Patents

Literature

104 results about "Epicycloid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, an epicycloid or hypercycloid is a plane curve produced by tracing the path of a chosen point on the circumference of a circle—called an epicycle—which rolls without slipping around a fixed circle. It is a particular kind of roulette.

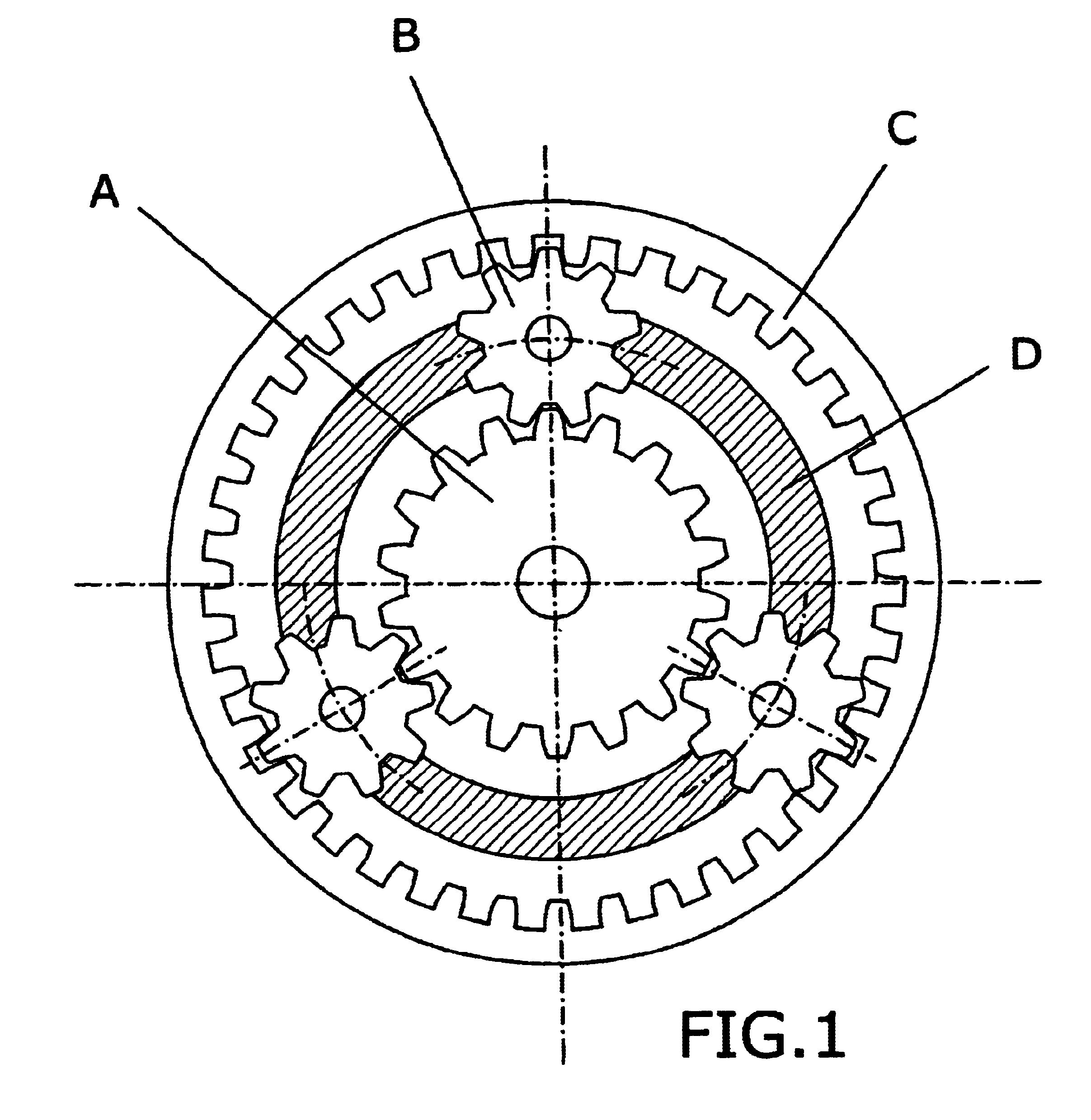

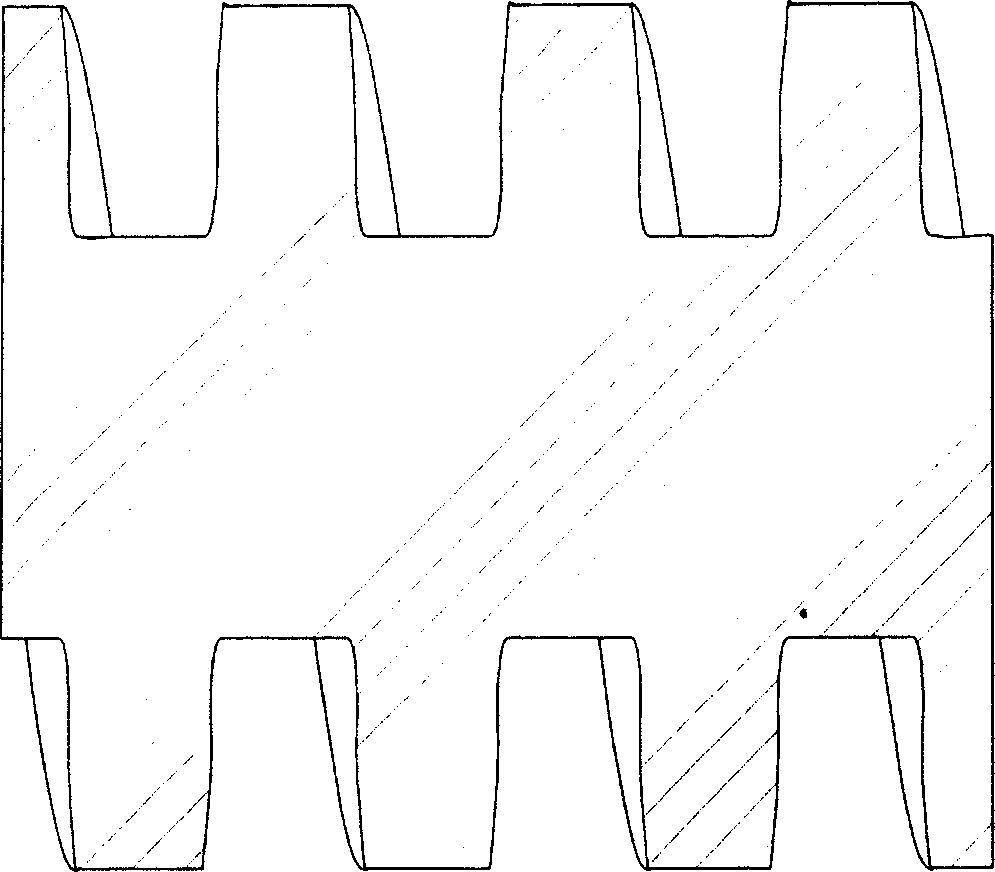

Internal gear pump

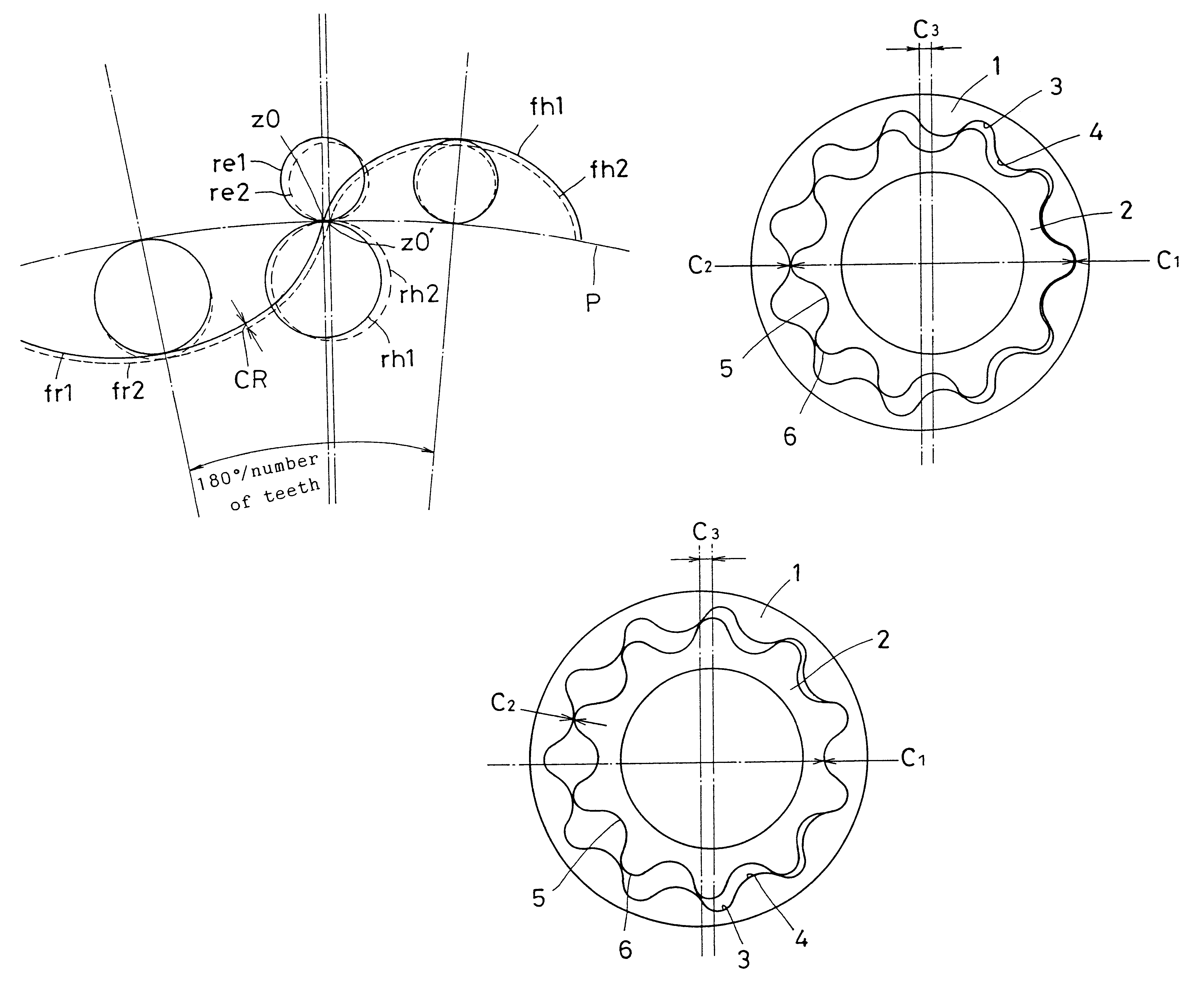

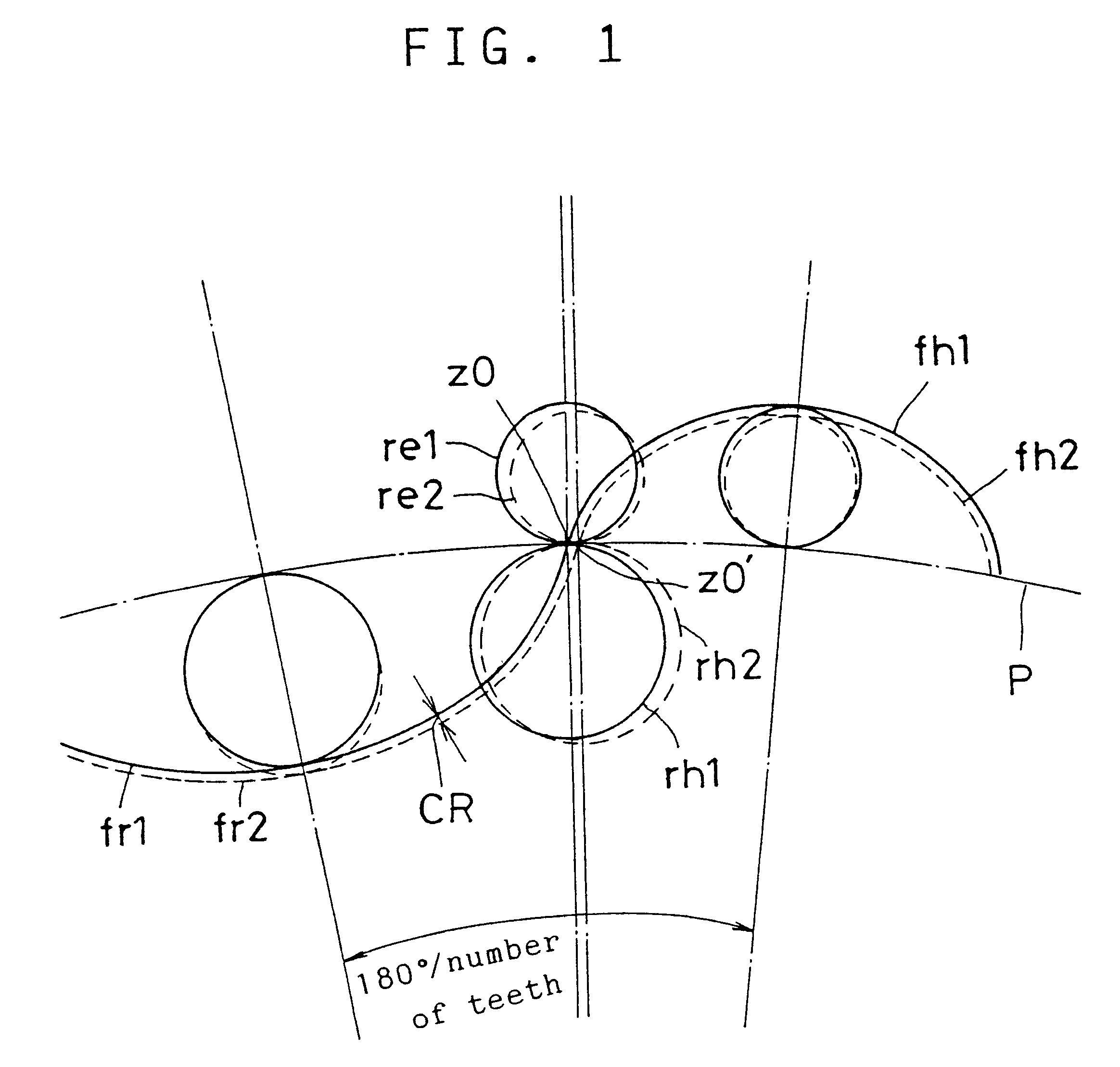

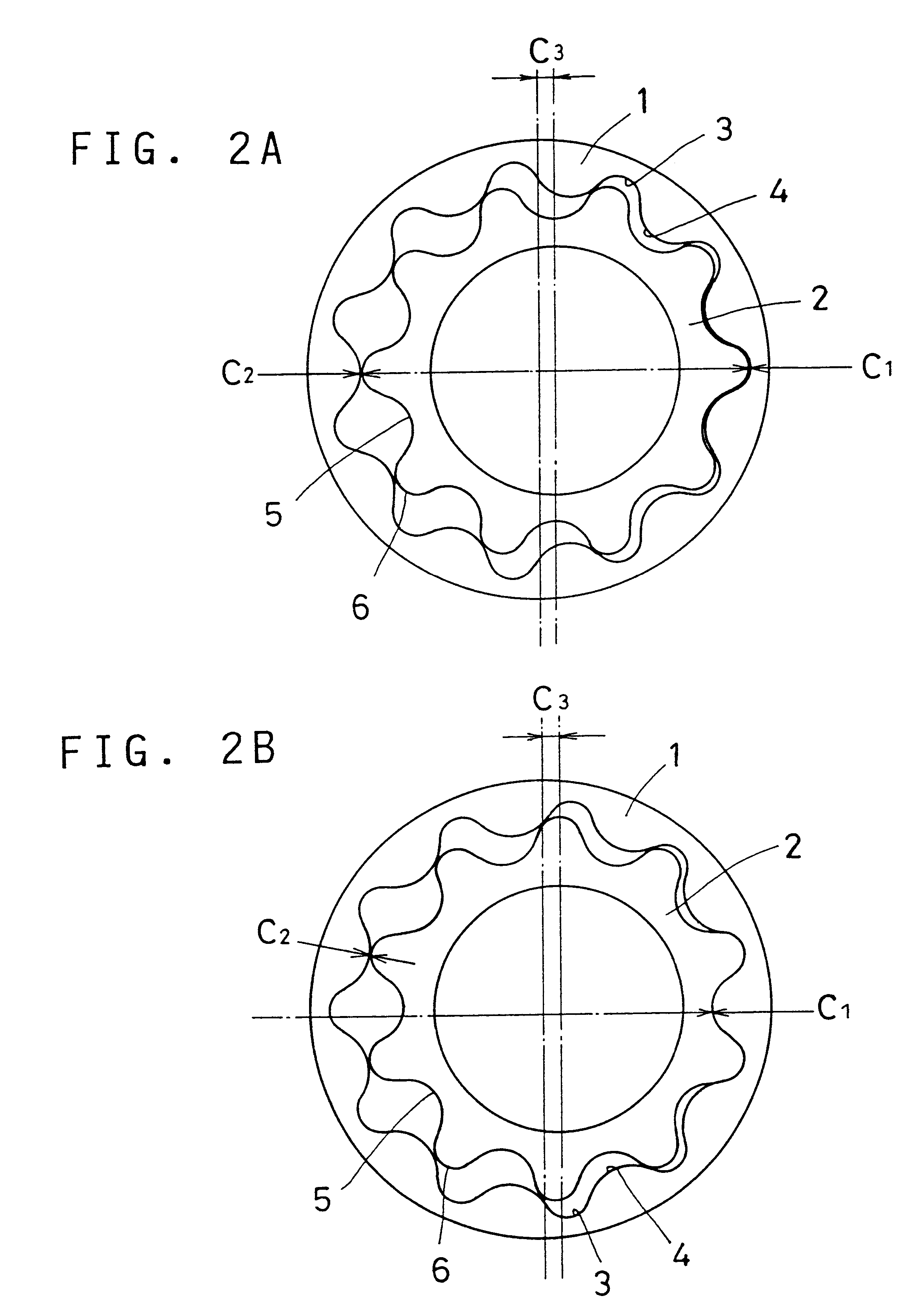

InactiveUS6244843B1Oscillating piston enginesEngine of intermeshing engagement typeGear pumpEngineering

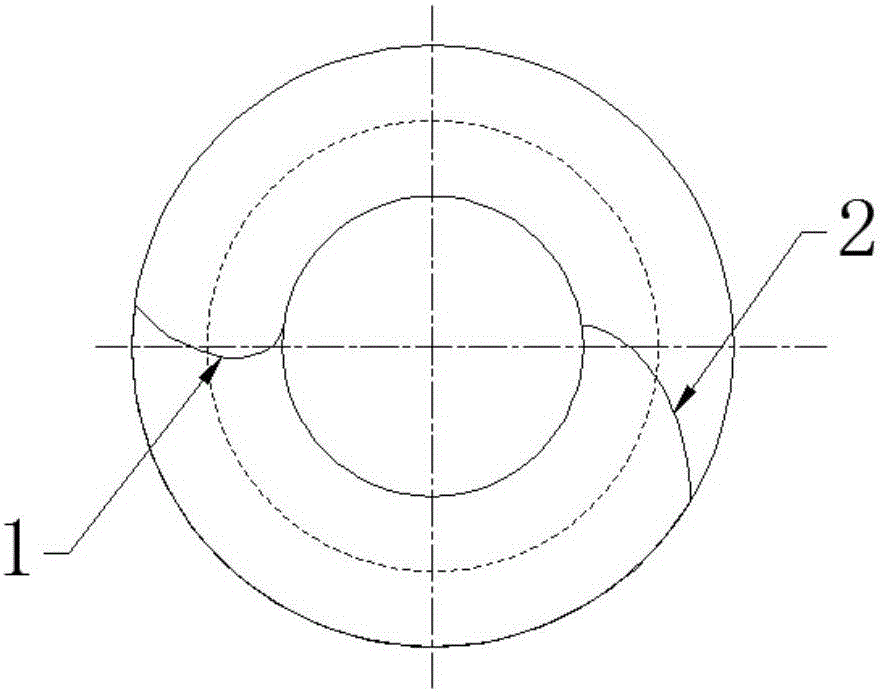

An internal gear pump which improves the mechanical efficiency and the life and reduces noises by eliminating non-uniformity of the gaps between teeth. In the internal gear pump wherein the tooth spaces of the outer gear and the tooth tips of the inner gear form an epicycloid and the tooth tips of the outer gear and the tooth spaces of the inner gear form a hypocycloid, these cycloids are formed by four circles that roll on the pitch circle of each gear such that the gap between teeth in a region where the outer and inner gears mesh most deeply with each other is substantially equal to the gap between teeth in a region where the depth of mesh between the outer and inner gears are the shallowest.

Owner:SUMITOMO ELECTRIC SINTERED ALLOY LTD

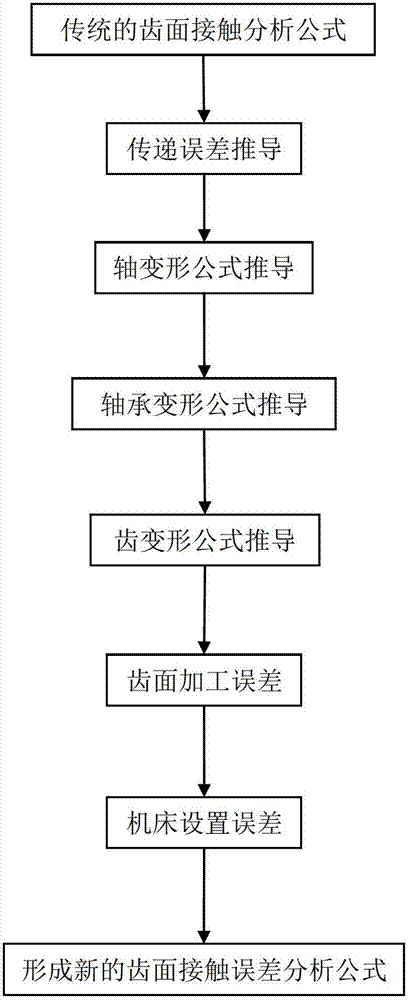

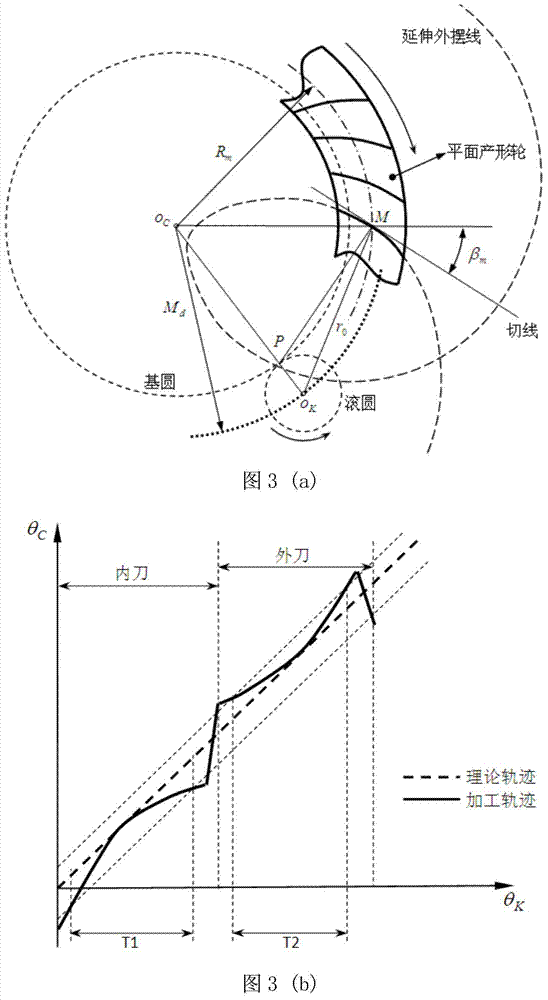

Loaded tooth surface contact analysis method direct at epicycloid bevel gear errors

InactiveCN103206515AImprove the delivery effectPortable liftingGearing elementsSupporting systemEngineering

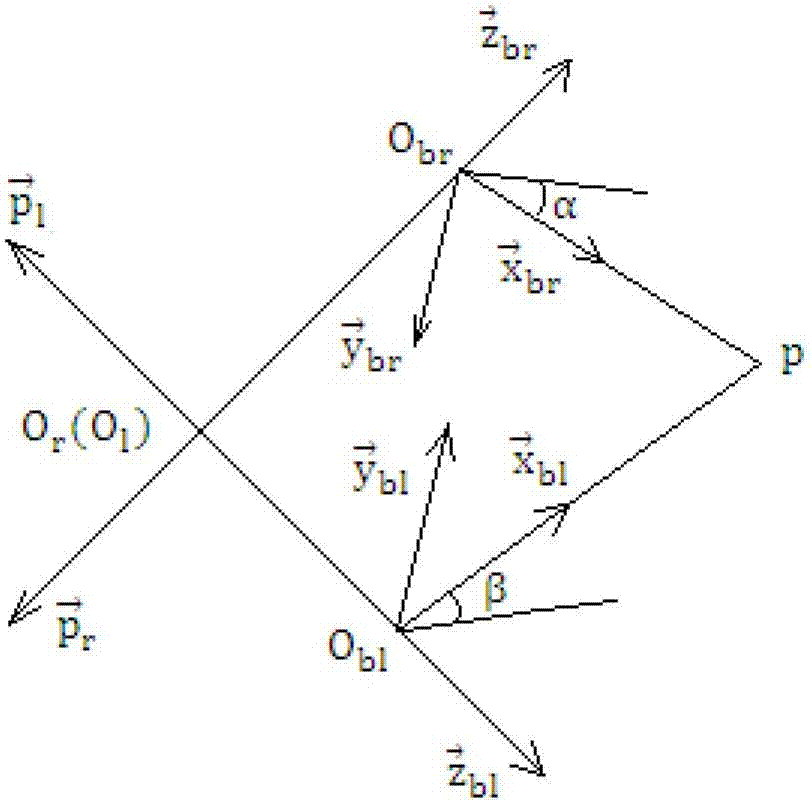

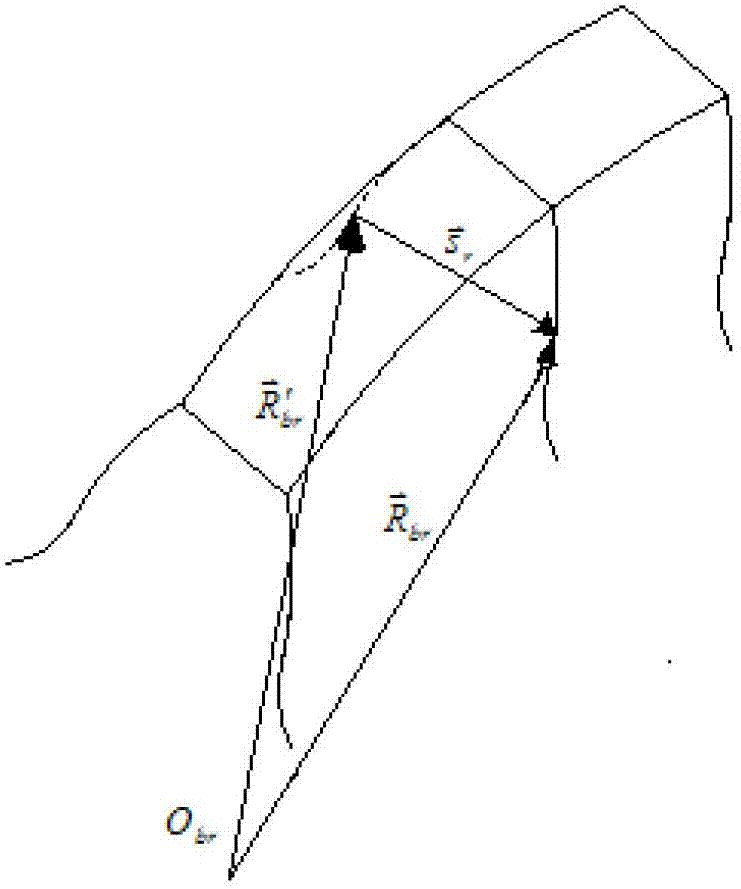

The invention relates to a loaded tooth surface contact analysis method direct at epicycloid bevel gear errors, and belongs to the field of theory of non linear vibration. Gear pair elastic deformation, support system torsion, gear processing errors and machine tool setting errors are taken into consideration to derive a novel error loaded contact analysis method. When analyzing one loaded tooth surfaced contact, real situation can be closer. The loaded tooth surface contact analysis method is usually used for setting parameters and machine tool parameters via V-H-J (V is the longitudinal set parameter of a gear pair, and the upward direction of a small gear is active; H is a coordinate set parameter of the gear pair, and the direction facing towards the big end of the small gear is active; J is the adjusting parameter along a coordinate direction, and the direction, distant from a big gear, of the small gear is active) within a real contact area under the conditions of loading and delivering errors and simulated load distribution and processing, so that impact of the errors is compensated to improve delivering performance and correct size and position of the contact area.

