Transfer car of conjoined fermentation tank turning machine

A technology of flipping machine and fermentation tank, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of fixed wheel distance, high investment, difficult matching of ground rails, etc., so as to avoid mismatch and reduce investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

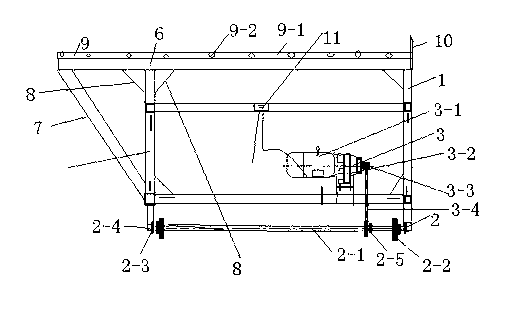

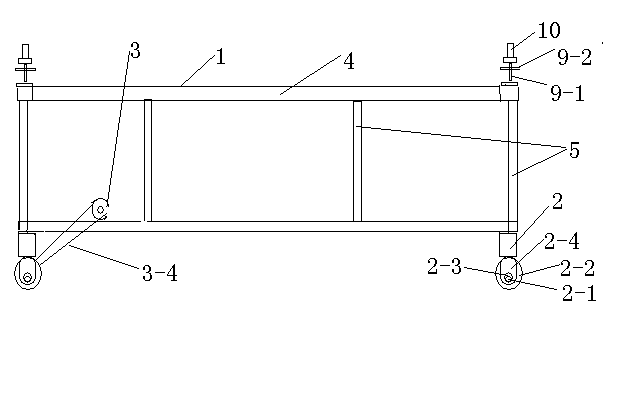

[0018] A conjoined fermentation tank turning and throwing machine transfer vehicle, including a vehicle frame 1, a wheel combination 2, and a driving device 3, characterized in that: the vehicle frame 1 is a steel structure, and is composed of a beam 4, a column 5, and a frame 6. 7. Reinforcing ribs 8 are formed; frame 1 top, left and right sides frame 6 is provided with a toothed track 9 matching the fermentation tank walking track, and the end of the toothed track 9 is provided with a gear lever 10; a power switch 11 is installed on the frame 1; The bottom of the frame 1 is equipped with a drive unit 3 and a wheel combination 2 matched with the ground track.

[0019] The wheel combination 2 is composed of an axle 2-1, a rail wheel 2-2, a bearing 2-3 and a bearing sleeve 2-4; the axle 2-1 is a round steel structure with a diameter of 55 mm, and the axle 2-1 is provided with a chain Wheel 2-5; the rail wheel 2-2 has a diameter of 200 mm.

[0020] Described driving device 3 is...

Embodiment 2

[0024] A conjoined fermentation tank turning and throwing machine transfer vehicle, including a vehicle frame 1, a wheel combination 2, and a driving device 3, characterized in that: the vehicle frame 1 is a steel structure, and is composed of a beam 4, a column 5, and a frame 6. 7. Reinforcing ribs 8 are formed; frame 1 top, left and right sides frame 6 is provided with a toothed track 9 matching the fermentation tank walking track, and the end of the toothed track 9 is provided with a gear lever 10; a power switch 11 is installed on the frame 1; The bottom of the frame 1 is equipped with a drive unit 3 and a wheel combination 2 matched with the ground track.

[0025] The wheel combination 2 is composed of an axle 2-1, a rail wheel 2-2, a bearing 2-3 and a bearing sleeve 2-4; the axle 2-1 is a round steel structure with a diameter of 50 mm, and the axle 2-1 is provided with a chain Wheel 2-5; the rail wheel 2-2 has a diameter of 180 mm.

[0026] Described driving device 3 is...

Embodiment 3

[0030] A conjoined fermentation tank turning and throwing machine transfer vehicle, including a vehicle frame 1, a wheel combination 2, and a driving device 3, characterized in that: the vehicle frame 1 is a steel structure, and is composed of a beam 4, a column 5, and a frame 6. 7. Reinforcing ribs 8 are formed; frame 1 top, left and right sides frame 6 is provided with a toothed track 9 matching the fermentation tank walking track, and the end of the toothed track 9 is provided with a gear lever 10; a power switch 11 is installed on the frame 1; The bottom of the frame 1 is equipped with a drive unit 3 and a wheel combination 2 matched with the ground track.

[0031] The wheel assembly 2 is composed of an axle 2-1, a rail wheel 2-2, a bearing 2-3 and a bearing sleeve 2-4; the axle 2-1 is a round steel structure with a diameter of 60 mm, and the axle 2-1 is provided with a chain Wheel 2-5; the diameter of said rail wheel 2-2 is 220 mm.

[0032] Described driving device 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com