Patents

Literature

104results about "Device details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

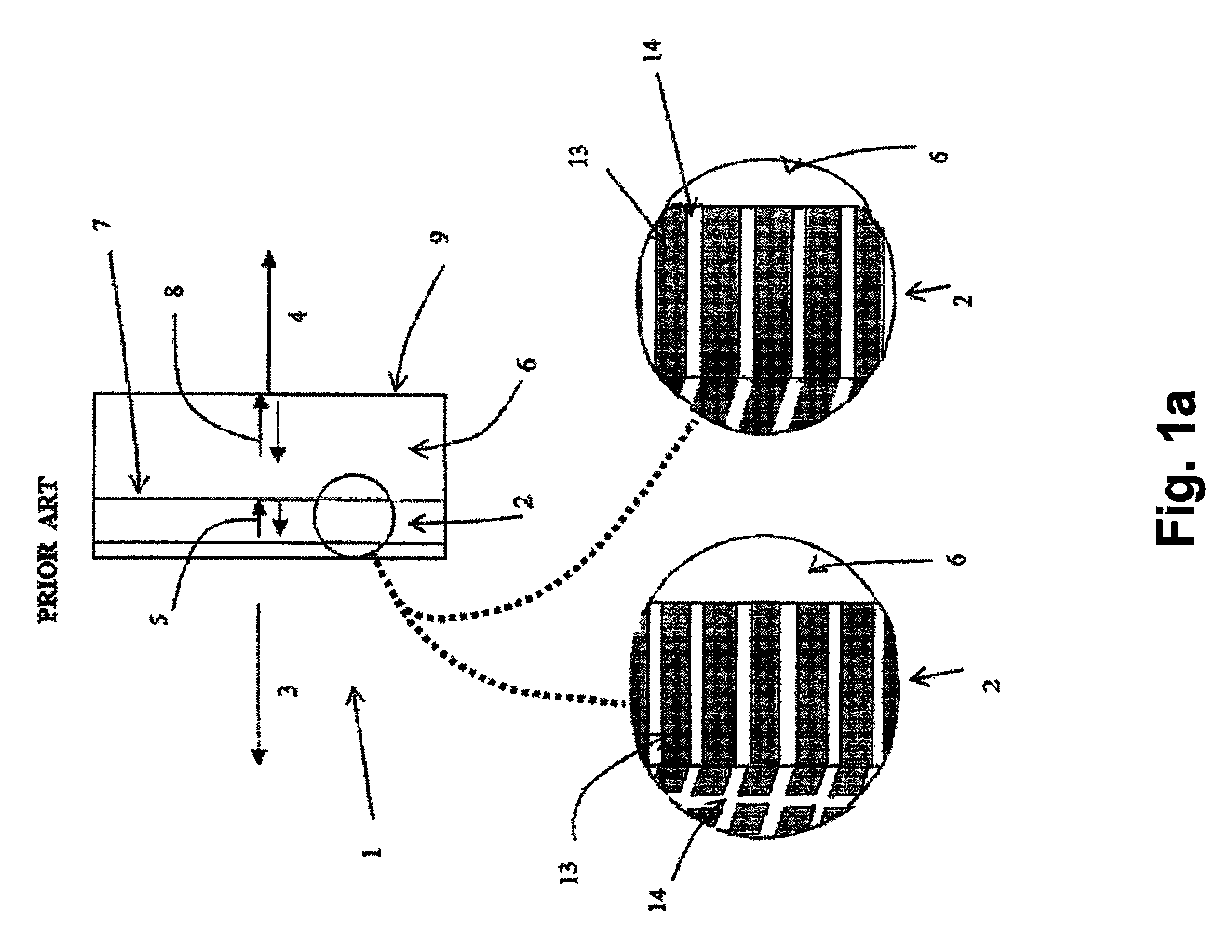

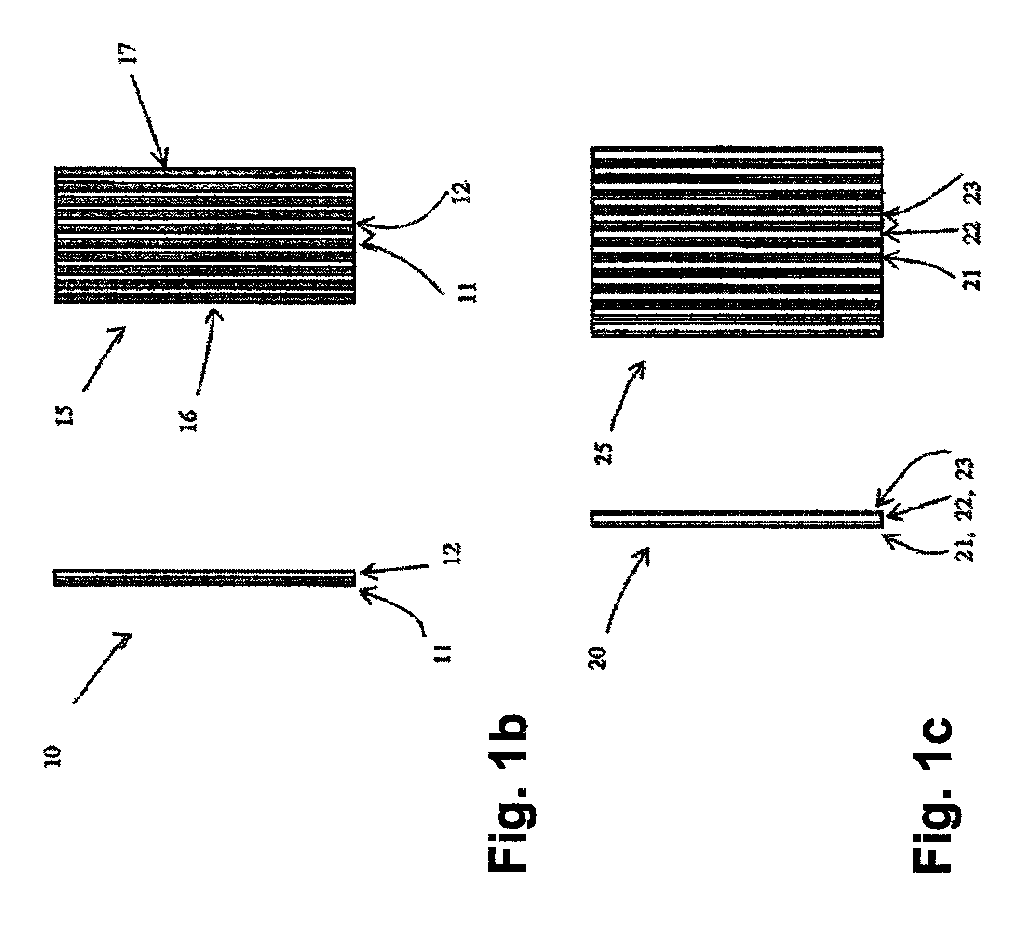

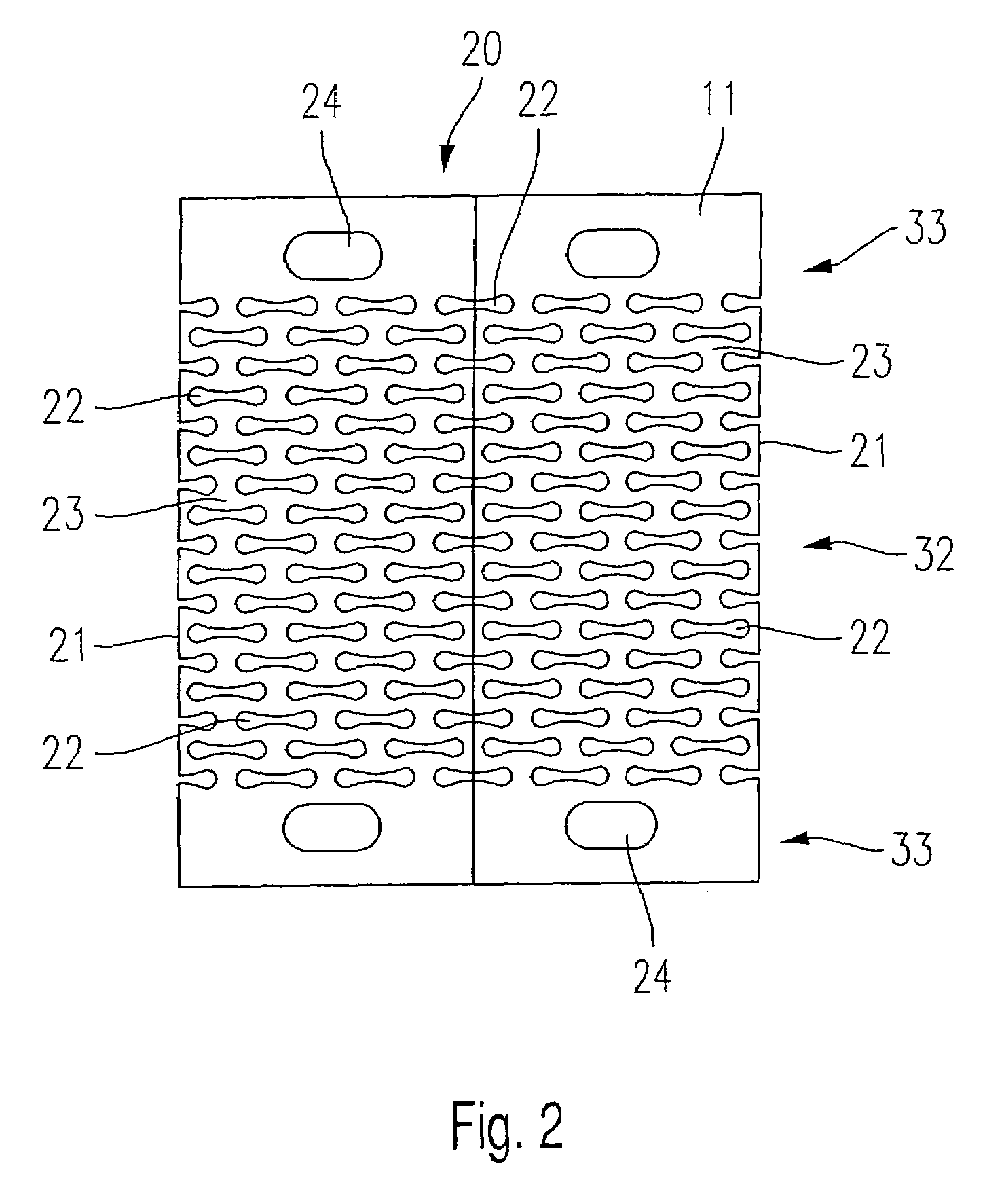

Electroactive polymer devices for moving fluid

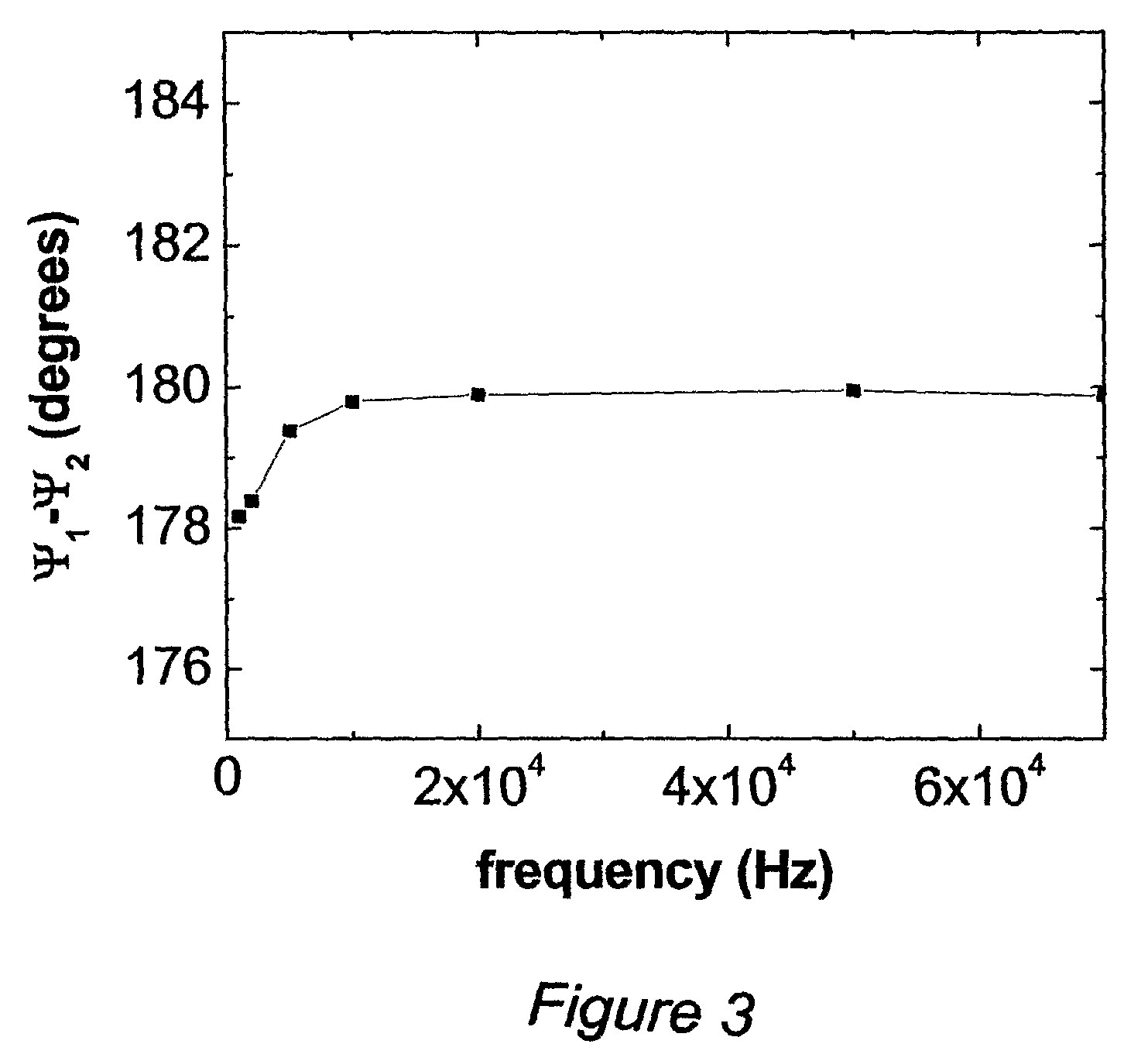

InactiveUS7064472B2Improve mechanical responseImprove responseTransducer detailsFlexible member pumpsHearing rangeThermal force

