Large commercial remote sensing satellite platform configuration and assembly method

A technology for remote sensing satellites and satellite platforms, which is applied in the fields of artificial satellites, transportation and packaging, and space navigation equipment. It can solve the problems of small installation space for stand-alone equipment, large moment of inertia of the whole satellite, and high power consumption of remote sensing satellites, etc., to achieve improved support Rigidity and overall stability, reduced structural weight ratio, and high utilization of structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

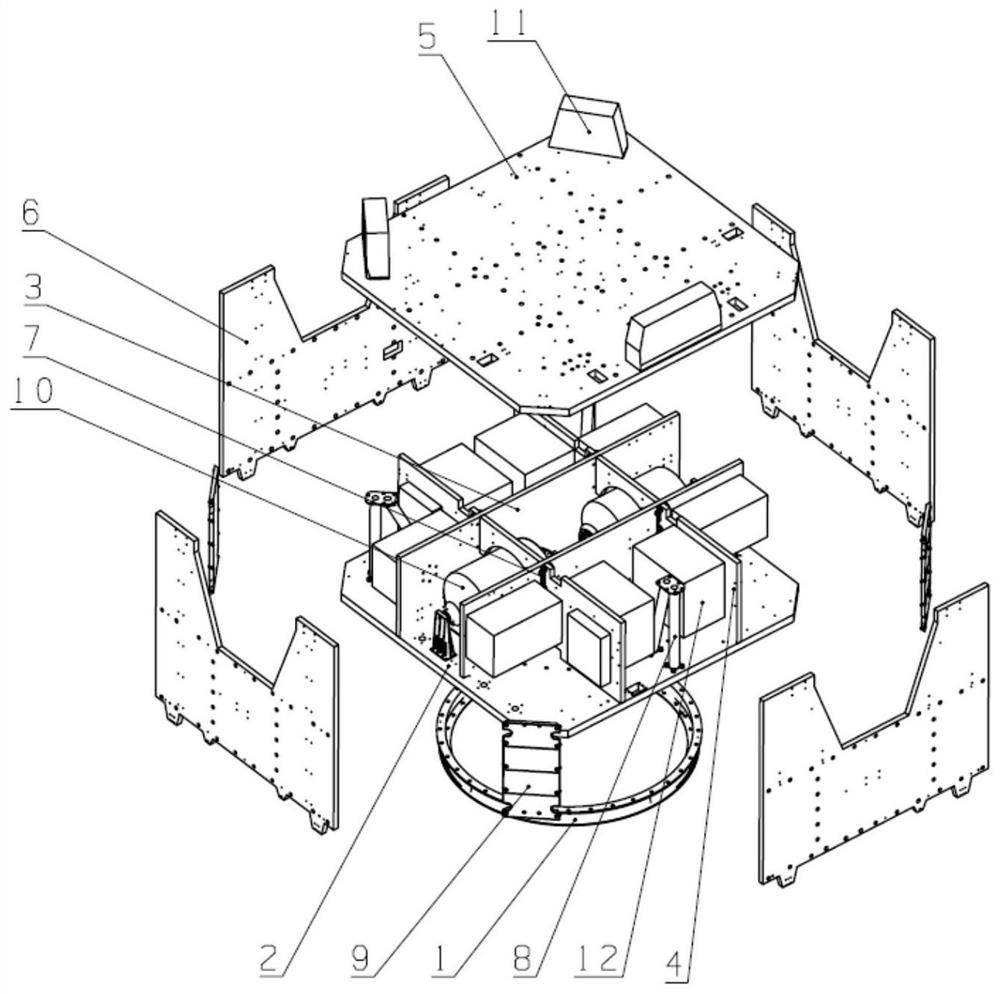

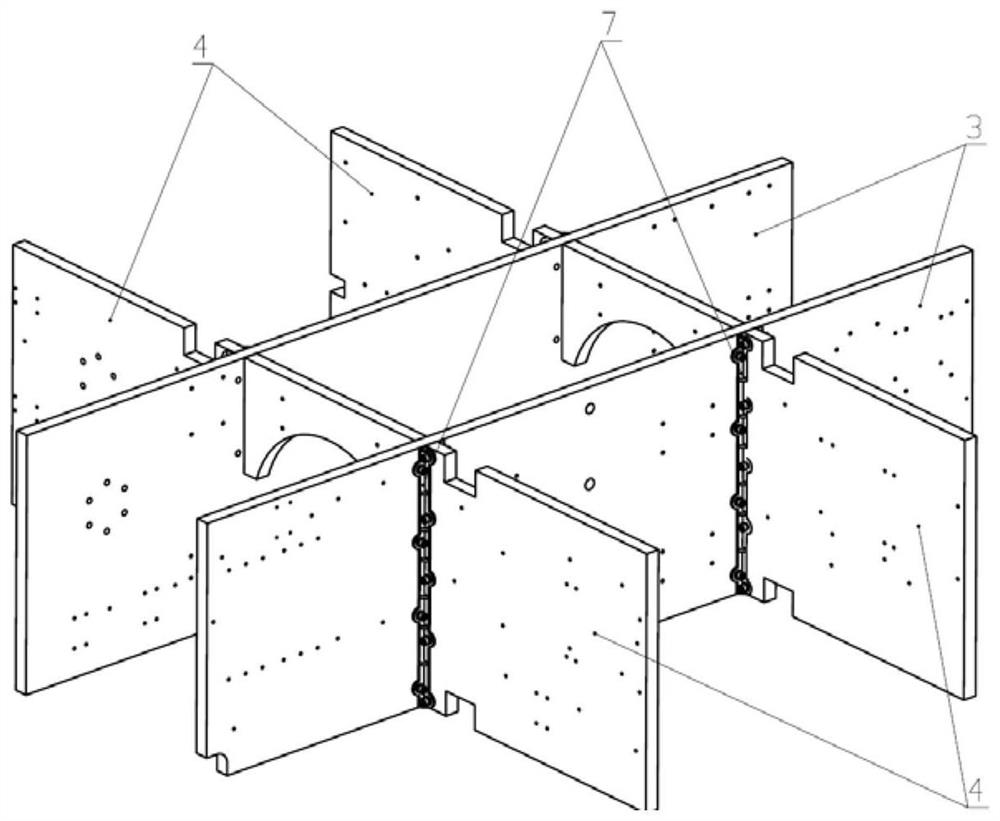

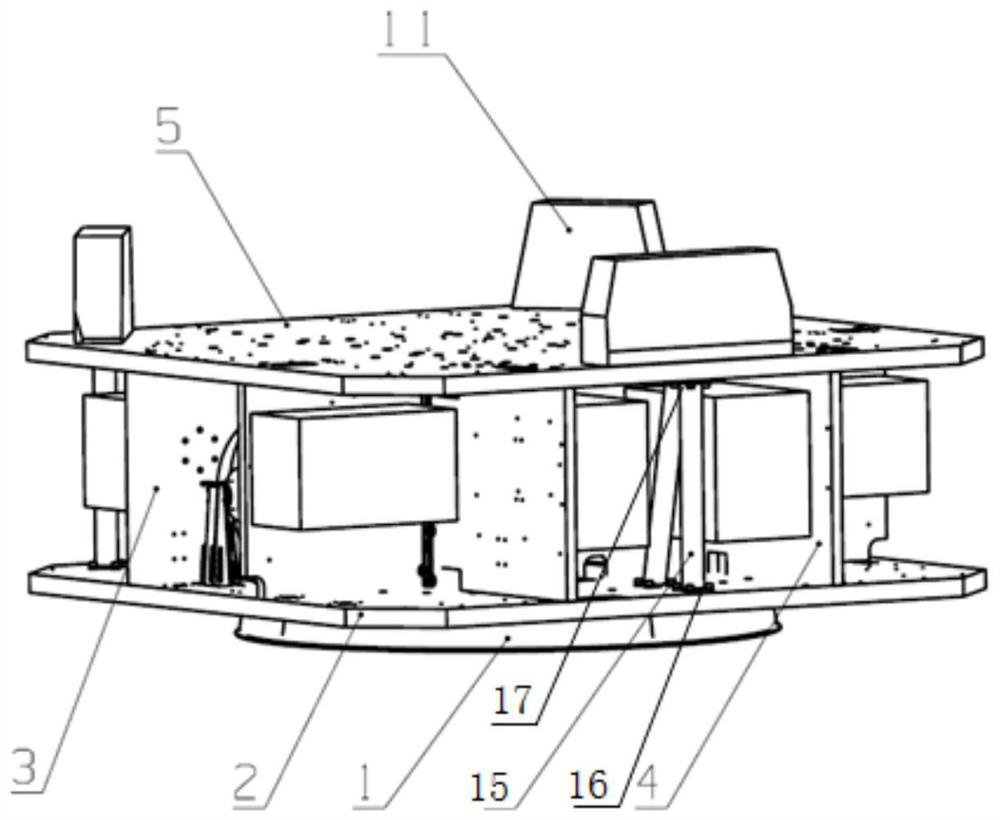

[0035] Such as Figure 1-Figure 5 As shown, a large-scale commercial remote sensing satellite platform configuration, including the main structure of the satellite platform, the docking ring 1 and the solar cell array, the main structure of the satellite platform, the cabin structure composed of carbon fiber panels and aluminum honeycomb sandwich panels and the truss rod assembly Combined way to form a deck-type and truss-type composite structure;

[0036] The main structure of the satellite platform includes a docking plate 2, a tank plate 3, a partition plate 4, a camera plate 5, an outer plate 6, a truss rod assembly 8 and an outer skin 9, and the tank plate 3 and the partition plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com