Patents

Literature

39results about How to "No surge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

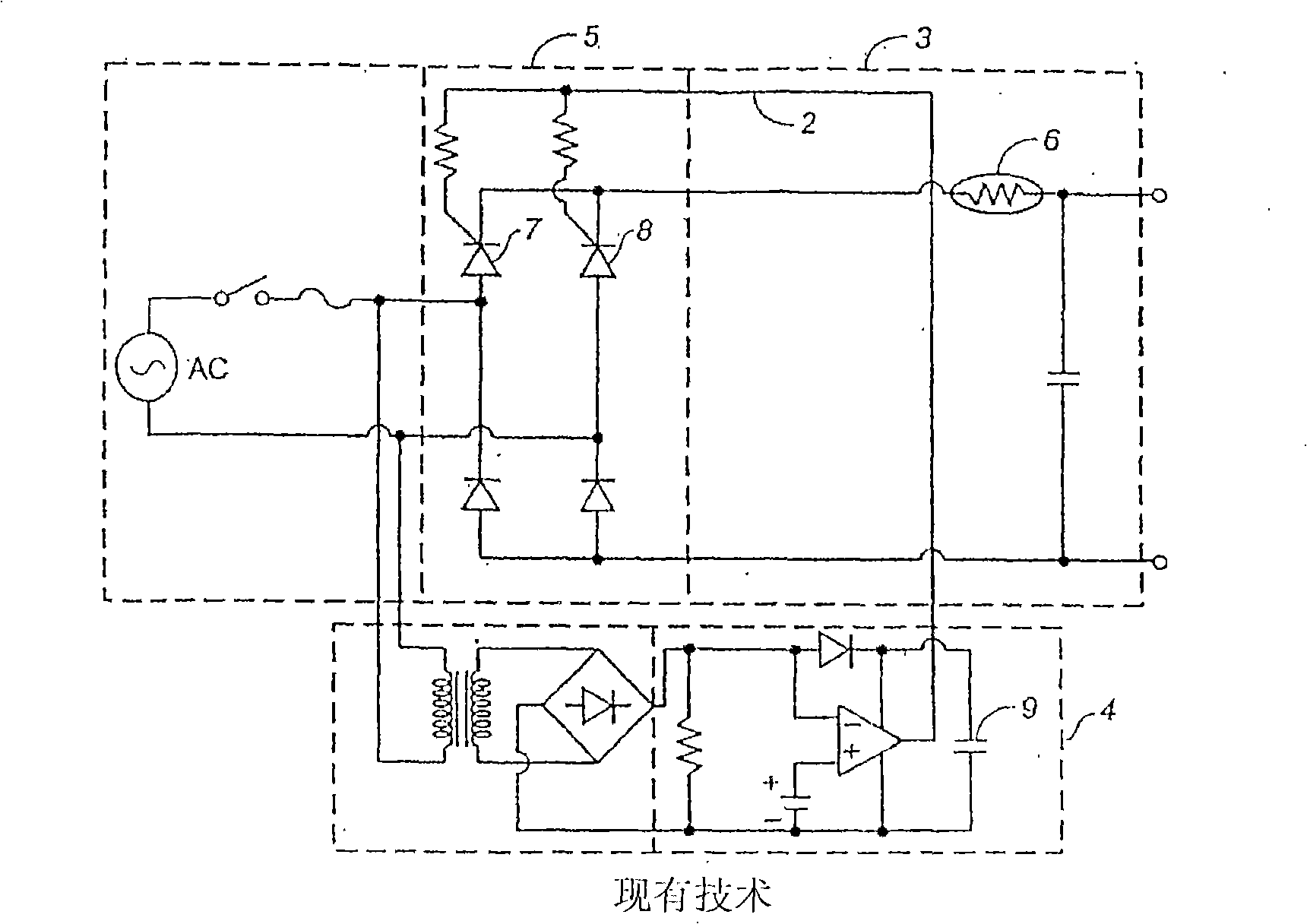

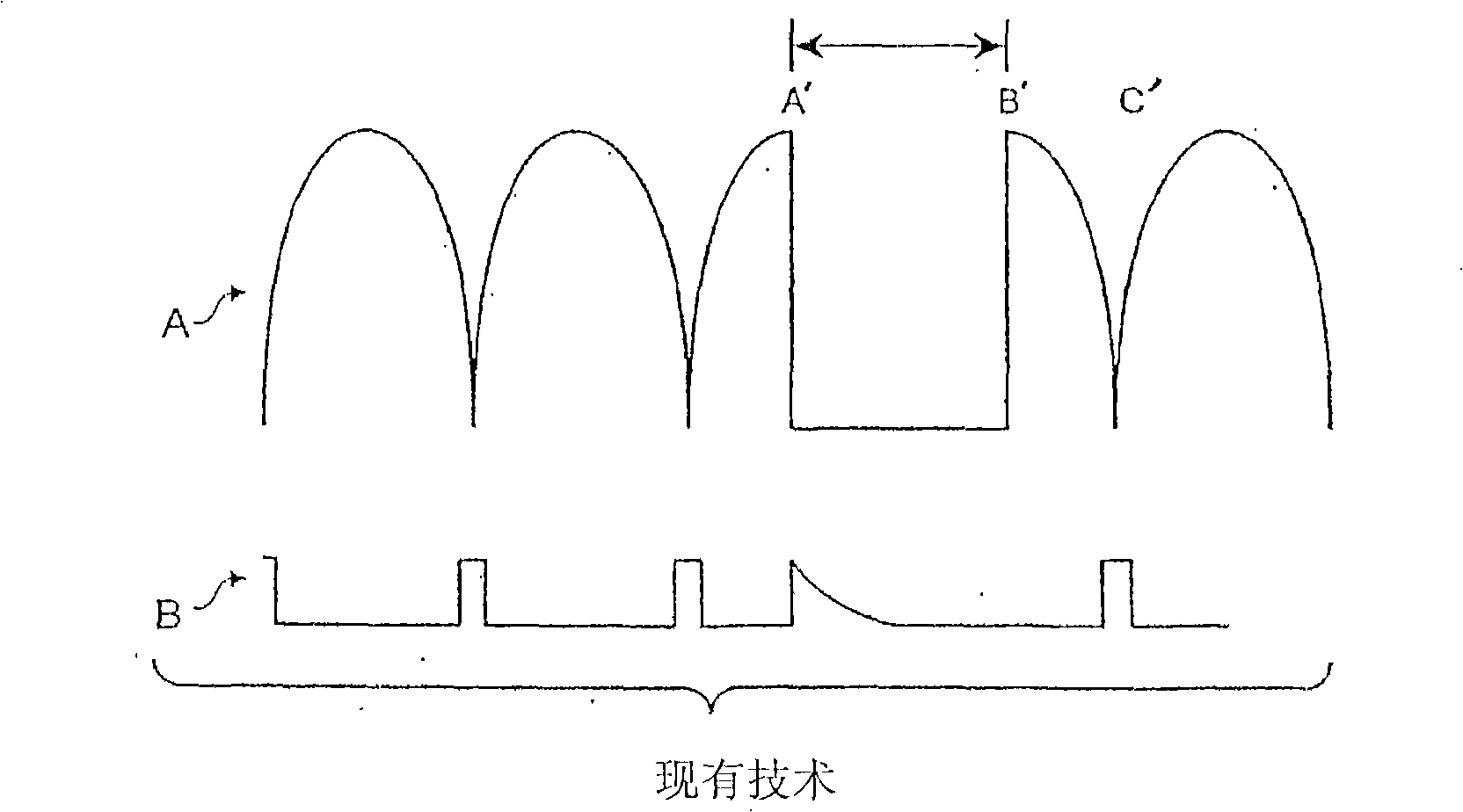

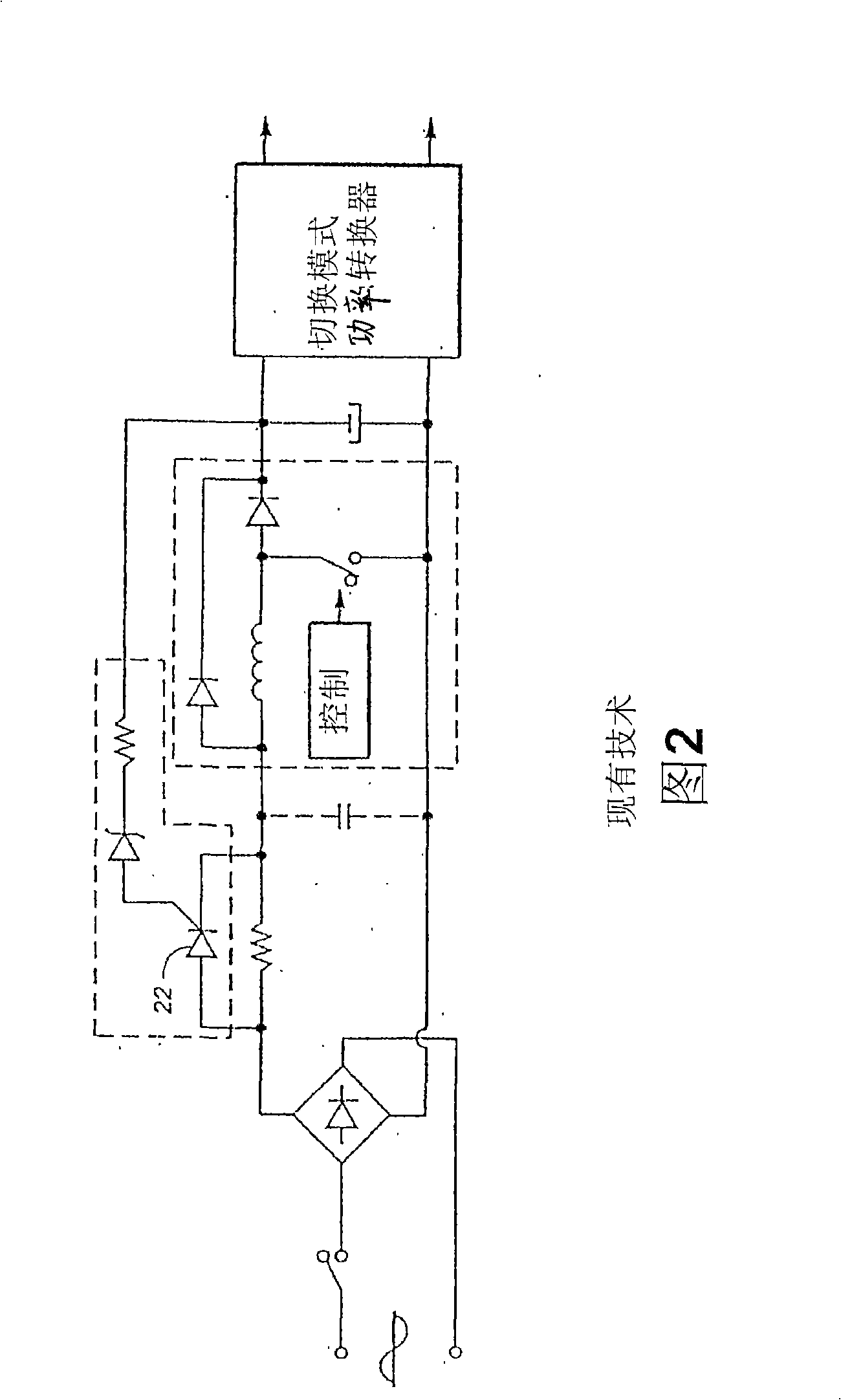

Active inrush current control using a relay for AC to DC converters

InactiveCN101268597ANo surgeControl surgeAc-dc conversionEmergency protective arrangements for limiting excess voltage/currentActive power factor correctionTransverter

A circuit and corresponding method for controlling inrush current in an AC-DC power converter by providing a relay and a control circuit for limiting inrush current efficiently during cold startup, warm startup, and power line disturbance conditions. The relay is preferably connected in series with a bulk capacitor of the converter and in parallel with a limiting resistor and switch for shunting the resistor and switch so as to improve efficiency during operating conditions, at reduced size and cost. A preferred embodiment includes use of the circuit for AC-DC converters having active power factor correction.

Owner:ASTEC INT LTD

Dynamic split-phase compensation method and device for reactive power

InactiveCN1404197ANo surgeFrequent switchingReactive power adjustment/elimination/compensationReactive power compensationPower qualityCapacitor voltage

The present invention is dynamic split phase compensation method and device of reactive power. Thyristor and diode in inverse parallel connection are used as the switch for compensation capacitor and controlled with industrial PC, and multistage capacitor combination is split phase thrown in and thrown off via tracking the reactive current and reactive power. The capacitors are thrown in while the capacitor voltage is equal to the system voltage and this eliminates the transient course for fast and accurate compensation. The present invention can also compensate unbalanced reactive power. The present invention is correct, practical and effective, and may be used in reactive compensation of power network to raise the power factor of load and electric energy quality.