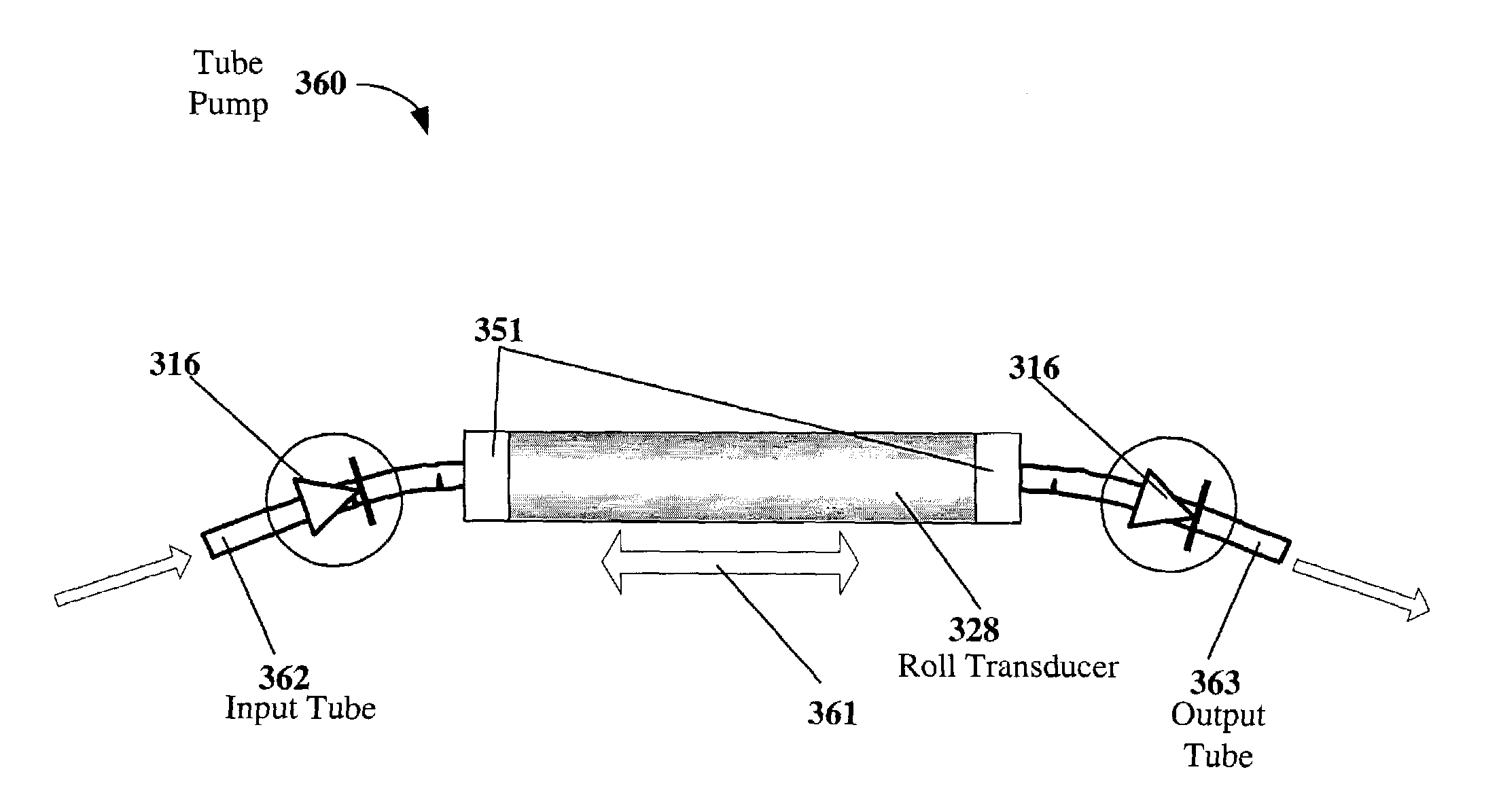

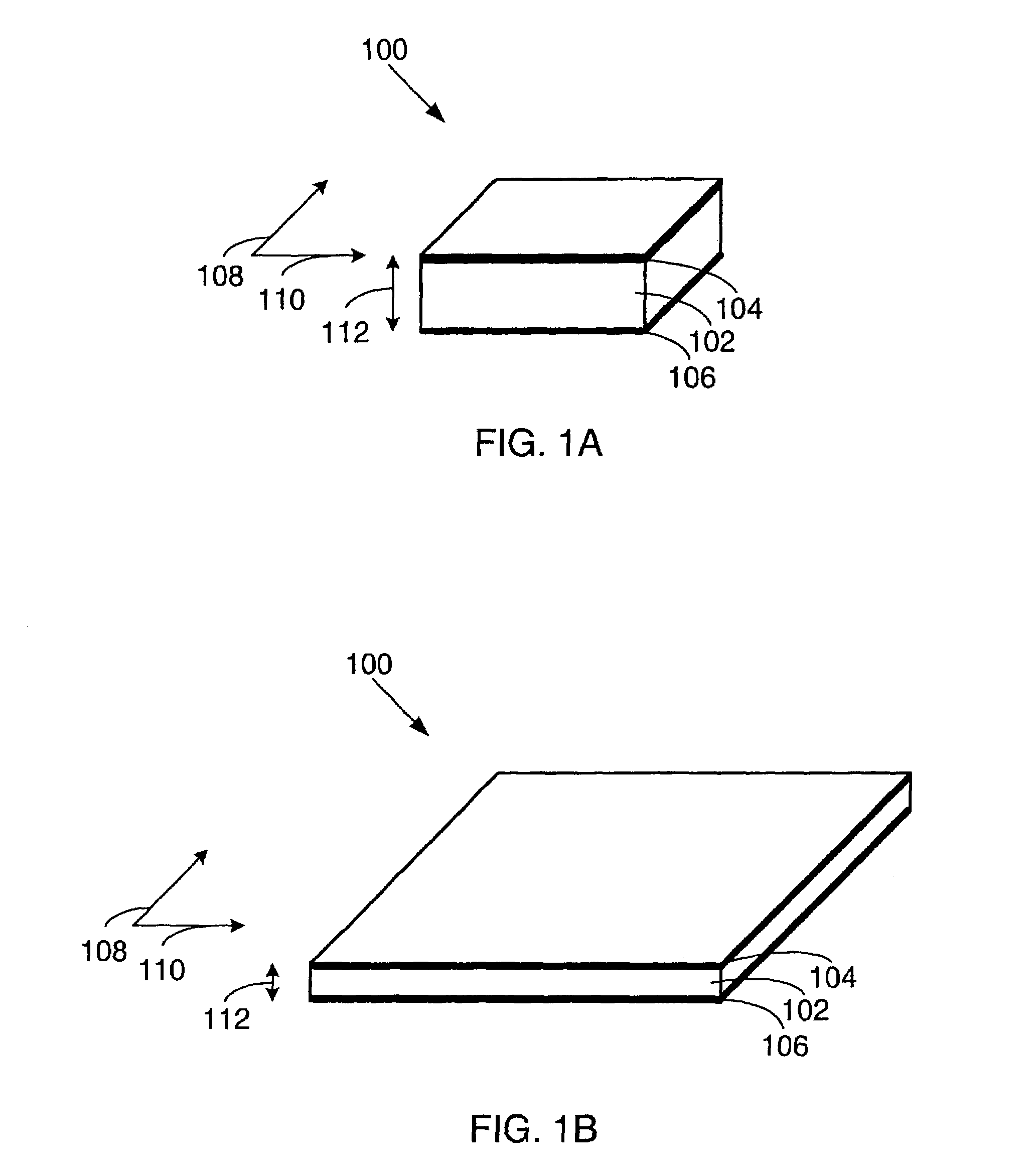

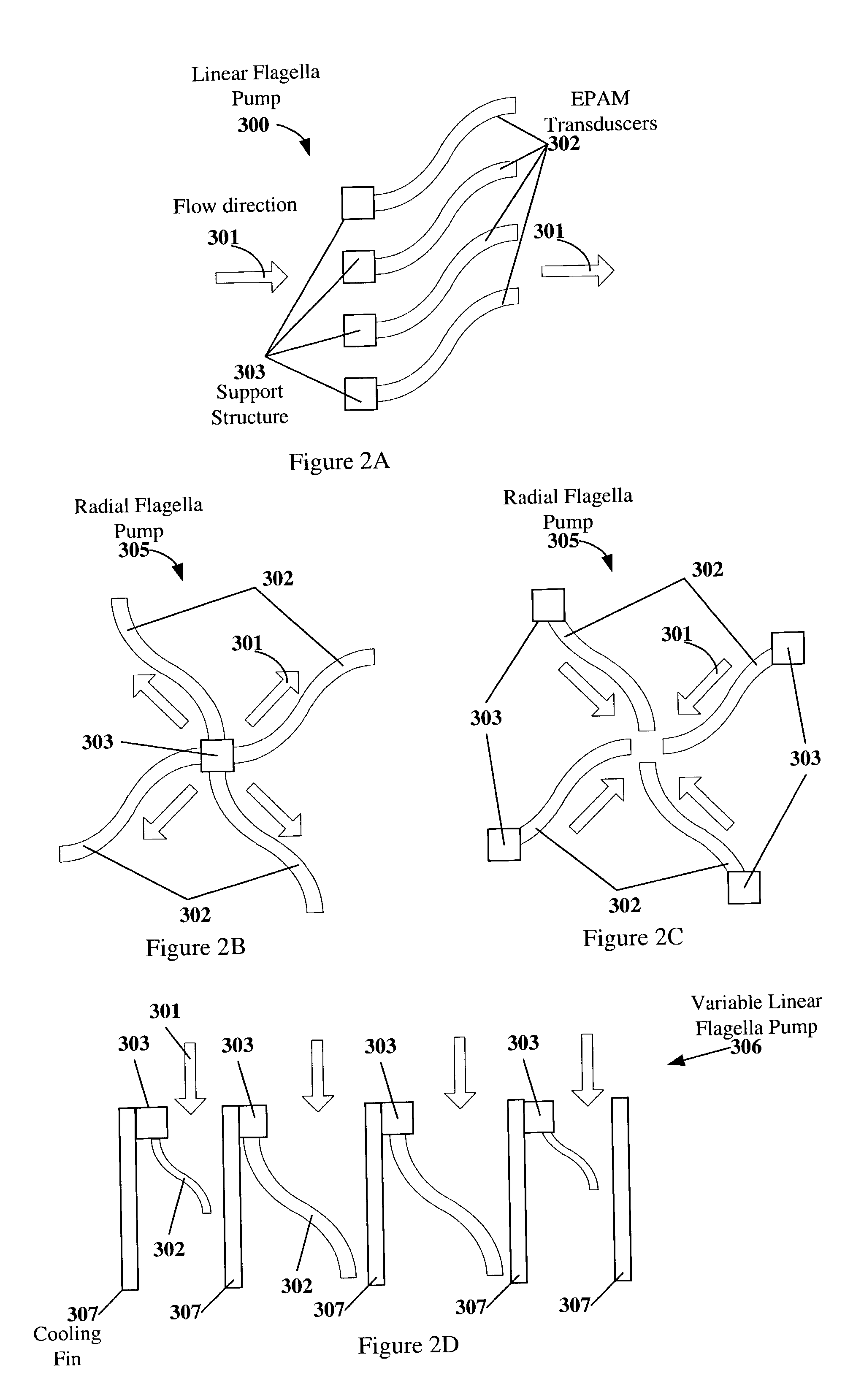

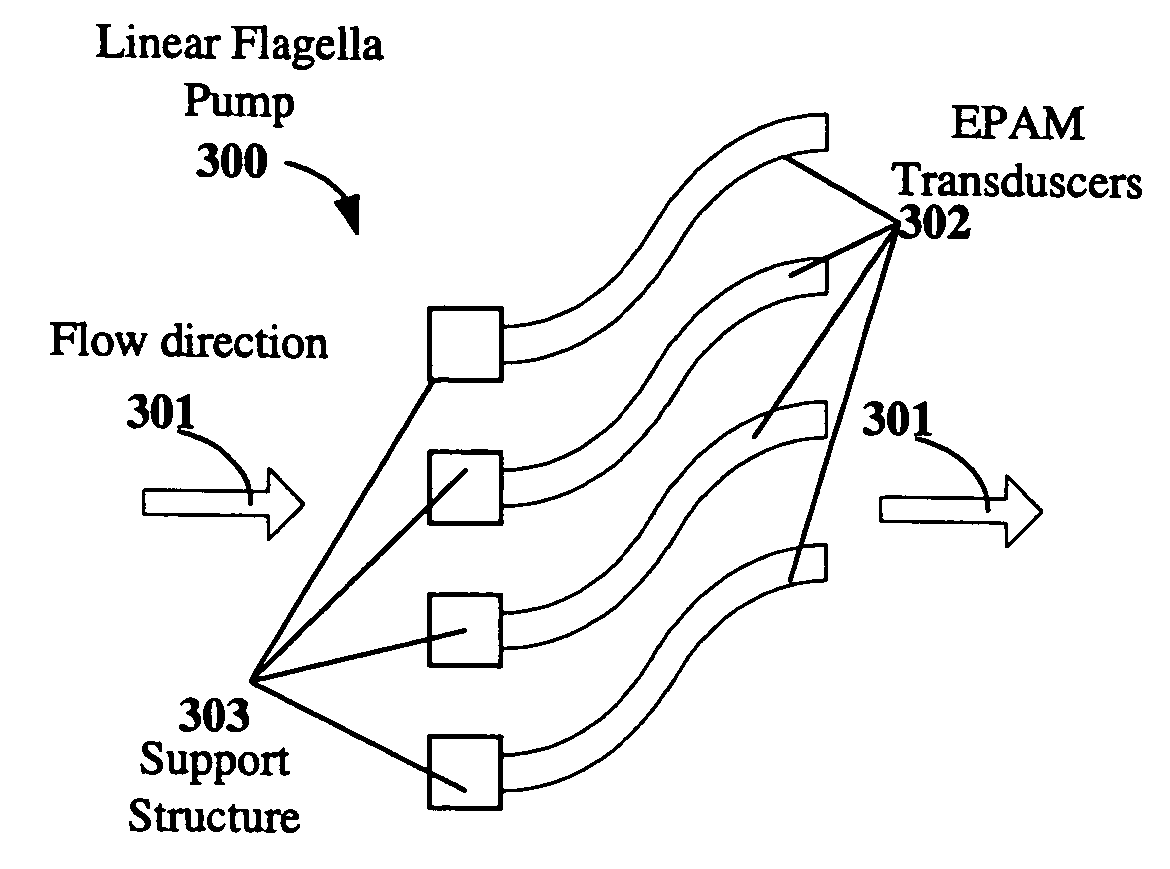

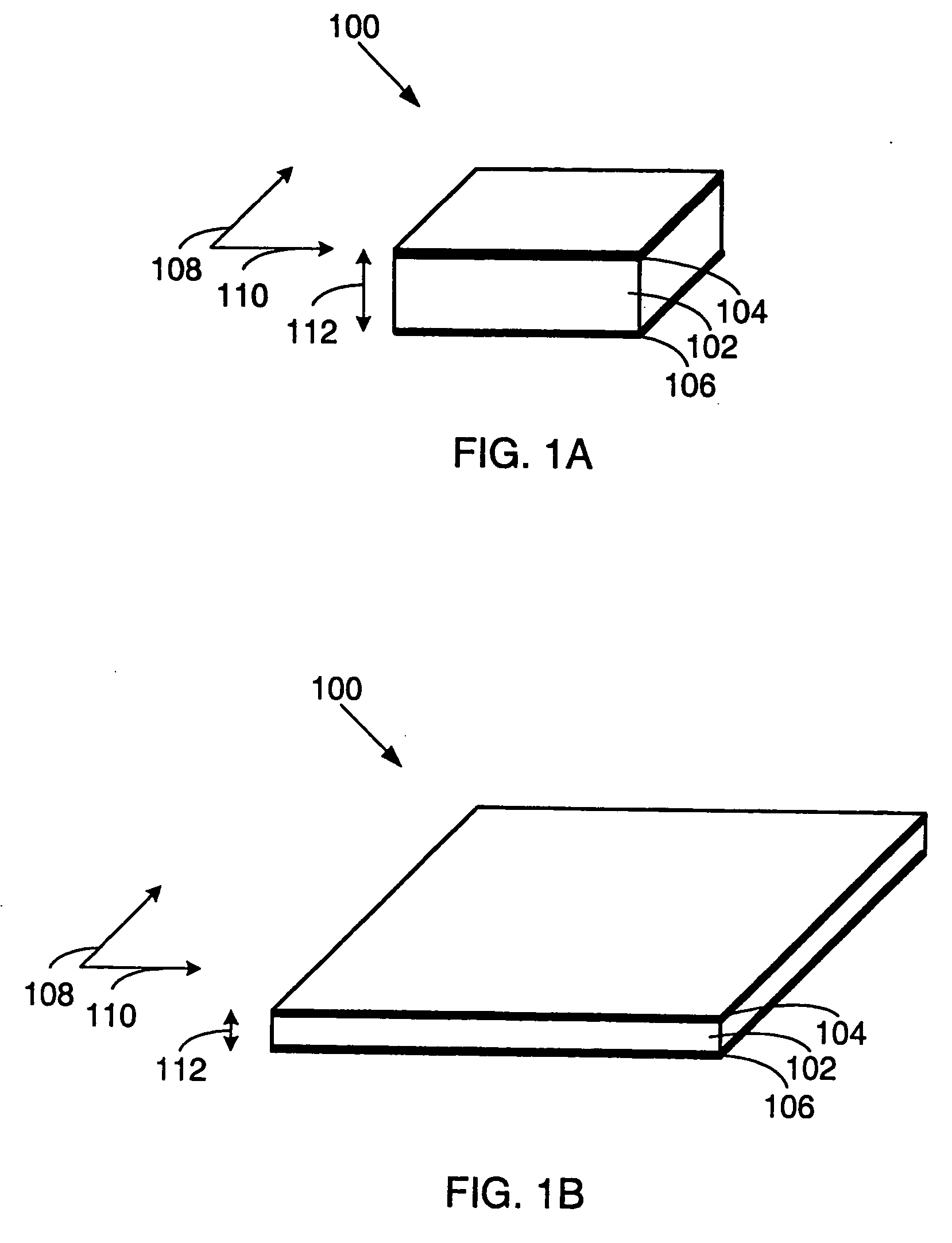

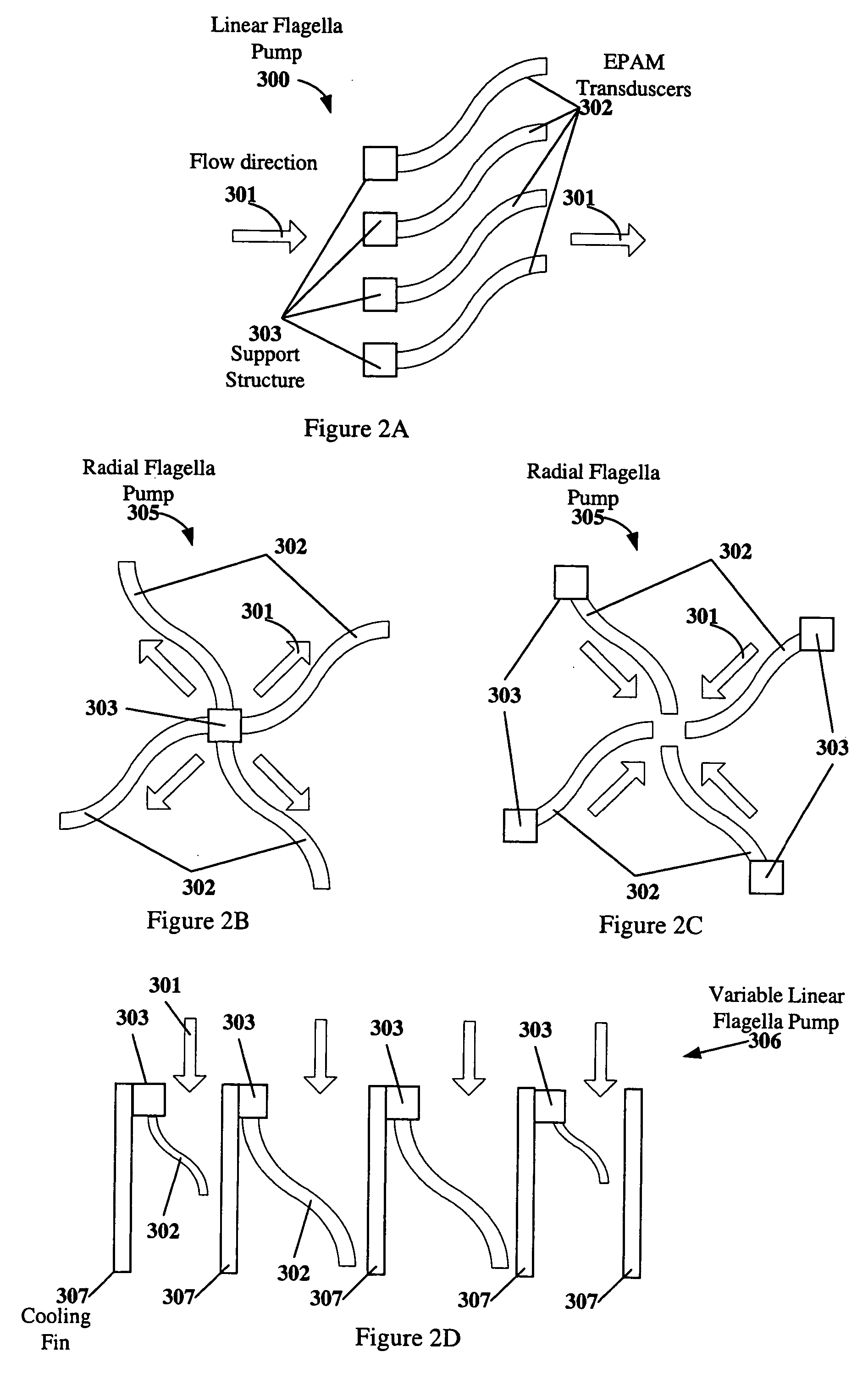

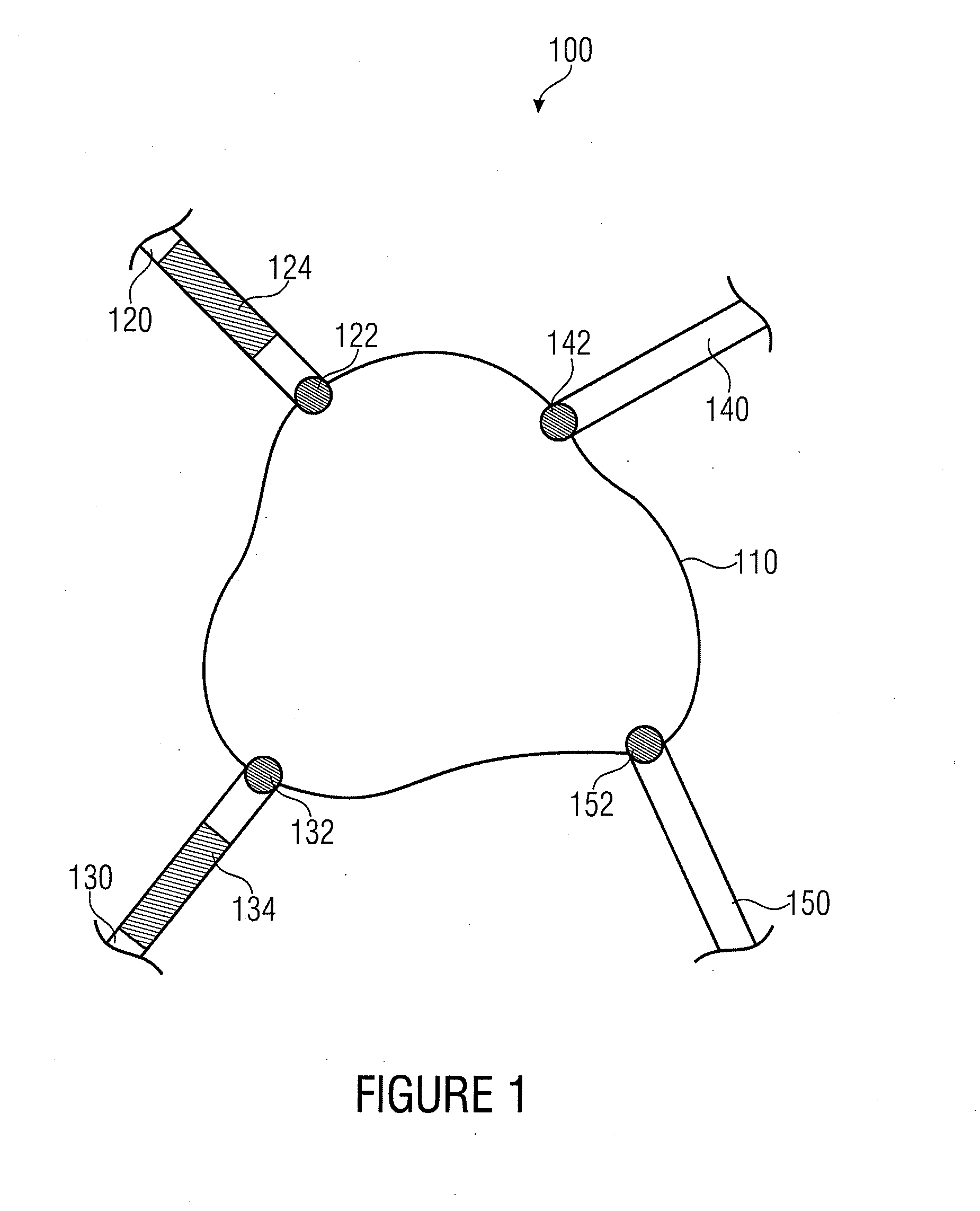

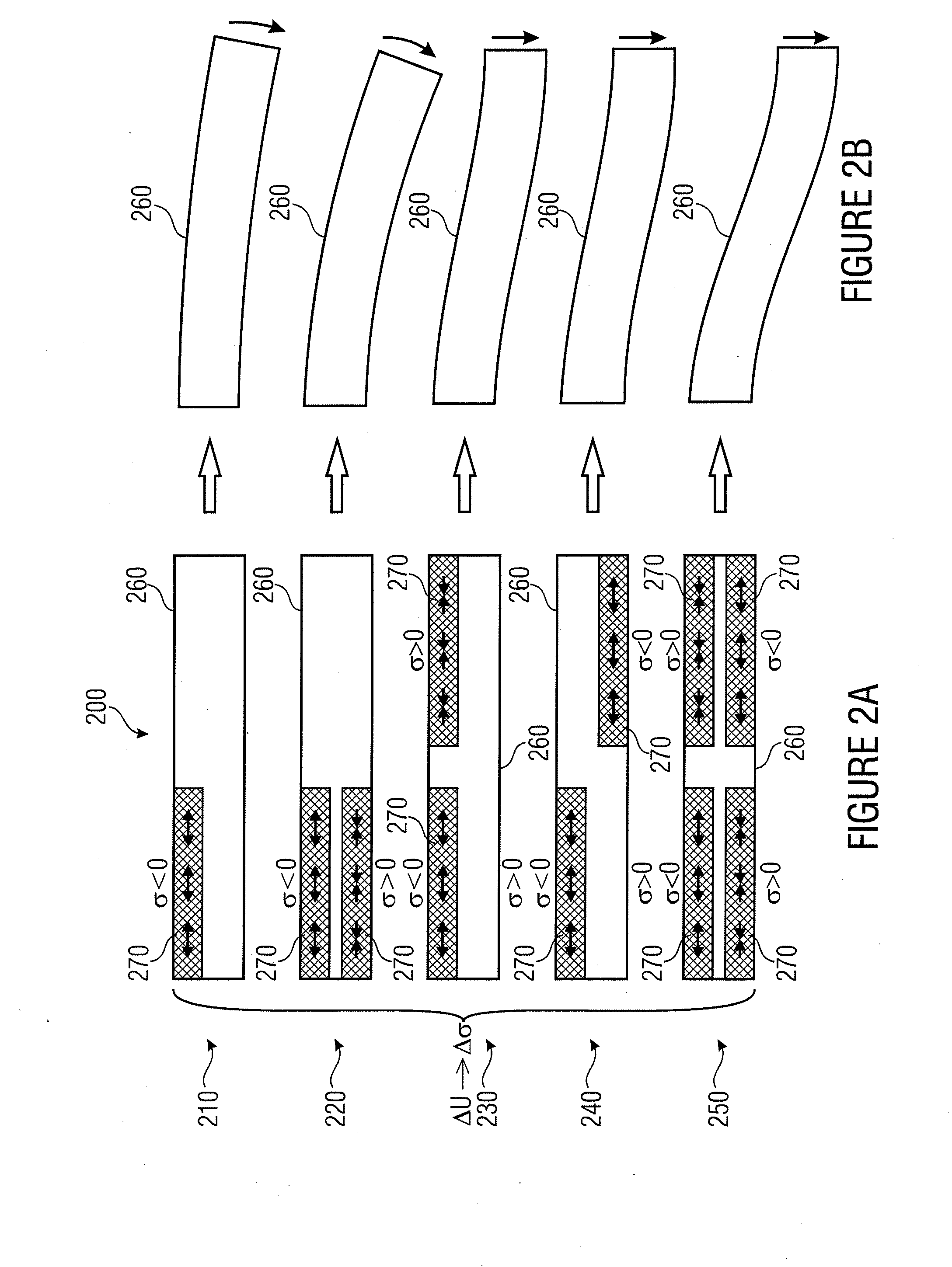

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

Electroactive polymer devices for moving fluid

InactiveUS20060158065A1Improve responseTransducer detailsFlexible member pumpsHearing rangeThermal force

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

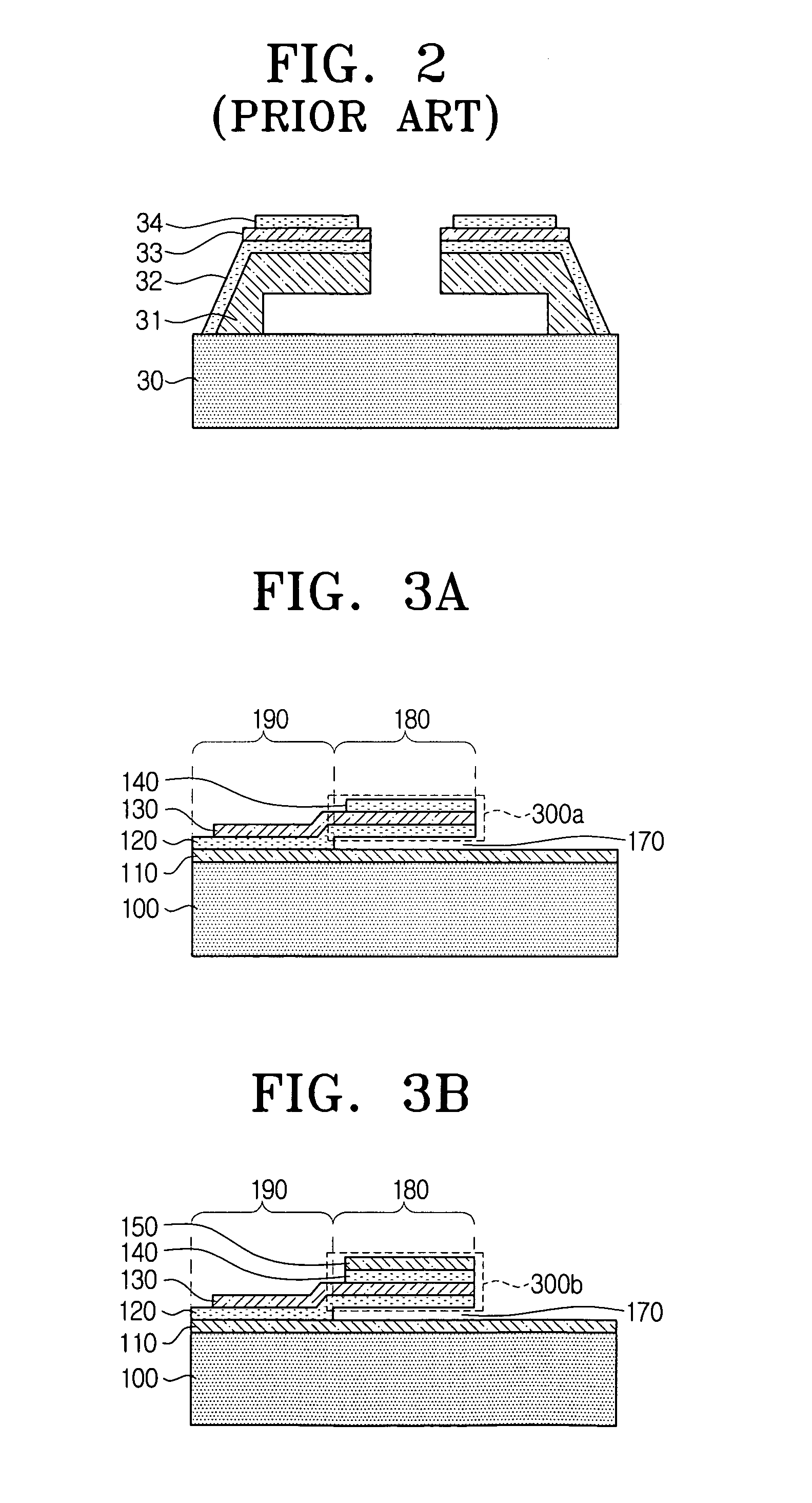

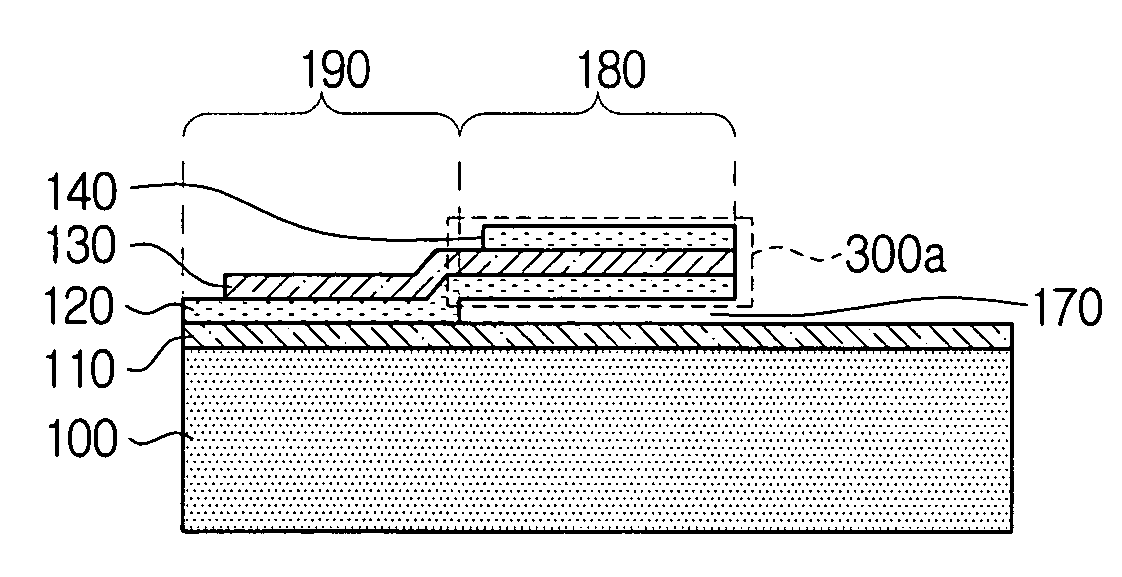

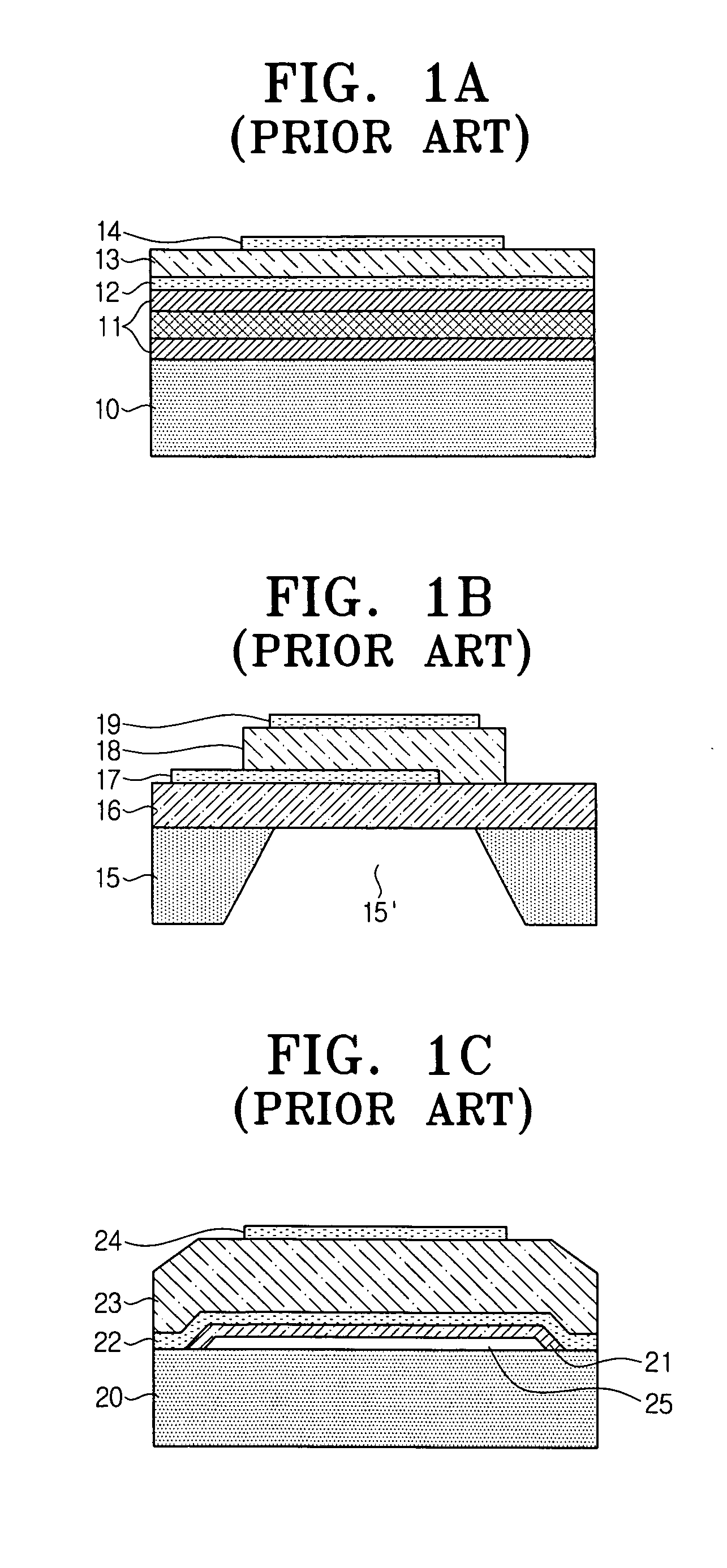

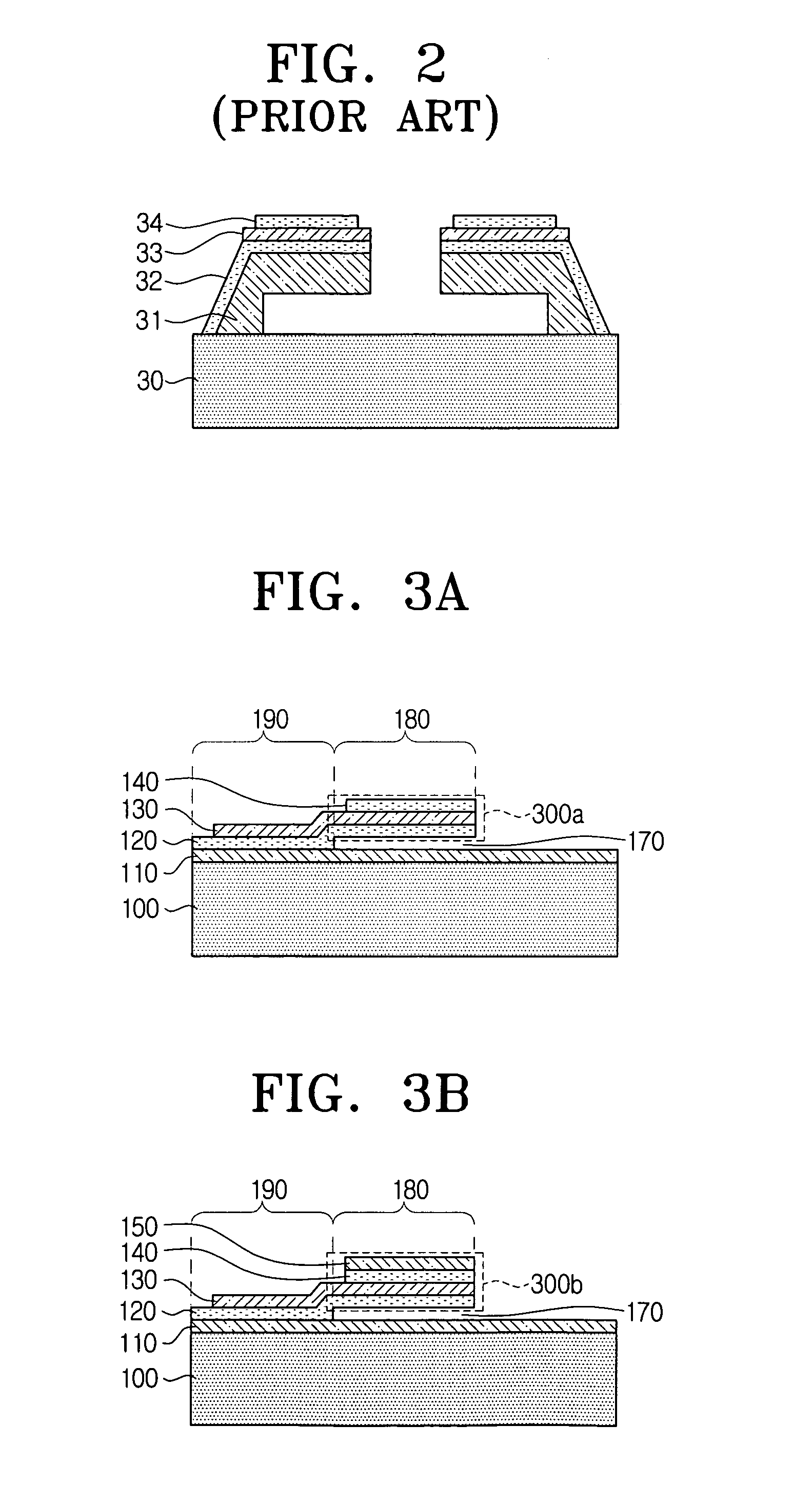

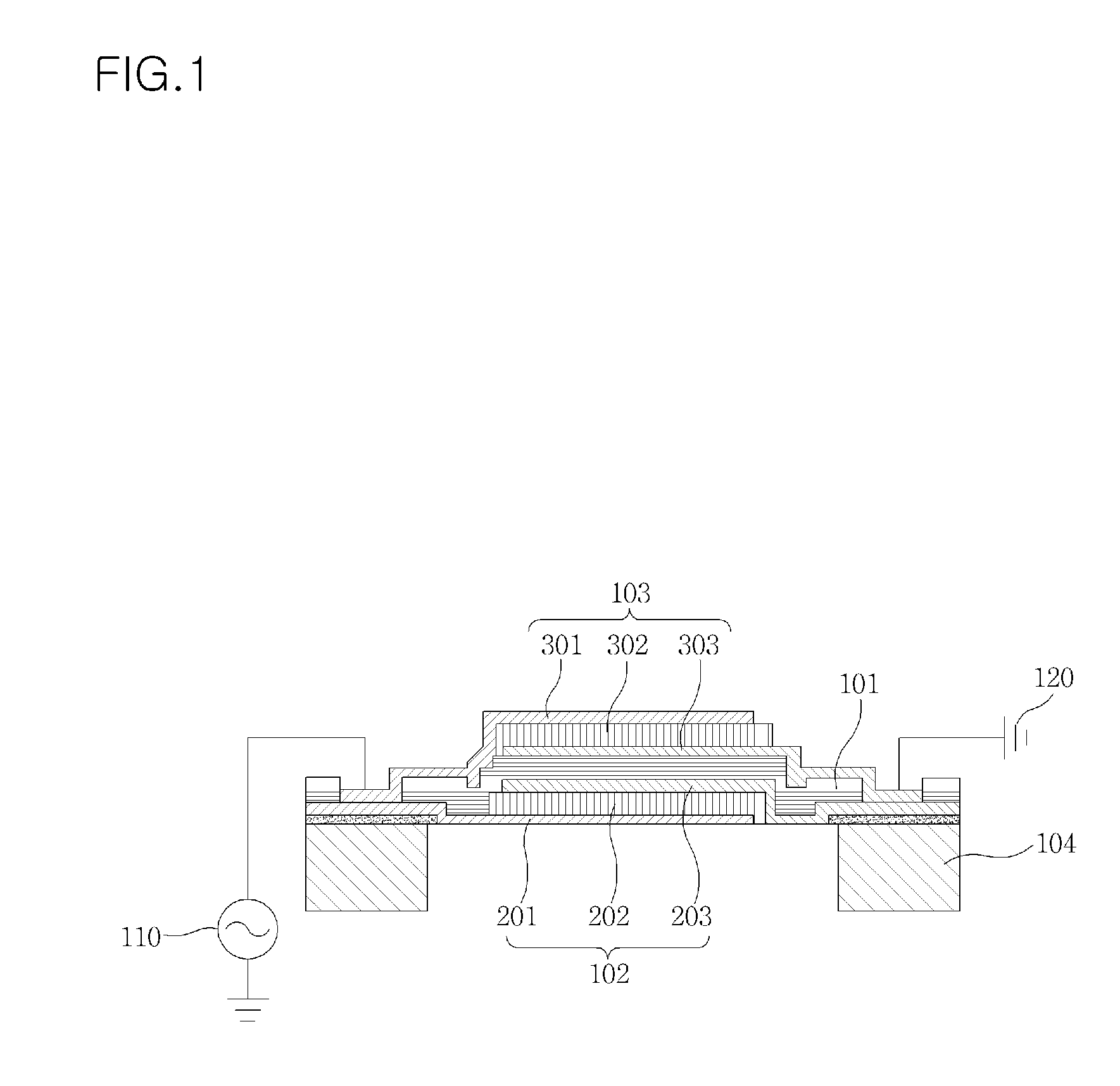

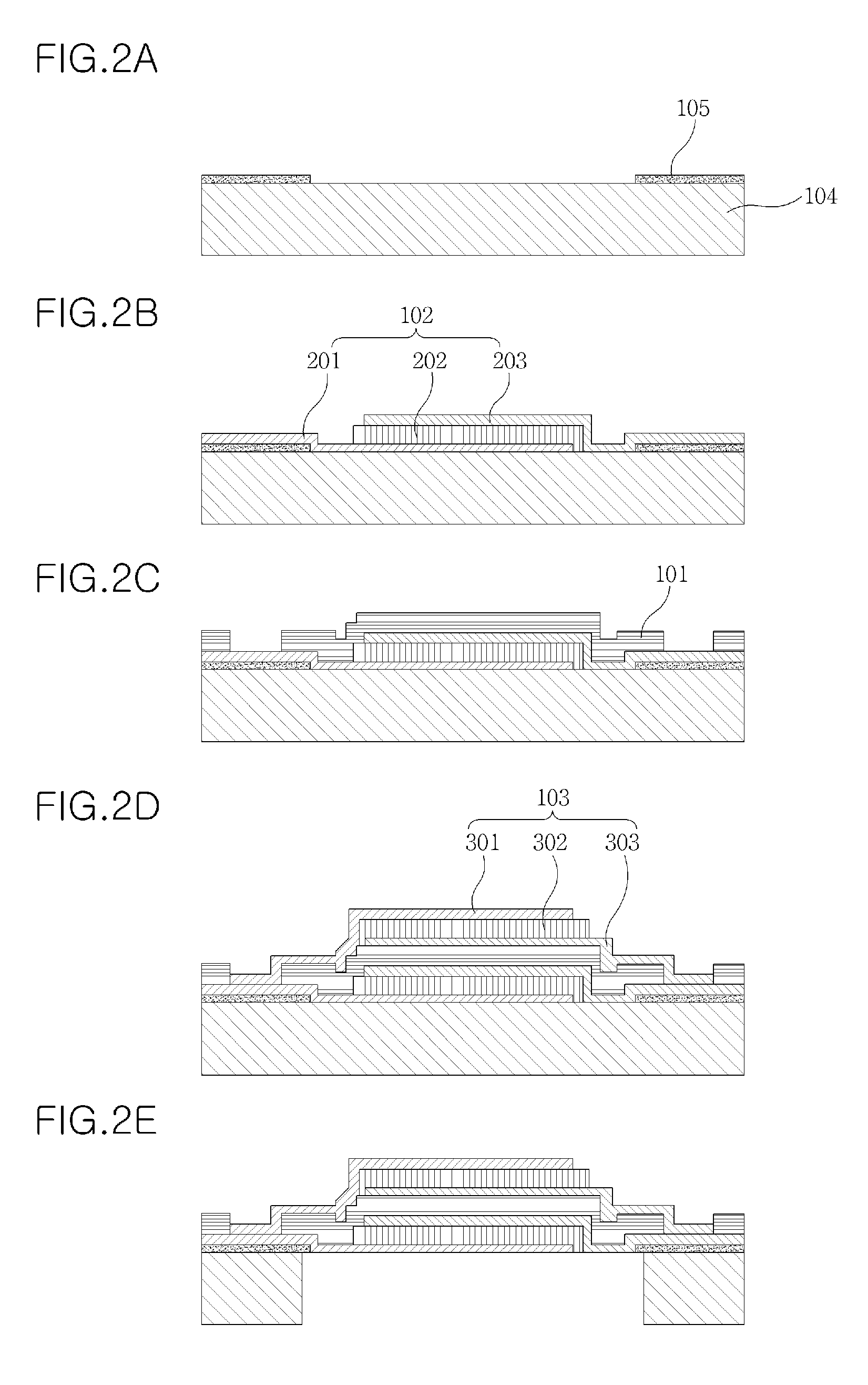

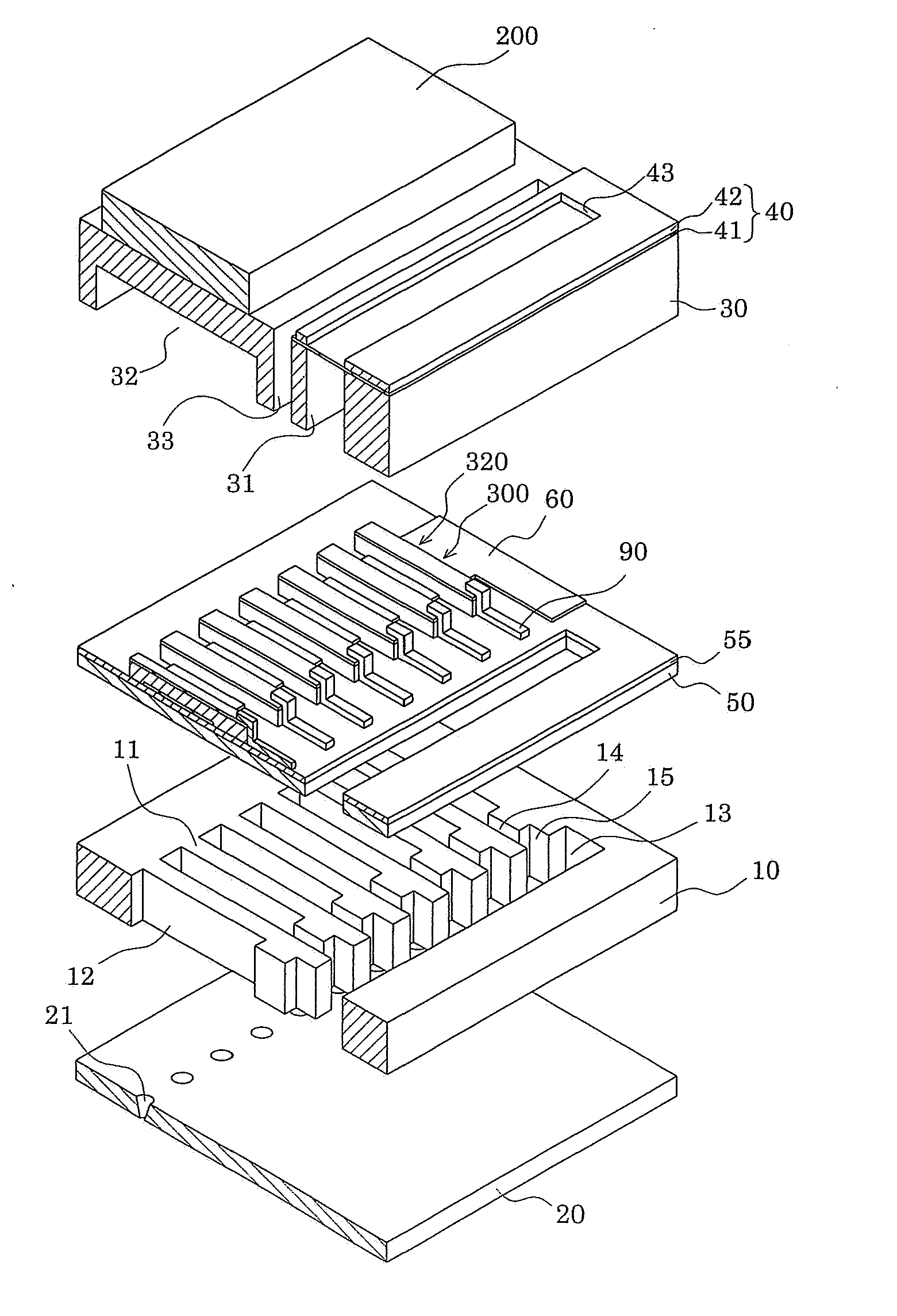

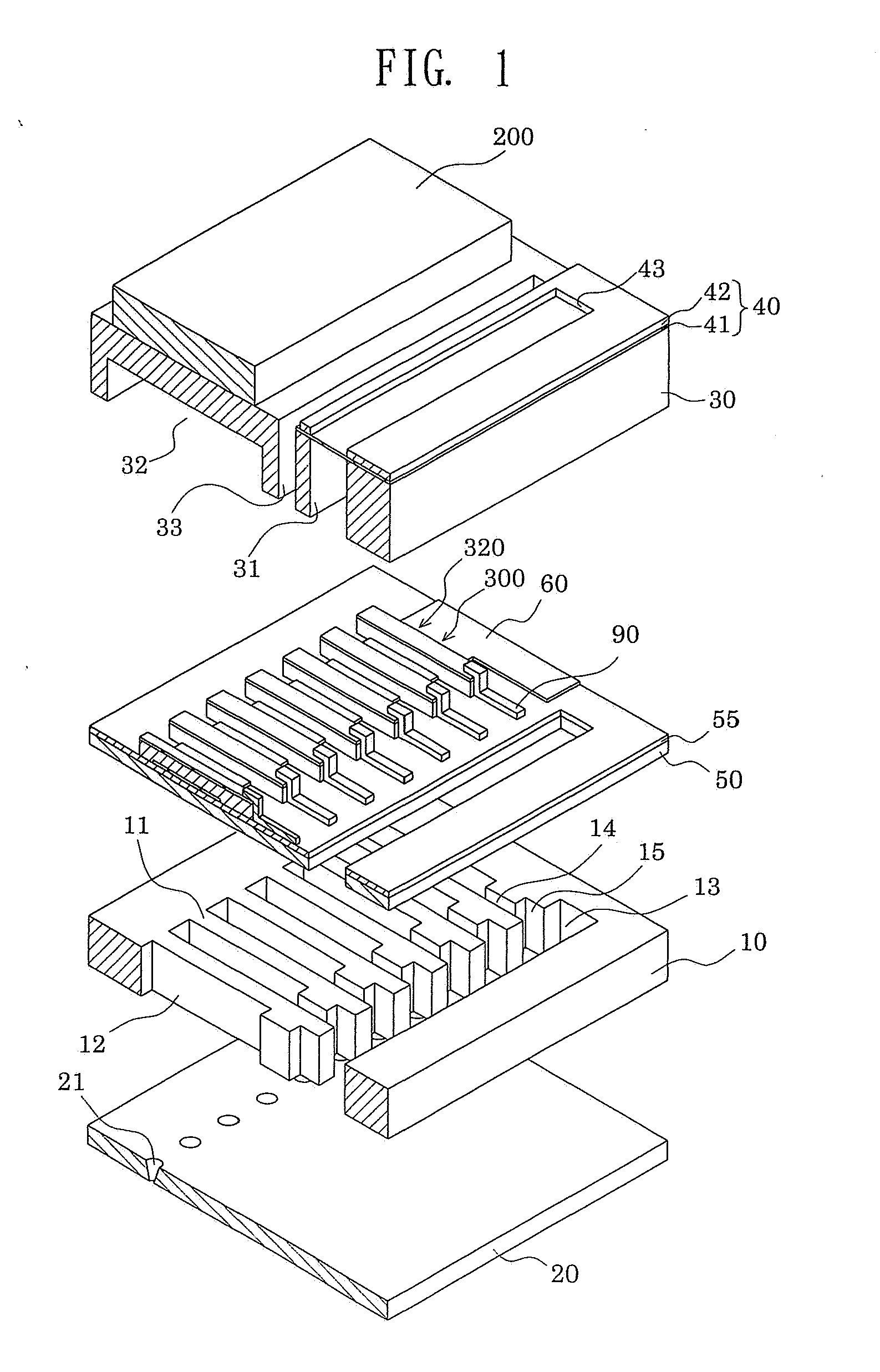

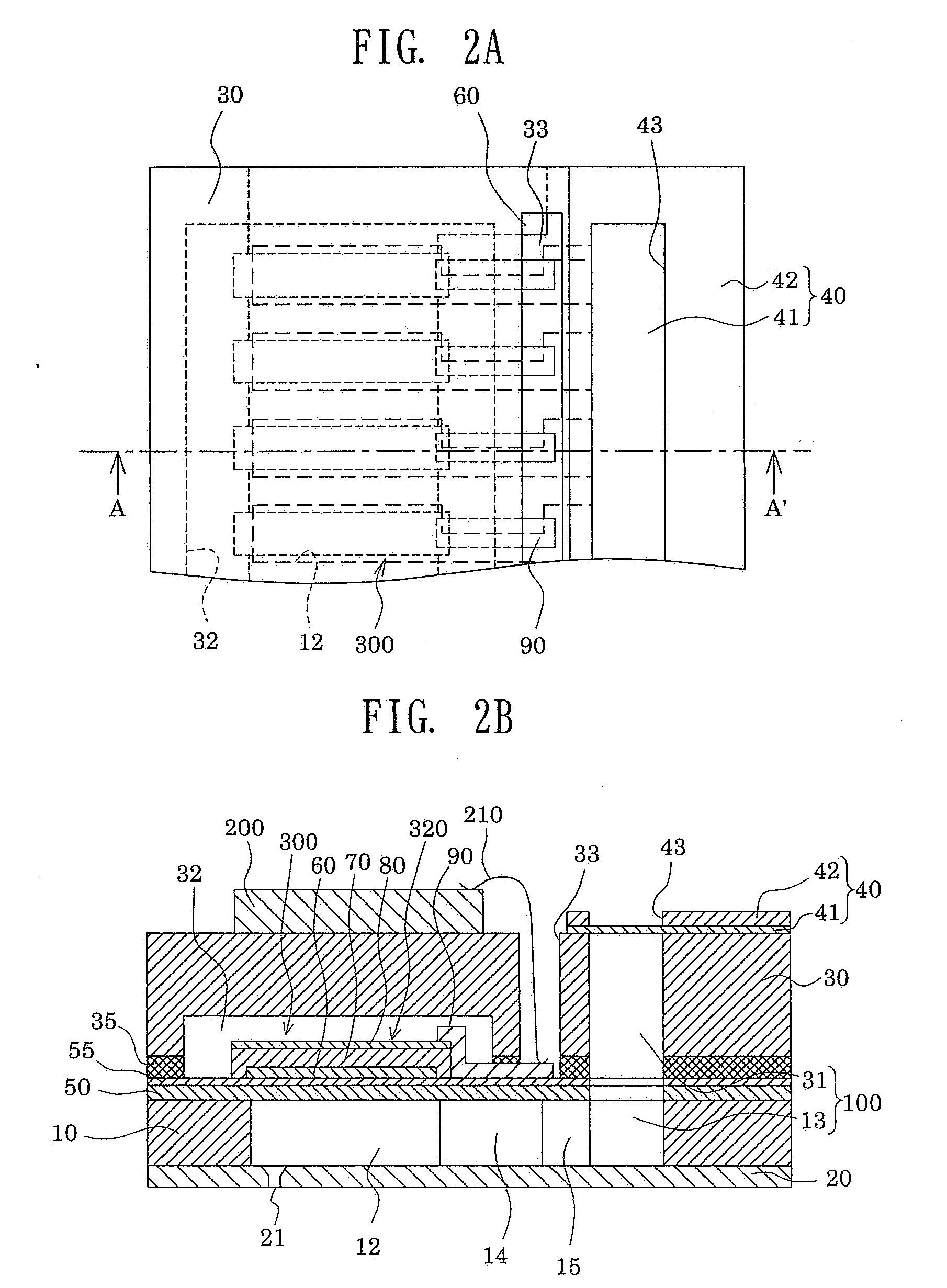

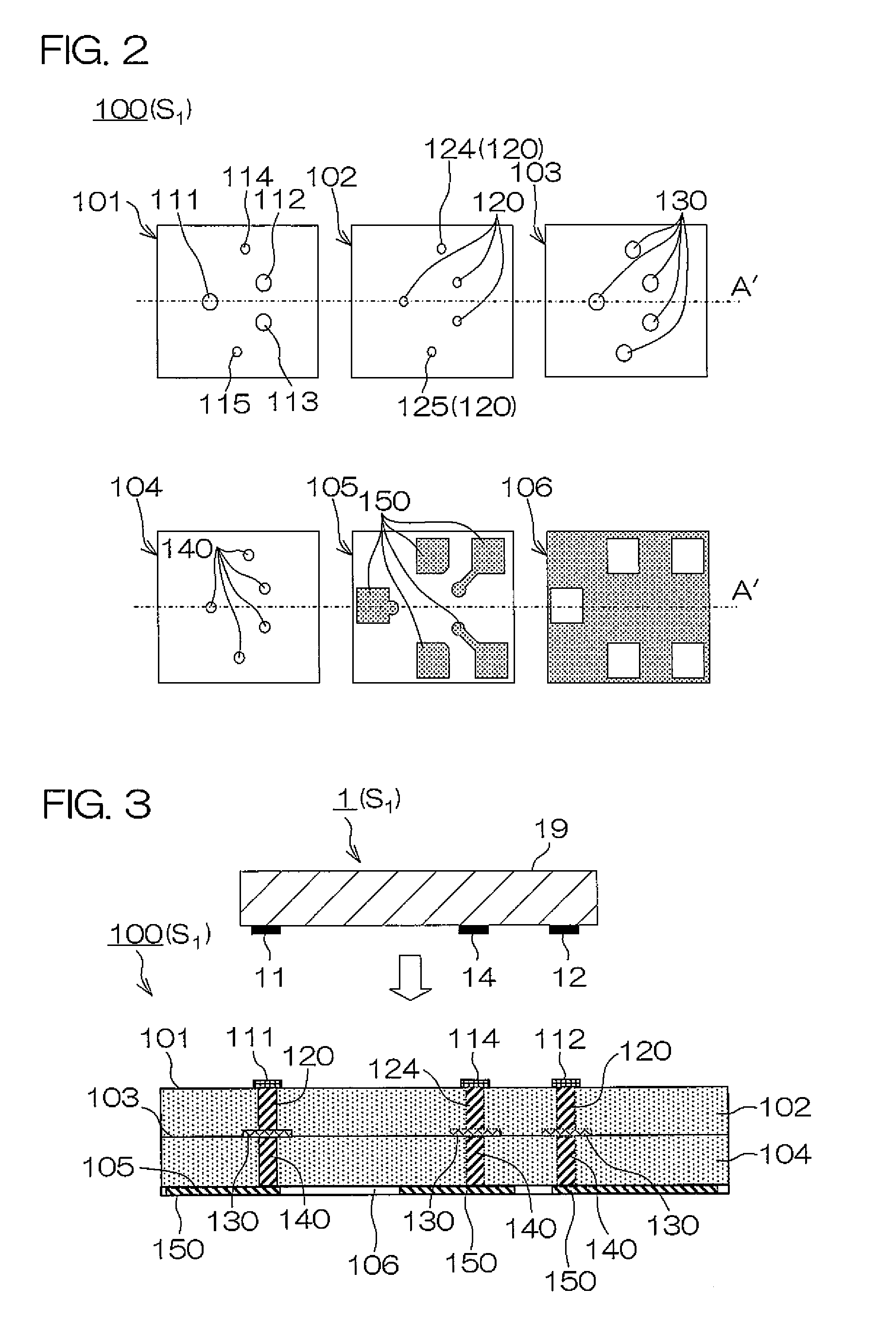

Method for fabricating cantilevered type film bulk acoustic resonator and film bulk acoustic resonator fabricated by the same

