Bending machine for steel bars for construction and bending method thereof

A bending machine and construction technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of hard to determine, easily damaged steel bars at the bend, and reduced toughness, so as to avoid post-cutting, Bending is convenient and fast, and the effect of preventing excessive extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

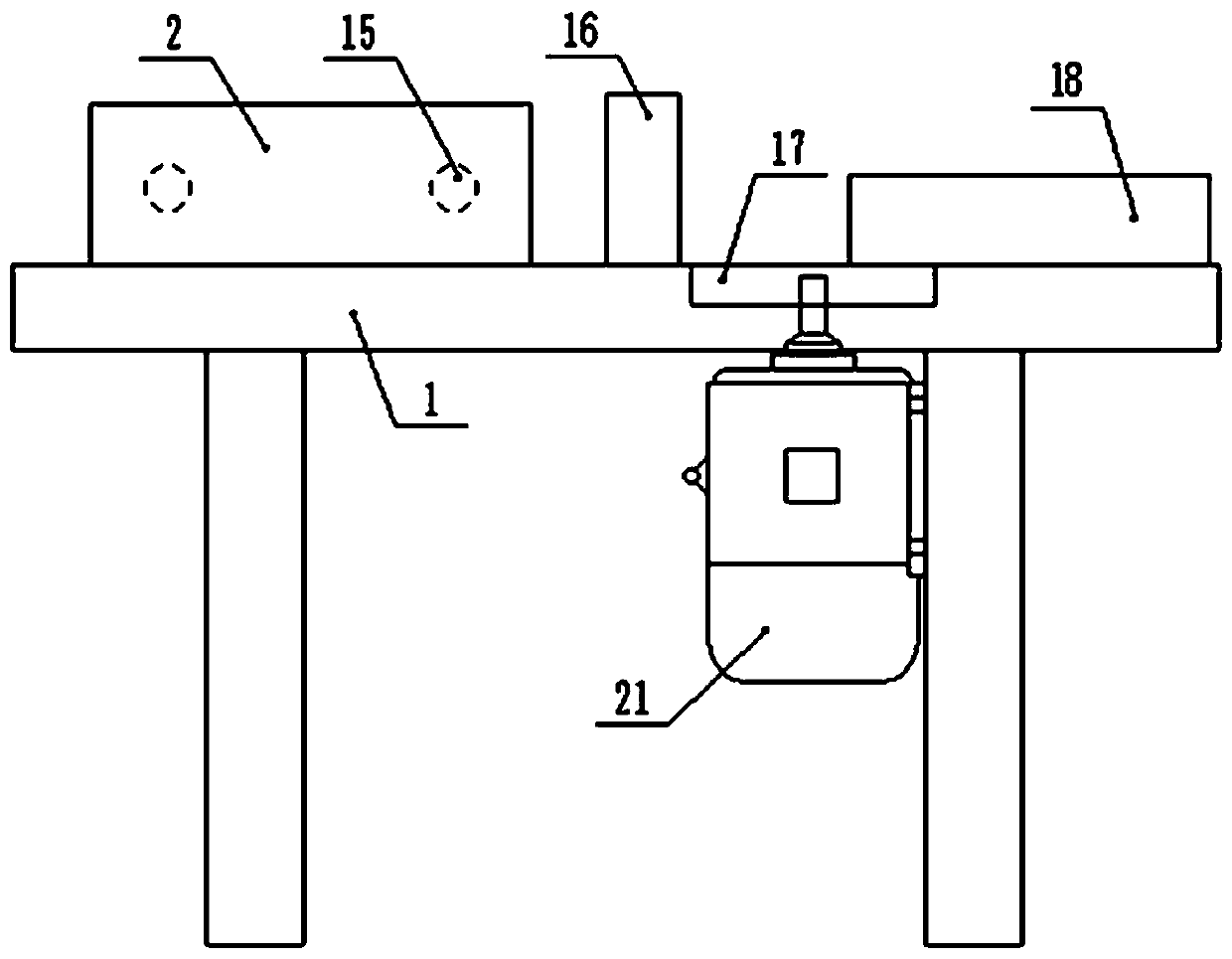

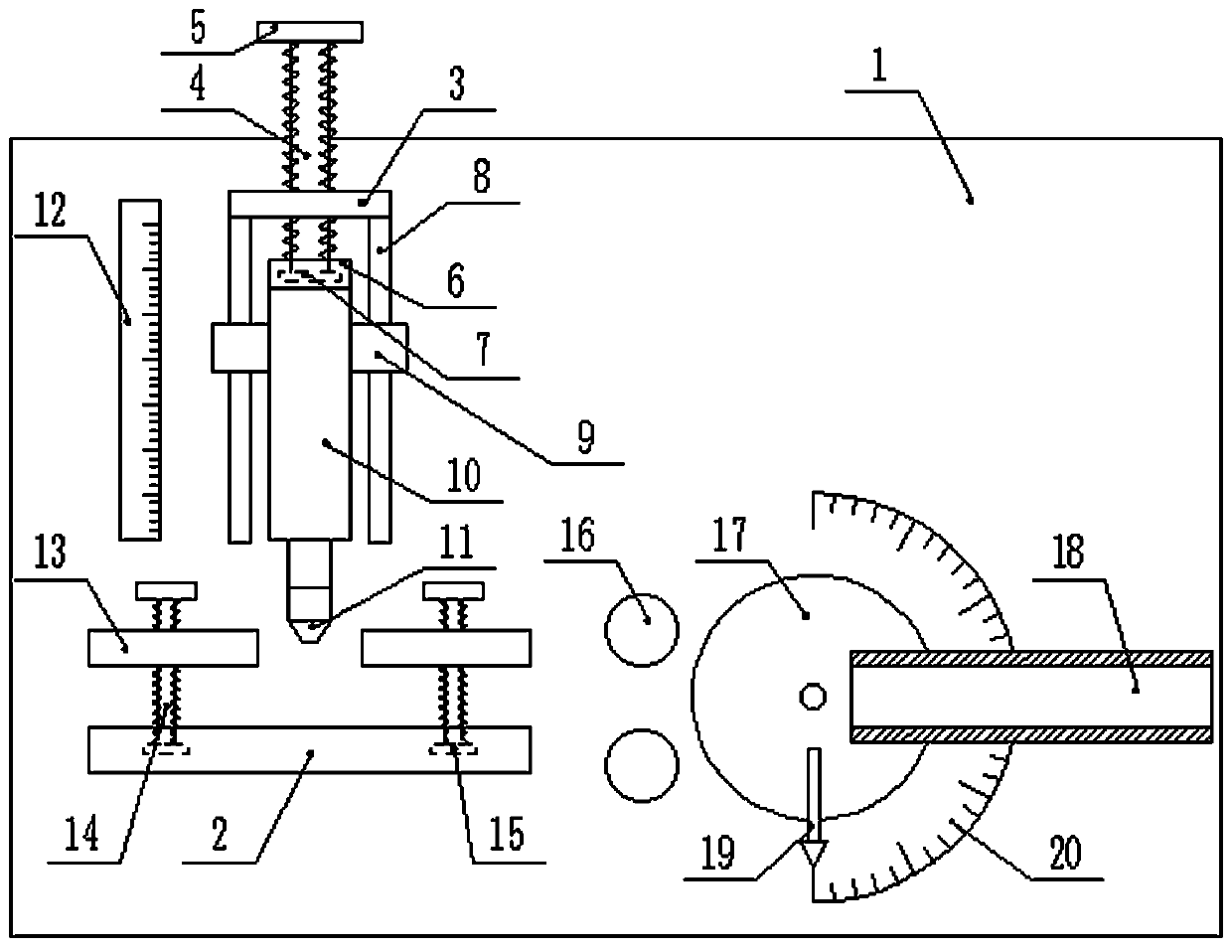