Owner:WUHAN UNIV

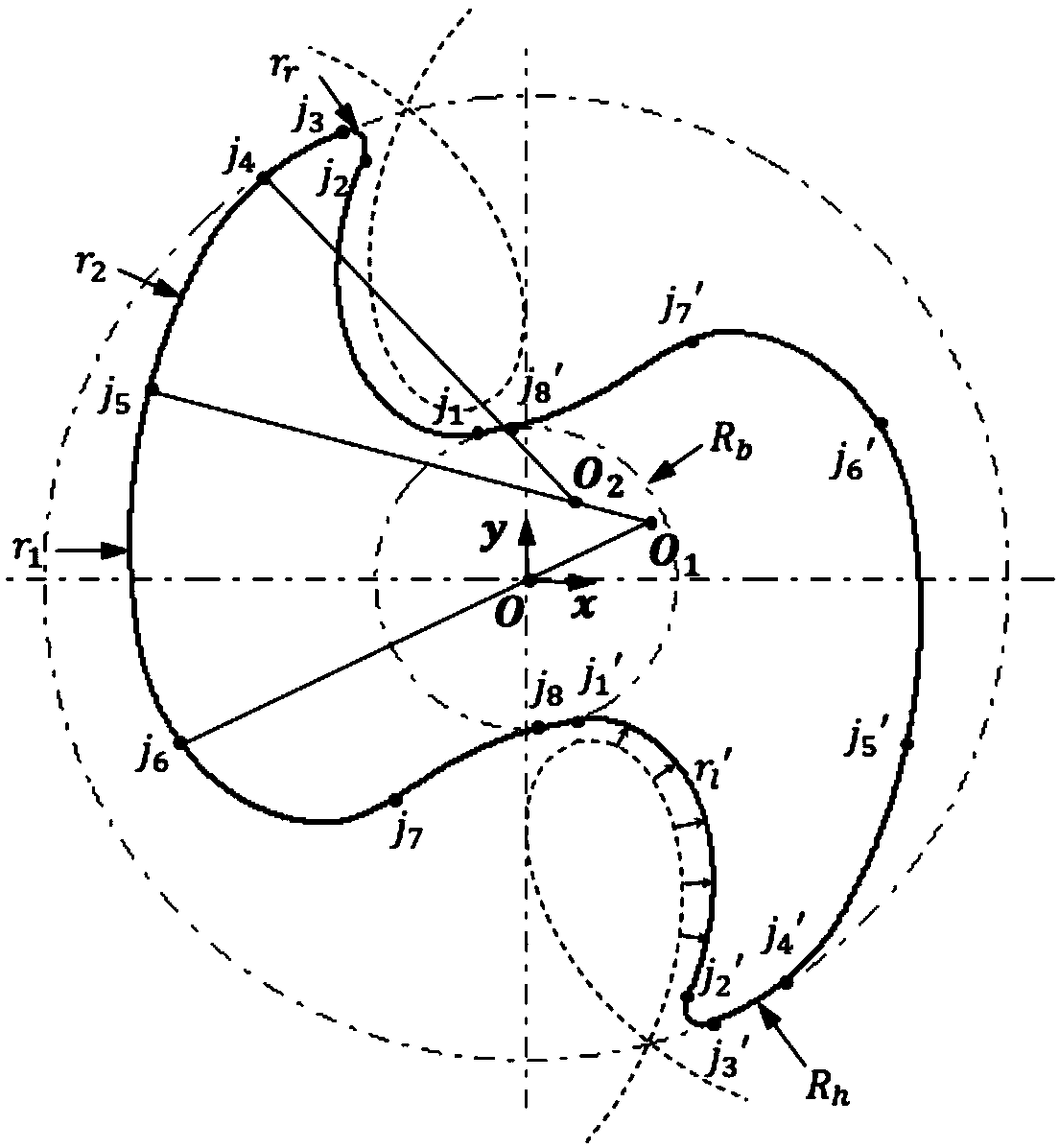

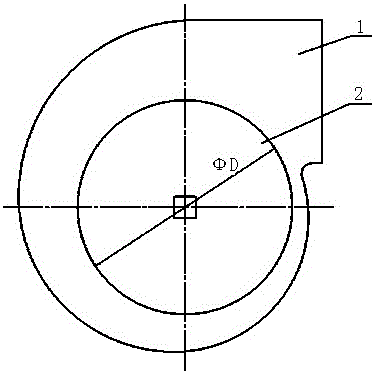

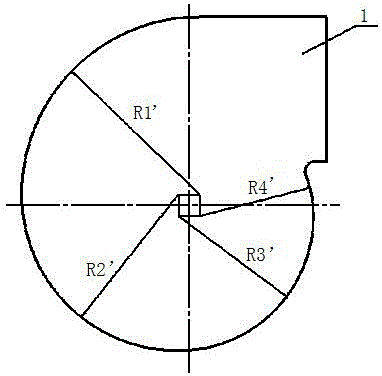

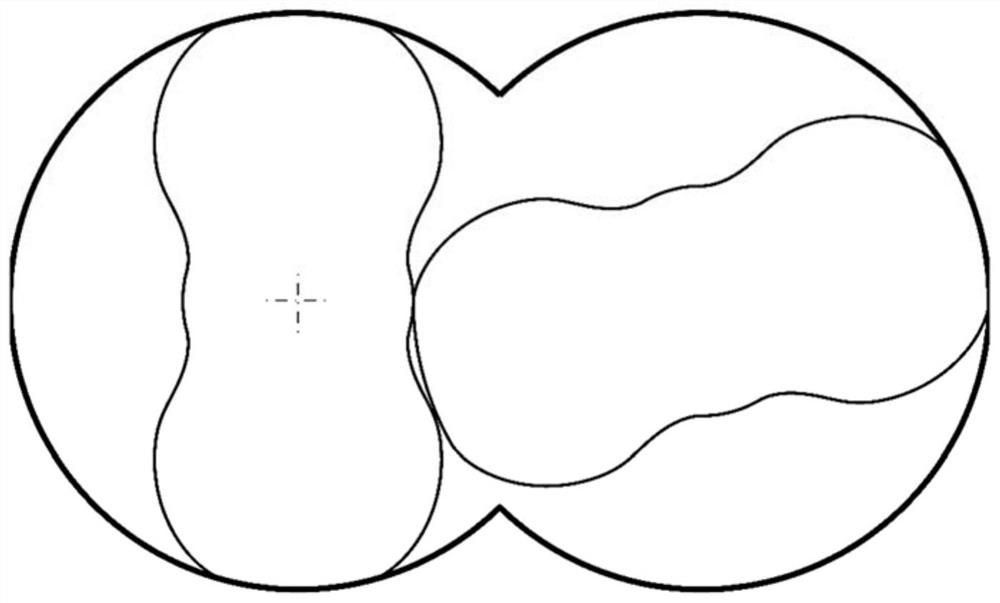

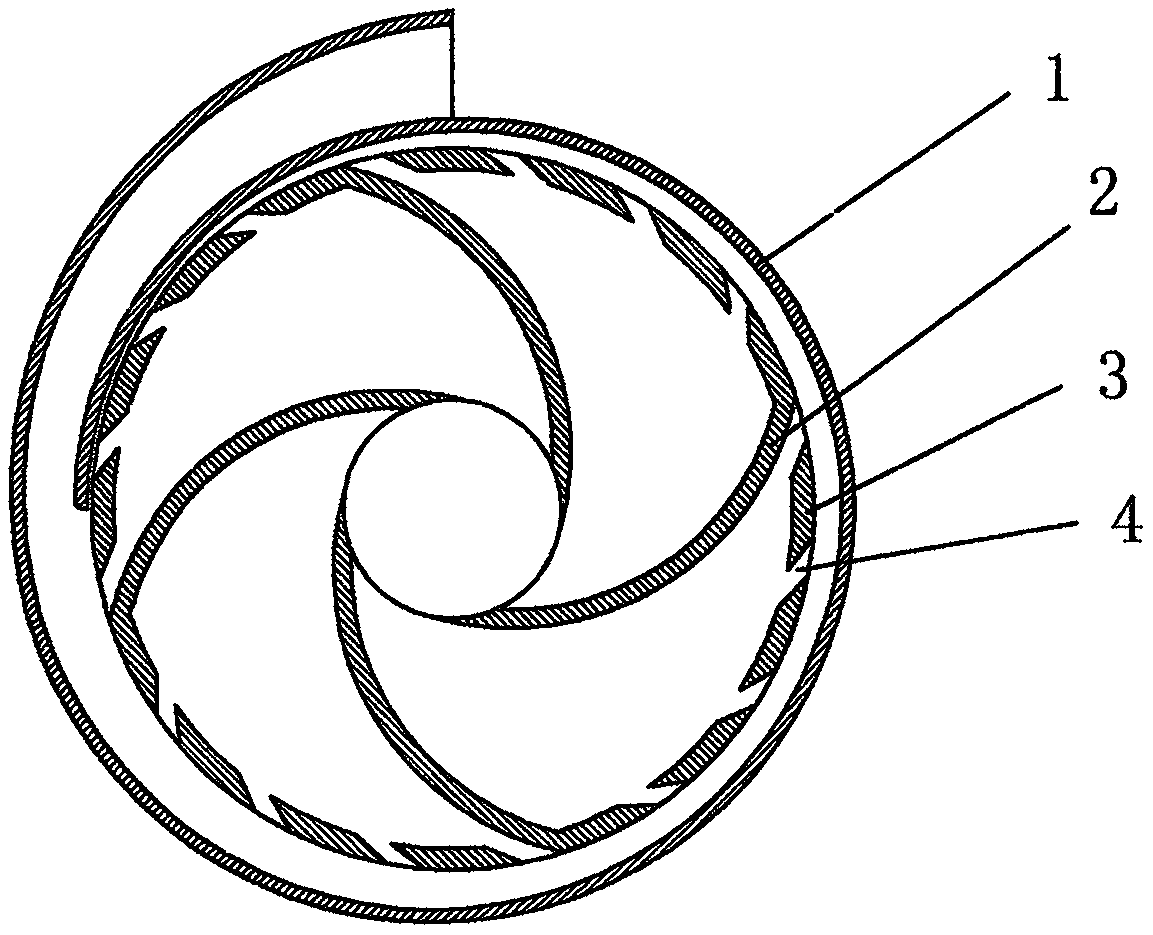

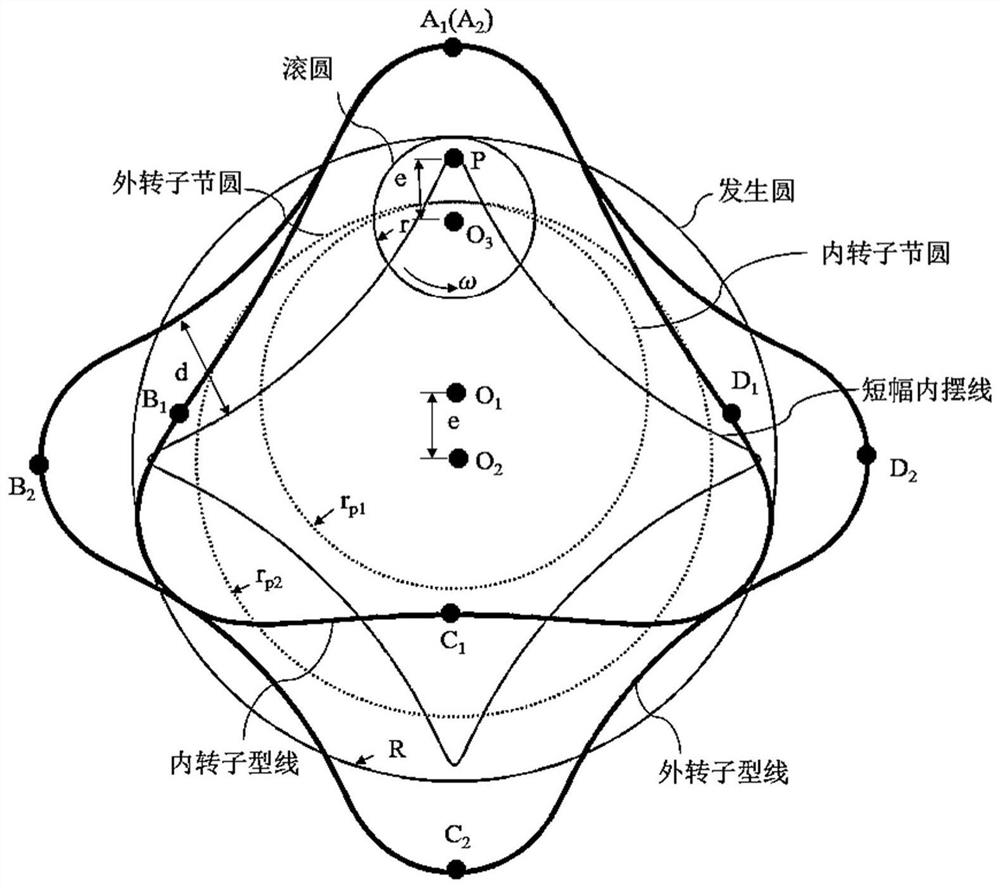

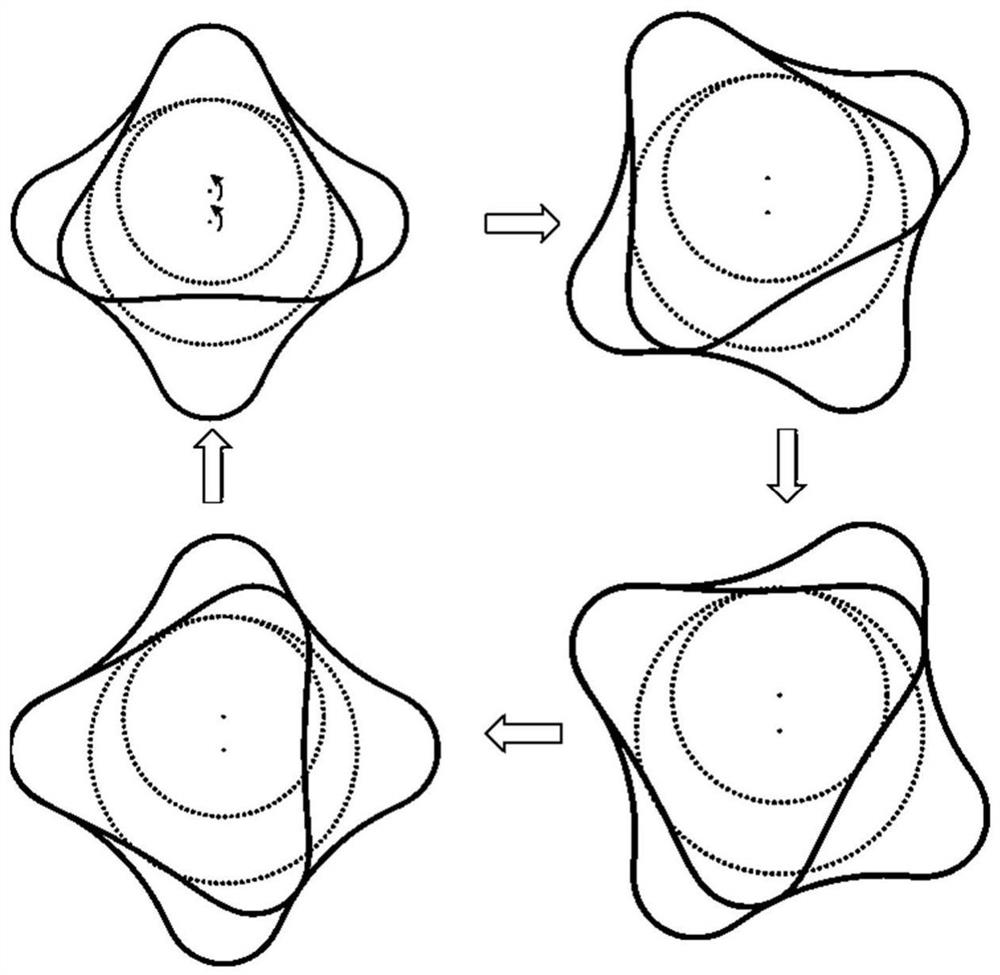

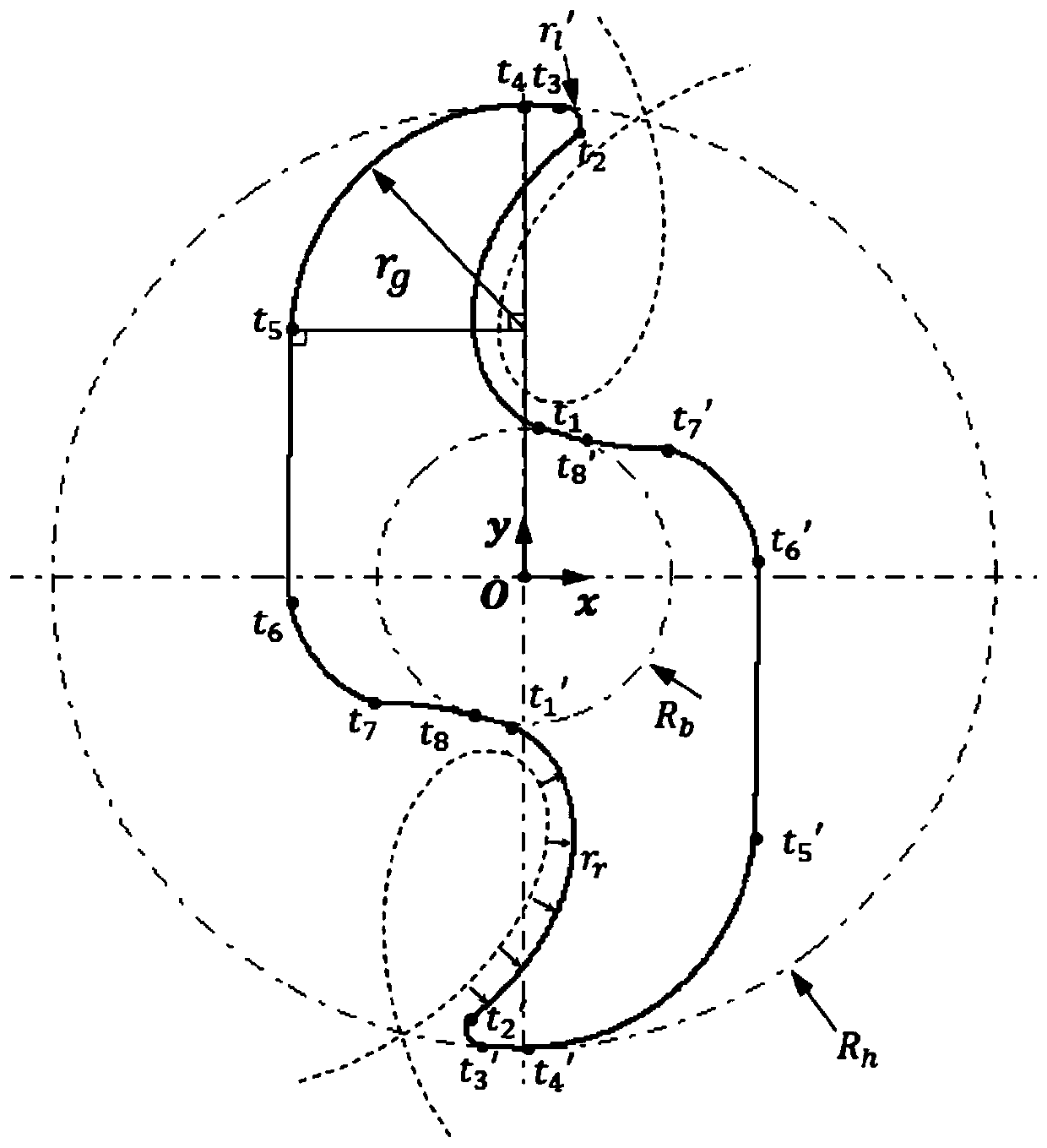

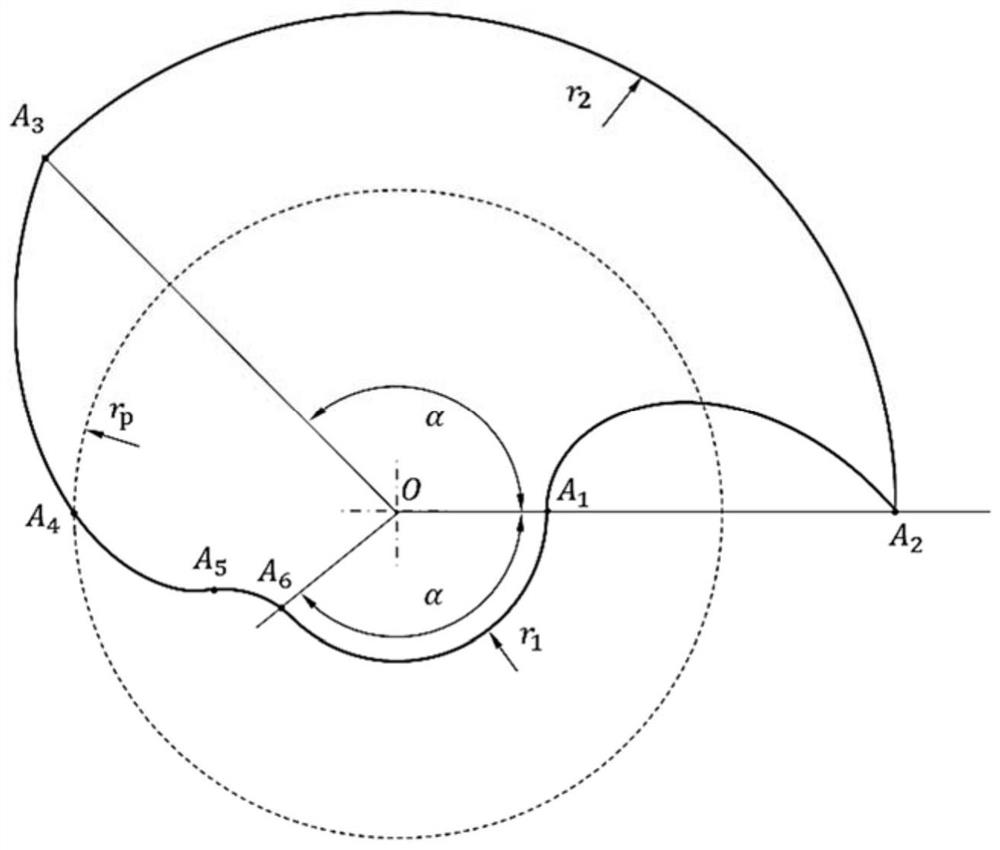

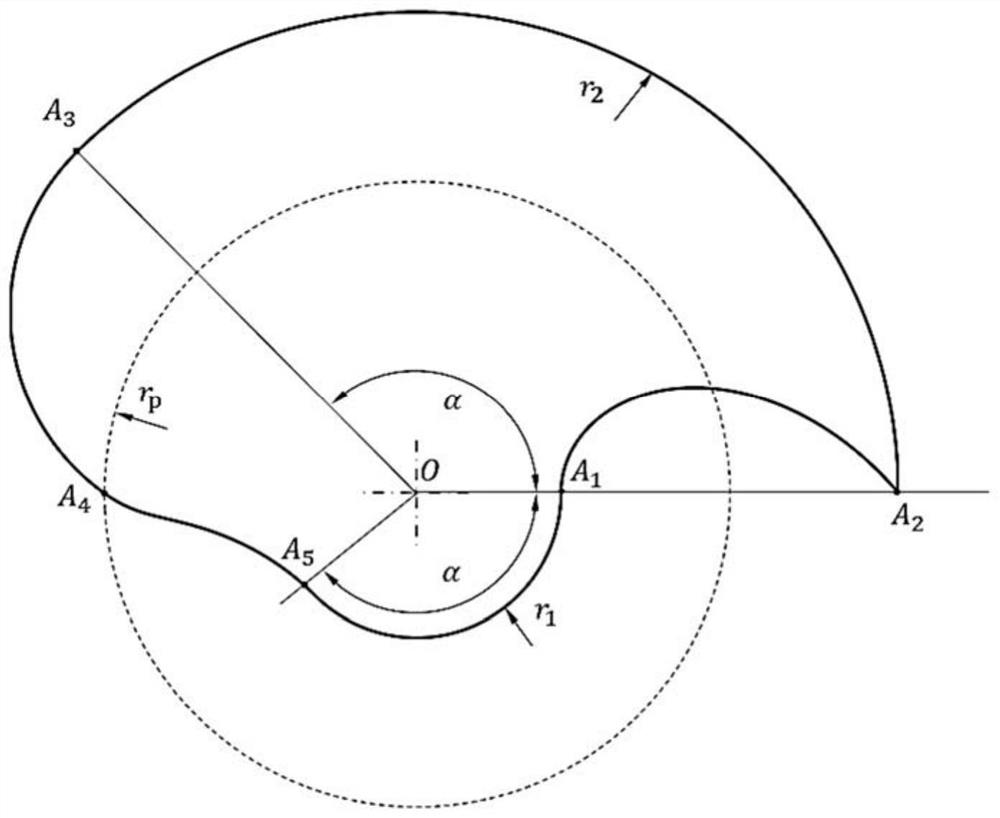

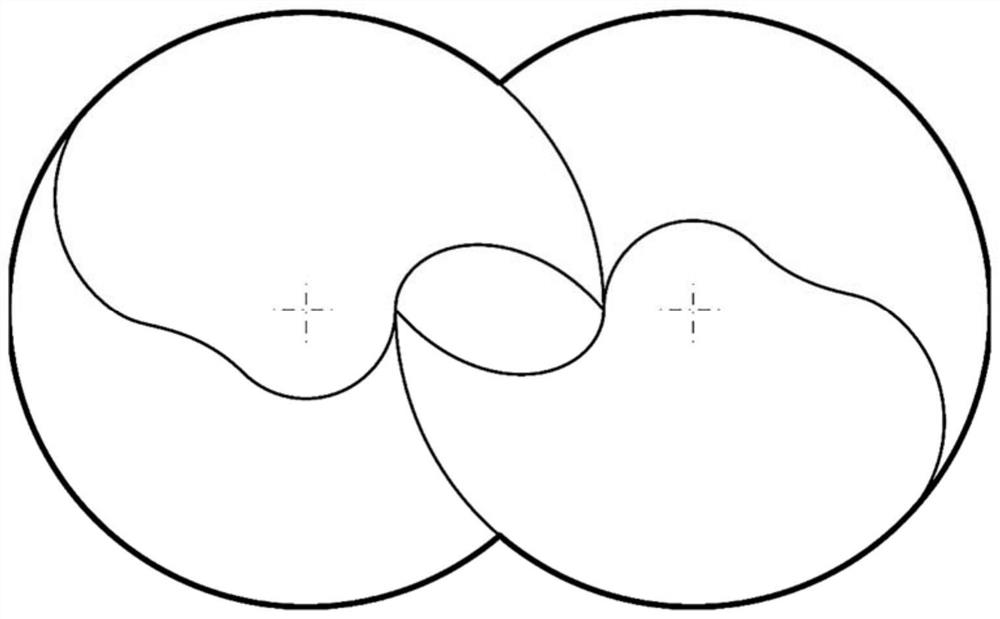

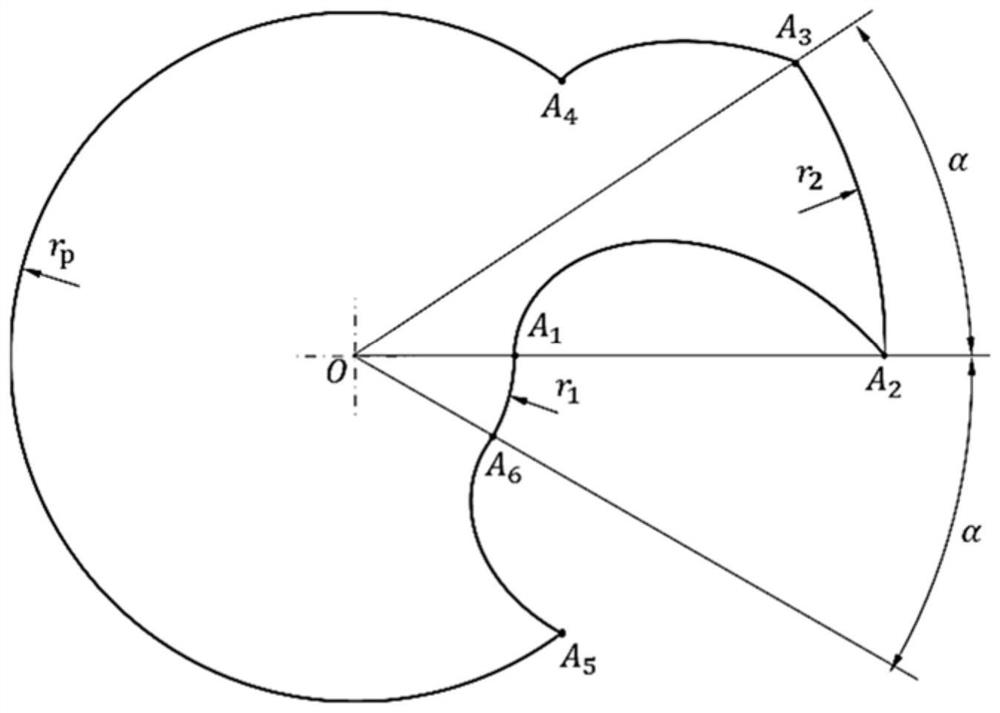

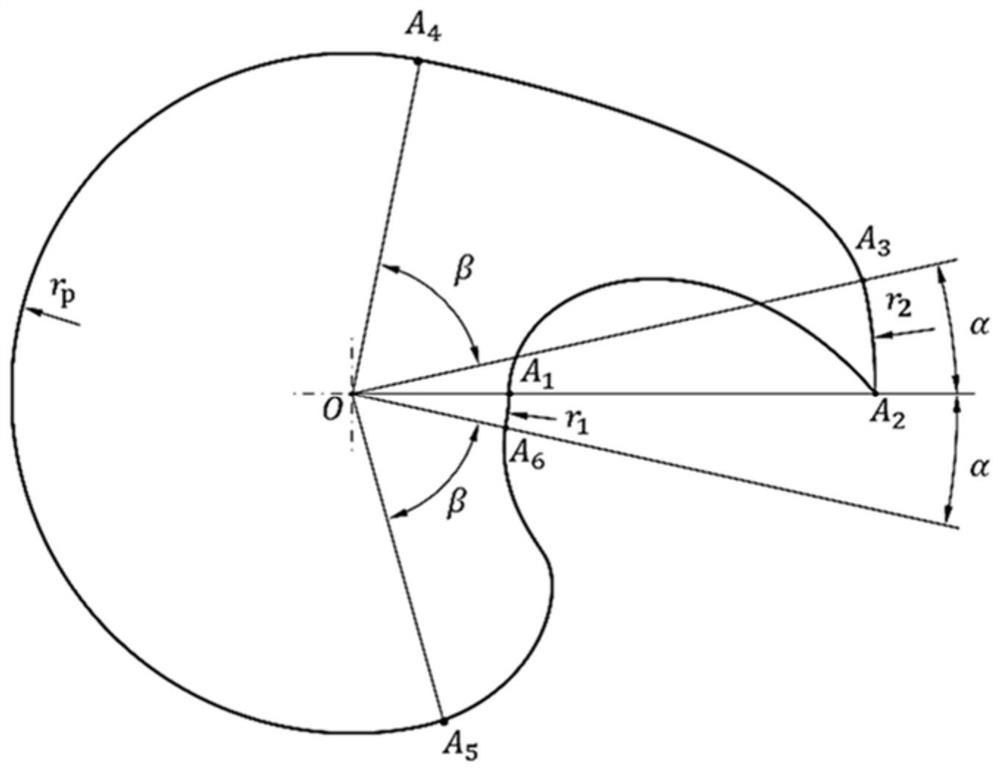

Double-head claw pump rotor and its molded line

ActiveCN108930650AAvoid severe wear and tearIncrease design parameter spaceRotary piston pumpsRotary piston liquid enginesEngineeringSharp point

The invention relates to a double-head claw pump rotor and its molded line. The molded line comprises an equidistance curve of a point meshing epicycloid, a modified arc segment, a tooth top arc segment, an intermediate connecting arc segment, an arc conjugate curve segment, and a tooth root arc segment. Two rotors adopt a central symmetrical structure. By setting the modified arc segment, the sharp points are eliminated, and severe wearing phenomenon of the rotors during operation can be avoided. The equidistance curve of the point meshing epicycloid and the modified arc segment are always spaced apart to avoid the formation of suction and exhaust closed volume, and a design parameter space of the rotor molded line is increased, the power consumption is reduced, and the pump efficiency isimproved. The molded line is designed in the double-head claw pump, compared with the other conventional pumps, the pump in the invention has the advantages of less wearing parts, compact structure,high pumping rate, no surge, and low vibration noise.