ActiveUS20050034822A1Simpler FBAR fabricationAvoid damagePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorDielectric layer

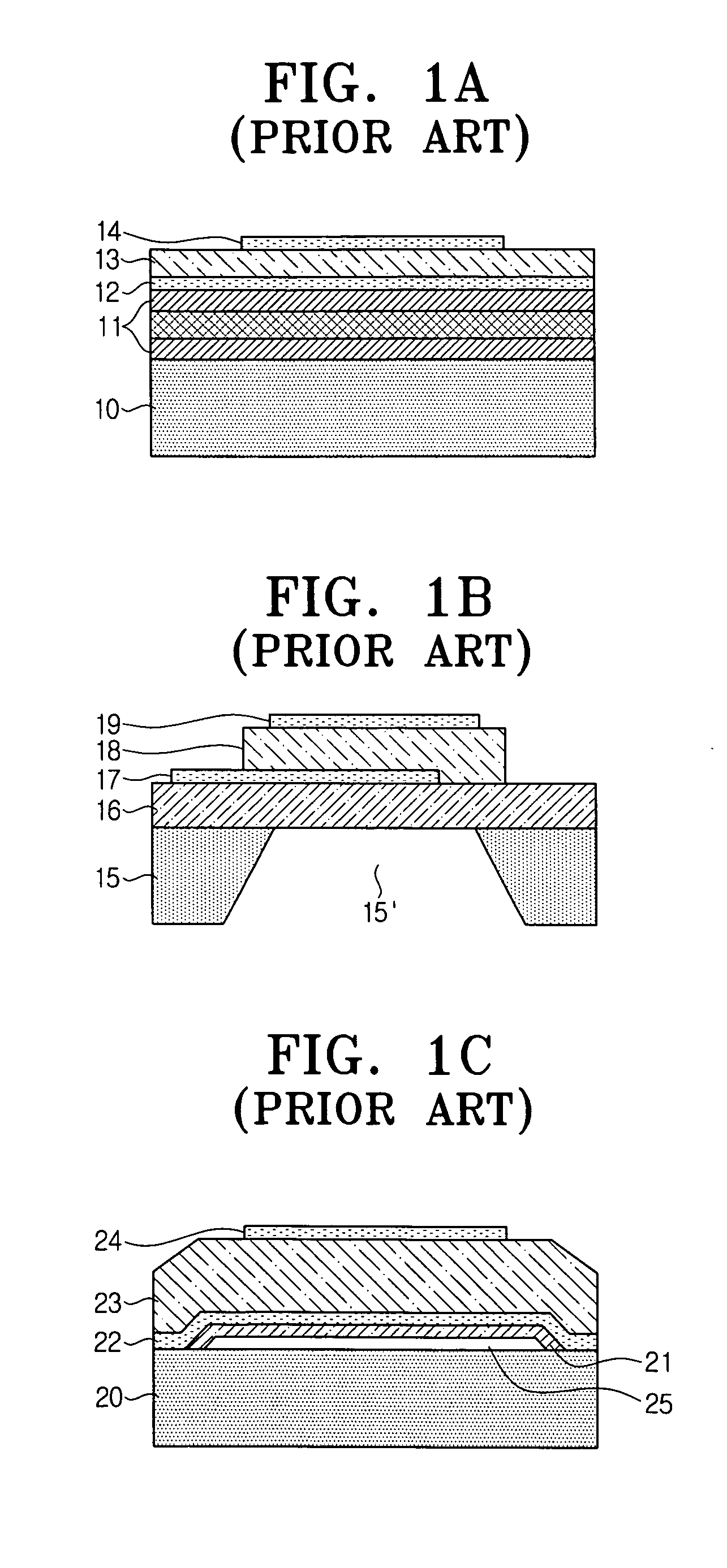

A method for fabricating a film bulk acoustic resonator (FBAR) includes depositing a dielectric layer on a substrate, providing a sacrificial layer on part of the dielectric layer; providing a bottom electrode on part of the sacrificial layer on part of the dielectric layer; providing a piezoelectric layer on the bottom electrode; patterning a top electrode on the piezoelectric layer; and removing the sacrificial layer. The substrate may have a cavity receiving the sacrificial layer. As a result, a cantilevered resonator having an air gap between the bottom electrode and the dielectric layer may be simply fabricated.

Owner:SAMSUNG ELECTRONICS CO LTD

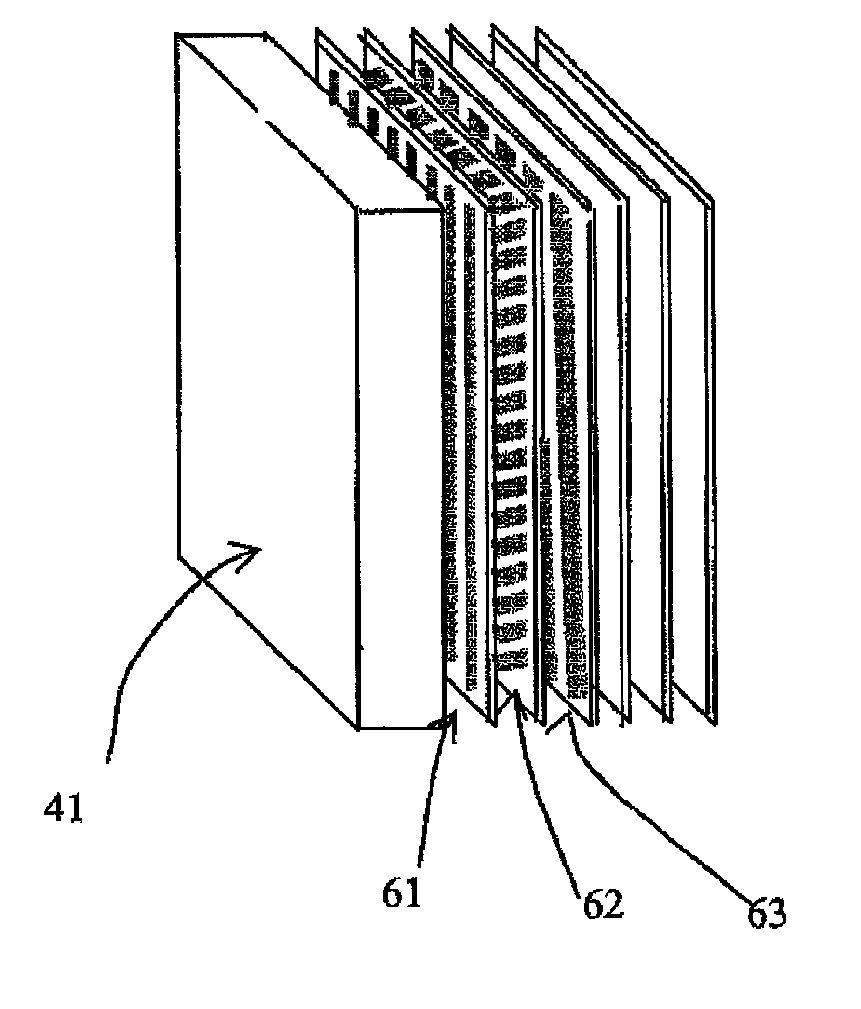

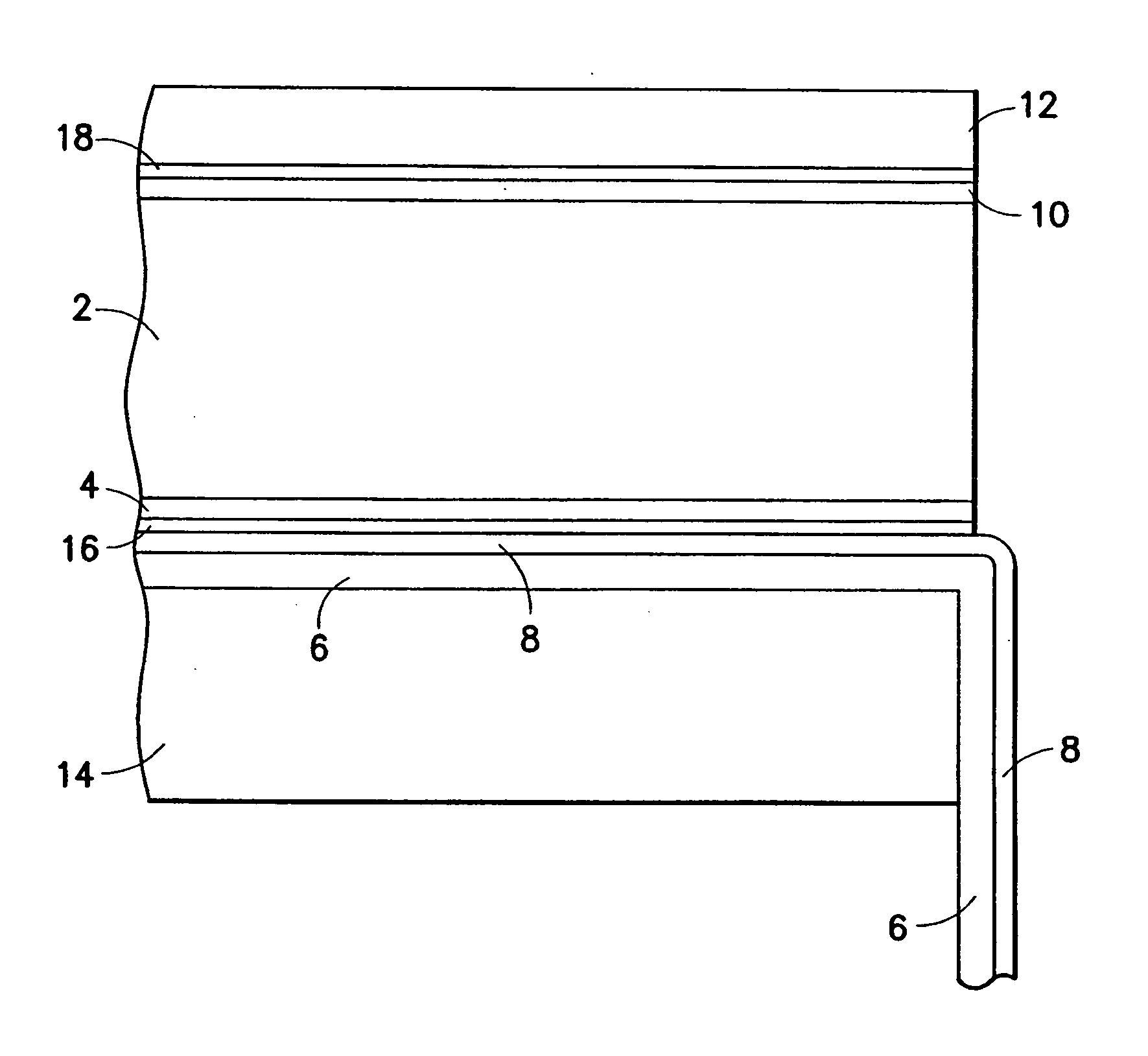

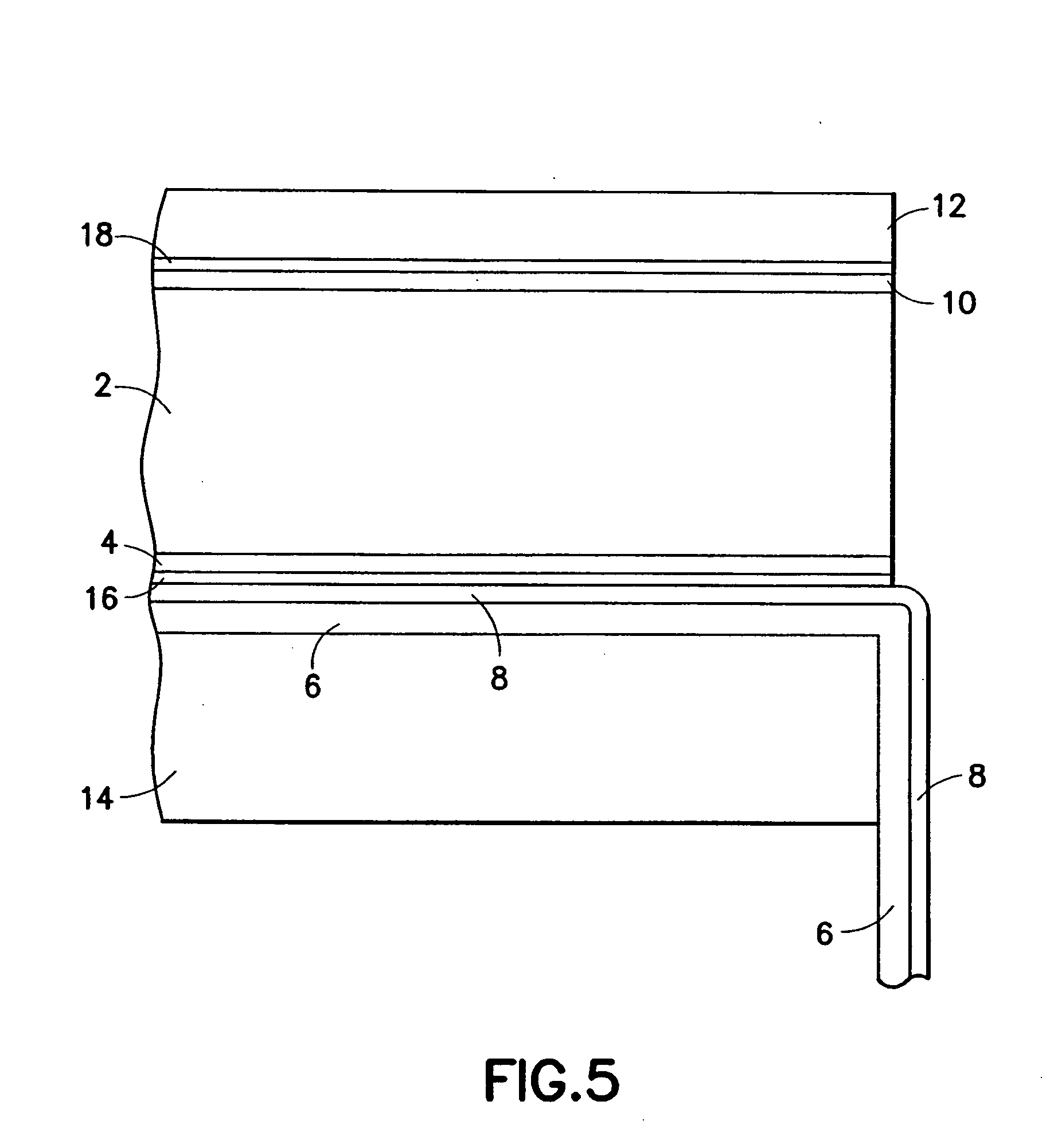

Multilayer backing absorber for ultrasonic transducer

ActiveUS8570837B2Piezoelectric/electrostriction/magnetostriction machinesSynthetic resin layered productsUltrasonic sensor

A multilayer backing absorber for use with an ultrasonic transducer comprises an elemental multilayer having at least one metal layer and at least one adhesive layer, wherein the backing absorber is adapted to be coupled to a vibrating layer of the ultrasonic transducer.

Owner:MEASUREMENT SPEC

Method for fabricating a film bulk acoustic resonator

ActiveUS7281304B2Avoid damageQ-value increasingPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyThin-film bulk acoustic resonatorDielectric layer

A method for fabricating a film bulk acoustic resonator (FBAR) includes depositing a dielectric layer on a substrate, providing a sacrificial layer on part of the dielectric layer; providing a bottom electrode on part of the sacrificial layer on part of the dielectric layer; providing a piezoelectric layer on the bottom electrode; patterning a top electrode on the piezoelectric layer; and removing the sacrificial layer. The substrate may have a cavity receiving the sacrificial layer. As a result, a cantilevered resonator having an air gap between the bottom electrode and the dielectric layer may be simply fabricated.

Owner:SAMSUNG ELECTRONICS CO LTD

Lithium niobate substrate and method of producing the same

ActiveUS20050145165A1Color non-uniformityPoor resolutionPiezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthMaterials scienceHeat treated

In a method of producing a lithium niobate substrate by the use of a lithium niobate crystal grown by the Czochralski process, the lithium niobate crystal is heat-treated at a temperature of from 300° C. or more to less than 500° C. in the state the lithium niobate crystal is buried in a powder constituted of at least one element selected from the group consisting of Al, Ti, Si, Ca, Mg and C, or in the state the lithium niobate crystal is held in a container constituted of at least one element selected from the group consisting of Al, Ti, Si, Ca, Mg and C.

Owner:SUMITOMO METAL MINING CO LTD

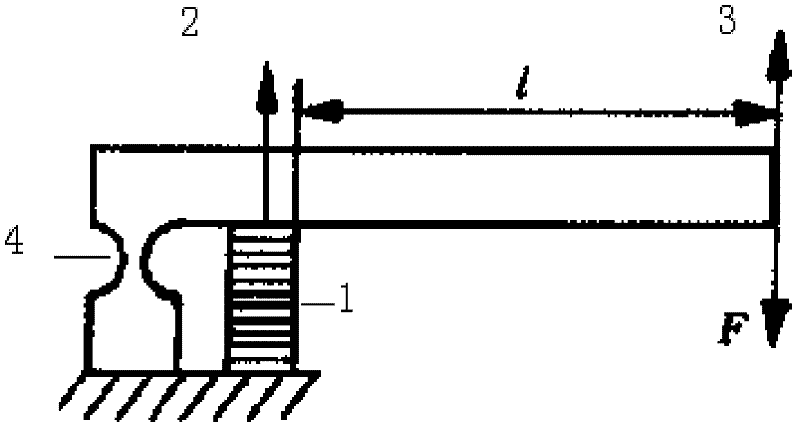

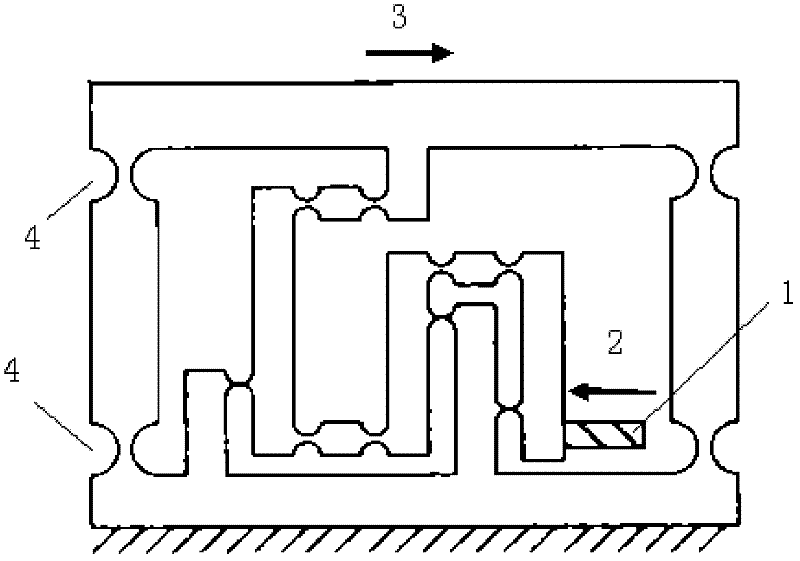

Two-stage micro-displacement amplification mechanism

InactiveCN102394270AEasy external connectionThe principle is simplePiezoelectric/electrostrictive devicesDevice detailsStructural deformationControl theory

The invention discloses a two-stage micro-displacement amplification mechanism which is characterized in that two triangle displacement zooms are arranged and respectively are a first stage triangle displacement zoom and a second stage triangle displacement zoom, each triangle displacement zoom comprises four sloping sides; the input end of the first stage triangle displacement zoom is linked with a driven element; the output end of the first stage triangle displacement zoom is linked with the input end of the second stage triangle displacement zoom. In the optimized scheme, flexibility hinges are respectively arranged at the joint of the displacement input end and the four sloping sides of the triangle displacement zoom and the joint of the displacement output end and the four sloping sides; the displacement input end of each triangle displacement zoom is provided with a positioning step. Two-stage micro-displacement amplification mechanism provided with by the invention has the advantages of zero friction, zero clearance and zero delay, and is easy to maintenance and service; the mechanism avoids oversized elastic counterforce caused by structural distortion, ensures direction stabilization of the displacement output; the displacement enlargement ratio of the two-stage displacement amplification is greatly improved, and the mechanism has very high practicability.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

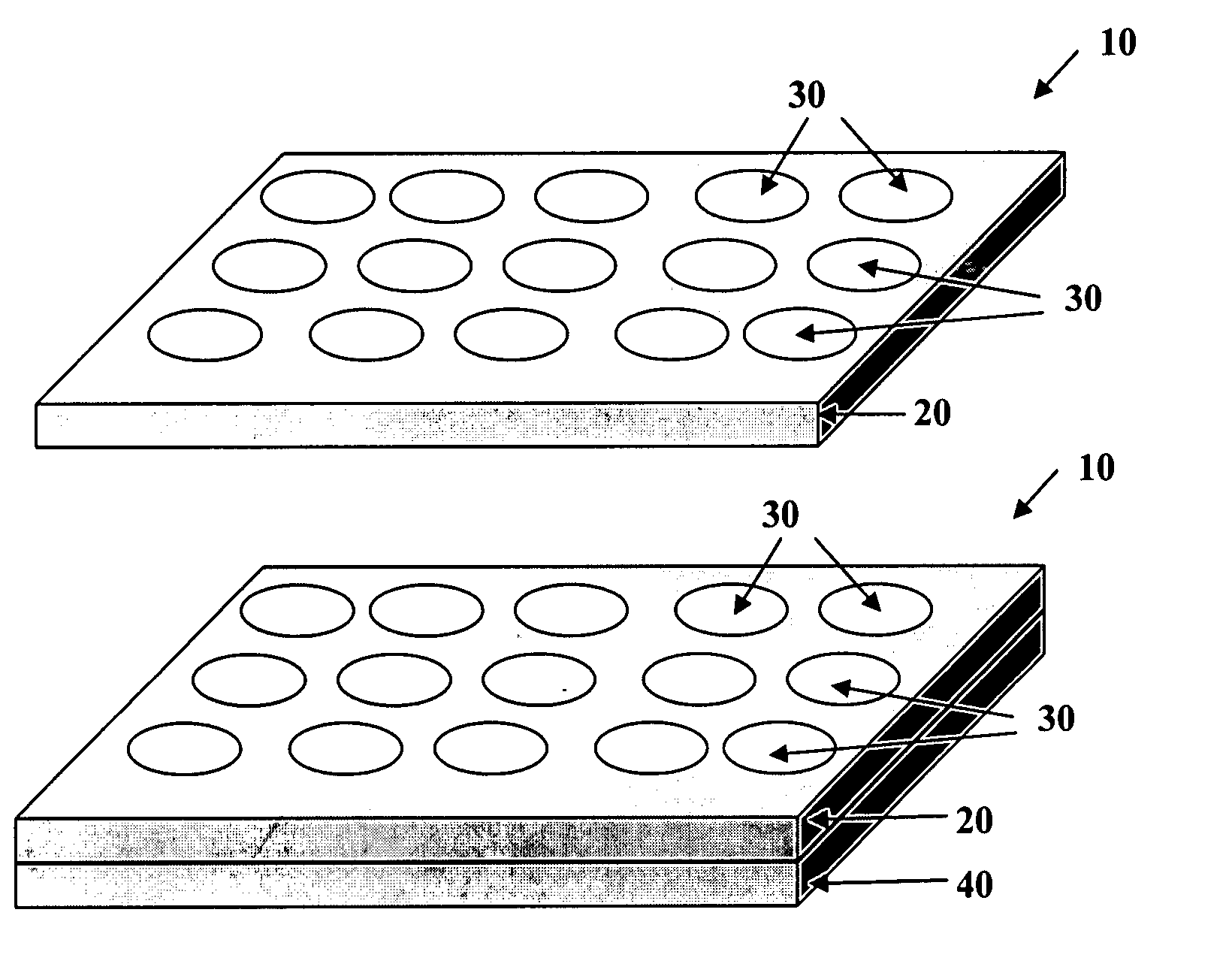

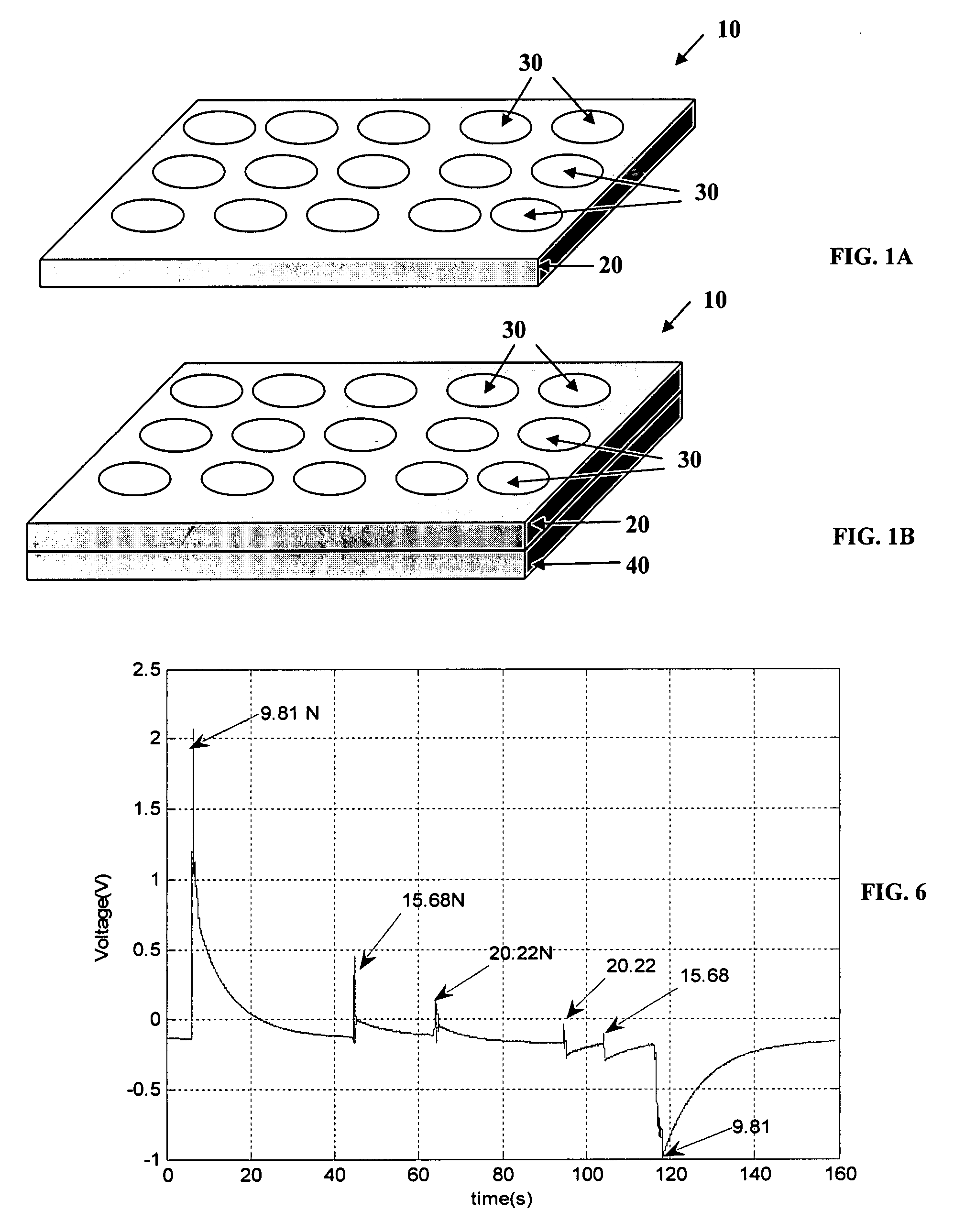

Compliant Wireless Sensitive Elements and Devices

InactiveUS20080297340A1Easy to useImprove sensitivity/dexterity/rotation/motionPiezoelectric/electrostriction/magnetostriction machinesElectric signalling detailsElectricityControl system

Sensitive elements and devices include at least one piezoelectric material and a compliant polymer substrate having elastomeric properties to lend flexibility without affecting sensitivity of the element and / or device. Sensitive elements are in operable communication with a control system; communication is wireless. Interaction of a sensitive element / sensitive device with an operator / environmental object / device is provided through use of an impedance controller and filter.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

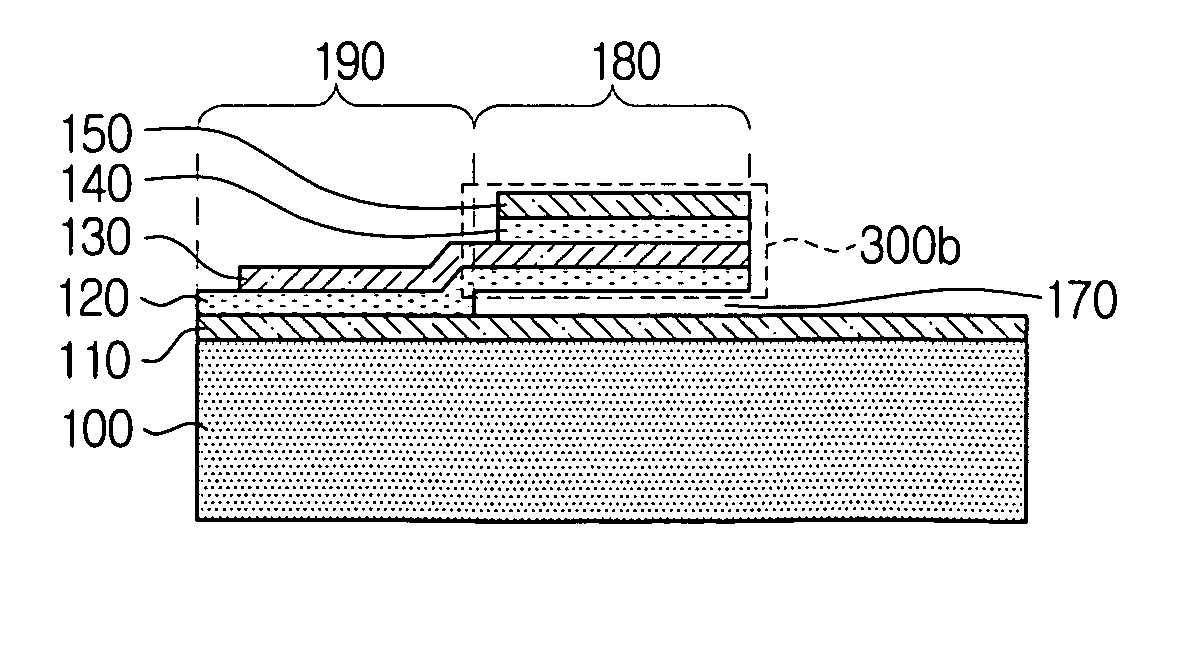

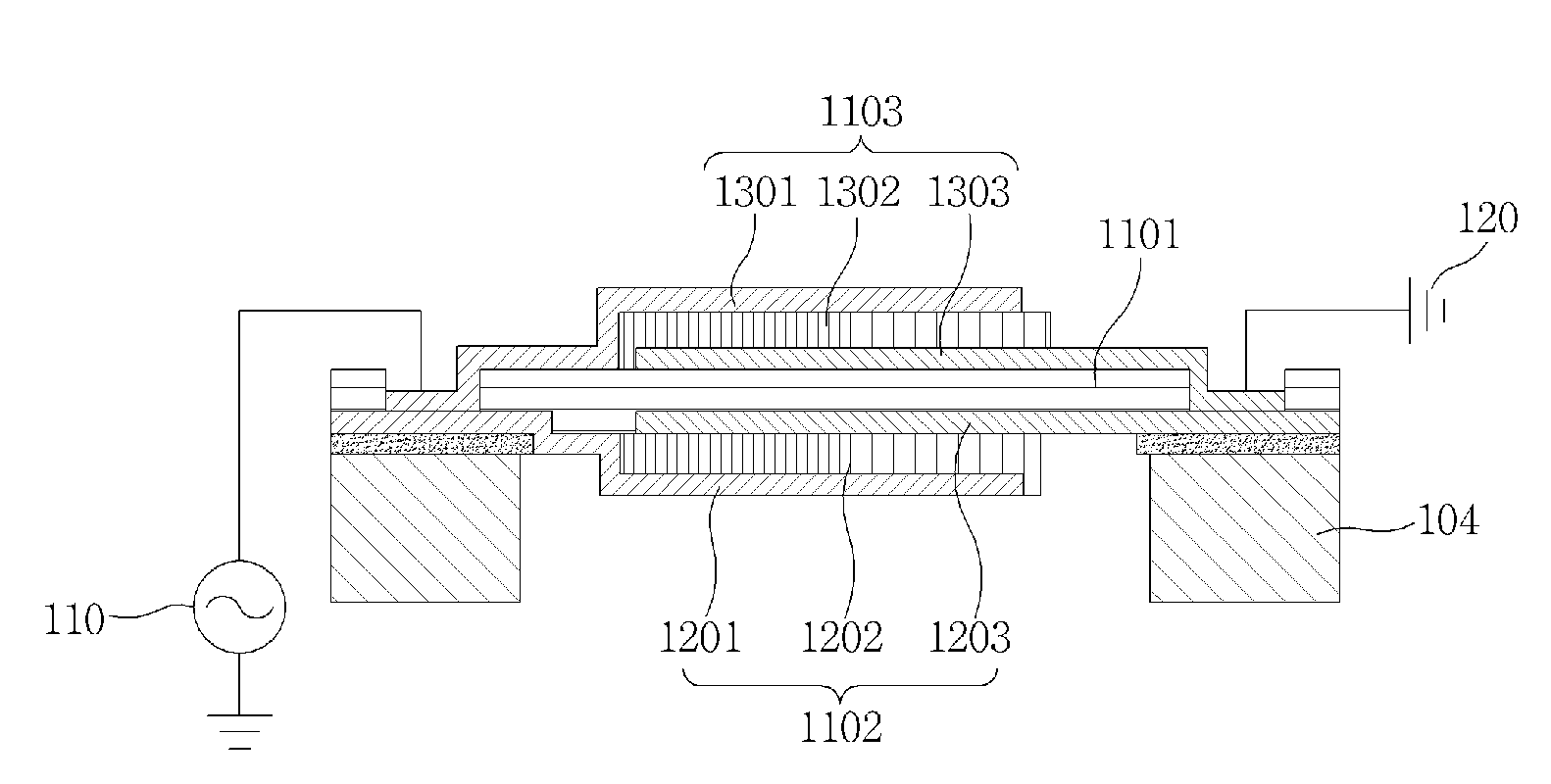

Piezoelectric microspeaker and method of fabricating the same

InactiveUS20100072860A1Piezoelectric/electrostrictive device manufacture/assemblyMicrophonesEngineeringLoudspeaker

Provided is a method of fabricating a piezoelectric microspeaker. According to the method, drive units having a piezoelectric layer and an electrode are symmetrically formed so as to be disposed over and under a diaphragm, respectively. When a thin conductive layer is used as the diaphragm, the diaphragm can be used as a common electrode. On the other hand, when a thin non-conductive layer is used as the diaphragm, a common electrode is necessary in each of the drive units.