Owner:BEIJING UNIV OF TECH

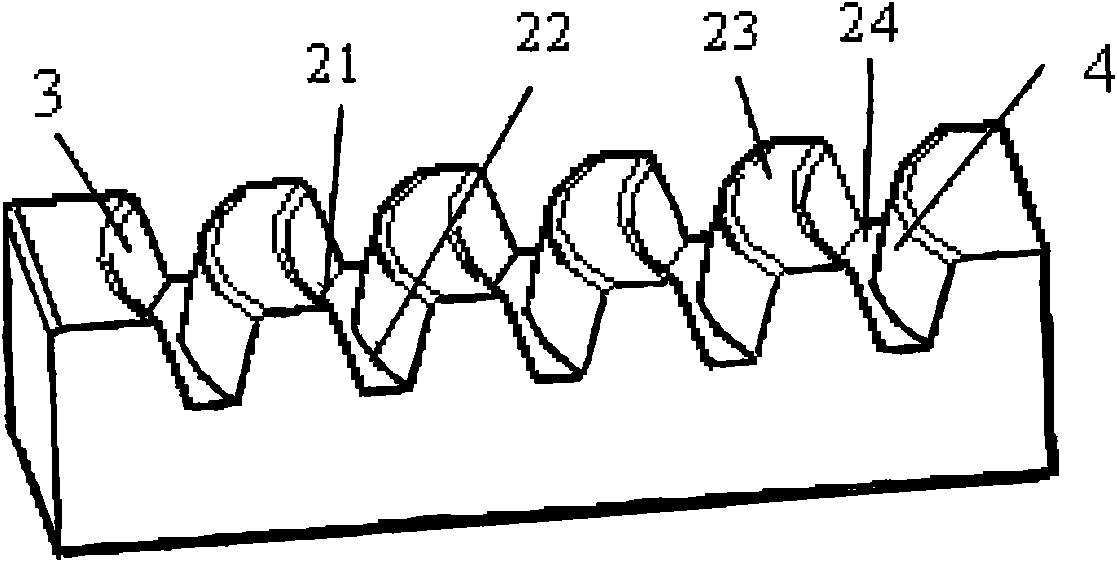

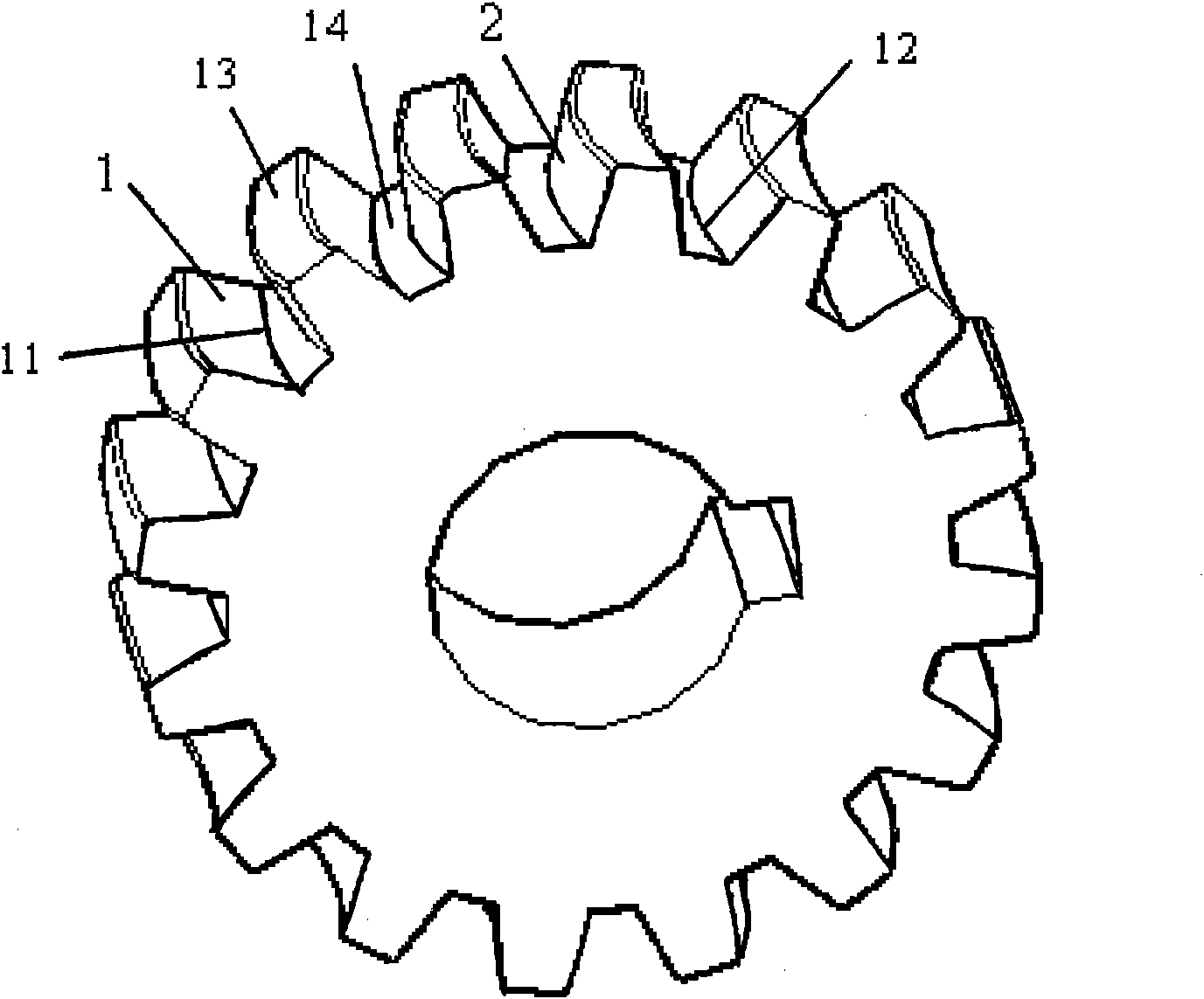

Machining method for epicycloid gear

ActiveCN103934513AHigh precisionSimple structureGear teeth manufacturing toolsGear teethGear wheelGear tooth

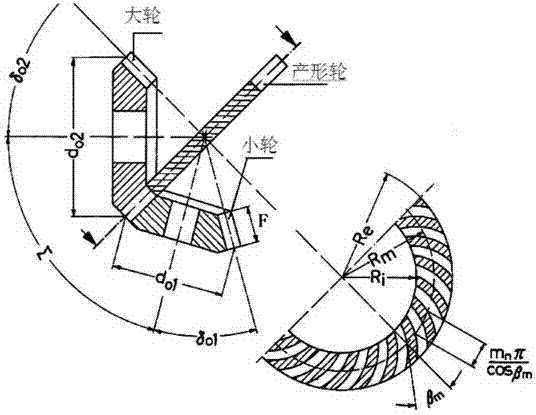

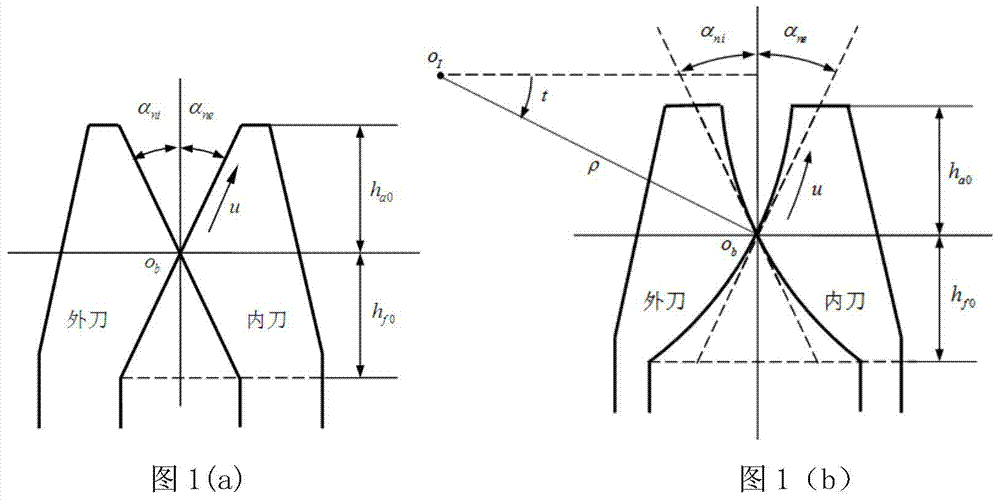

The invention discloses a machining method for an epicycloid gear. The machining method comprises the steps that (1) basic parameters of a generating gear are determined; (2) the motion mode forming the tooth surface of the generating gear is determined; (3) generating gear tooth surface shape correction is determined; (4) a tool path for forming the tooth surface of the generating gear is planned; (5) the motion through which the generating gear generates the gear is determined; (6) generation of the machined gear is completed. The machining method for the epicycloid gear has the advantages that compared with the Klingelnberg method, the structure of a cutterhead is greatly simplified, no crosshead shoe mechanisms are needed, and rigidity is improved; compared with the Oerlikon method, no knife tilt mechanisms are needed, the structure of a machine tool is greatly simplified, and rigidity is improved; an epicycloid gear and a hypoid gear can be machined on a knife-tilt-free rolled plate type bevel gear milling machine; tooth surface correction is achieved through software; second order precontrol over the positions, sizes and shapes of tooth surface contact spots can be achieved; required second order precontrol over transmission errors can be achieved; an epicycloid gear pair which is completely conjugated in theory can be machined.

Owner:TIANJIN TEEK TRANSMISSION

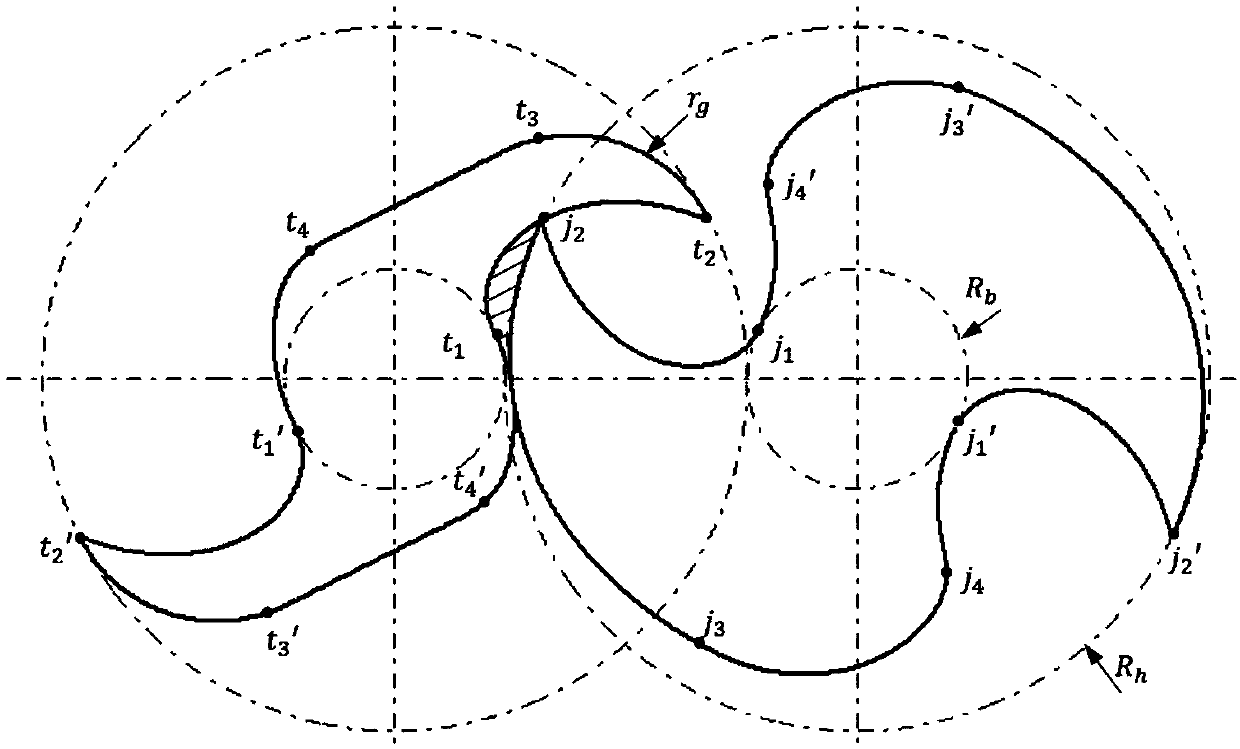

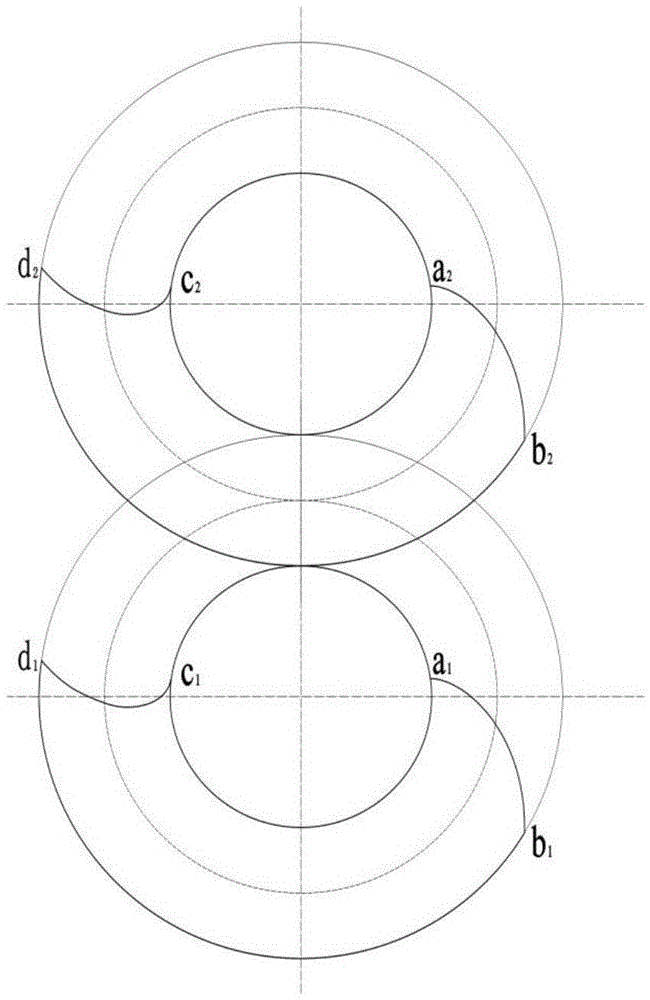

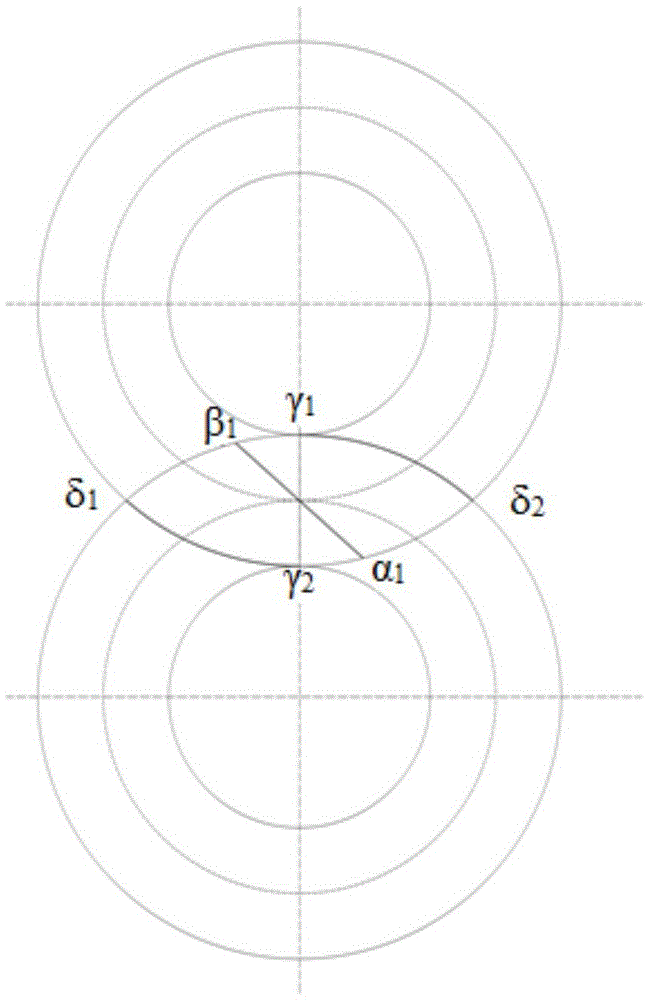

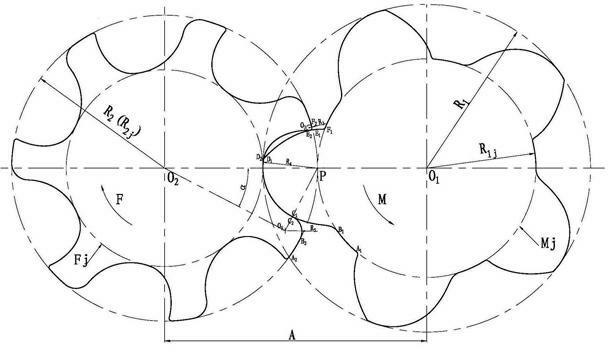

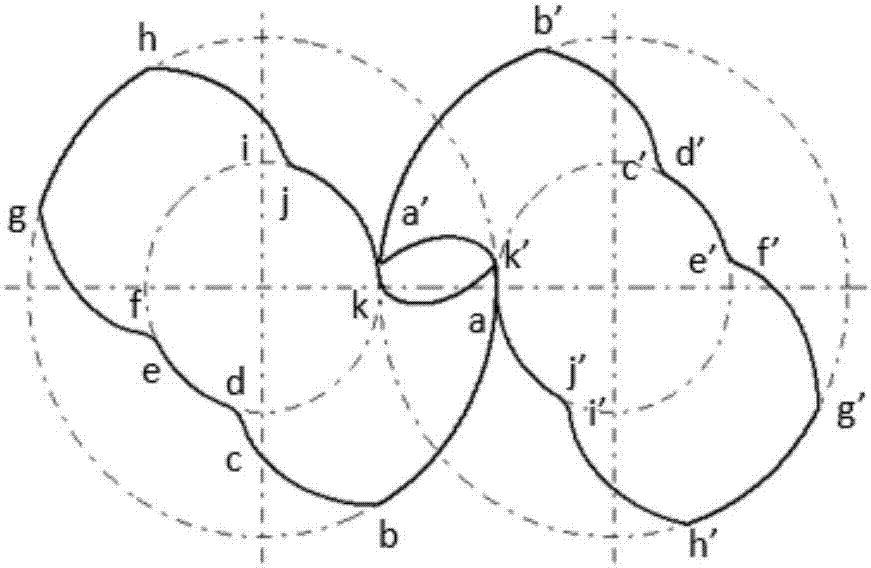

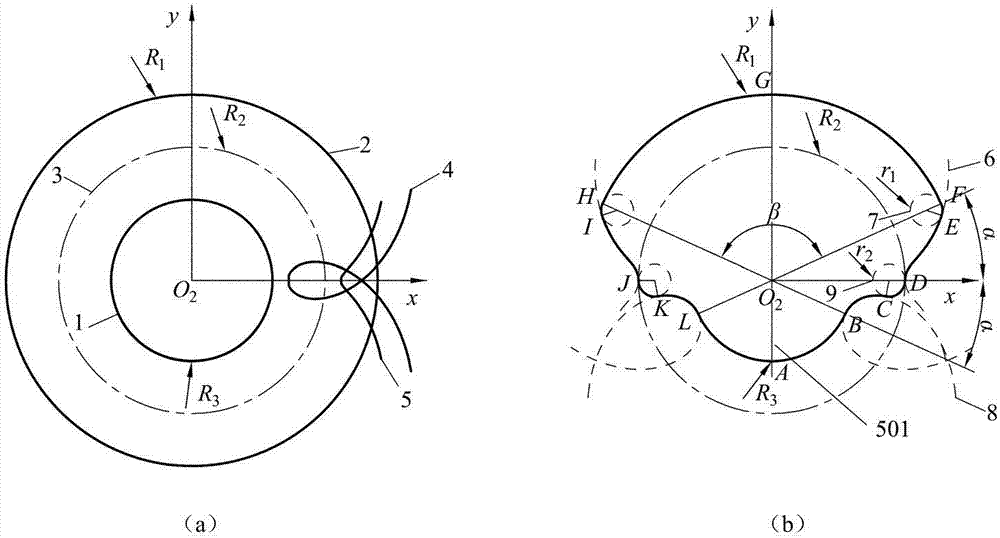

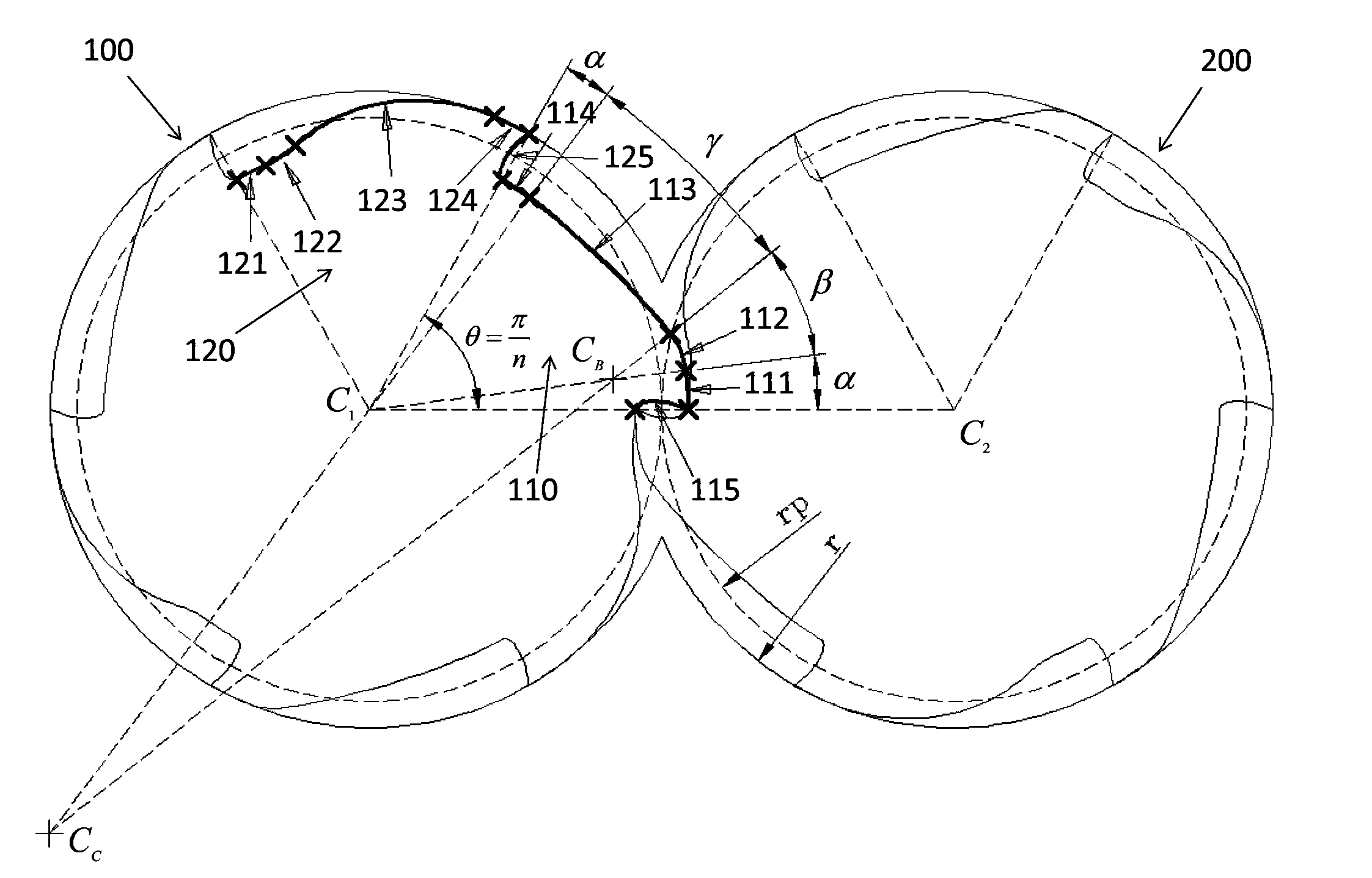

Double-head claw pump rotor and its molded line

ActiveCN108930650AAvoid severe wear and tearIncrease design parameter spaceRotary piston pumpsRotary piston liquid enginesEngineeringSharp point

The invention relates to a double-head claw pump rotor and its molded line. The molded line comprises an equidistance curve of a point meshing epicycloid, a modified arc segment, a tooth top arc segment, an intermediate connecting arc segment, an arc conjugate curve segment, and a tooth root arc segment. Two rotors adopt a central symmetrical structure. By setting the modified arc segment, the sharp points are eliminated, and severe wearing phenomenon of the rotors during operation can be avoided. The equidistance curve of the point meshing epicycloid and the modified arc segment are always spaced apart to avoid the formation of suction and exhaust closed volume, and a design parameter space of the rotor molded line is increased, the power consumption is reduced, and the pump efficiency isimproved. The molded line is designed in the double-head claw pump, compared with the other conventional pumps, the pump in the invention has the advantages of less wearing parts, compact structure,high pumping rate, no surge, and low vibration noise.

