Thin floor heating floor capable of intelligently inducting and adjusting temperature

An adjustable and floor technology, applied in the field of thin floor heating floor, can solve the problems of long startup time, low electrical efficiency, high heat loss, and achieve the effect of centralized utilization and saving of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

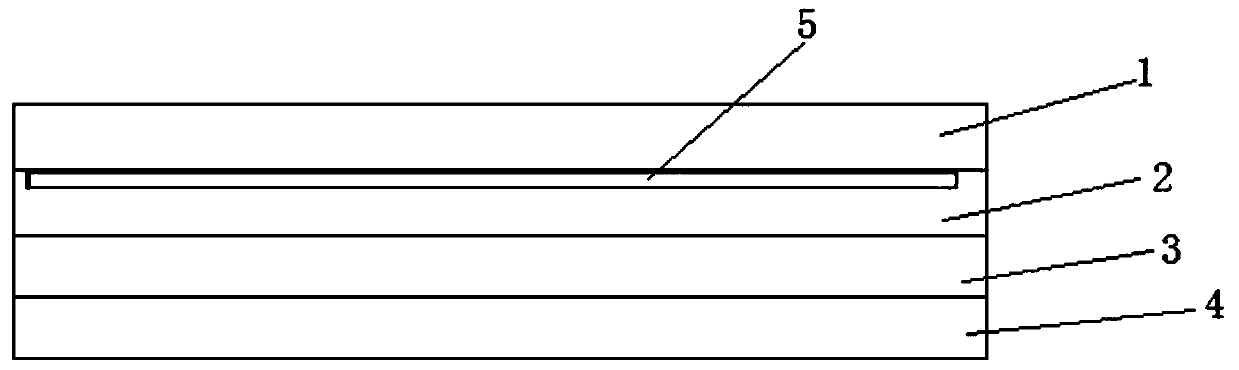

[0030] Such as figure 1 As shown, a thin floor heating floor with intelligent induction and adjustable temperature, the thin floor heating floor includes a wood veneer skin layer 1, a polymer base layer 2, a heat source fiber layer 3 and a heat-resistant protective layer 4; The surface of the floor heating floor is a wood veneer skin layer 1, and the lower part of the wood veneer skin layer is a polymer base layer 2, and an intelligent heat source induction gasket 5 is installed on the polymer base layer 2. Below the molecular base layer 2, a heat source fiber layer 3 and a heat-resistant protective layer 4 are arranged in sequence.

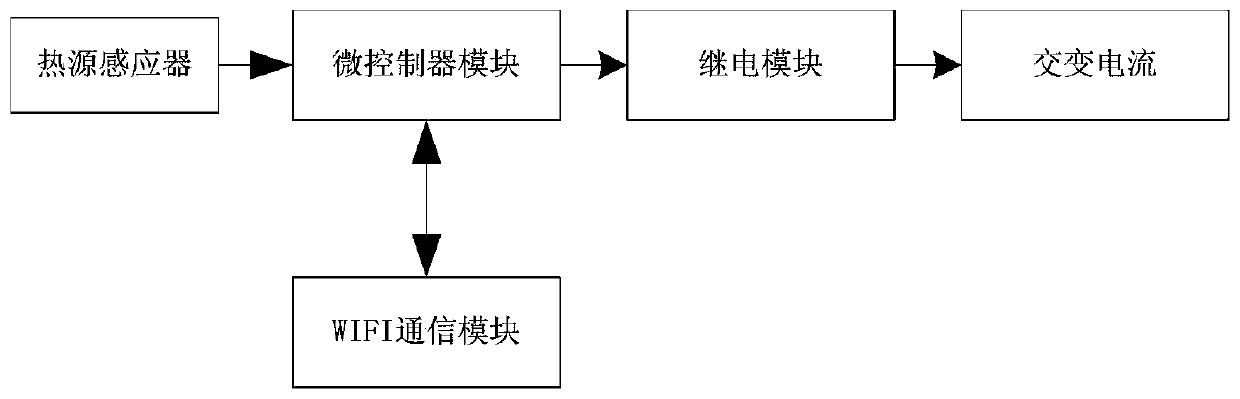

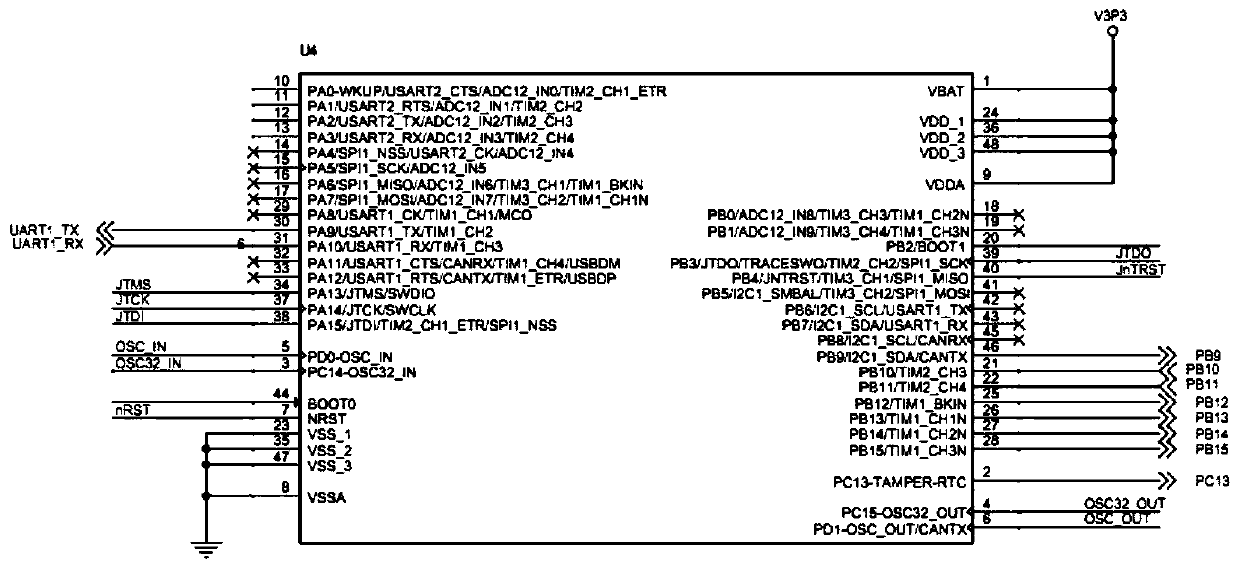

[0031] The intelligent heat source sensing gasket 5 is attached to the polymer base layer 2. When the body weight exerts pressure, the sensing mode will be automatically turned on, and wirelessly controlled by a mobile phone or a computer, so that the floor can intelligently sense the temperature of the human body. Feedback to the heat source fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com