Owner:SAMSUNG ELECTRONICS CO LTD

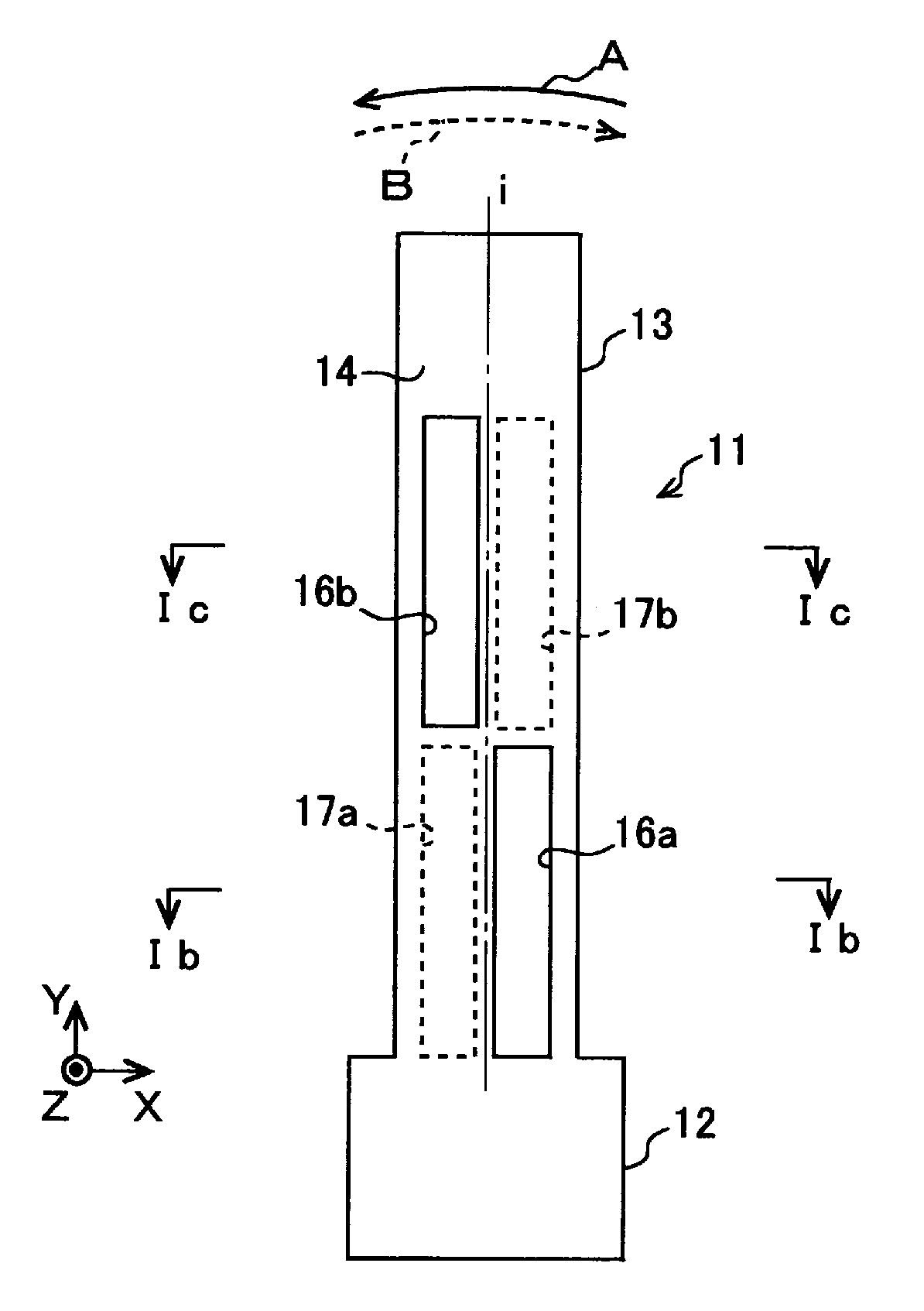

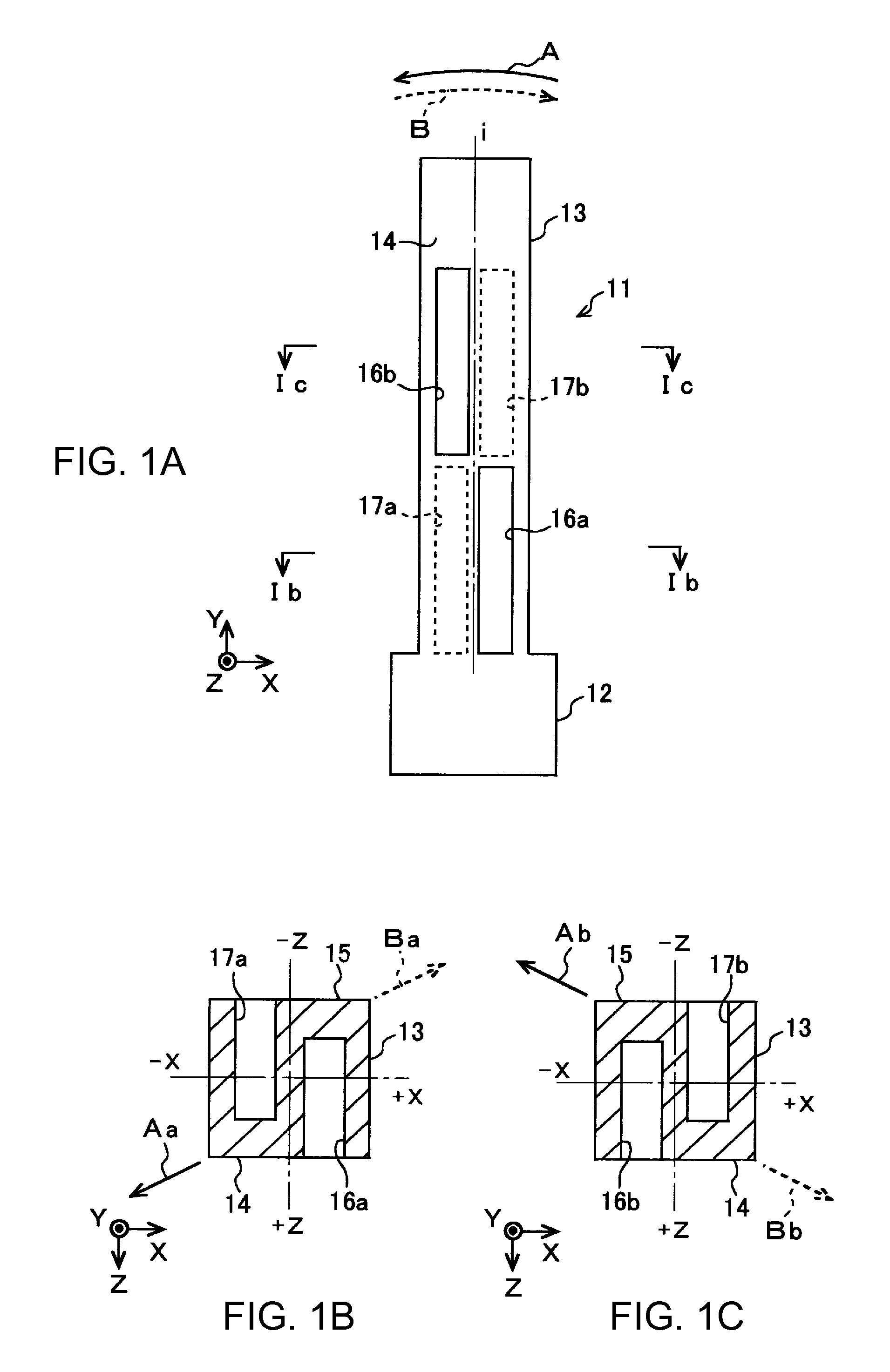

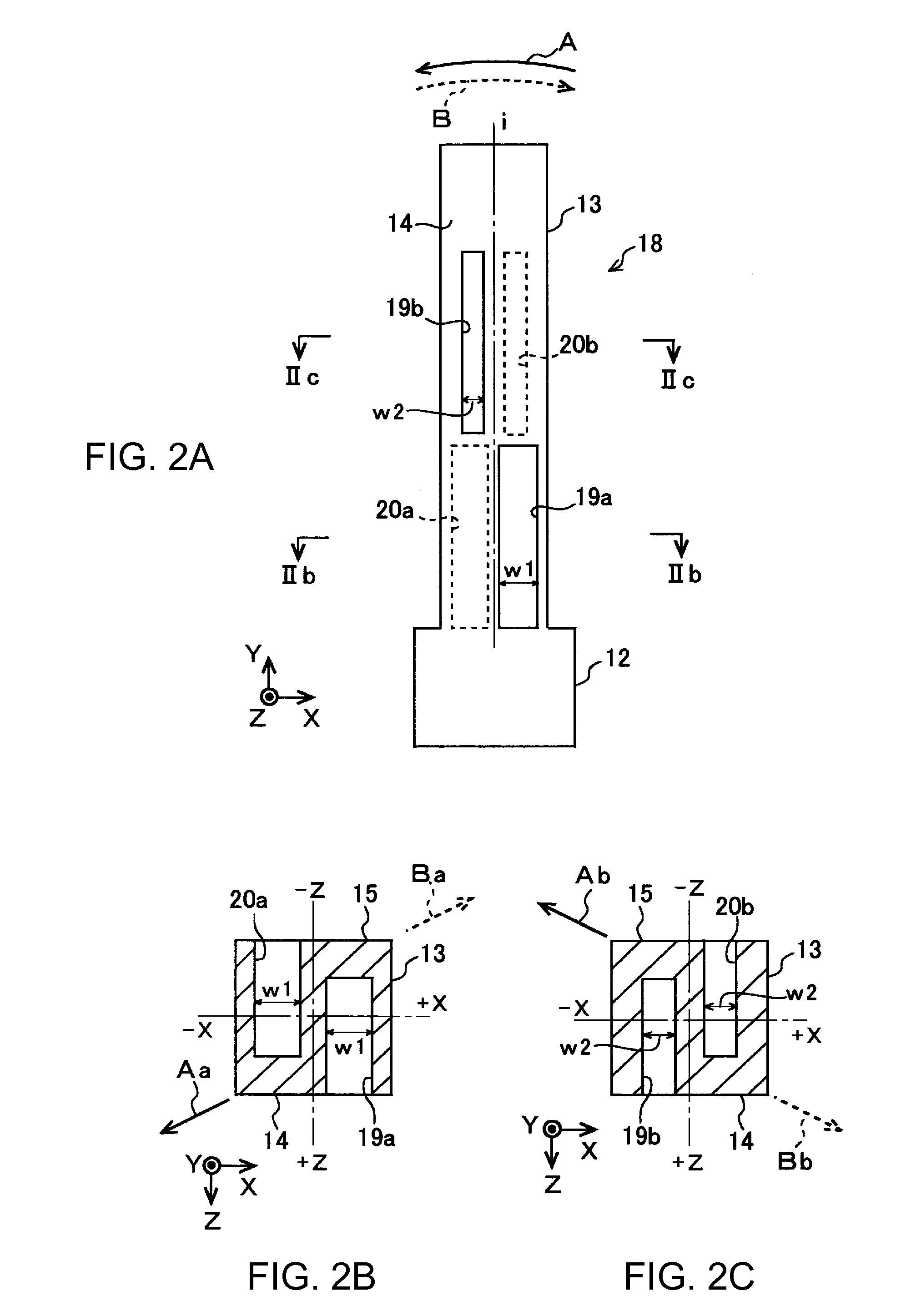

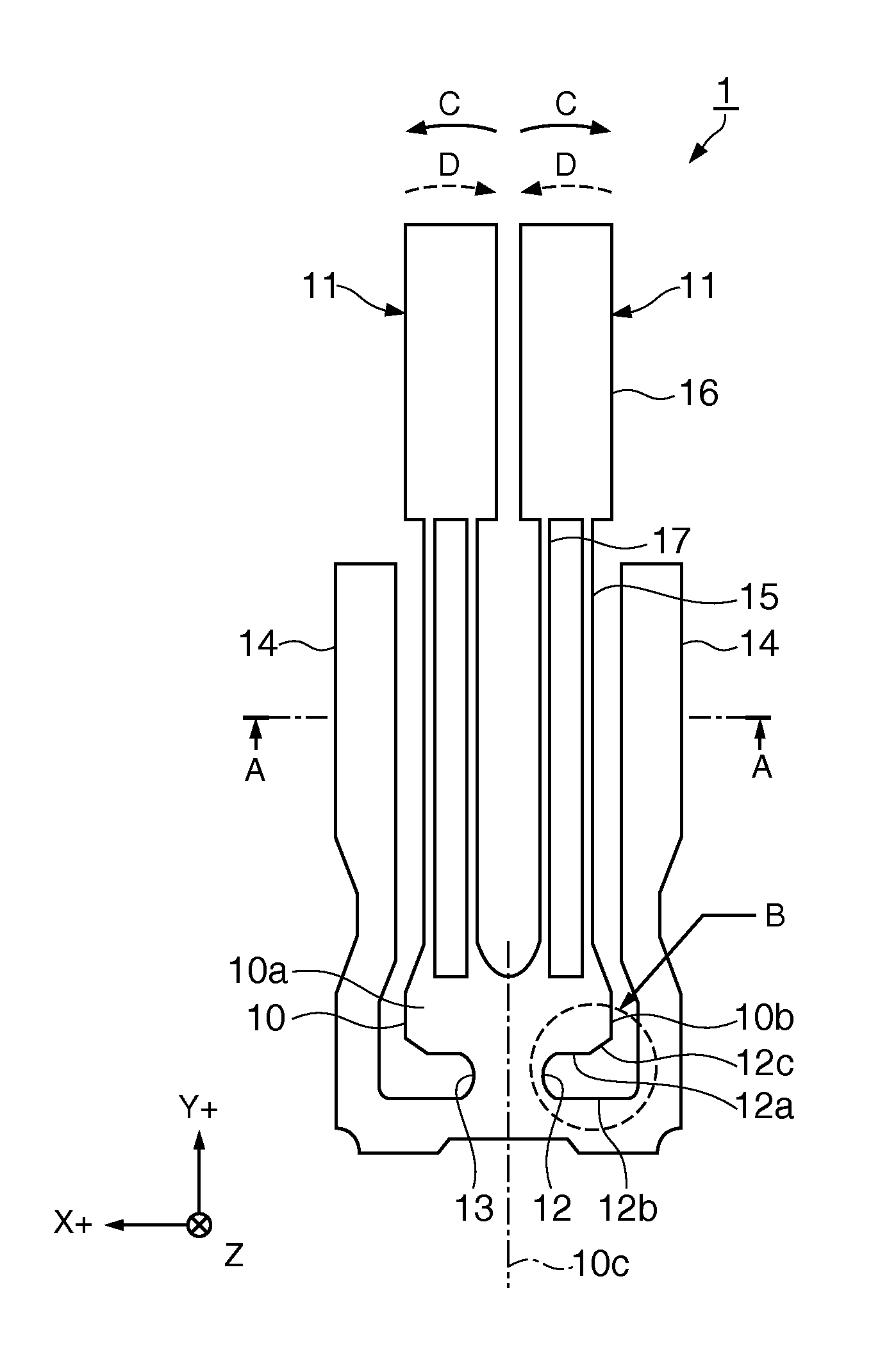

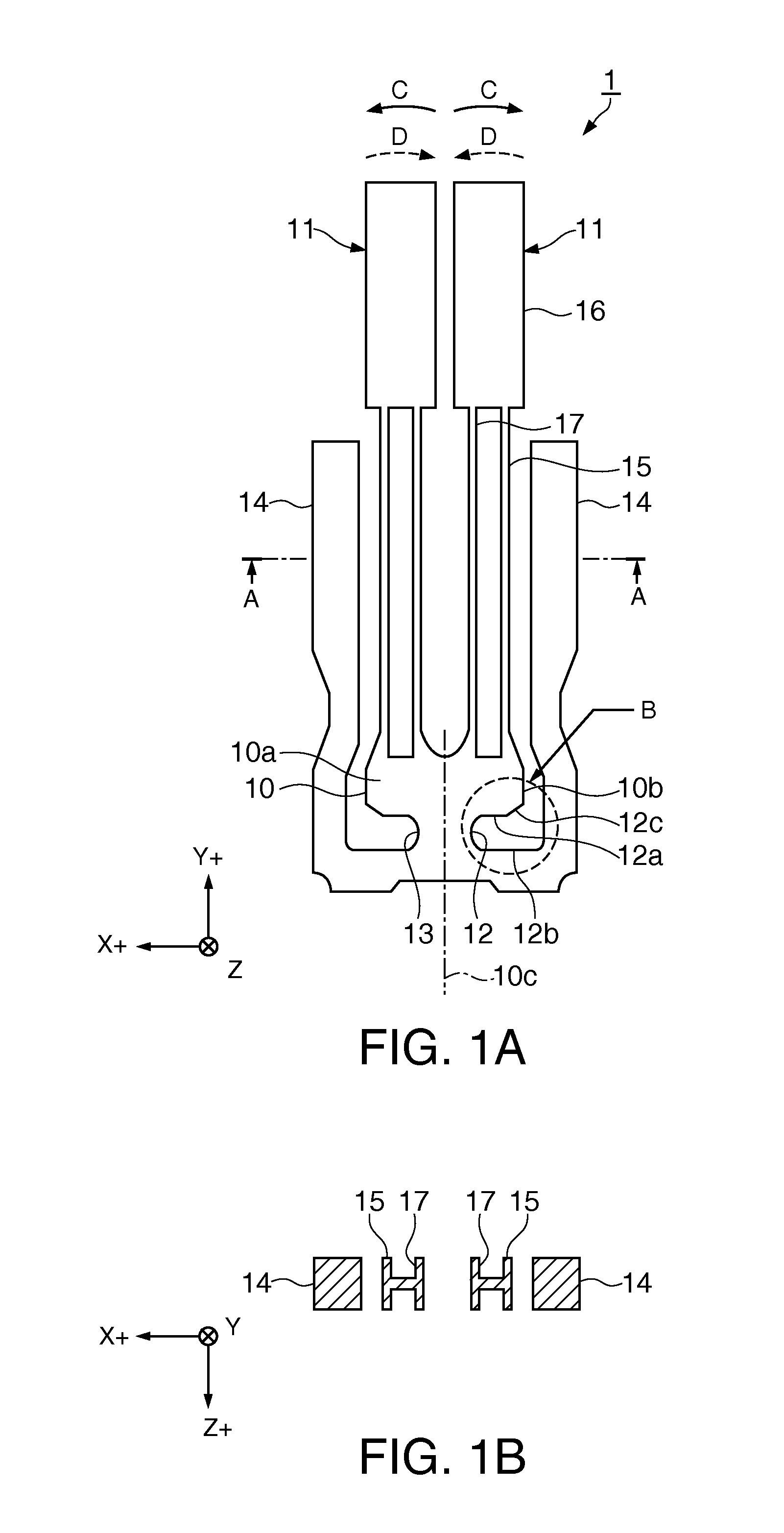

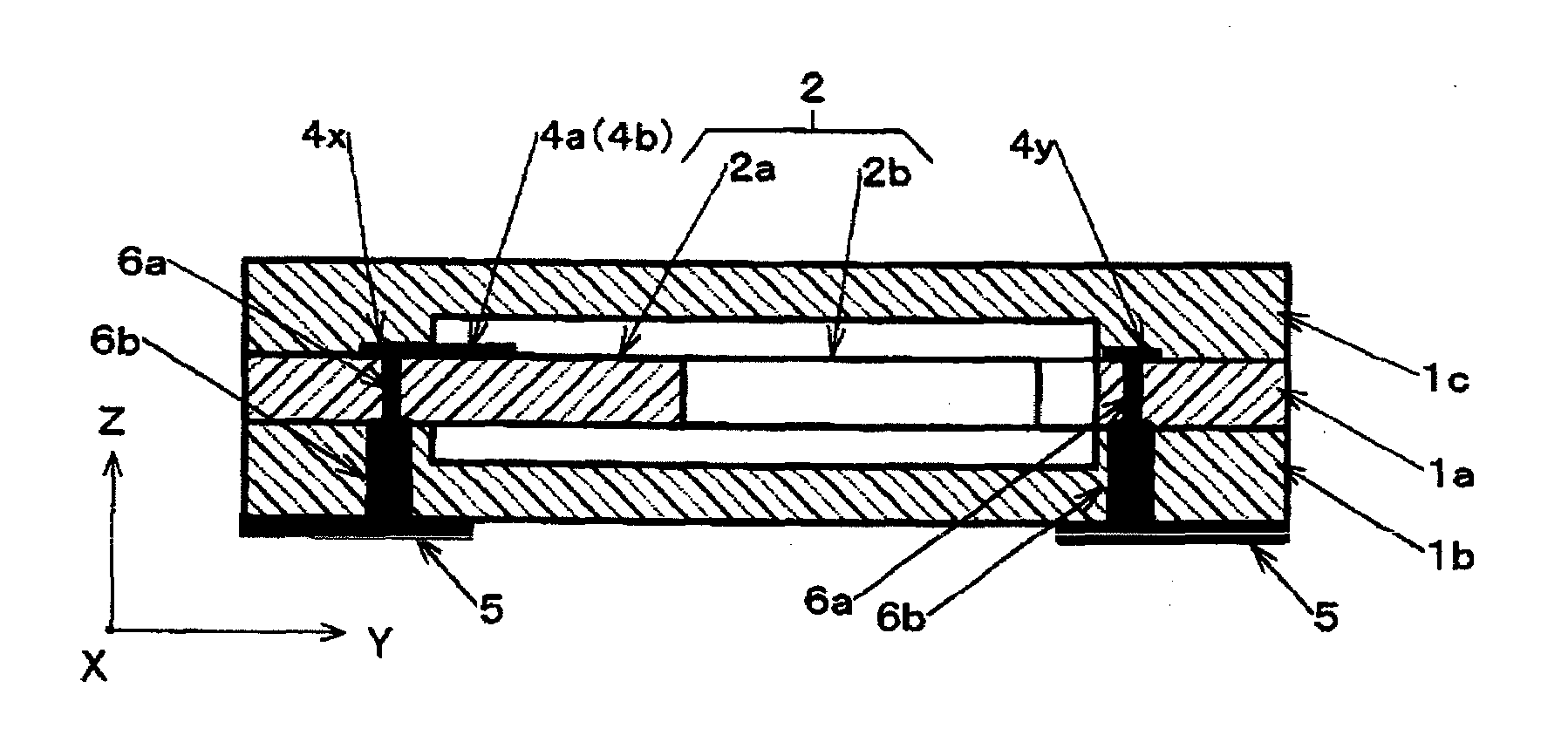

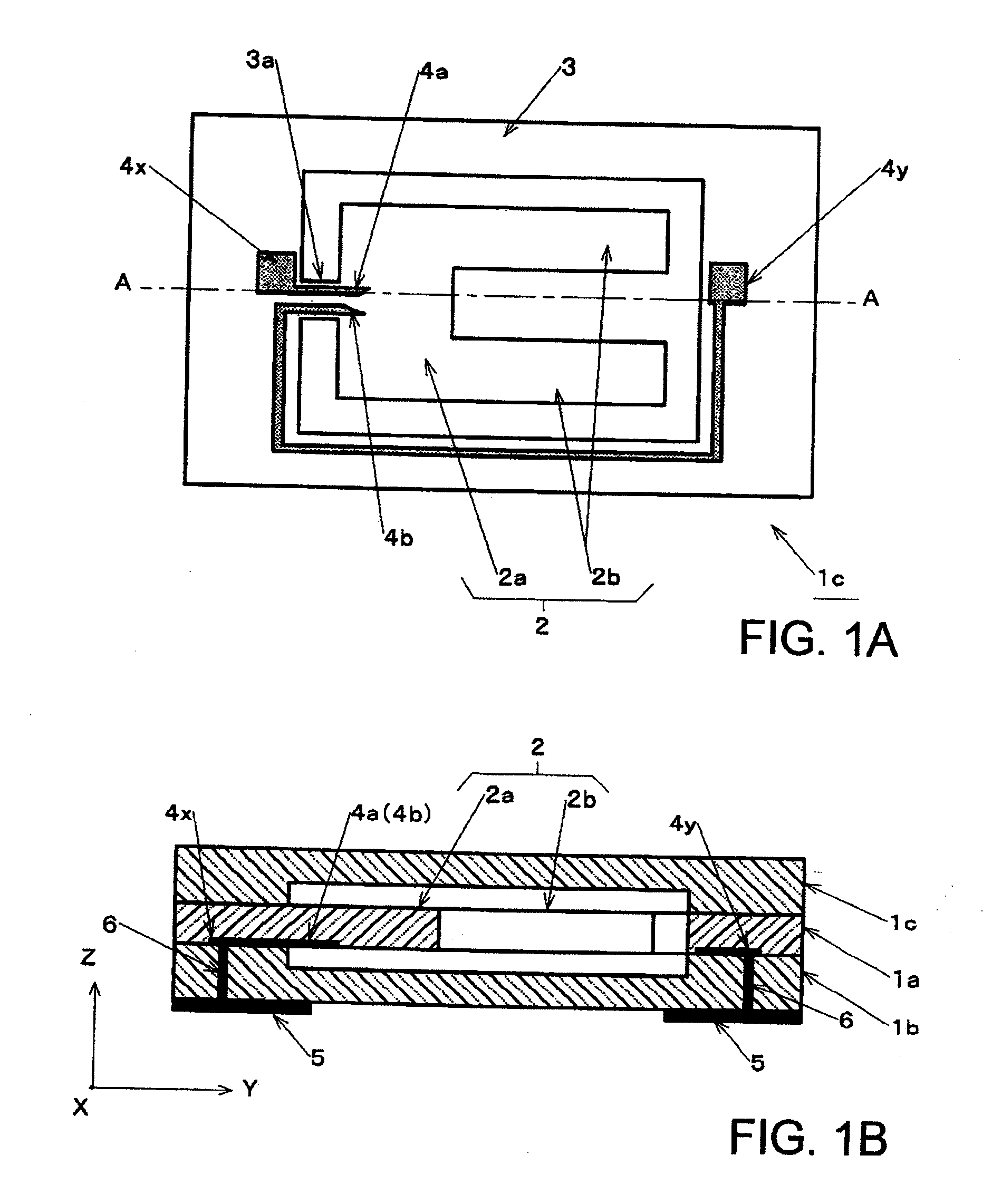

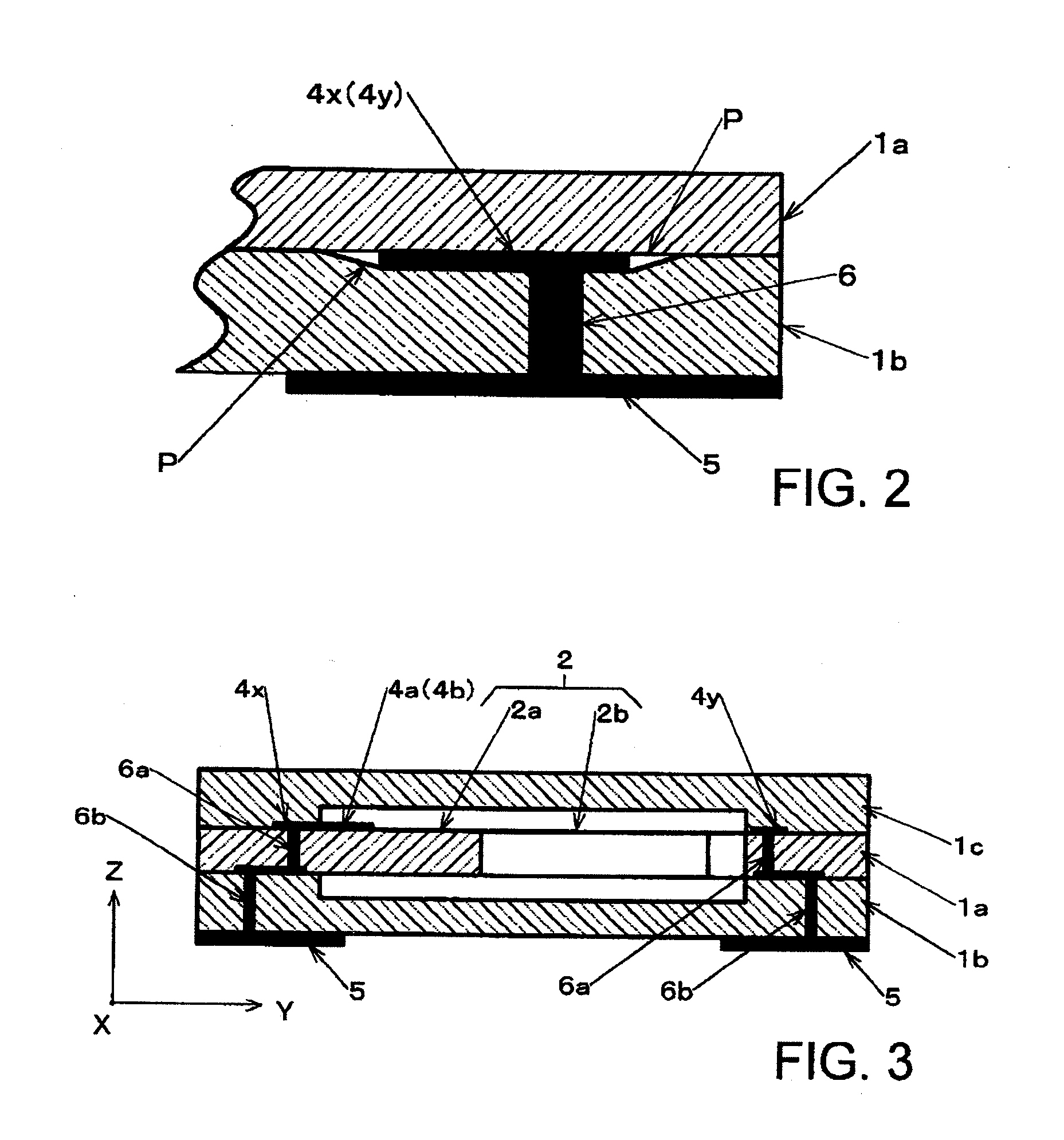

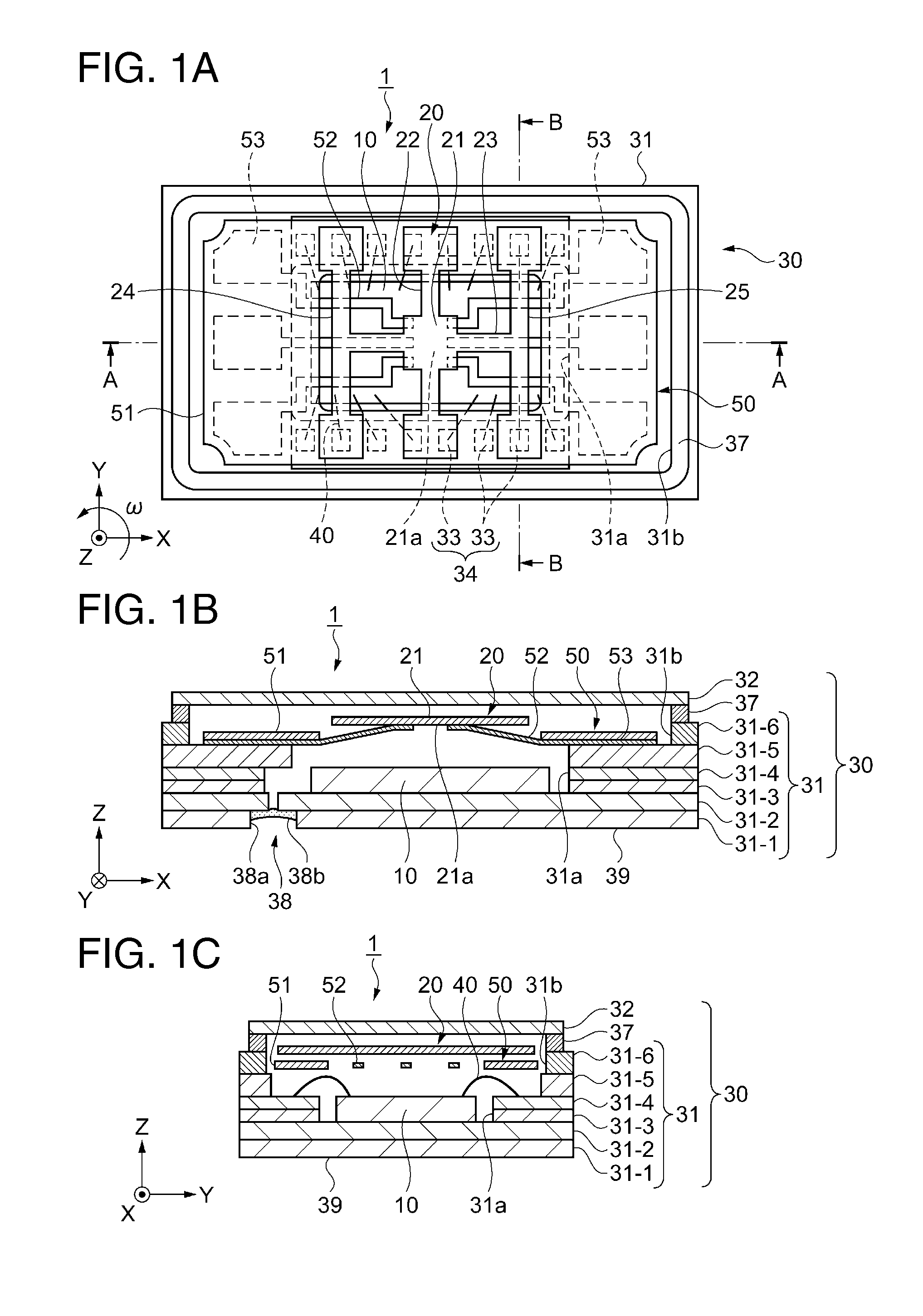

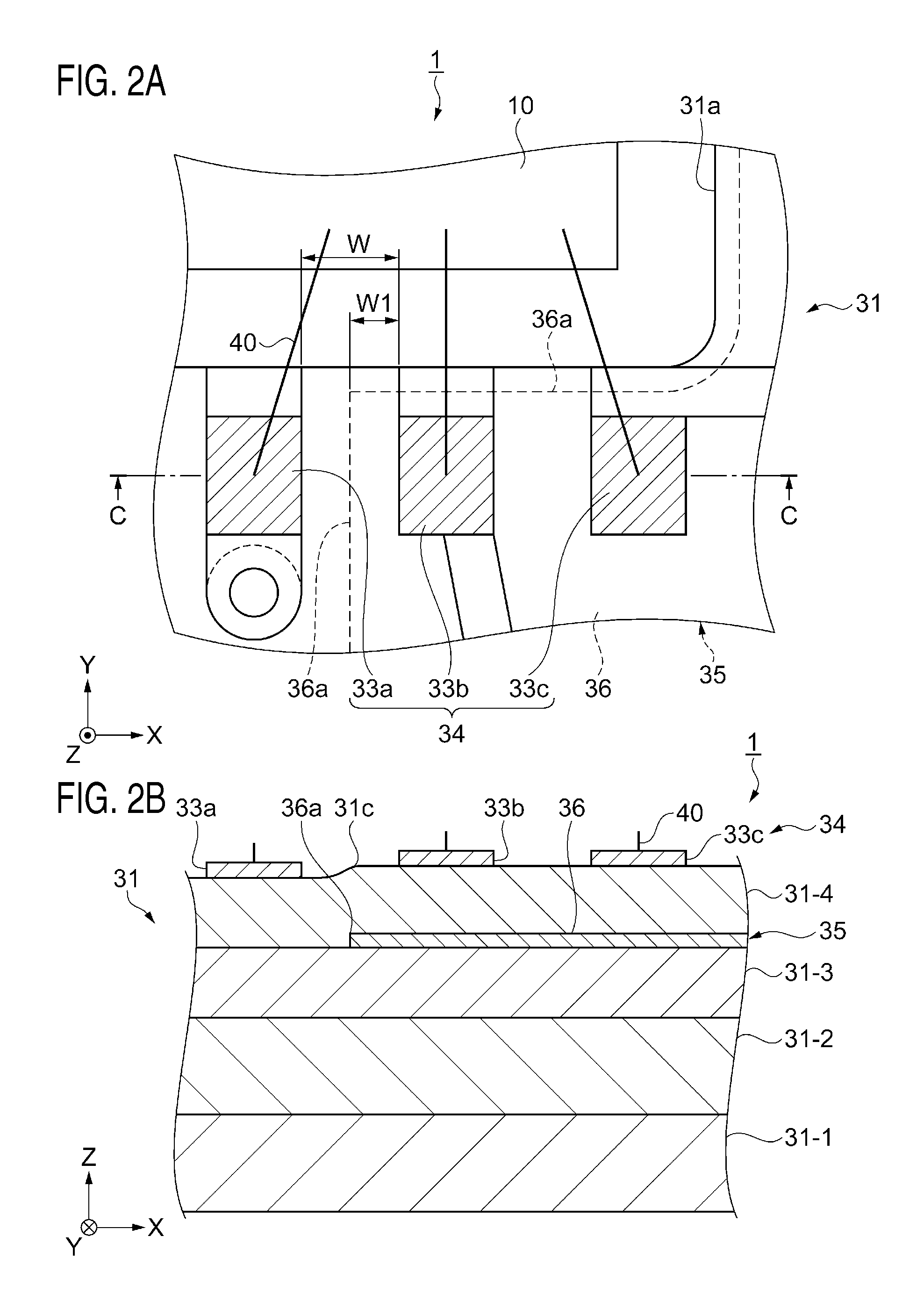

Flexural vibration piece

InactiveUS20100277041A1Reducing and eliminating leakageIncrease valueImpedence networksPiezoelectric/electrostriction/magnetostriction machinesIn planeEngineering

A flexural vibration piece includes: a base portion; and a vibration arm extending from the base portion, wherein the vibration arm has first and second main faces which are arranged to be opposite each other, the first and second main faces respectively have first and second grooves which are formed in the longitudinal direction of the vibration arm, the first groove has a plurality of first groove portions which are divided in the longitudinal direction of the vibration arm and arranged to be alternately shifted on both sides with respect to the longitudinal center line of the vibration arm in the longitudinal direction, the second groove has a plurality of second groove portions which are divided in the longitudinal direction of the vibration arm, and arranged to be alternately shifted on both sides with respect to the longitudinal center line of the vibration arm in the longitudinal direction and on an opposite side to the first groove portions with respect to the longitudinal center line, and a predetermined voltage is applied to first excitation electrodes provided at the first groove and the second groove and second excitation electrodes provided on both side faces of the vibration arm, such that the vibration arm flexural-vibrates in the in-plane direction of the first or second main face.

