Strict sealing type double-tooth double-screw-rod vacuum pump rotor molded line

A rotor profile and sealing technology, applied in pumps, pump components, rotary piston pumps, etc., can solve the problems of single-tooth structure affecting the dynamic balance performance of the screw rotor, affecting the working performance of the vacuum pump, and the working chamber is not sealed, etc., to achieve Compact structure, low vibration and noise, avoid mismatching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

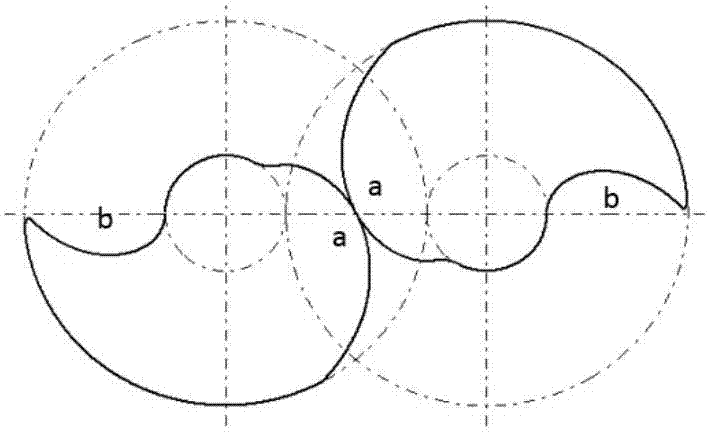

[0030] see figure 1 , the present invention adopts the original single-head twin-screw vacuum pump profile as the original shape and can be transformed. In the original profile, the a curve of the two circular arc connecting lines meshes with the a curve of the other rotor, and the b curve meshes with the b curve. The asymmetry between the curve and the b-curve results in an increased distance between the center of the area and the axis.

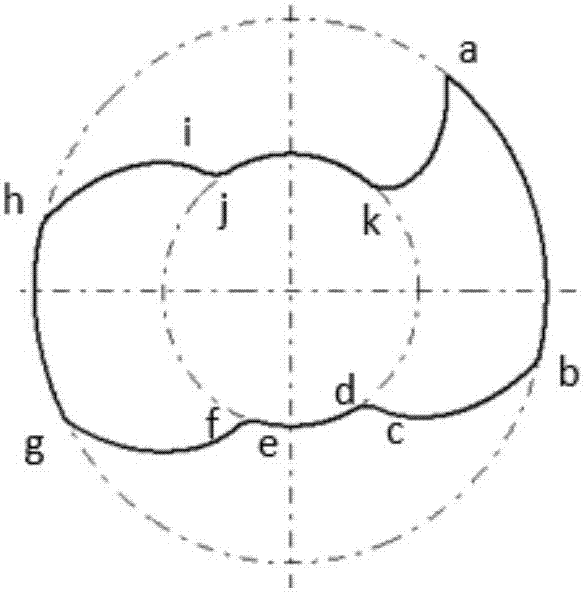

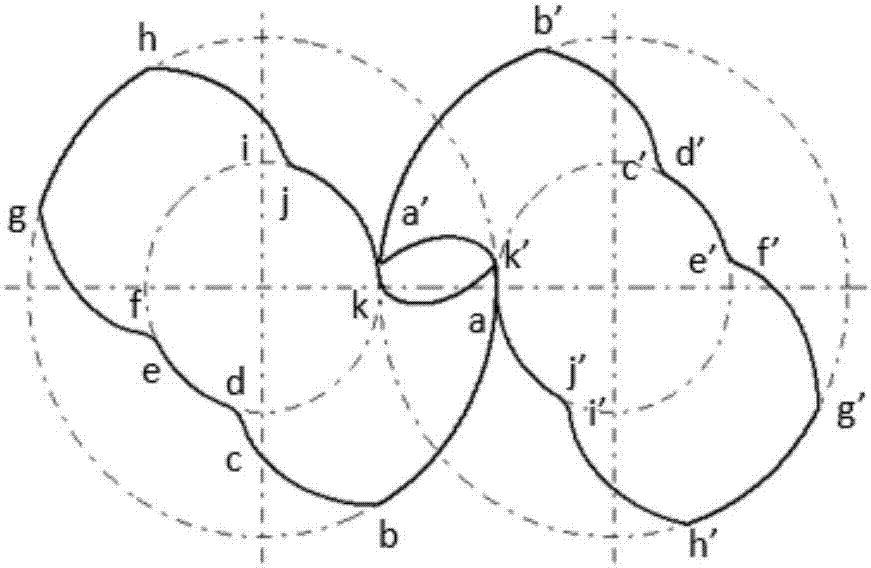

[0031] The present invention adopts a double-tooth structure, that is, one a-curve and three a-curves respectively connect the two ends of the addendum arc and the dedendum arc, which not only improves the asymmetry of the profile, but also ensures the sealing performance of the vacuum pump rotor during operation. .

[0032] see Figure 2-3 and Figure 4 (a)- Figure 4 (h), the profile line of the rotor of the twin-scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com