Double screw mixed transport pump gear type

A mixed pump and twin-screw technology, used in pumps, rotary piston pumps, rotary piston machines, etc., can solve problems such as poor sealing, and achieve the effect of convenient processing and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

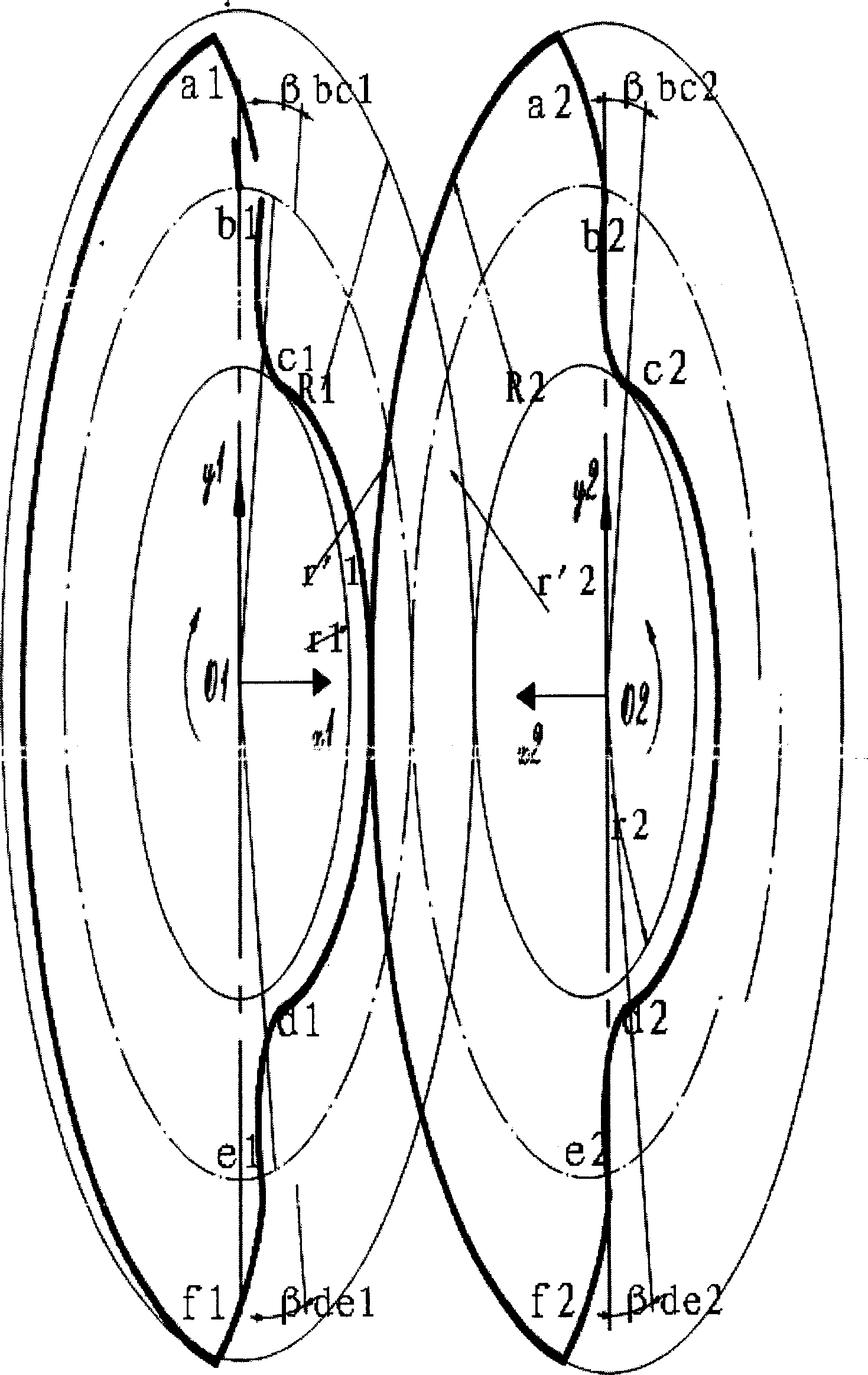

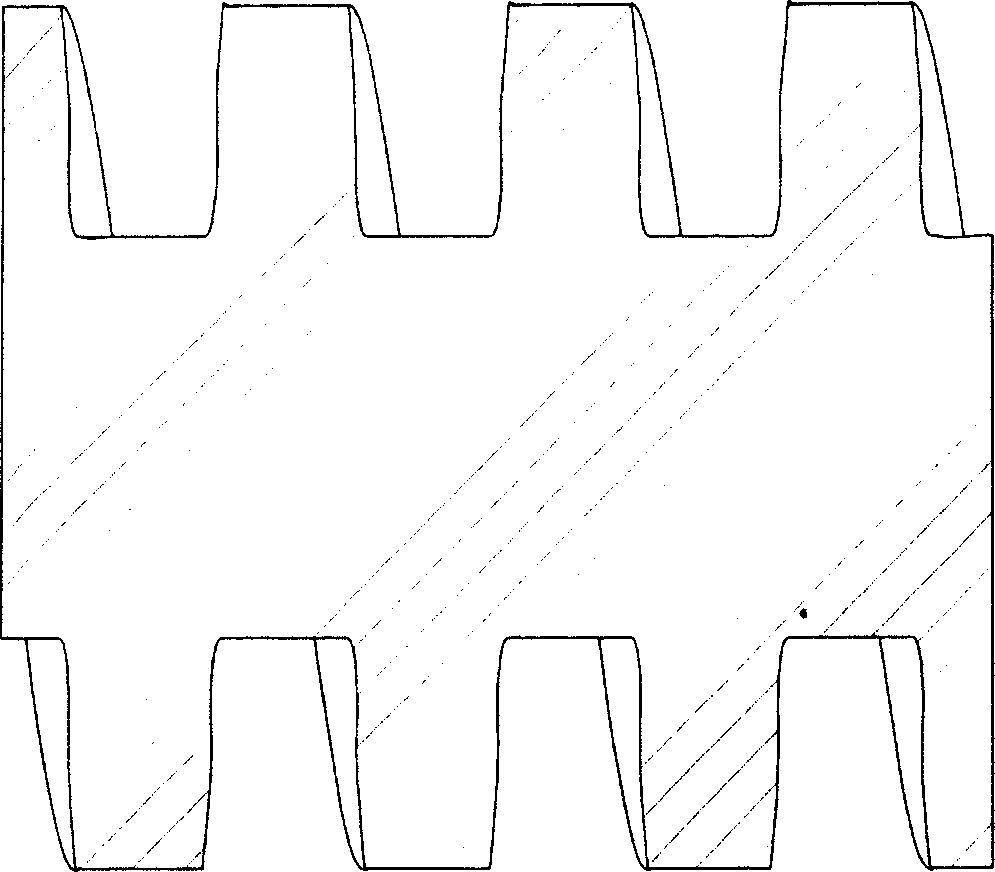

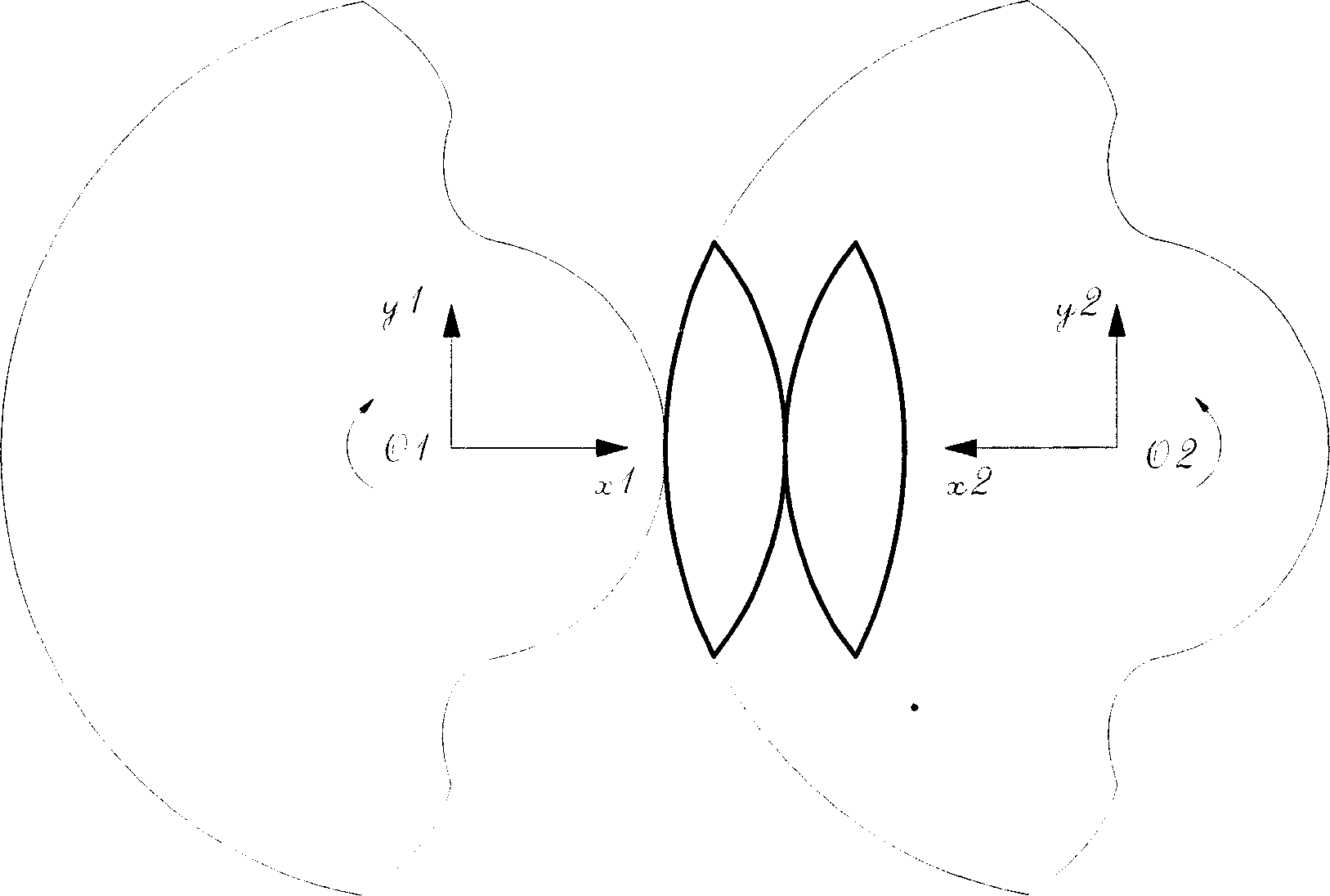

[0016] In the tooth profile of a twin-screw mixed-transport pump of the present invention, the profiles are composed of arc-arc envelopes and point meshing cycloids. In the main meshing area, focusing on reducing the area of the leakage triangle, point meshing cycloids are adopted, including the first cycloid ab, the second cycloid fe, the first long-leg epicycloid bc, the second long-leg epicycloid ed, and the second long-leg epicycloid ed. The point b on the first cycloid ab and the point e on the second cycloid fe are on the pitch circle, and they are collinear at the center of the pitch circle; in other areas, focusing on shortening the length of the contact line and facilitating processing and manufacturing, arc- The circular arc envelope includes the concentric tooth bottom arc cd and tooth top arc af, the tooth bottom arc cd and the tooth top arc af are opposite, the two arcs are concentric with the pitch circle, and the radii are r, R and r'.

[0017] figure 1 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com