Owner:宝风压缩机科技(浙江)有限公司

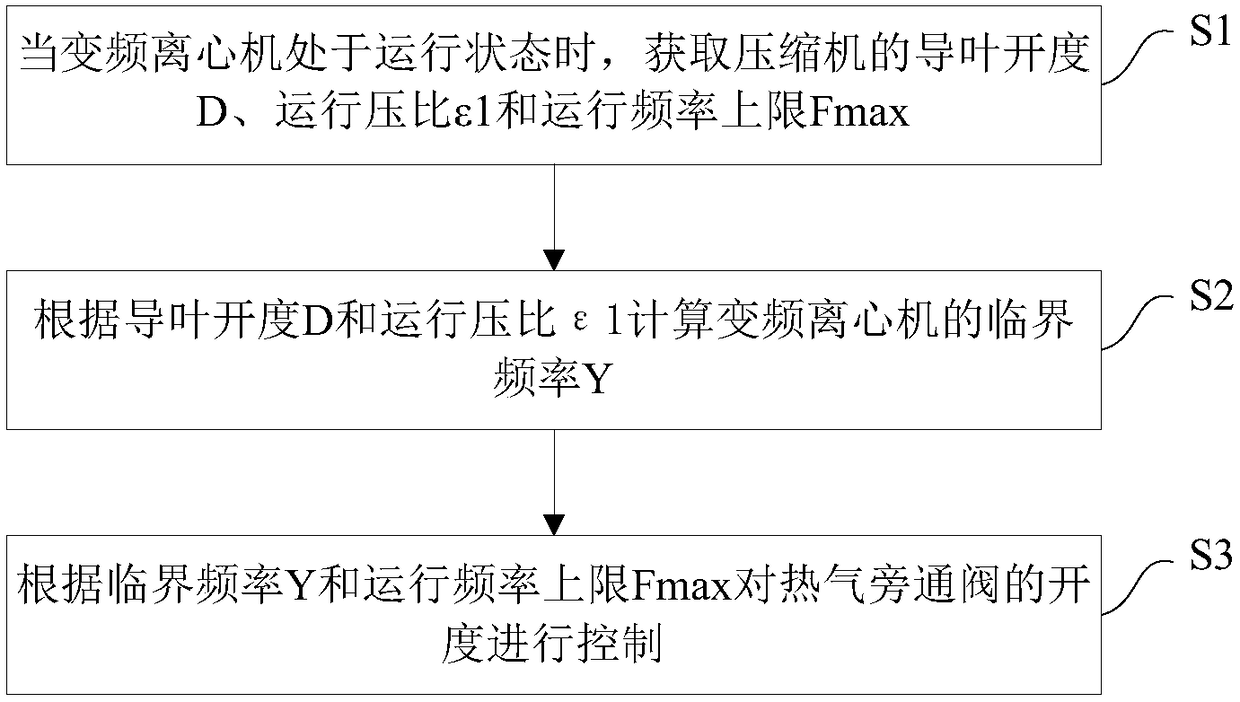

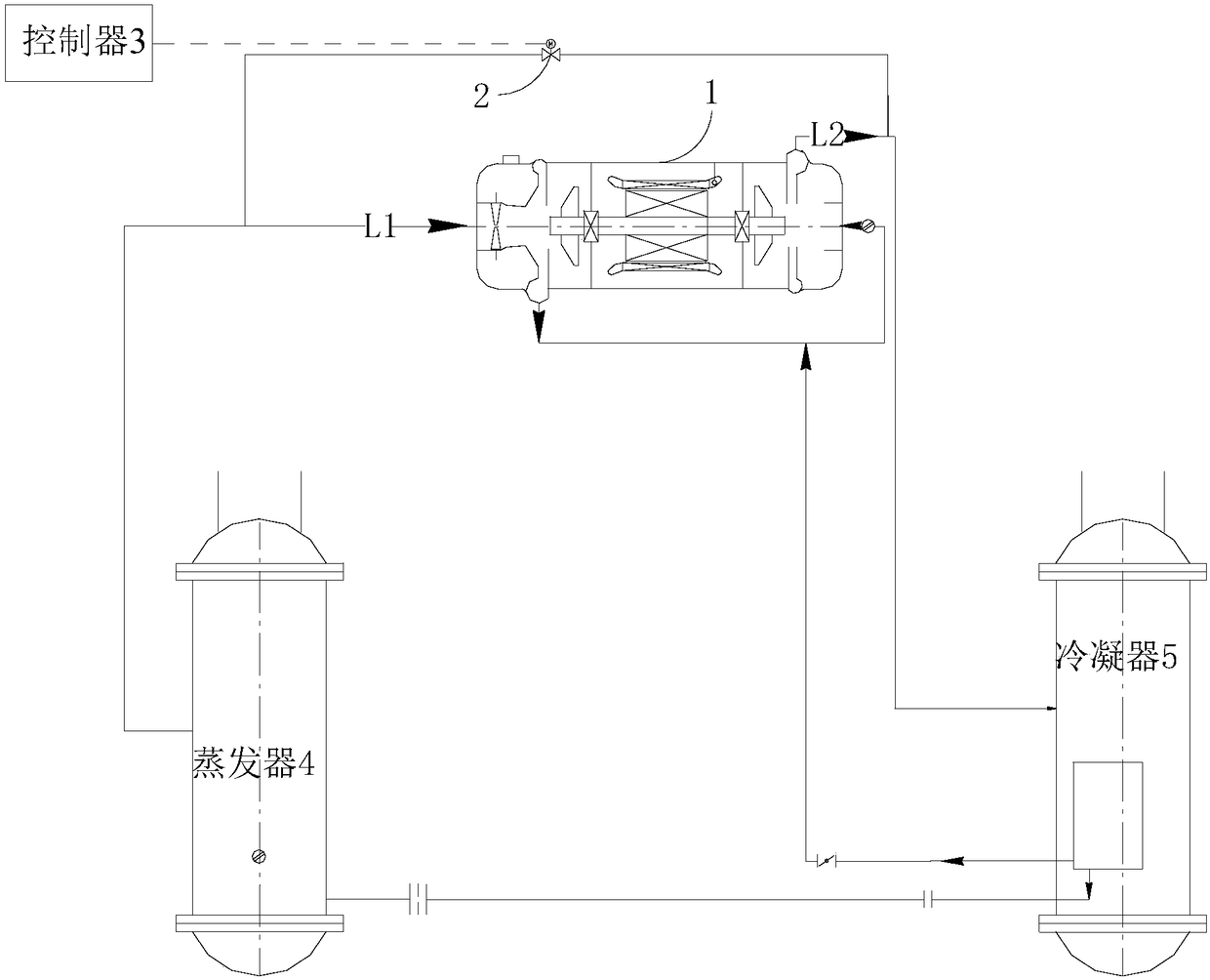

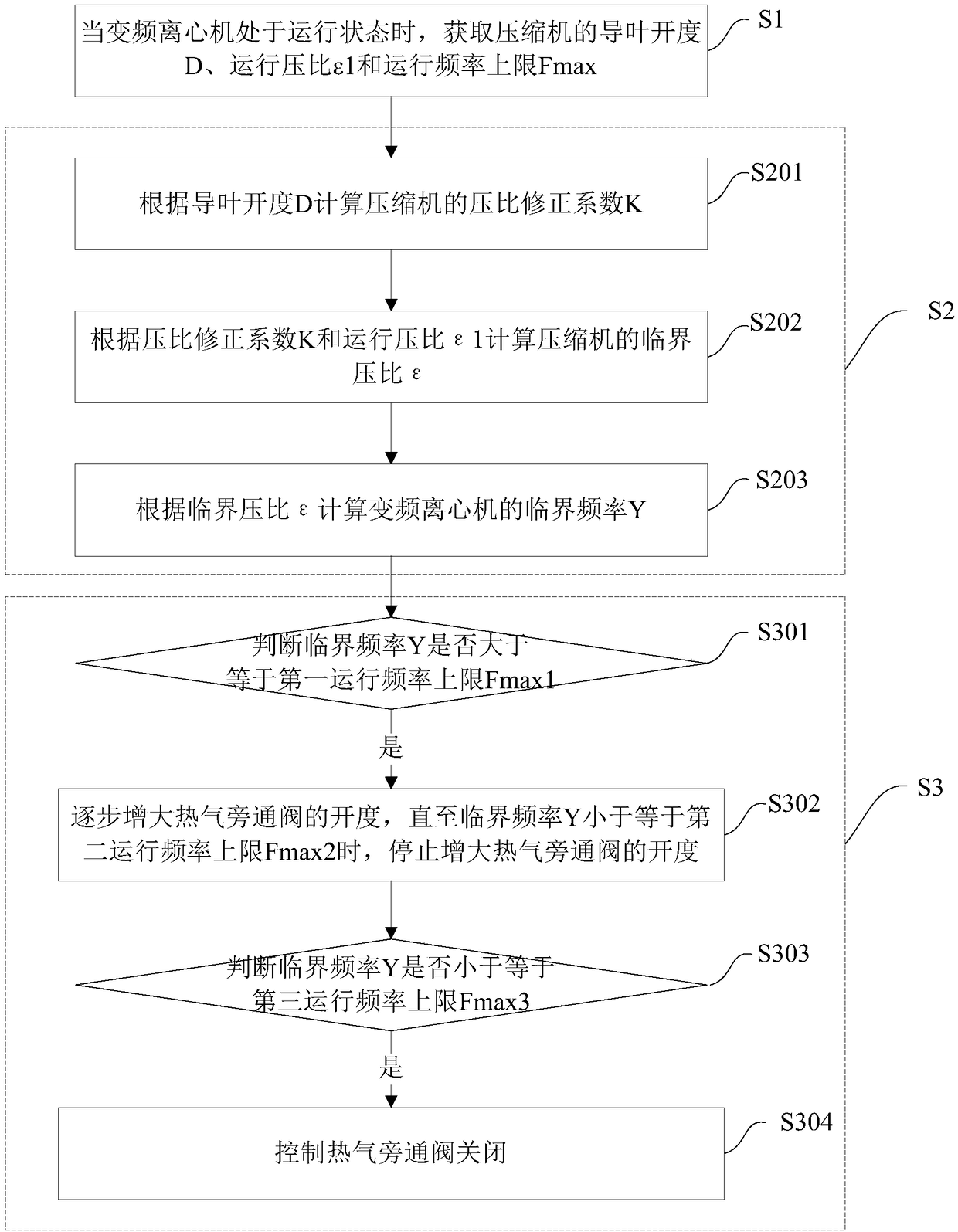

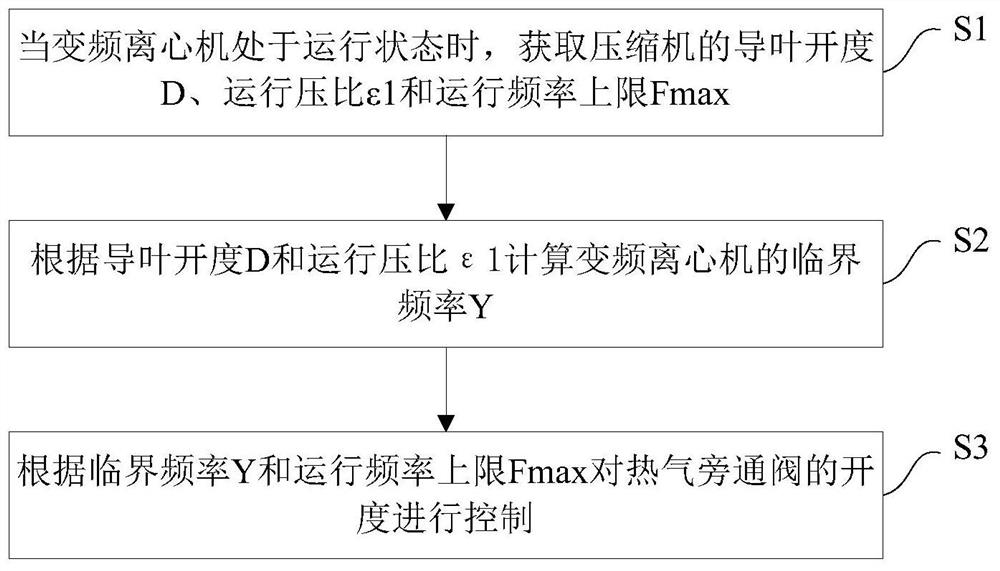

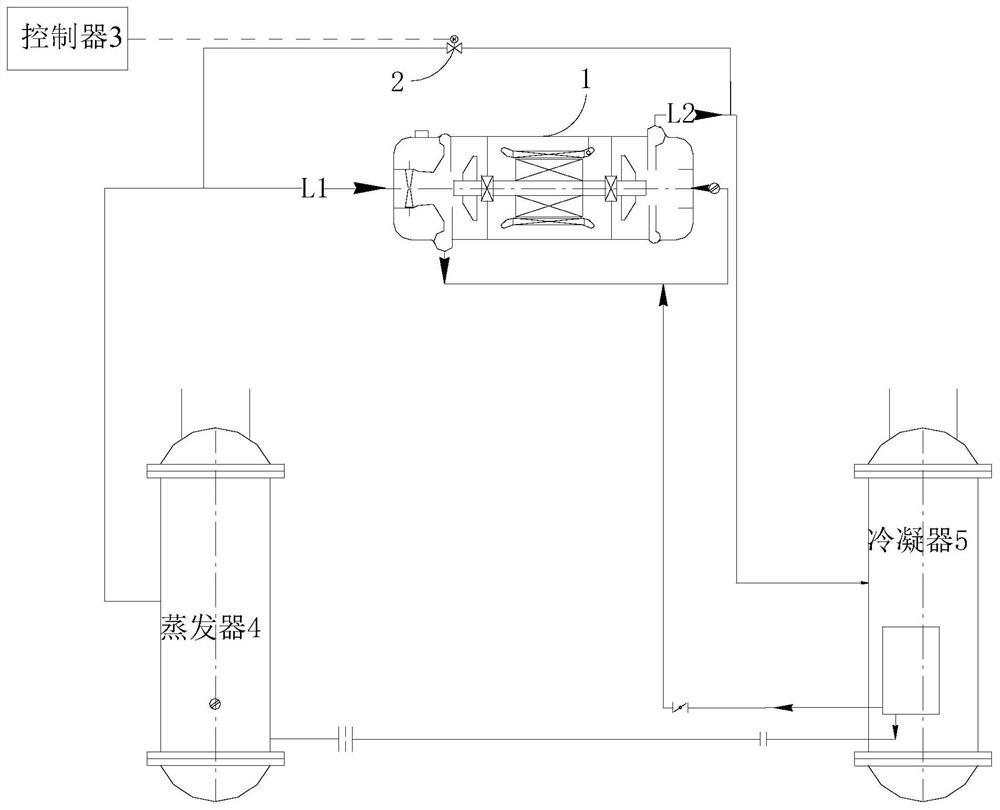

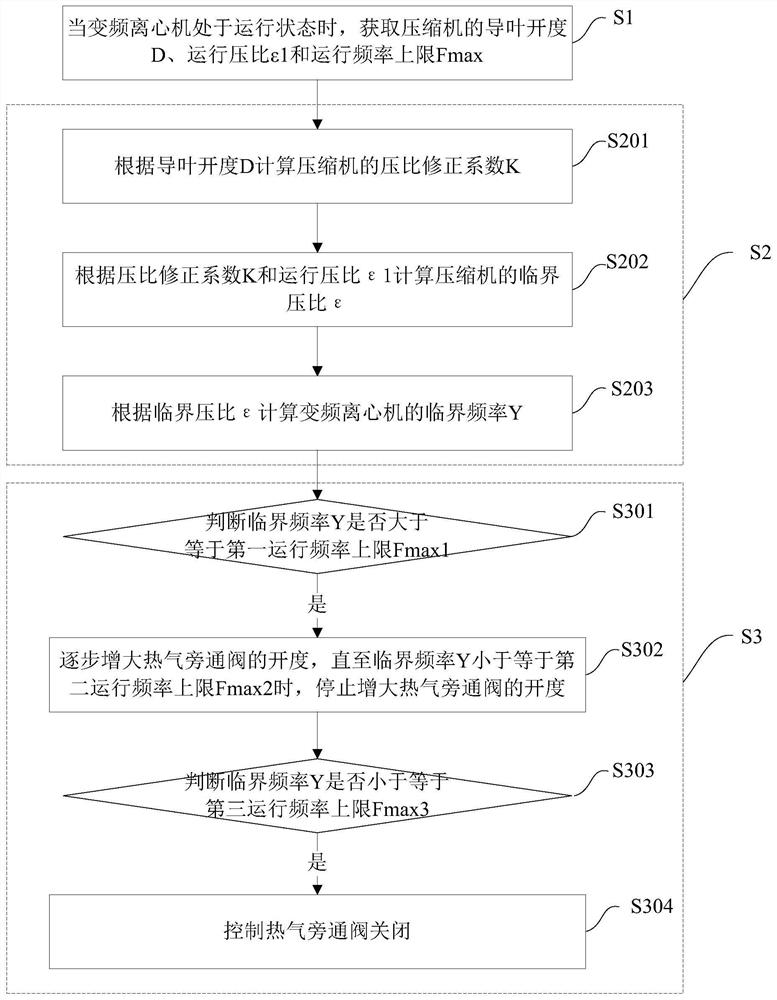

Variable frequency centrifuge and control method of hot gas bypass valve in variable frequency centrifuge

ActiveCN108131871AImprove reliabilityNo surgeMechanical apparatusFluid circulation arrangementControl theoryOperating frequency

The invention discloses a variable frequency centrifuge and a control method of a hot gas bypass valve in the variable frequency centrifuge. The variable frequency centrifuge includes a compressor, and the hot gas bypass valve is disposed between an air suction pipe and an air exhaust pipe of the compressor. The method comprises the following steps of when the variable frequency centrifuge is in an operating state, obtaining a guide vane opening degree, an operating pressure ratio and the upper limit of the operating frequency of the compressor, wherein the operating pressure ratio is a ratioof an air exhaust absolute pressure value to an air suction absolute pressure value of the compressor; calculating the critical frequency of the variable frequency centrifuge according to the guide vane opening degree and the operating pressure ratio; controlling the opening degree of the hot gas bypass valve according to the critical frequency and the upper limit of the operating frequency. By controlling the opening degree of the hot gas bypass valve, the variable frequency centrifuge can safely operate with a small load under high ambient temperature and large pressure ratio, and at the same time, the compressor surging phenomenon does not occur under small load operation, so that the operation reliability of the variable frequency centrifuge is improved.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