Owner:宝风压缩机科技(浙江)有限公司

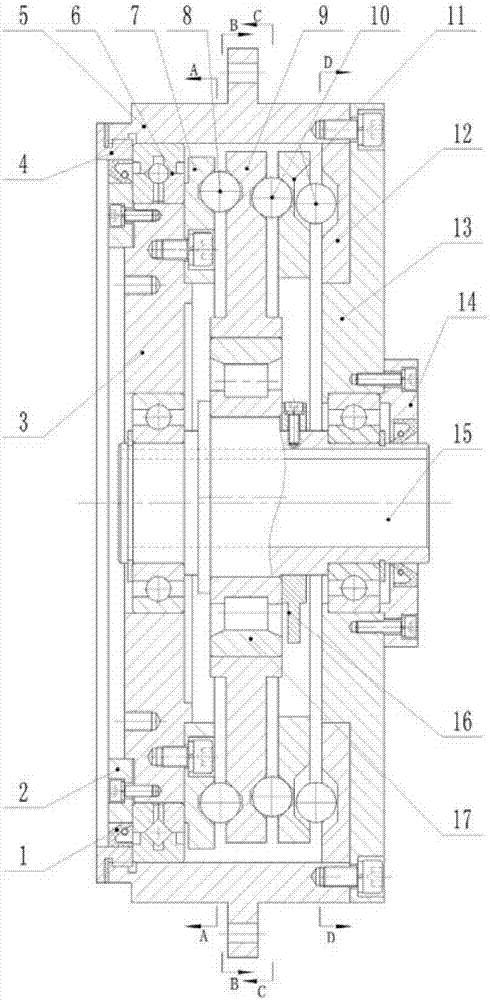

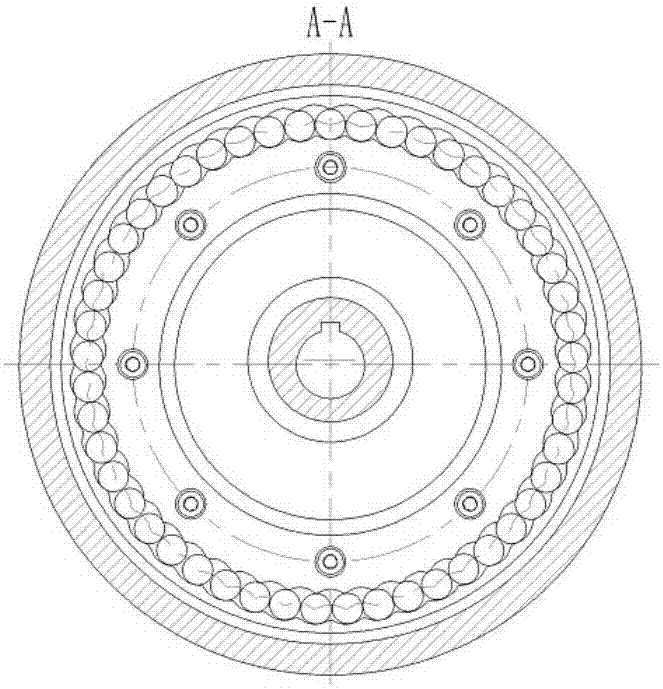

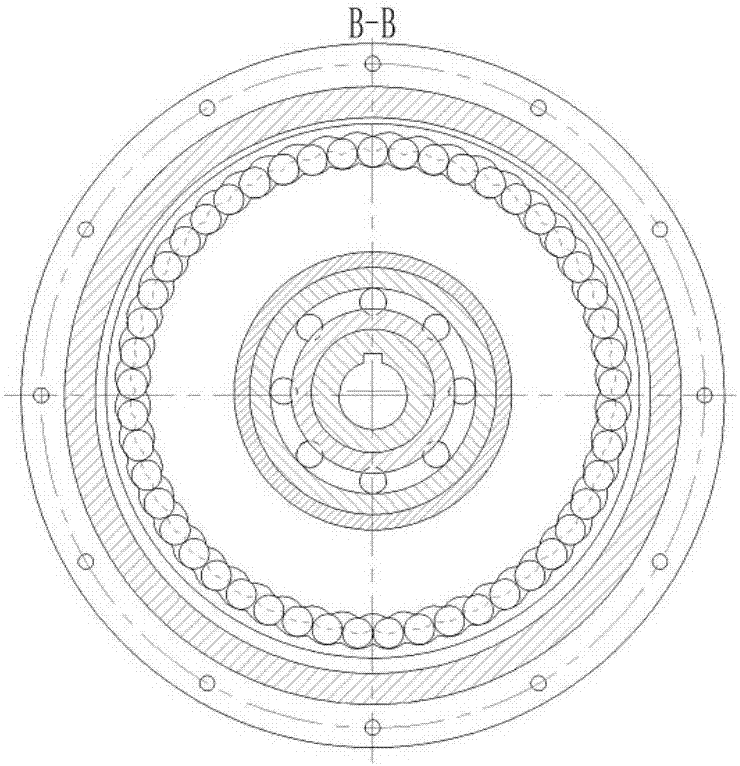

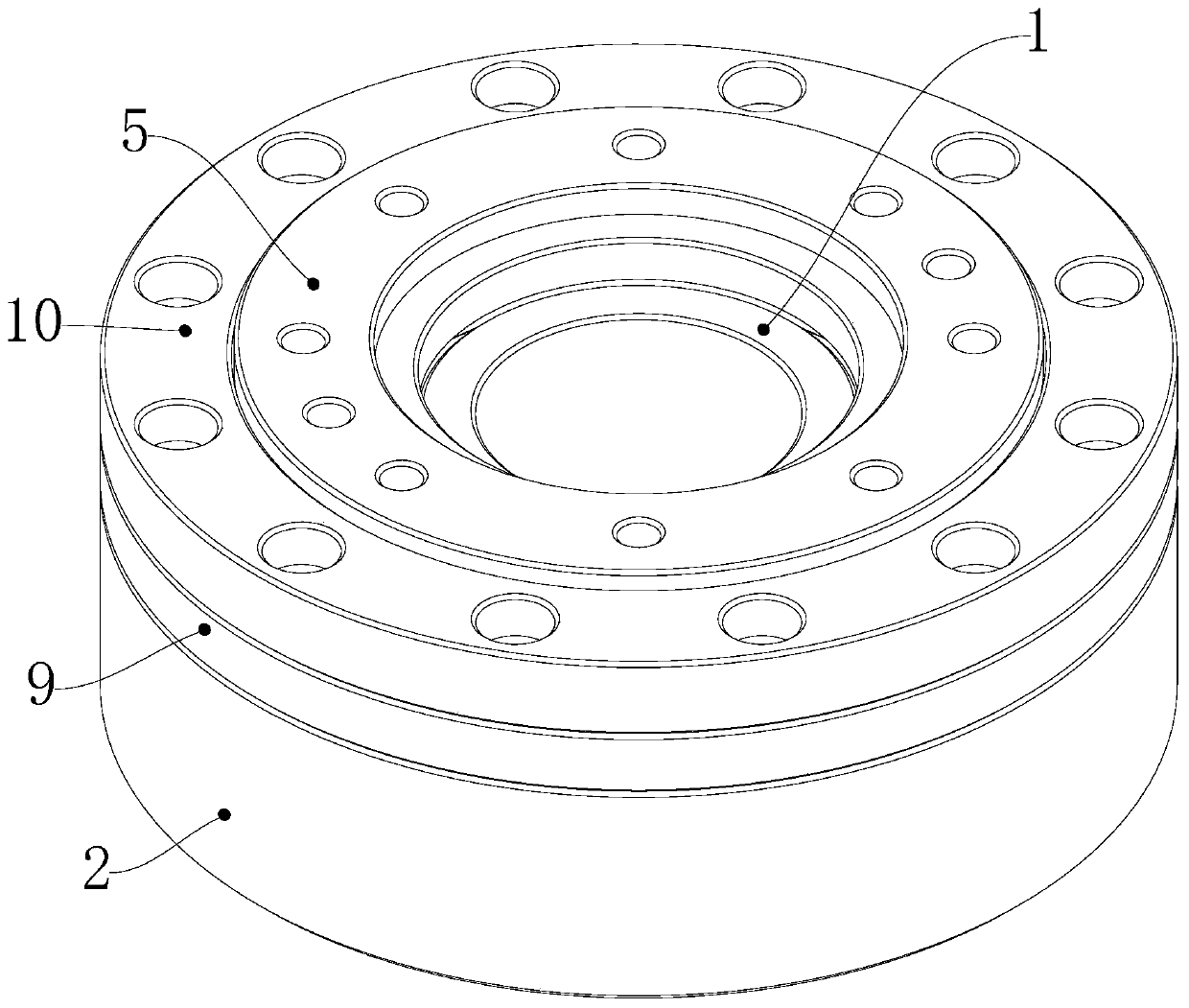

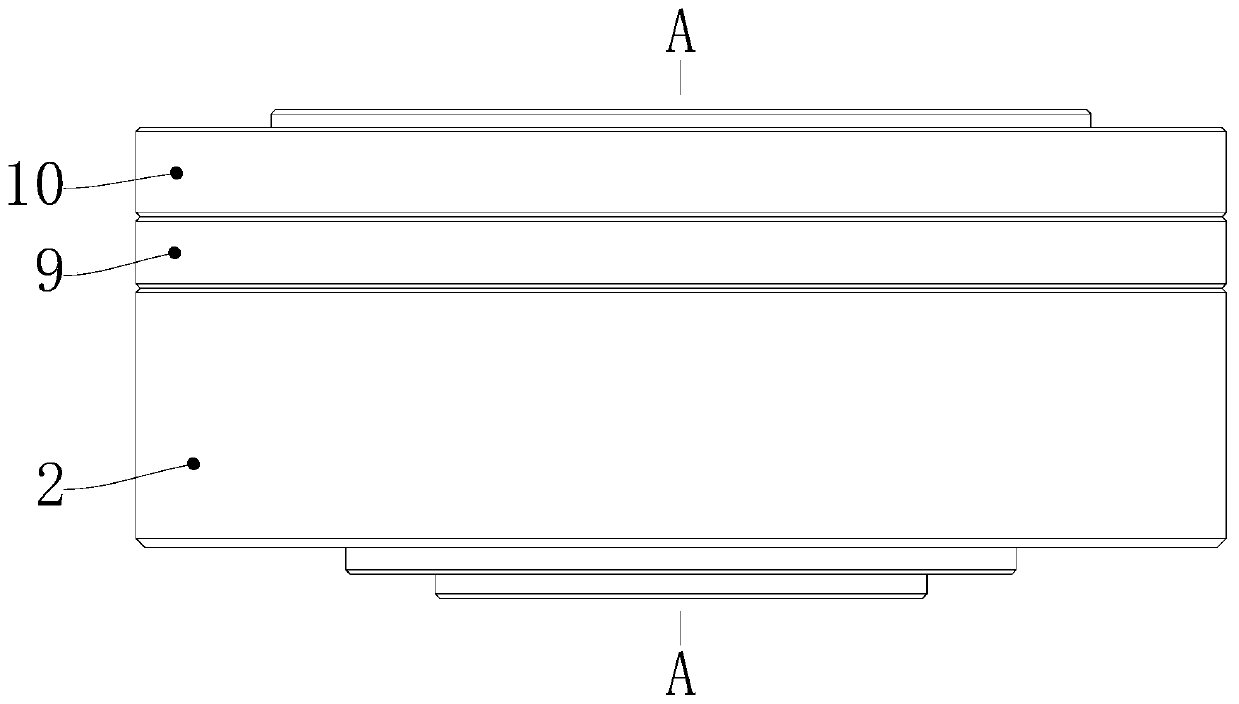

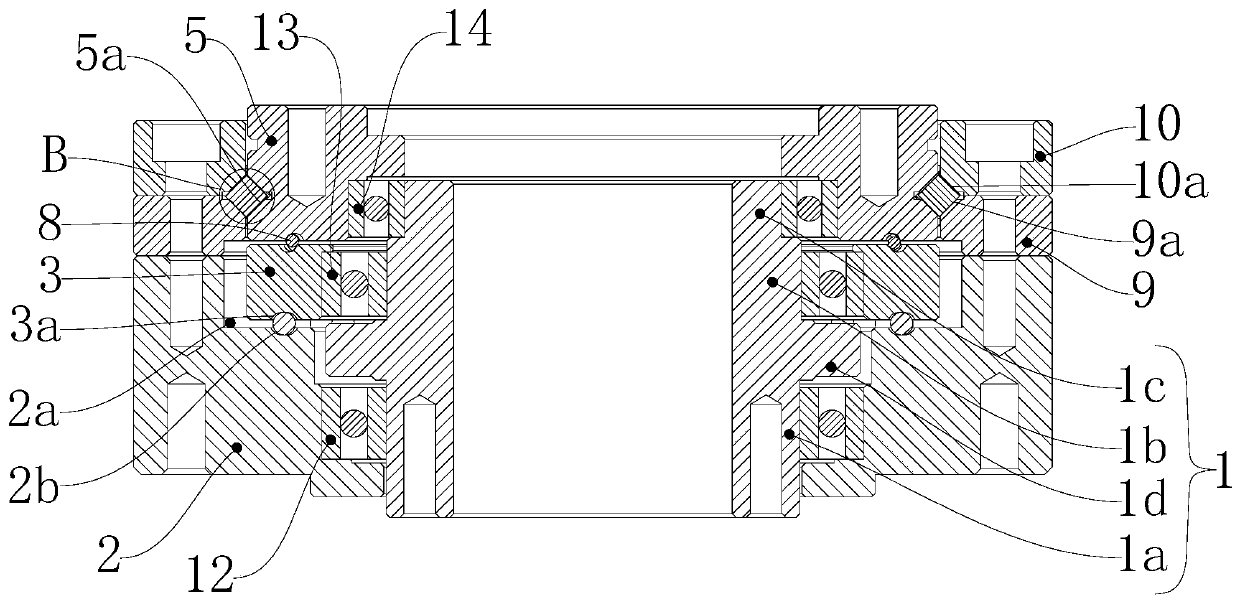

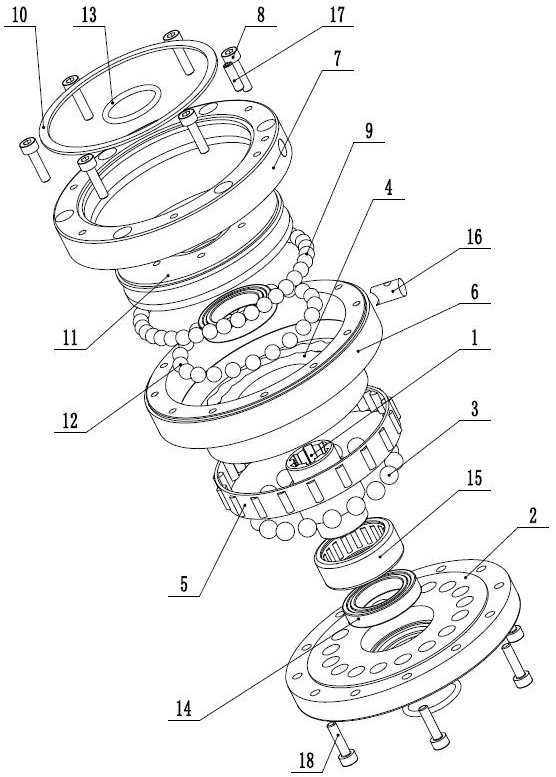

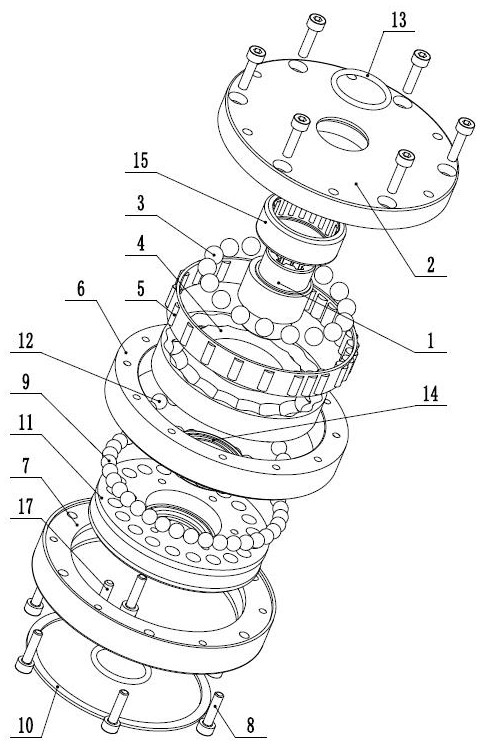

Cycloid steel ball planetary transmission mechanism and robot joint speed reduction device thereof

PendingCN107327543AAvoid over-squeezingExtended service lifeProgramme-controlled manipulatorJointsEngineeringSteel ball

The invention discloses a cycloid steel ball planetary transmission mechanism and a robot joint speed reduction device thereof and belongs to the field of speed reduction transmission devices. The cycloid steel ball planetary transmission mechanism disclosed by the invention comprises a planetary plate, a central plate and a steel ball group. A gap d [d=Z0(h+delta) / 2pi] is reserved between every two steel balls in the steel ball group; a tooth space, the tooth profile of which is a profiled hypocycloid, is formed in the end surface of the central plate, and a tooth space, the tooth profile of which is a profiled epicycloid, is formed in the end surface of the planetary plate. A cross steel ball constant speed transmission mechanism comprises the planetary plate, the steel ball group, a cross plate and an end cover plate; and structurally optimized straight line grooves are formed in the end surfaces of the planetary plate, the cross plate and the end cover plate. On the basis of retainment of a small speed ratio performance, the actual bearing capacity of the robot joint speed reduction device can be effectively enhance and the service life of the robot joint speed reduction device can be effectively prolonged, so that the cycloid steel ball planetary transmission mechanism is in particular suitable for an electric rotary joint of a high speed carrying robot.

Owner:马鞍山一众机电有限公司

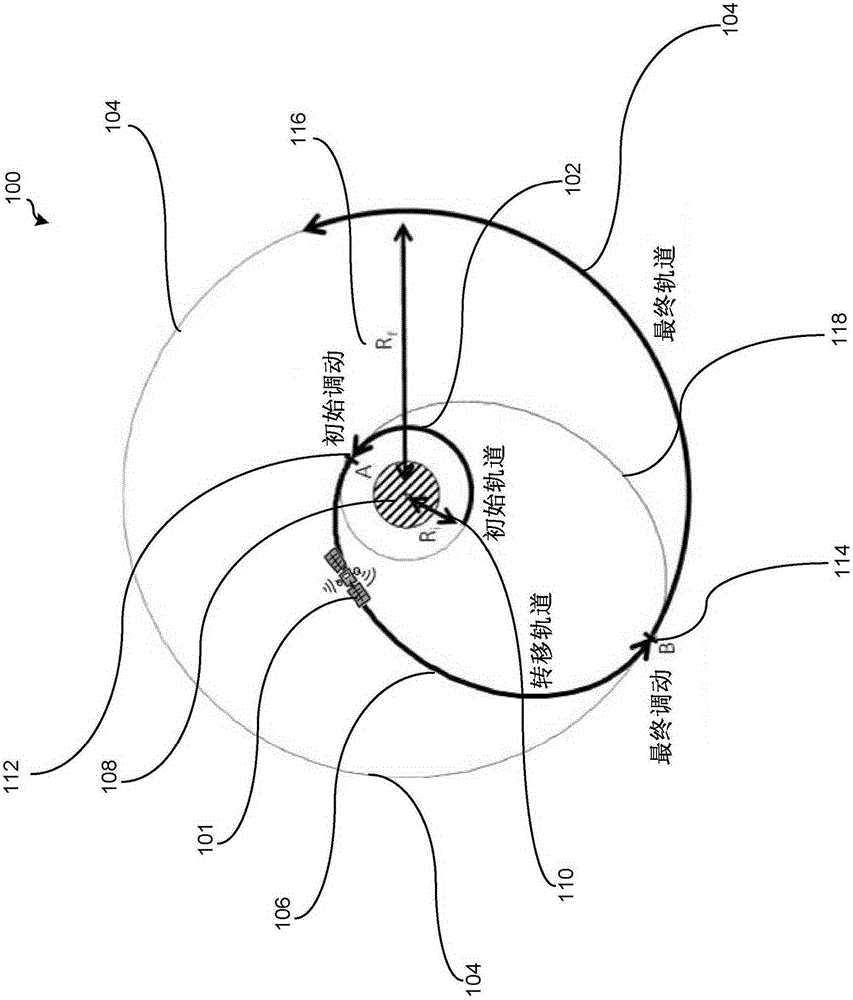

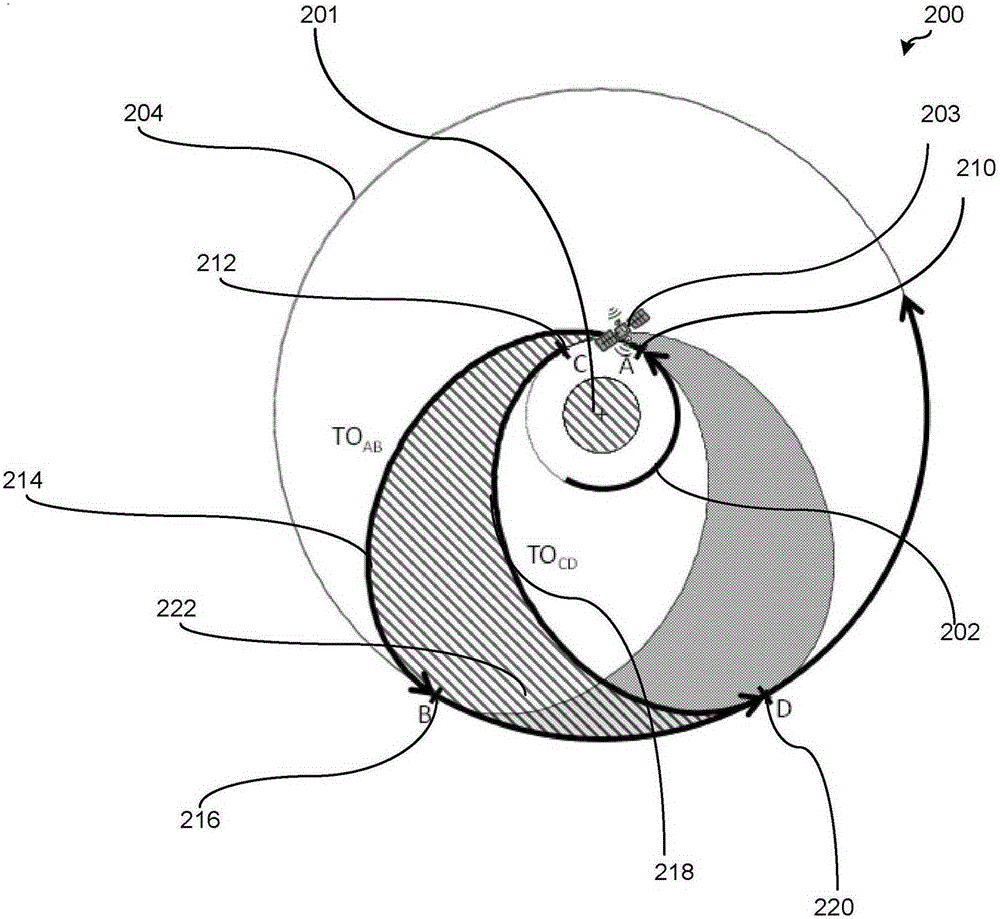

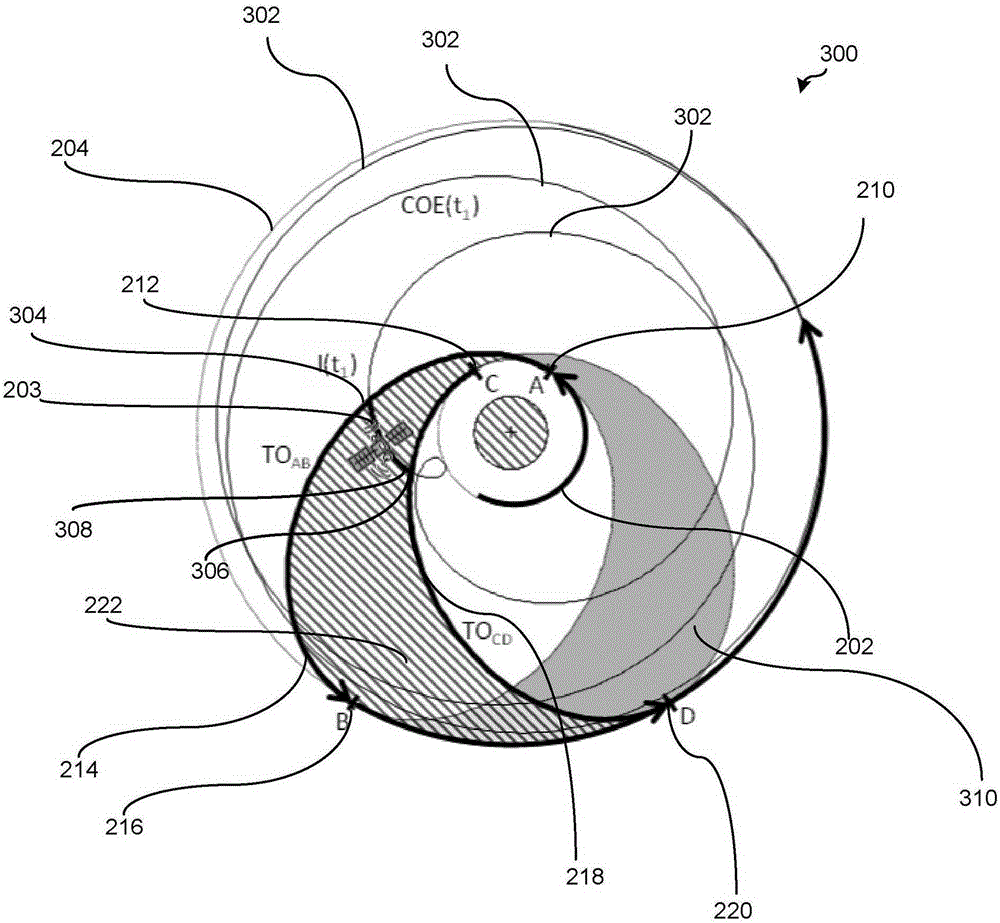

Satellite transfer orbit search methods

Satellite transfer orbit search methods are described herein. One disclosed example method includes determining, based on boundary transfer orbits of a satellite, end points of an oblate epicycloid segment related to a transfer orbit of the satellite, and calculating, using a processor, a shape of the oblate epicycloid segment based on satellite data and the end points to define a search zone to determine a position of the satellite as the satellite moves along the transfer orbit.

Owner:THE BOEING CO

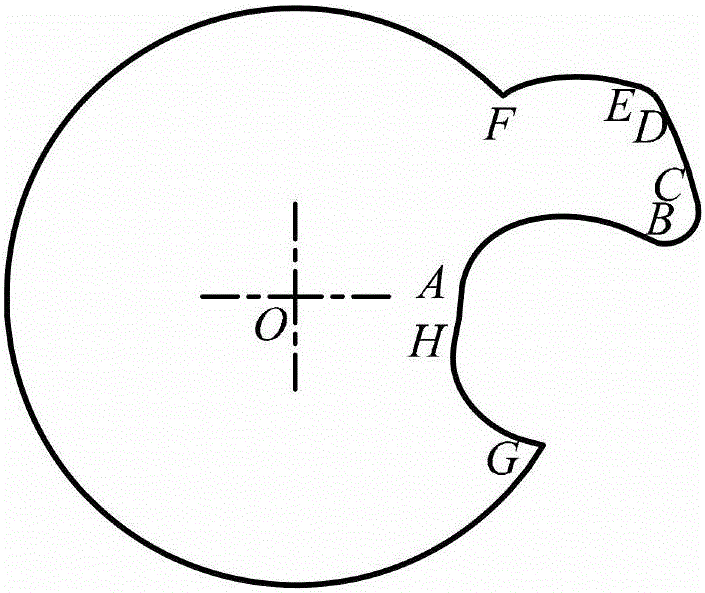

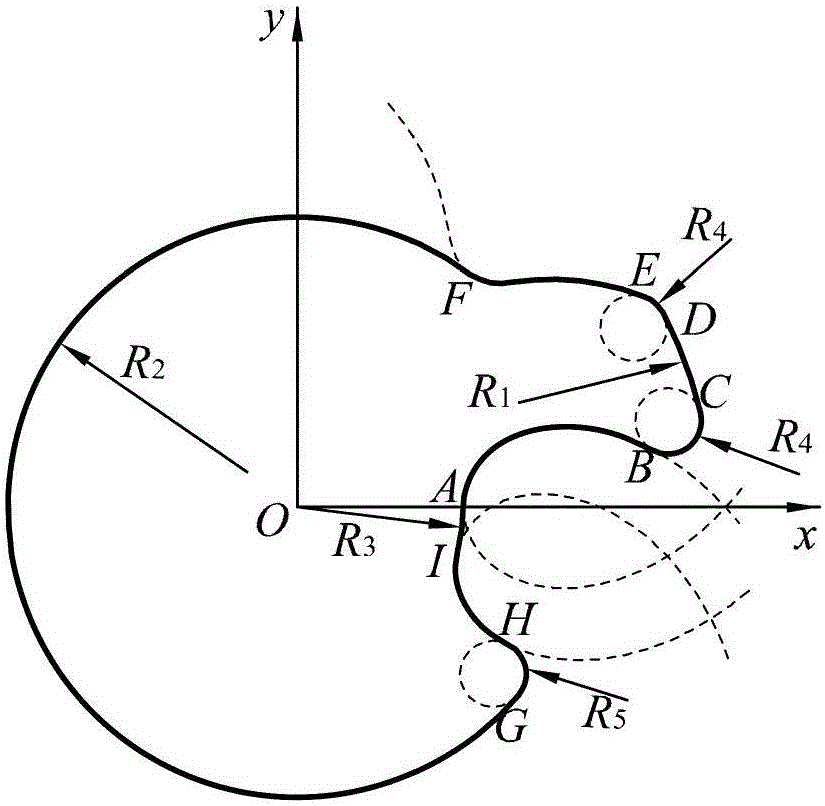

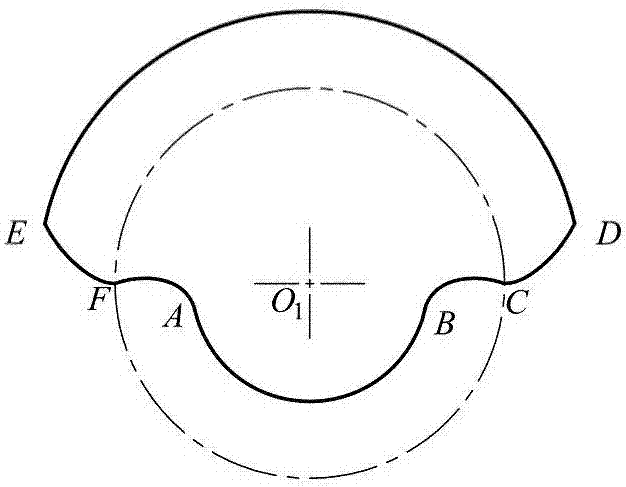

Total-smooth claw type rotor

InactiveCN105822548AImprove performanceAchieve smooth connectionEngine of intermeshing engagement typeRotary piston pumpsStress concentrationEngineering

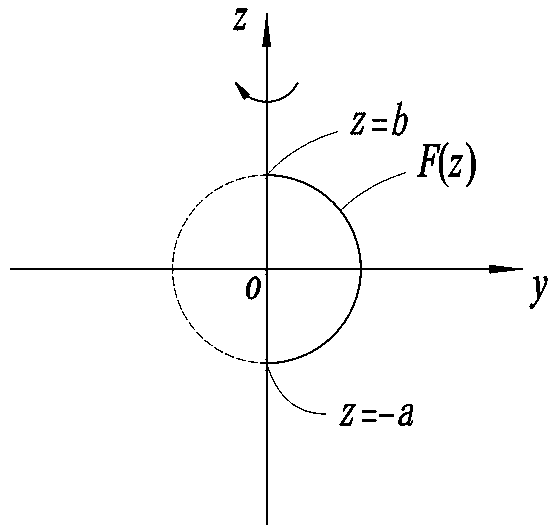

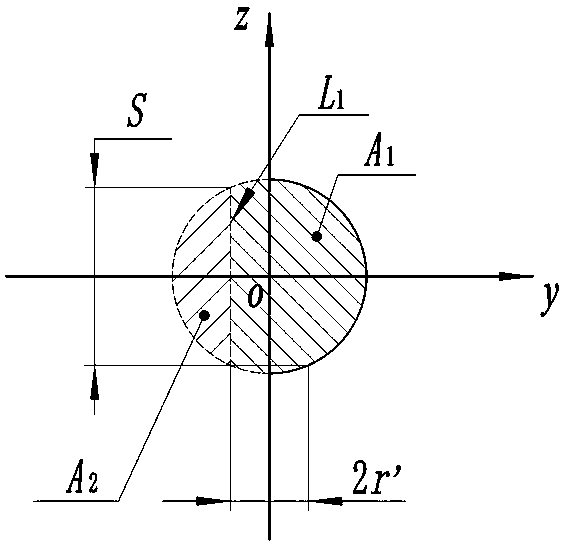

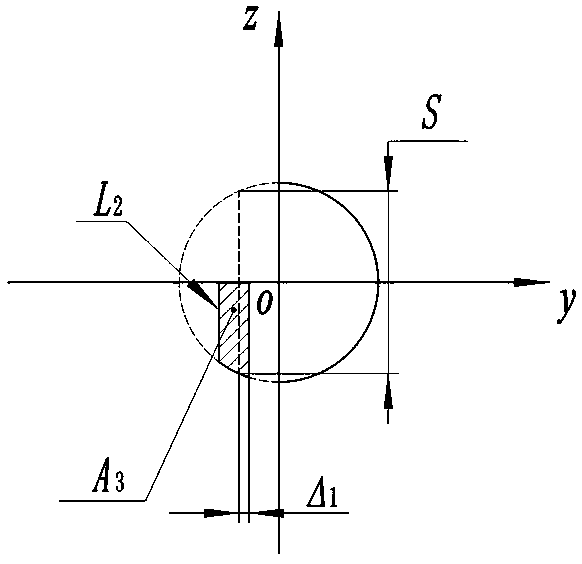

The invention discloses a total-smooth claw type rotor. The rotor profile line is composed of 9 curves including the equidistant curve AB of the prolate epicycloid of a front claw arm, the front claw tip arc BC, the claw top arc CD, the rear claw tip arc DE, the equidistant curve EF of the curtate epicycloid, the pitch circle arc FG, the bottom claw tip arc GH, the equidistant curve HI of the prolate epicycloid of a rear claw arm and the claw bottom arc IA. Every two adjacent curves are connected smoothly, no non-smooth connection point or cuspidal point exists, and thus areas prone to abrasion, deformation and stress concentration are effectively avoided; the two claw type rotors which conduct synchronous opposite-direction double-rotation motion can be engaged correctly, and thus the sealing property, the mechanical property and the engagement property of the claw type rotors can be effectively improved; and the clearance volume is reduced, local high pressure is avoided in the mixing process, the power consumption of a claw type vacuum pump can be effectively reduced, the working efficiency of the claw type vacuum pump is remarkably improved, and the claw type rotor has important significance in the development of the claw type vacuum pump.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

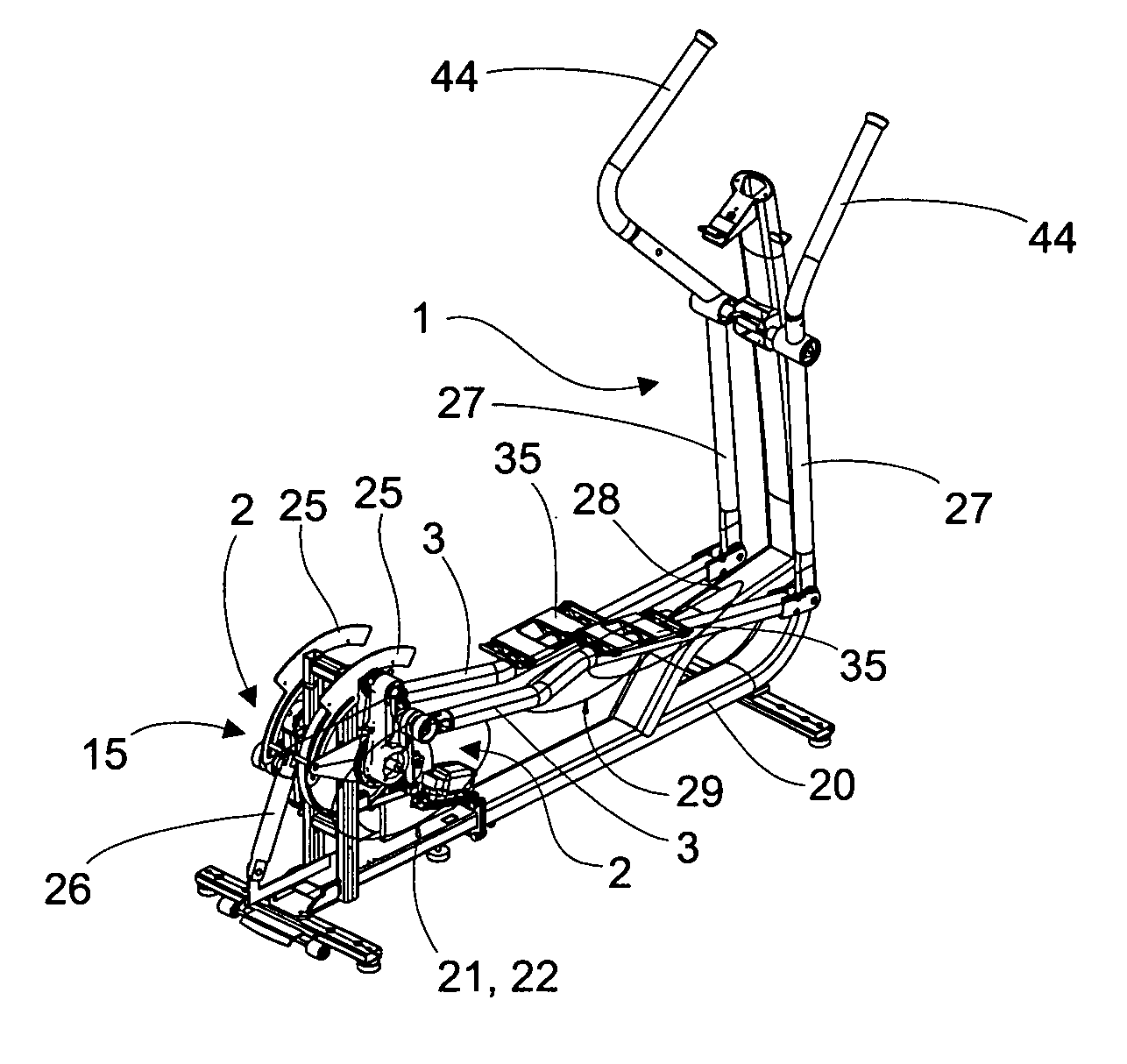

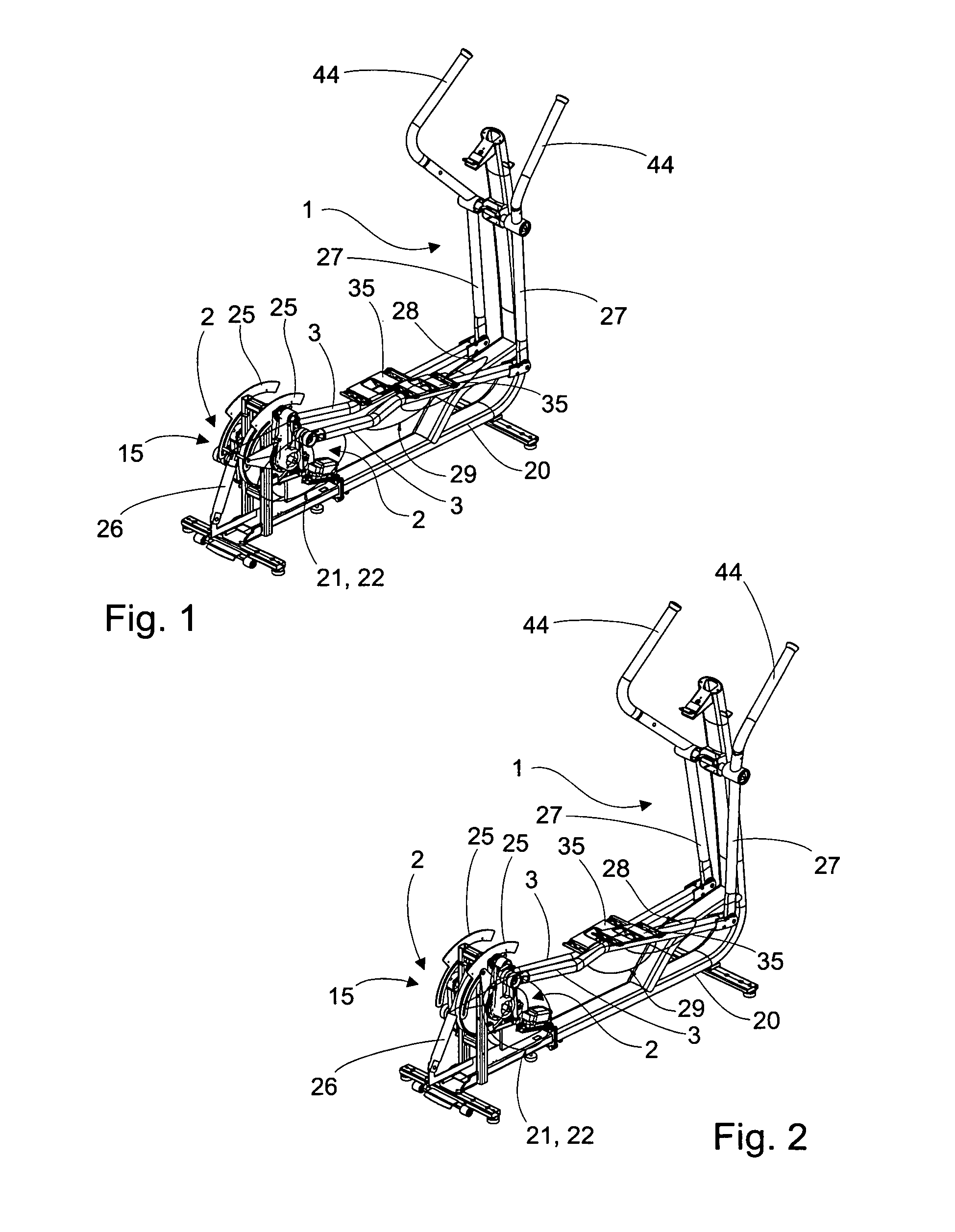

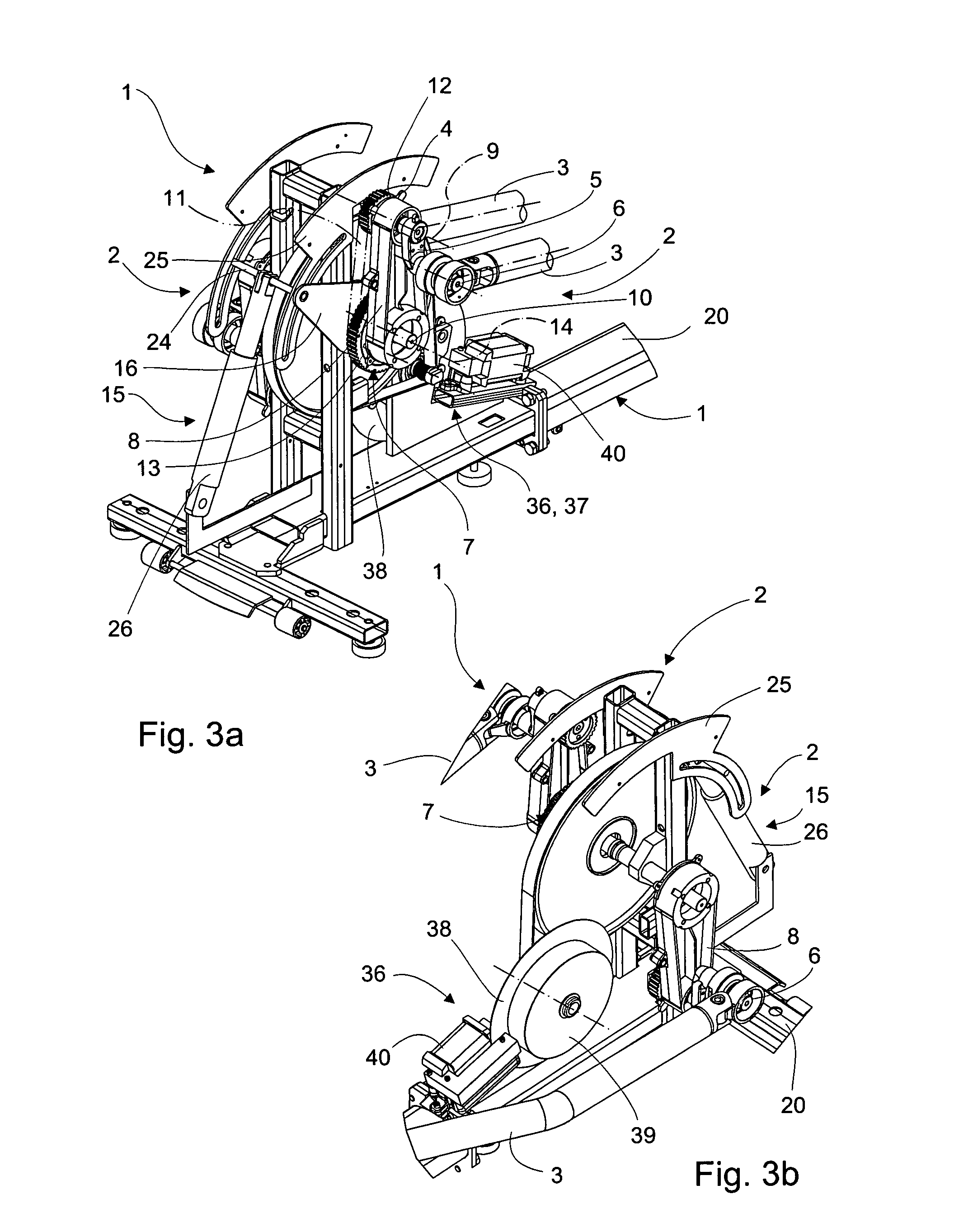

Gymnastic machine

InactiveUS20070032350A1Muscle exercising devicesMovement coordination devicesEngineeringAngular variation

Gymnastic machine including an epicycloidal mechanism (2) for connecting an application member (3) of a driving device to resistive means (36); the mechanism (2) being provided with a satellite member (4) connected to the application member (3) by means of a first crank (5) having a pin (6); with a planetary member (7); with a second crank (8) which rotationally connects a movable rotation centre (9) on the satellite member (4) to a fixed centre (10) on the planetary member (7); and with transmission devices (11, 12, 13) for transmitting a relative motion between the satellite member (4) and the planetary member (7); the planetary member (7) being supported in freely rotatable manner around an axis (14) passing through the fixed centre (10); actuating members (15) being provided for imparting to planetary member (7) an angular movement (α) around the fixed centre (10) which corresponds to a relative angular variation (β) of the first and second cranks (5, 8), and a corresponding variation of the orientation of the path (21, 22) of the pin (6) of the satellite member (4).

