Sleeved ultrasonic transducer

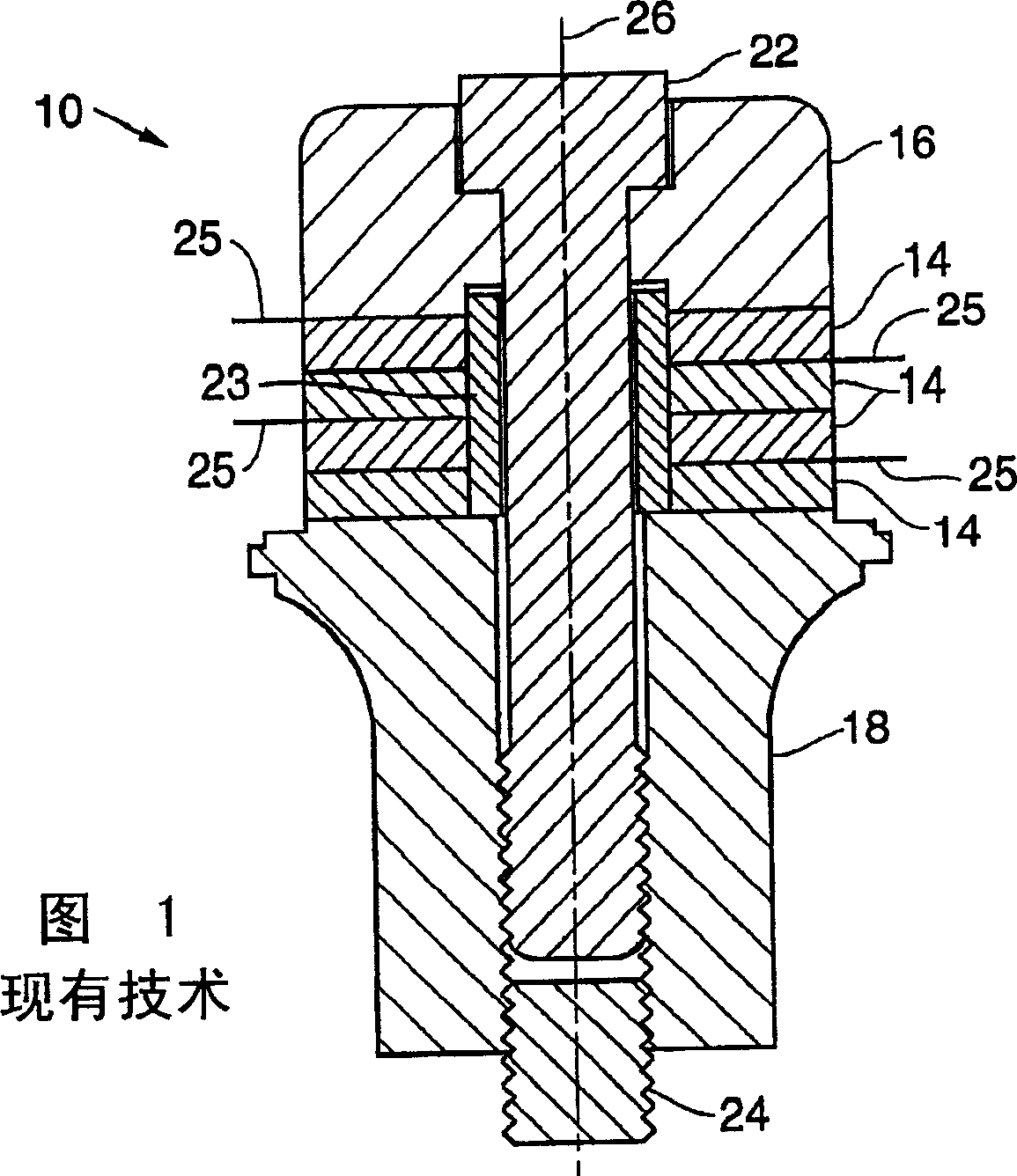

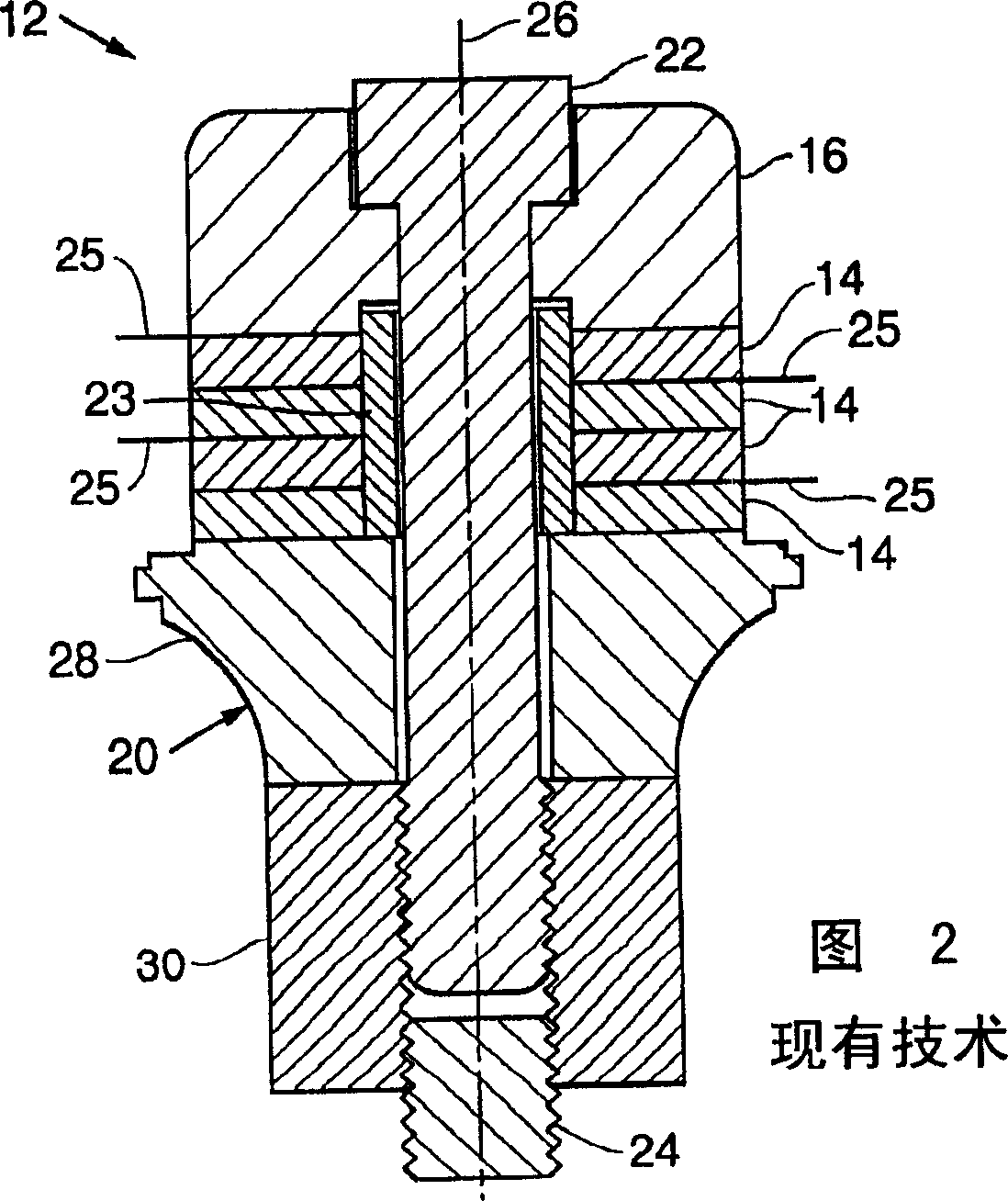

An ultrasonic transducer, piezoelectric transducer technology, applied in piezoelectric/electrostrictive transducers, sensors, device parts and other directions, can solve the problems of inconsistent thermal expansion coefficient, bonding failure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The drawings show various preferred embodiments of the invention for purposes of illustration only. It will be readily apparent to those skilled in the art from the following discussion that alternative embodiments of the structures and methods described herein may be employed without departing from the principles of the invention as described herein.

