Arch bridge buckling characteristic coefficient increase based half-through steel arch bridge reinforcement method

A characteristic coefficient, steel arch bridge technology, applied in the direction of bridge reinforcement, arch bridges, bridge forms, etc., can solve the problems of separation of new and old materials, affecting the effect of reinforcement, and decreasing cohesion.

Active Publication Date: 2017-05-17

GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

A large number of examples show that the effect of the original method of reinforcement is very little, and the degree of adhesion of the old and new materials directly affects the effect of the reinforcement. Soon after the bridge is

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

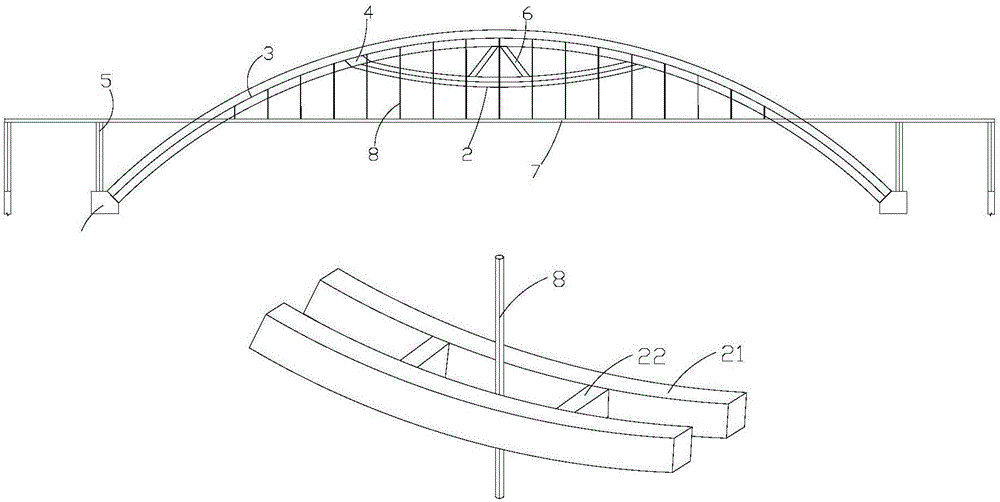

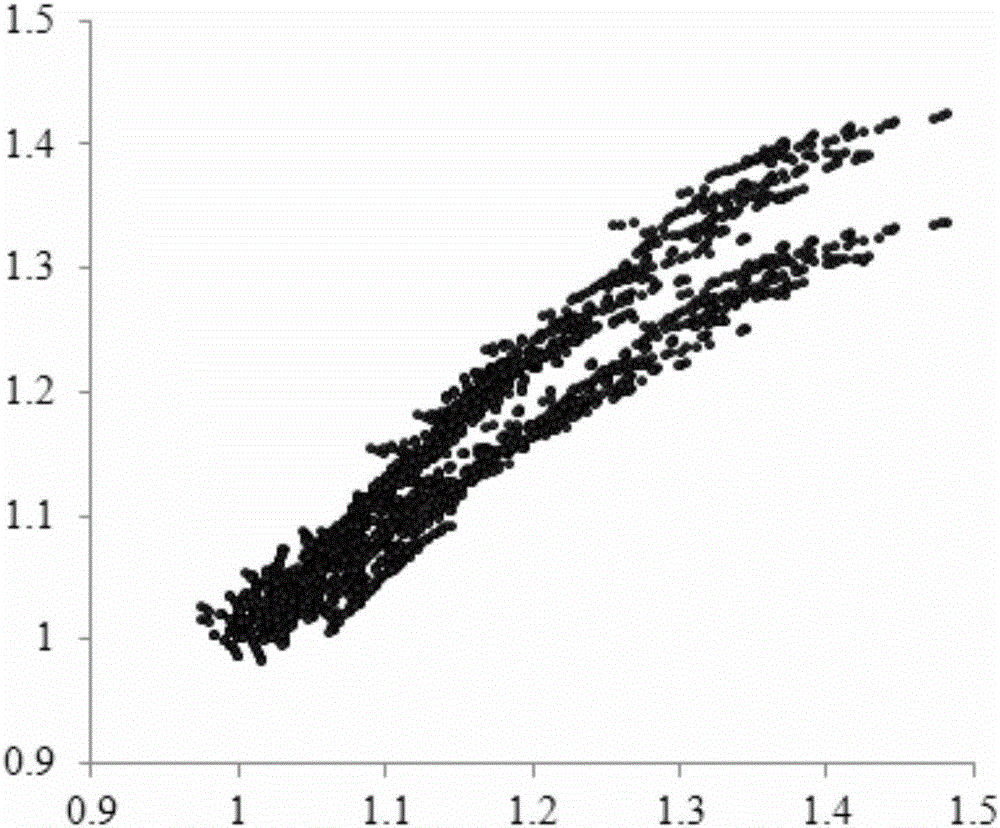

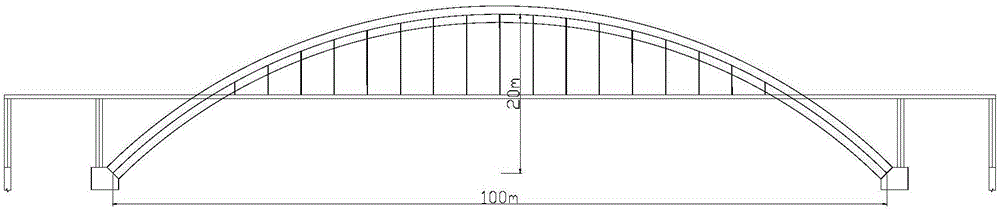

The invention discloses an arch bridge buckling characteristic coefficient increase based half-through steel arch bridge reinforcement method. An inverted arch is arranged below a main arch ring arch rib of a half-through steel arch bridge, the inverted arch and the arch rib are connected through oblique rods, and the inverted arch and an original arch rib are connected by inverted arch connectors welded to the original arch rib, so that the inverted arch structure for reinforcement and an original main arch ring form a rigid restraint supporting system; the arch bridge buckling characteristic coefficient increase degree in the rigid restraint supporting system is in close relation with seven parameters of the inverted arch and a to-be-reinforced arch, and by setup of different variable values of the seven parameters, a mid-span moment ratio of the to-be-reinforced arch and