Sealed single-head spiral screw and double screws thereof

A helical screw and screw technology, which is applied in the field of screw pumps, can solve problems such as gaps in meshing lines, low pump volume ratio, and incomplete sealing of tooth profile lines, so as to facilitate manufacturing and processing, reduce leakage, and increase volumetric efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

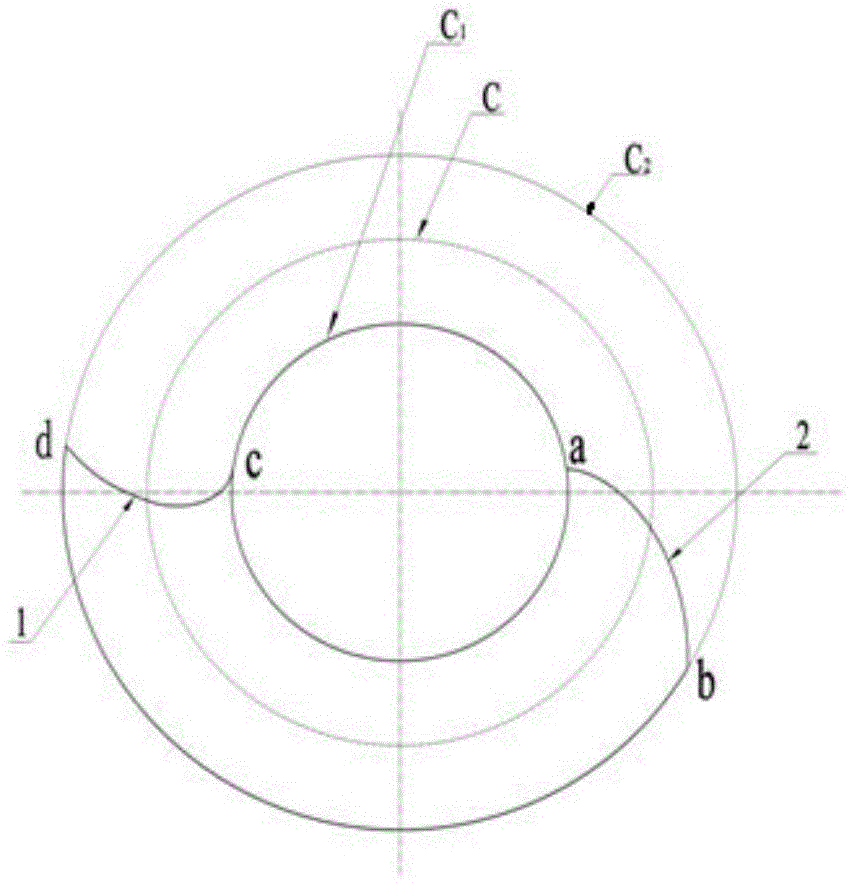

[0039] In this embodiment, a sealed single-head helical screw is provided. like Figure 5 As shown, the screw rod in this embodiment is a single-headed screw, and the two sides of its tooth shape are the force transmission side abcd and the sealing side ef respectively, and the force transmission side abcd is divided into three sections ab, bc, and cd. Among them, ab is the elongated epicycloid tooth profile, bc is the involute tooth profile, cd is the short epicycloid tooth profile, and the sealing edge ef is the elongated epicycloid tooth profile.