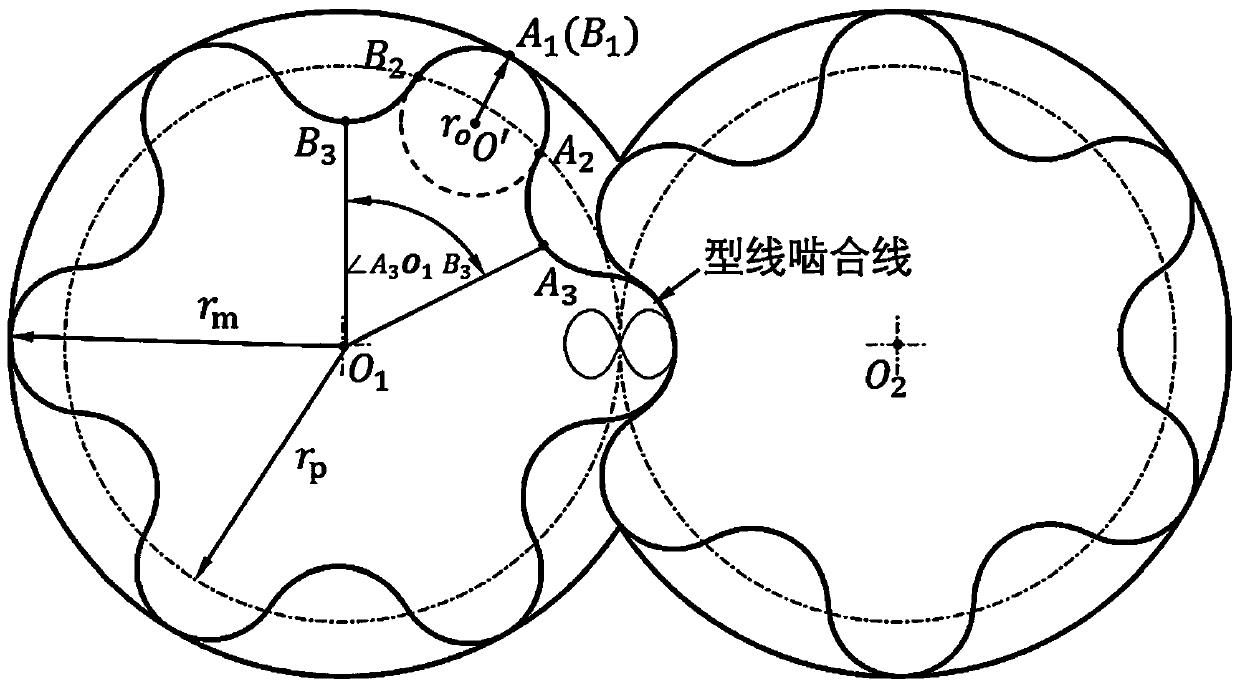

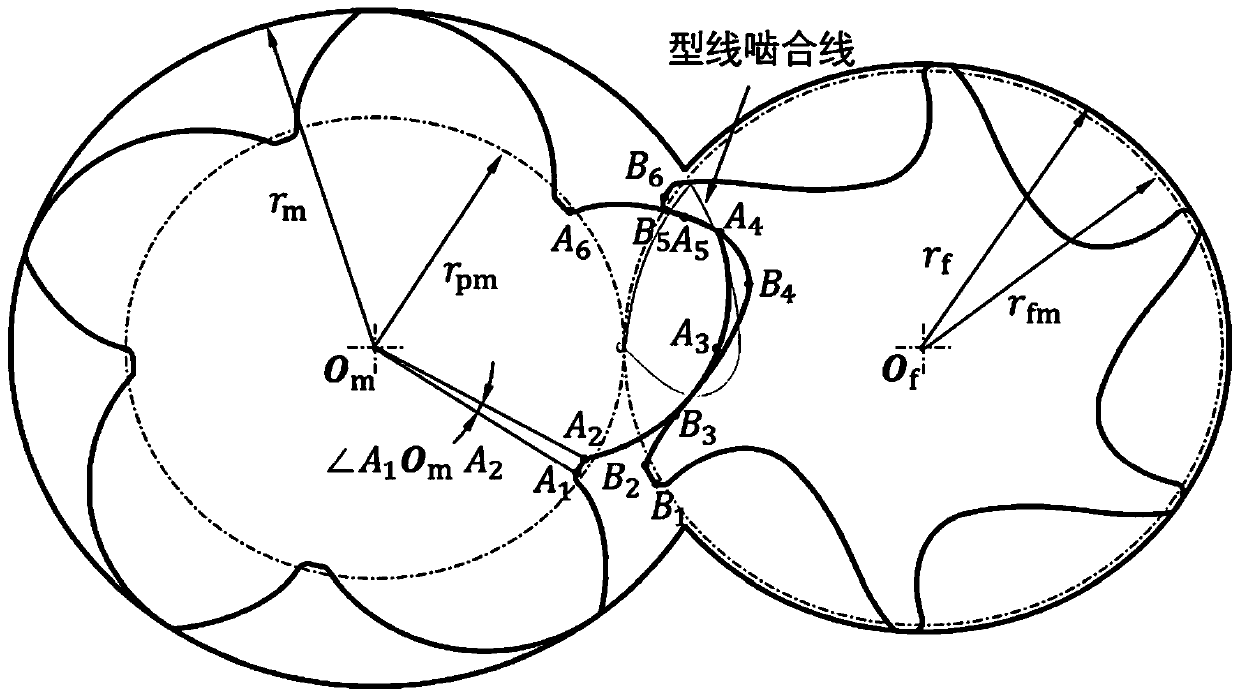

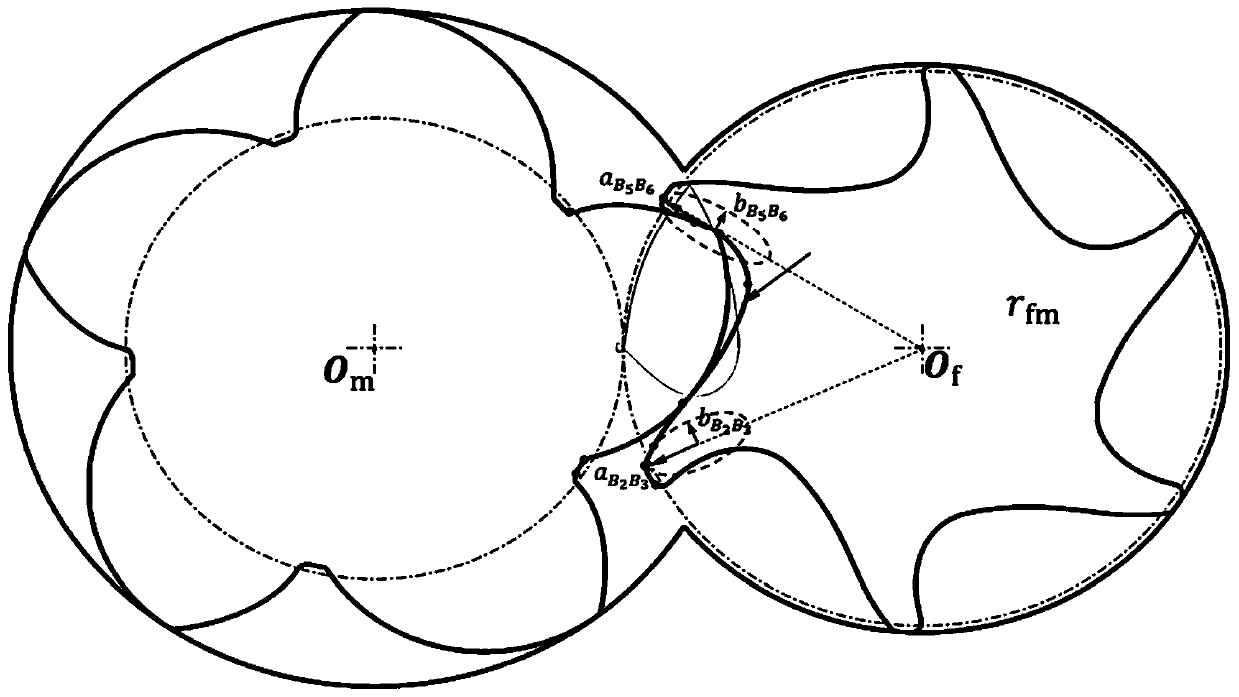

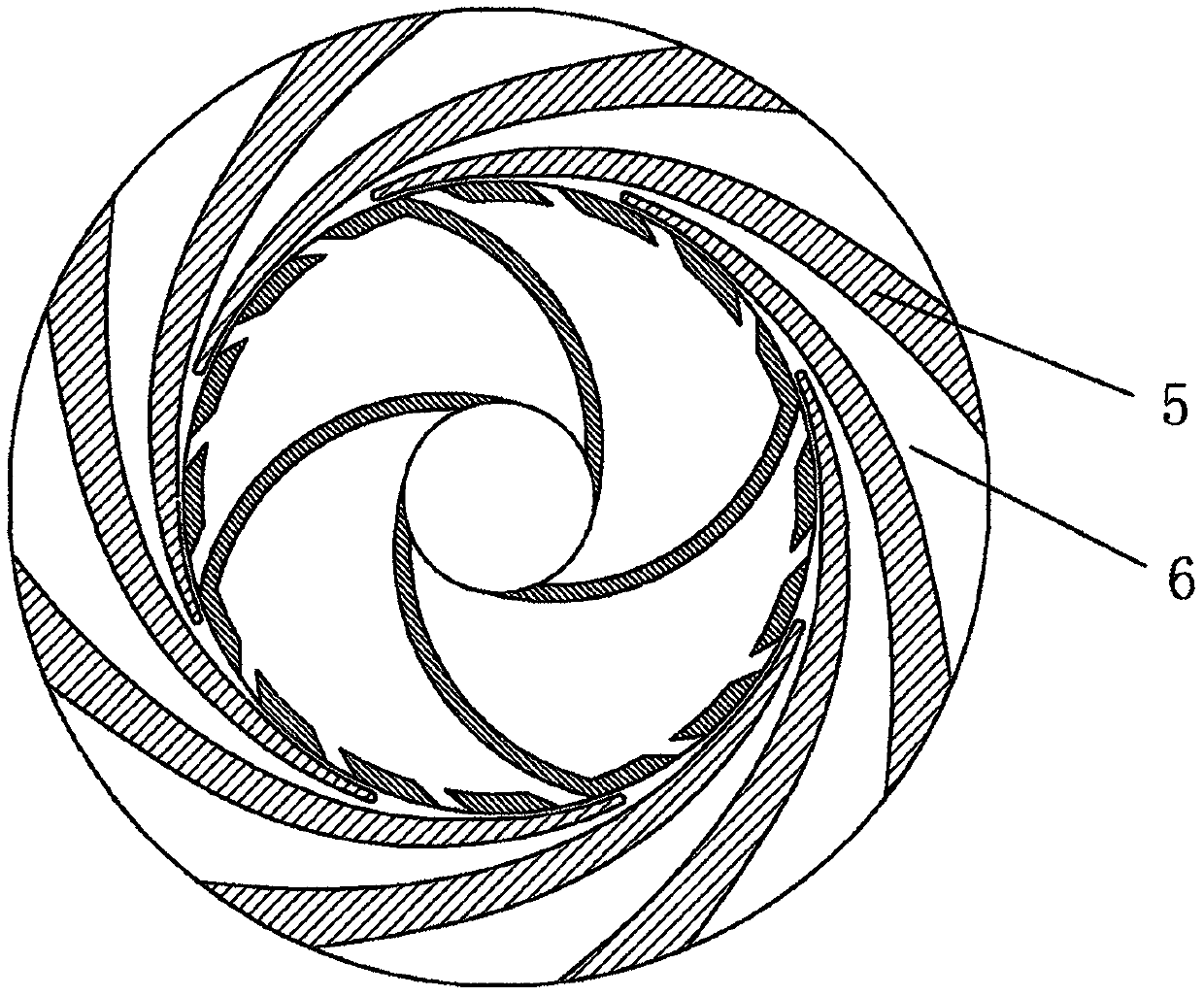

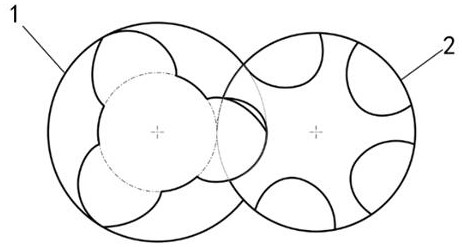

Asymmetric elliptic twisted blade roots rotor, compressor and expander

ActiveCN110762004AImprove machine performanceImprove volumetric efficiencyPump componentsEngine of intermeshing engagement typeShaft lengthSingle tooth

The invention discloses an asymmetric elliptic twisted blade roots rotor, a compressor and an expander. A single-tooth shape B3B2AlA2A3 of a rotor molded line consists of an elliptic arc section A1A2,an elliptic arc section B1B2, an elliptic envelope line section B2B3 and an elliptic envelope line section A2A3 connected end to end in sequence; two rotors can realize correct engagement in the rotary engagement process; the long and short shaft lengths of the elliptic arc section A1A2 and the long and short shaft lengths of the elliptic arc section B1B2 have different values; a complete rotor molded line is formed by repeating the following operations by n times: the single-tooth shape B3B2AlA2A3 is connected with a tooth shape B3B2A1A2A3 end to end after rotation around a rotor molded lineorigin O1; and n is the tooth number of the molded line. The asymmetric elliptic twisted blade roots rotor can effectively inhibit leakage between working cavities to improve overall performance of the twisted blade roots compressor or expander.

Owner:XI AN JIAOTONG UNIV

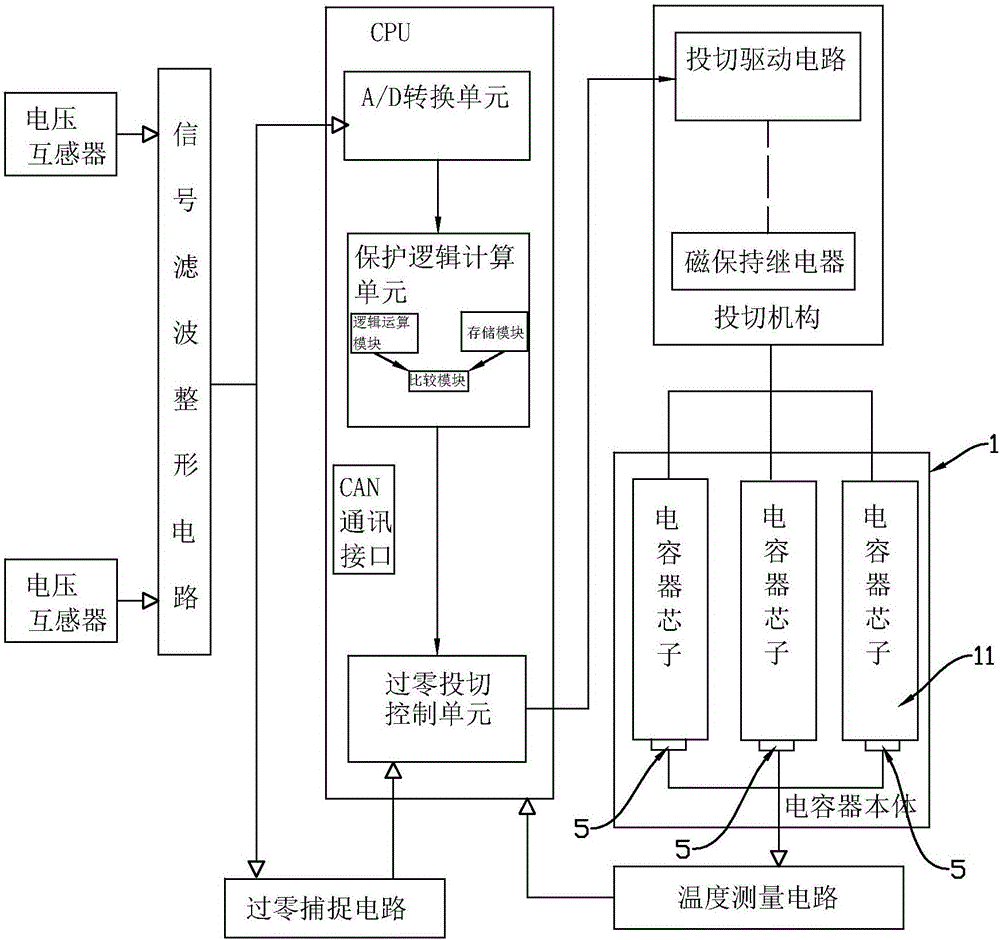

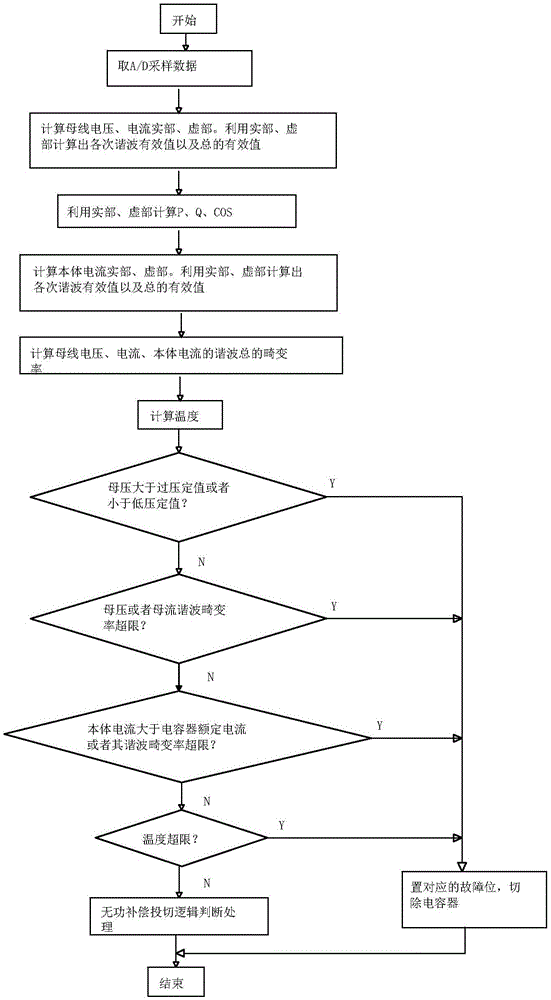

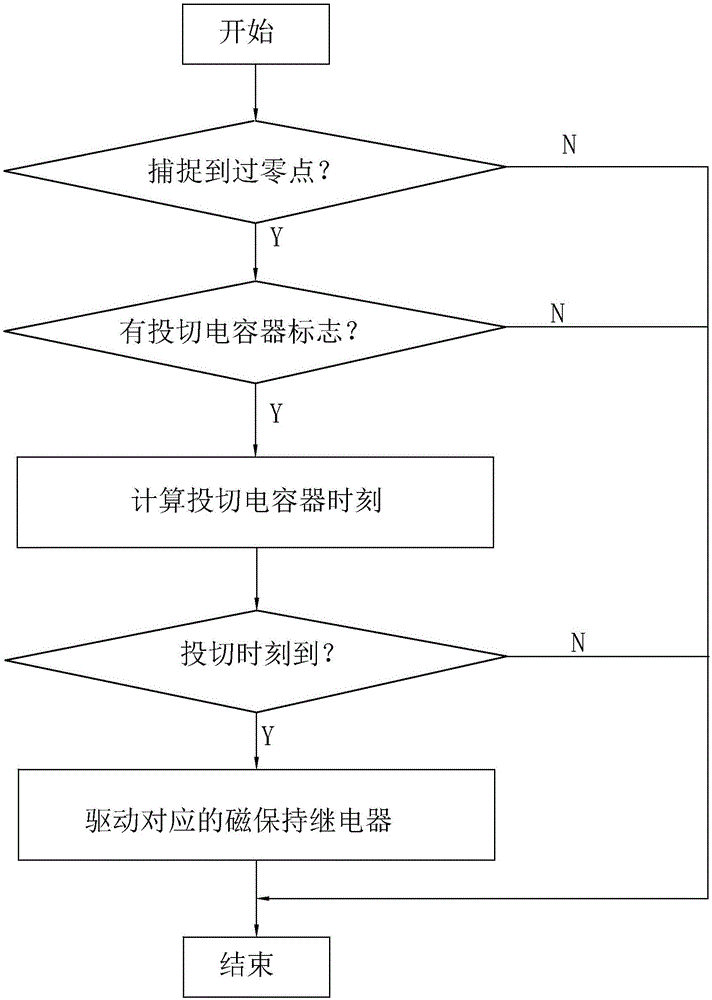

Intelligent low-voltage power capacitor

InactiveCN106451489AWork reliablyComplete protection functionsEmergency protective circuit arrangementsReactive power adjustment/elimination/compensationMicrocontrollerCapacitance

The invention relates to an intelligent low-voltage power capacitor comprising a capacitor body with a capacitor core and a control unit. The control unit consists of a circuit breaker, a voltage and current signal acquisition circuit, a switching mechanism and a single-chip microcomputer. A signal filtering and shaping circuit, an A / D conversion unit, a logic protection calculation unit, a zero-crossing capturing circuit and a zero-crossing switching control unit are arranged inside the single-chip microcomputer in an integrated mode. The logic protection calculation unit including a logic operation module, a storage module and a comparison module is used for calculation to obtain a voltage, a current, an active power, a reactive power, a power factor, and a harmonic quantity and controlling the zero-crossing switching control unit to execute capacitor core cutting for the switching mechanism when the voltage, current and harmonic quantity exceeds standards, thereby realizing over-voltage, under-voltage, and harmonic protection. Therefore, on the basis of reactive compensation logic, the switching mechanism is controlled to execute zero-crossing switching based on zero-crossing determination, thereby realizing reactive compensation. According to the intelligent low-voltage power capacitor provided by the invention, harmonic, voltage and current protection is realized based on the logic operation of the single-chip microcomputer; and the intelligent low-voltage power capacitor has advantages of complete protection functions and compact structure.