Owner:SEIKO EPSON CORP

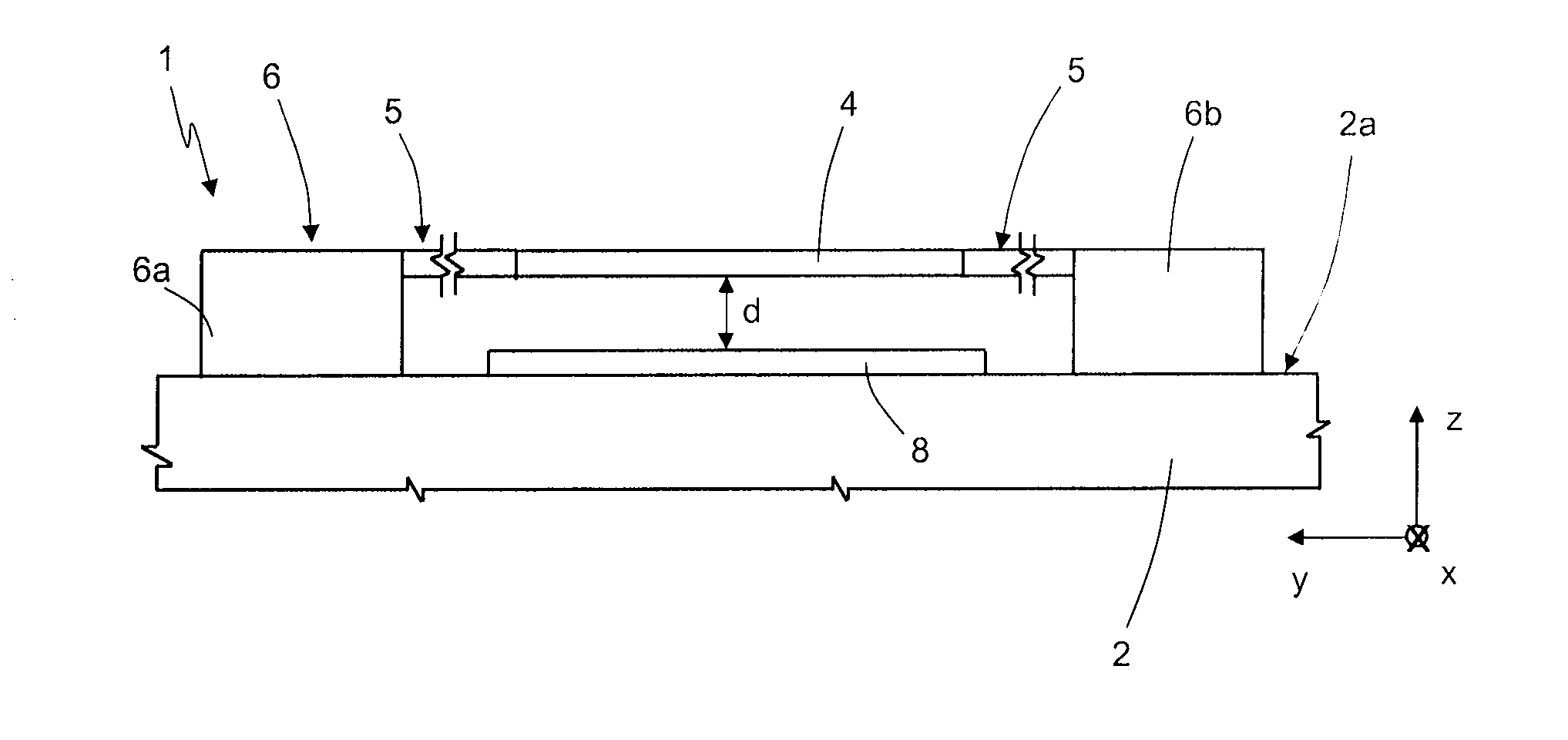

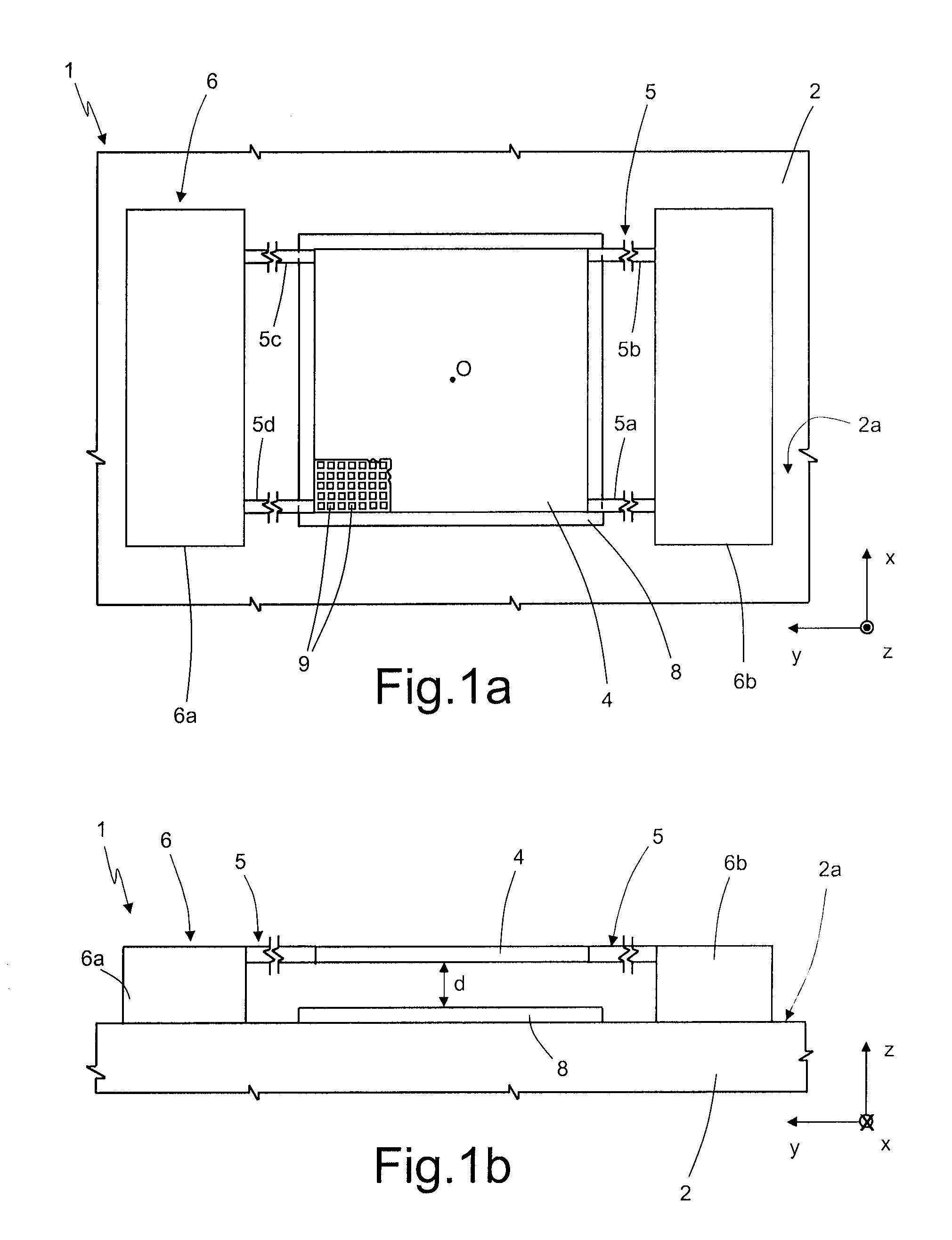

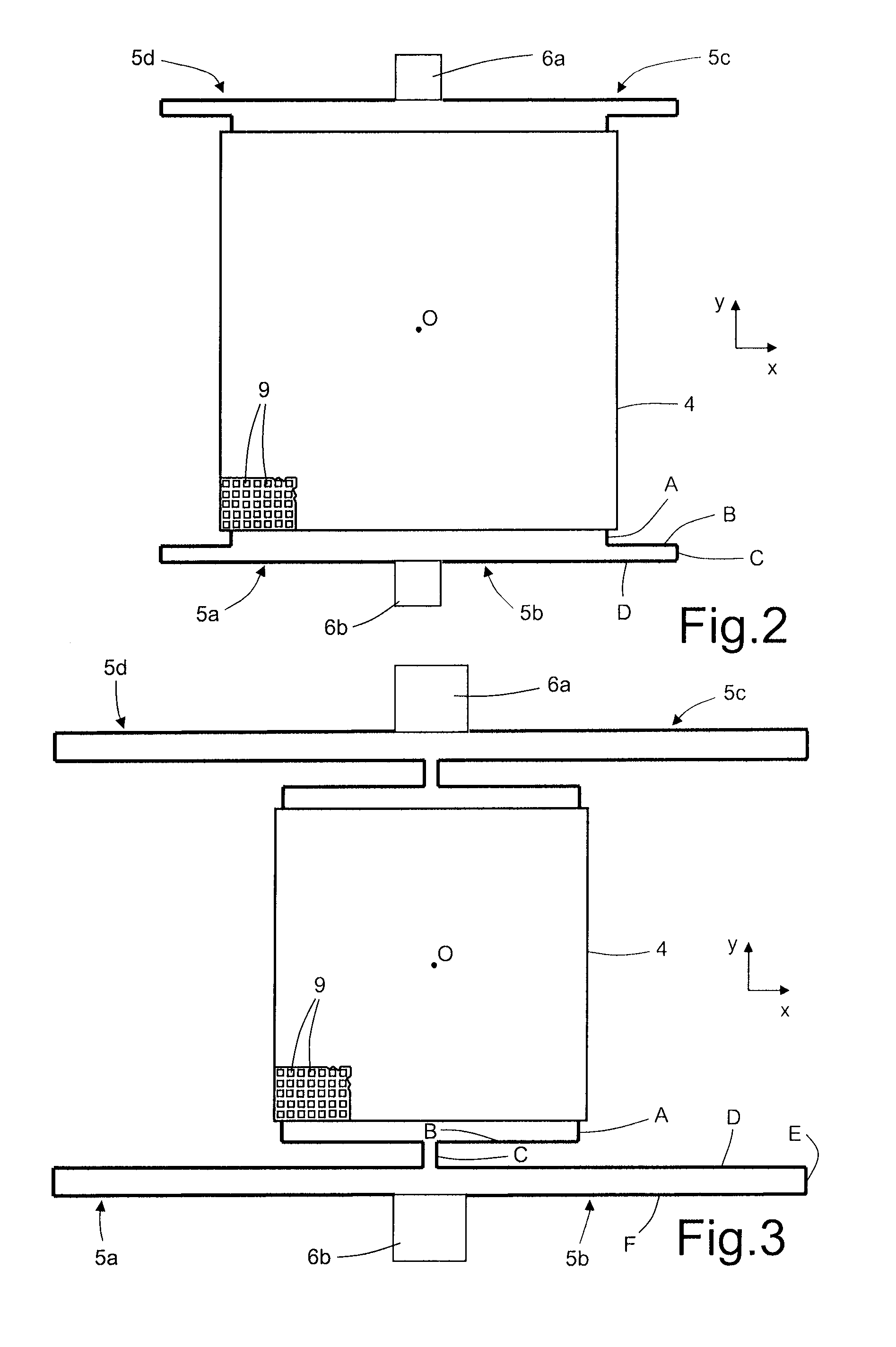

Micromechanical element and sensor for monitoring a micromechanical element

ActiveUS20100097681A1Space minimizationSmall space requirementOptical radiation measurementControl mechanismEngineeringDriven element

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

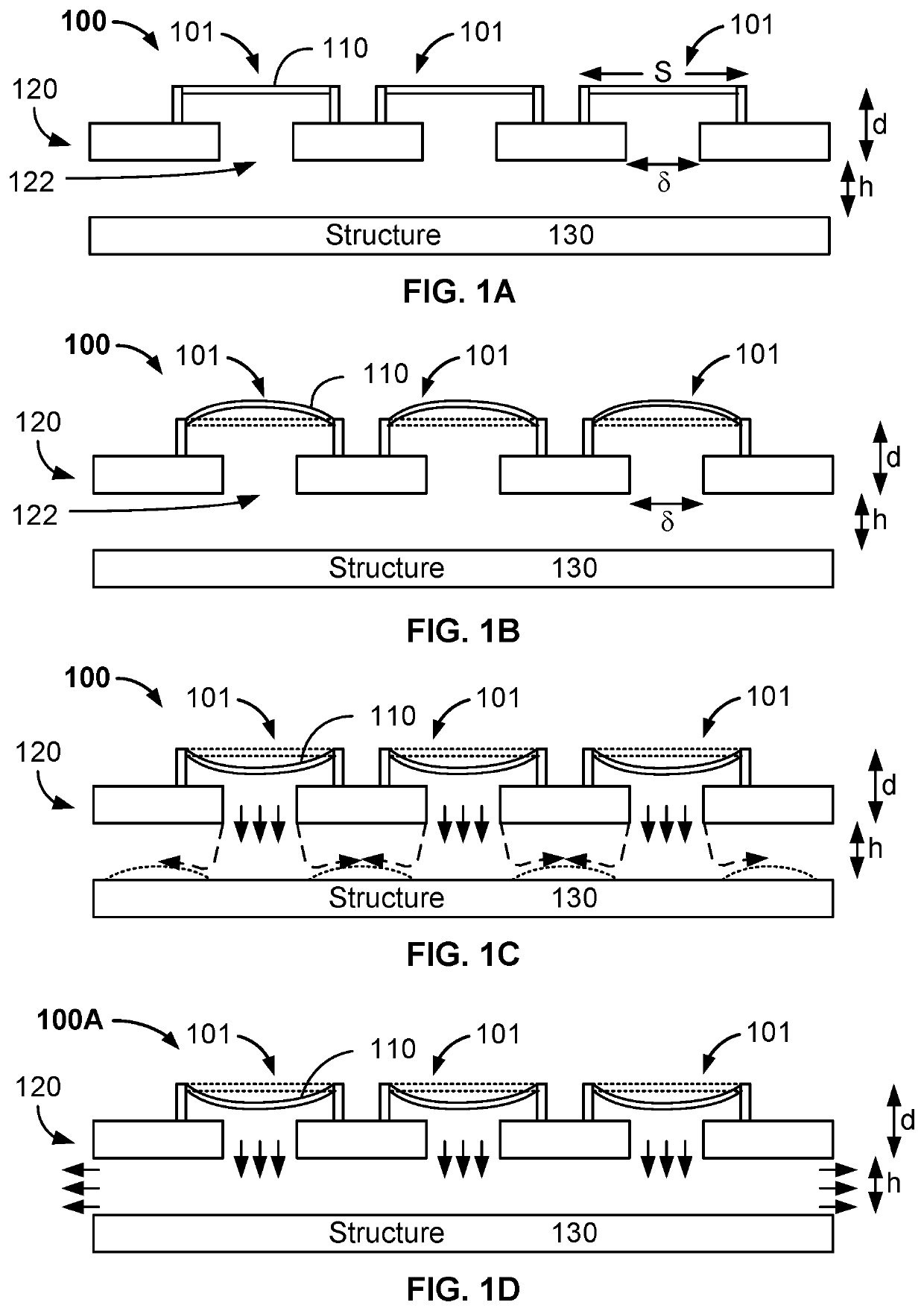

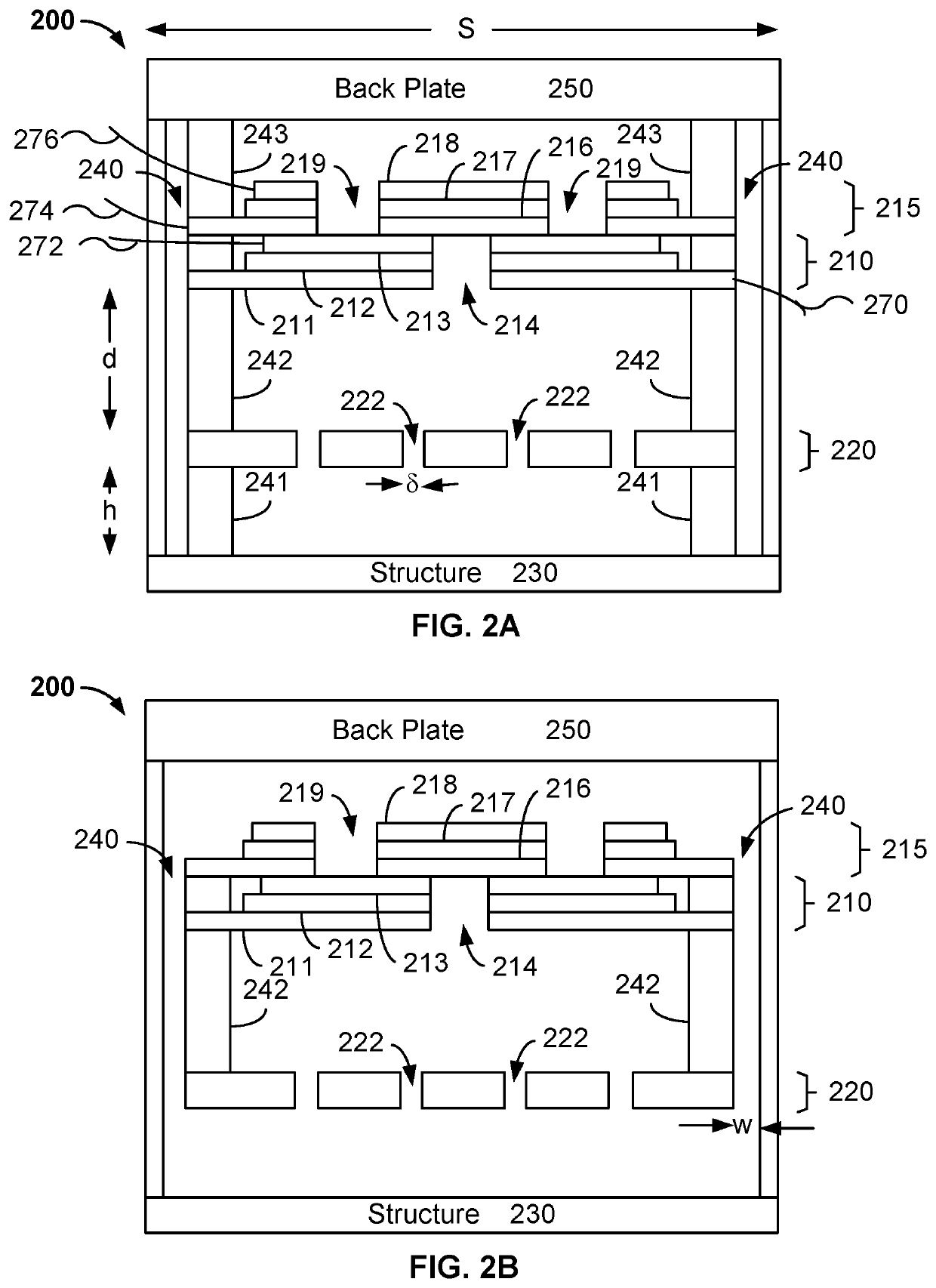

Piezoelectric MEMS-based active cooling for heat dissipation in compute devices

ActiveUS10943850B2Semiconductor/solid-state device detailsFlexible member pumpsThermodynamicsActive cooling

Owner:FRORE SYST INC

Piezoelectric element, actuator device, liquid-jet head, and liquid-jet apparatus

ActiveUS20080062228A1Improve reliabilityIncreased durabilityPiezoelectric/electrostriction/magnetostriction machinesPrintingPlatinumLiquid jet

A piezoelectric element includes: a lower electrode film provided on a substrate; a piezoelectric layer provided on the lower electrode film; and an upper electrode film provided on the piezoelectric layer, wherein the lower electrode film includes columnar crystals of platinum, and an oxide exists in the grain boundaries of the crystals of platinum.

Owner:SEIKO EPSON CORP

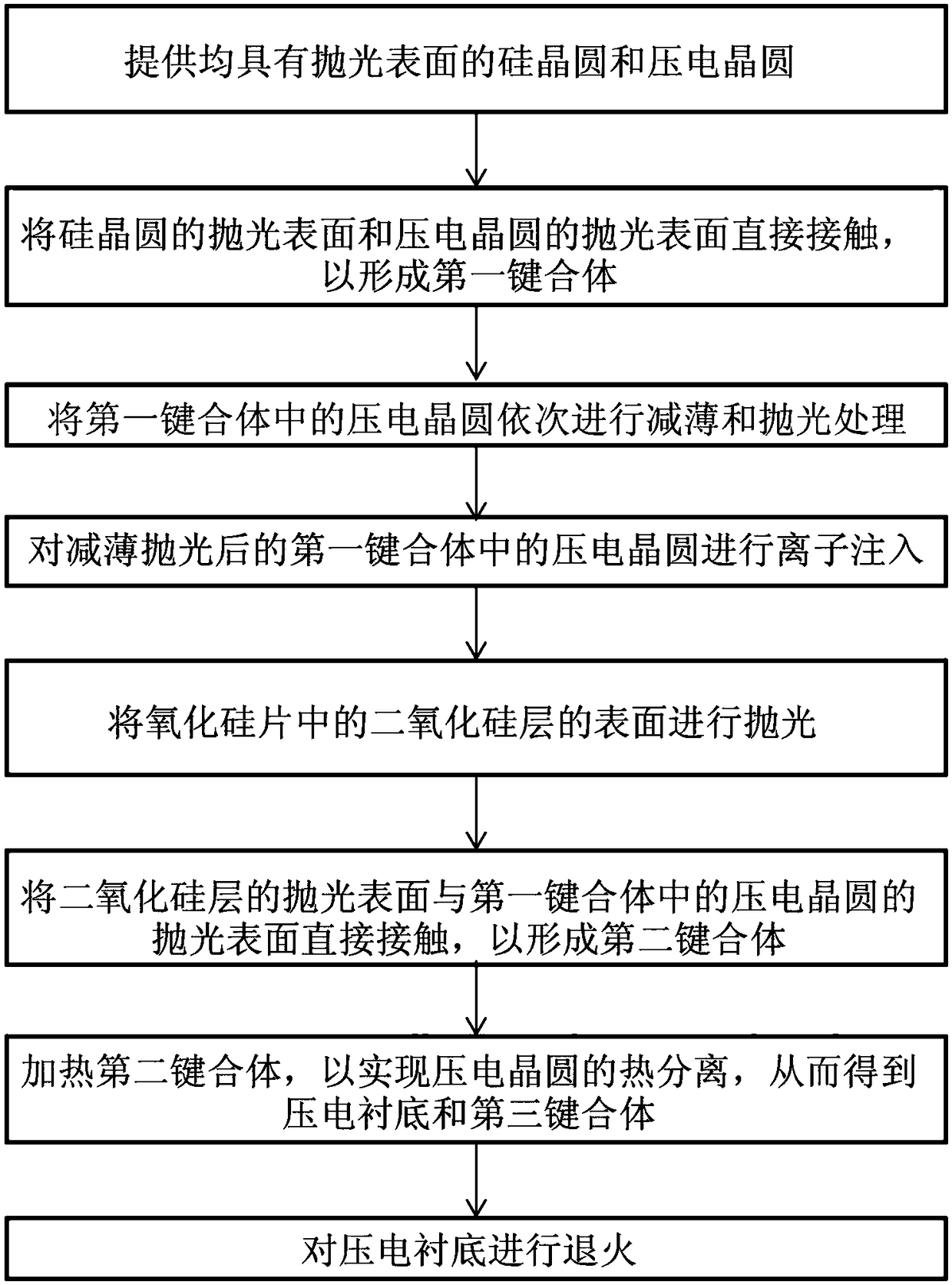

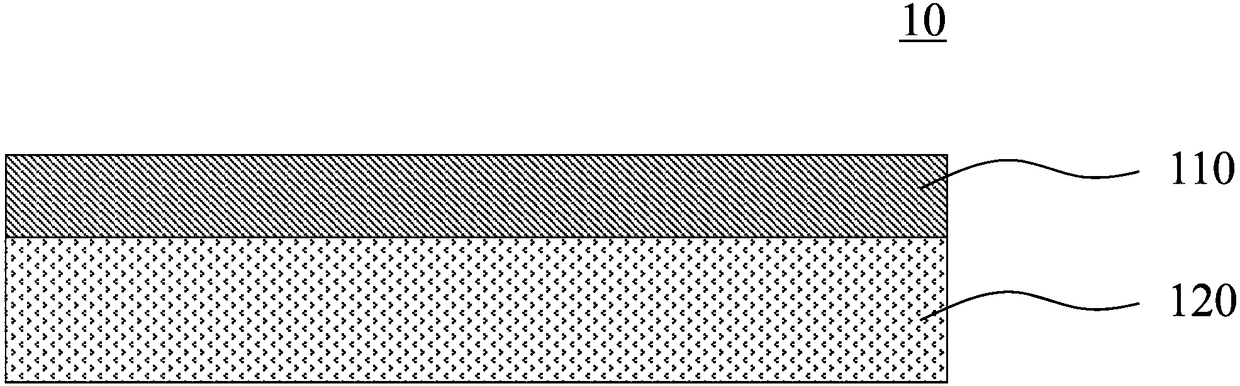

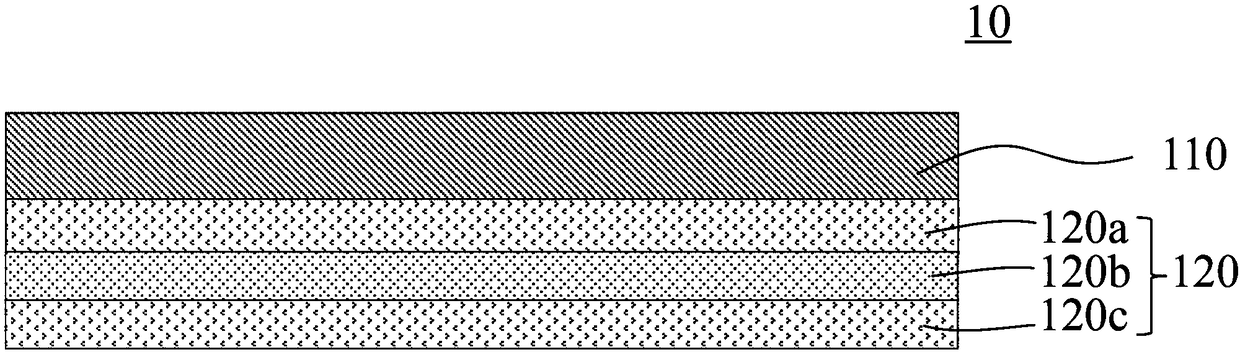

Manufacturing method of composite piezoelectric substrate for surface acoustic wave device

ActiveCN108365083AIncrease profitImprove injection efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSurface acoustic wave sensorIon implantation

The invention provides a method for manufacturing a composite piezoelectric substrate for a surface acoustic wave device. The method comprises the following steps of providing a silicon wafer and a piezoelectric wafer which are provided with polishing surfaces, and performing semiconductor-level cleaning on the silicon wafer and the piezoelectric wafer; forming a first bonding body; sequentially thinning and polishing the piezoelectric wafer of the first bonding body; performing ion injection onto the piezoelectric wafer in the first bonding body after thinning and polishing; forming a secondbonding body; heating the second bonding body to achieve thermal separation of the piezoelectric wafer so as to obtain the composite piezoelectric substrate and a third bonding body; and annealing thecomposite piezoelectric substrate. The third bonding body is obtained after recycling and thermal separation, so that the raw material utilization ratio is improved.

Owner:JINAN JINGZHENG ELECTRONICS

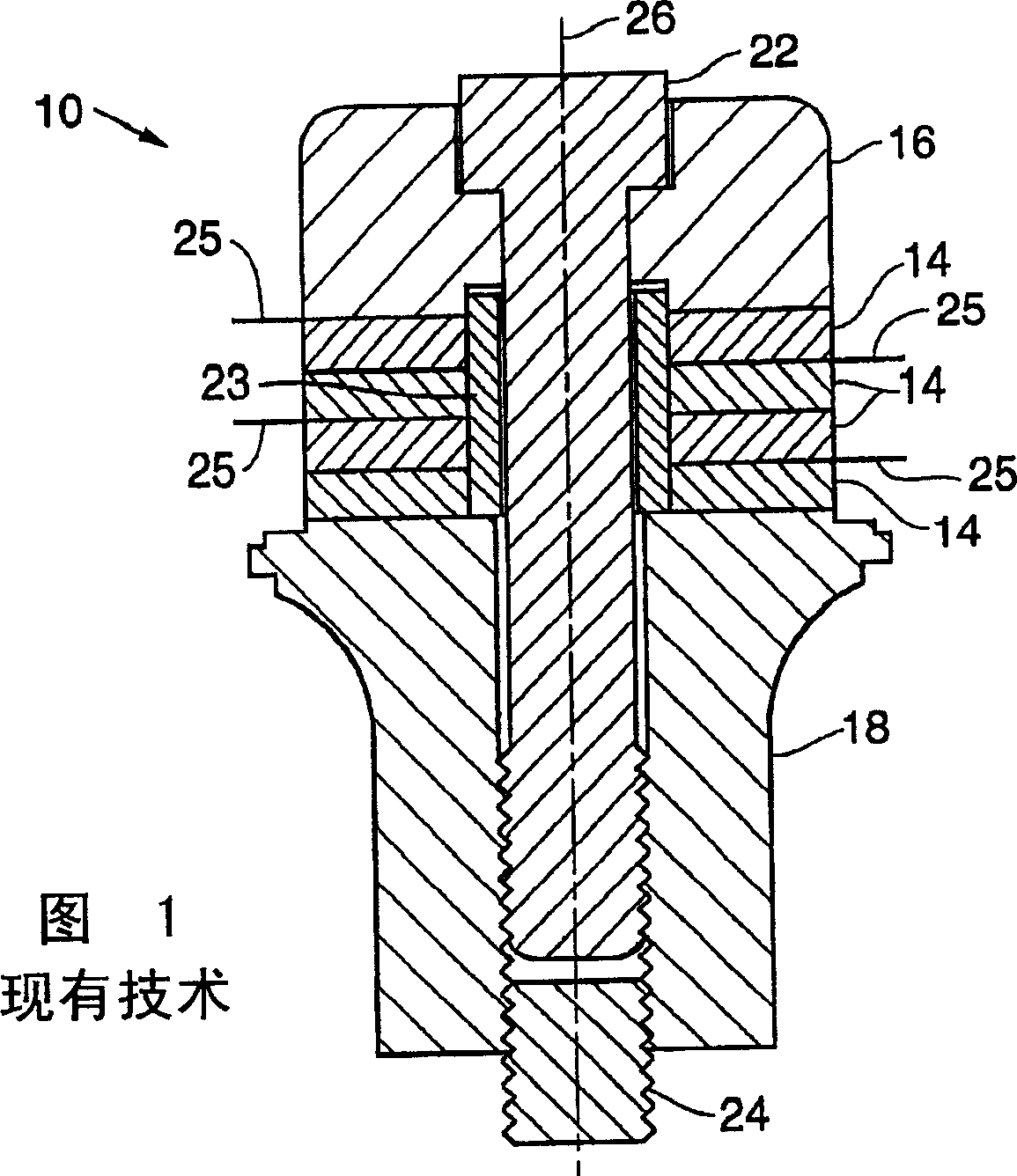

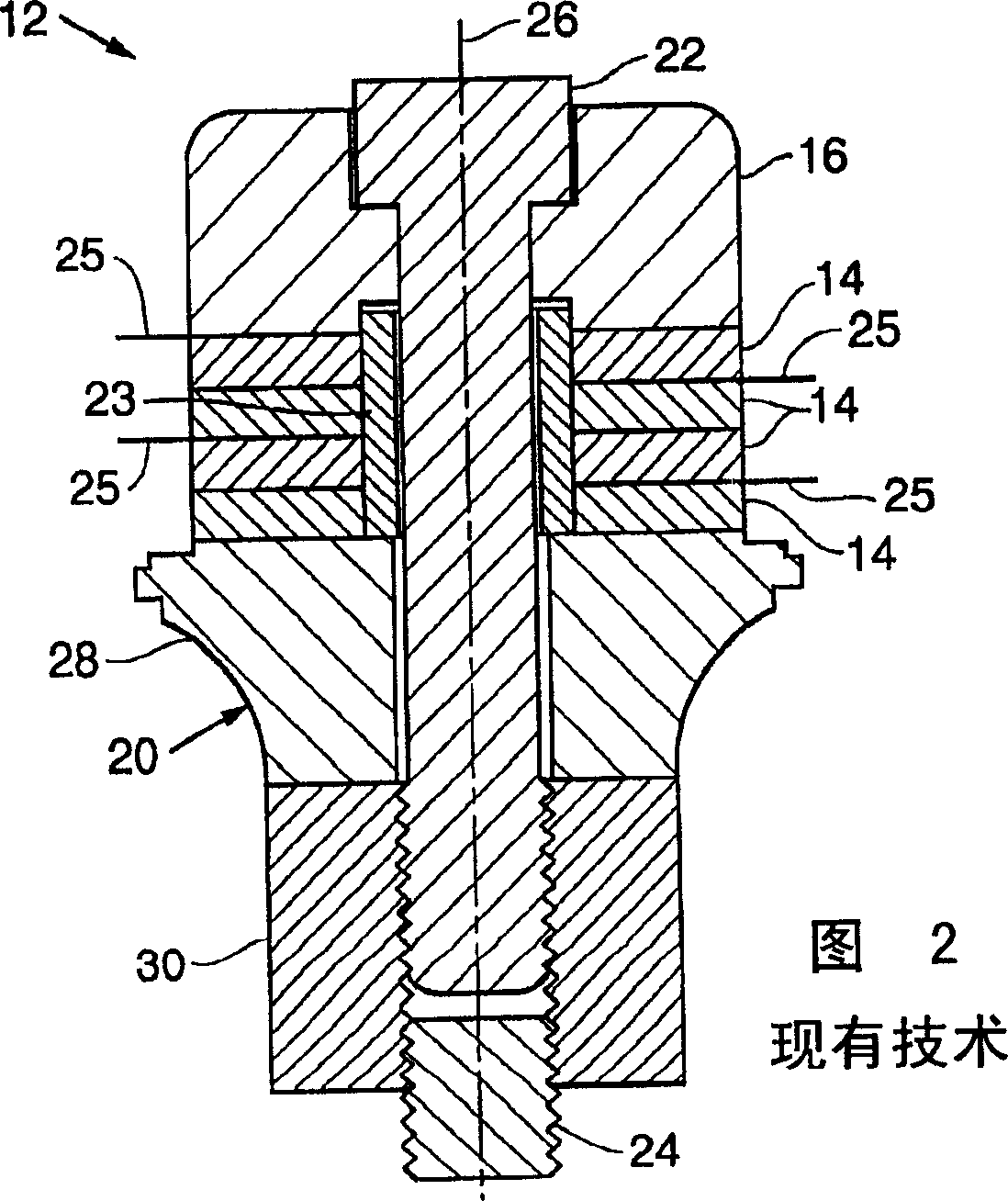

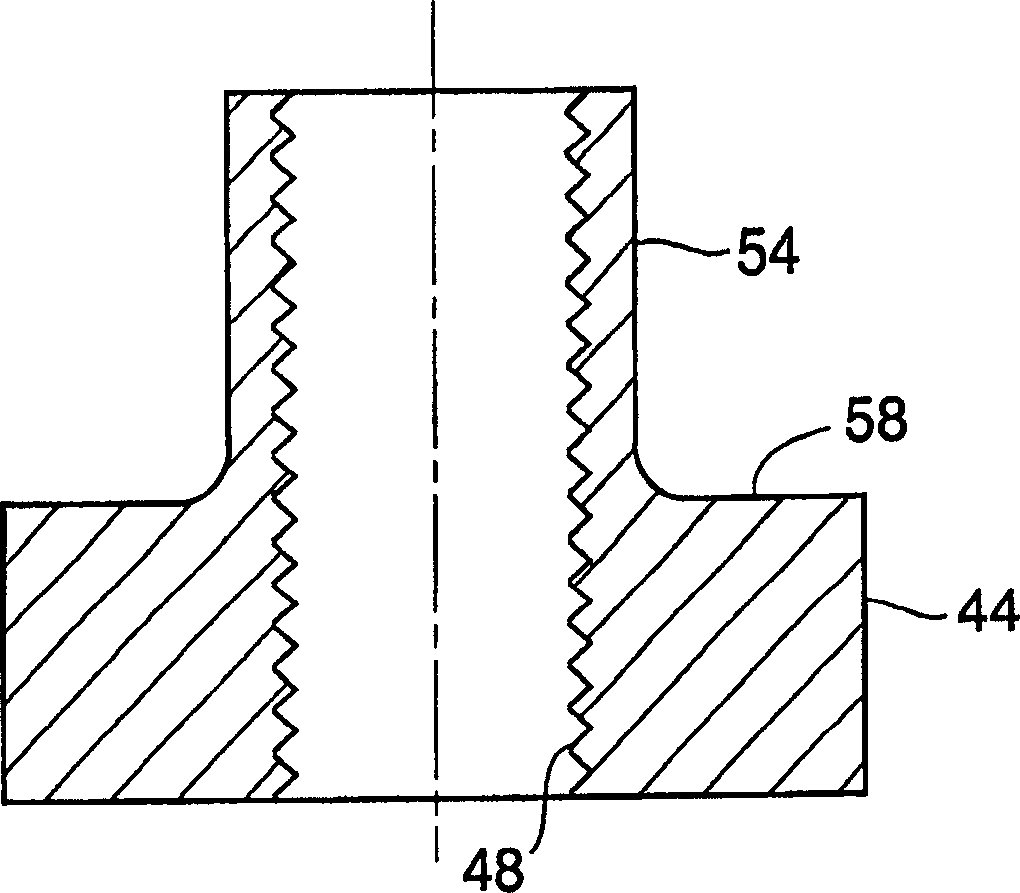

Sleeved ultrasonic transducer

The sleeved ultrasonic transducer (40) has a two-part head end block (42), which includes a threaded sleeve (44) and a housing (46) made of different materials. The threaded sleeve (44) is preferably a metal such as titanium, which provides superior thread strength for mating with the extrusion bolt (24), while the housing (46) is preferably aluminum or ceramic or other metal or Non-metallic material that provides good heat sink capacity and / or transmission of vibration energy. The combination of these two components (44, 46) provides an improved ultrasound transducer.