the reinforced arch is used as a bending moment change characterization quantity to obtain a relation between the seven parameters and the bending moment change characterization quantity on the basis of a finite element parameter analysis fitting method. In application of the arch bridge buckling characteristic coefficient increase based half-through steel arch bridge reinforcement method, a structural characteristic internal force can be solved according to the relation, and accordingly an optimal scheme can be selected for inverted arch reinforcement.

Description

technical field [0001] The invention belongs to the technical field of arch bridge reinforcement, and in particular relates to a method for reinforcing a mid-supporting steel arch bridge based on the increase of the buckling characteristic coefficient of the arch bridge. Background technique [0002] Arch bridge is a bridge structure type that is widely used on highways in my country and has a long history, especially in Guangxi. However, with the aging of materials and increasing traffic volume, most bridges can no longer meet operational needs. Some concrete arch bridges have a large self-weight, and the main arch ring mainly bears pressure. Often, due to insufficient pressure bearing, the arch ring cracks increase, and a few have obvious downward deflection in the mid-span, and the stability, bearing capacity and comfort are reduced; if it is demolished and rebuilt, it will take time. It is laborious, but there is no good reinforcement method at present. [0003] Common...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01D22/00E01D4/00E01D101/30

CPCE01D4/00E01D22/00E01D2101/30

Inventor 陈齐风刘世建郝天之李丽琳高建明徐赵东王龙林朱思蓉于孟生万杰刘雪雷卓小丽李保军杨雨厚

Owner GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com