Owner:亚驰电力科技有限公司

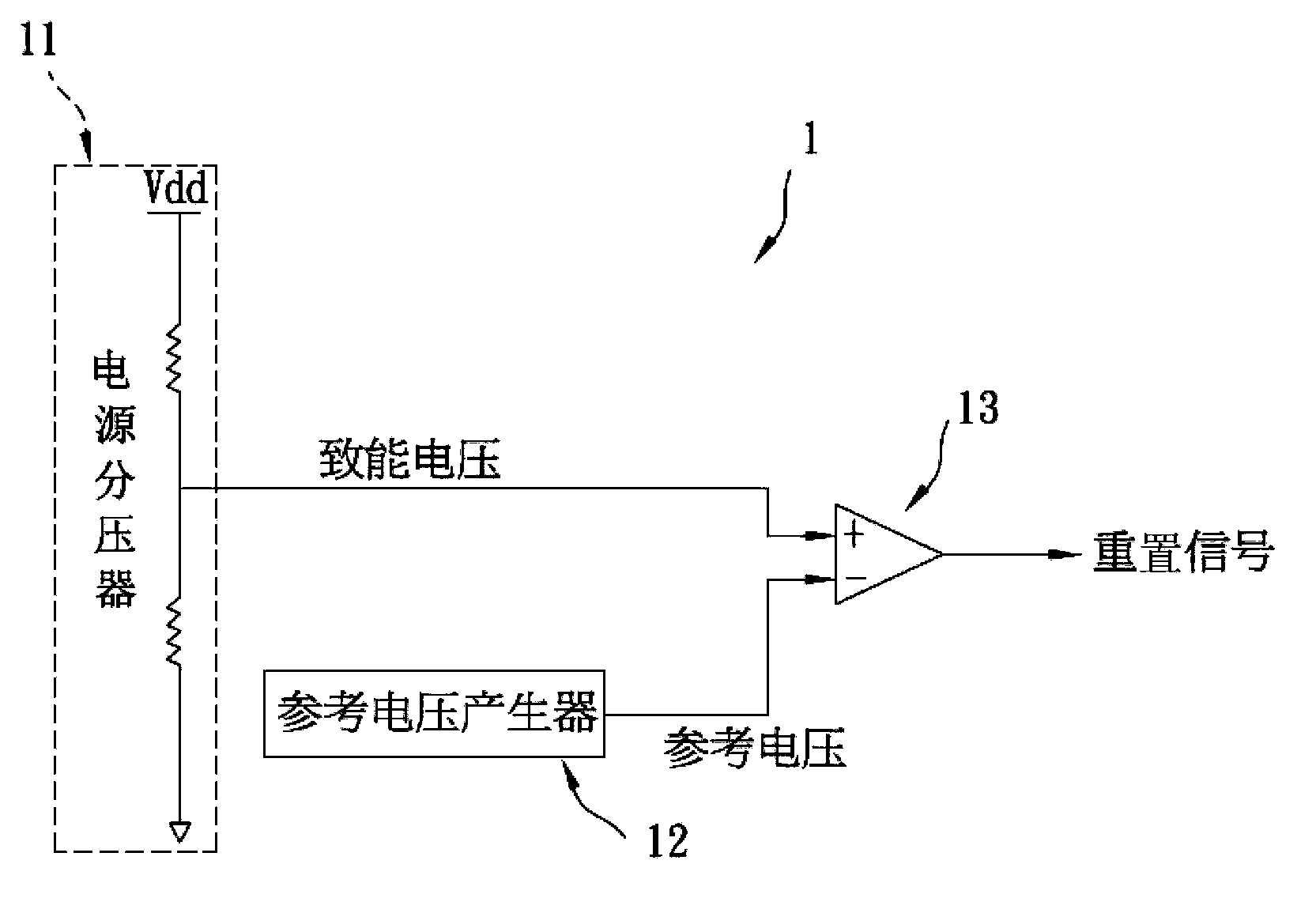

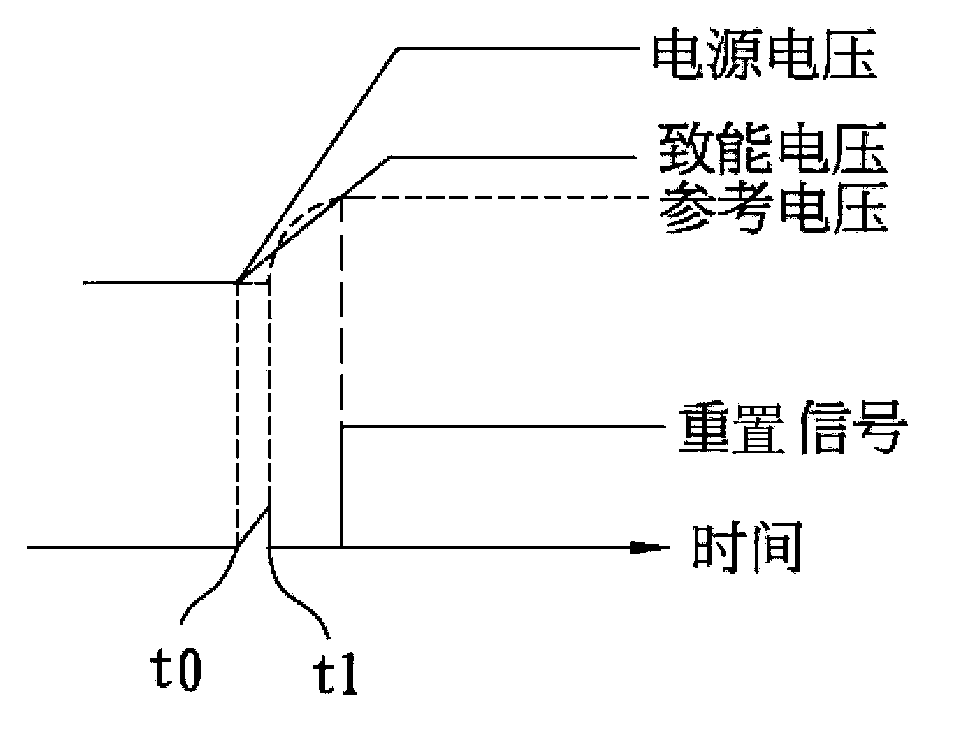

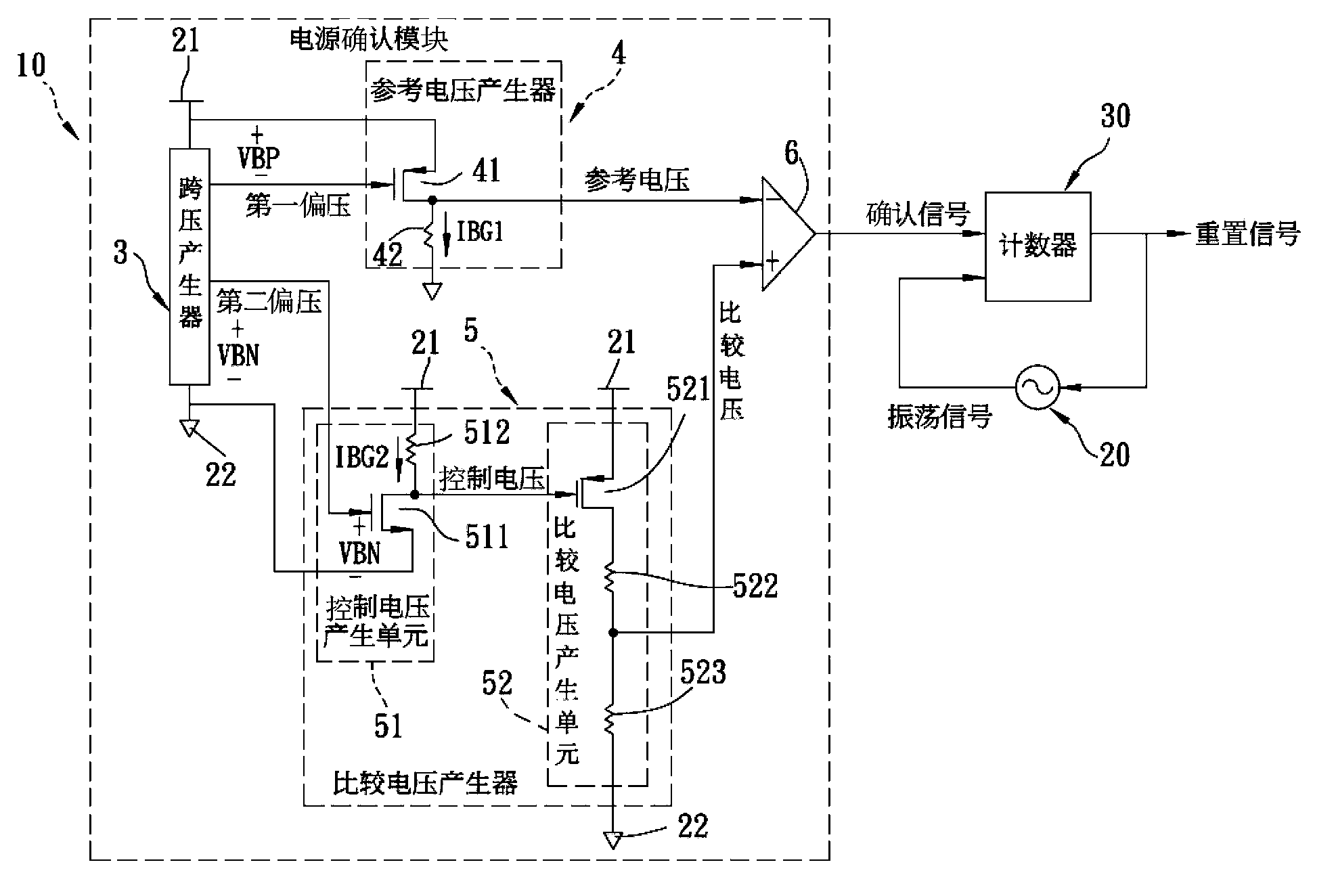

Power-on reset circuit

Owner:成一电子股份有限公司

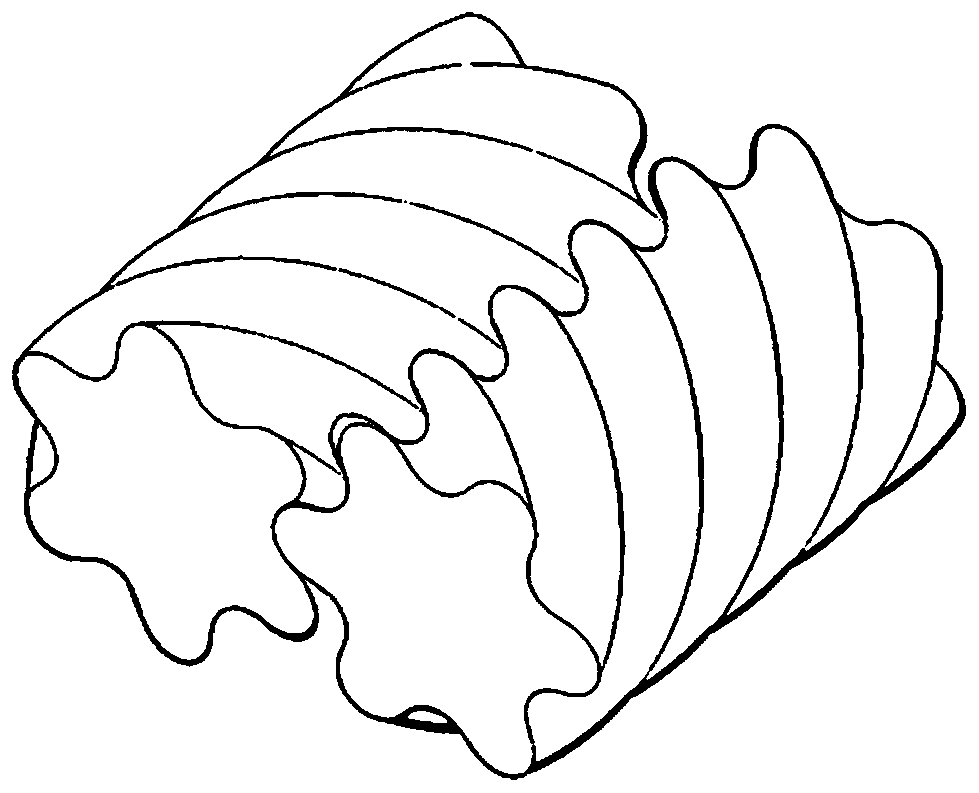

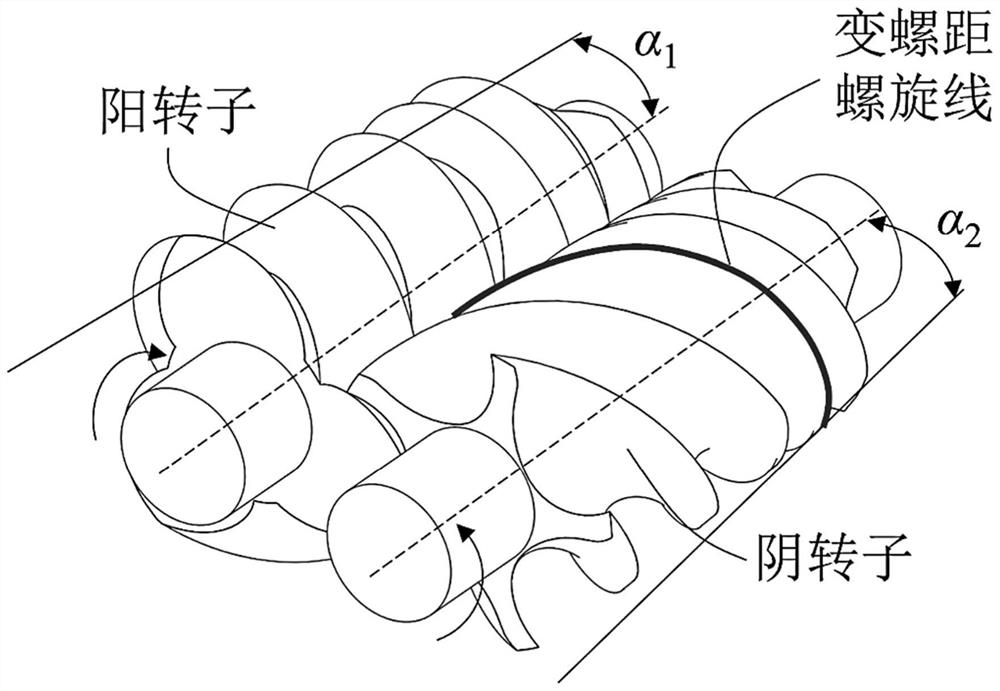

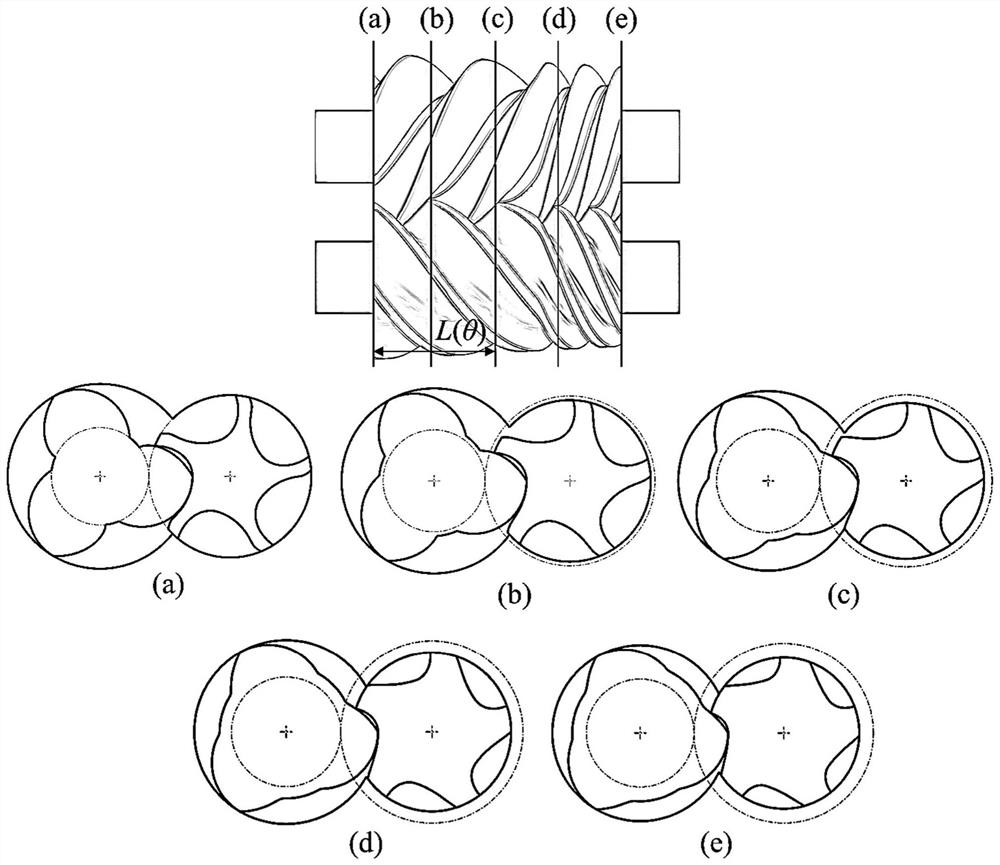

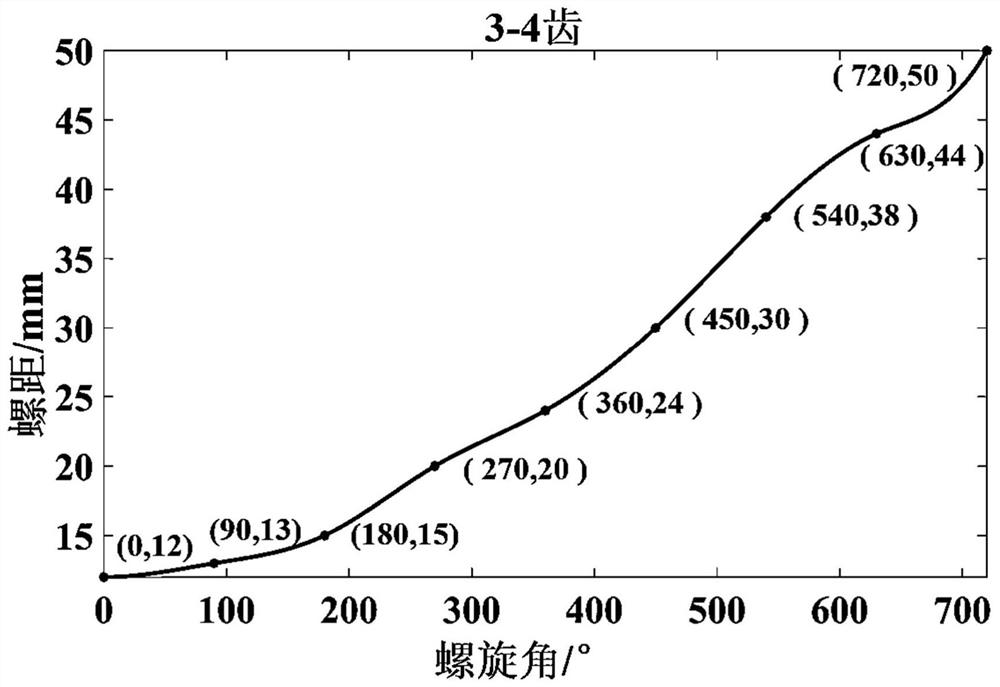

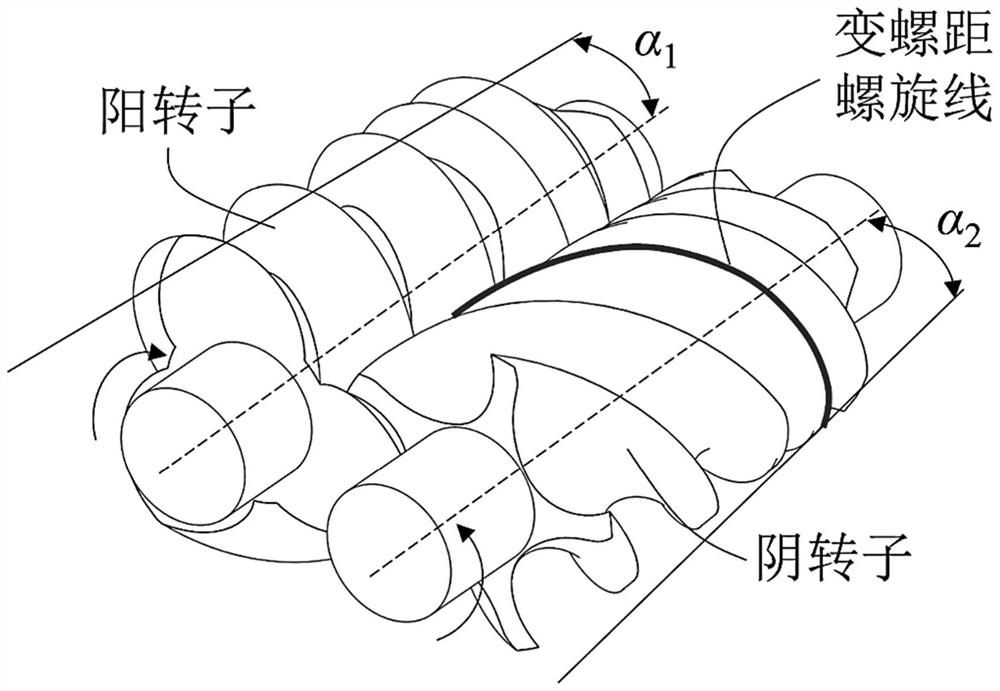

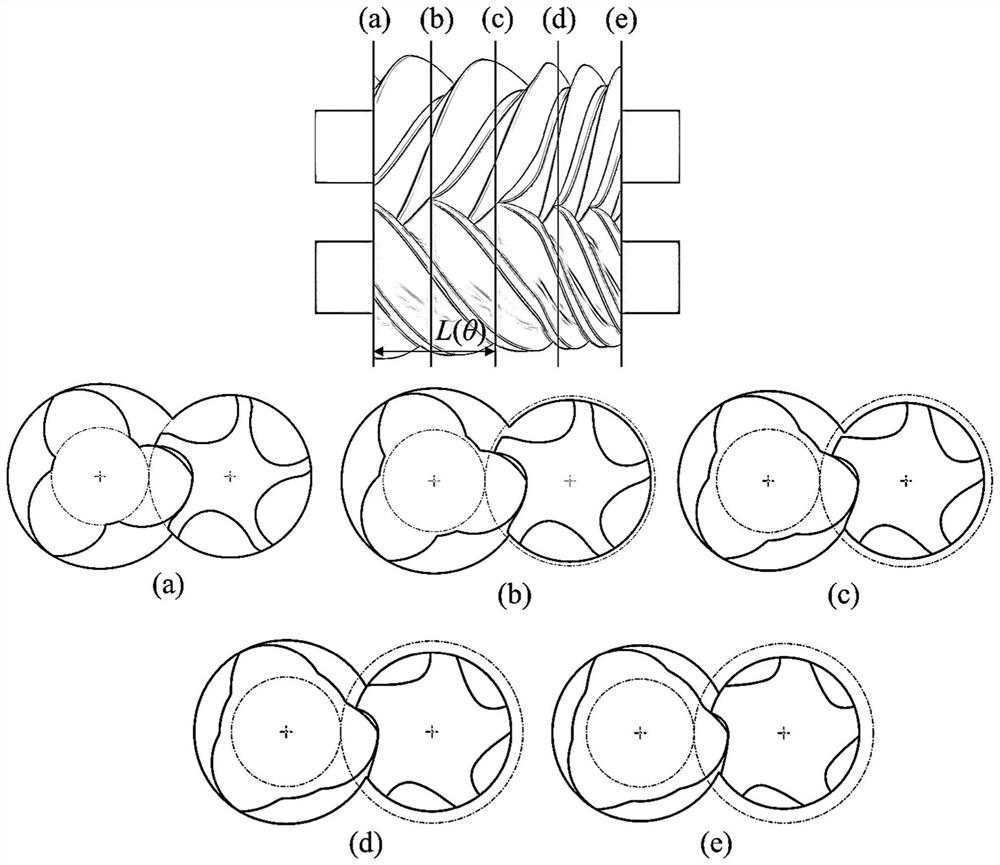

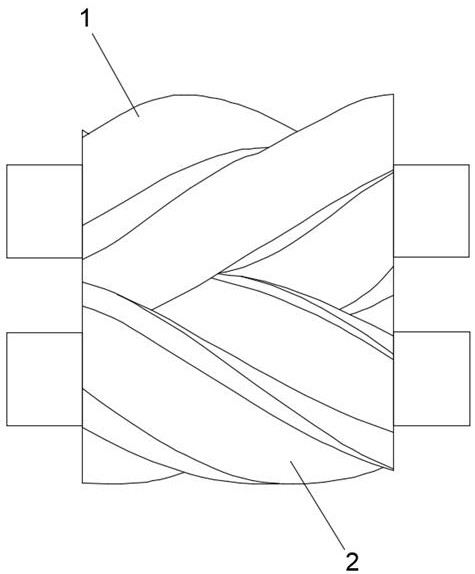

Variable-line double-screw rotor and design method thereof

ActiveCN113153742AIncrease the areaImprove efficiencyGeometric CADInternal combustion piston enginesClassical mechanicsAxial distance

The invention discloses a variable-line double-screw rotor and design method thereof. A rotor structure comprises a female screw rotor and a male screw rotor with the outer contours of conical structures, guide spiral lines of the female screw rotor and the male screw rotor both adopt a variable pitch mode, the guide spiral lines are divided into two parts, when the rotor rotation angle is smaller than a set value, a larger rotor pitch is adopted, when the rotor rotation angle is larger than the set value, and a smaller rotor screw pitch is adopted, so that axial exhaust ports of the rotors are enlarged, along with the increase of the axial distance of the rotors, the tooth crest radius of the female screw rotor and male screw rotor is linearly reduced to form taper angles of the female screw rotor and male screw rotor, and the volume of the working cavity of the double-screw rotors is reduced along with the opening corner of an exhaust orifice, so that the opening corner of the exhaust orifice is opened in advance under the same internal volume ratio, and the area of the exhaust orifice is increased. According to the variable-line double-screw rotor and design method thereof, the area of the exhaust orifice of a screw compressor is effectively enlarged, resistance loss at the exhaust position is reduced, pressure pulsation of the exhaust side is reduced, and therefore the effects of improving the efficiency of the screw rotors and reducing noise are achieved.