Owner:TECHNOGYM SPA

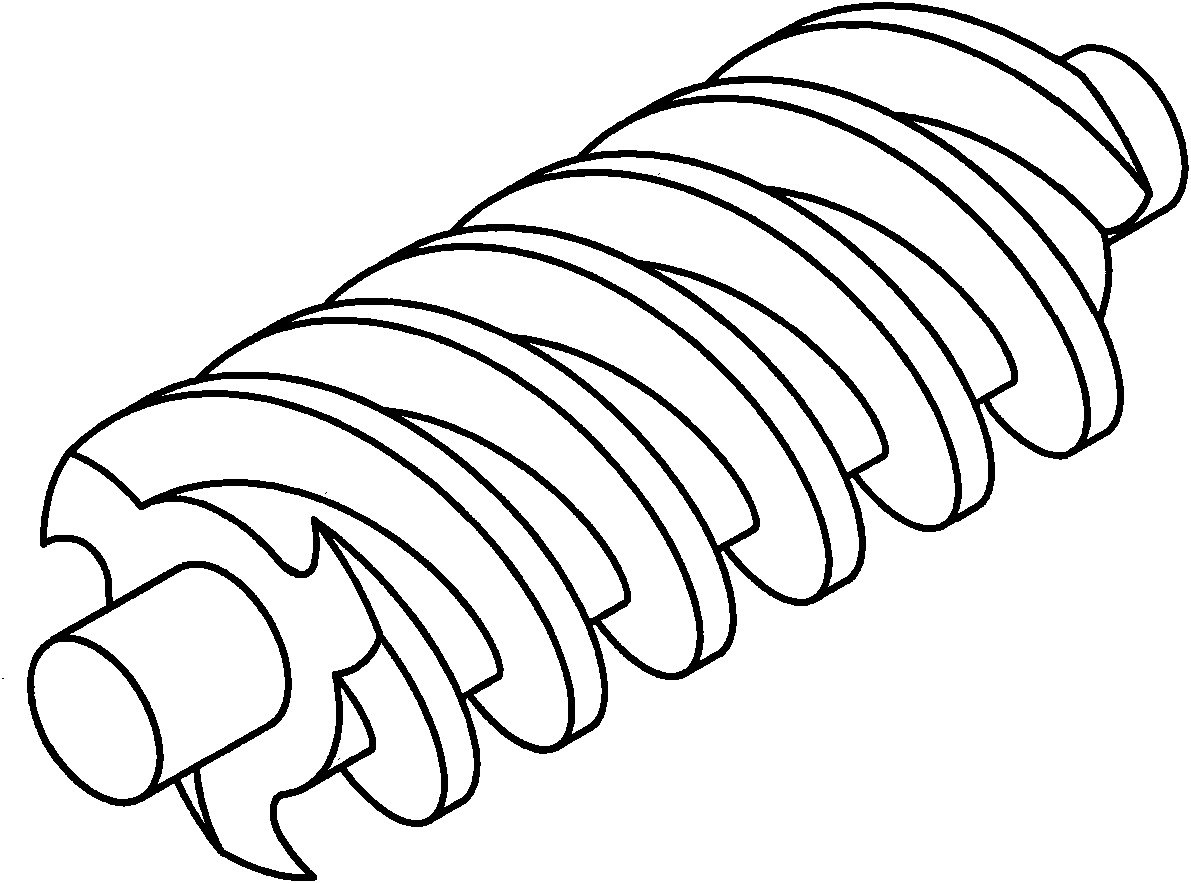

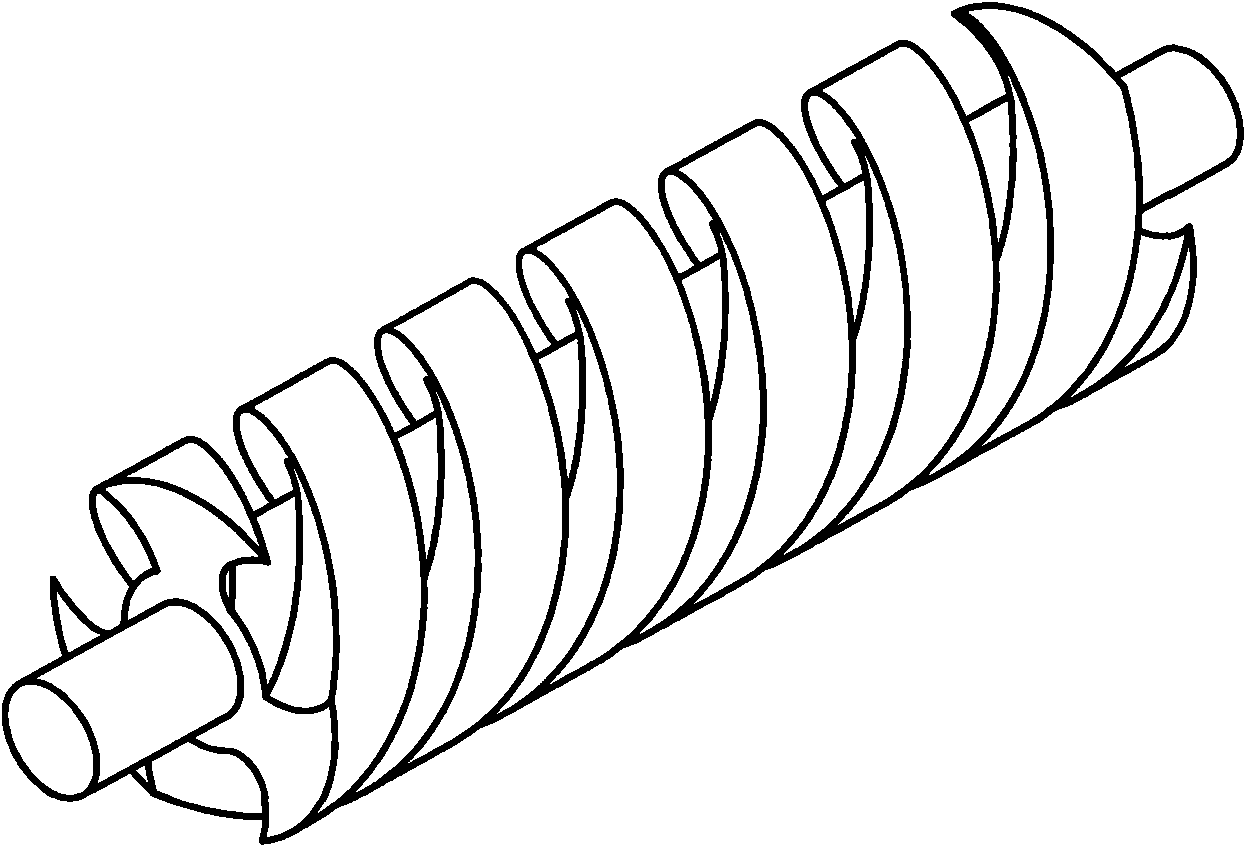

Sealed single-head spiral screw and double screws thereof

ActiveCN105484999ANo gapAchieve a tight sealRotary piston pumpsRotary piston liquid enginesInvoluteVacuum pump

The invention provides a sealed single-head spiral screw and double screws thereof and belongs to the technical field of screw pumps. The spiral of the single-head spiral screw is in an asymmetric tooth shape. A force transmission edge and a sealing edge are arranged on the two sides of the tooth shape respectively. The tooth-shaped profile of the sealing edge is an elongated epicycloid. The tooth-shaped profile of the force transmission edge is a combined profile of an elongated epicycloid, an involute and a curtate epicycloid. According to the tooth-shaped profile of the single-head spiral screw, the sealing edge on one side is the elongated epicycloid, the force transmission edge on the other side is combination of the elongated epicycloid, the involute and the curtate epicycloid, the engagement lines are continuous, and no gap exists between the engagement lines. According to a double-screw pump or a double-screw type vacuum pump with the sealed singe-head spiral screws, the tight sealing effect can be achieved, and torque is transmitted to the tooth-shaped profile of the force transmission edge of the involute segment of the drive screw from the tooth-shaped profile of the force transmission edge of the involute of the driven screw.

Owner:TIANJIN HUAKE SCREW PUMP TECH CO LTD

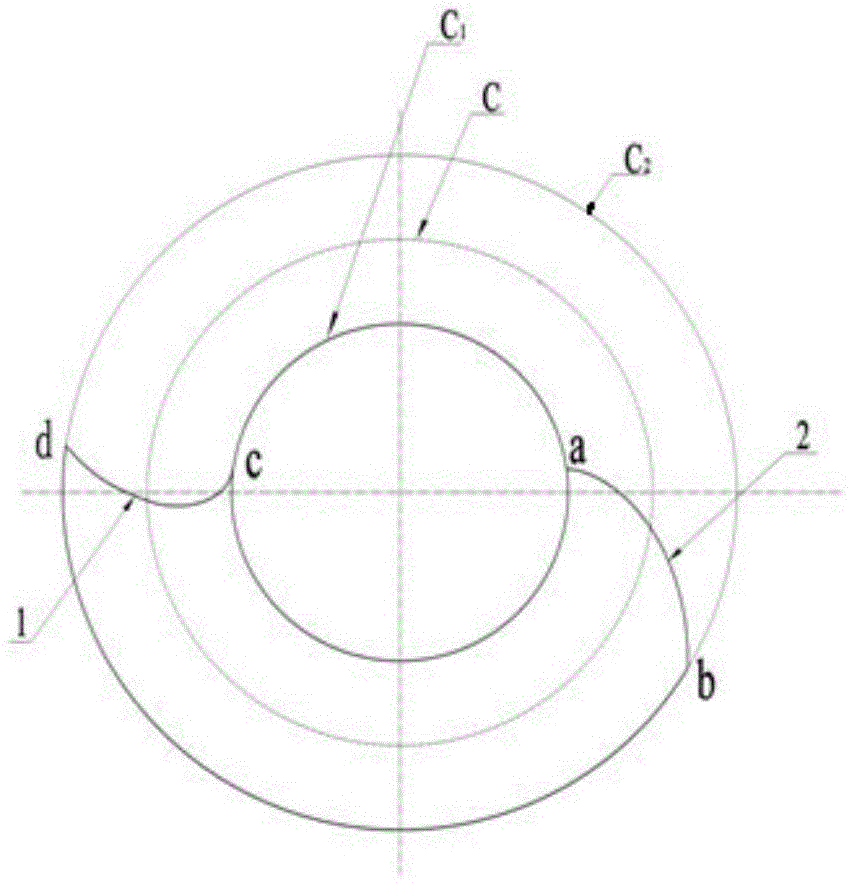

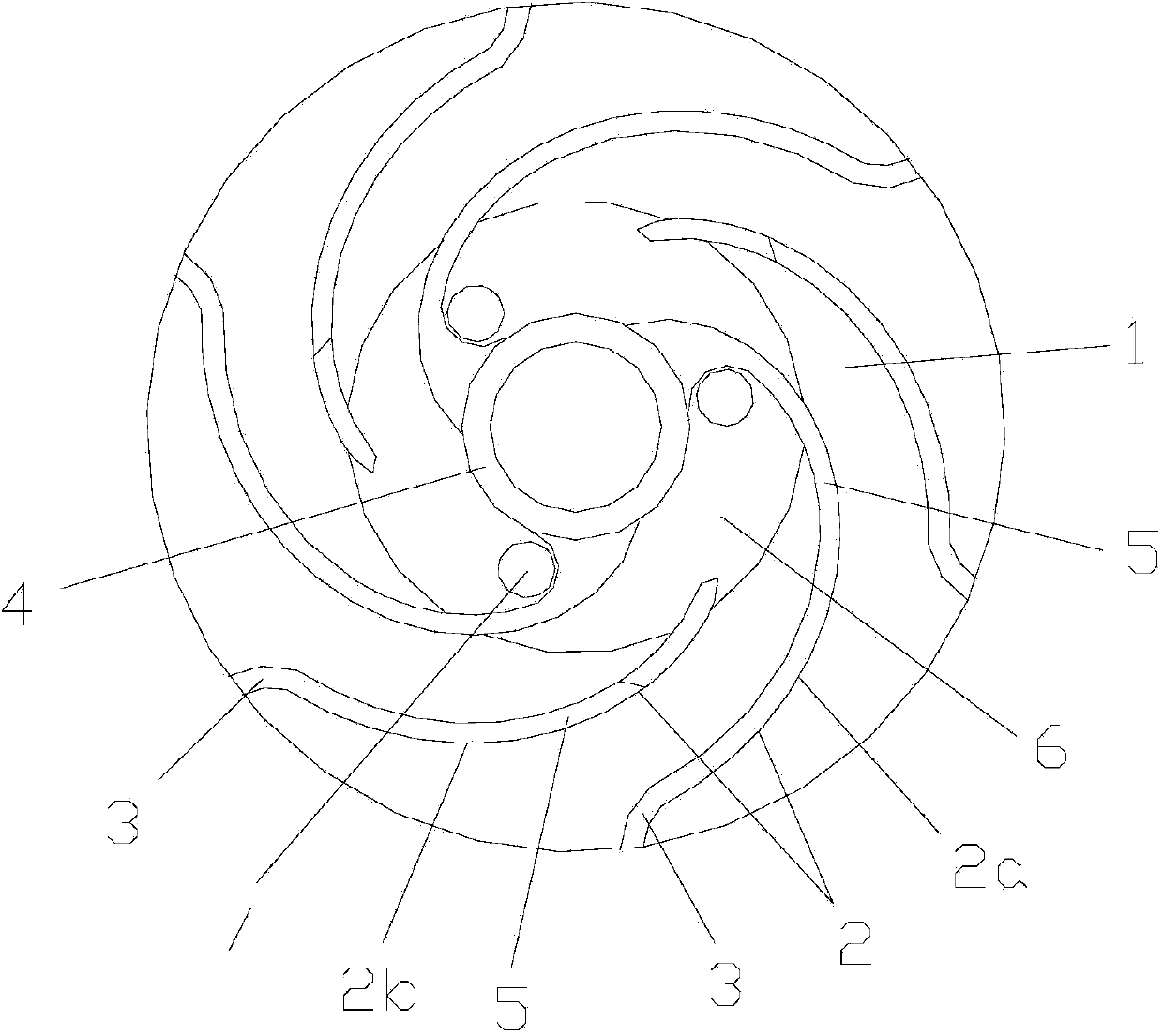

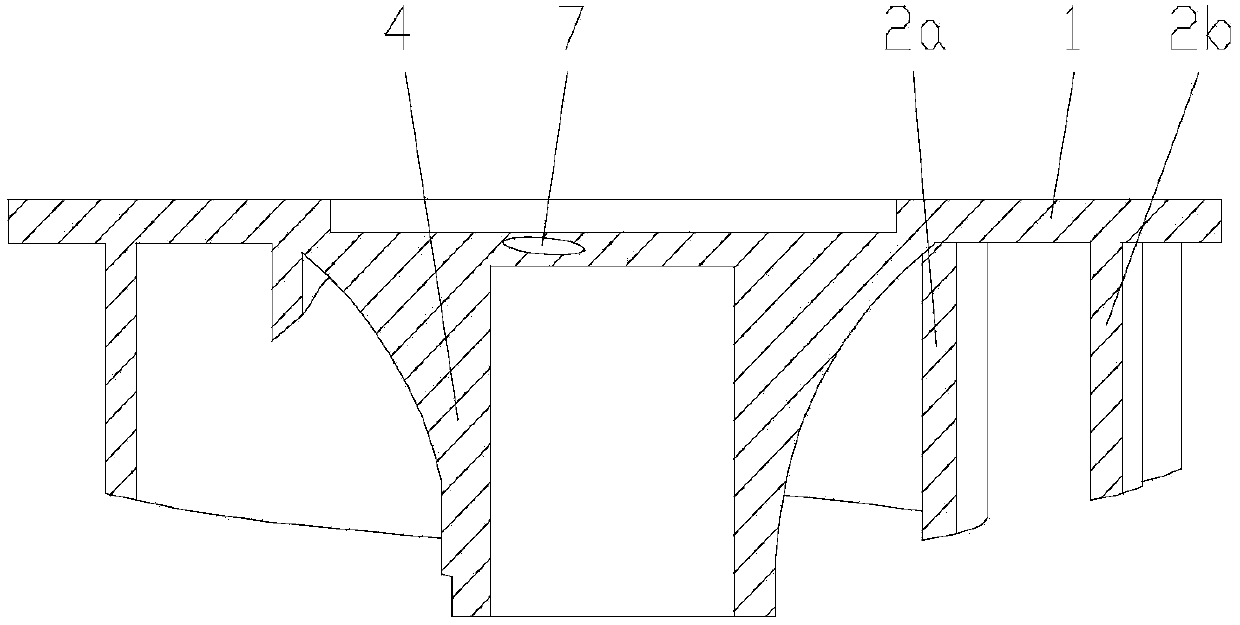

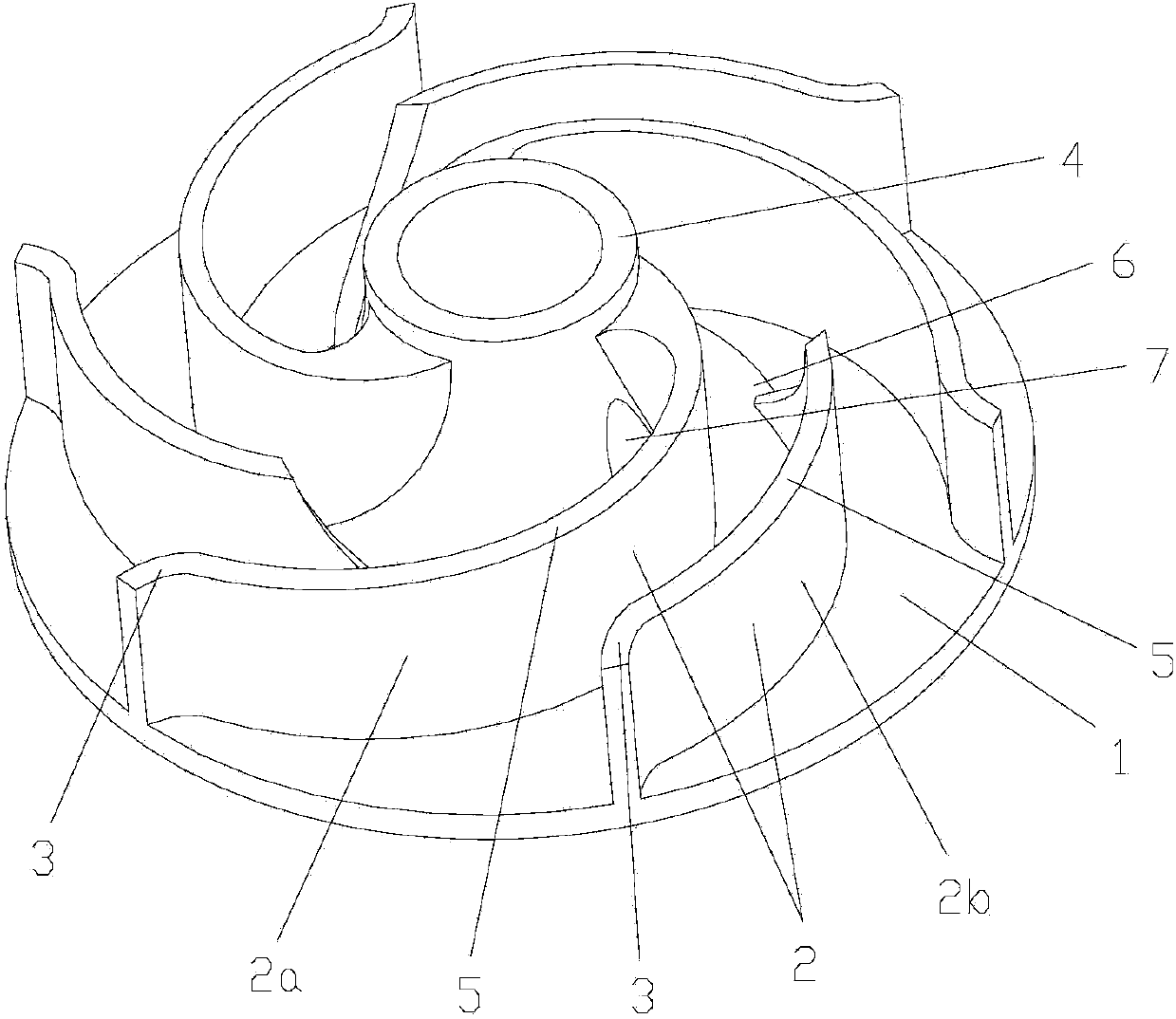

Epicycloid centrifugal pump impeller

The invention discloses an epicycloid centrifugal pump impeller. The epicycloid centrifugal pump impeller comprises a wheel disc and blades which are fixedly arranged on one end face of the wheel disc. The tail sections of the blades are gradually changed to be of an epicycloid structure which extends in the radial direction of the wheel disc. According to the epicycloid centrifugal pump impeller, molded lines on the tail sections of the blades are epicycloids close to the fluid motion law, the impeller is designed to be in a half-open type, compared with a common centrifugal pump, loss at an outlet of the impeller can be reduced, the partial reflux phenomenon is reduced, and water pumping efficiency is improved.

Owner:CHONGQING UNIV

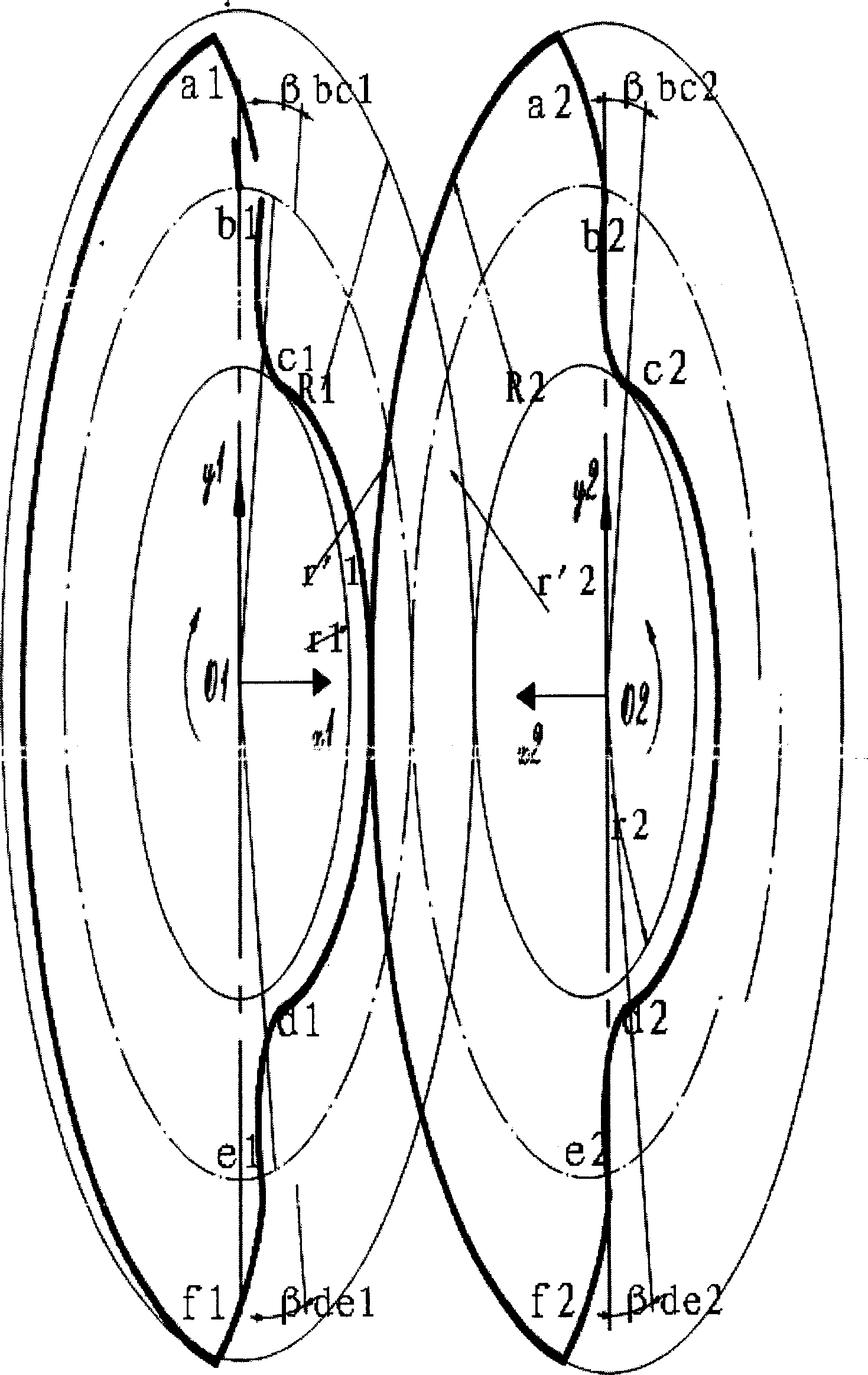

Double-screw mixing transmission pump tooth type

InactiveCN101603532AEasy to processImprove efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringContact line

The invention discloses a double-screw mixing transmission pump tooth type. The shaped line of the double-screw mixing transmission pump tooth type is composed of two triple-head screw shaped lines, wherein, one screw shaped line is a convex screw shaped line, and the other screw shaped line is a concave screw shaped line. The convex screw shaped line is defined by an equation, the tooth shape of each screw is the same, and is distributed evenly along circumference; the tooth shape of each screw is composed of an arc-arc envelope curve and a point meshing cycloid; a main meshing zone adopts the point meshing cycloid and a long limb epicycloid ; other zones adopt the arc-arc envelope curves; the concave screw shaped line is totally obtained with the method that the convex screw adopts the meshing principle for conjugation calculation. The double-screw mixing transmission pump tooth type line of the invention totally conforms to the meshing principle, two rotor shaped lines are mutually conjugated, meshing lines formed by the shaped lines are closed, and contact lines formed by the rotors are continuous, so that the double-screw mixing transmission pump in the invention can be suitable for multiphase medium transmission places with higher transmission pressure and high air voids. Meanwhile, the screw adopting the double-screw mixing transmission pump tooth type of the invention has convenient manufacturing and high efficiency.

Owner:XI AN JIAOTONG UNIV

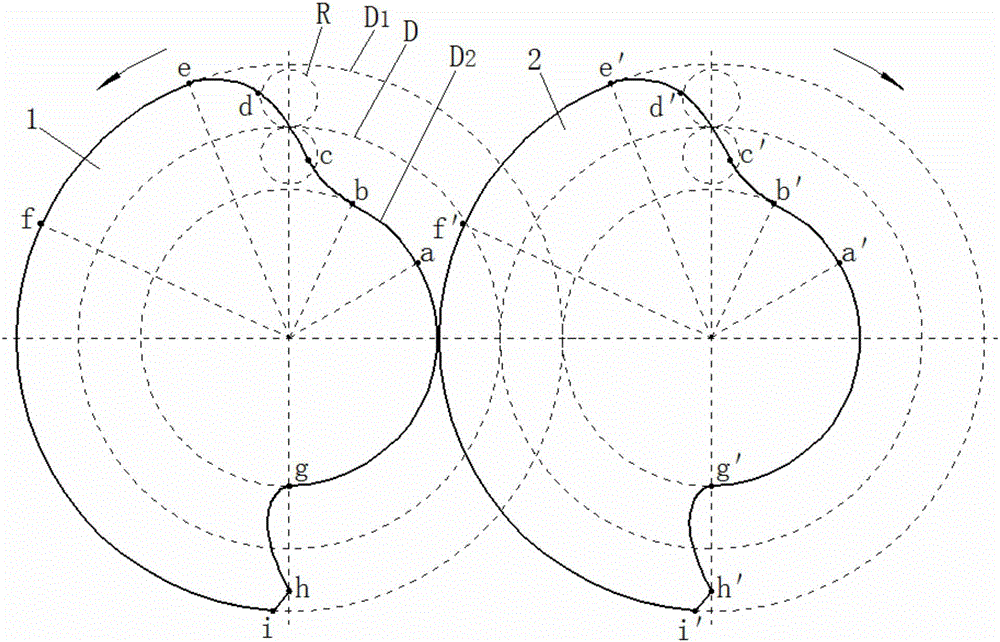

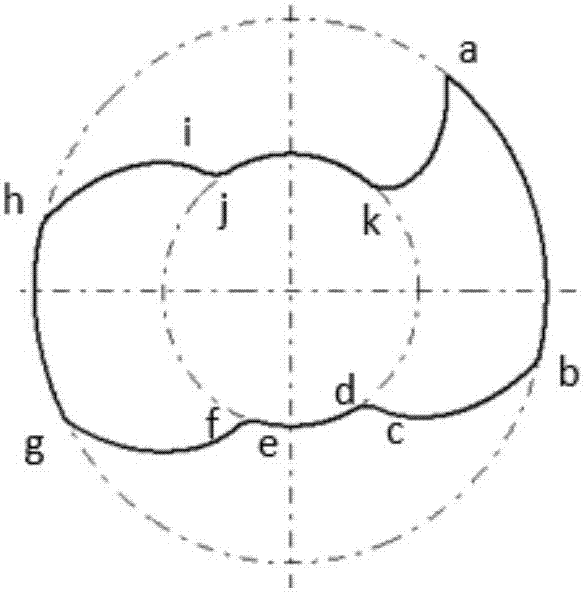

Rubber screw rotor molding line applicable to screw-type volumetric pump

ActiveCN106194717AImprove volumetric efficiencyImprove efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringSolid particle

The invention discloses a rubber screw rotor molding line applicable to a screw-type volumetric pump. The rubber screw rotor molding line comprises two sections of identical sealing curves g-h-i and five sections of identical force transferring curves a-b-c-d-e-f; and each of the five sections of force transferring curves a-b-c-d-e-f is formed by sequentially connecting a section of circular arc ab of a base circle D2, a section of equiamplitude hypocycloid bc which takes a small circle R as a movable circle and a pitch circle D as a fixed circle, a section of involute cd of the base circle D2, a section of equiamplitude epicycloid de which takes the small circle R as a movable circle and the pitch circle D as a fixed circle, and a section of Achimedean spiral ef beginning with the epicycloid apex e. When rubber screw rotors work, a contact area is reduced, the abrasion is reduced, the force transferring curves are completely continuously engaged, no leakage region or retention region exists, and strict sealing is formed; in addition, the transition is smooth, and the rubber screw rotor molding line is suitable for rubber molding; after assembly, the volumetric efficiency of the screw-type volumetric pump is high, and the overall efficiency is ideal; and the screw-type volumetric pump is especially suitable for use on working conditions of high flow rate, low lift and high abrasion requirement, and conveys a fluid containing micro solid particles.

