Epicycloid centrifugal pump impeller

A centrifugal pump impeller and epicycloid technology, applied to pumps, pump components, non-variable pumps, etc., can solve problems such as backflow, large loss at the outlet, and low pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

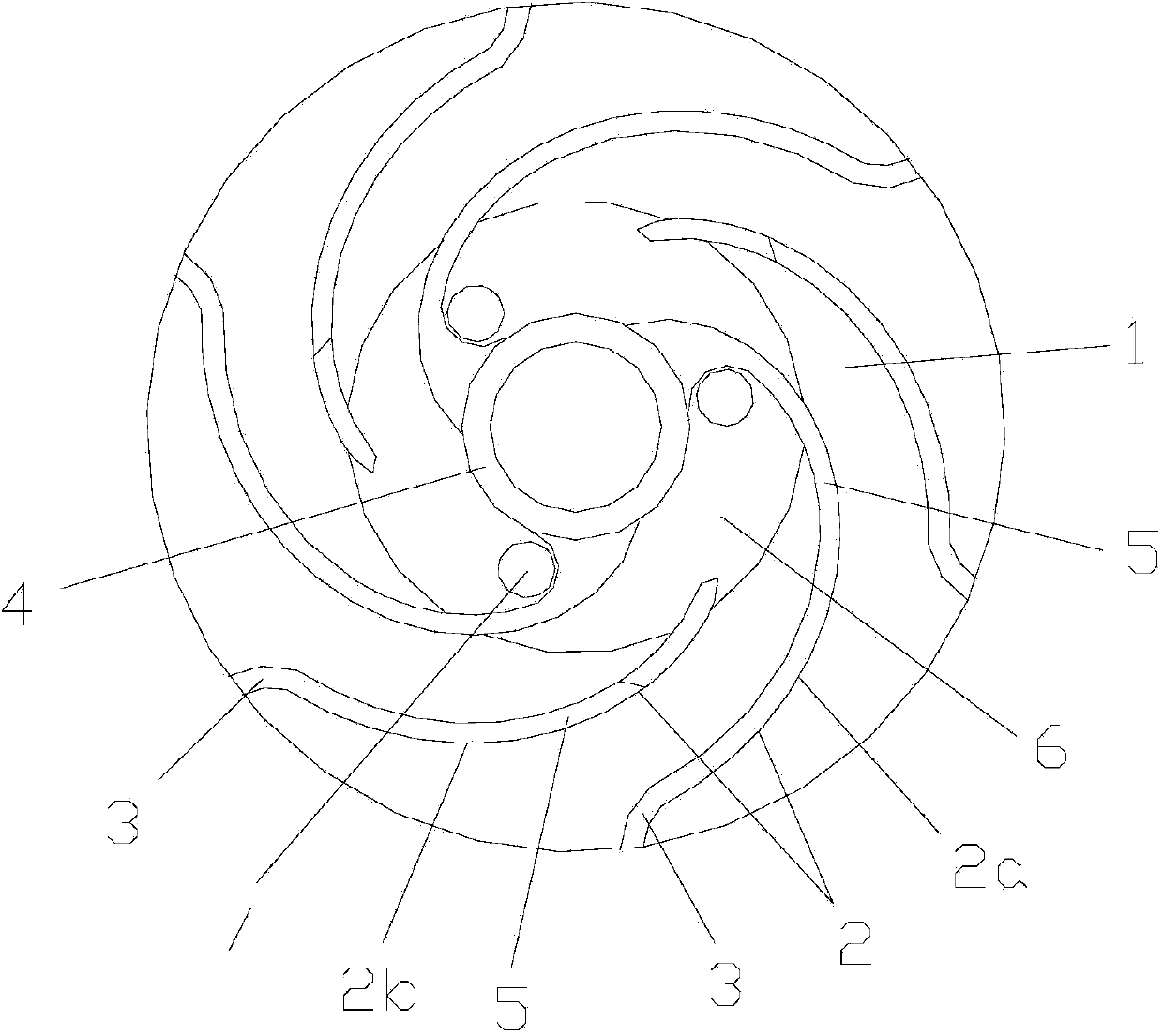

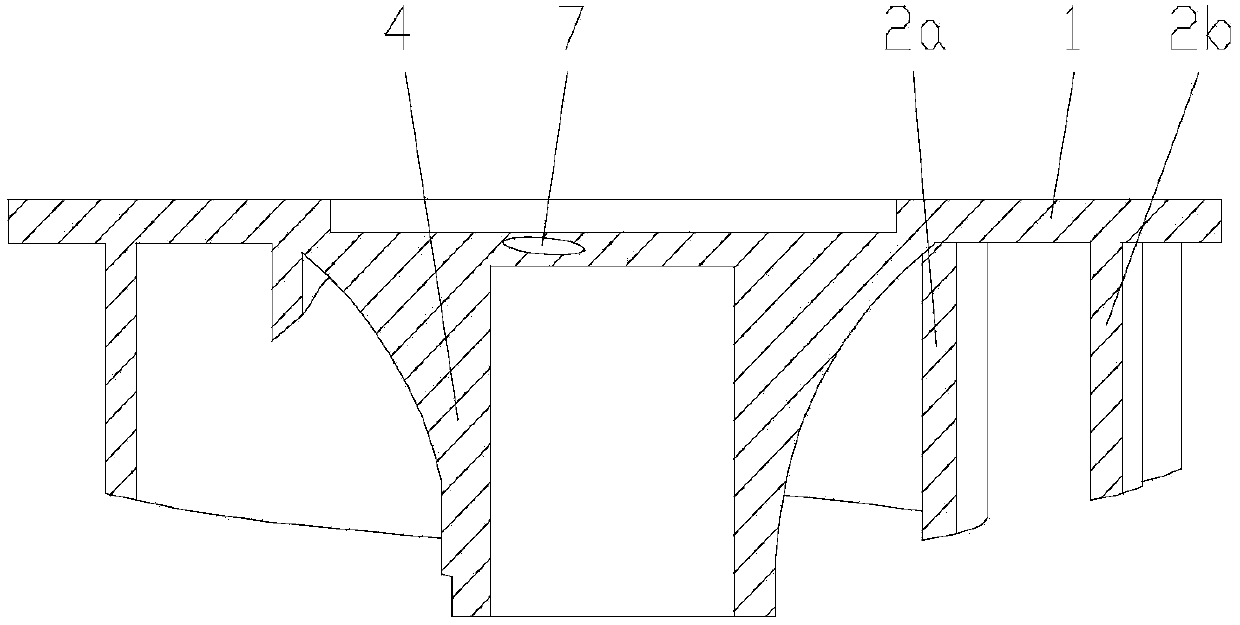

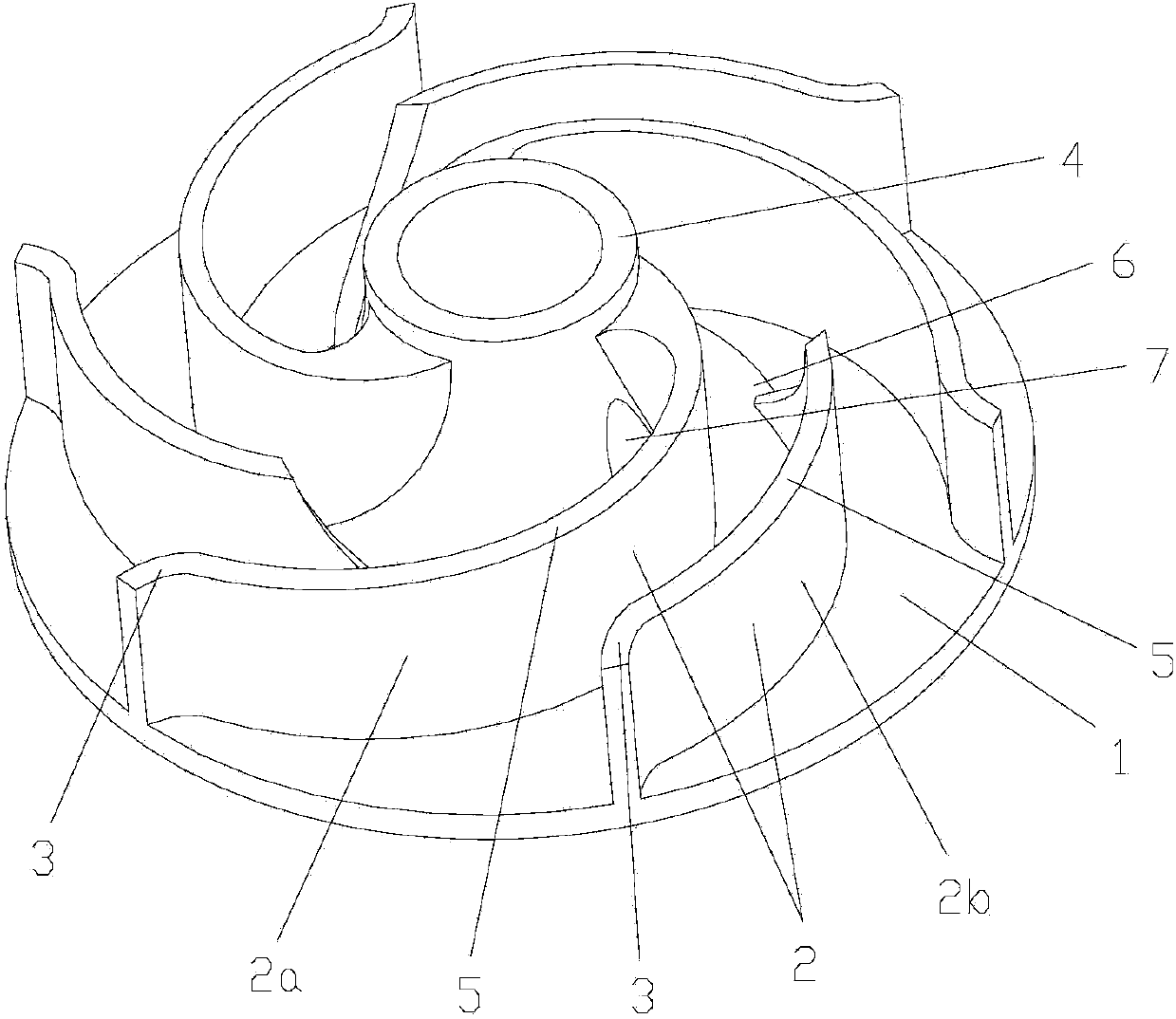

[0029] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 top view of image 3 For the perspective view of the present invention, Figure 4 is the schematic diagram of the elongated epicycloid, Figure 5 In order to shorten the epicycloid schematic diagram, as shown in the figure: the epicycloid centrifugal pump impeller of the present embodiment includes a wheel disc 1 and a blade 2 fixed on one end surface of the wheel disc 1; the tail section 3 of the blade 2 gradually becomes An epicycloid structure extending radially along the wheel disc 1; the wheel disc 1 is a disc structure with a hub 4 at its center, and the hub 4 extends axially to the side where the blade 2 is located. In this embodiment, the wheel disc 1 and the The blade 2 is combined into a semi-open impeller; the blade 2 is divided into two sections, namely the front section 5 close to the hub 4 and the tail section 3 far away from the hub 4; the front section 5 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com