Double-screw mixing transmission pump tooth type

A mixed pump, twin-screw technology, applied to pumps, pump components, rotary piston pumps, etc., can solve the problems of long contact line and increased leakage triangle area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings, so as to understand the implementation and features of the present invention more clearly.

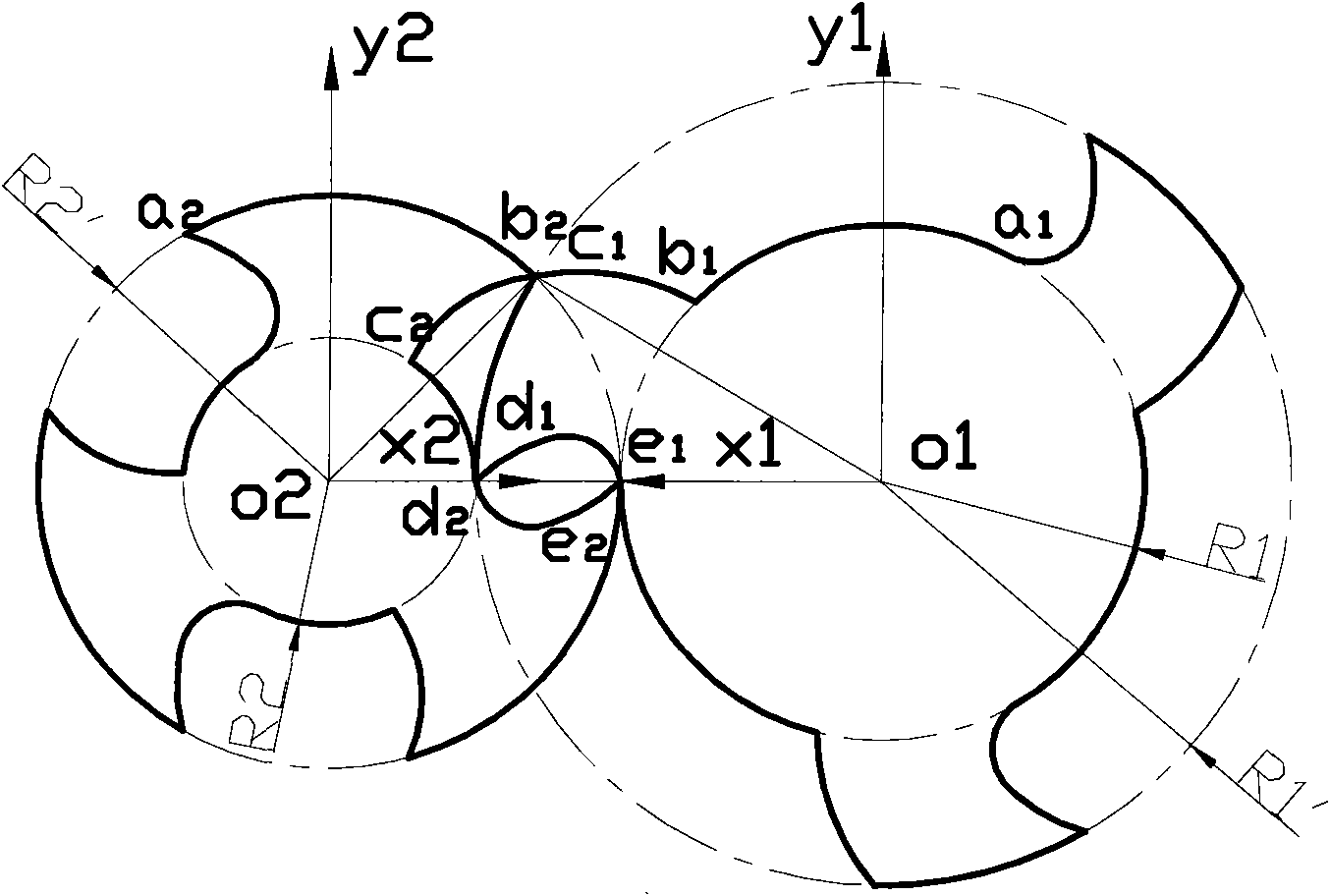

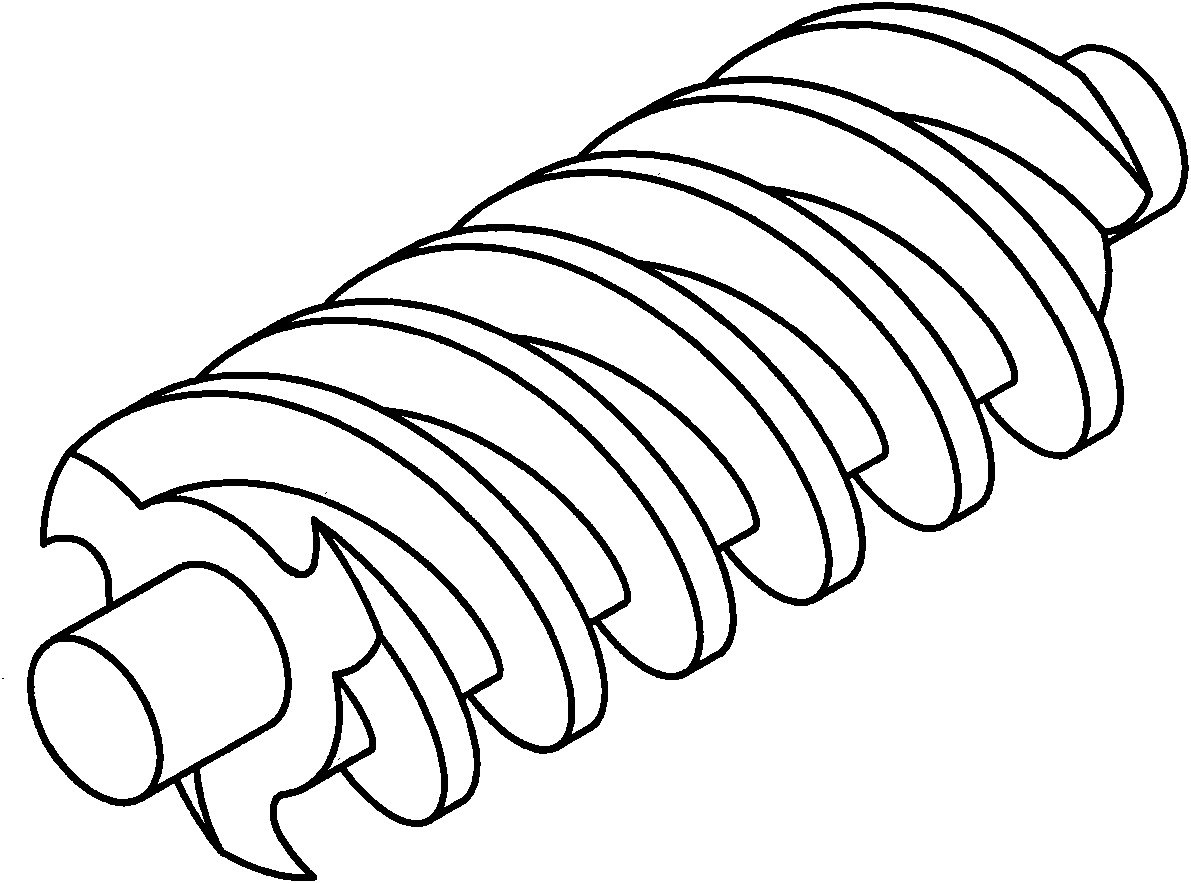