Owner:绍兴威格隆泵业有限公司

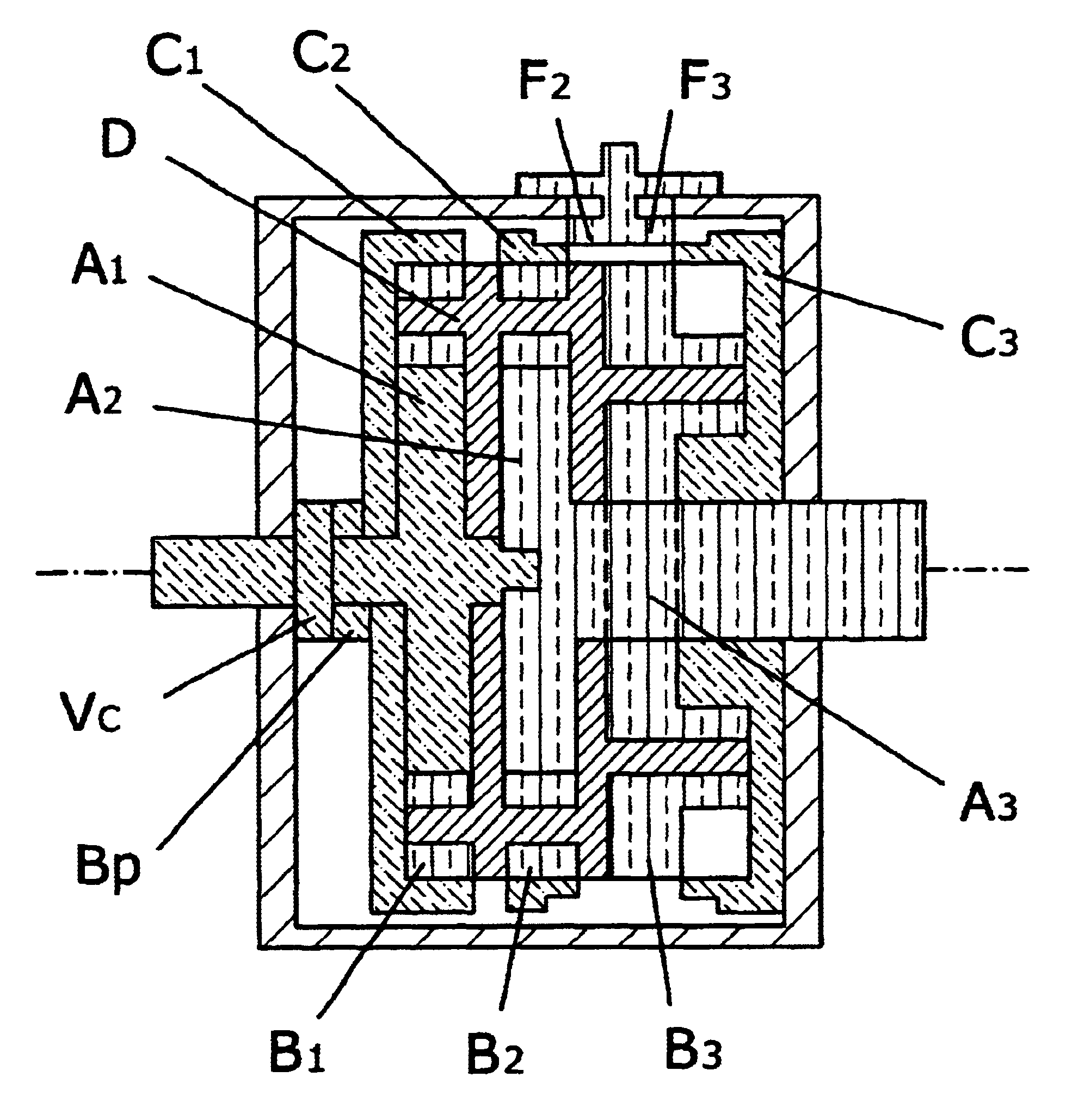

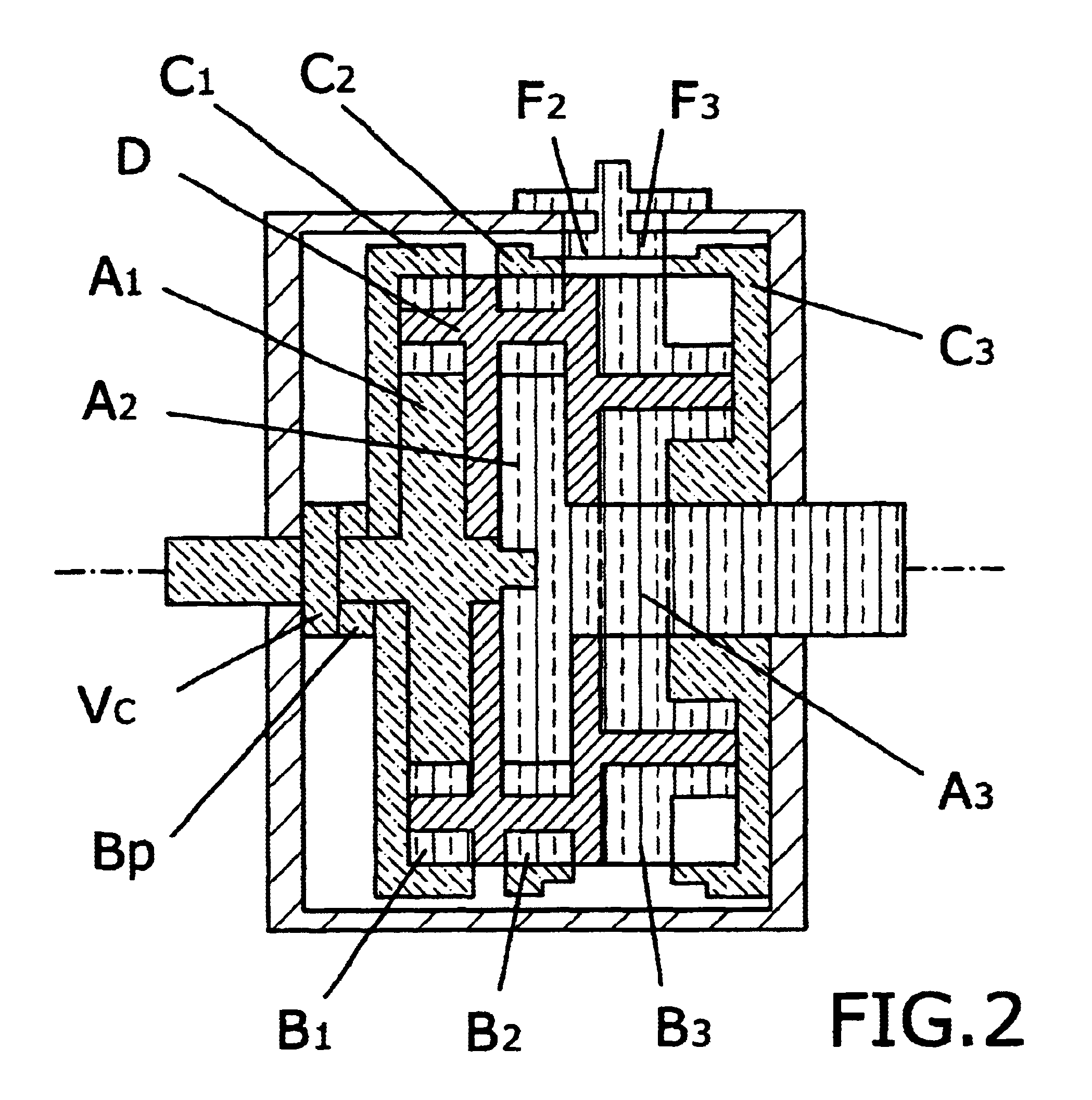

Continuous torque regulator

Continuous torque regulator formed by a transmission system and a regulating circuit, wherein the transmission system is formed by three epicycloid gears, in which each one is formed by a planetary gear, a series of satellite pinions and a crown wheel, wherein the second and third planetary gears are rigidly joined, and the satellite gears of the third train are double, the regulating circuit having a pressure pump (Bp) which is joined by means of a pinion to the crown wheel (C1), a control valve (Vc) which is joined by means of a pinion to the shaft of the planetary gear (A1) and a valve (N) which in the event of being actuated torque transmission ceases, the assembly permitting the regulation of torque in a continuous form without steps and without any need for interruption mechanisms, it being possible to interrupt the transmission at will.

Owner:GUTIERREZ VESGA EDUARDO

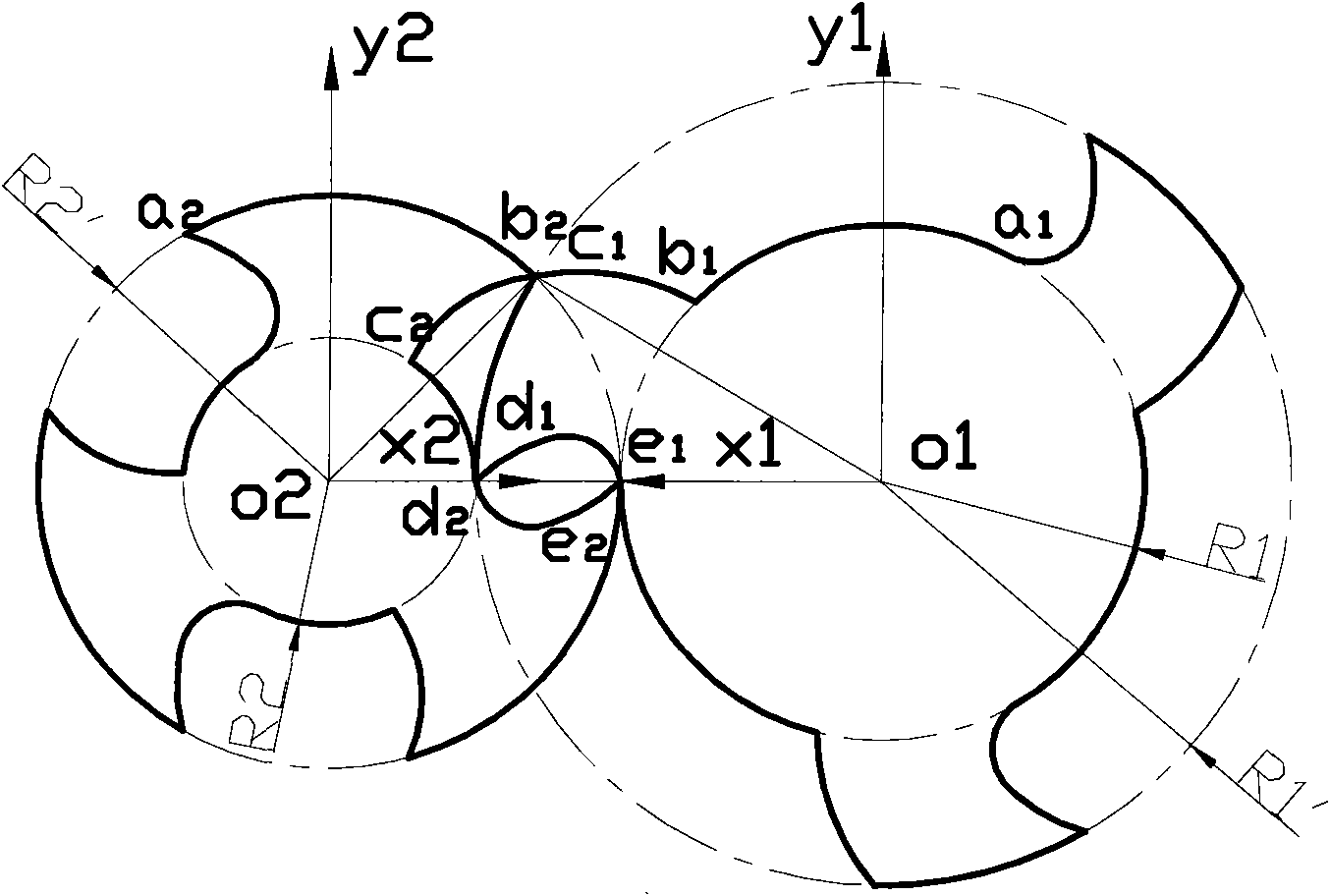

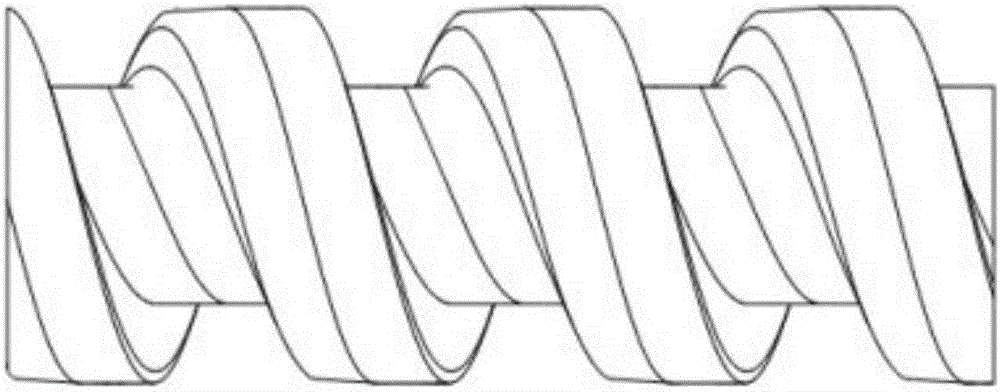

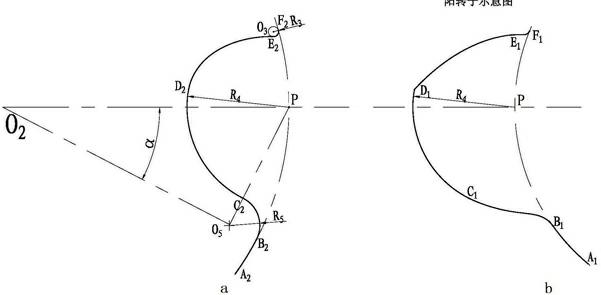

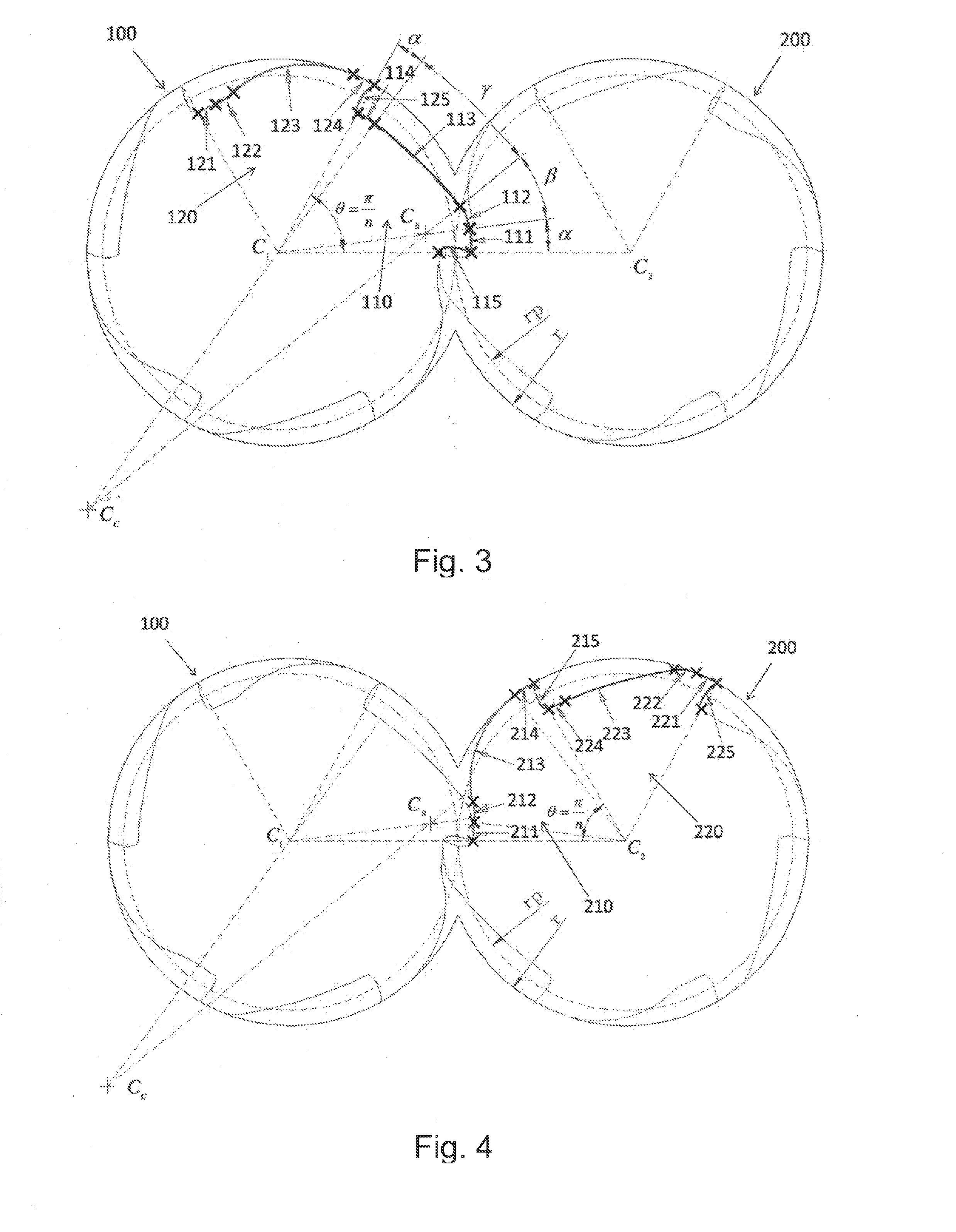

Tooth profile of a twin-screw compressor rotor

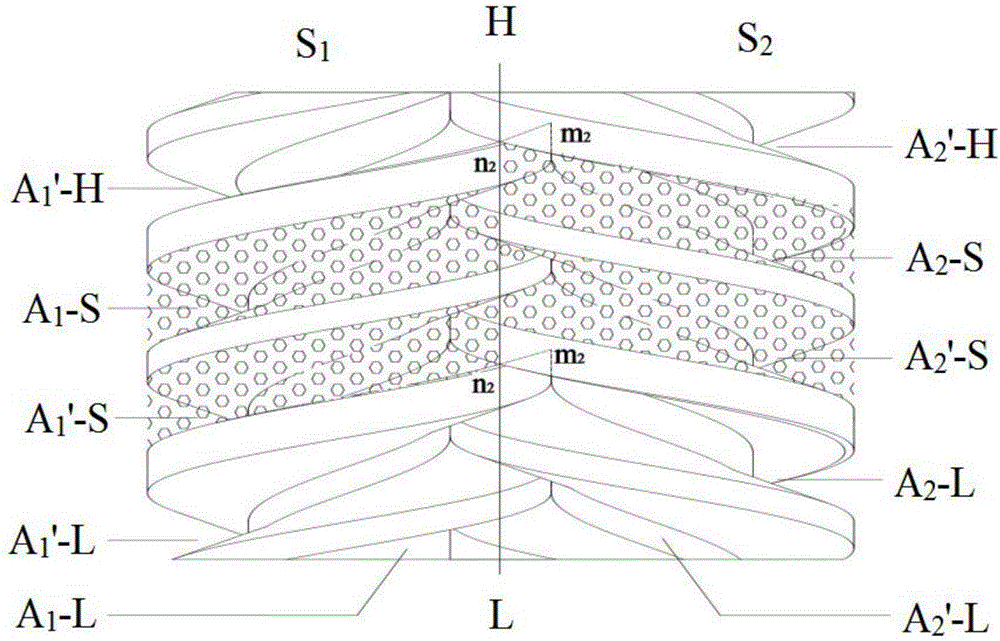

ActiveCN102287374AGood technical effectIncrease stiffnessRotary piston pumpsRotary piston liquid enginesRefrigeration compressorDifferential pressure

The invention discloses a tooth form of a twin-screw compressor rotor. The tooth form is characterized in that each tooth form of end faces of a female rotor and a male rotor is formed by smoothly connecting five sections of a quadratic curve, wherein a tooth curve of the end face of the female rotor comprises a circular arc line and an epicycloid; a tooth curve of the end face of the male rotor comprises a circular arc line, an epicycloid and a circular arc envelope curve. The five tooth curves of each tooth of the female rotor comprises a circular arc A2B2, a circular arc B2C2, a pin tooth circular arc C2D2, an epicycloid c D2E2 and a circular arc E2F2, which are smoothly connected; and the five tooth curves of each tooth of the male rotor comprises a circular arc A1B1, a circular arc B1C1, a pin tooth circular arc C1D1, an epicycloid D1E1 and a circular arc E1F1, which are smoothly connected. The tooth form of the twin-screw compressor rotor disclosed by the invention can ensure that rotors with the same size and rotation speed have a larger flow intertooth area coefficient and a relatively shorter contact line, thus the manufactured compressor has good axial sealing performance and high efficiency. The tooth form of the twin-screw compressor rotor disclosed by the invention is applicable to locations, such as process screw compressors with high differential pressure, mini-sized refrigeration compressors and the like.

Owner:SHANGHAI QIYAO SCREW MACHINERY

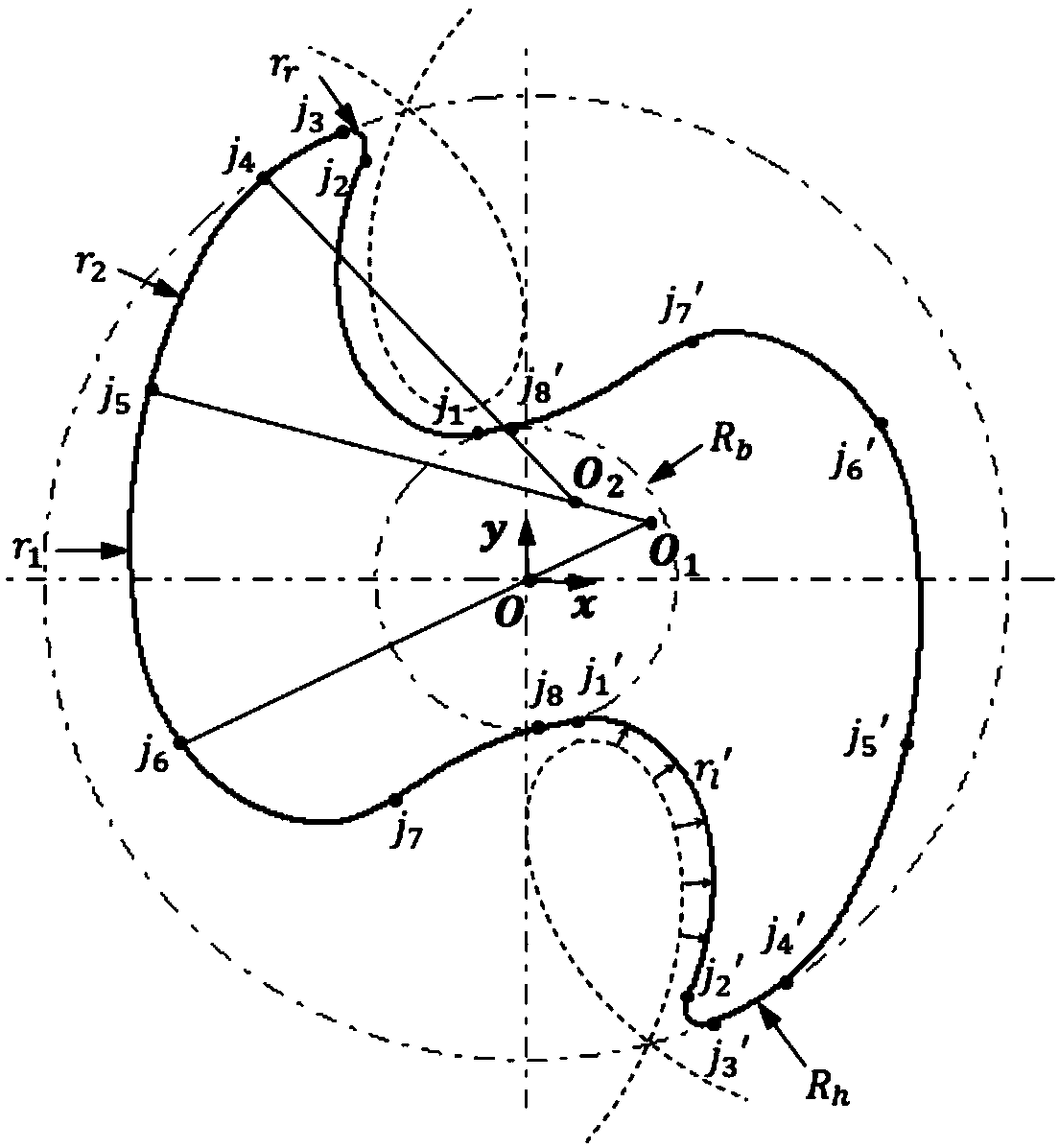

Strict sealing type double-tooth double-screw-rod vacuum pump rotor molded line

ActiveCN107882735AAvoid mismatchesImprove balanceRotary piston pumpsRotary piston liquid enginesDynamic balanceDouble teeth

The invention provides a strict sealing type double-tooth double-screw-rod vacuum pump rotor molded line. One of rotors comprises a first addendum circular-arc segment ab, a first involute segment bc,a first point engaging epicycloid segment cd, a first dedendum circular-arc segment de, a second point engaging epicycloid segment ef, a second involute segment fg, a second addendum circular-arc segment gh, a third involute segment hi, a third point engaging epicycloid segment ij, a second dedendum circular-arc segment jk and a fourth point engaging epicycloid segment ka which are all sequentially connected end to end, and the other rotor has the same structure. In the rotating process, the molded lines are continuous everywhere, one to more engaging points exist under each corner, power consumption is reduced, and the limit vacuum degree is improved. A double-screw-rod vacuum pump adopts the molded line and can make dynamic balance performance of the female rotor and the male rotor be improved, no leakage triangle occurs in the running process, and the strict sealing type double-tooth double-screw-rod vacuum pump rotor molded line has the advantages that vulnerable parts are less, the structure is compact, the pumping rate is high, no surge occurs, and vibration noise is low.

Owner:NINGBO BAOSI ENERGY EQUIP

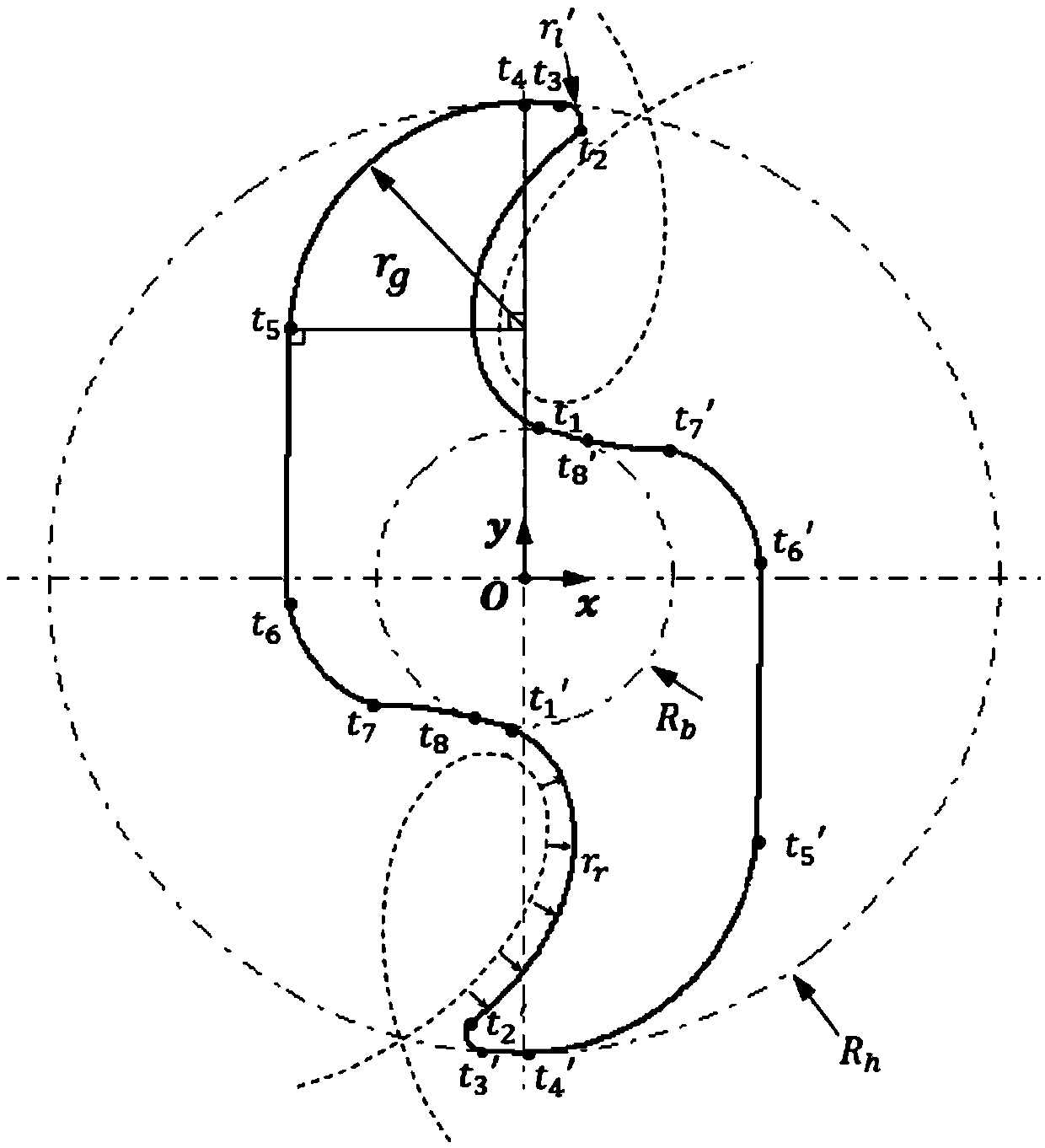

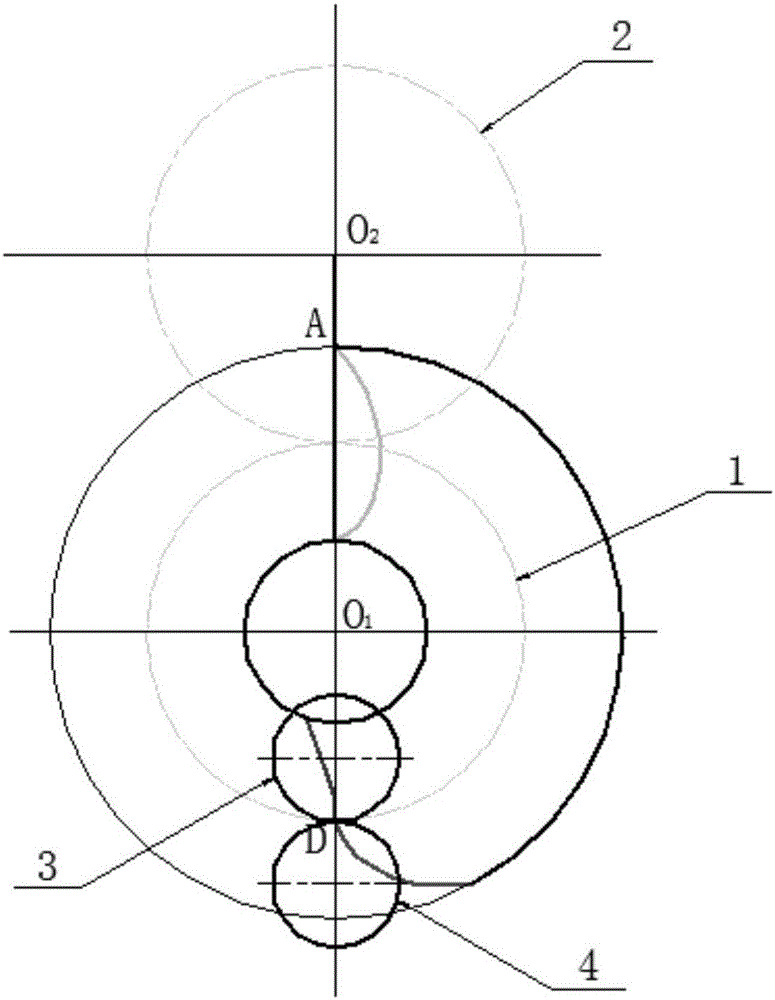

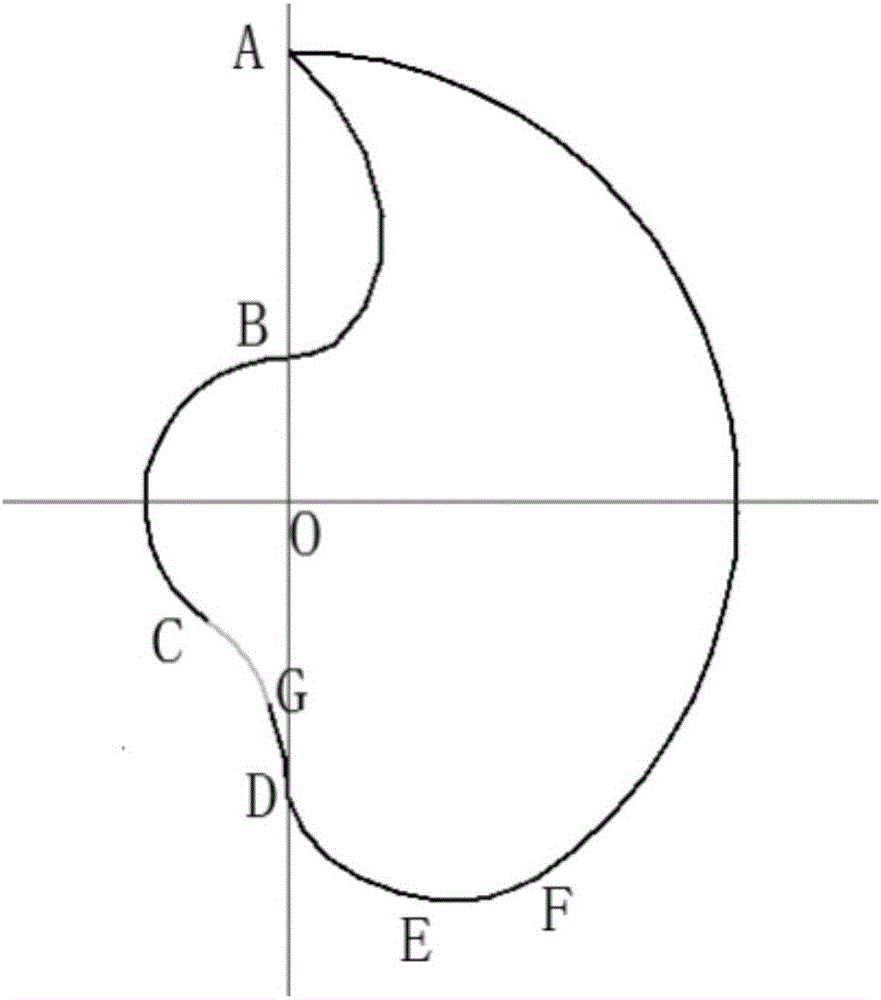

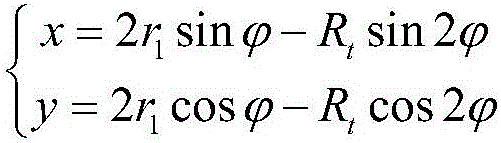

Screw vacuum pump rotor profile

ActiveCN106401958AImprove volumetric efficiencyImprove area utilization factorRotary piston pumpsRotary piston liquid enginesHigh pressureVacuum pump

The invention discloses a screw vacuum pump rotor profile. The screw vacuum pump rotor profile comprises a prolate epicycloid AB, a root circle BC with radius of Rr, a transition arc CG with radius of r1-Rr, a hypocycloid GD, an epicycloids DE, a transition arc EF with radius of Rt-r1, and an addendum circle FA with radius of Rt. Compared with the prior art, the screw vacuum pump rotor profile is novel conjugated rotor profile; two rotors are totally identical, and are both single-head asymmetric teeth; screw rotors are driven by synchronous gears to correct engage; and in synchronous rotation, any position and rotating angle cannot generate inter-tooth interference to own a complete engagement curve. Meanwhile, the rotors with the profile effectively transfer the torque, and solve leakage of gas from higher-pressure inter-tooth volume to lower-pressure adjacent inter-tooth volume caused by leakage triangle, so that a pump is higher in volume efficiency; and compared with other rotor molded lines, the screw vacuum pump rotor profile is higher in area utilization coefficient and low in machining and detecting costs.