Owner:顶峰集团有限公司

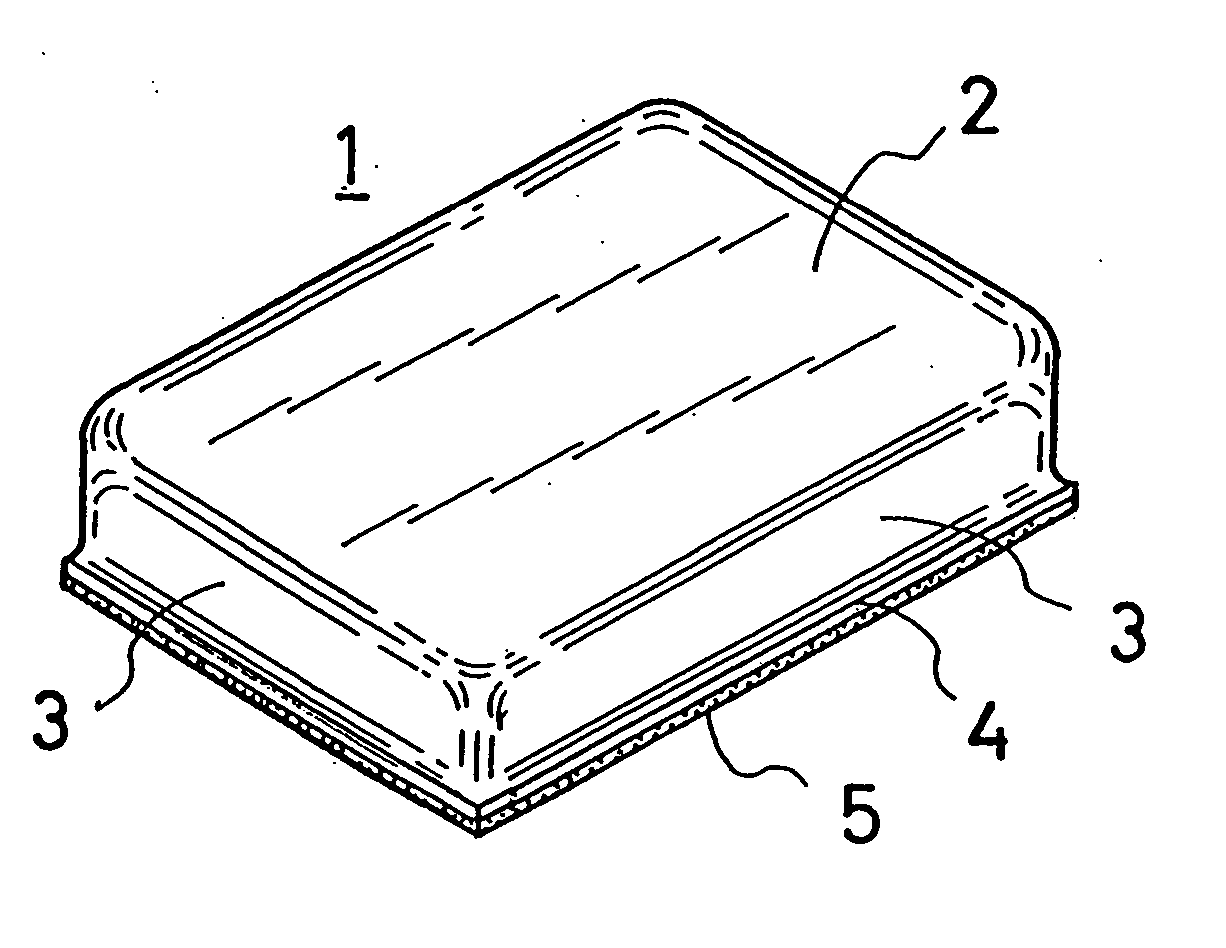

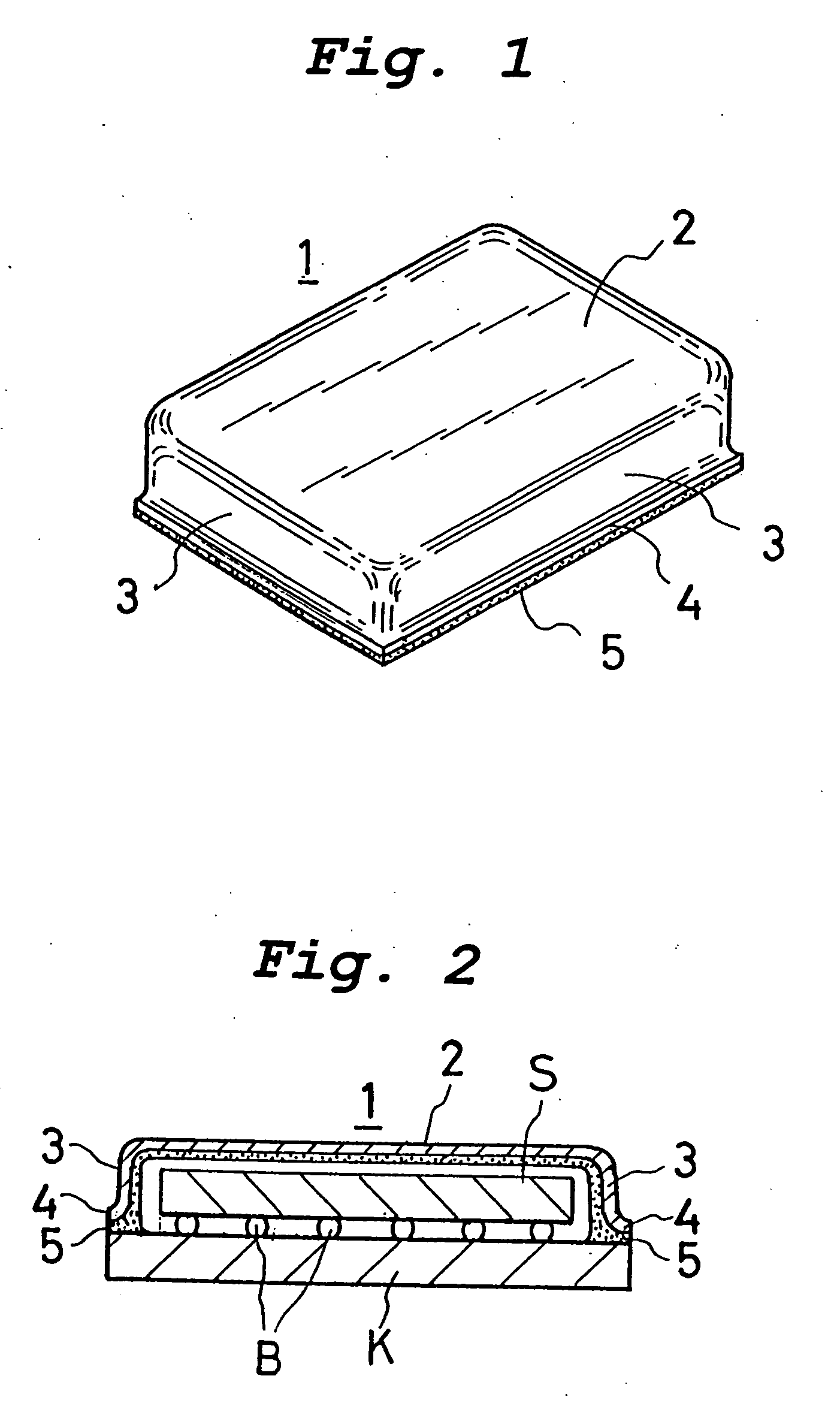

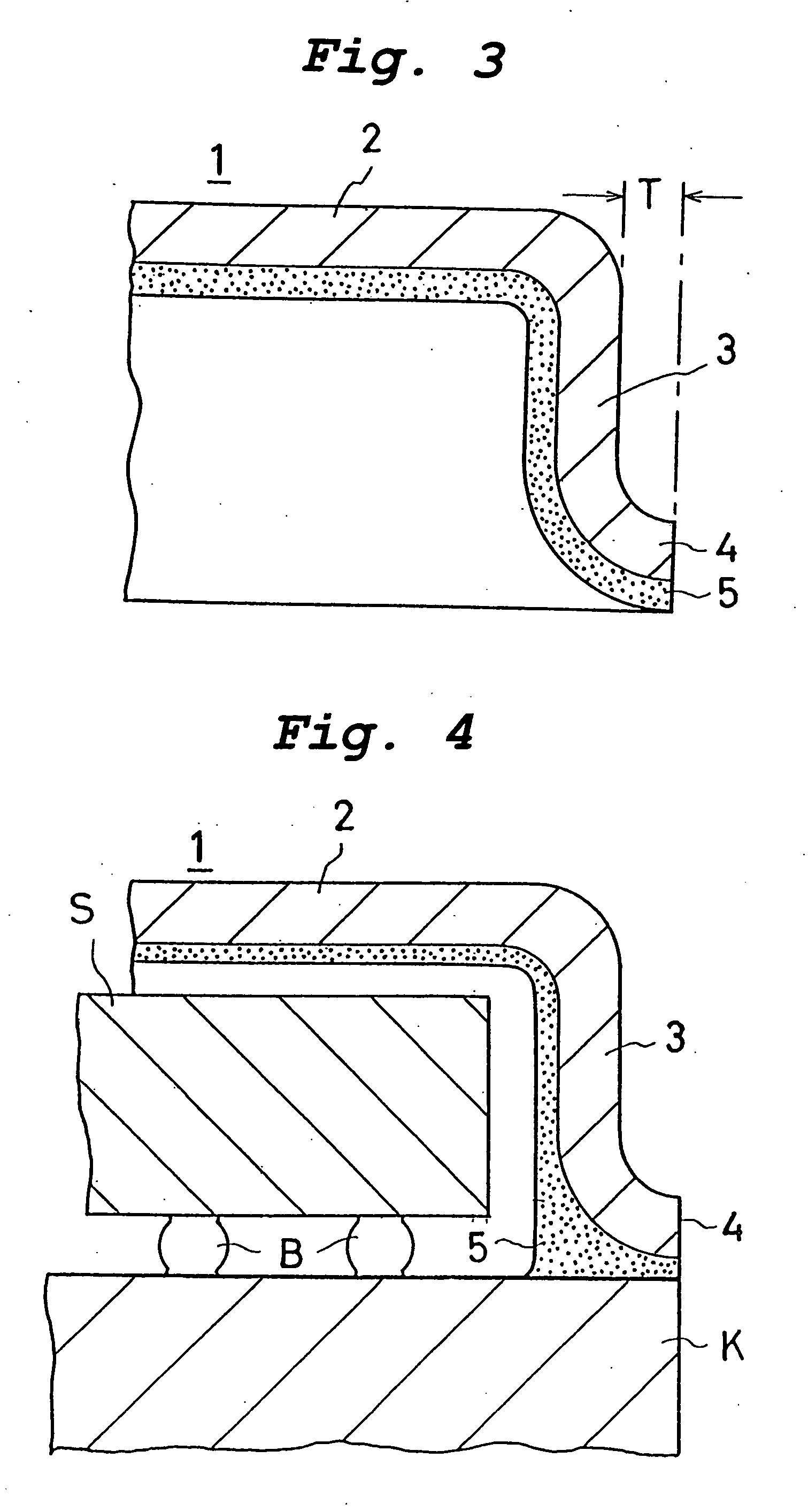

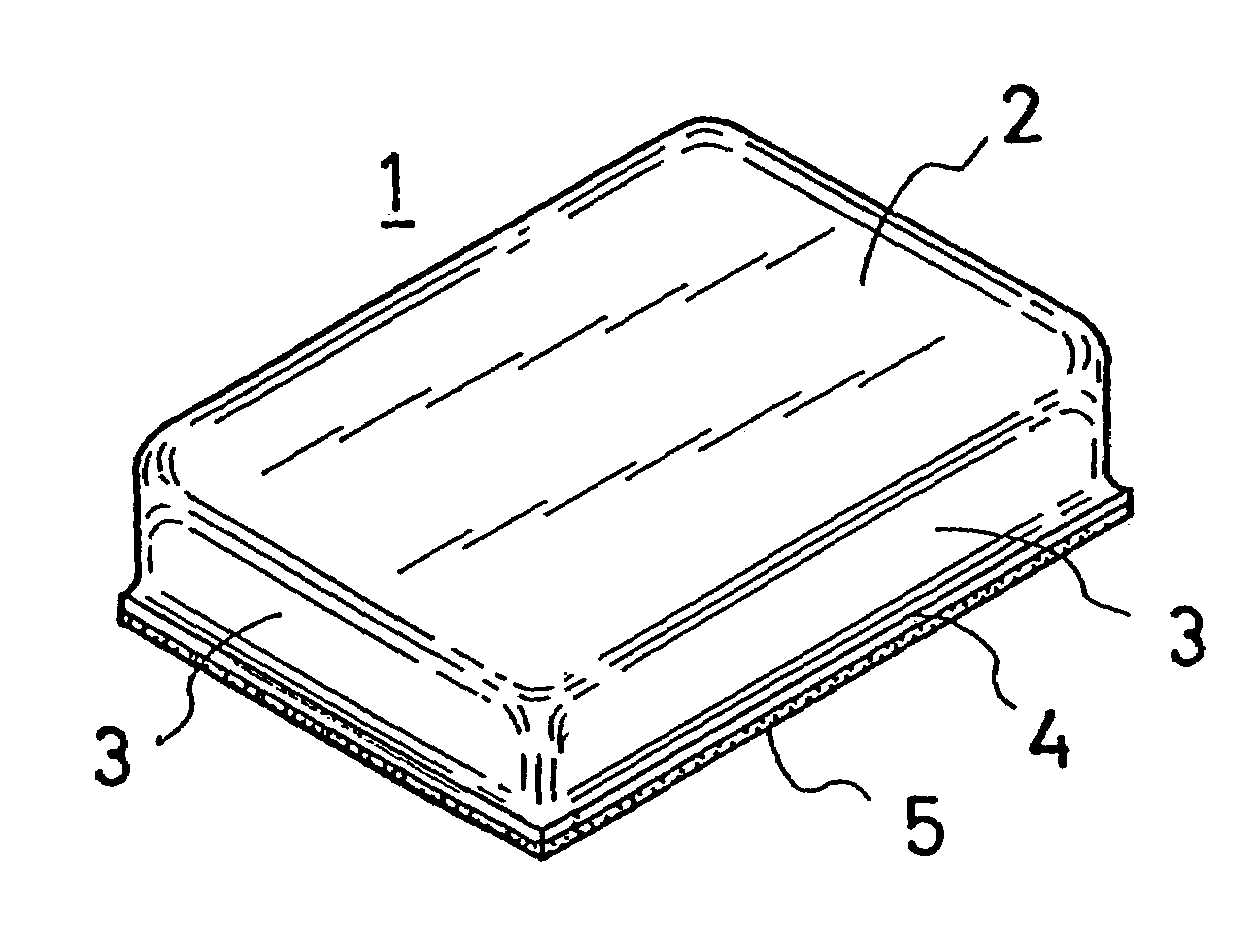

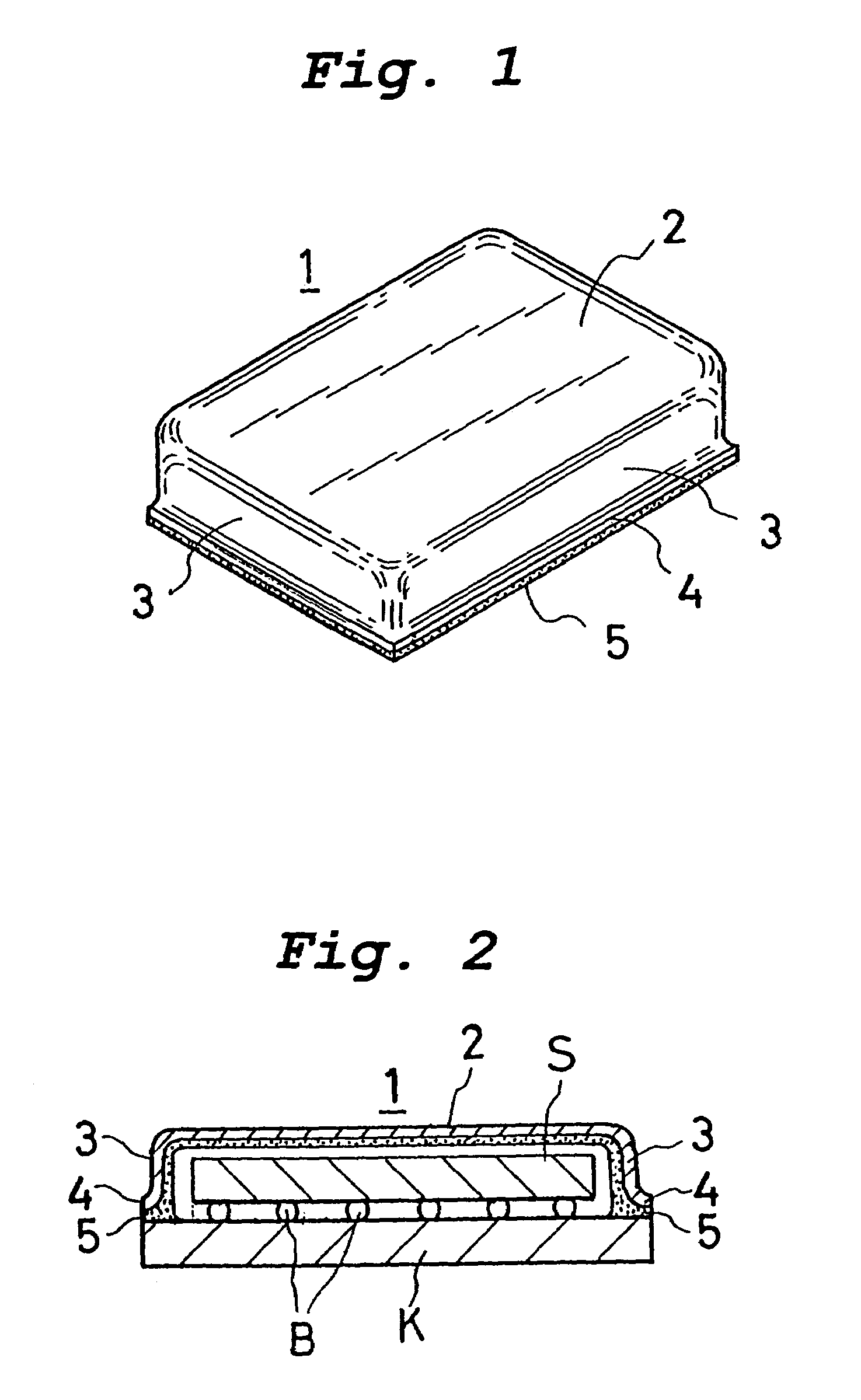

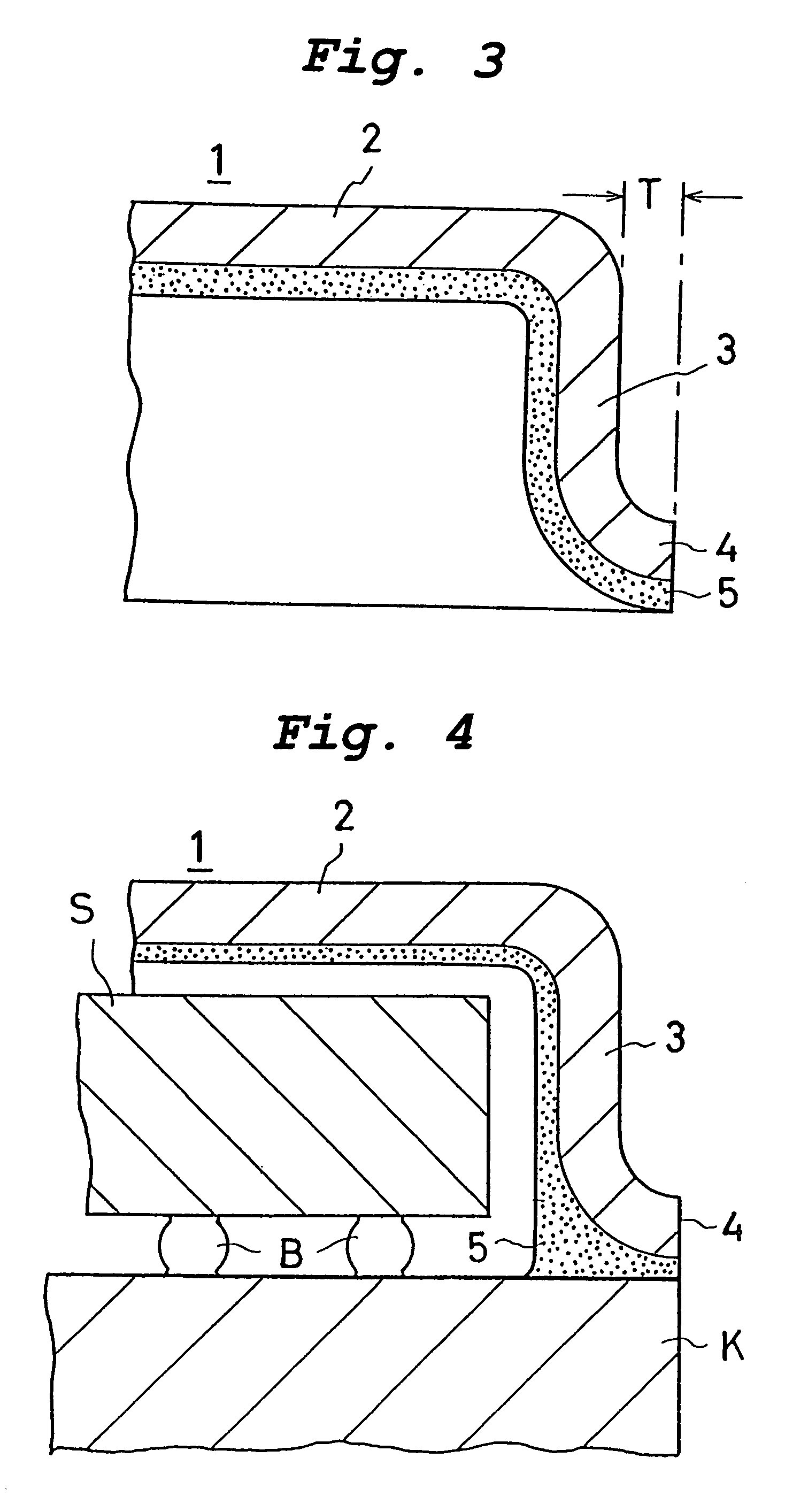

Lid for use in packaging an electronic device and method of manufacturing the lid

A lid for use with a plate-shaped base to seal an electronic device such as a SAW device includes a top portion, a wall structure extending from the top portion, and a lip connected to the lower end of the wall structure. The lip extends outwards from an outer surface of the wall structure by 10-500 mum and has solder on an inner surface thereof. The lid can be soldered to a plate-shaped base to form a package. The lid can be conveniently formed by performing drawing of a metal strip coated with solder to define a recessed shape, and then severing a flange of the recessed shape to define the lip.

Owner:SENJU METAL IND CO LTD

Resonator element, resonator, oscillator, and electronic device

ActiveUS20110204985A1Improve impact resistanceContainment leakImpedence networksApparatus using electrochemical resonatorsQuartz crystal resonatorElectron

A resonator element capable of improving impact resistance is provided. A quartz crystal resonator element is a resonator element formed by etching a Z plate which is cut at predetermined angles with respect to the crystal axes of a quartz crystal. The quartz crystal resonator element includes a base, a pair of resonating arms extending from the base in the Y-axis direction, and a positive X-axis notch and a negative X-axis notch formed by notching the base in the X-axis direction. The positive X-axis notch is formed by notching the base from the negative side of the X axis towards the positive side so that the width of the positive X-axis notch increases as it approaches the outer circumference.

Owner:SEIKO EPSON CORP

Lithium niobate substrate and manufacturing method thereof

ActiveCN1621578ALess uneven hueLower volume resistivityPiezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthOptoelectronicsHeat treated

The present invention provides a method for manufacturing a lithium niobate substrate by using lithium niobate crystals cultivated by the Zokoralski method, which is characterized in that the lithium niobate crystals are embedded in a substrate composed of Al, Ti, Si, In the state of powder consisting of at least one element selected from the group consisting of Ca, Mg, and C, or contained in at least one element selected from the group consisting of Al, Ti, Si, Ca, Mg, and C In the state in the container composed of elements, heat treatment is carried out at a temperature of 300°C or higher and less than 500°C.

Owner:SUMITOMO METAL MINING CO LTD

Lid for use in packaging an electronic device and method of manufacturing the lid

ActiveUS7142435B2Minimized in sizeSuitable for useImpedence networksMagnetic/electric field screeningMetal stripsEngineering

A lid for use with a plate-shaped base to seal an electronic device such as a SAW device includes a top portion, a wall structure extending from the top portion, and a lip connected to the lower end of the wall structure. The lip extends outwards from an outer surface of the wall structure by 10–500 μm and has solder on an inner surface thereof. The lid can be soldered to a plate-shaped base to form a package. The lid can be conveniently formed by performing drawing of a metal strip coated with solder to define a recessed shape, and then severing a flange of the recessed shape to define the lip.

Owner:SENJU METAL IND CO LTD

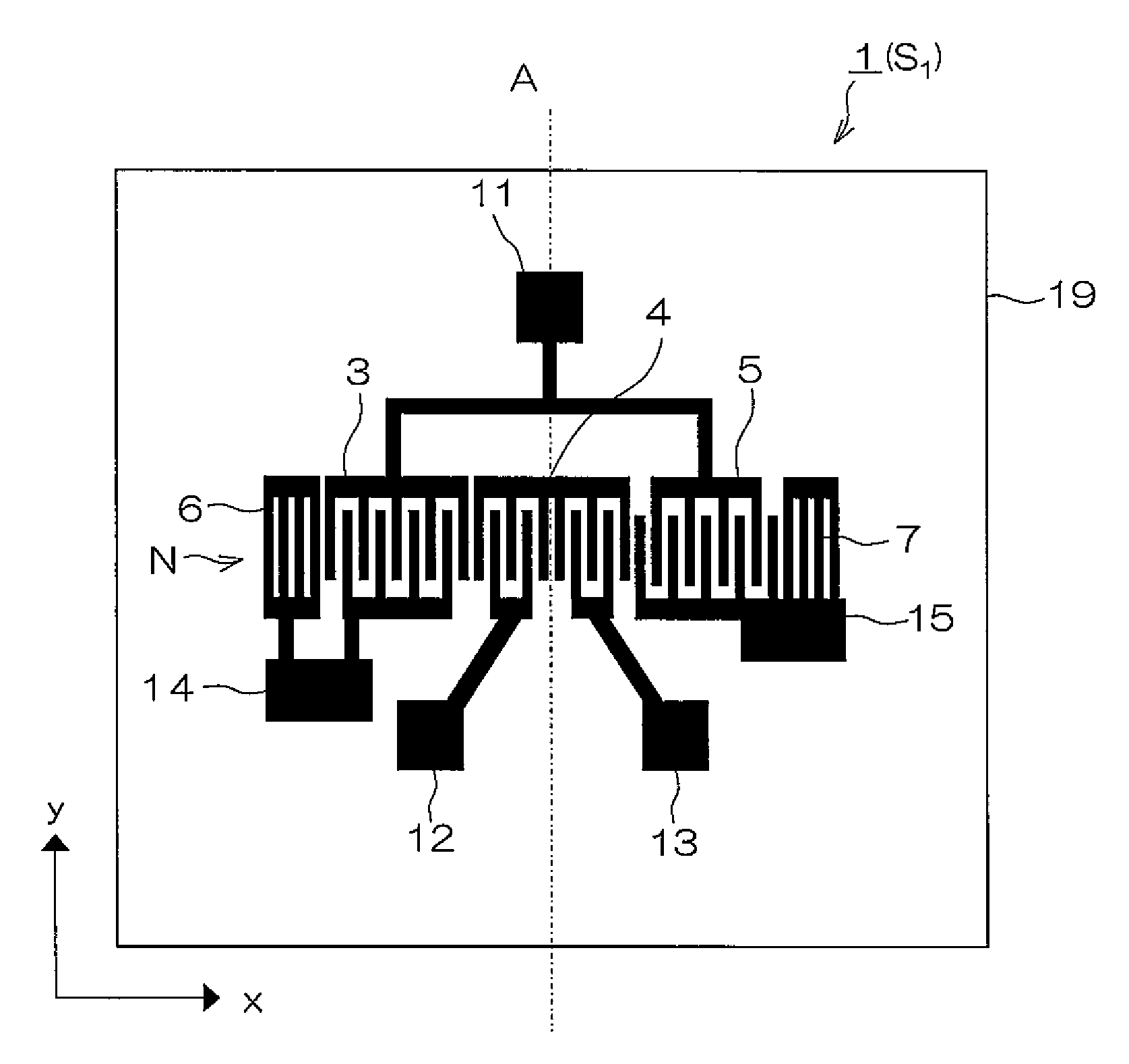

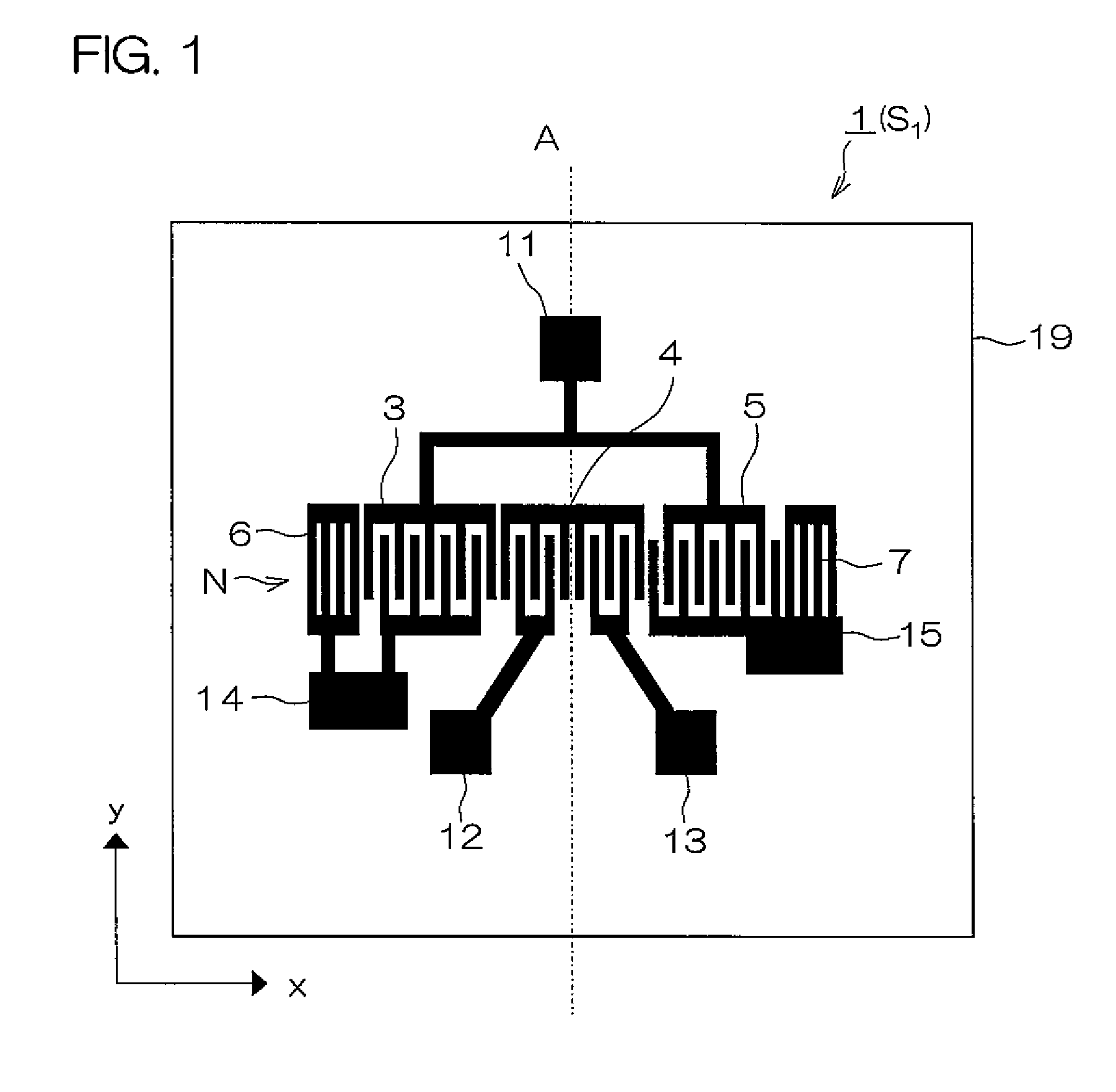

Surface acoustic wave element, surface acoustic wave device and communication device including the same

ActiveUS7518470B2Reduced insertion lossDeterioration in amplitude balanceImpedence networksDevice detailsSurface acoustic wave sensorCommunication device

A surface acoustic wave element 1 comprises a piezoelectric substrate 19, IDT electrodes 3, 4, 5 of an odd number not less than three formed along a propagation direction of surface acoustic waves that propagates on the piezoelectric substrate, wherein IDT electrodes 3, 5 of the odd number of IDT electrodes 3, 4, 5 disposed on both sides of an IDT electrode 4 that is located at the center are connected to first and second reference potential terminals 14, 15, respectively, and the first and second reference potential terminals 14 and 15 are formed asymmetrically with respect to a virtual central axis A that passes through the center of the IDT electrode 4 located at the center and provided in a direction perpendicular to the propagation direction.