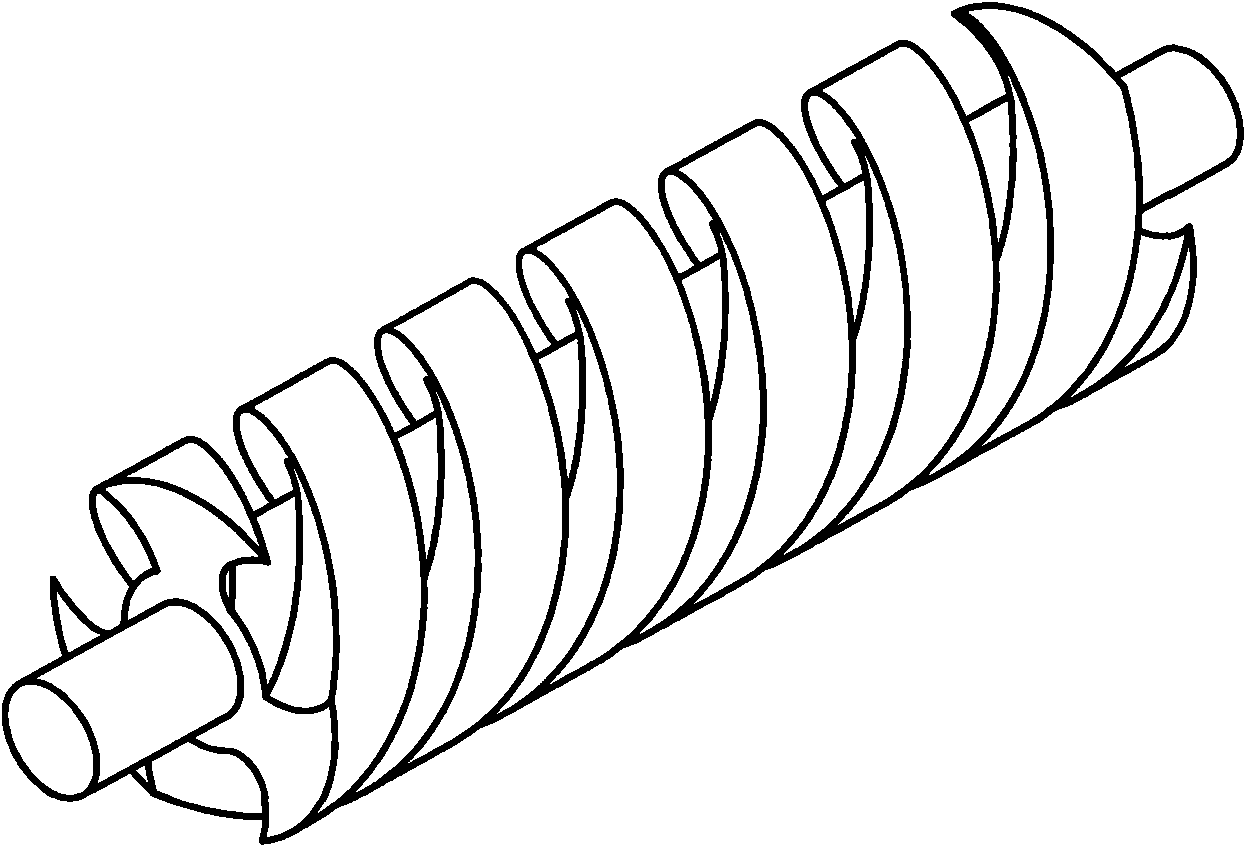

[0051] see figure 1 , the present invention is composed of two three-headed screws, one of which is a convex screw and the other is a concave screw, and the profile is composed of an arc-arc envelope and a point meshing cycloid. In the meshing section where the end surface meshing line is generated in the main meshing area, point meshing cycloids are used to reduce the leakage triangle area, including convex screw point meshing cycloids b 1 c 1 , Convex screw addendum arc c 1 d 1 , Convex screw long leg cycloid d 1 e 1 , concave screw point meshing cycloid b 2 c 2 and concave screw long leg cycloid d 2 e 2 ; In other areas, focusing on shortening the length of the contact line and facilitating manufacturing, the arc-arc envelope is adopted, including the convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com