Owner:HEFEI UNIV OF TECH +1

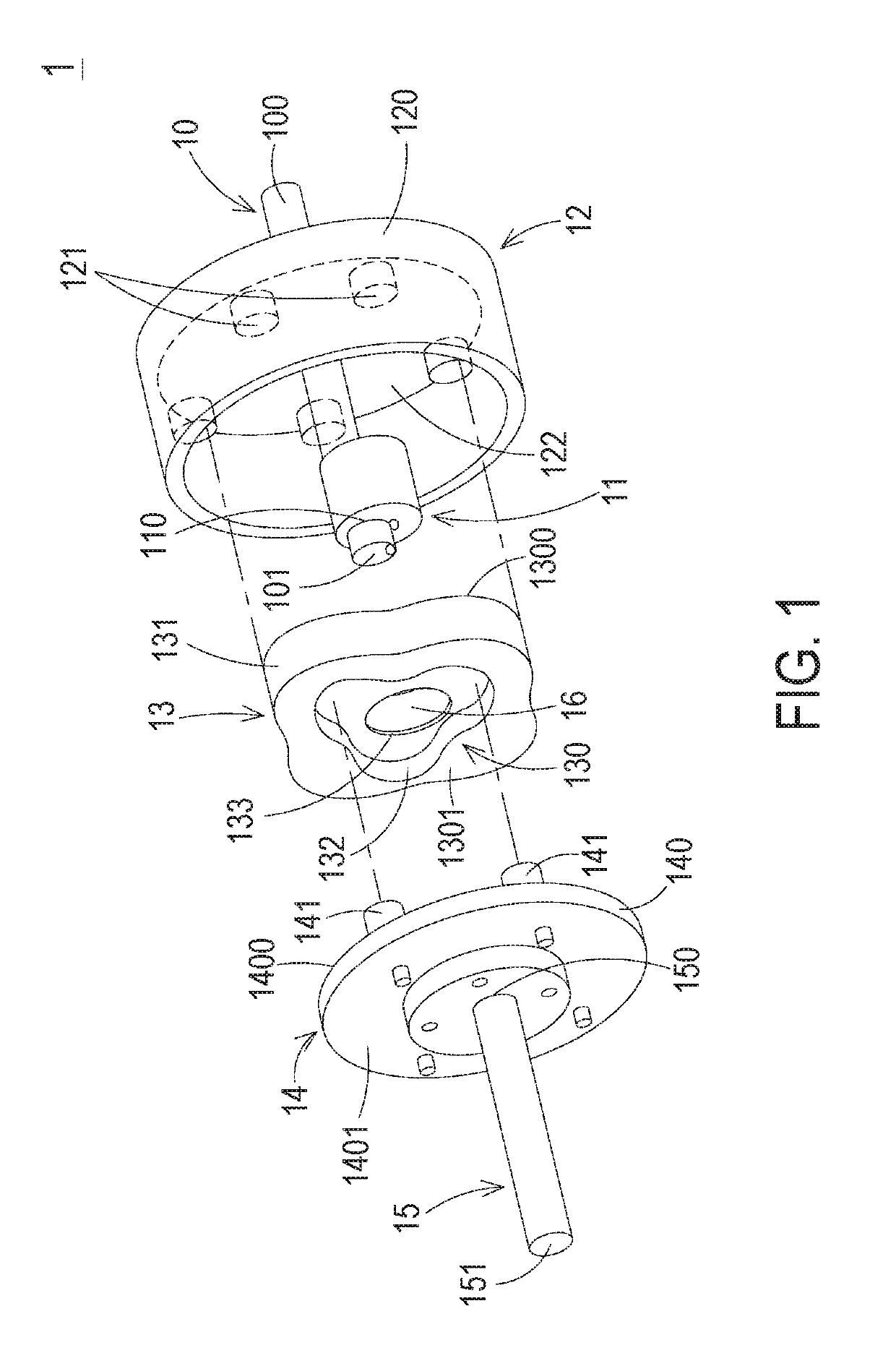

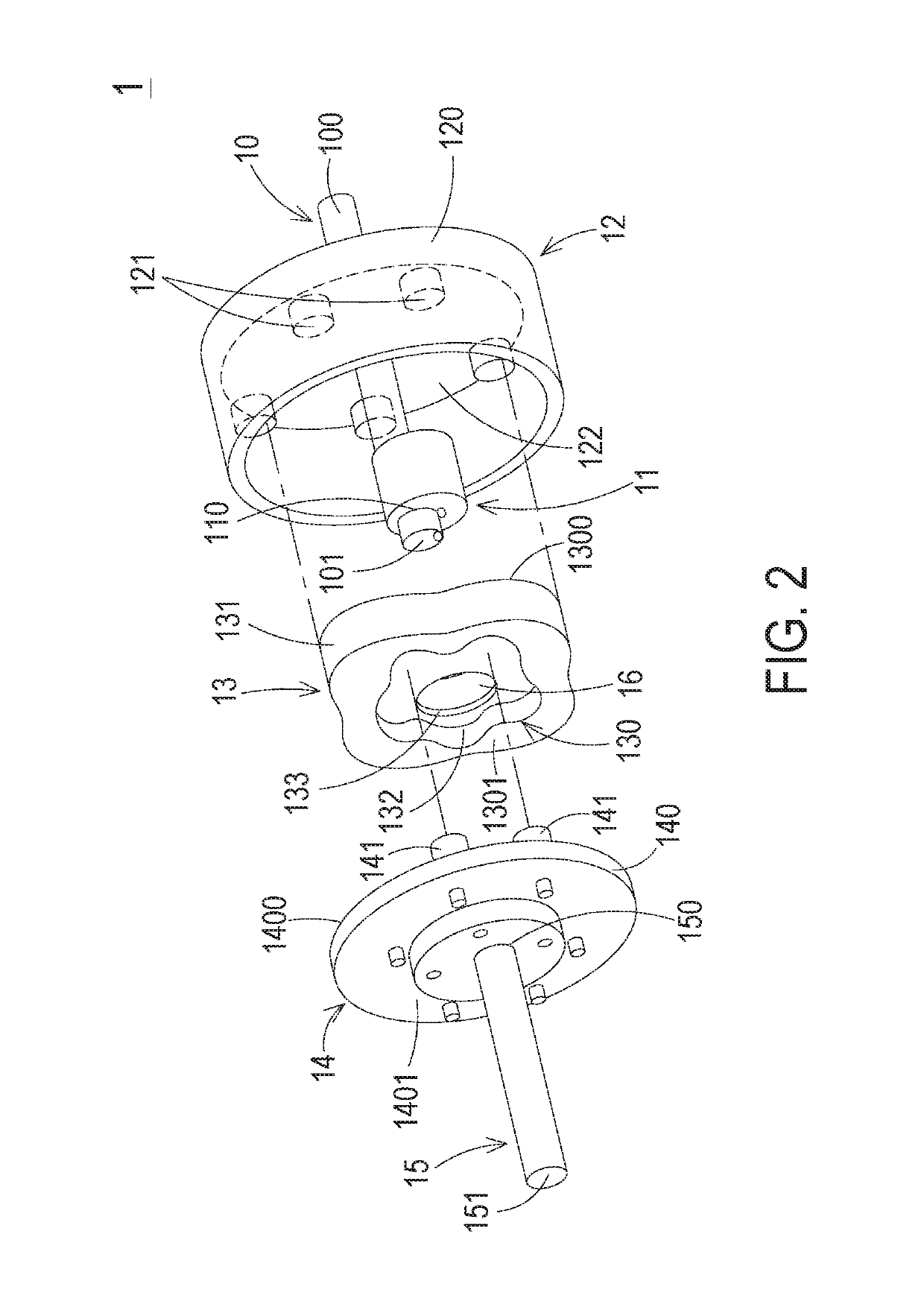

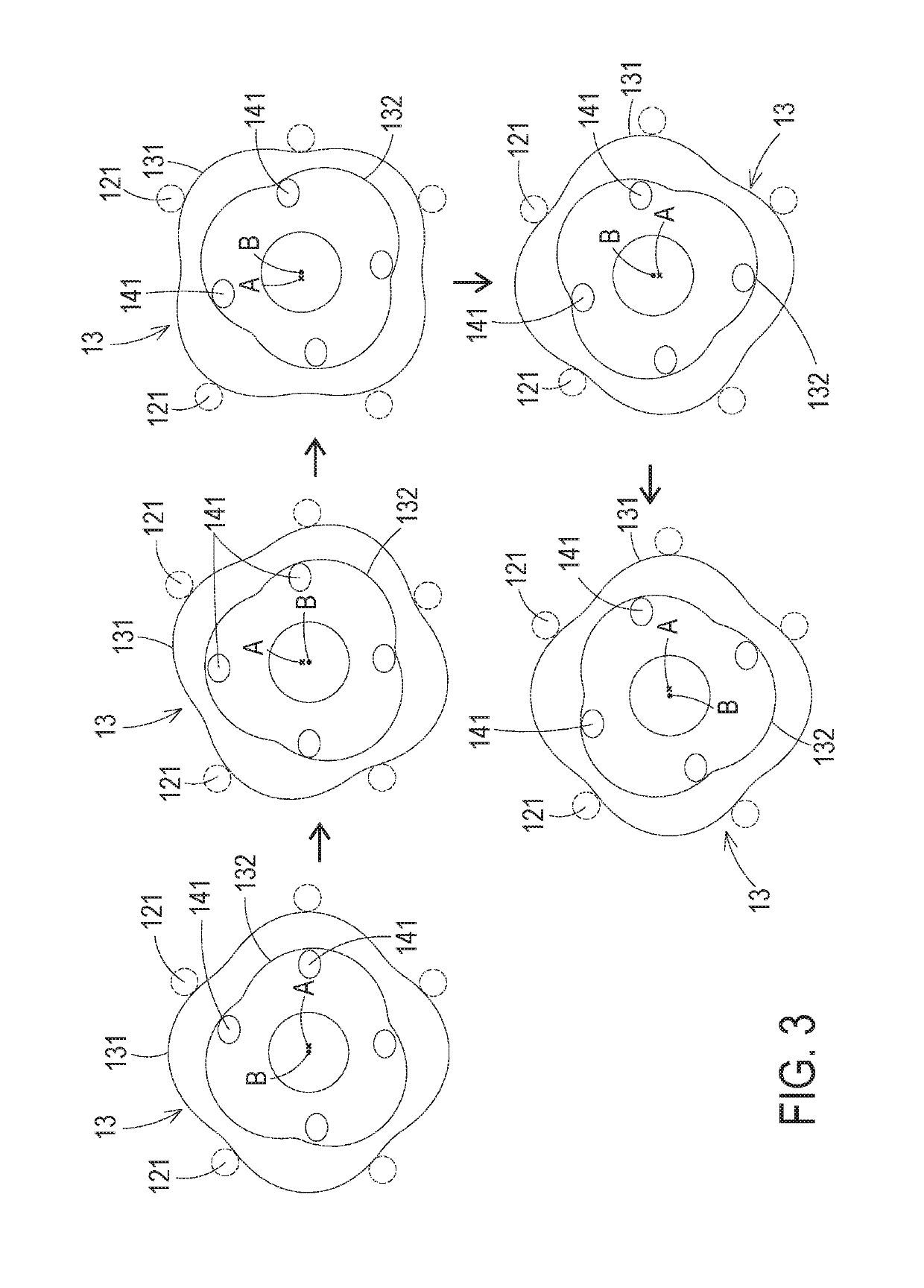

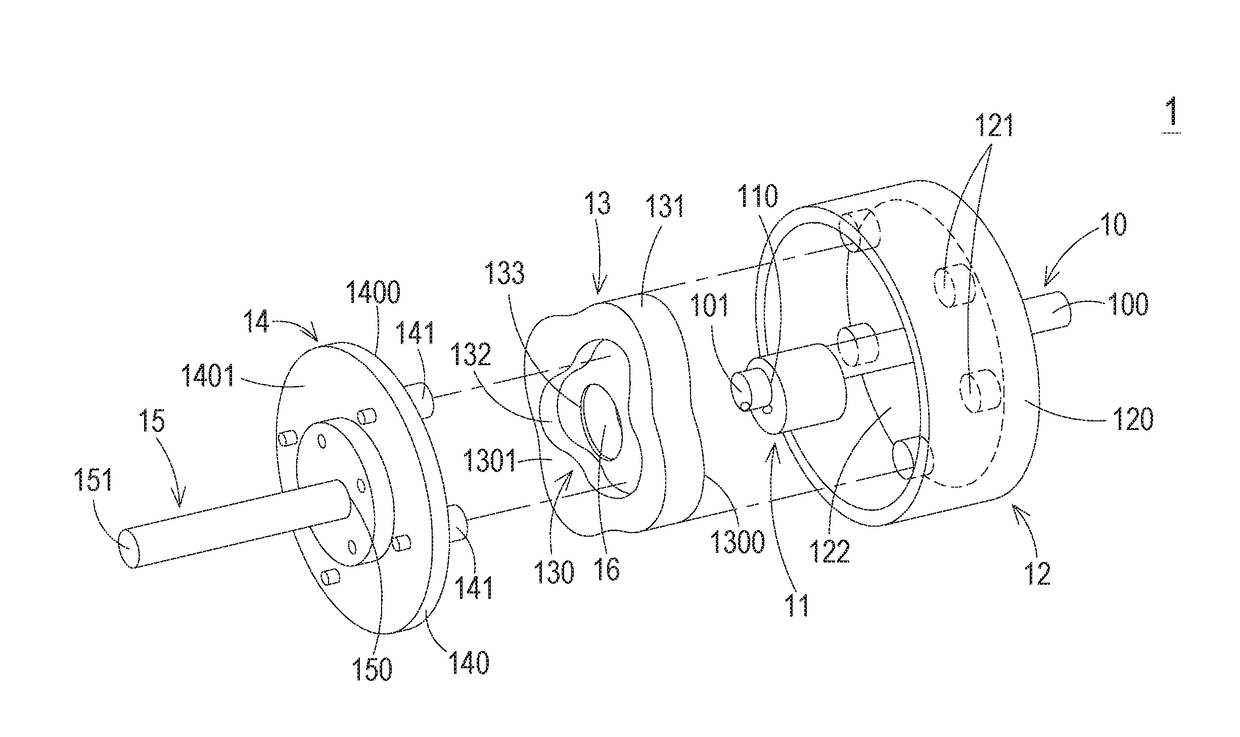

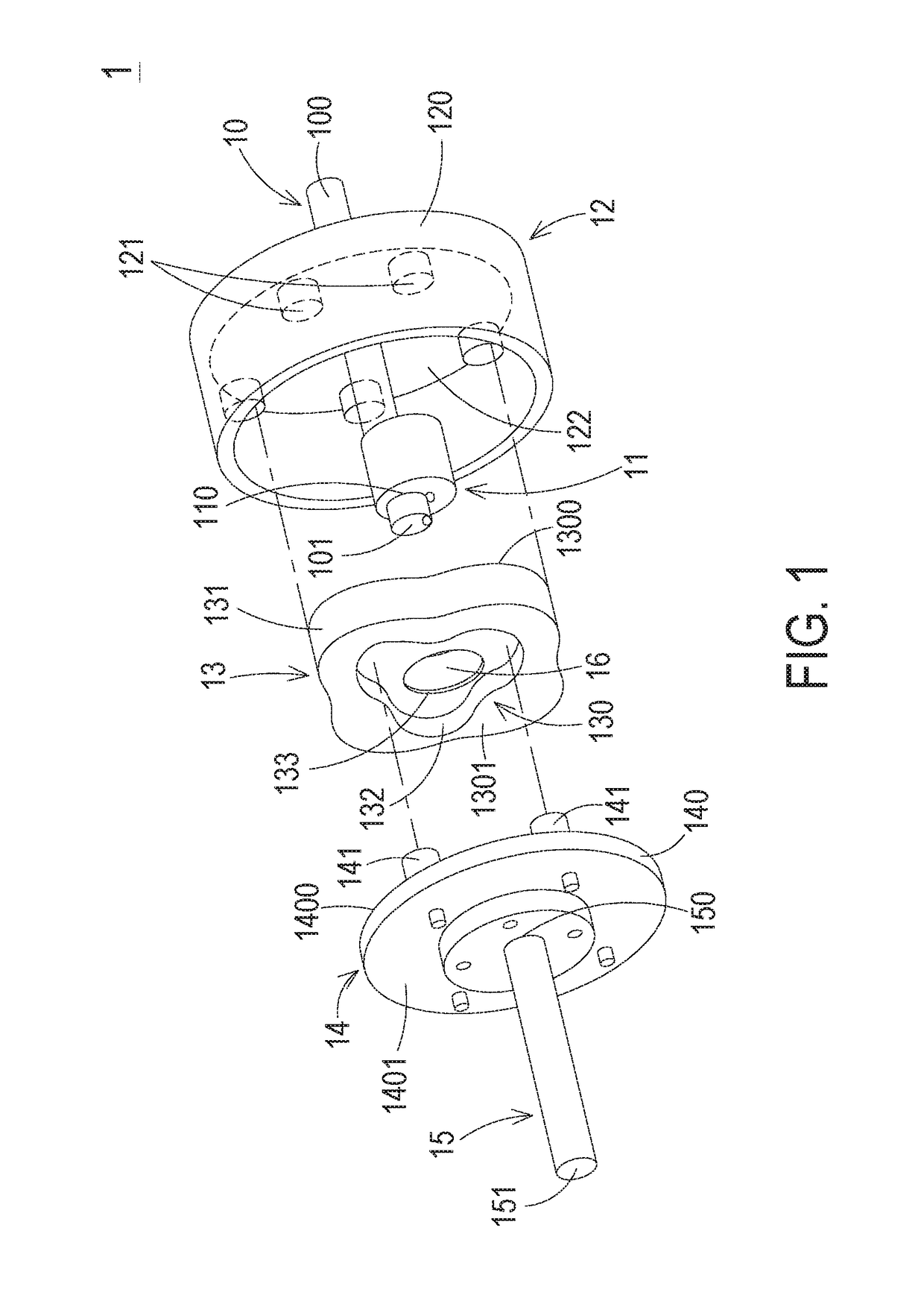

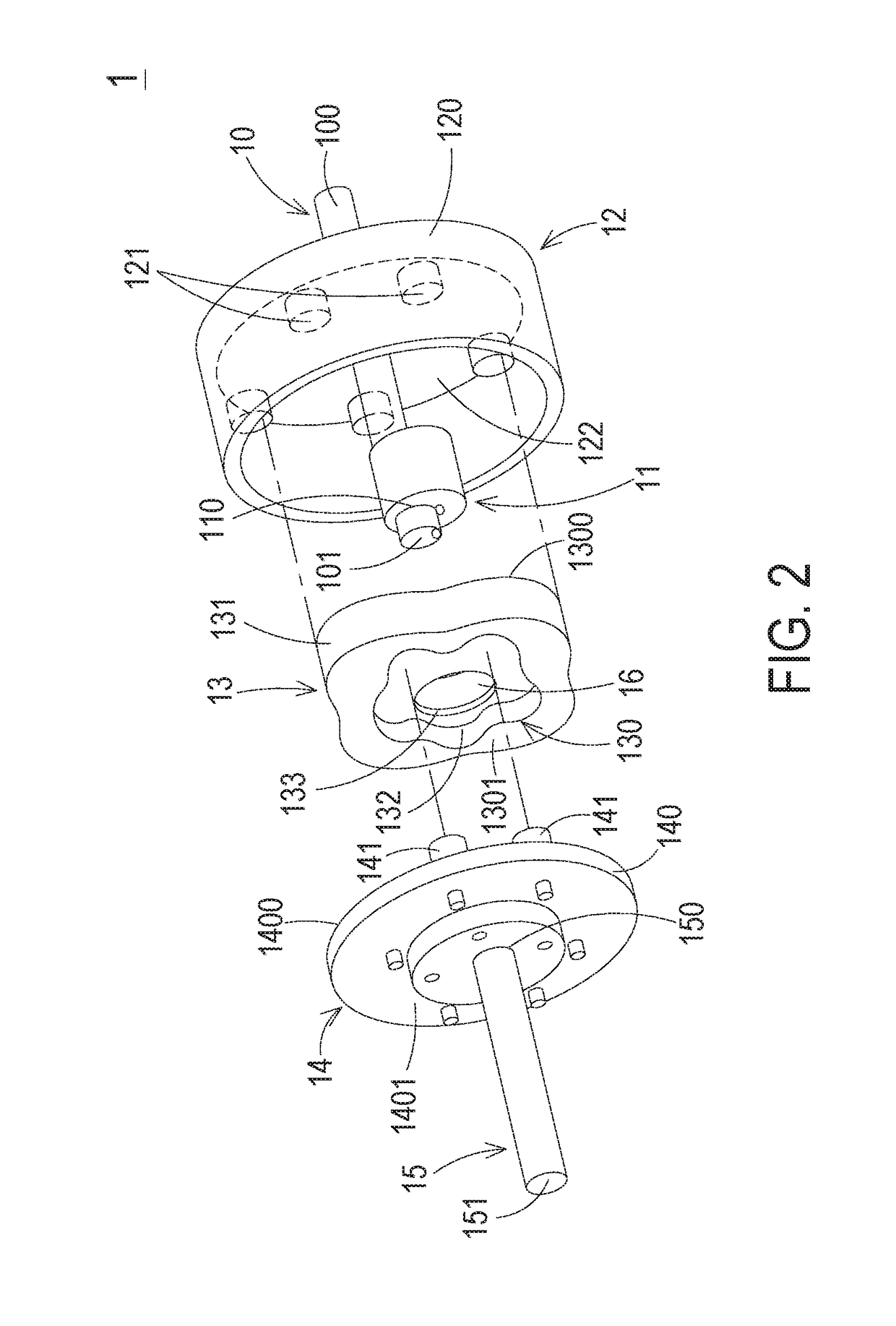

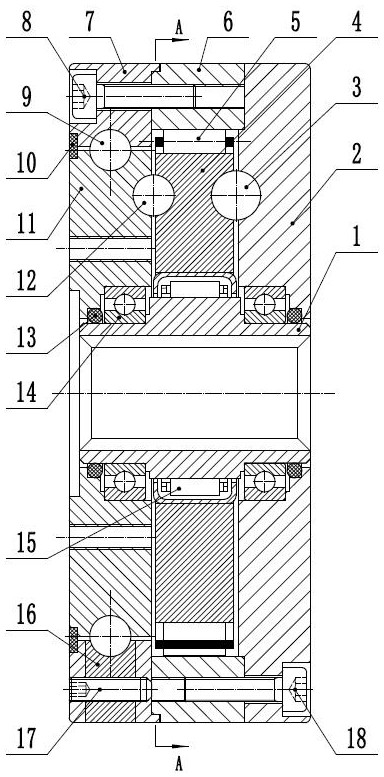

Speed reducer

ActiveUS10422414B2Meet high volumeHigh weightToothed gearingsControl devicesConvex structureDrive shaft

A speed reducer includes a first transmission shaft, an eccentric wheel, a first roller assembly, a rotating wheel, a second roller assembly and a second transmission shaft. The rotating wheel includes a main body and an axle hole. The main body includes a convex structure and a concave structure. The convex structure is protruded from an outer periphery of the main body and has outer teeth. The outer teeth are contacted with the corresponding first rollers. The concave structure is concavely formed in a surface of the main body and includes inner teeth. The inner teeth are contacted with plural second rollers of the second roller assembly. The speed reducer of the present invention is an epicycloid-epicycloid speed reducer or a hypocycloid-hypocycloid speed reducer. Since the speed reducer is designed to have four operating situations, the speed reducer can have various reduction ratios.

Owner:DELTA ELECTRONICS INC

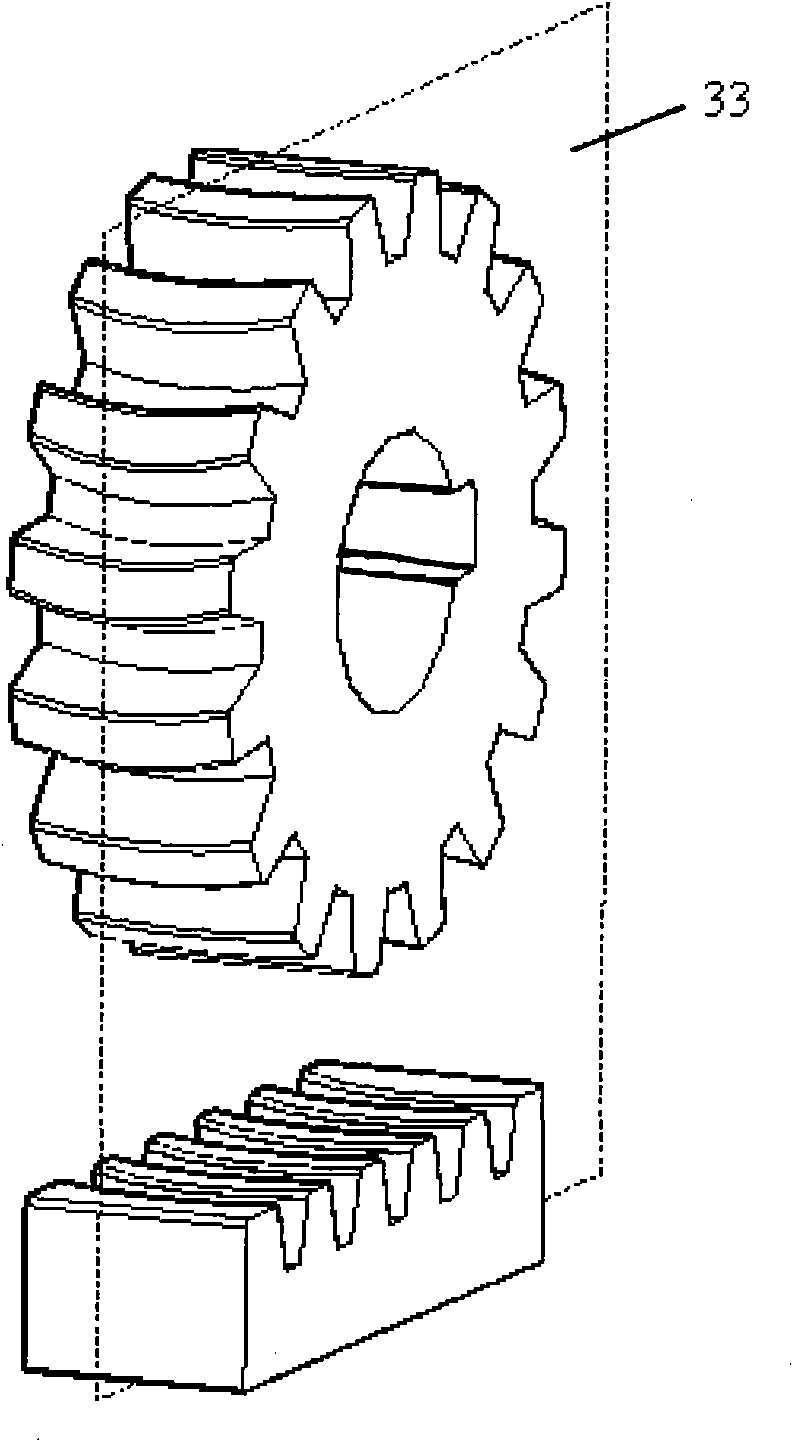

Rack with tooth trace shape of epicycloid

InactiveCN101832384AReduce meshing shockHigh coincidencePortable liftingGearing elementsInvolute gearAxial force

The invention discloses a rack with a tooth trace shape of an epicycloid. Intersection lines of wheel teeth of the rack with a dividing plane, a tooth root plane and a tooth top plane are all prolate epicycloids; intersection lines of wheel teeth of a cylinder gear which is meshed with the rack with a dividing cylinder plane, a tooth root cylinder plane and a tooth top cylinder plane are also prolate epicycloids; in a central section of a tooth width direction, a toothed curve of the rack is a straight line; a toothed curve of the cylinder gear meshed with the rack is an involute; in the central section of the tooth width direction, the meshing of the rack with the matched cylinder gear is equivalent to the meshing of a traditional involute gear with the rack; therefore, the rack has constant transmission rate. In other sections parallel to the central section, the rack mutually corresponds to tooth outlines of the matched cylinder gear in a convex-concave mode; because of small comprehensive curvature and large comprehensive curvature radius among contact planes, the rack has large coincidence degree, stable transmission, high carrying capability and long service life. The rack has the advantages of overcoming the defects of small coincidence degree, large meshing impact and the like of a traditional rack with straight tooth lines, and solving the problem of axial force in the meshing of a rack with oblique tooth lines and the gear. The rack is suitable for high-speed overloaded transmission occasions, can be used as an up-to-date product of a traditional rack with straight teeth and a rack with oblique teeth, and has high popularization value.

