Machining method for epicycloid gear

A technology of cycloid bevel gear and processing method, which is applied to gear tooth manufacturing tools, components with teeth, metal processing equipment, etc. The effect of simplifying the structure, simplifying the structure of the machine tool, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

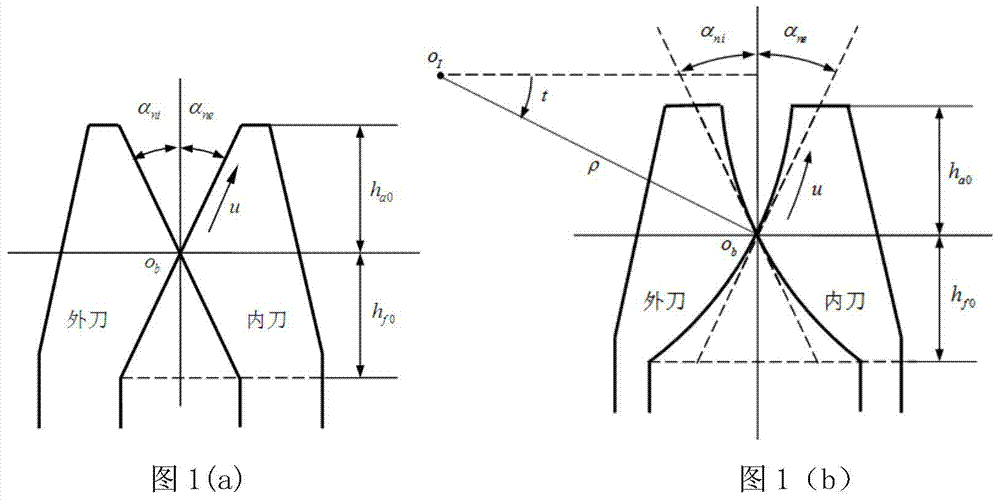

[0043] refer to Figure 4 ,in, Figure 4 (a) is a schematic diagram of the inner edge of a right-handed cutterhead, Figure 4 (b) is a schematic diagram of the outer edge of a right-handed cutterhead, assuming that the gear secondary shaft intersection angle Σ=90°, and the offset distance a v =25mm, number of gear teeth z 2 =39, the number of teeth of the small wheel z 1 =8, outer pitch circle diameter of big wheel d 02 =265mm, midpoint helix angle β m =34.63°, average pressure angle α n =21.5°, tooth width b 2 =40mm, cutterhead radius r c =106.5mm, number of cutter head z 0 =5, small wheel inner knife α ni =22°, small wheel outer knife α ne =20.5°, the big wheel cutter adopts a straight blade, and the pressure angle is opposite to that of the small wheel.

[0044] The specific implementation is as follows:

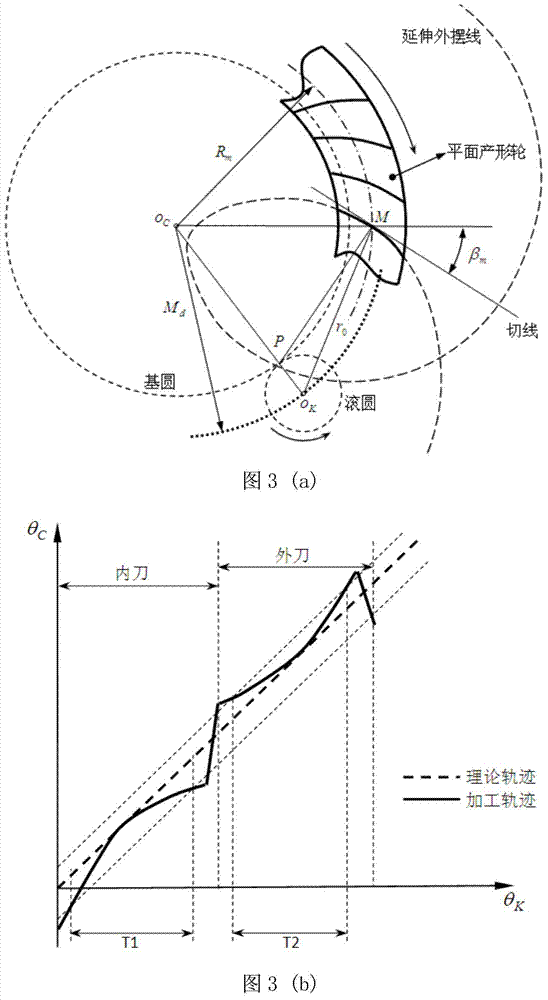

[0045] (1) Determine the basic parameters of the shape wheel

[0046]

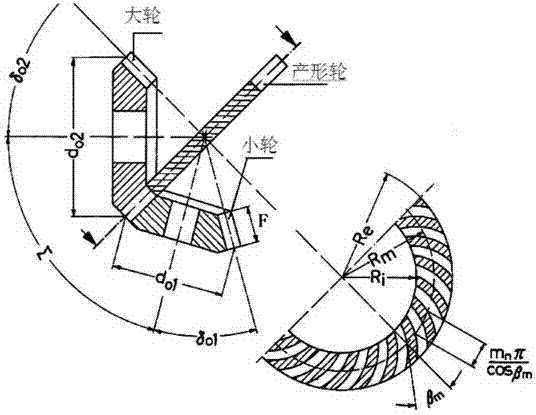

[0047] The midpoint radius Rm is equal to the midpoint taper distance of the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com