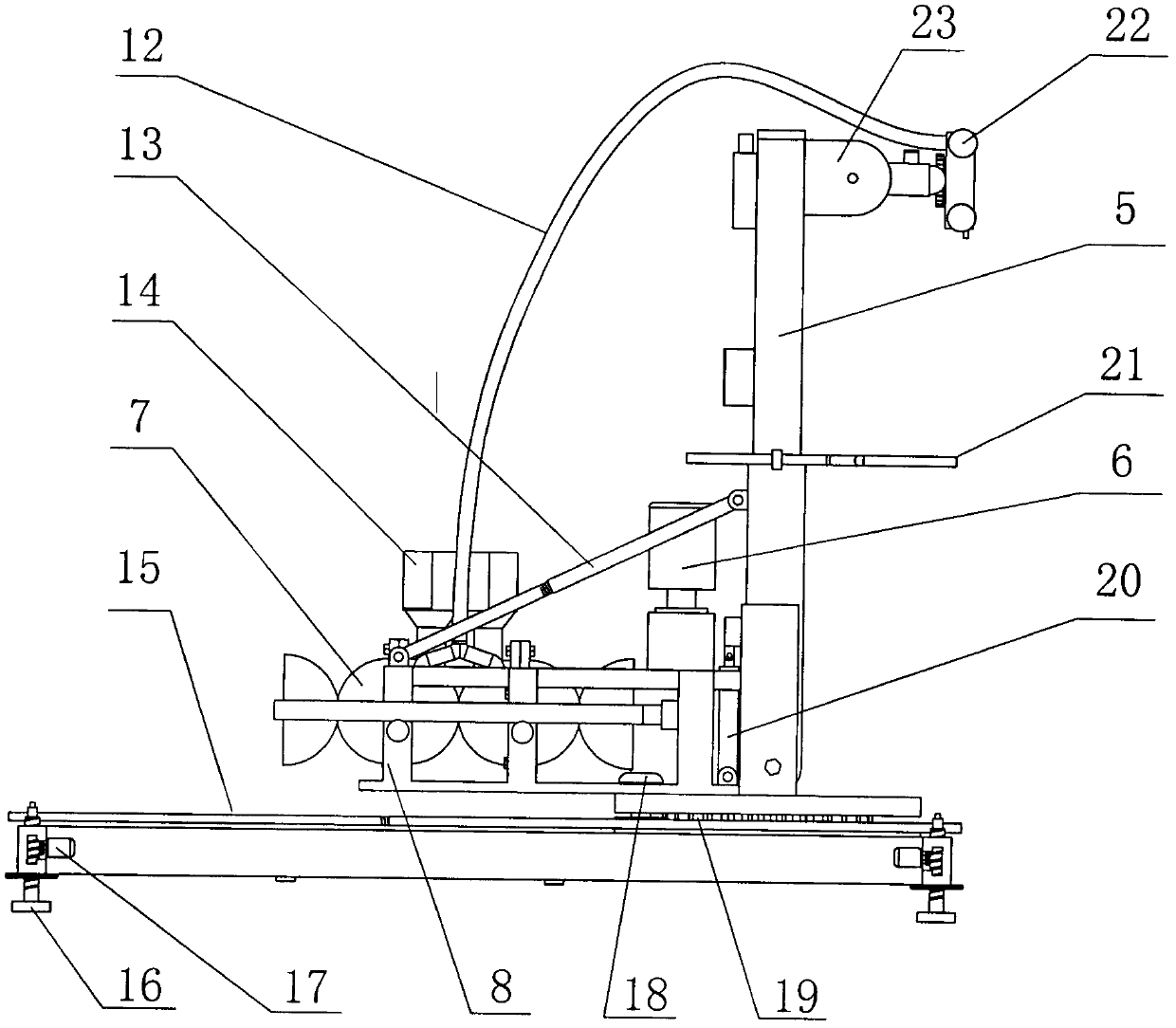

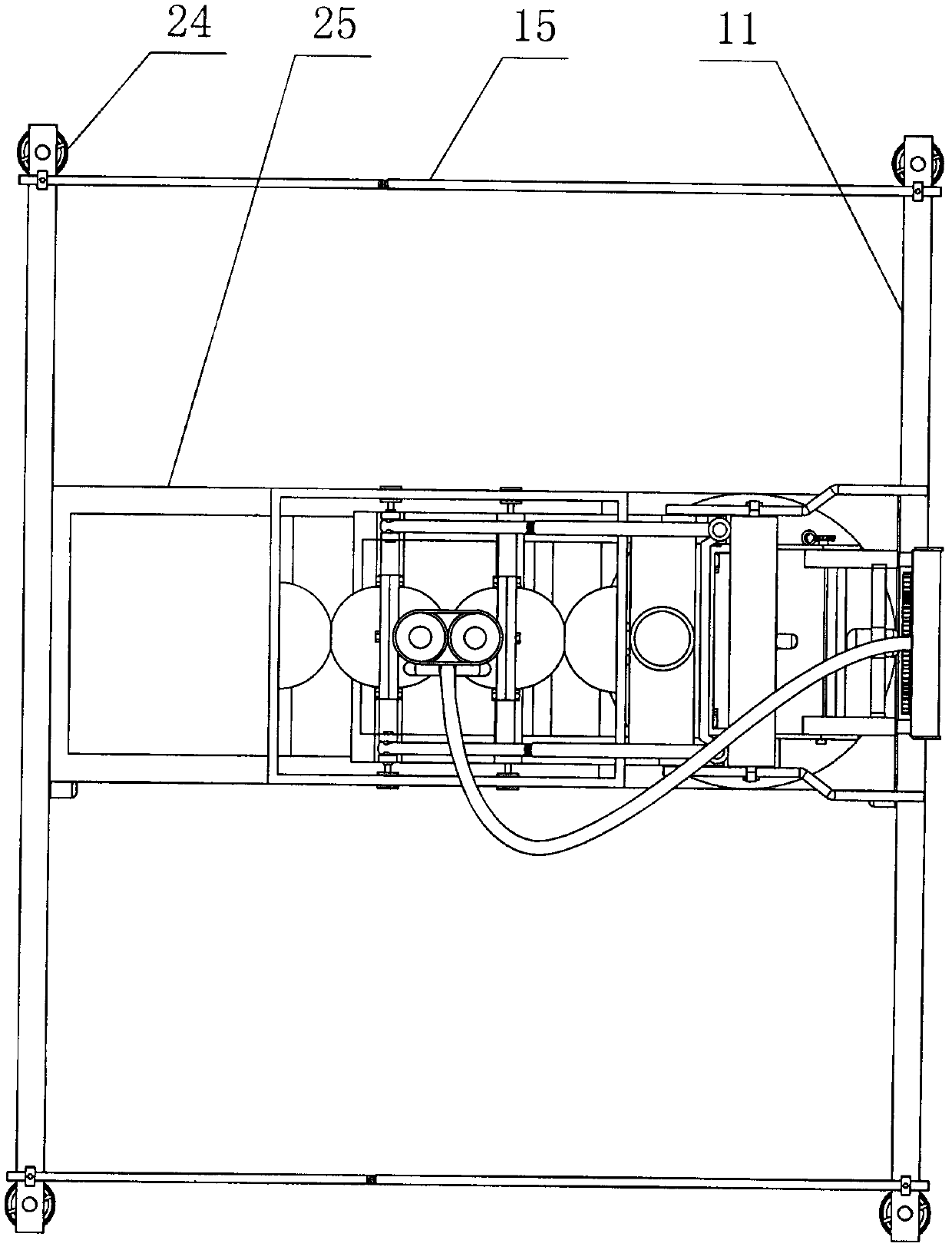

[0043] refer to Figure 1 to Figure 3 As shown, a multifunctional remote-controlled automatic plastering machine includes a hydraulic conveyor, a plastering device, a telescopic lifting track, a rotating chassis, a frame, a walking track, and a remote controller, wherein the rotating chassis 9 is installed The frame 8 and the telescopic lifting track 5, the large gear 19 and the sliding base plate 10 are installed under the rotating chassis 9, the sliding base plate 10 is placed in the horizontal rail 25, the horizontal rail 25 is placed in the longitudinal track 11, and the hydraulic transmission is installed on the frame 8. Machine 7, steering motor 4, worm turbine 3 and telescopic arm 35 are installed on the fixed plate 23 of the plastering device, and the telescopic arm 35 is connected to the plastering head 2, and the plastering head 2 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com