Owner:CHANGZHOU UNIV

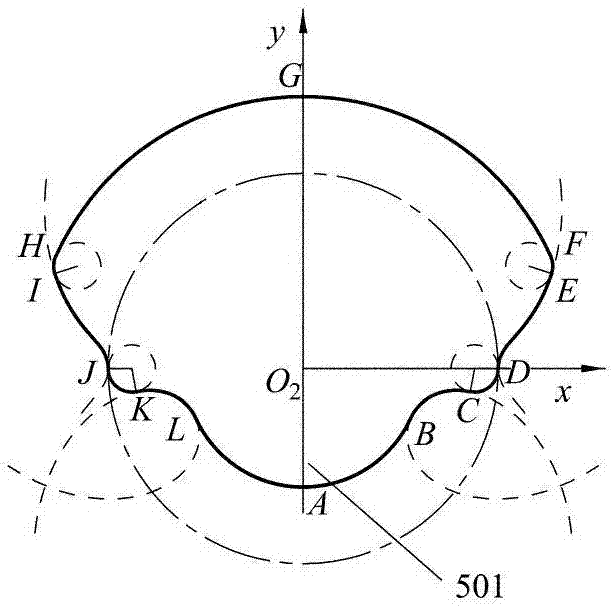

All-smooth screw rotor of double-screw liquid pump

InactiveCN107023480AImprove the force characteristicsImprove wear lifeRotary piston pumpsRotary piston liquid enginesMechanical engineeringEpicycloid

The invention discloses an all-smooth screw rotor of a double-screw liquid pump. The all-smooth screw rotor of the double-screw liquid pump is characterized in that a left end surface molded line (501) comprises six circular arc sections, equidistant lines of two prolate epicycloid sections, and equidistant lines of two epicycloid sections, namely, a tooth root circular arc LAB, an equidistant line BC of a first prolate epicycloid, a first transition circular arc CD, an equidistant line DE of a first epicycloid, a first circular arc EF, a tooth top circular arc FGH, a second circular arc HI, an equidistant line IJ of a second prolate epicycloid, a second transition circular arc JK, and an equidistant line KL of a second prolate epicycloid, which are anticlockwise arranged; adjacent curves in the left end surface molded line (501) are in smooth connection, so that unsmooth connecting points are avoided, and an all-smooth end surface molded line is formed; the left end surface molded line (501) is completely the same as a right end surface molded line (502) and can be accurately engaged with the right end surface molded line (502) during the synchronous different-direction double-gyring movement, thus obtaining the all-smooth screw rotor.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Single-stage densely-arranged combined tooth surface cycloid oscillating tooth transmission unit

InactiveCN111237398AFlexible designAccurate and continuous transmission processPortable liftingToothed gearingsEngineeringMechanical engineering

The invention provides a single-stage densely-arranged combined tooth surface cycloid oscillating tooth transmission unit which comprises oscillating teeth, a combined tooth surface transmission wheel, a combined groove surface transmission wheel and the like. On the basis of cycloid oscillating tooth transmission, the radius of the oscillating tooth distribution circle is firstly confirmed, and under the condition that the radius of the oscillating tooth distribution circle is definite, the size of oscillating teeth capable of densely arranged on the distribution circle by a whole circle is unique and definite; then, a roller way with a large roller way amplitude is selected, the engagement curve of the roller way meets the undercut condition, on the basis, the oscillating tooth section is subjected to discretization into four different sections, each section is swept along the hypocycloid or the epicycloids to obtain a corresponding engaged tooth surface or spins along the edge to obtain the corresponding tooth surface, the three specific tooth surfaces are combined into a whole, and the combined tooth surface roller way is formed; a combined groove on the combined groove surfacetransmission wheel is formed by contact groove surfaces an noncontact groove surfaces of the same number; and the densely-arranged combined tooth surface cycloid oscillating tooth transmission unit is jointly formed by the combined tooth surface transmission wheel, the oscillating teeth and the combined groove surface transmission wheel.

Owner:HENAN ZHULONG HI TECH CO LTD

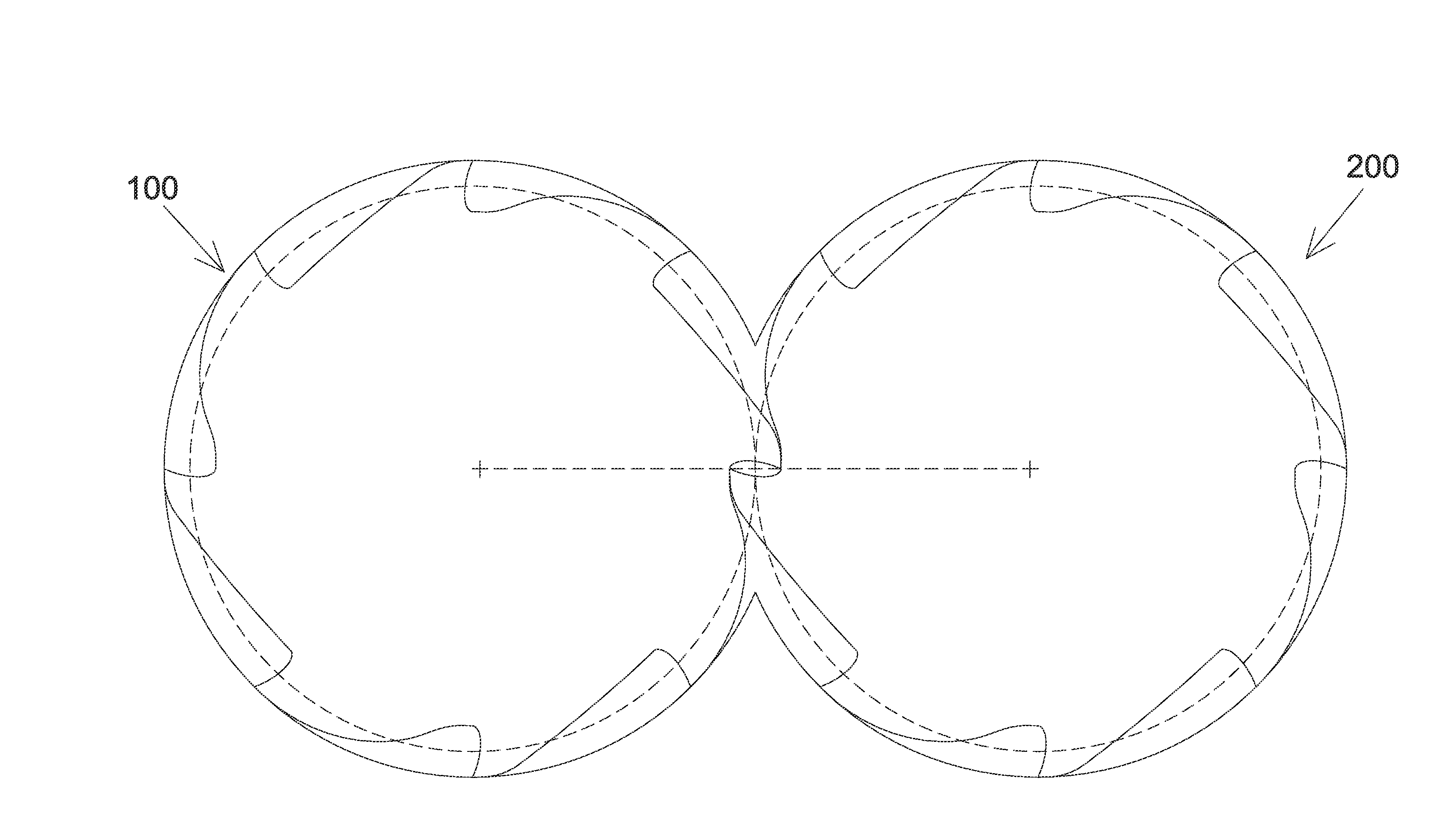

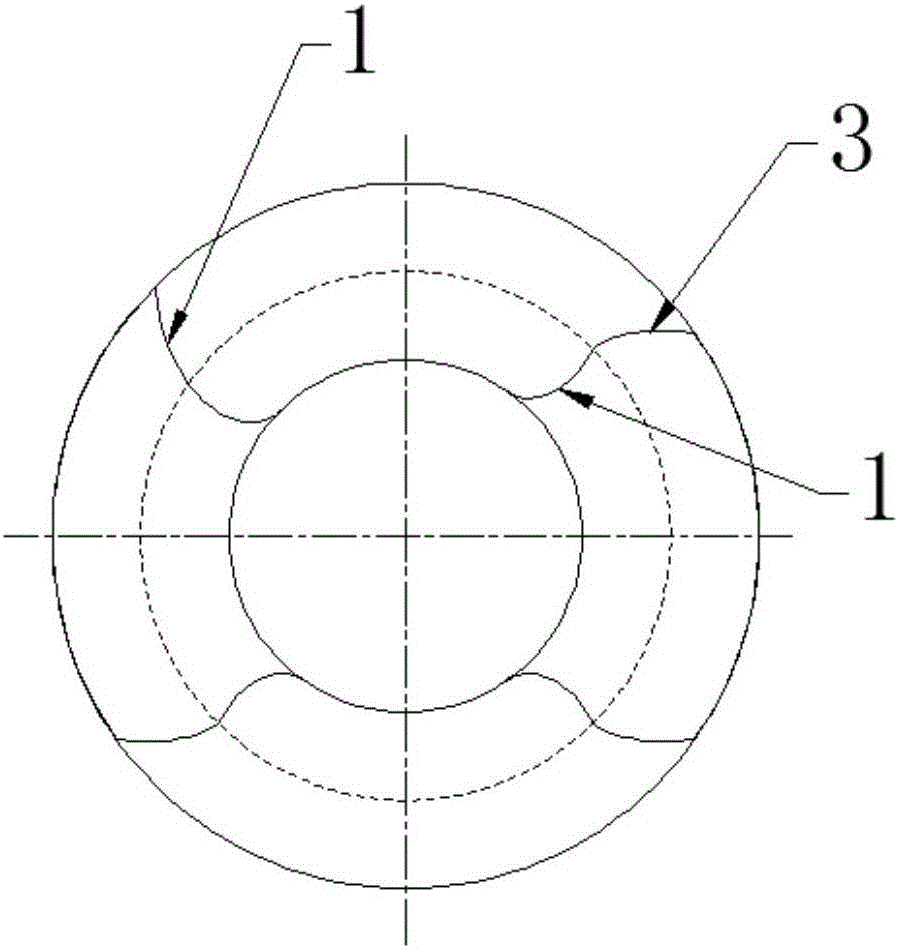

Double-wave-line ball deceleration bearing with high rotary precision

PendingCN110374991AIncrease the reduction ratioTransmission structure is stableRolling contact bearingsToothed gearingsReduction ratioEngineering

The invention discloses a double-wave-line ball deceleration bearing with high rotary precision. The bearing comprises an input shaft, wherein the input shaft comprises a first mounting part, an eccentric part and a second mounting part sequentially connected in the axial direction; a first shell is movably arranged on the periphery of the first mounting part in a sleeving manner; an annular avoiding groove is formed in the first shell; a driving disc is movably arranged on the periphery of the eccentric part in a sleeving manner and is positioned in the avoiding groove; a ball mechanism is arranged between the driving disc and the inner end face of the avoiding groove; a second shell is movably arranged on the periphery of the second mounting part in a sleeving manner; a hypocycloid groove is formed in the second shell; an epicycloid groove is formed in the driving disc; the wave number of the hypocycloid groove is greater than that of the epicycloid groove; and a plurality of first balls are distributed between the hypocycloid groove and the epicycloid groove. The invention aims to provide the double-wave-line ball deceleration bearing which can increase the reduction ratio and reduce the wear loss, is small in error and transmission ratio error, and has multiple output modes.

Owner:佛山市力普鑫精密技术有限公司

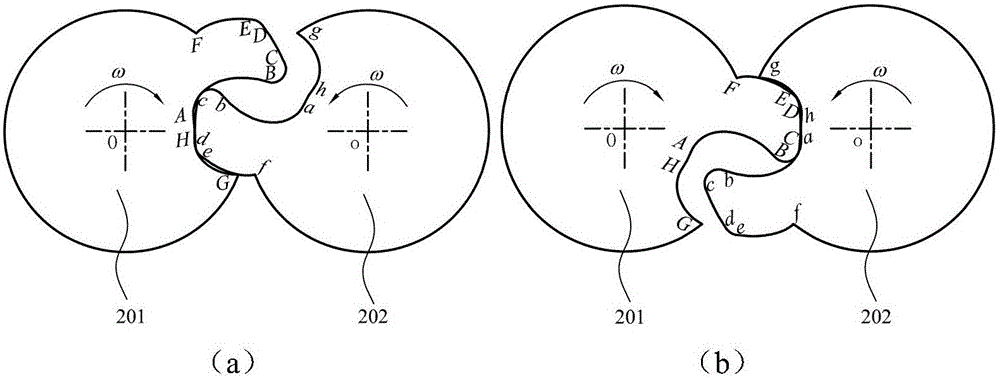

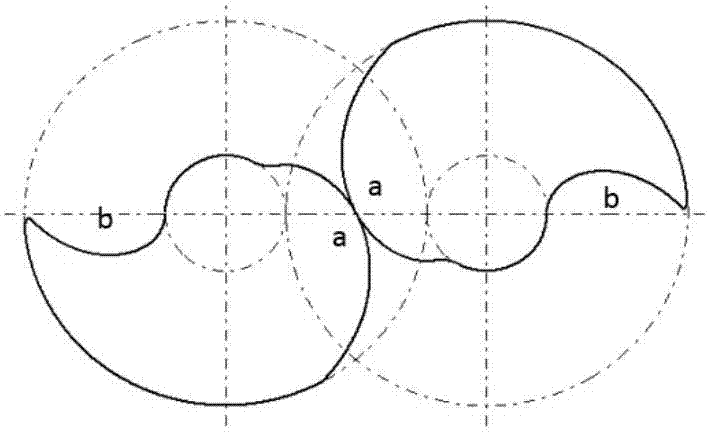

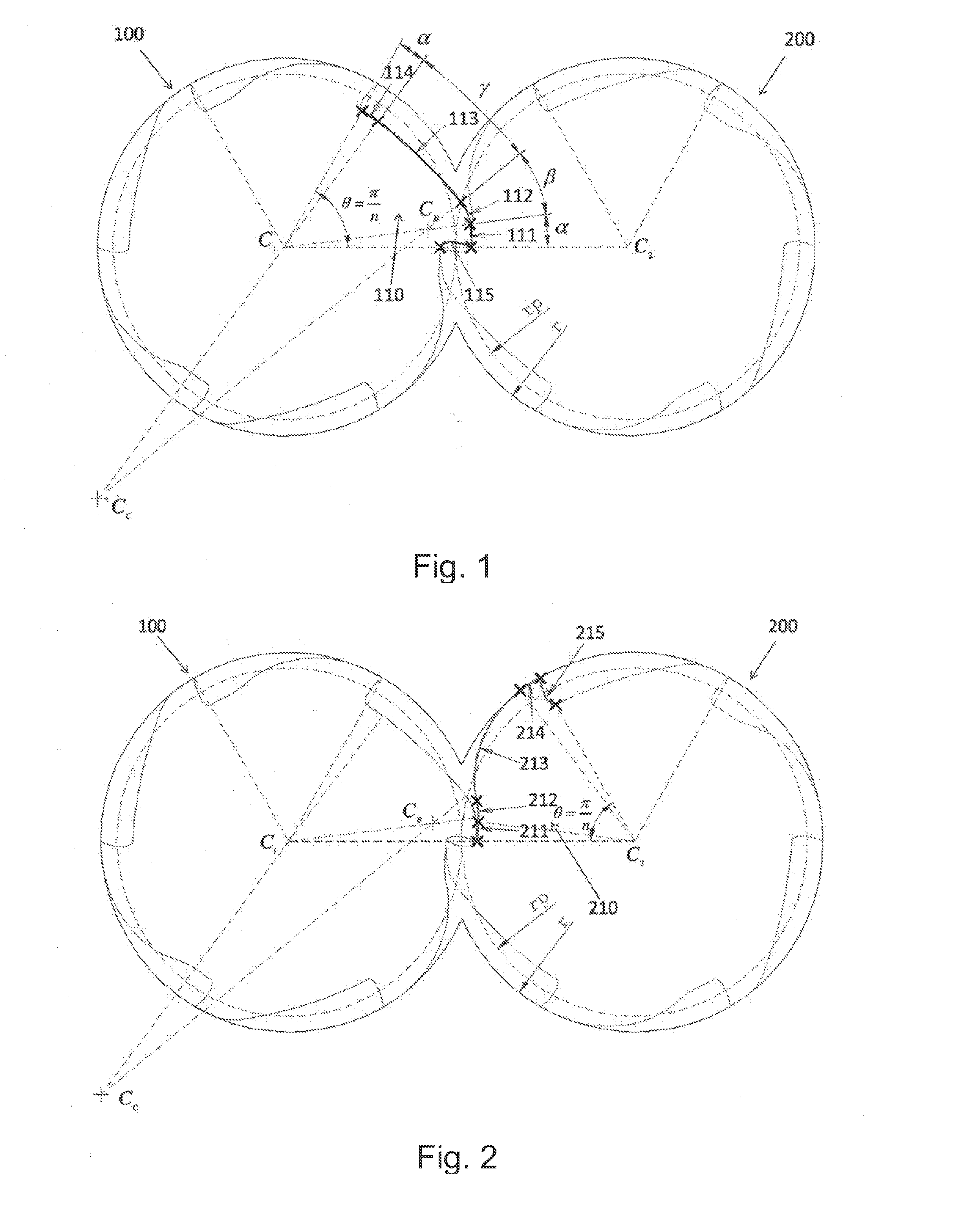

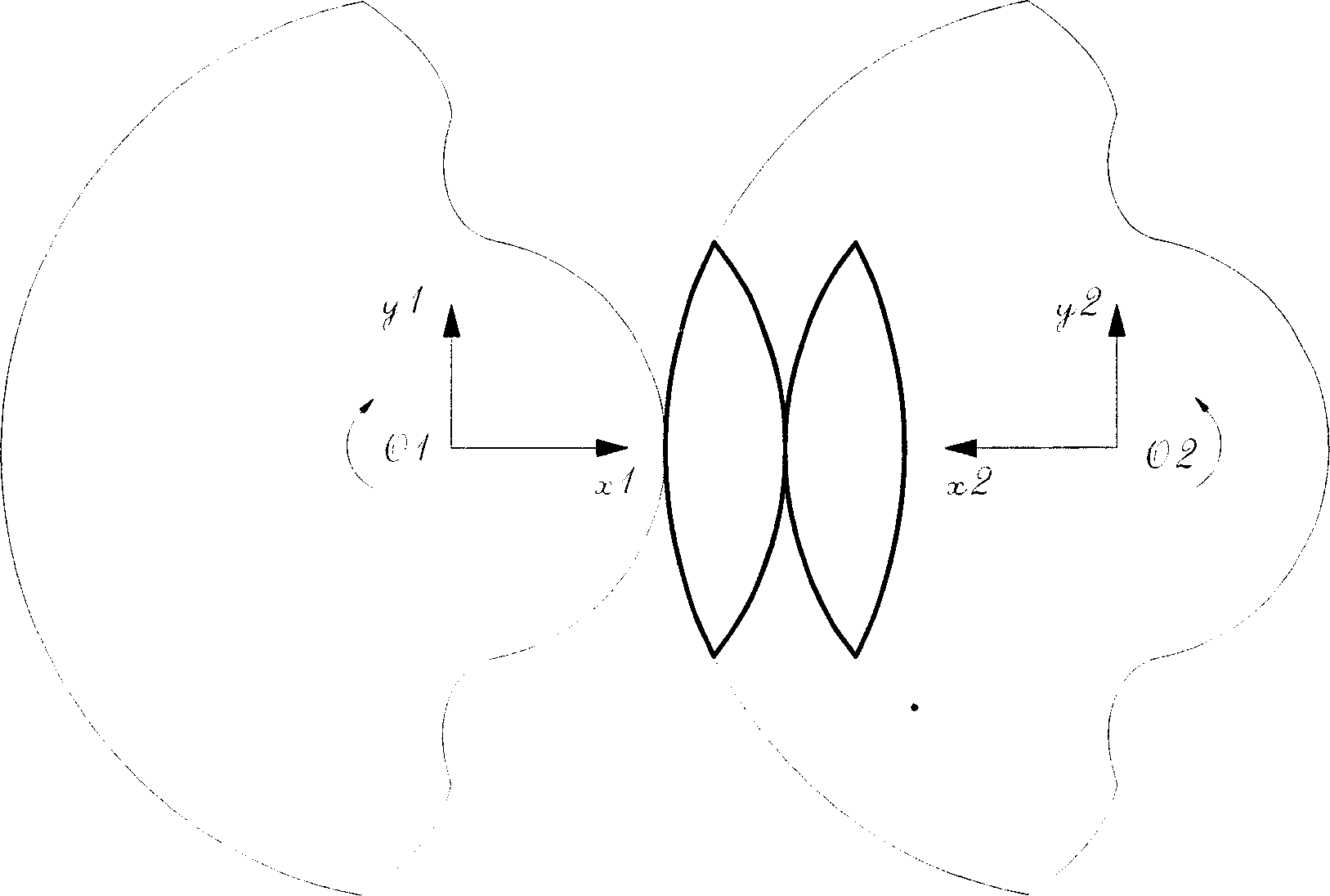

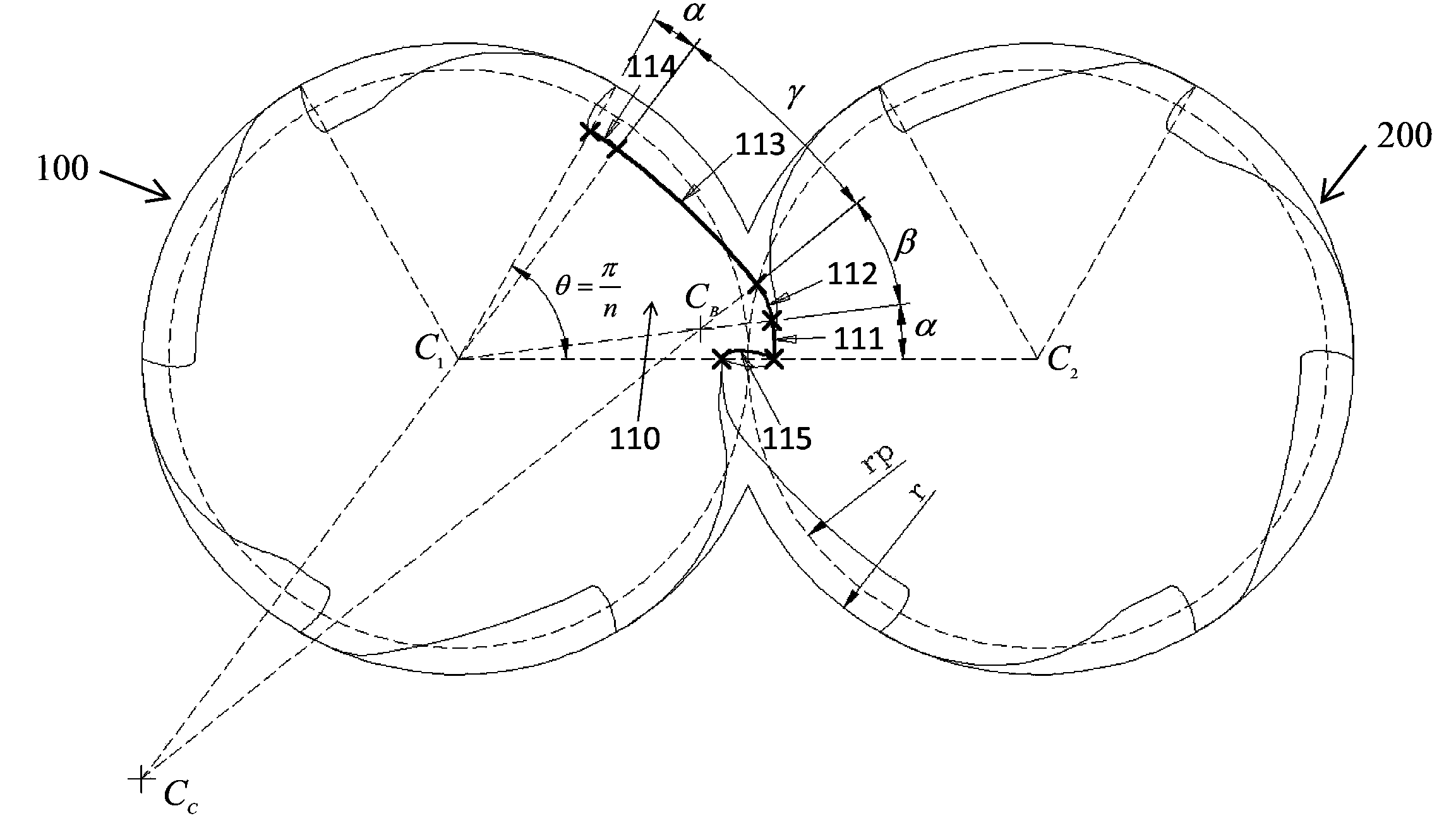

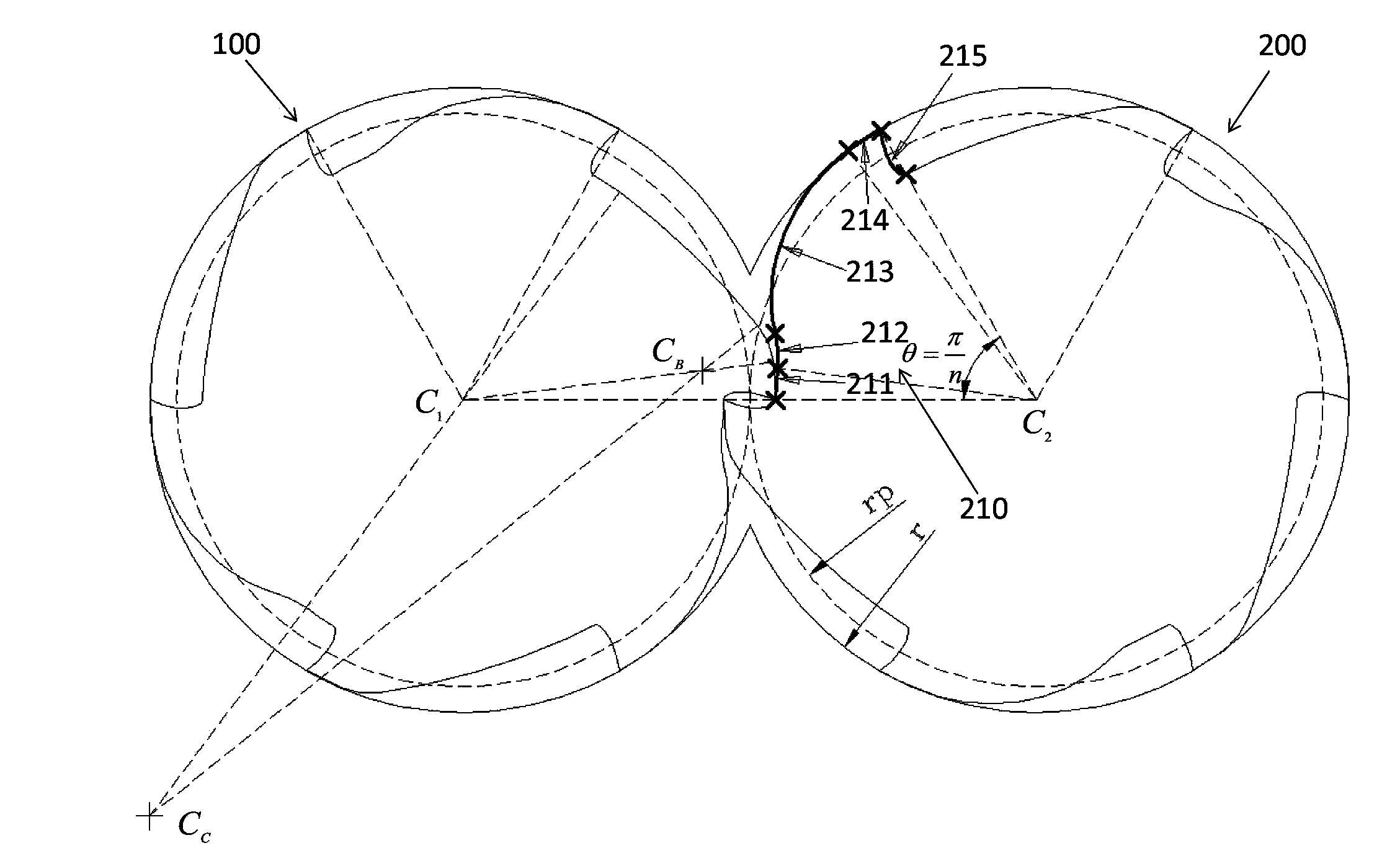

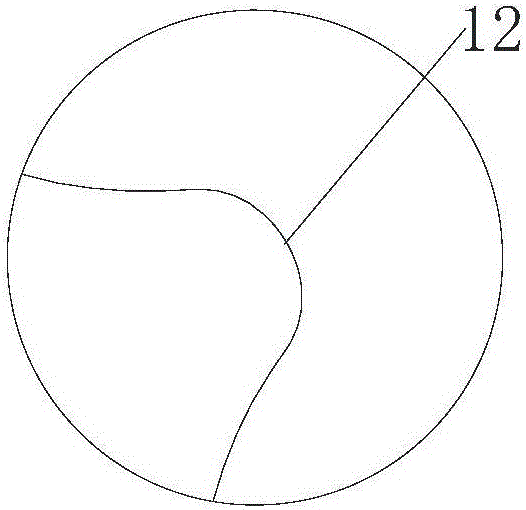

Device of a Pair of Claw-Type Rotors Having Same Profiles

ActiveUS20140102233A1Avoid noiseAvoid vibrationGearboxesToothed gearingsGeometric relationsMechanical engineering

The present invention is to provide a device of a pair of claw-type rotors having same profiles, the device includes a defined rotor and a conjugate rotor intermeshing with and conjugating to each other. The defined rotor includes a first claw having a cross-section profile having an epicycloid, a first arc, a second arc, a third arc, and a fourth arc all connected together in sequence in a counterclockwise direction. The first, second, third, and fourth arcs are connected with slope continuity, whereby locations of centers, values of radiuses and arc angles of the second and third arcs are capable of being defined in accordance with the slope continuity and geometric relations between the first and fourth arcs. The conjugate rotor has a first claw having a cross-section profile generated by utilizing a conjugate curve corresponding to the first claw of the defined rotor.

Owner:LIUNG FENG INDAL

Double screw mixed transport pump gear type

InactiveCN1900525AEasy to processImprove efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringEpicycloid

Arc-arc envelope curve and cycloid of point gearing are adopted in molded lines of tooth form of twin-screw mix transportation pump. Cycloid of point gearing and long limb epicycloids are utilized in main region of engagement, and arc-arc envelope curve is utilized in other region. Molded lines utilized in the invention are accorded with principle of engagement, and relevant curves are adopted for characteristics in different region of engagement. Thus, the molded lines of tooth form of twin-screw mix transportation pump are suitable to transporting polyphase media in higher transportation pressure, and high gas rate. Features are: easy of production and high efficiency.