Owner:XI AN JIAOTONG UNIV

Re-improved inlet for third-generation light fighter

InactiveCN102887230AReduced reflective cross-sectional areaIncrease air intakePower plant air intake arrangementsFront edgeWorkload

The invention discloses a re-improved inlet for a third-generation light fighter, comprising an inlet side wall, an inlet lower wall and a boundary layer push bump. The front edge of the inlet lower wall is provided with an adjustable lower lip edge; the inlet side wall causes the upper edge firstly to be arranged outwards at the same horizontal position with a wing and then to be changed into an inward-retracting shape; and the bending position of the inlet side wall is provided with an obvious adjacent line. The re-improved inlet for the third-generation light fighter has the advantages that the radar cross section, flight drag, maintenance workload and structural weight of the third-generation light fighter are reduced; and the re-improved inlet allows the light fighter to fly at the speed of 2 Mach.

Owner:王长存

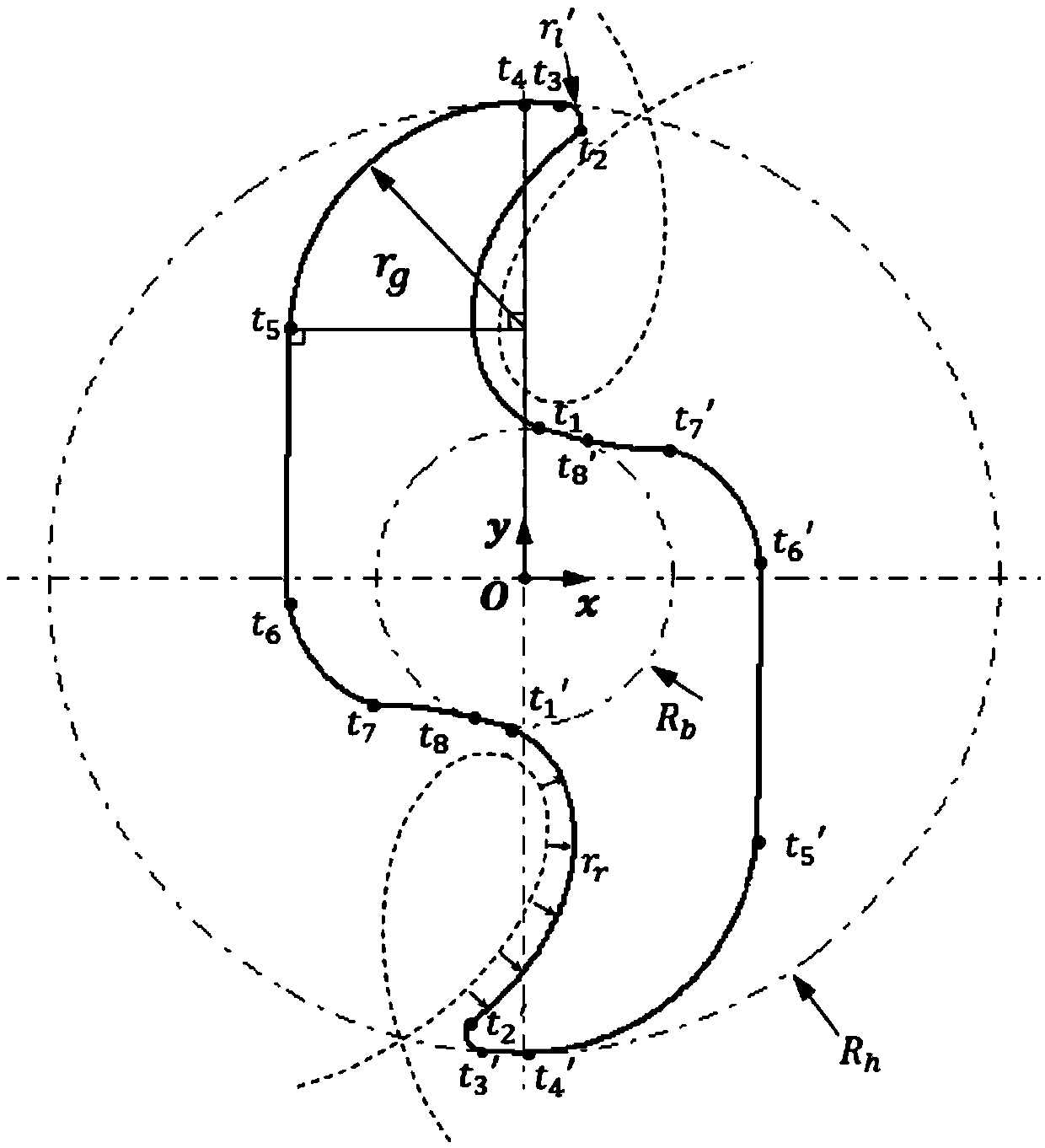

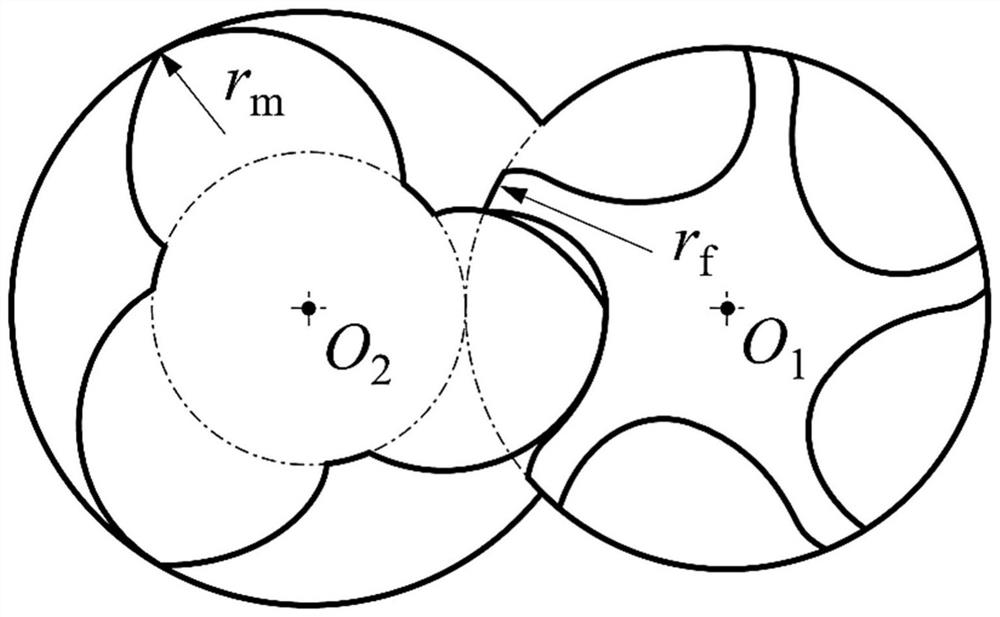

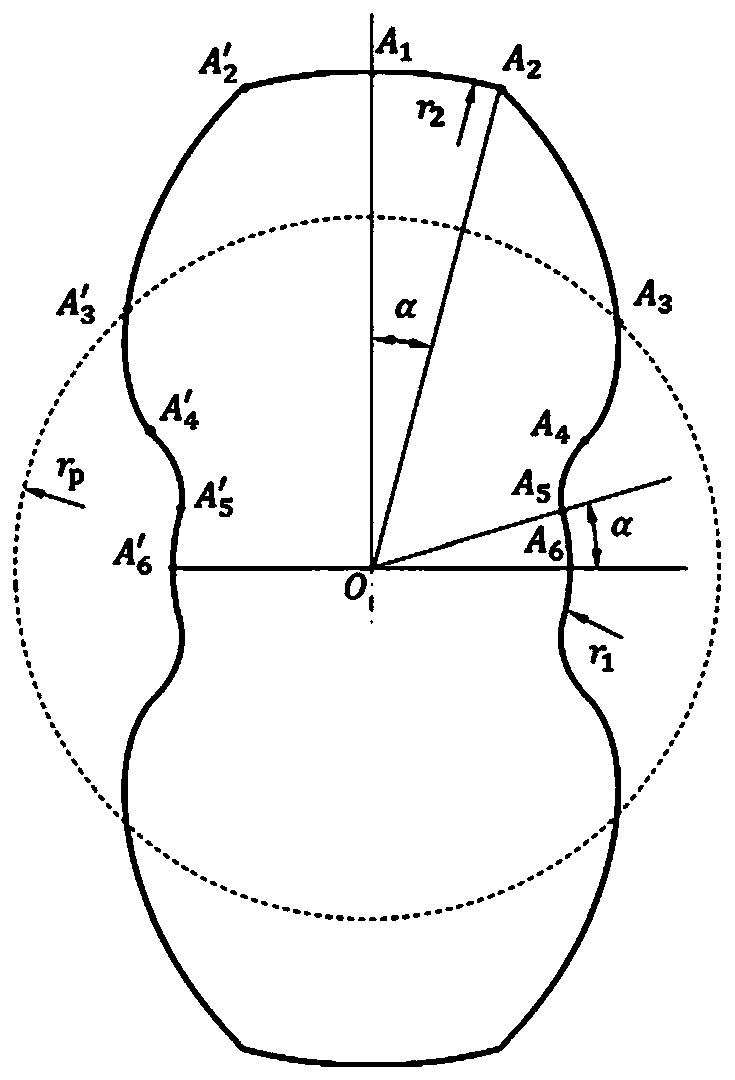

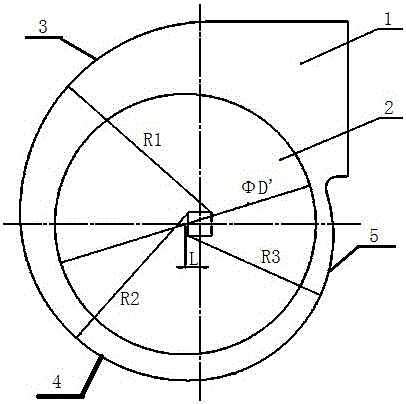

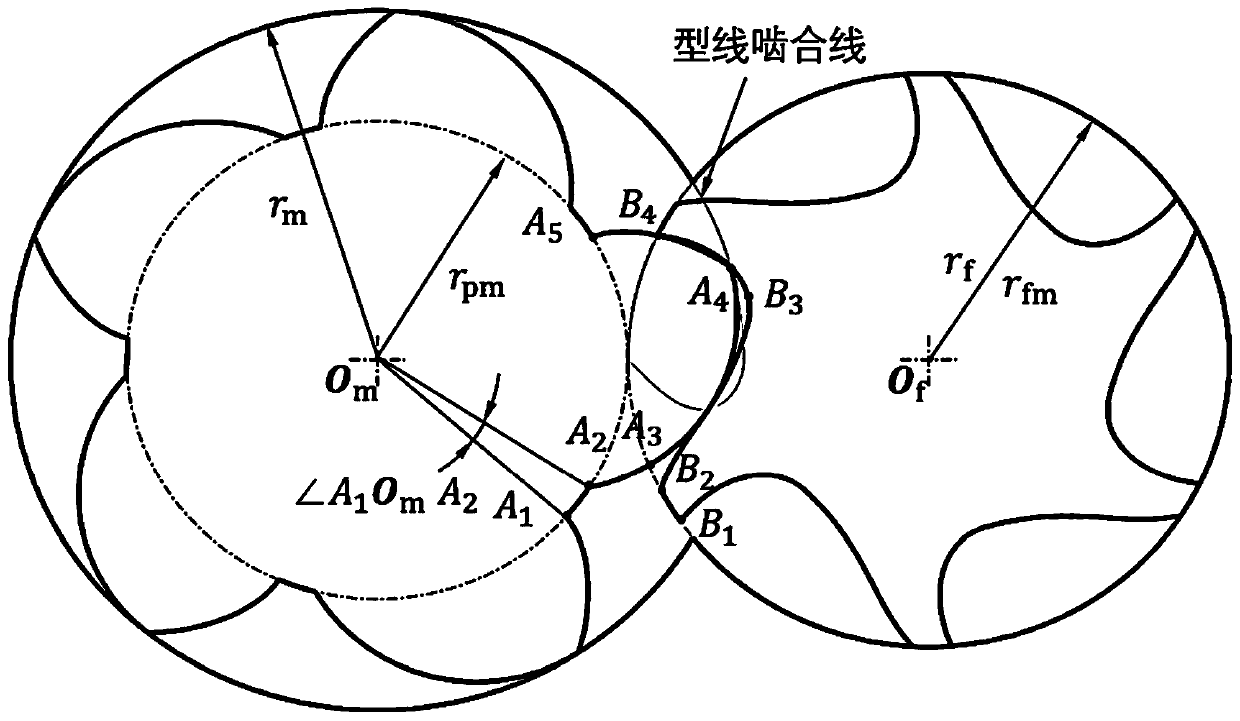

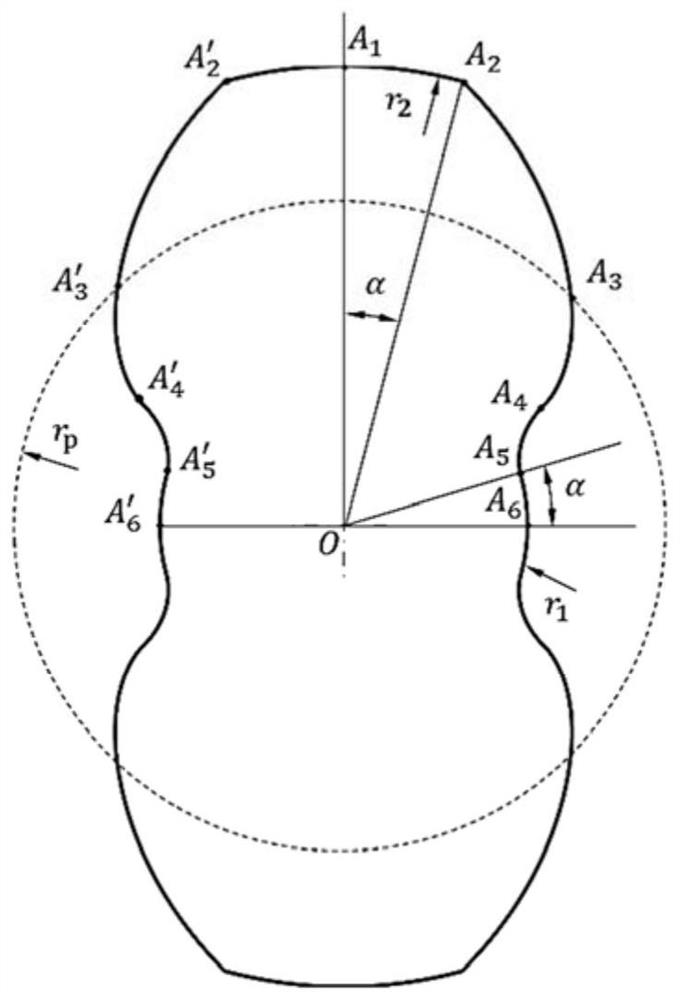

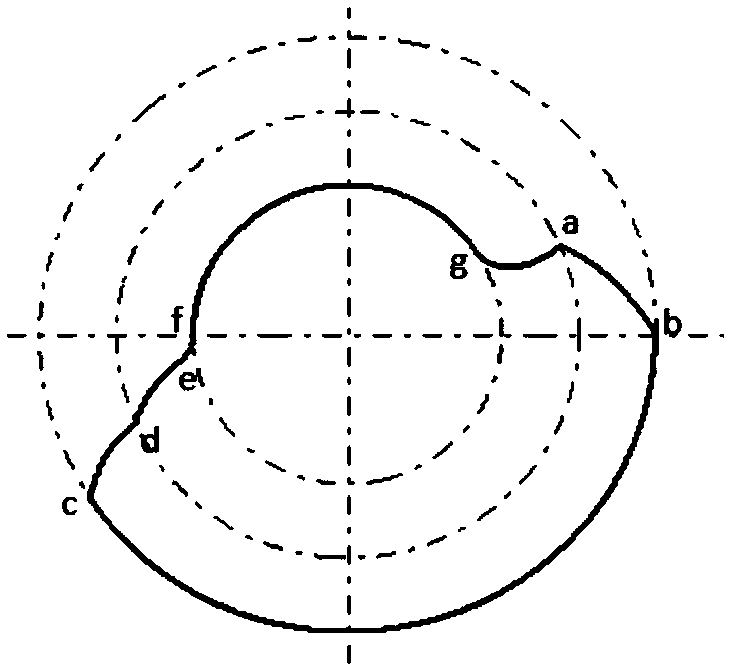

Rotor of roots pump and roots pump

ActiveCN110685906AEliminates closed volume problemsFew independent parametersPump componentsRotary piston pumpsRooted toothEngineering

The invention discloses a rotor of a roots pump and the roots pump. The basic forming curved section A1A2A3A4A5 of the molded line of the rotor is composed of a tooth crest arc section, a pseudo polynomial curved section, a conjugate curved section of a pseudo polynomial curve and a tooth root arc section, all of which are sequentially connected end to end. The pseudo polynomial curved section A2A3 is tangent to the tooth crest arc section A1AA1. The basic forming curved section A1A2A3A4A5 and a curved section A1A'2A'3A'4A'5A'6 symmetric with the basic forming curved section A1A2A3A4A5 are combined into a tooth molded line A'6A'5A'4A'3A'2A1A2A3A4A5 of a tooth. The tooth molded line A'6A'5A'4A'3A'2A1A2A3A4A5 is repeated according to the number n of teeth of the molded line of the rotor of the roots pump to generate n tooth molded lines, and the tooth molded lines are sequentially connected end to end to generate a complete rotor molded line. The two rotor molded lines are the same and can be engaged in the rotating process. By means of the rotor, part of points of original molded lines are eliminated, the design parameter space of the molded line of the rotor of the roots pump is expanded, and the performance of the roots pump is improved.