Owner:KYOCERA CORP

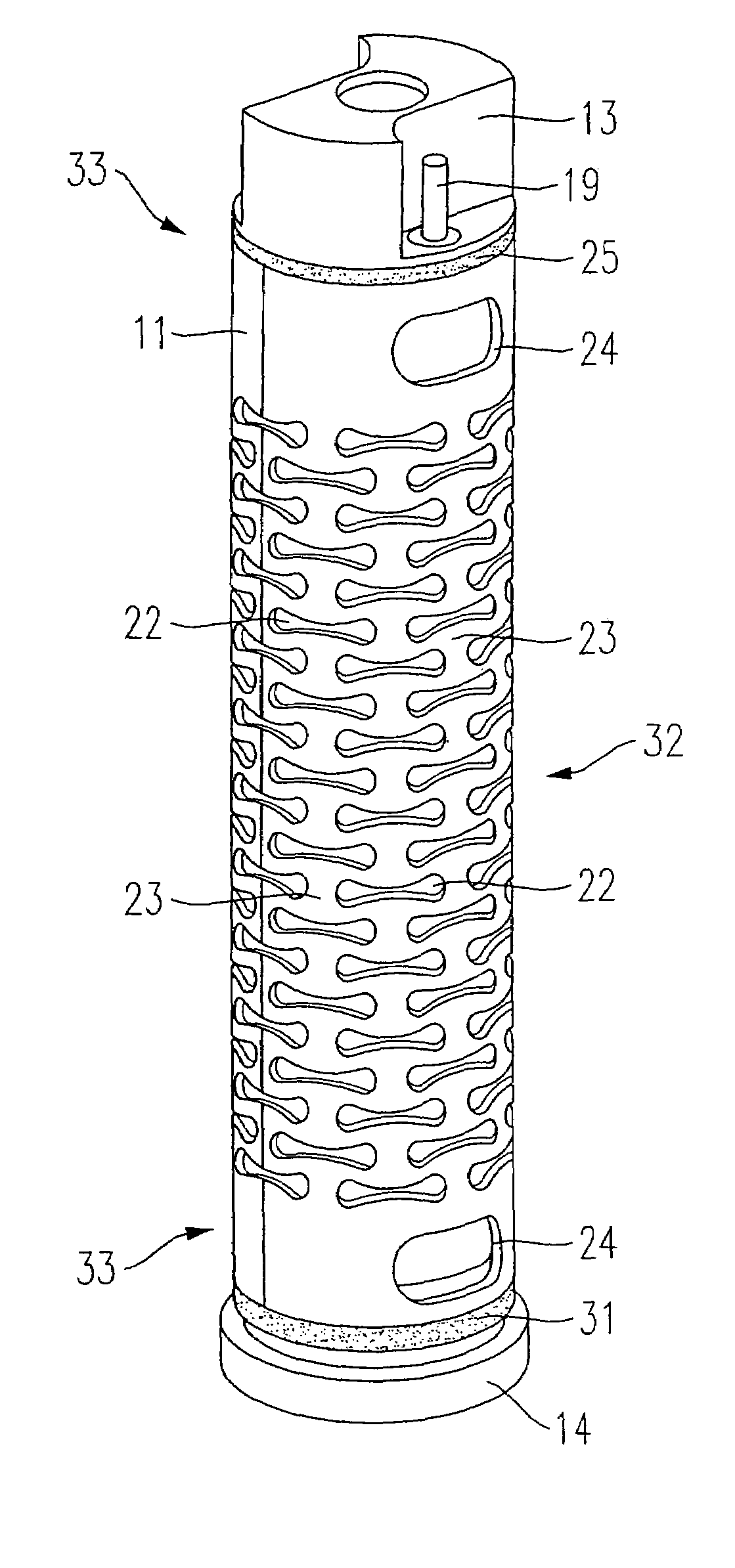

Tubular spring for actuator, and method for assembling the tubular spring

InactiveUS7564175B2Characteristic is not negativelyProtection from damagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCombustionMagnetostrictive actuator

Owner:ROBERT BOSCH GMBH

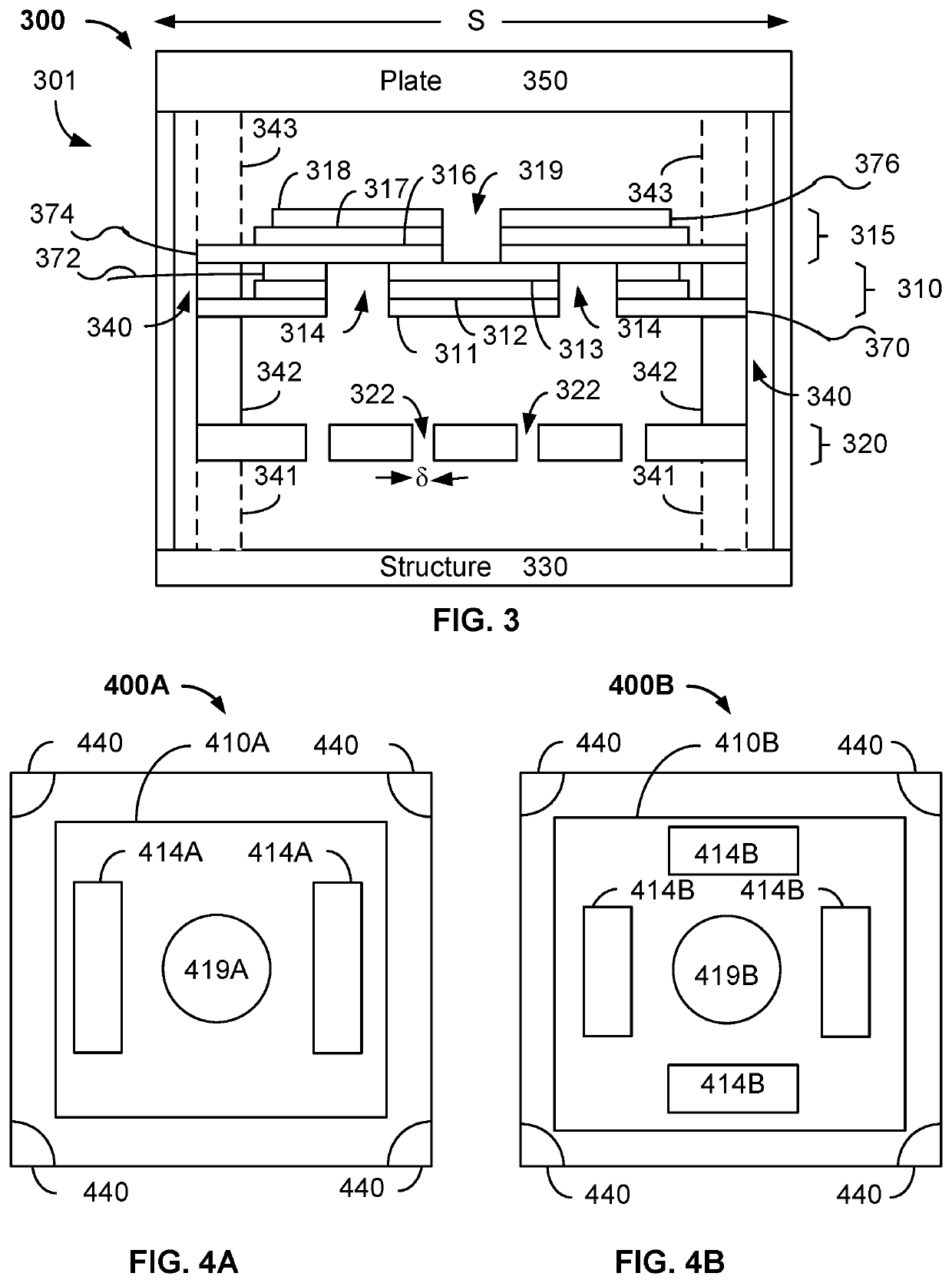

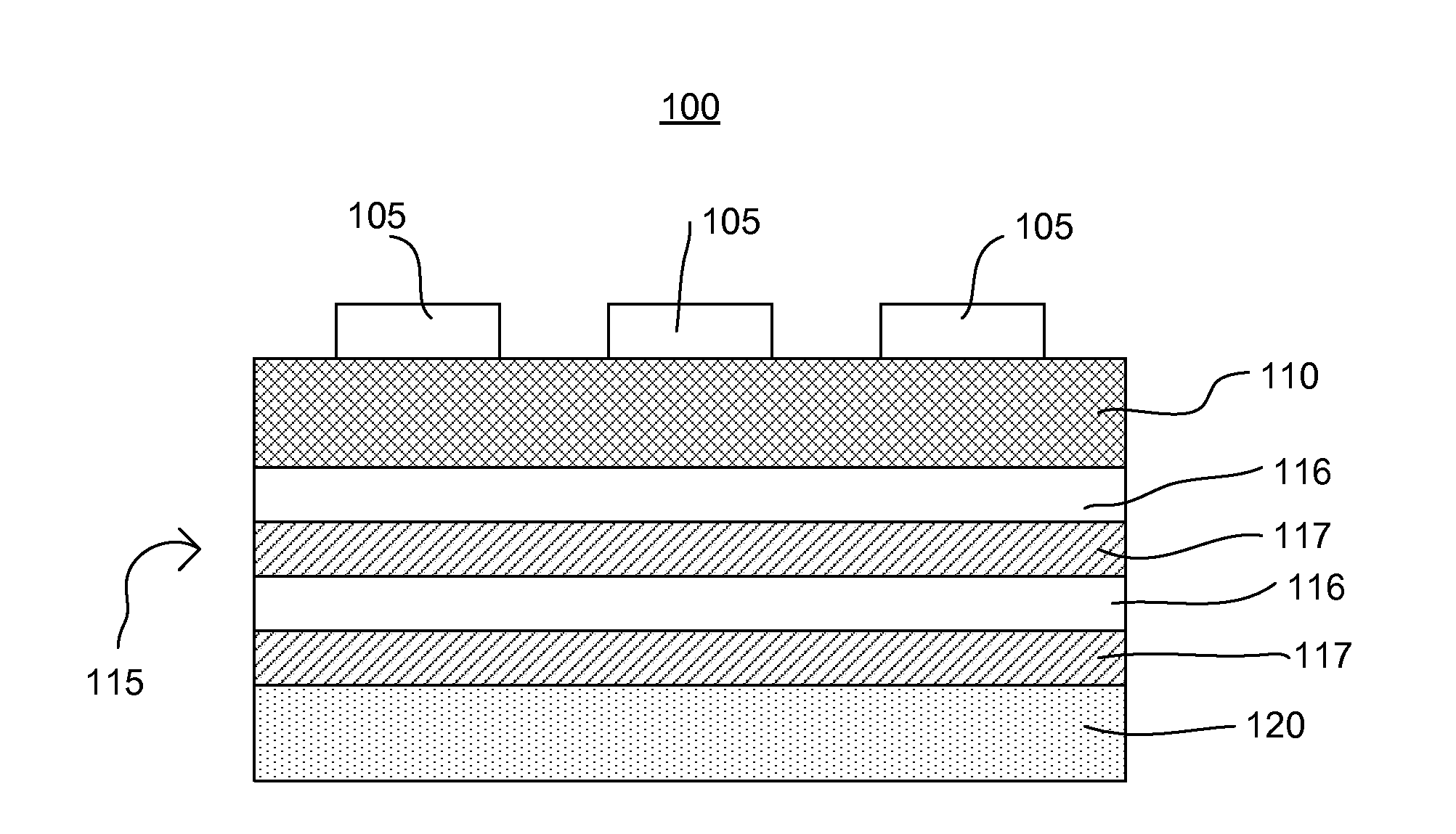

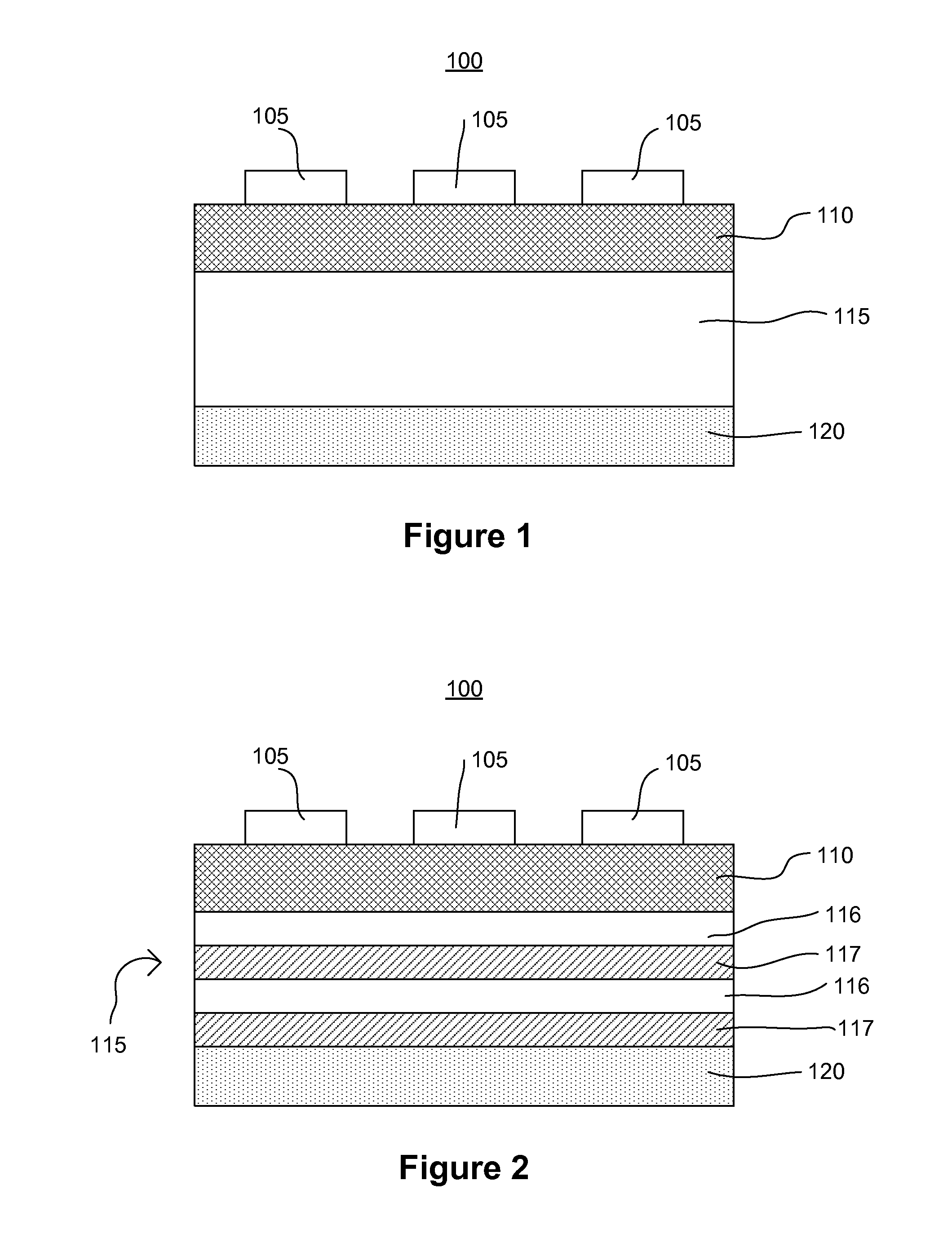

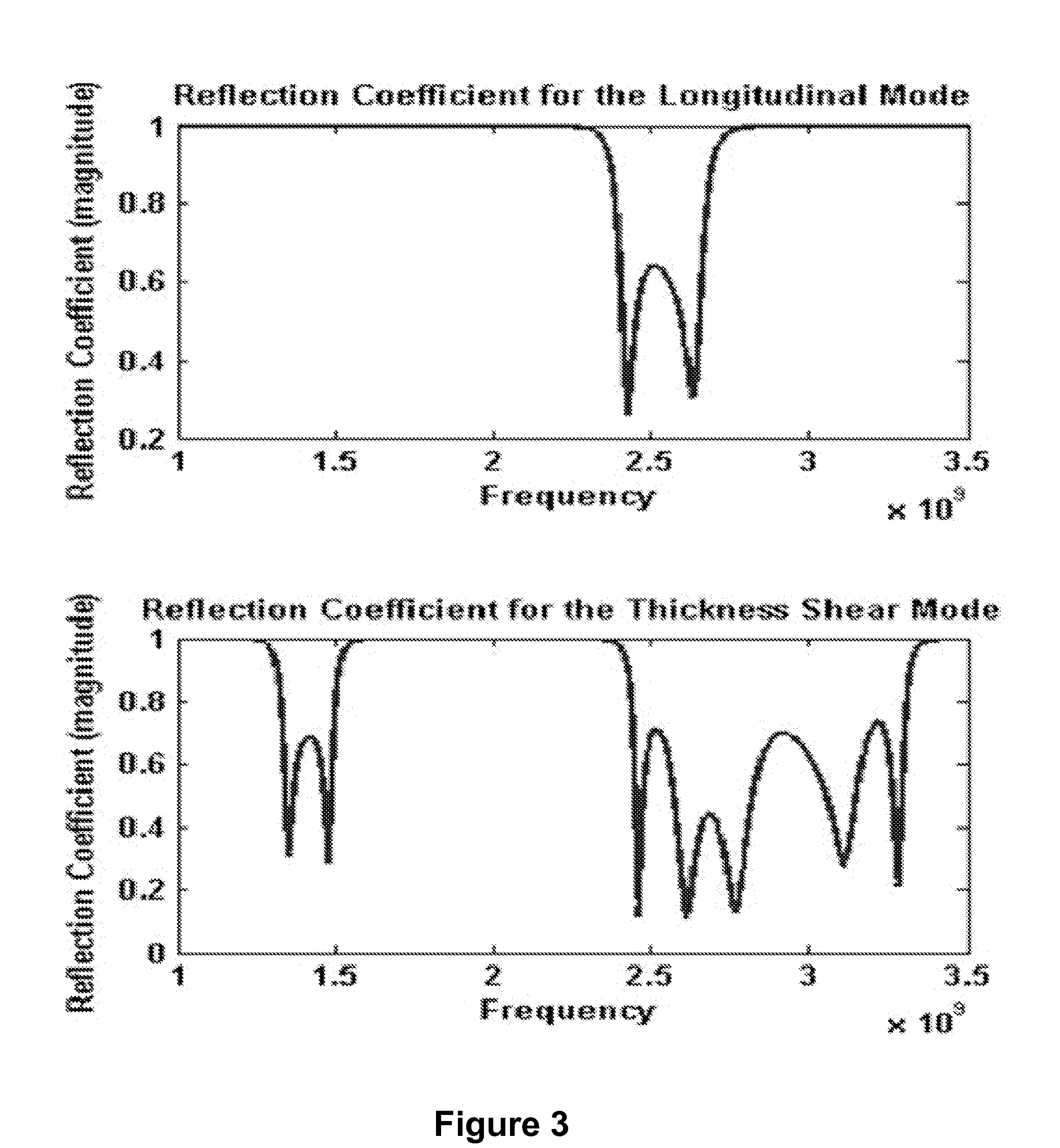

Multi-mode bulk-acoustic-wave resonators

ActiveUS20120062068A1Piezoelectric/electrostriction/magnetostriction machinesImpedence networksCrystal structureAcoustics

The various embodiments of the present disclosure relate generally bulk-acoustic-wave resonators. An exemplary embodiment of the present invention provides a bulk-acoustic-wave resonator comprising an acoustic reflector, a substantially c-axis oriented hexagonal crystal structure, and a plurality of electrodes. The crystal structure is solidly-mounted to the acoustic reflector. The bulk-wave resonator resonates in at least two non-harmonically-related operational modes.

Owner:GEORGIA TECH RES CORP

Crystal unit having stacked structure

InactiveUS20080150398A1Improve sealingSecure airtightnessWindingsPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectrode

A stacked crystal unit includes: a first crystal plate in which a vibration member links to an outer circumferential frame portion, and a pair of extending electrode extends to the frame portion from excitation electrodes; and a second and third crystal plates which have a concave portion in an area opposite to the vibration member and whose open end surfaces are joined by direct bonding to both principal surfaces of the frame portion in the first crystal plate. The extending electrodes are electrically extended to an outer surface of at least one of the second and third crystal plates via electrode through-holes provided in the frame portion. The electrode through-hole includes: a first electrode through-hole penetrating through the frame portion from the principal surface of the frame portion where the extending electrode extends; and a second electrode through-hole provided in the second or third crystal plate.

Owner:NIHON DEMPA KOGYO CO LTD

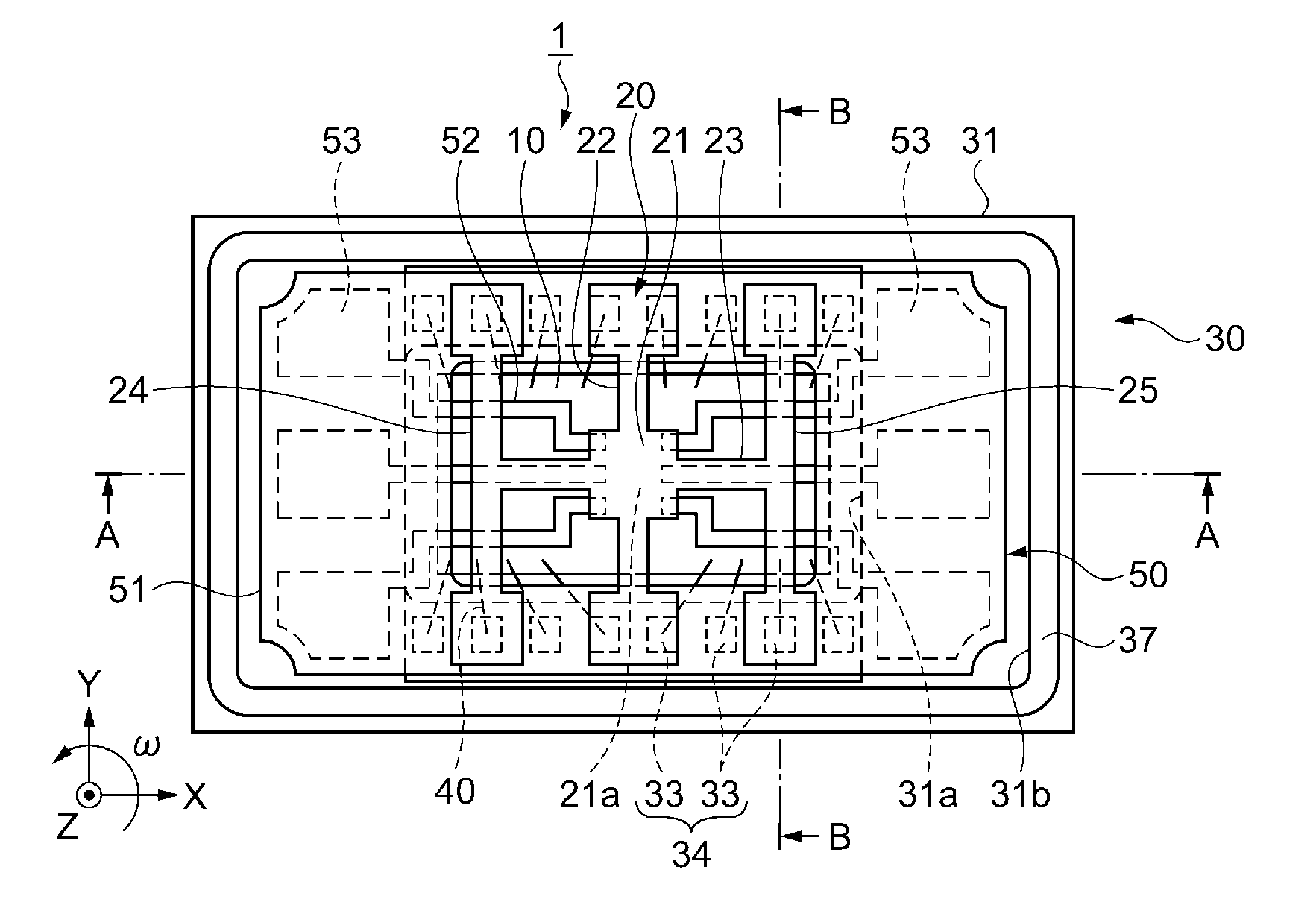

Electronic device, package, electronic apparatus, and moving object

InactiveUS20140239422A1Improve reliabilityWire bondability of the bonding wire to the bonding pad (Semiconductor/solid-state device detailsSolid-state devicesPhysical quantityTextile

A physical quantity sensor includes an IC chip and a package base mounted with the IC chip. The package base includes a first wiring layer provided with bonding pads connected to the IC chip via a bonding wire, a second wiring layer overlapping the first wiring layer in plan view, and an insulating layer provided between the first wiring layer and the second wiring layer. A contour of a wiring pattern provided on the second wiring layer (of the second wiring layer) is arranged in a position not overlapping the bonding pads in plan view.