Owner:XI AN JIAOTONG UNIV

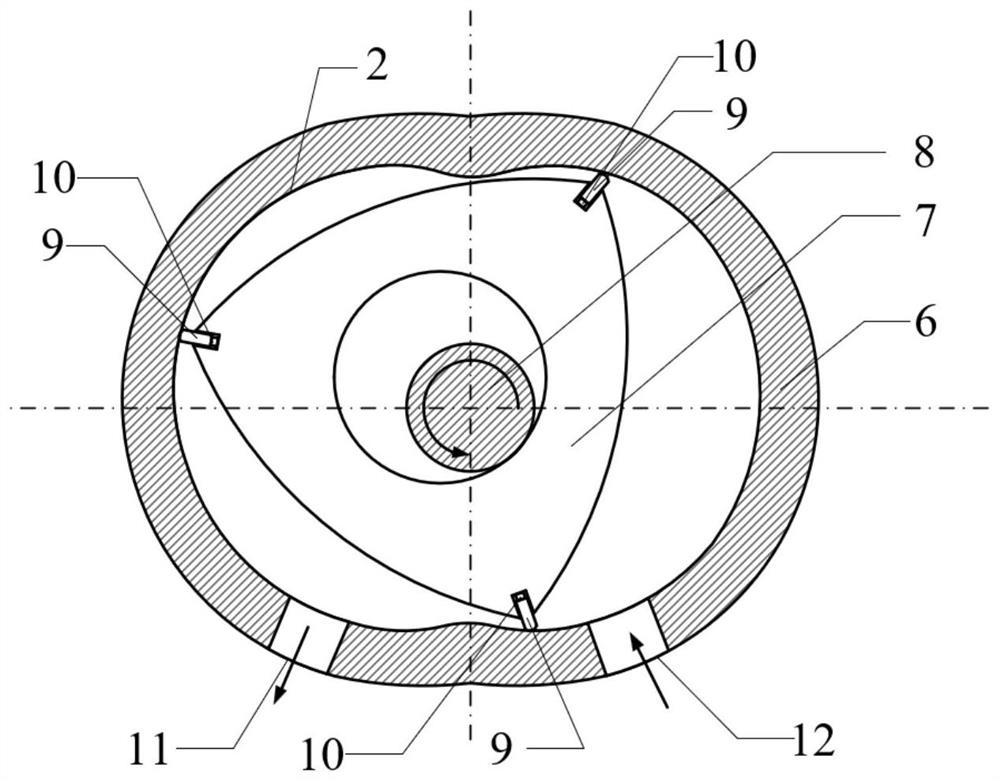

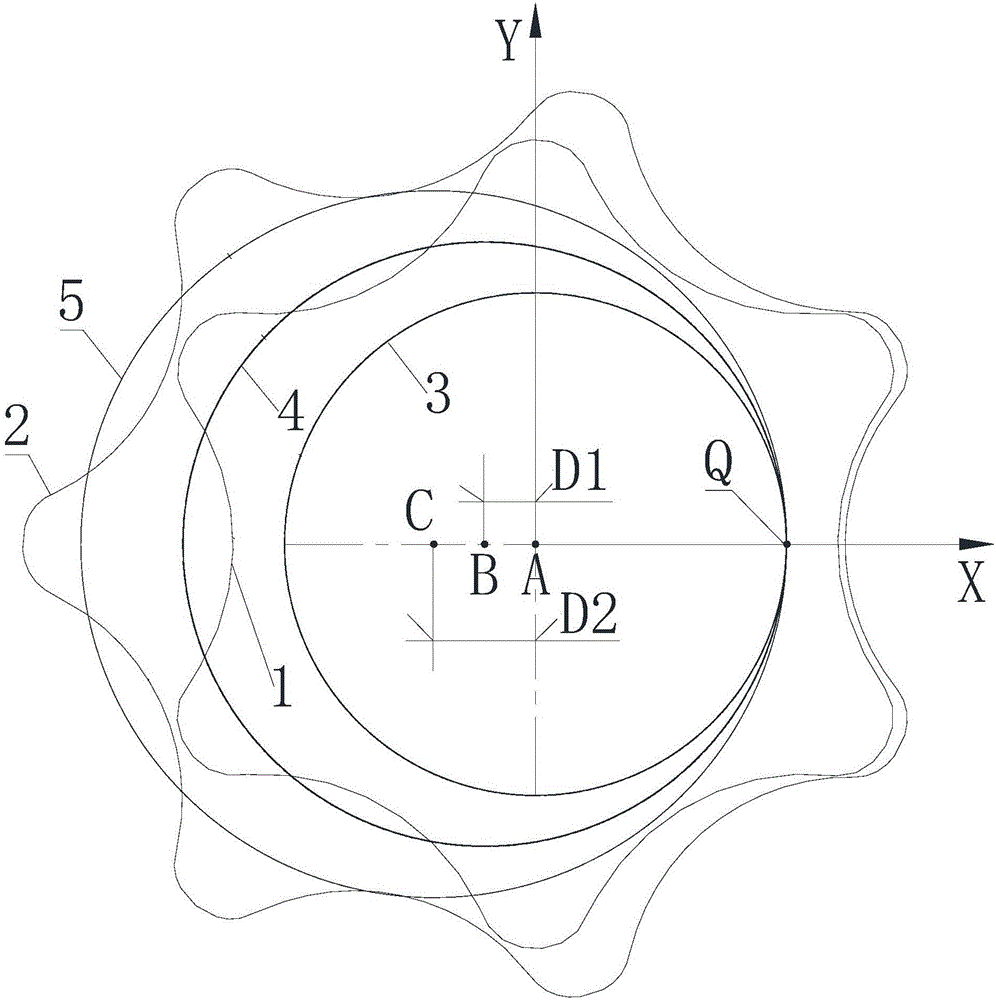

A triangular rotor engine combined cylinder molded line design method

PendingCN113836687AImprove flutterImprove sealingGeometric CADInternal combustion piston enginesCylinder moldEngineering

The invention discloses a triangular rotor engine combined cylinder molded line design method, and belongs to the field of rotor engines. The method comprises the following steps: determining three double-arc long-short-amplitude epicycloids, and establishing the three double-arc long-short-amplitude epicycloids in a Cartesian coordinate system by utilizing an eccentric distance and different generated radiuses; selecting a specified eccentric shaft rotation angle to determine three control points A, B and C; drawing inscribed circular arcs of the epicycloid at the three control points A, B and C, and connecting the three double-arc long-short epicycloid; selecting local curves of three double-arc long-short-amplitude extrochoids to be combined with four inscribed circular arcs, so that a combined type air cylinder theoretical molded line of the rotor engine can be drawn, and the combined type air cylinder theoretical molded line is deviated outwards by a certain distance to obtain a combined type air cylinder actual molded line. The influence of gas pressure on the radial sealing fin in the compression and combustion stages of the rotor engine is reduced, and the chatter condition of the radial sealing fin and the abrasion condition between the radial sealing fin and the molded surface of the air cylinder are improved; the combustion performance of the rotor engine is improved.

Owner:BEIJING UNIV OF TECH

Speed reducer

A speed reducer includes a first transmission shaft, an eccentric wheel, a first roller assembly, a rotating wheel, a second roller assembly and a second transmission shaft. The rotating wheel includes a main body and an axle hole. The main body includes a convex structure and a concave structure. The convex structure is protruded from an outer periphery of the main body and has outer teeth. The outer teeth are contacted with the corresponding first rollers. The concave structure is concavely formed in a surface of the main body and includes inner teeth. The inner teeth are contacted with plural second rollers of the second roller assembly. The speed reducer of the present invention is an epicycloid-epicycloid speed reducer or a hypocycloid-hypocycloid speed reducer. Since the speed reducer is designed to have four operating situations, the speed reducer can have various reduction ratios.

Owner:DELTA ELECTRONICS INC

Asymmetric-tooth-shaped two-end spiral screw with involute force transmission side

InactiveCN105697363AAchieve a tight sealSatisfy the requirement of high torque transmissionRotary piston pumpsRotary piston liquid enginesInvoluteEngineering

The invention provides an asymmetric tooth-shaped two-end spiral screw with an involute force transmission side and belongs to the technical field of screw pumps. The screw has spirals on two ends; the spiral on one end is asymmetric-tooth-shaped; two tooth-shaped sides respectively comprise a force transmission side and a sealing side; the force transmission side takes involutes tooth-shaped lines; the sealing side takes extended epicycloids as tooth-shaped lines; the spiral on the other end of the screw is symmetric-tooth-shaped; two tooth-shaped sides respectively comprise a force transmission side and a sealing side; both the force transmission side and the sealing side take involutes as tooth-shaped lines. With perfect combination of two types of tooth-shaped lines including the involutes and the extended epicycloids, the two-screw pump with application of the screw is reliable in force transmission of a tooth-shaped surface of a screw rotator during operation, balanced in running, low in vibration noise and high in volumetric efficiency.

Owner:TIANJIN HUAKE SCREW PUMP TECH CO LTD

Claw type rotor pair apparatus with two rotors having the same shape

ActiveCN103775341AReduce fatigueReduce frictionToothed gearingsEngine of intermeshing engagement typeEngineeringClockwise

Owner:LIUNG FENG INDAL

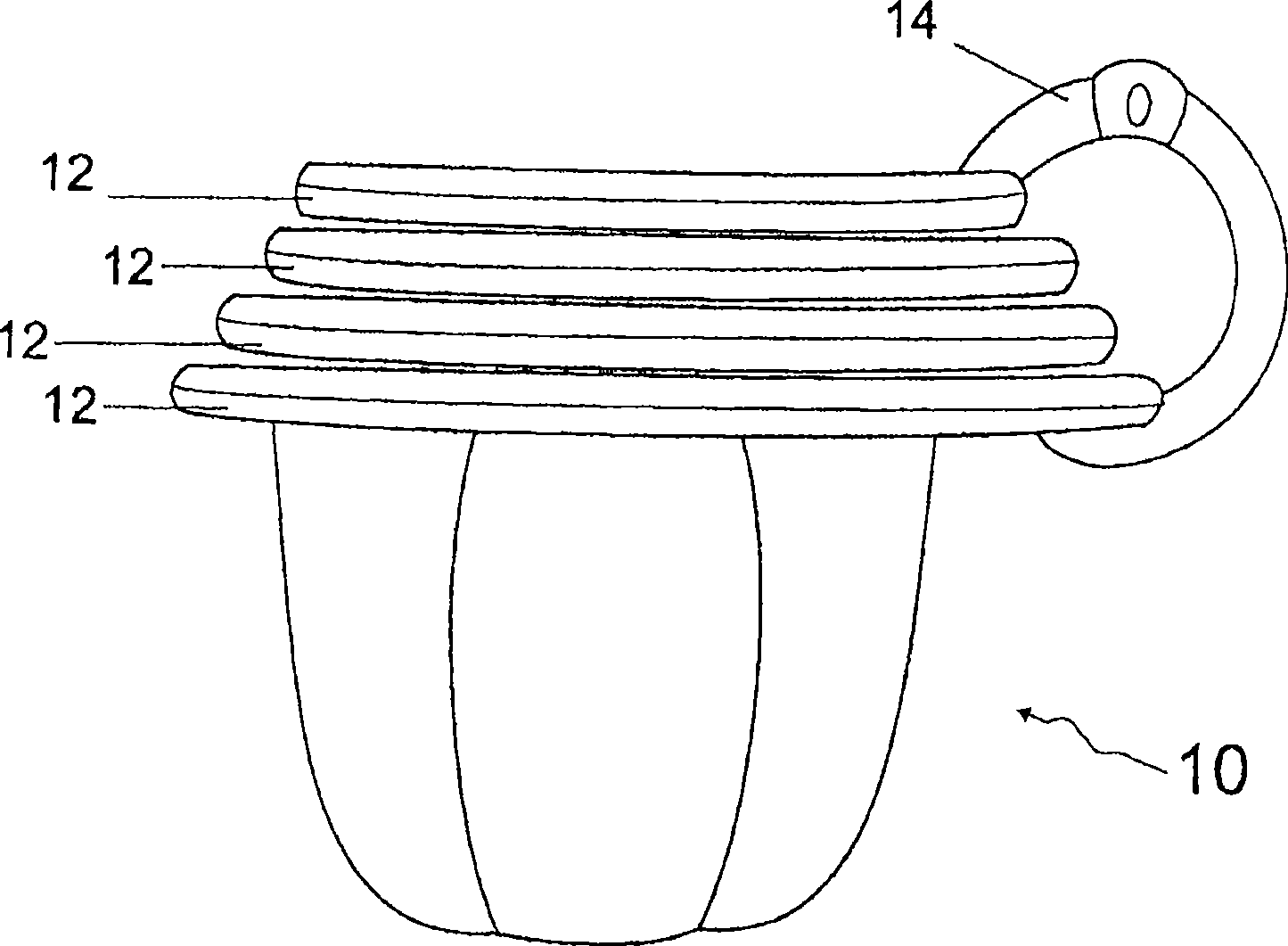

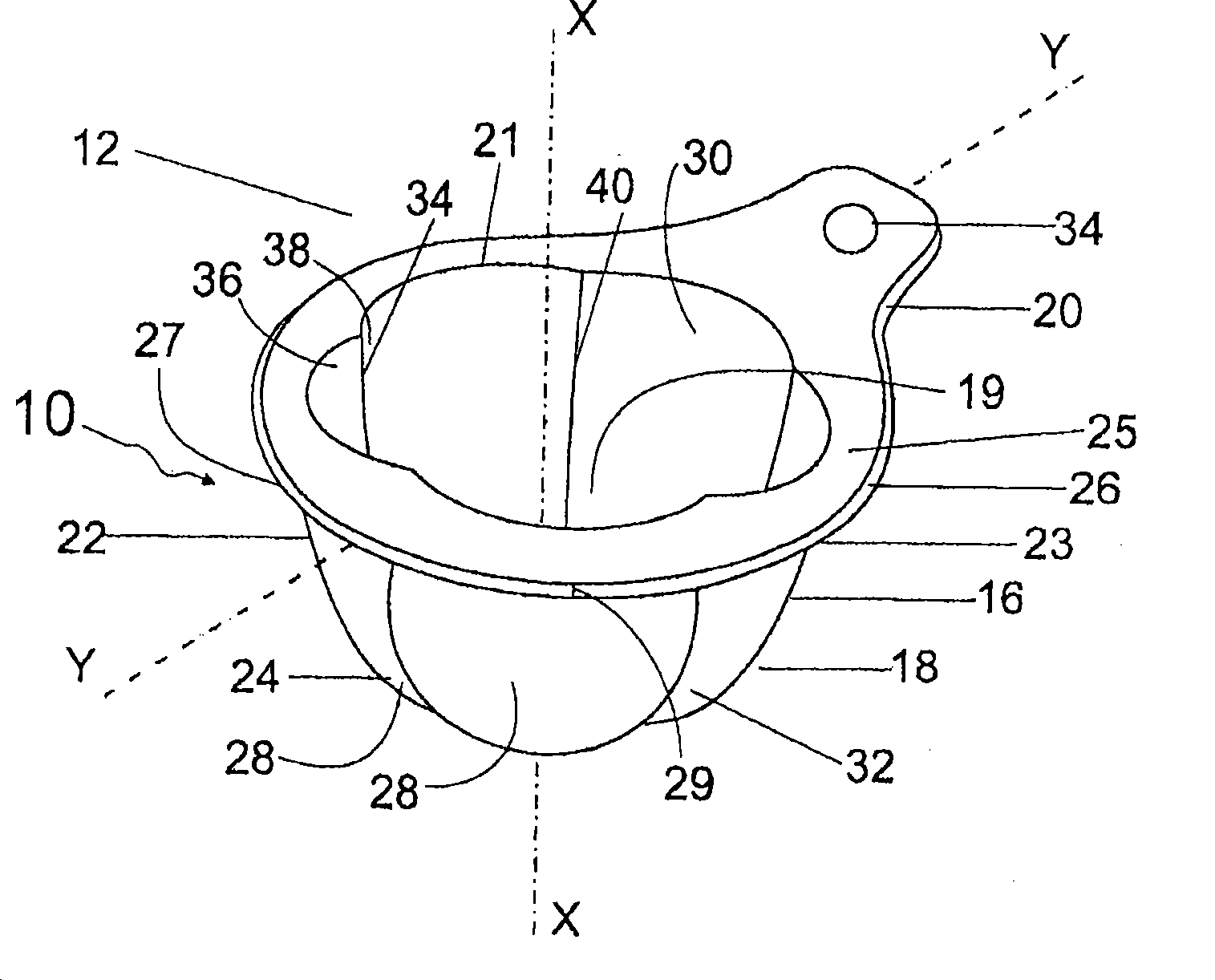

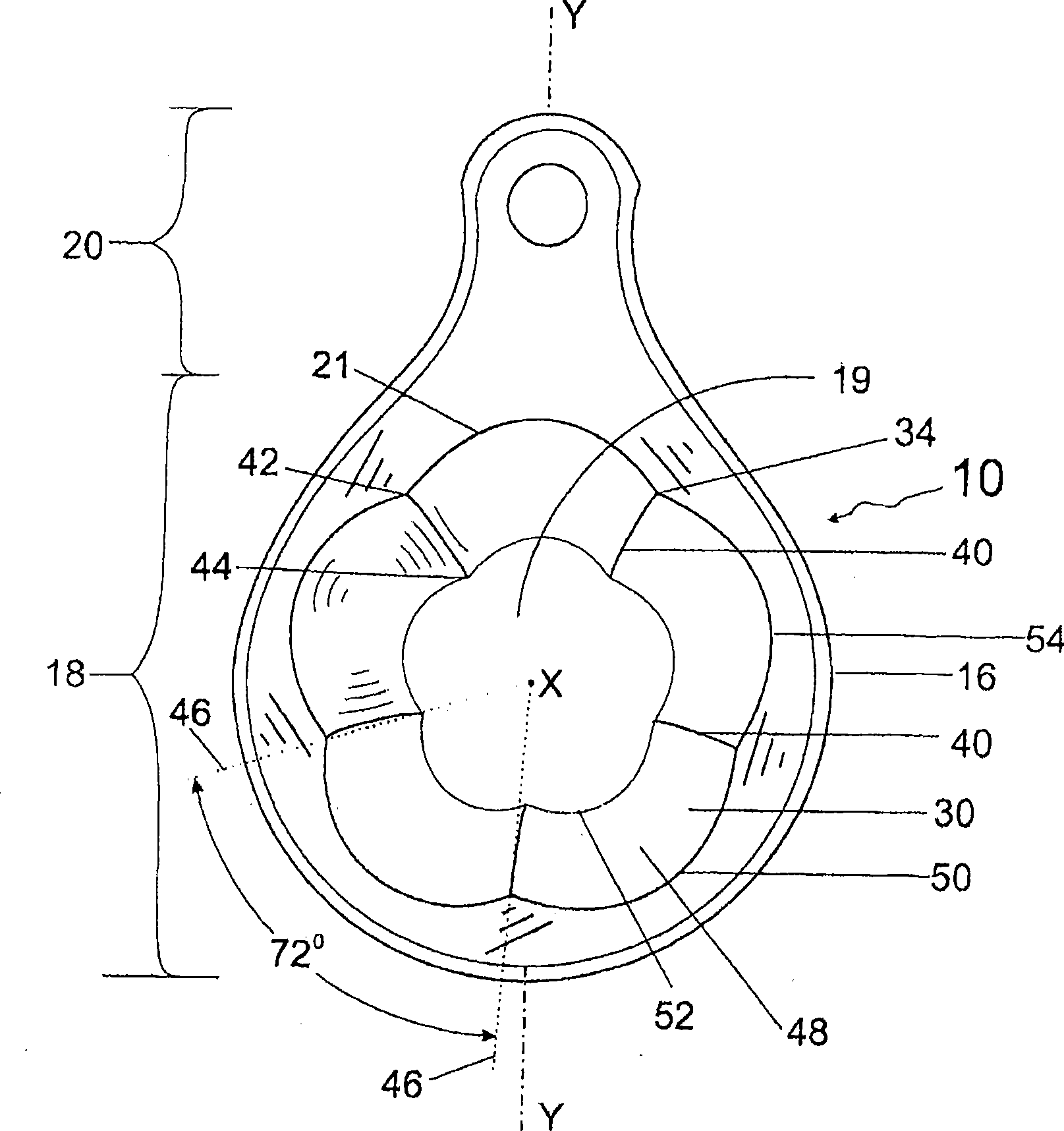

Measuring device

The invention discloses a measuring device which comprises a plurality of measuring cups which are connected by a ring. Each measuring cup is provided with a flap-shaped side wall, and a plurality of flaps formed by epicycloids are defined on the side wall. Each flap of a smaller measuring cup is contacted with the inner surface of a bigger measuring cup to define the space between the measuring cups, therefore, the flowing of air between the measuring cups is convenient. The air flow blocks the suction between the measuring cups. The epicycloids structure defines a plurality of longitudinal raising parts, is applicable to preventing the axes of the smaller measuring cup from moving inward and fixing the smaller measuring cup in a position. The epicycloids structure of the side wall defines a plurality of channels, and a plurality of outflow openings are formed in a container part, thus allowing liquid drop to freely flow out. The channels minimize the inner surface contact between the measuring cups, thus preventing the bonding of the surfaces of the measuring cups.

Owner:SAR HLDG INT

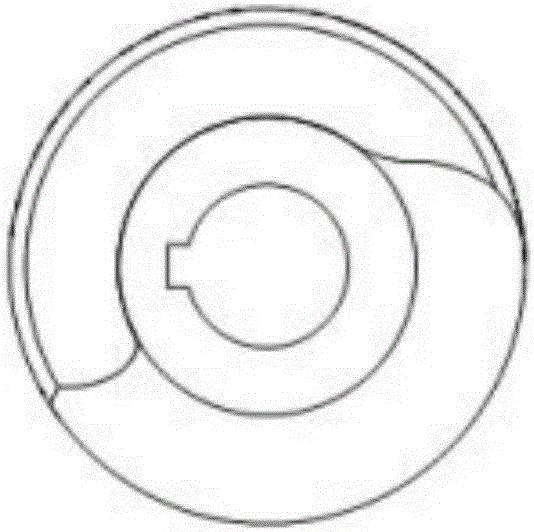

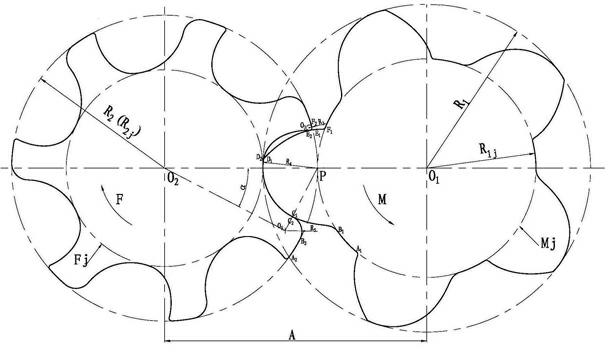

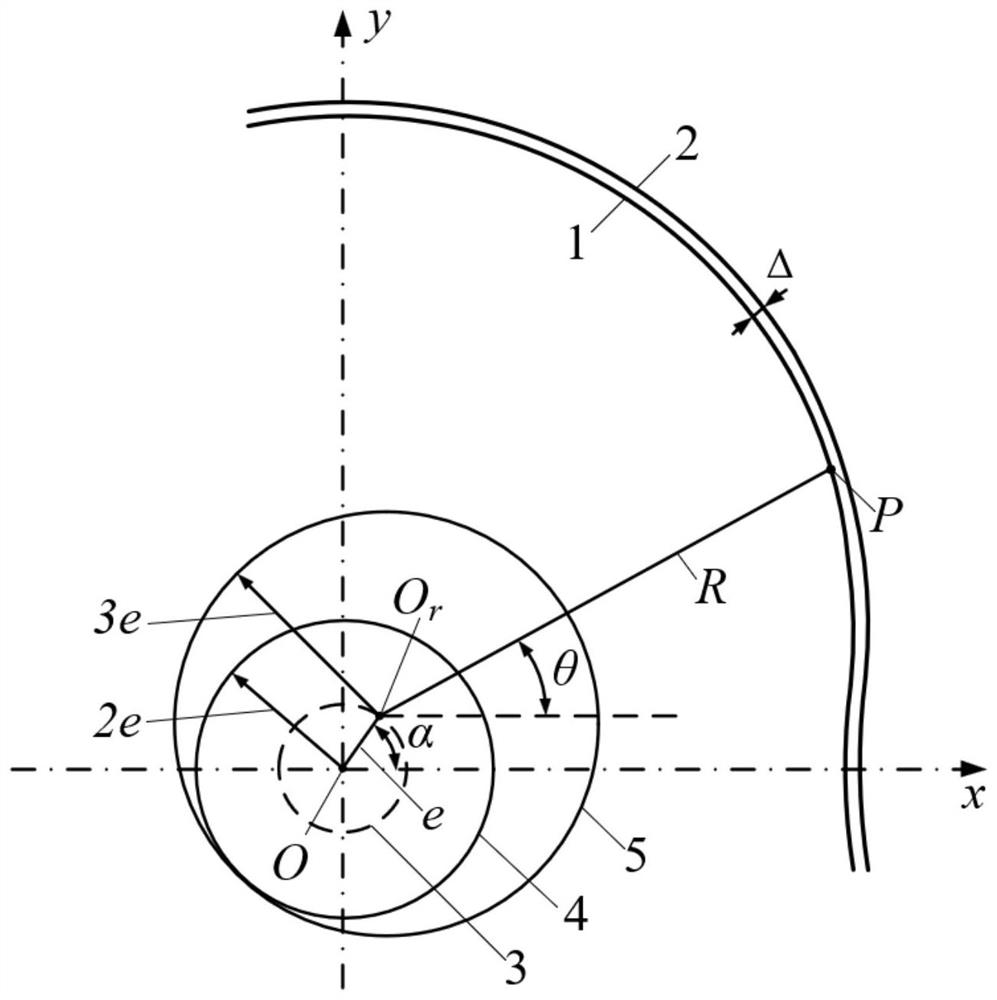

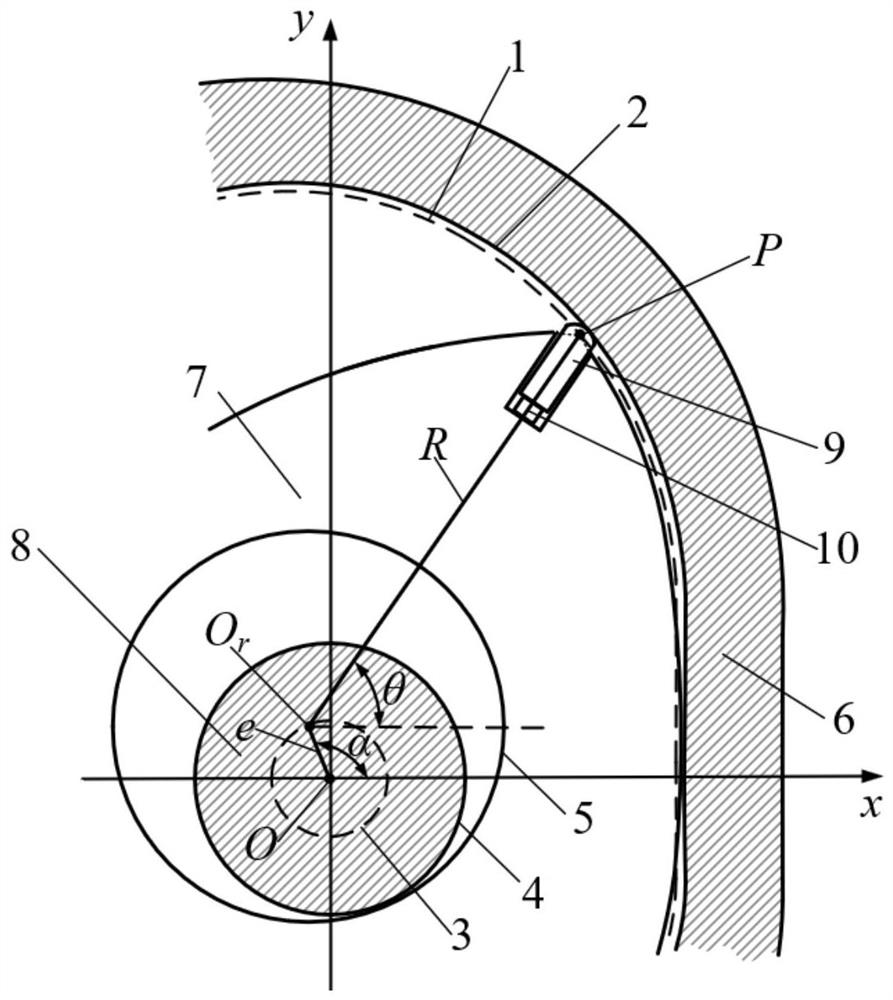

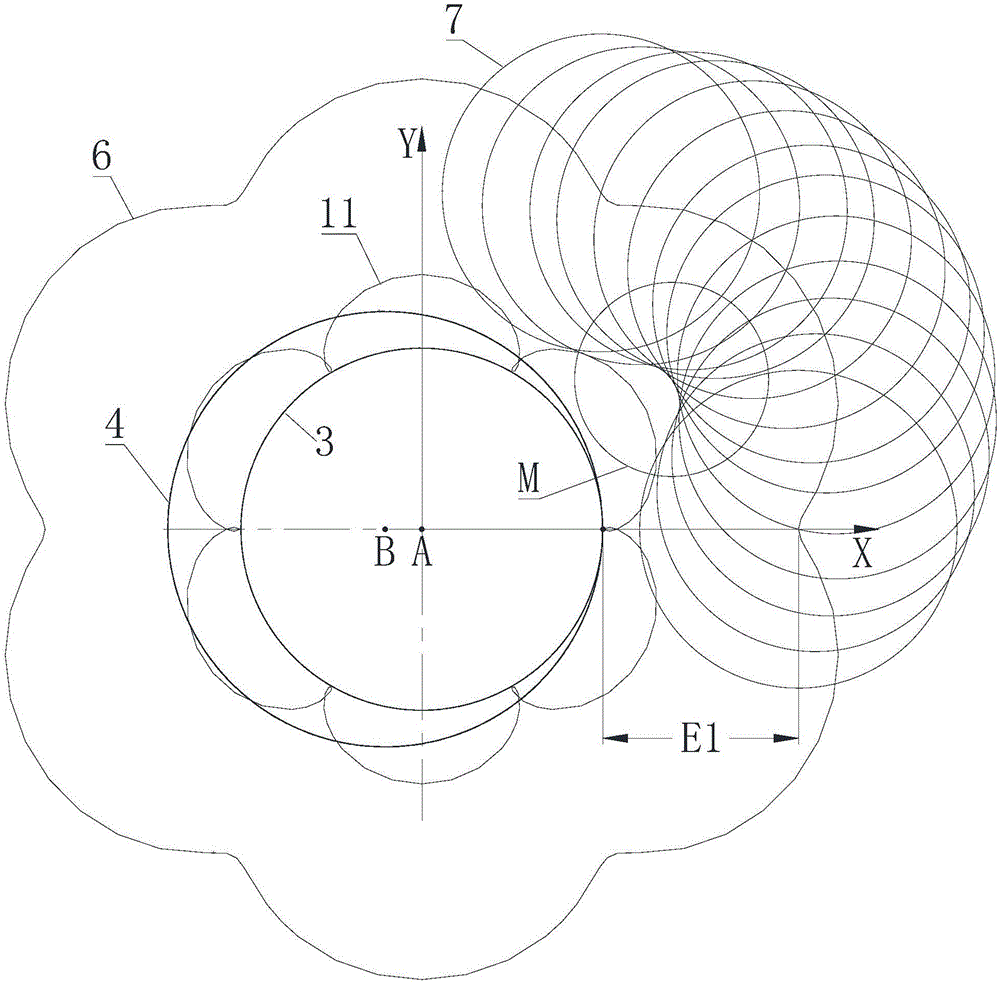

Method for determining gear pump tooth profile molded line and crescent gear pump

ActiveCN106224237AEasy to adjustAdjust shapeRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention provides a method for determining gear pump tooth profile molded line and a crescent gear pump. The method includes: provided a first formation circle, a second formation circle and a tooth circle; an eccentric distance for geometric compensation is arranged between the second formation circle and the first formation circle; a fixed point is determined on the circumference of the second formation circle, in the circle or outside the circle, so that the second formation circle rotates around the center of the first formation circle on the premise of keeping the first formation circle immobile; the locus of the fixed point forms a first epicycloid; a first distance is used for vector amplification on the first epicycloid to obtain a second epicycloid; and an envelope line formed by the center of the tooth circle moving along the second epicycloid used as the tooth profile molded line of the gear pump. Through the above technical scheme, the method is convenient for adjusting the shape, size and tooth gap of the tooth profile, so as to avoid large noise and ripple due to collision caused by larger gap.

Owner:GREE ELECTRIC APPLIANCES INC

Cycloid oscillating tooth speed reducer with mechanical balance combined tooth surface raceway

InactiveCN112081878AIncrease stiffnessHigh torque/volume ratioRotating vibration suppressionToothed gearingsReduction driveGear wheel

The invention provides a cycloid oscillating tooth speed reducer with a mechanical balance combined tooth surface raceway. The cycloid oscillating tooth speed reducer comprises an input shaft, a fixedoscillating gear, a transition oscillating gear, an output oscillating gear, a first-stage steel ball oscillating tooth, a second-stage steel ball oscillating tooth, a mechanical balance rolling body, densely-arranged steel balls and the like, wherein a transmission mechanism is composed of a two-stage differential cycloid oscillating tooth transmission unit, and movement of the transition oscillating gear serves as input of a two-stage transmission part, the mechanical balance rolling body is mounted on the outer side of the transition oscillating gear and used for reducing the rotational inertia of the whole machine and increasing the rigidity, the output end of the speed reducer adopts a densely-arranged steel ball bearing structure, so that the processing cost is reduced, the cycloidraceway adopts a root cutting tooth surface raceway or a combined tooth surface raceway, and the root cutting tooth surface raceway can be regarded as a special form of the combined tooth surface raceway, so that the cycloid raceway is collectively called as the combined tooth surface raceway, the combined tooth surface raceway is divided into the hypocycloid raceway and the epicycloid raceway, sothat sixteen configurations can be formed through permutation and combination, the configuration modes are flexible and variable, and the transmission ratio range is wide.

Owner:HENAN ZHULONG HI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com