Cycloid steel ball planetary transmission mechanism and robot joint speed reduction device thereof

A technology of robot joints and planetary transmission, which is applied to transmission devices, transmission device parts, gear transmission devices, etc., can solve the problems of poor actual load capacity and small speed ratio of reducers, so as to improve service life, reduce contact stress, Ensure the effect of lubrication environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

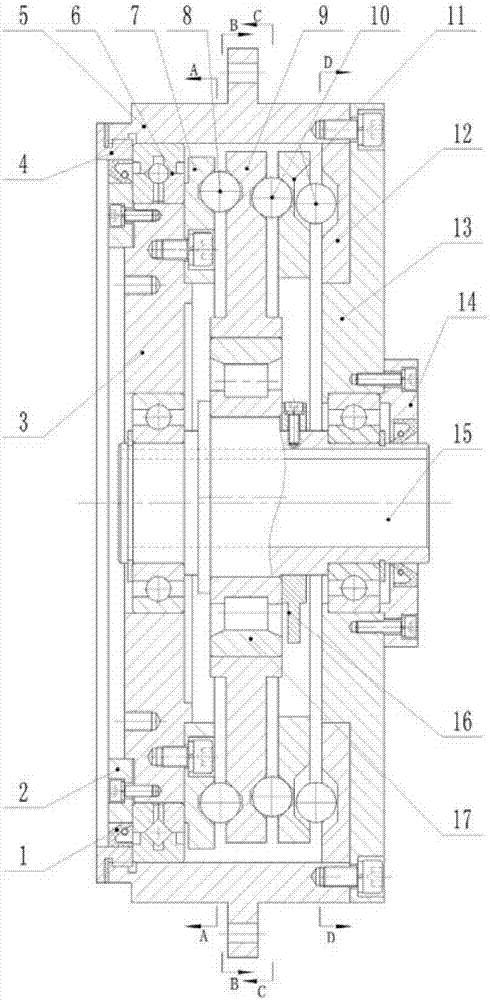

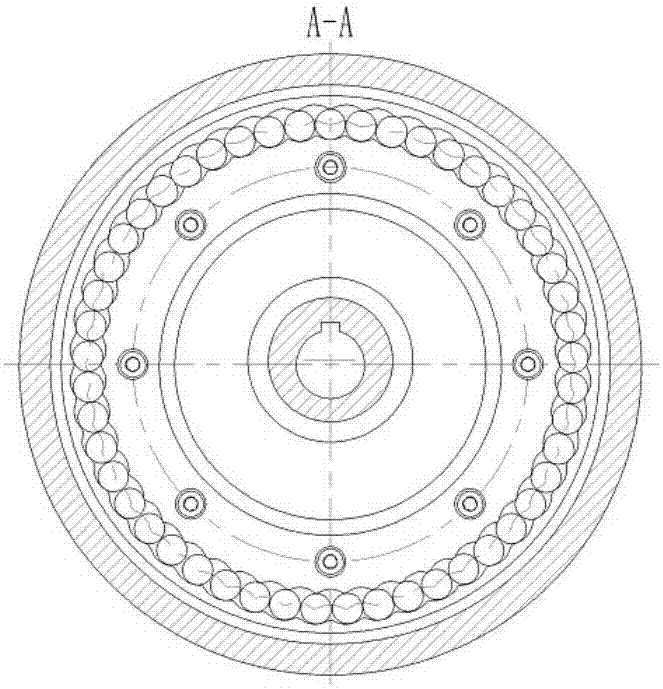

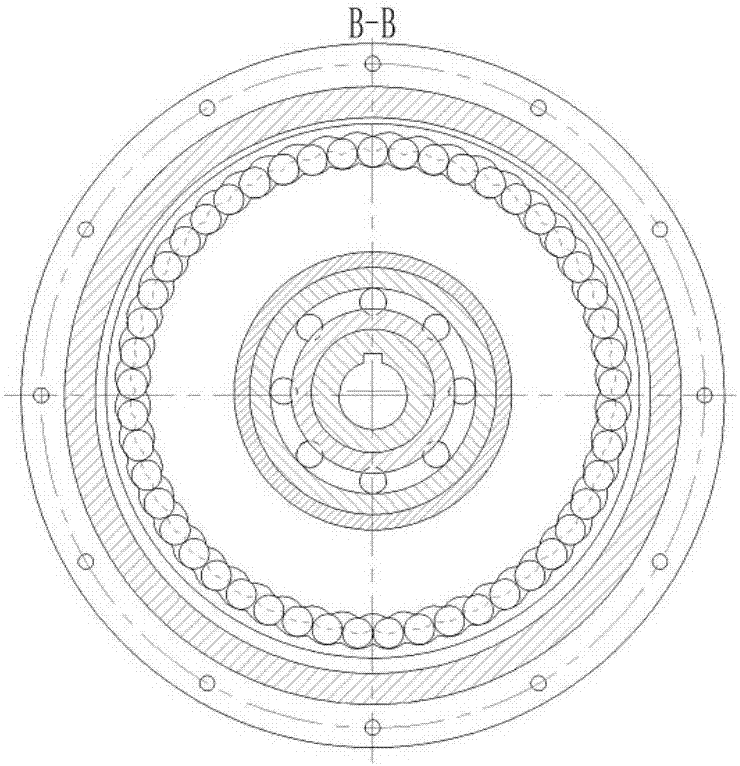

[0075] combine figure 1 , a robot joint reduction device in this embodiment includes a cross steel ball constant velocity transmission mechanism and a cycloidal steel ball planetary transmission mechanism. The cross steel ball constant velocity transmission mechanism is mainly composed of a planetary disc 9, a steel ball group 10, and a cross disc 11 , End cover plate 12 is formed, and cycloid steel ball planetary transmission mechanism is mainly made up of central plate 7, steel ball group 8, planetary plate 9.

[0076] As a specific embodiment, the reduction gear of this embodiment includes a sealing device 1, a baffle plate 2, a flange 3, a preload screw 4, a casing 5, a crossed roller bearing 6, a center disc 7, a steel ball group 8, a planetary disc 9. Steel ball group 10, swash plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com