Owner:SEIKO EPSON CORP

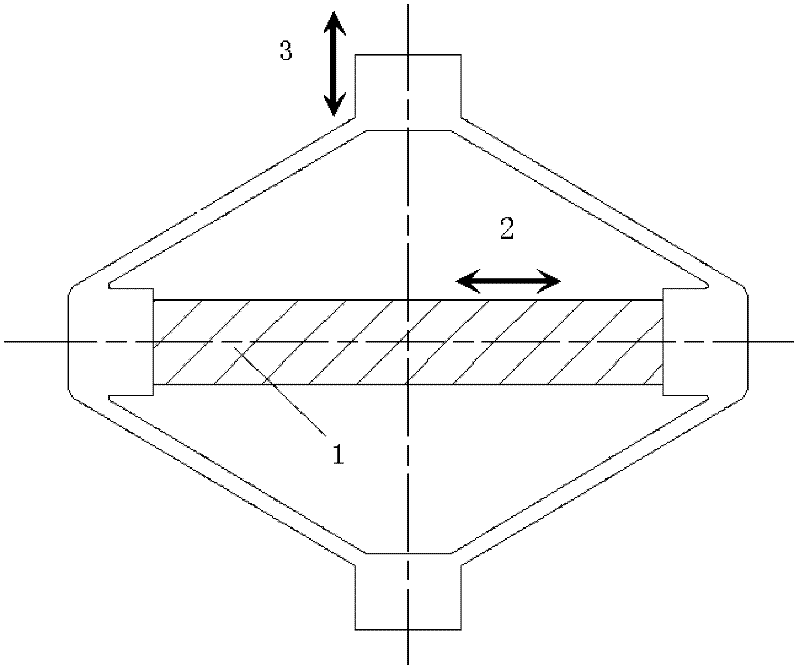

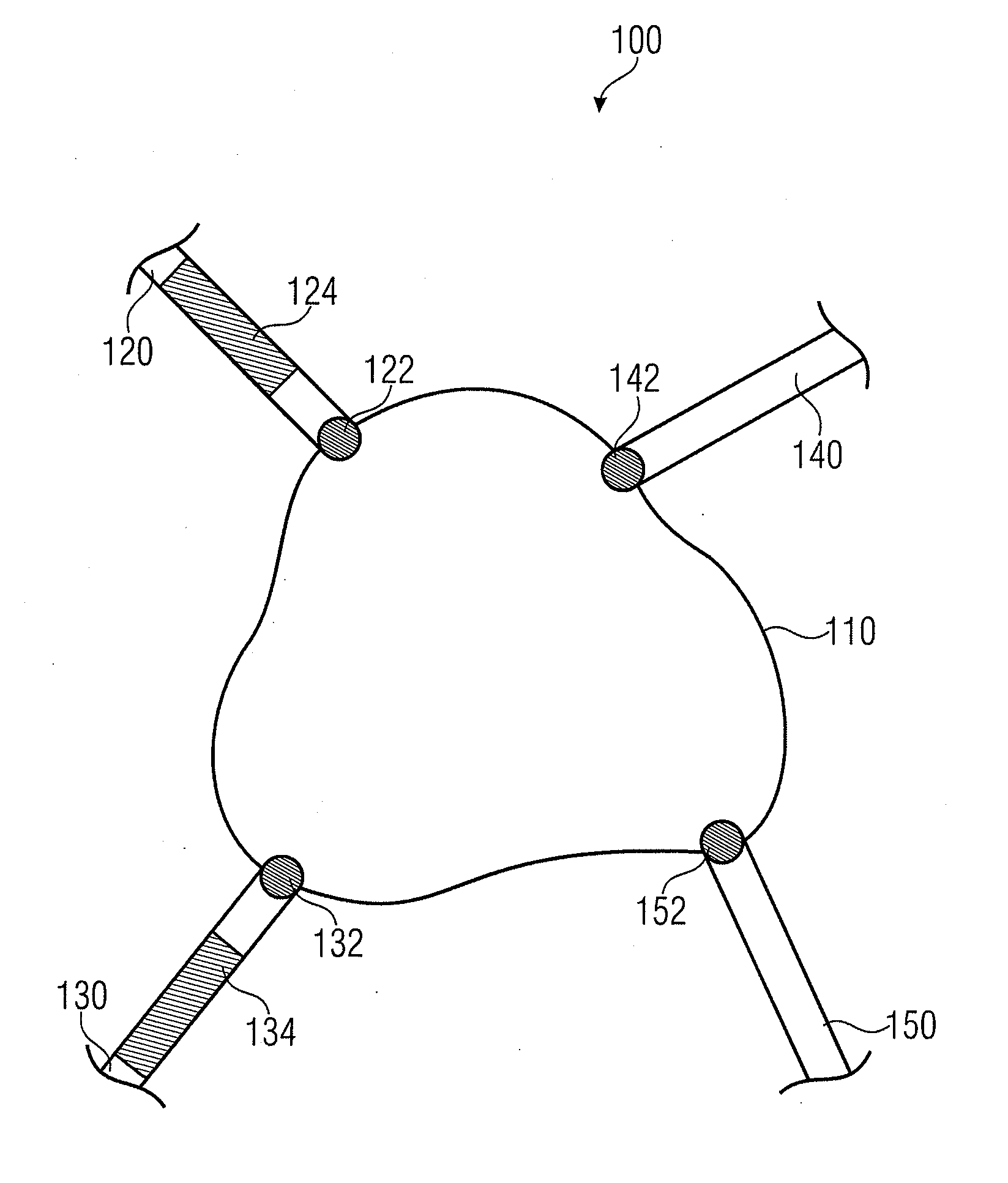

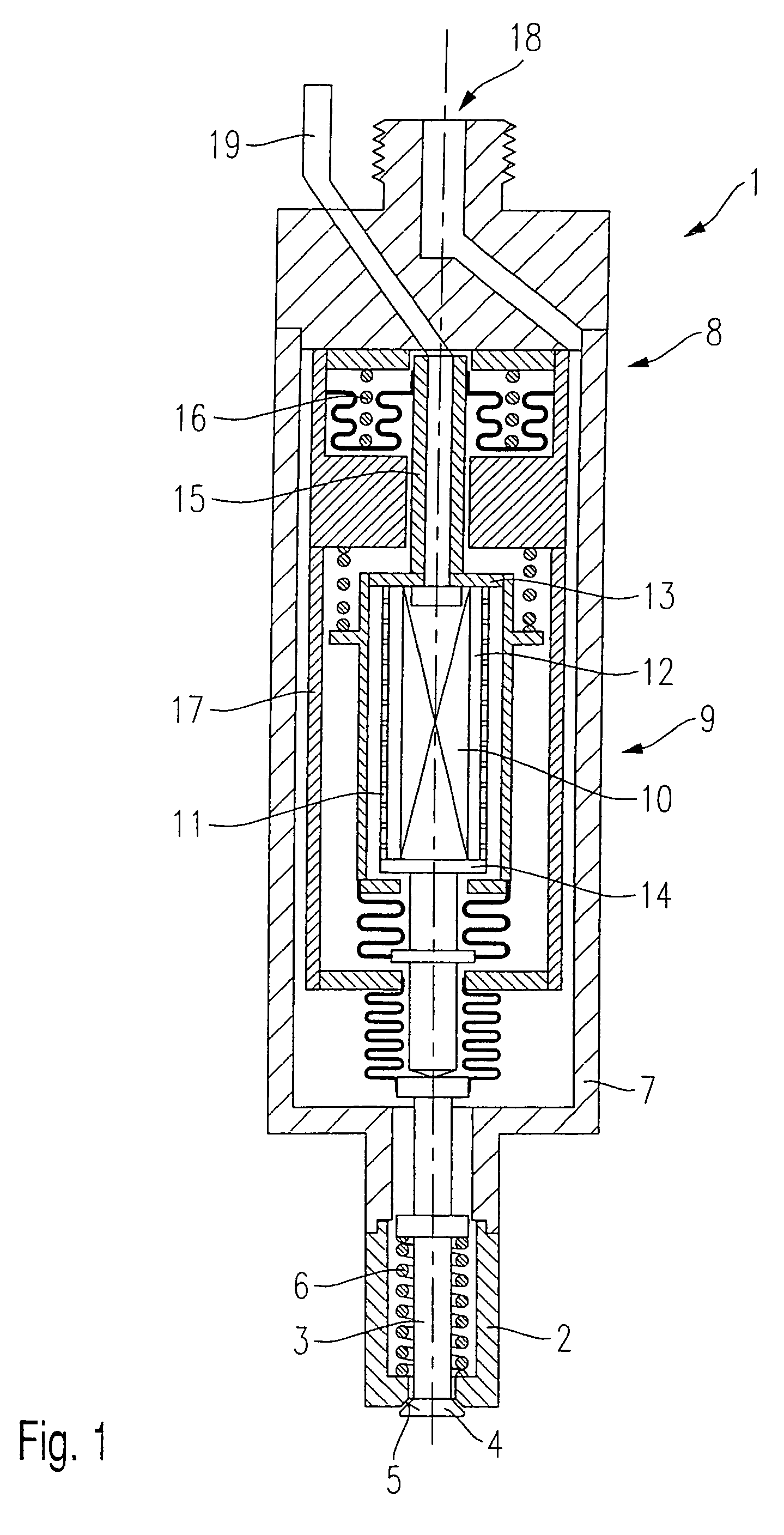

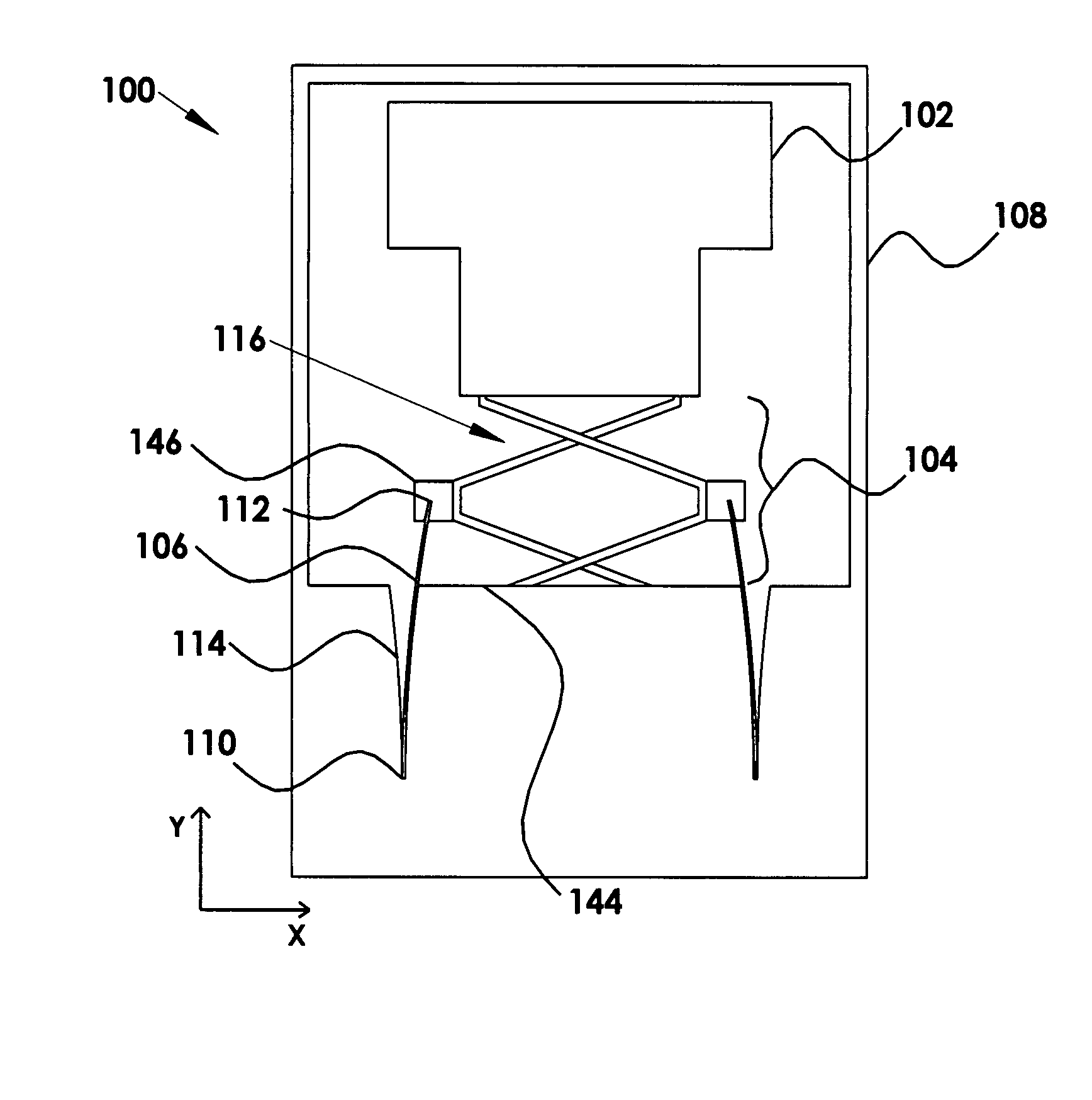

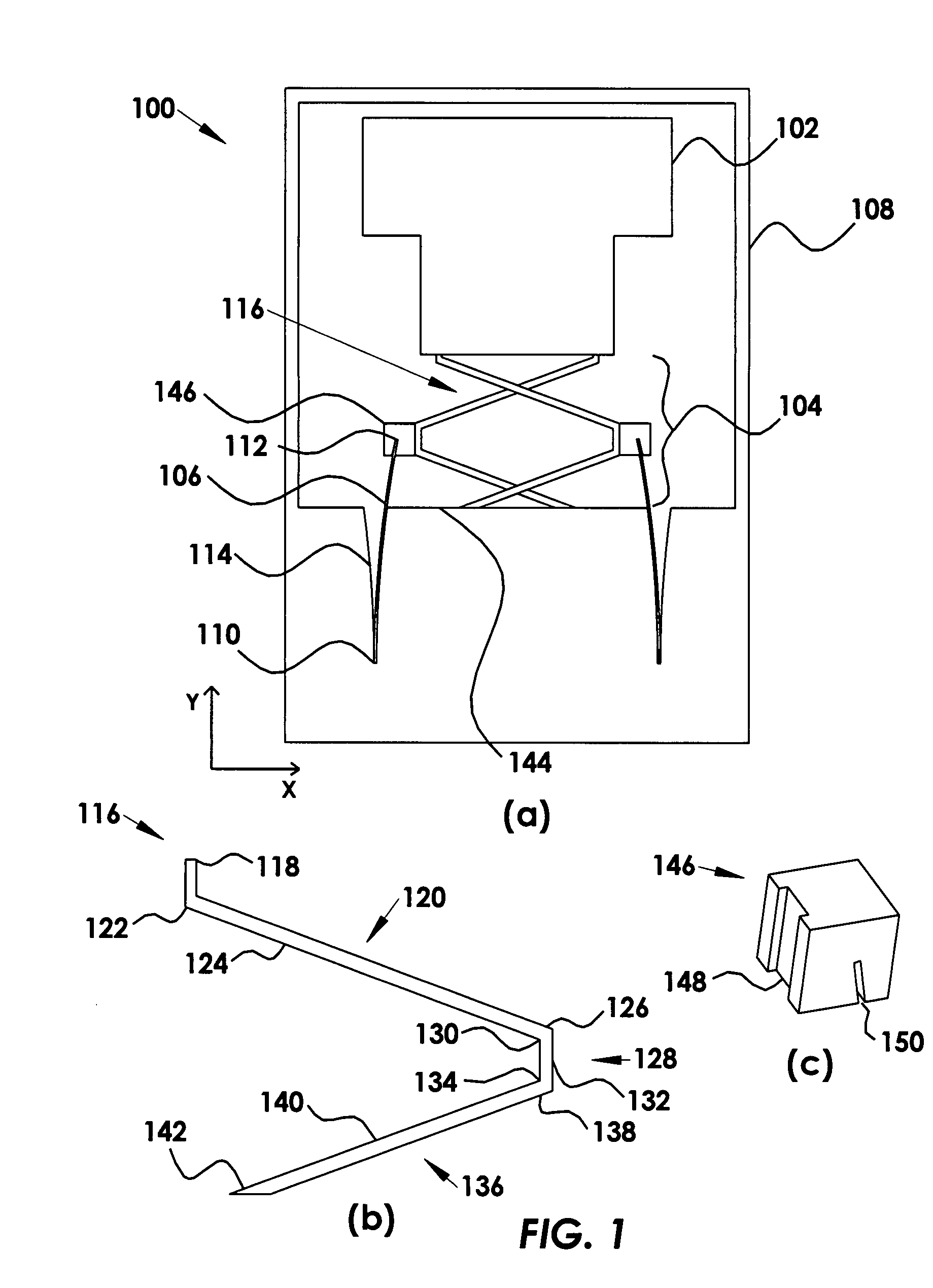

Inertial energy scavenger

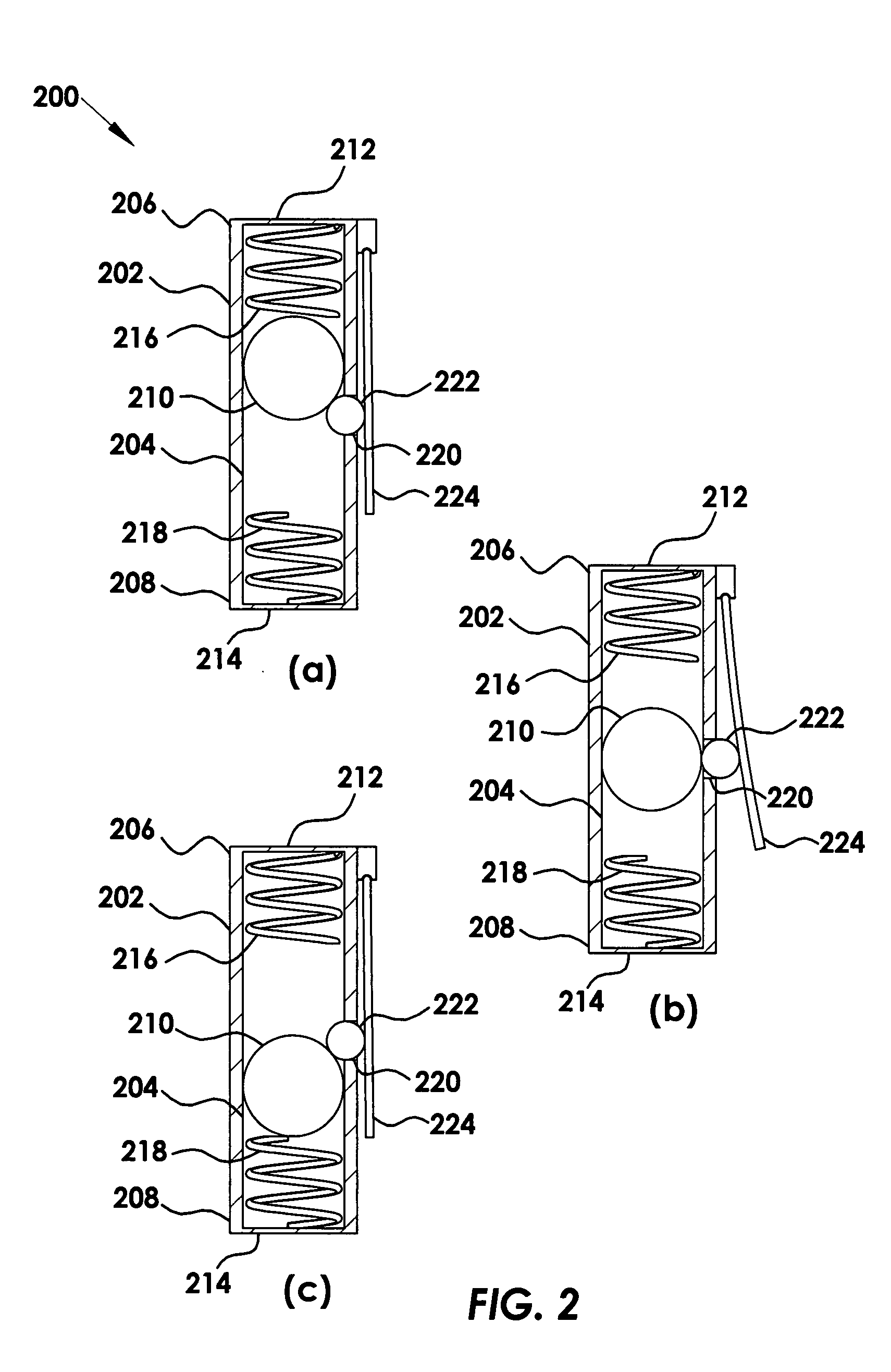

InactiveUS20080129153A1Improve performanceIncrease energy outputPiezoelectric/electrostriction/magnetostriction machinesDevice detailsEnergy scavengerEngineering

The present invention provides an inertial energy scavenger that includes at least one piezoelectric element held by a housing, a proof mass that is movable within the housing in a direction parallel to the piezoelectric element, and a mechanical assembly disposed between the proof mass and the piezoelectric element. The mechanical assembly transfers work from the proof mass to the piezoelectric element, where the work from the proof mass is a first force along a first distance and the work to the piezoelectric element is a second force along a second distance. The first distance is greater than the second distance and the first force is smaller than the second force. Force amplification is determined by the geometry of the mechanical transfer assembly and can range anywhere from just above 1 to at least 10, where some embodiments include a bi-lever configuration, a tube-shaped configuration and a reverse actuation configuration.

Owner:LV SENSOR

Microelectromechanical resonant structure having improved electrical characteristics

ActiveUS8289092B2Efficient developmentReduce resistancePulse automatic controlPiezoelectric/electrostriction/magnetostriction machinesCapacitanceSemiconductor materials

The present disclosure is directed to a MEMS resonant structure, provided with a substrate of semiconductor material; a mobile mass suspended above the substrate and anchored to the substrate by constraint elements to be free to oscillate at a resonance frequency; and a fixed-electrode structure capacitively coupled to the mobile mass to form a capacitor with a capacitance that varies as a function of the oscillation of the mobile mass; the fixed-electrode structure arranged on a top surface of the substrate, and the constraint elements being configured in such a way that the mobile mass oscillates, in use, in a vertical direction, transverse to the top surface of the substrate, keeping substantially parallel to the top surface.

Owner:STMICROELECTRONICS SRL

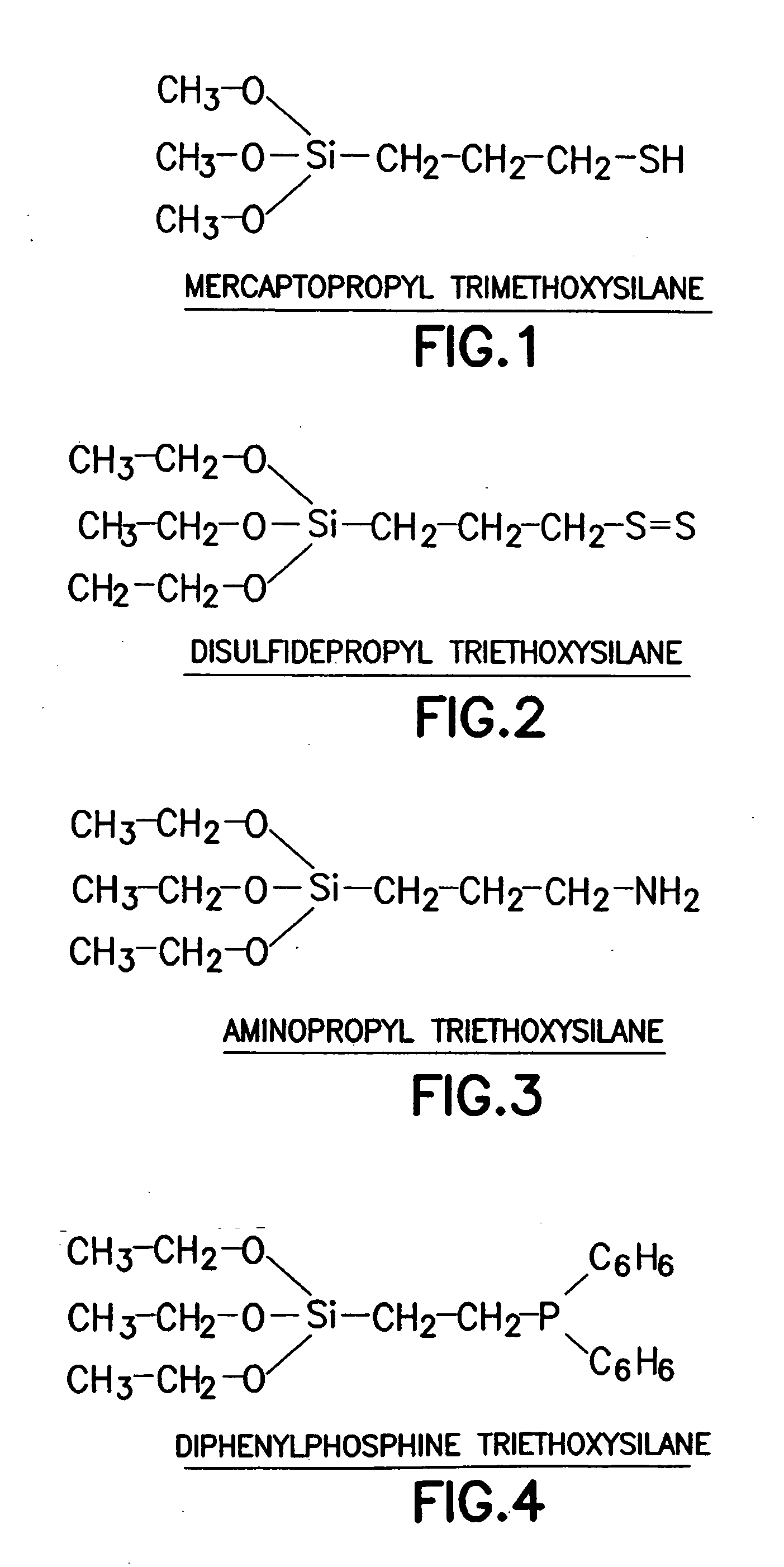

Method for enhancing epoxy adhesion to gold surfaces

InactiveUS20050099089A1Improve adhesionImprove developmentNon-macromolecular adhesive additivesPiezoelectric/electrostriction/magnetostriction machinesEpoxyAdhesive materials

A method for bonding one surface to a gold surface comprises the following steps: (a) mixing a solution containing sulfur-containing alkoxysilane; (b) treating the gold surface with the solution; (c) adding sulfur-containing alkoxysilane to an adhesive material; (d) applying the adhesive material with additive on one of both surfaces; and (e) pressing the surfaces against each other while the adhesive material therebetween sets.

Owner:GENERAL ELECTRIC CO

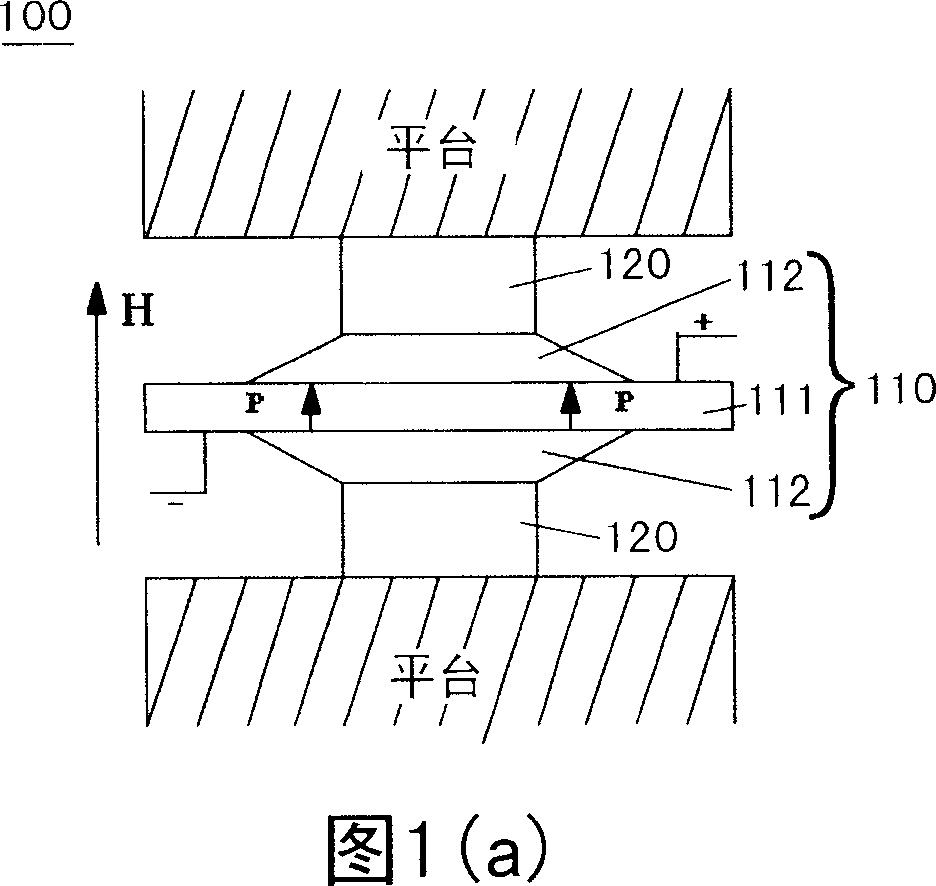

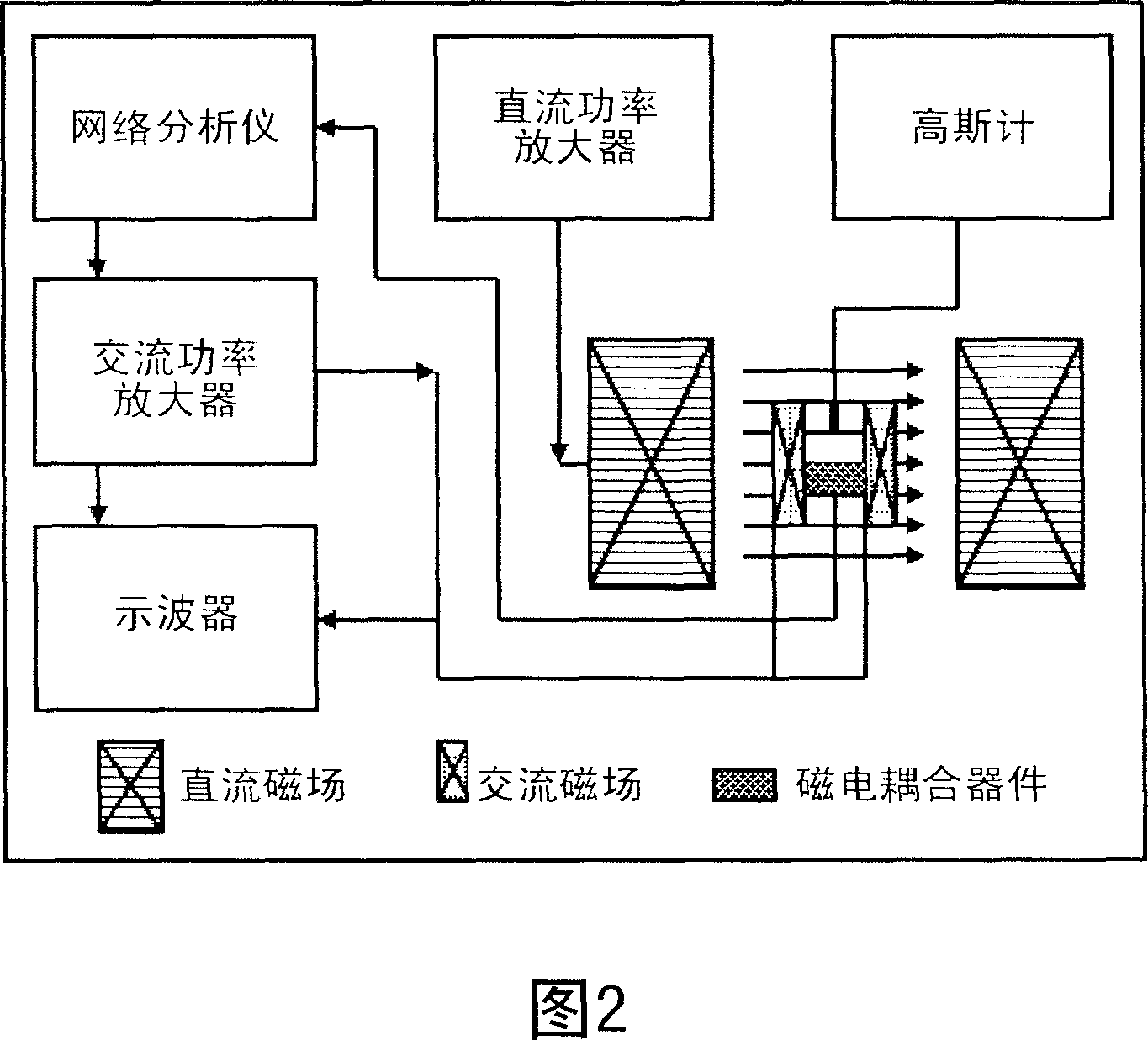

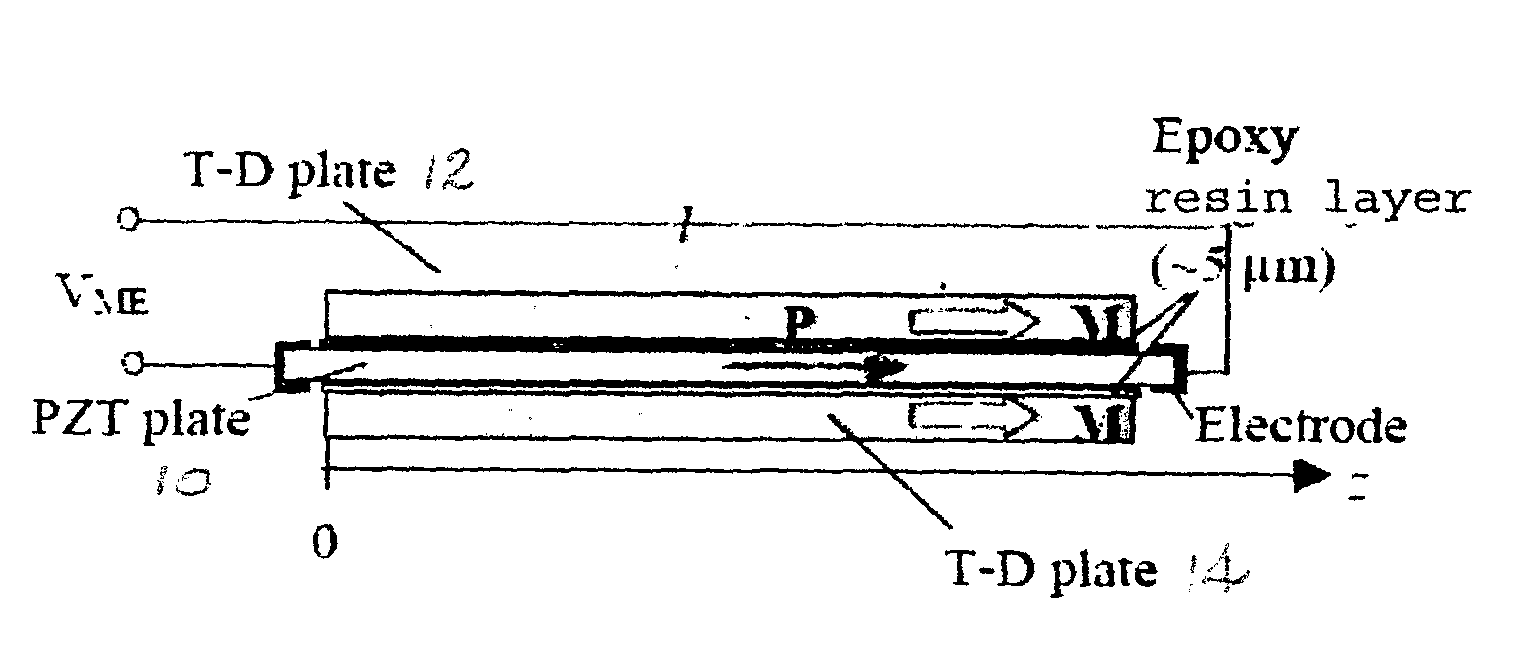

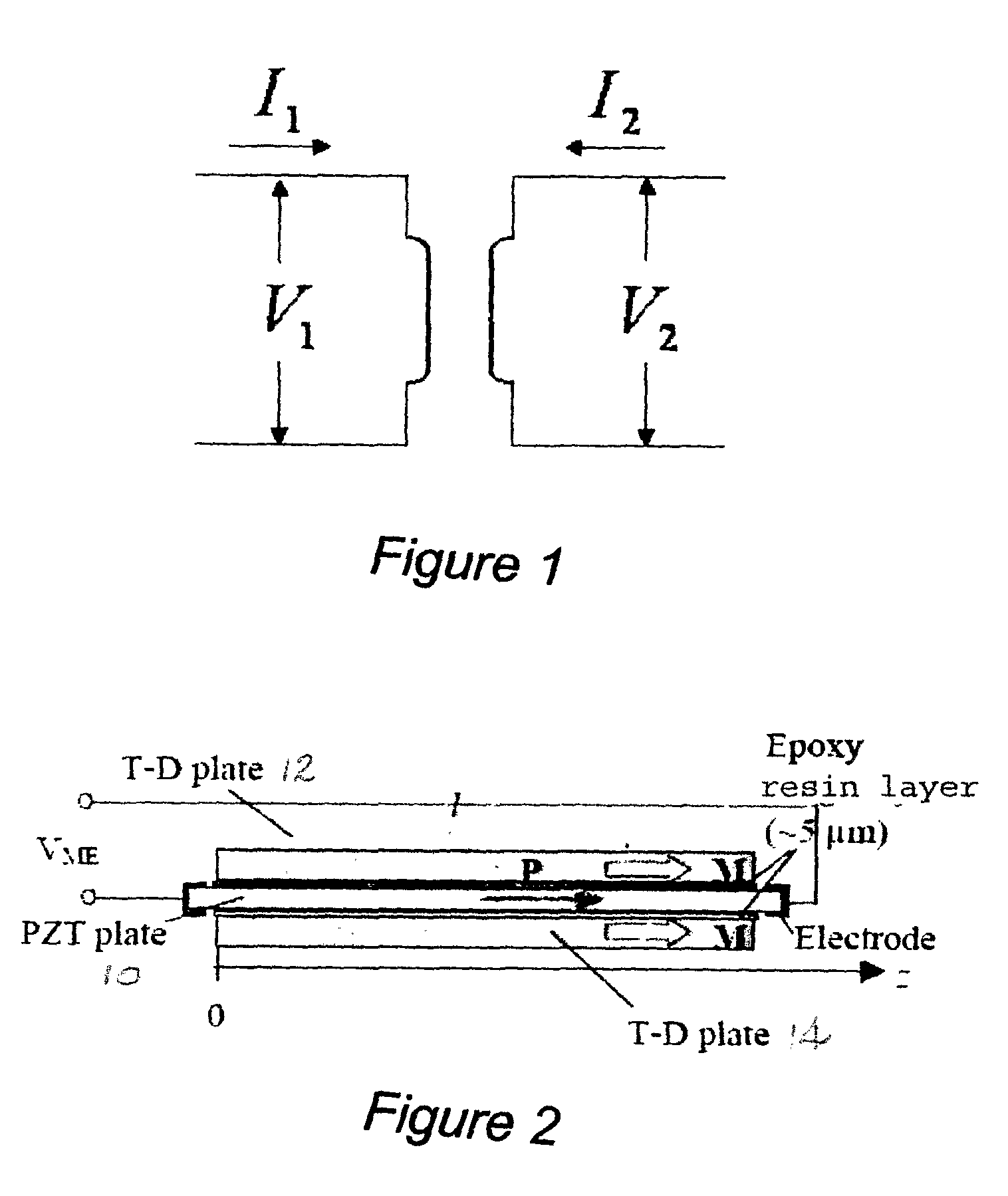

Magnetoelectric coupling device

InactiveCN101047225AHigh sensitivityPiezoelectric/electrostrictive device material selectionMagnetostrictive material selectionElectric couplingElectric signal

A magneto-electric coupling component is prepared as setting piezoelectric component between two magnetostrictive plates in order to convert displacement generated by said magnetostrictive plates to be electric signal and holding said piezoelectric component being coupled together with two magnetostrictive plates by clamping fixture.

Owner:CITY UNIVERSITY OF HONG KONG

Broadband, Nonreciprocal Network Element

InactiveUS20080203855A1Impedence networksPiezoelectric/electrostriction/magnetostriction machinesDielectricPassive networks

Owner:NOVGOROD STATE UNIV +1

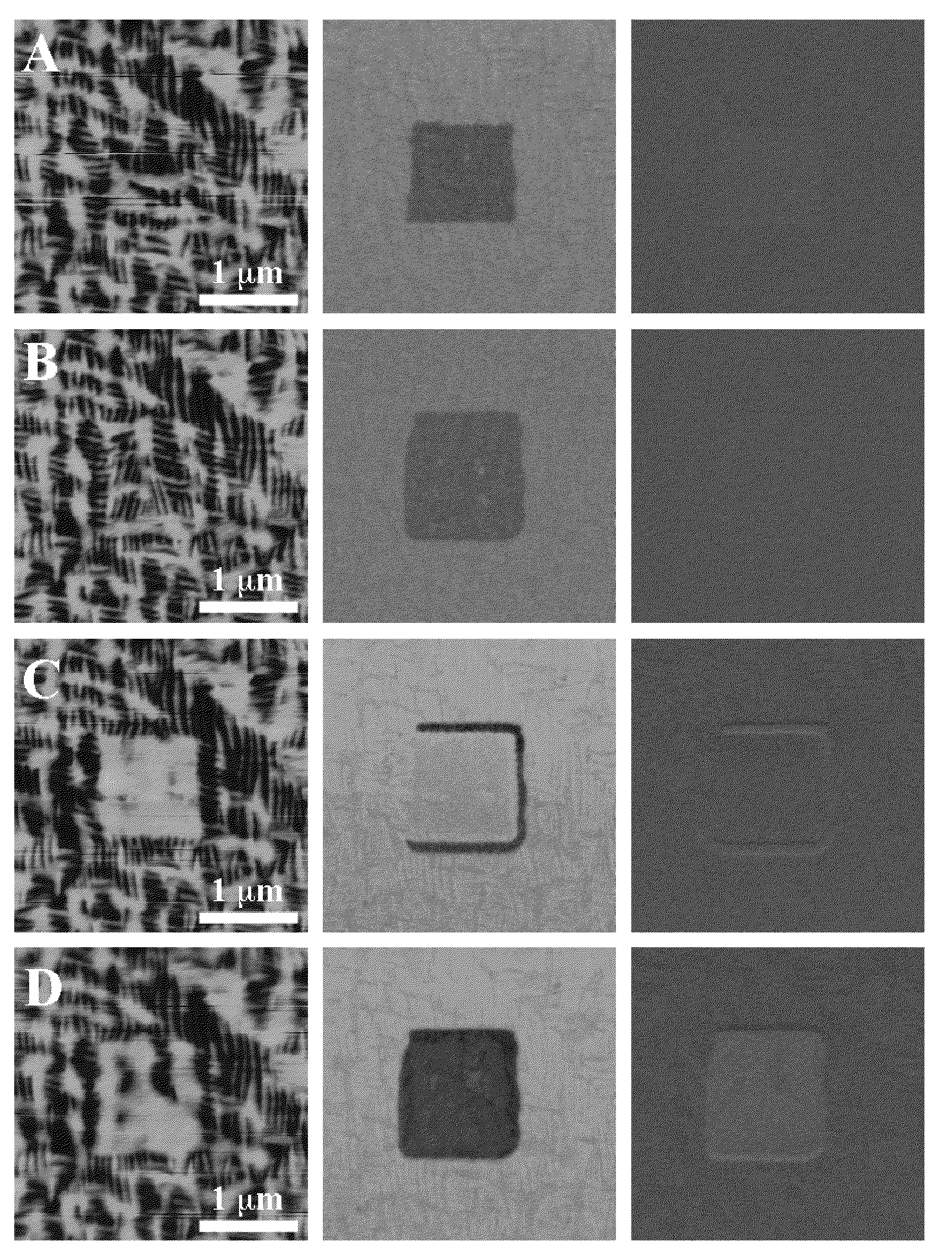

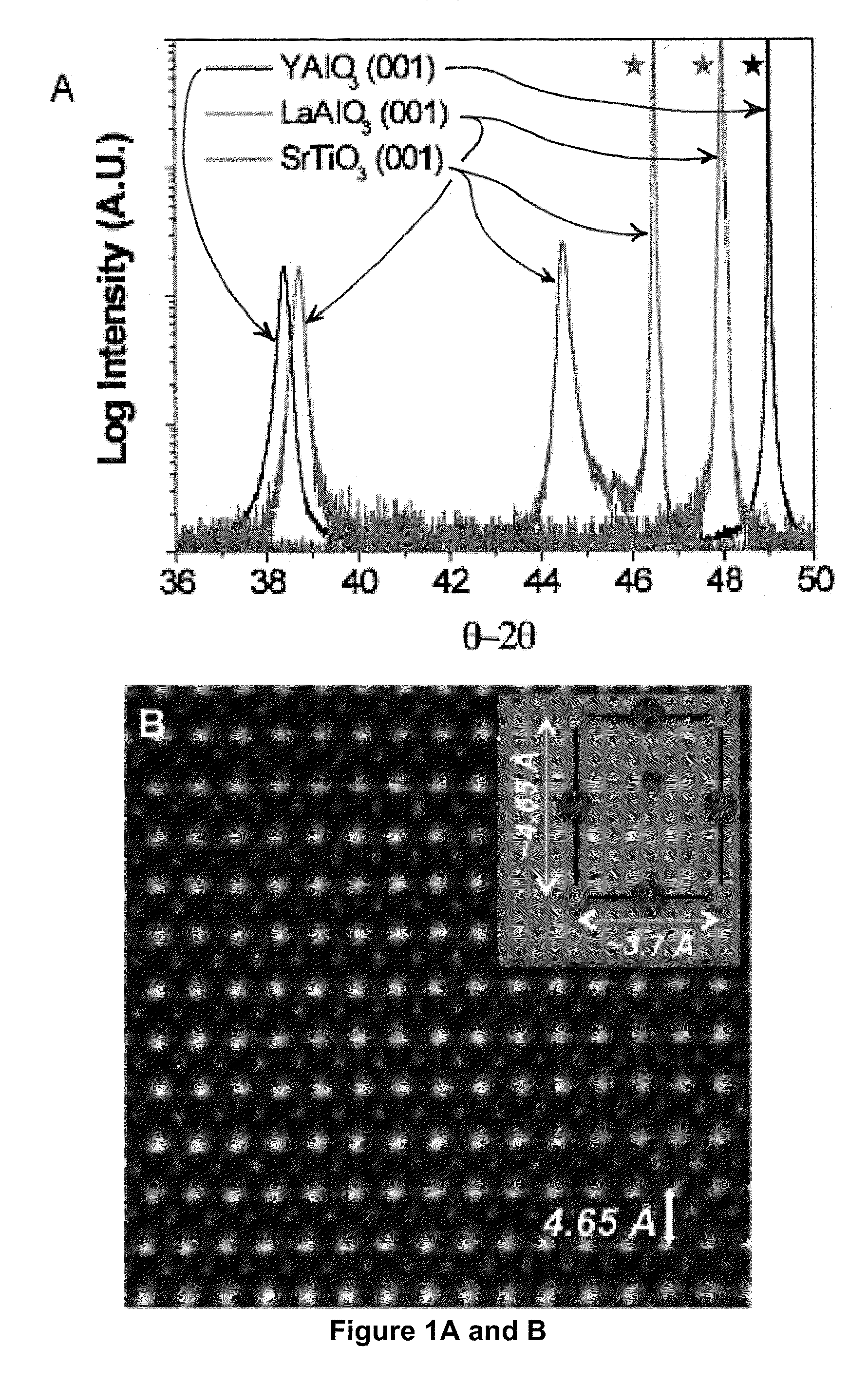

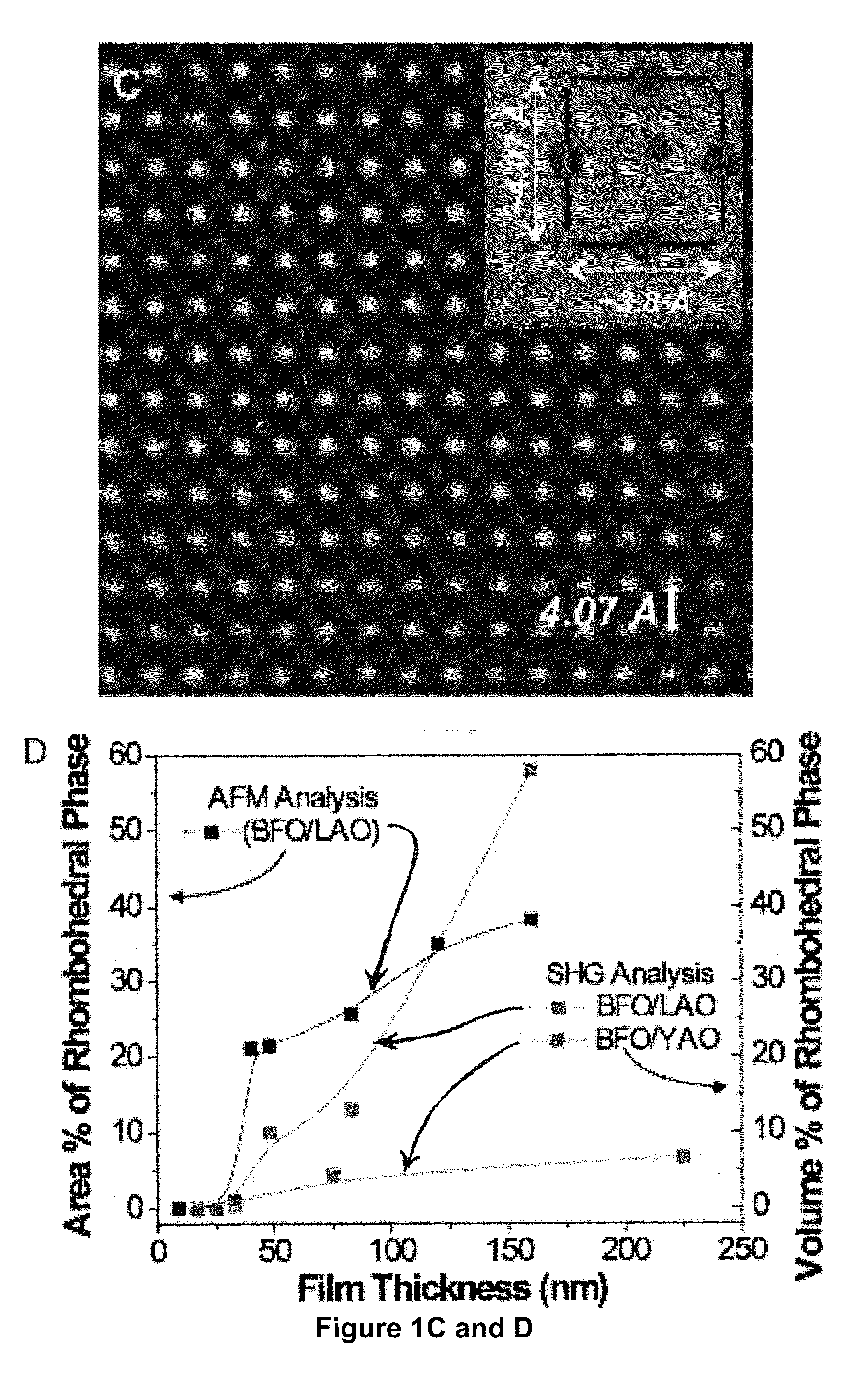

Thin Film Bismuth Iron Oxides Useful for Piezoelectric Devices

ActiveUS20110133601A1High data densityPiezoelectric/electrostrictive device manufacture/assemblyElectric discharge heatingIron oxideBismuth

The present invention provides for a composition comprising a thin film of BiFeO3 having a thickness ranging from 20 nm to 300 nm, a first electrode in contact with the BiFeO3 thin film, and a second electrode in contact with the BiFeO3 thin film; wherein the first and second electrodes are in electrical communication. The composition is free or essentially free of lead (Pb). The BFO thin film is has the piezoelectric property of changing its volume and / or shape when an electric field is applied to the BFO thin film.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com