Method for determining gear pump tooth profile molded line and crescent gear pump

A determination method, gear pump technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of pressure pulsation, loud noise, etc., and achieve the effect of avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

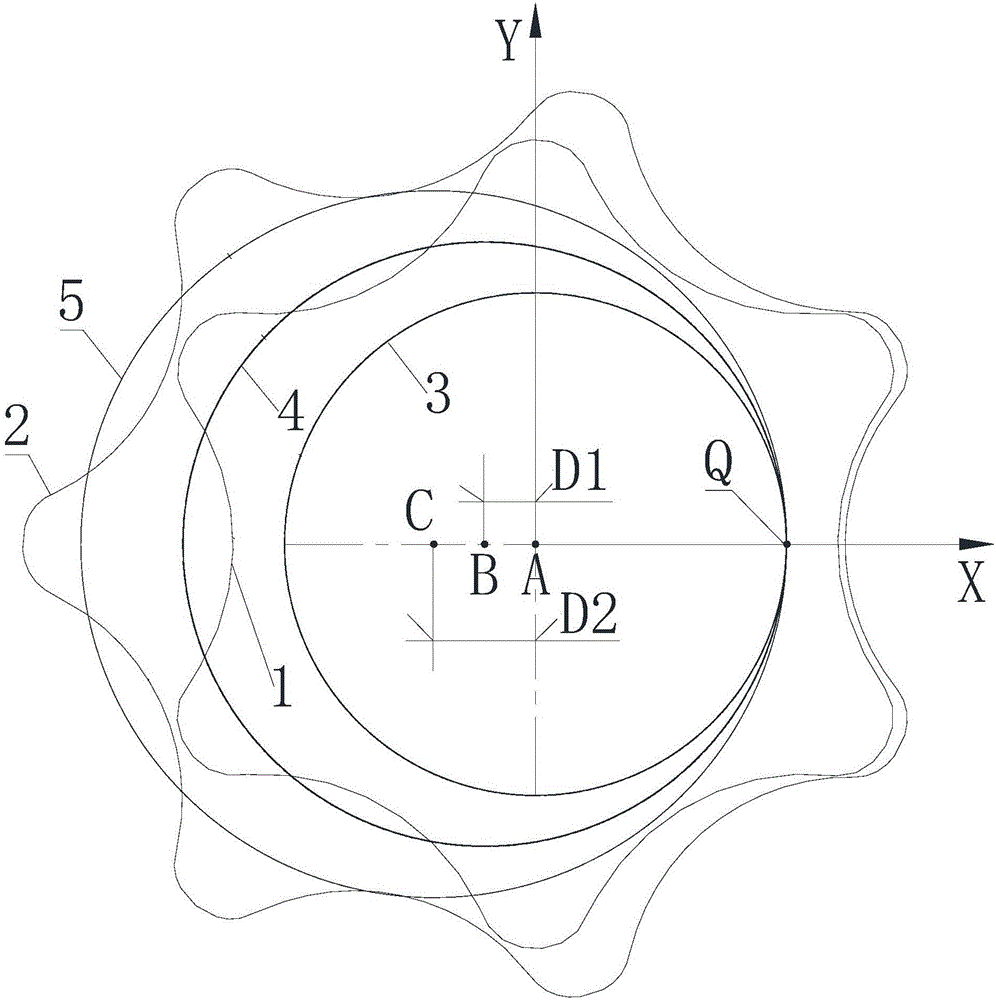

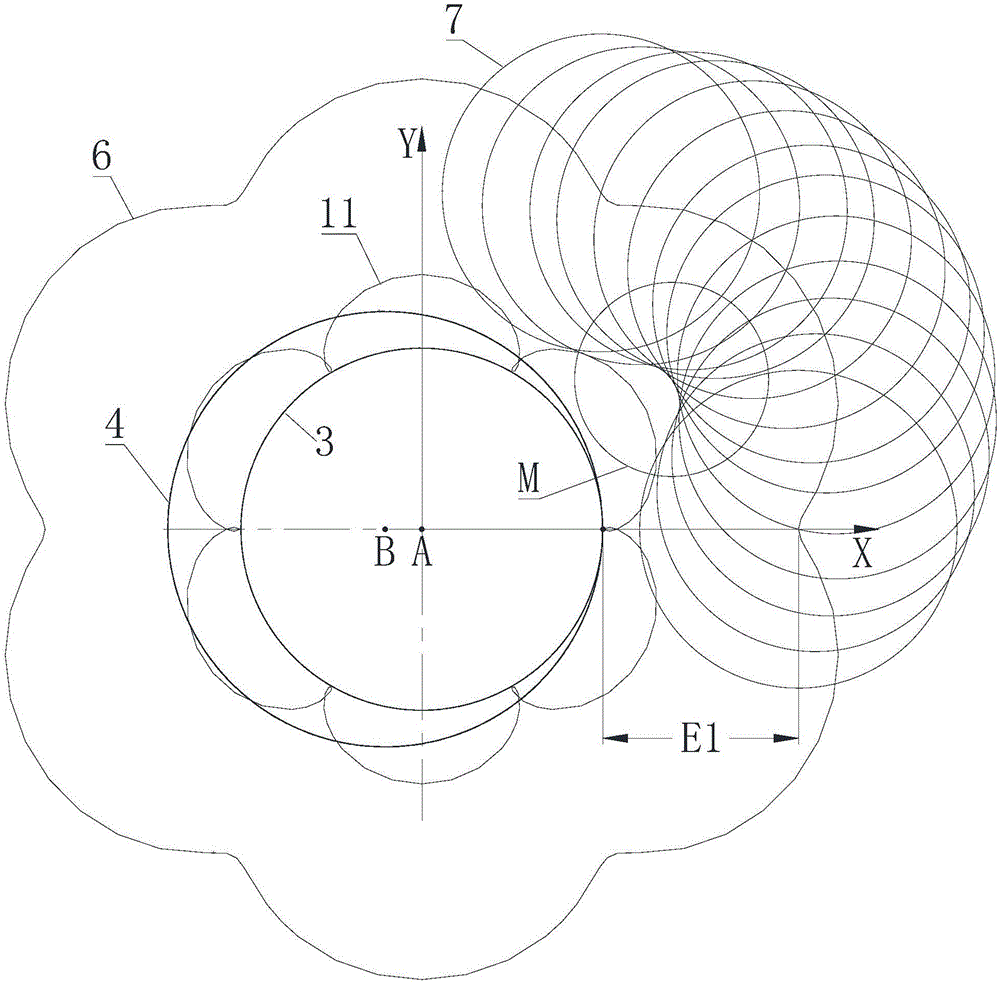

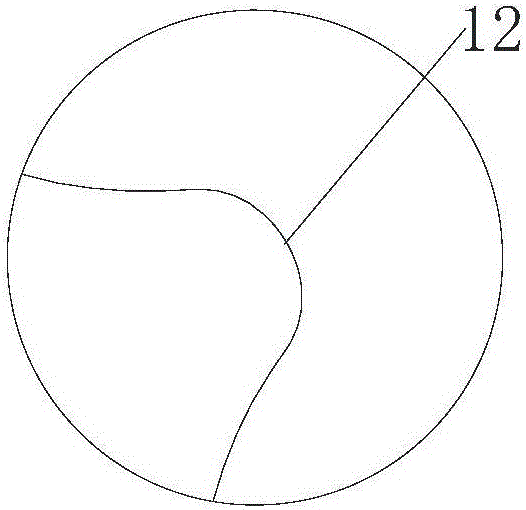

[0024] Please refer to Figure 1 to Figure 4 , the present invention provides a method for determining the tooth profile of a gear pump, which is especially suitable for determining the profile of the inner and outer tooth profiles of a cycloidal internal meshing gear pump. Using this method, the shape of the inner or outer tooth profile, The size and the adjustment of the tooth surface clearance, so as to improve the pressure pulsation and noise.

[0025] When using the method in the present invention to determine the gear pump tooth profile line, at first provide at least three circles, that is, the first forming circle, the second forming circle and the tooth shape circle, and make the second forming circle and the first forming circle There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com