Fabricated corrugated web steel box-UHPC composite beam bridge and construction method thereof

A corrugated web and construction method technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the difficulty of guaranteeing web stability and shear buckling performance, increasing the cost and difficulty of quality control, and multi-chamber structures Unclear force and other problems, to achieve the effect of easy guarantee of welding quality, convenient segmental transportation, and mature construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

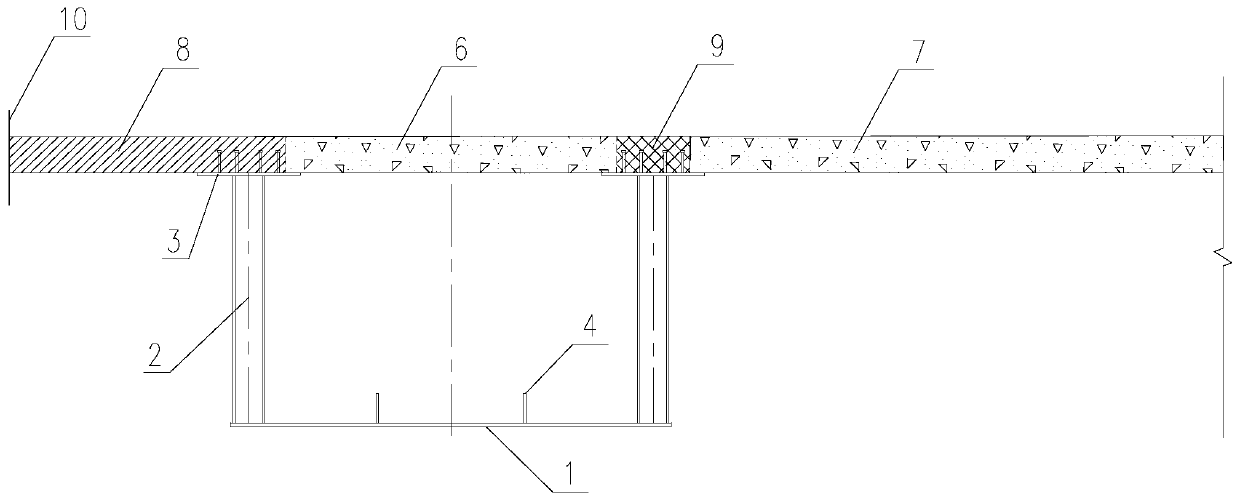

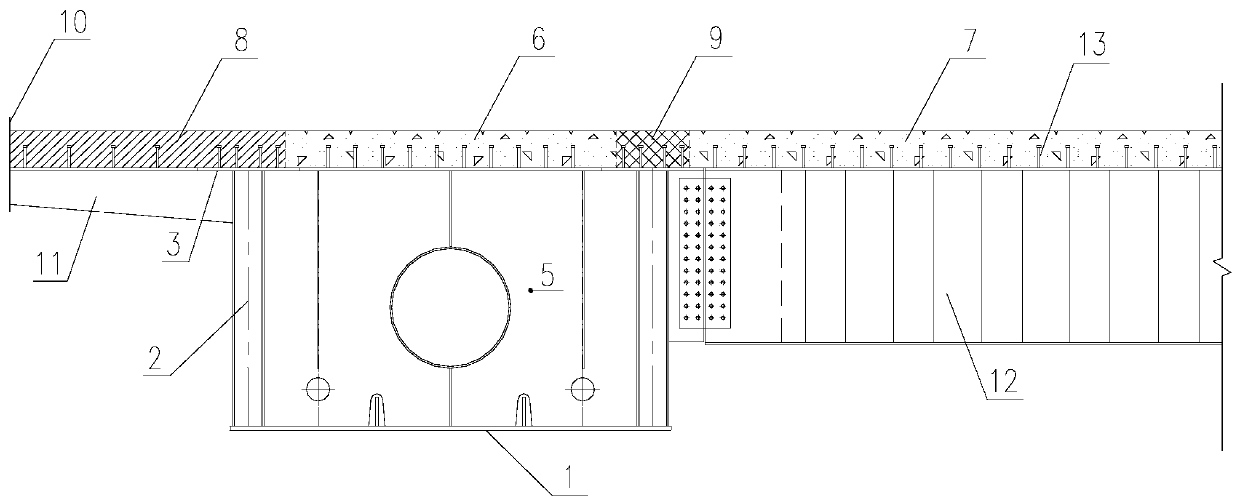

[0045]The present invention provides an assembled corrugated web steel box-UHPC composite beam and its construction method. This embodiment is a simply supported beam system with a span of 40m and a width of 16.5m and its construction method. The beam height of the simply supported beam is 2000mm , consisting of two steel boxes with corrugated webs, the distance between the boxes is 7500mm, the height of the steel boxes with corrugated webs is 1750mm, and the thickness of the bridge deck is 200mm, such as Figure 1-6 shown.

[0046] The corrugated web steel box in this embodiment consists of a flat steel bottom plate 1, two corrugated steel webs 2 vertically welded on both sides of the steel bottom plate, and a flat steel top plate arranged horizontally on the top of the corrugated steel web and welded thereon. 3, the flat steel bottom plate 1, corrugated steel web 2, and flat steel top plate 3 form an open box-shaped structure, wherein the flat steel bottom plate is 3000 mm w...

Embodiment 2

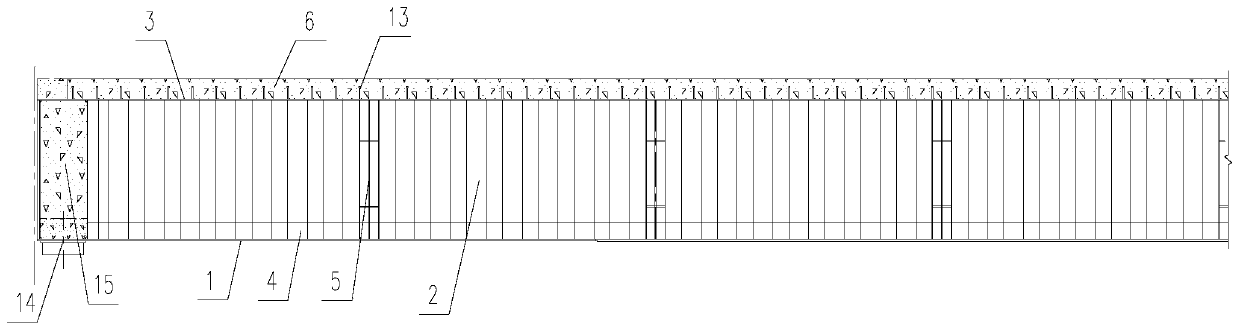

[0067] The present invention provides an assembled corrugated web steel box-UHPC composite girder bridge and its construction method. This embodiment is the continuous girder system and construction method of Embodiment 1. The continuous girder is a porous 40m span, and the bridge width is 16.5m wide, girder height 2000mm, the end span and middle span are composed of two steel boxes with corrugated webs, the distance between the boxes is 7500mm, the height of the corrugated web steel boxes is 1750mm, and the thickness of the bridge deck is 200mm, such as Figure 7-9 shown.

[0068] The continuous system bridge described in this embodiment includes an end span, a mid-span corrugated web steel box and a UHPC bridge deck. Steel web 2. The flat steel top plate 3 arranged horizontally on the top of the corrugated steel web and welded on it forms an open box structure. The width of the flat steel bottom plate is 3000mm. The thickness of the bottom plate within 10m of the side is 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com