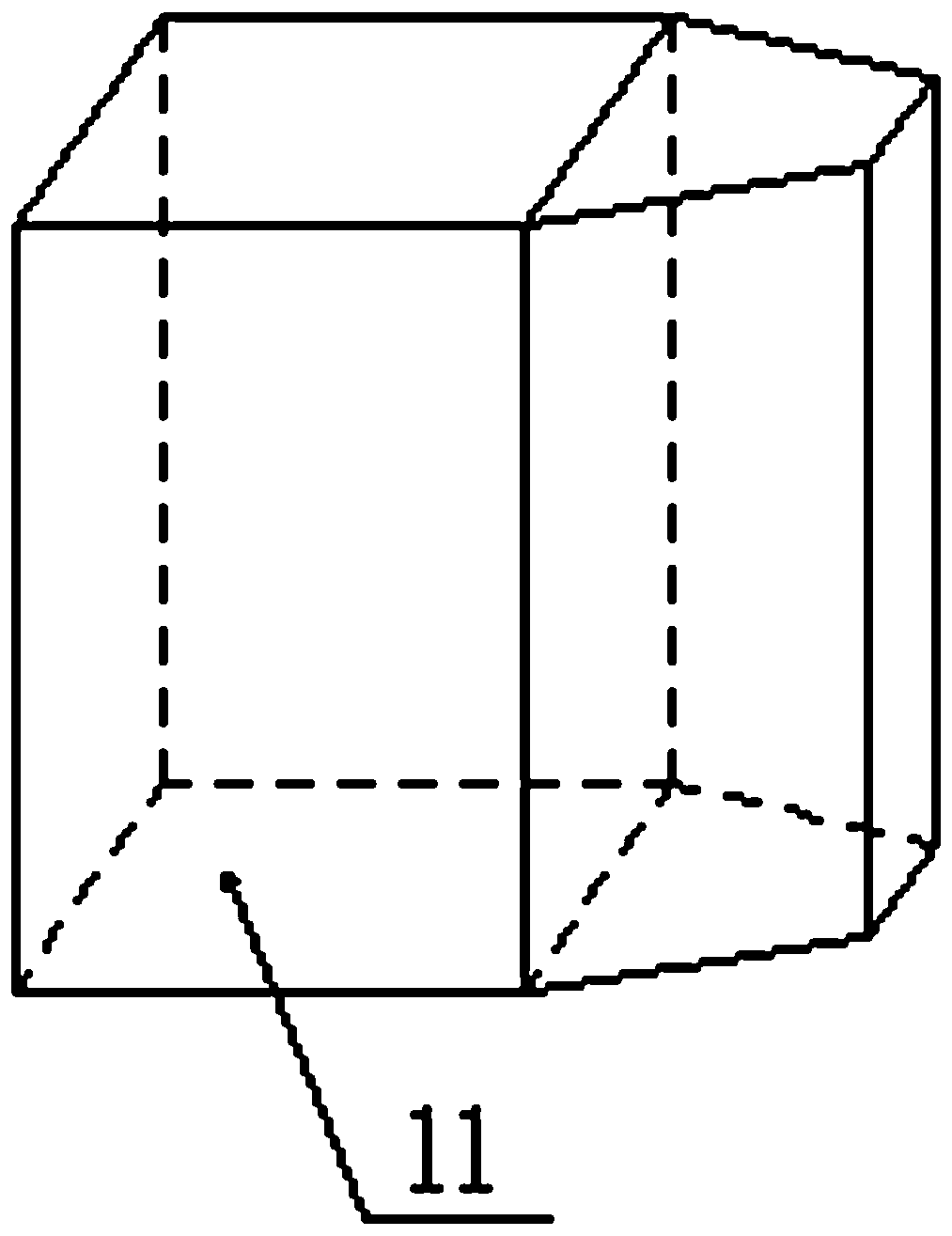

[0027] Such as figure 1 , figure 2 , image 3 The shown steel bar bending machine for construction includes an operation console 1, on which a baffle plate 2 and a fixed plate 3 are fixed, the positions of the baffle plate 2 and the fixed plate 3 are corresponding and parallel to each other, and the middle of the fixed plate 3 is threaded. There is a threaded rod A4, the two ends of the fixed plate 3 are vertically fixed with a fixed rod 8, one end of the threaded rod A4 is fixed with a handle 5, and the other end is fixed with a rotating disk A7, and the fixed rod 8 is covered with a sleeve 9 slidingly connected with it. 9 is fixed with a hydraulic rod 10, and a connecting block 6 is fixed on the hydraulic rod 10. The connecting block 6 is connected with a rotating disk A7 in rotation, and a trapezoidal block 11 is fixed on the top of the hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com