All-smooth screw rotor of double-screw liquid pump

A twin-screw and liquid pump technology, applied to liquid fuel engines, rotary piston/oscillating piston pump components, pumps, etc., can solve the problem of reducing the volume utilization of twin-screw liquid pumps, the screw rotor is prone to wear, and the pump can be reduced. Service life and other issues, to achieve the effect of enriching the type of end face, improving service life, improving wear resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

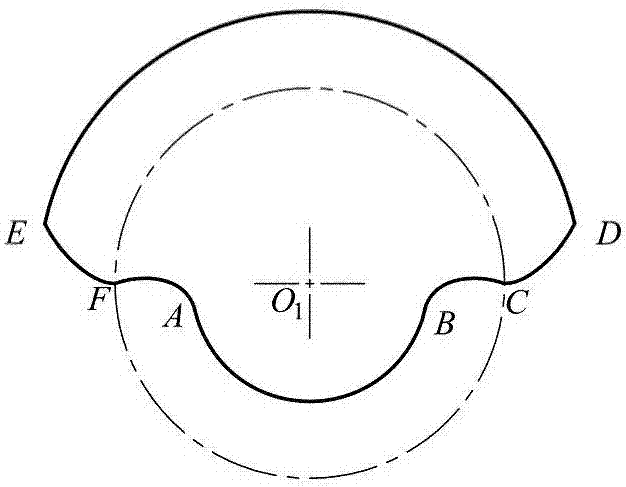

[0046] Such as figure 1 Shown is the profile diagram of the screw rotor end surface of a commonly used twin-screw liquid pump, consisting of root arc AB, long-width epicycloid BC, epicycloid CD, addendum arc DE, epicycloid EF, long-width Composed of epicycloid FA; there are two rough connection points at the joints of long epicycloid BC, FA and epicycloid CD, EF respectively, and also exist when epicycloid CD and EF are connected with addendum arc DE Two non-smooth connection points; due to the existence of non-smooth connection points, the profile line of the end surface of the screw rotor is not smooth, which reduces the wear resistance and mechanical performance of the screw rotor.

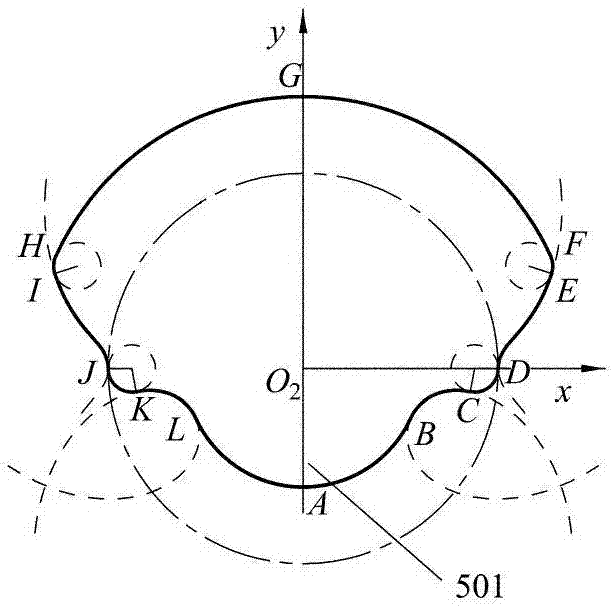

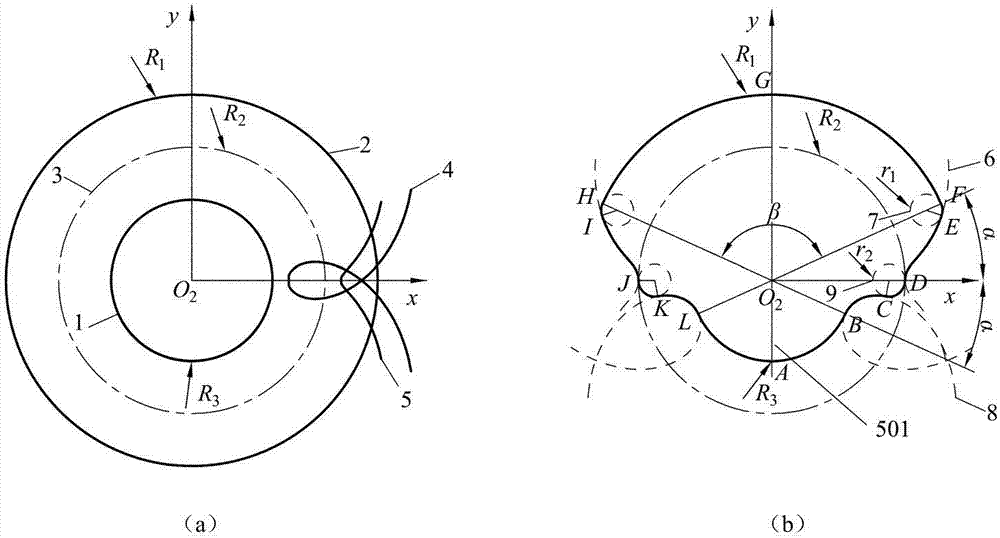

[0047] Such as figure 2 As shown, it is a diagram of the left end surface molding line (501) of the screw rotor of a fully smooth twin-screw liquid pump. The equidis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com