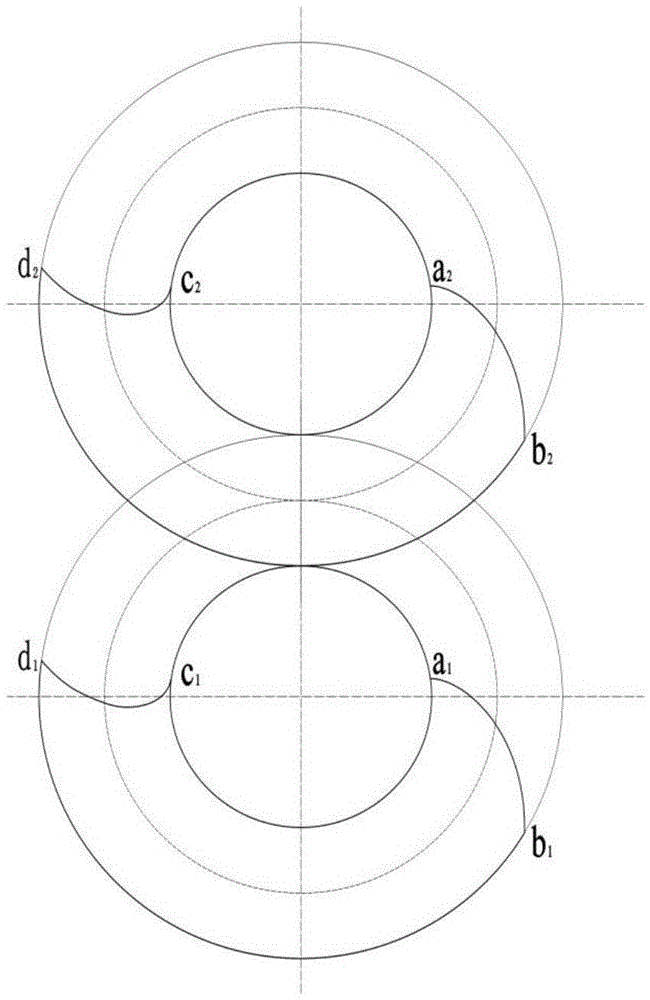

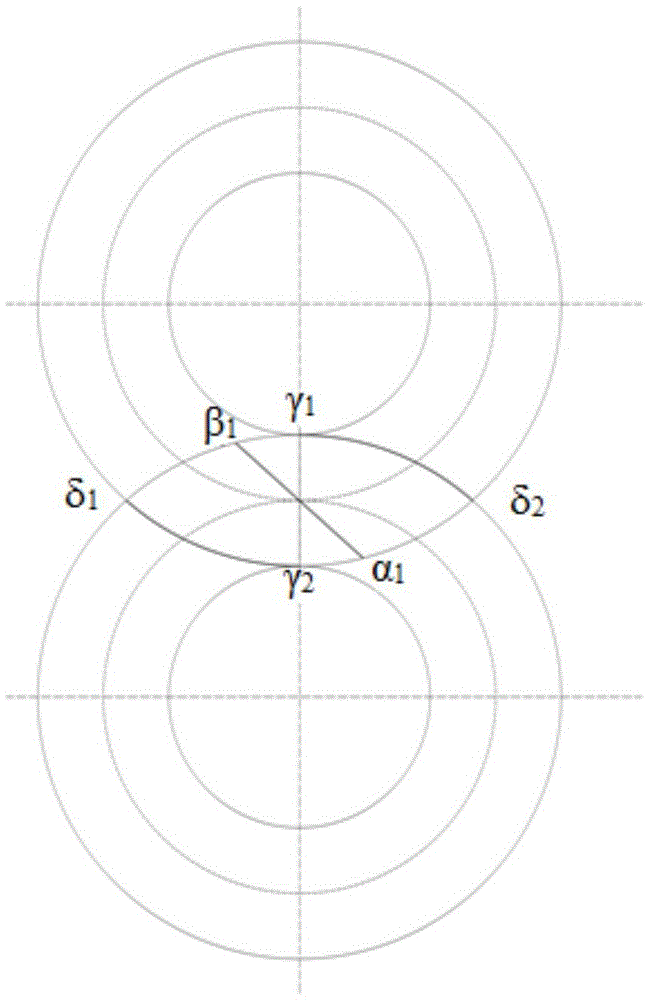

[0040] This embodiment also provides a twin-screw pump, the active screw S 1 and driven screw S 2 The tooth shape is the same, and they are all the above-mentioned single-head helical screws. Active screw S 1 The helical direction of the driven screw S 2 The helices have different directions of rotation, if one of them is right-handed, the other is left-handed. In the following logos, the subscript 1 means that it belongs t...

Embodiment 2

[0052] On the basis of Example 1, the screw rod of this example is a single-headed screw, and the side of the sealing edge adopts the elongated epicycloid 1 as the tooth profile, and further, the elongated epicycloid 1 is carried out on the tooth top section. Wear correction. As an implementation, in this embodiment, the wear correction adopts cycloid chamfer correction, such as Figure 12 As shown, in this embodiment, the extended epicycloid gg' chamfering is adopted, and the tooth profile of the sealing edge is composed of two sections, the elongated epicycloid segment eg and the extended epicycloid chamfer segment gg'. In other embodiments, other forms of modification may also be employed.

[0053] The main purpose of using the elongated epicycloid gg' chamfer to modify the tooth profile line ef of the sealing edge is to improve the wear resistance of the sealing edge.

[0054] In this embodiment, the force transmission principle of the screw is: the tooth profile of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com