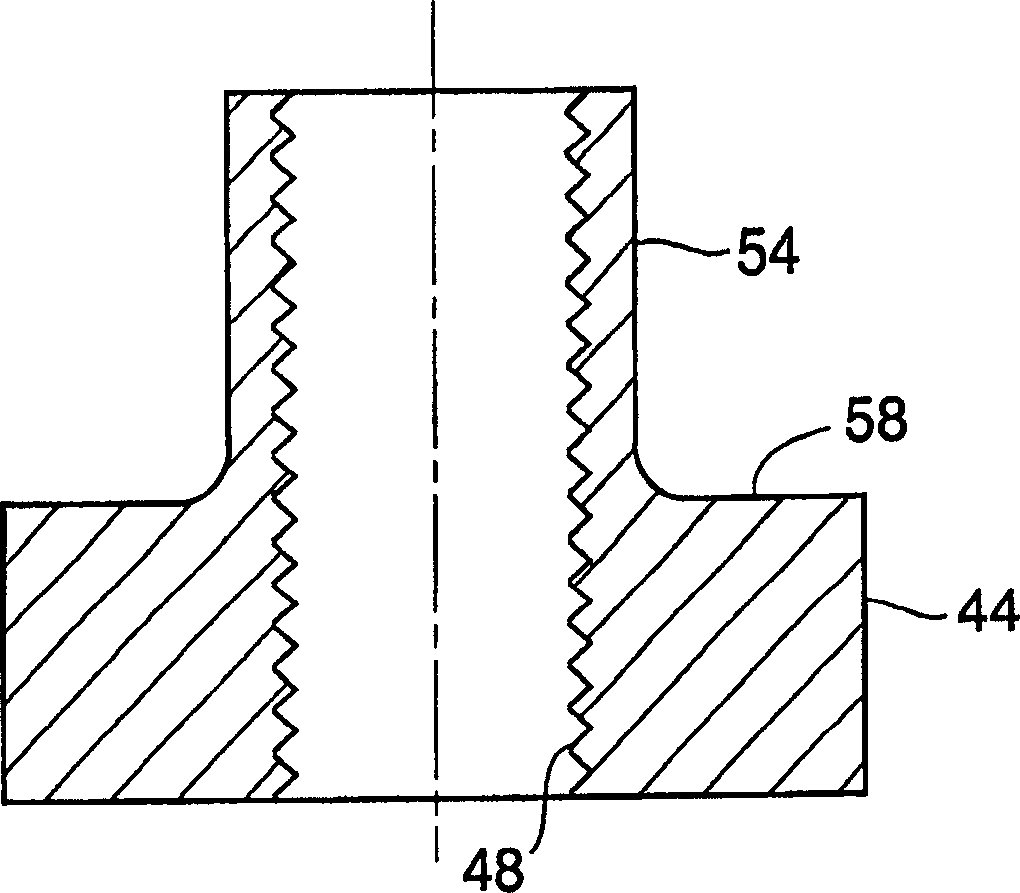

[0024] Such as Figure 3-6 As shown, a sleeved ultrasonic transducer 40 according to the present invention has a two-piece end piece 42 comprising an internally threaded sleeve 44 of one material and a counterbore housing of the other. 46. Preferably, the threaded sleeve 44 is composed of a material such as titanium or other metal that has sufficient strength for the threads. Additionally, preferably, the housing is comprised of materials such as aluminum, other metals, or ceramics or other non-metallic materials that provide favorable thermal and / or acoustic properties, including thermal conduction, thermal expansion,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com