Owner:XI AN JIAOTONG UNIV

Forward-curved multi-wing type centrifugal fan

The invention discloses a forward-curved multi-wing type centrifugal fan. The forward-curved multi-wing type centrifugal fan comprises a volute casing and an impeller, wherein the volute casing comprises a volute tongue as well as a first curved surface, a second curved surface and a third curved surface which are sequentially tangential and are smoothly connected, wherein the impeller and the volute casing are arranged in an eccentric manner for increasing the diameter of the impeller. According to the forward-curved multi-wing type centrifugal fan, the impeller is mounted in the eccentric manner relative to the volute casing, so that the diameter of the impeller is increased, parameters such as air quantity, air pressure and the like are obviously improved, noises are reduced, fan surge is avoided, and the performances of the fan are improved; and meanwhile, three sections of cambered surfaces form the volute casting, so that the profile of the volute casting is simplified, the space volume is saved, the structural form is simple, a welding process is avoided and the processing cost is low, and therefore, the volute casting is more convenient to manufacture.

Owner:SHANGHAI NAUTILUS GENERAL EQUIP MFG CO LTD

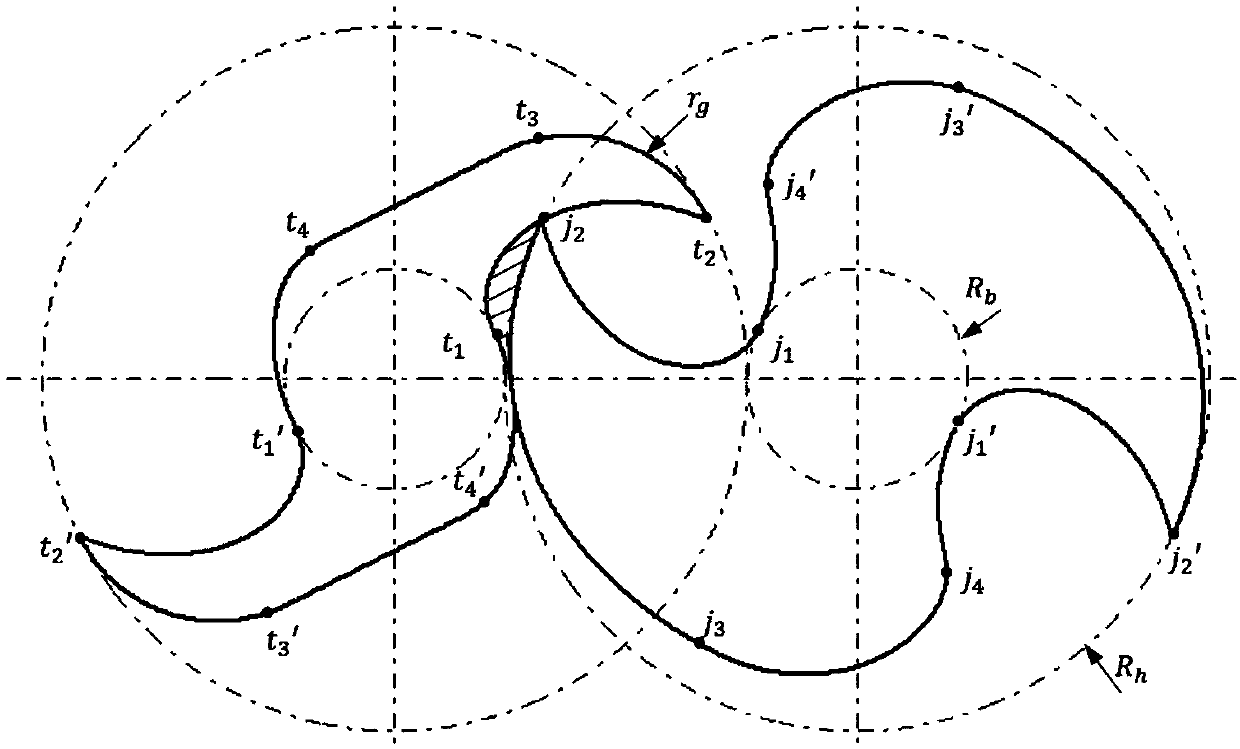

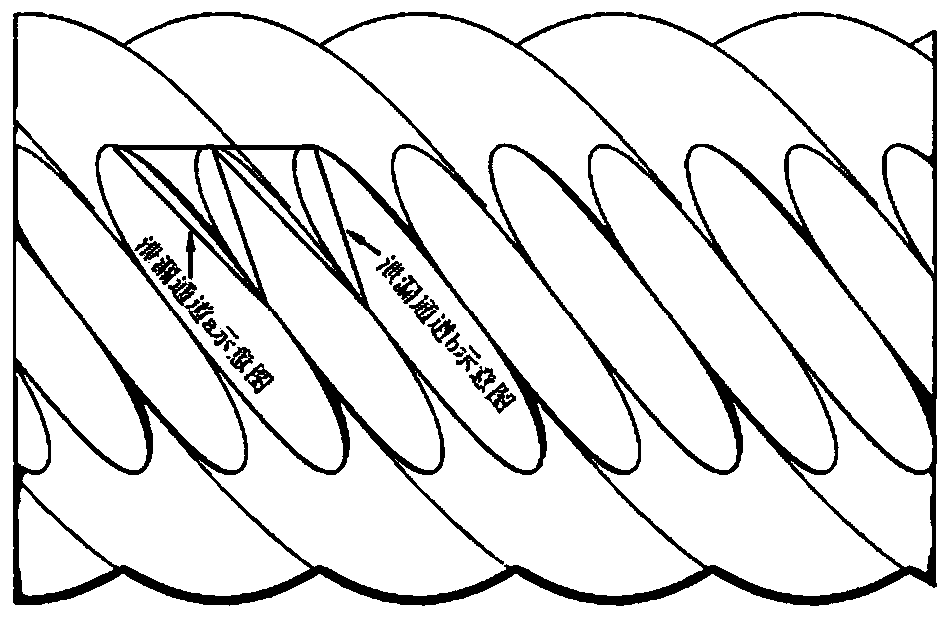

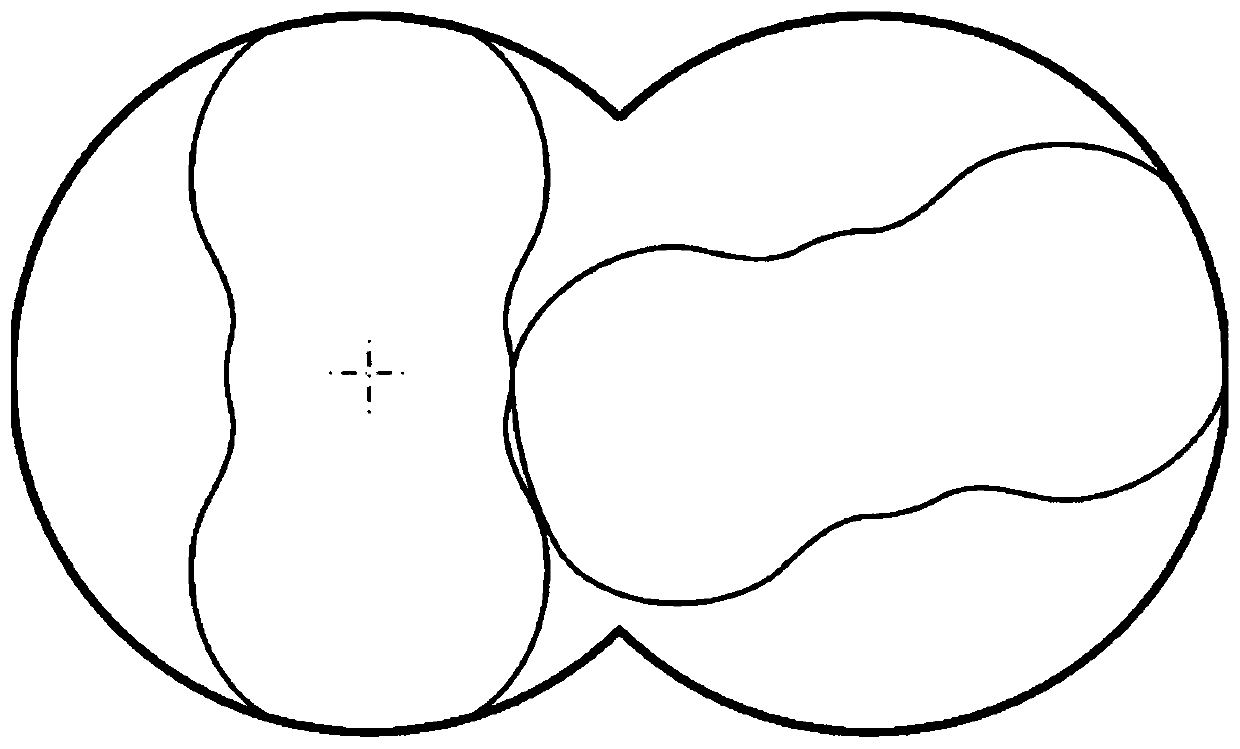

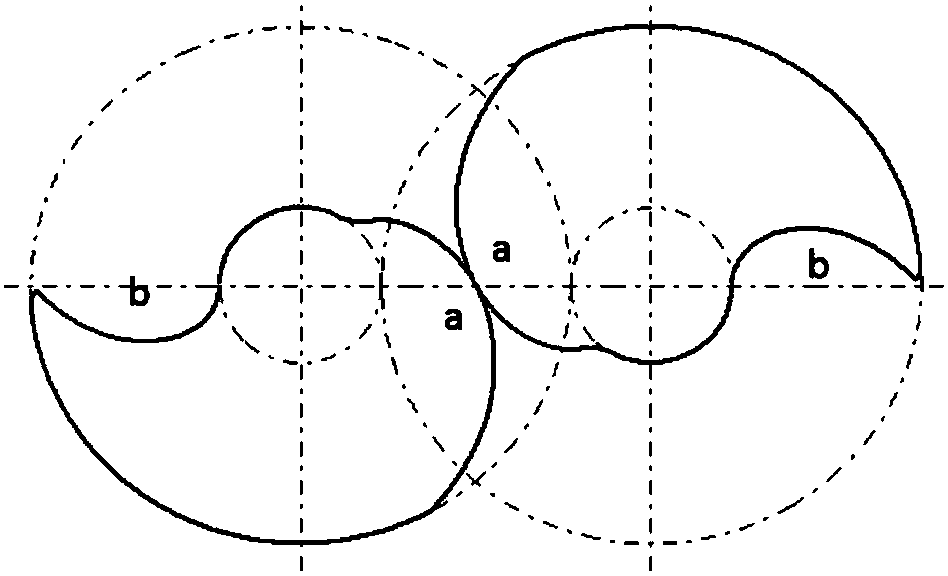

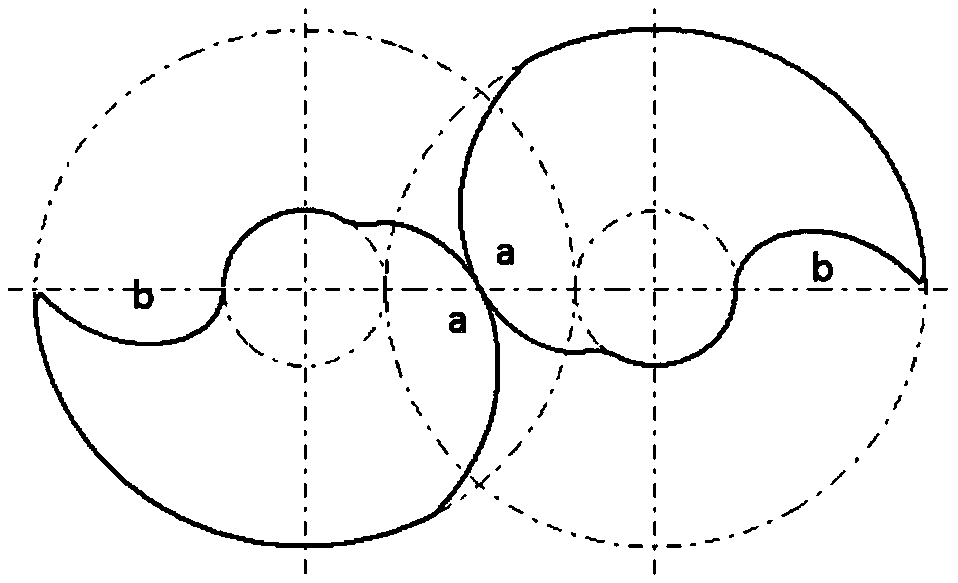

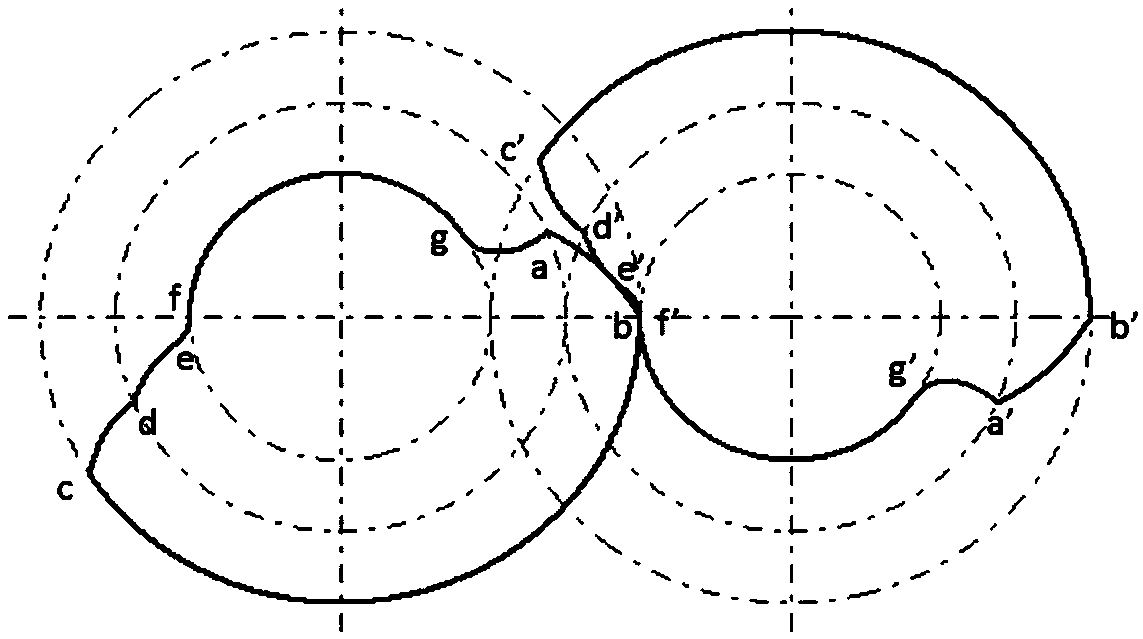

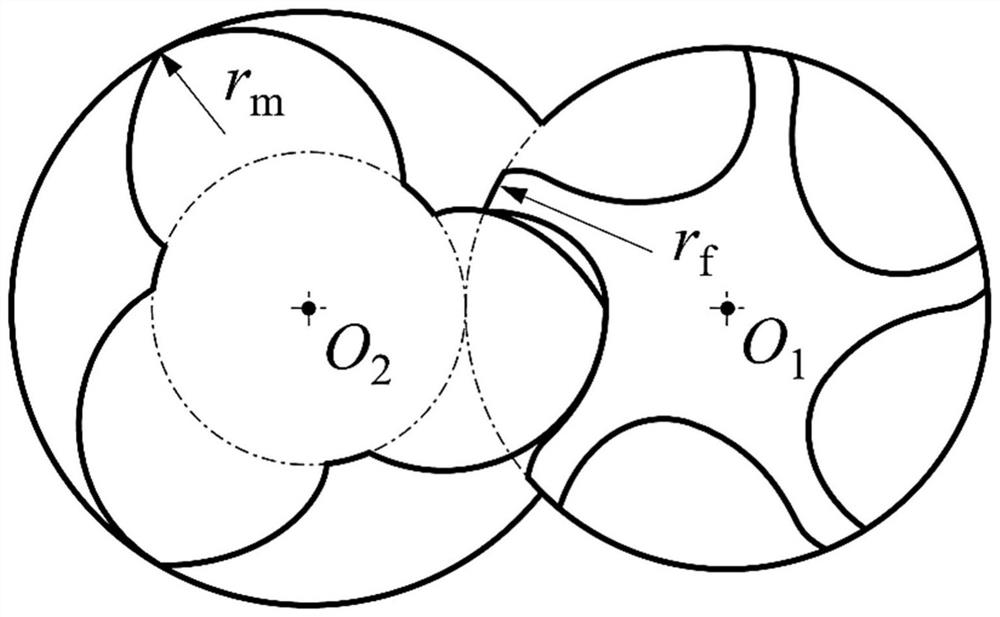

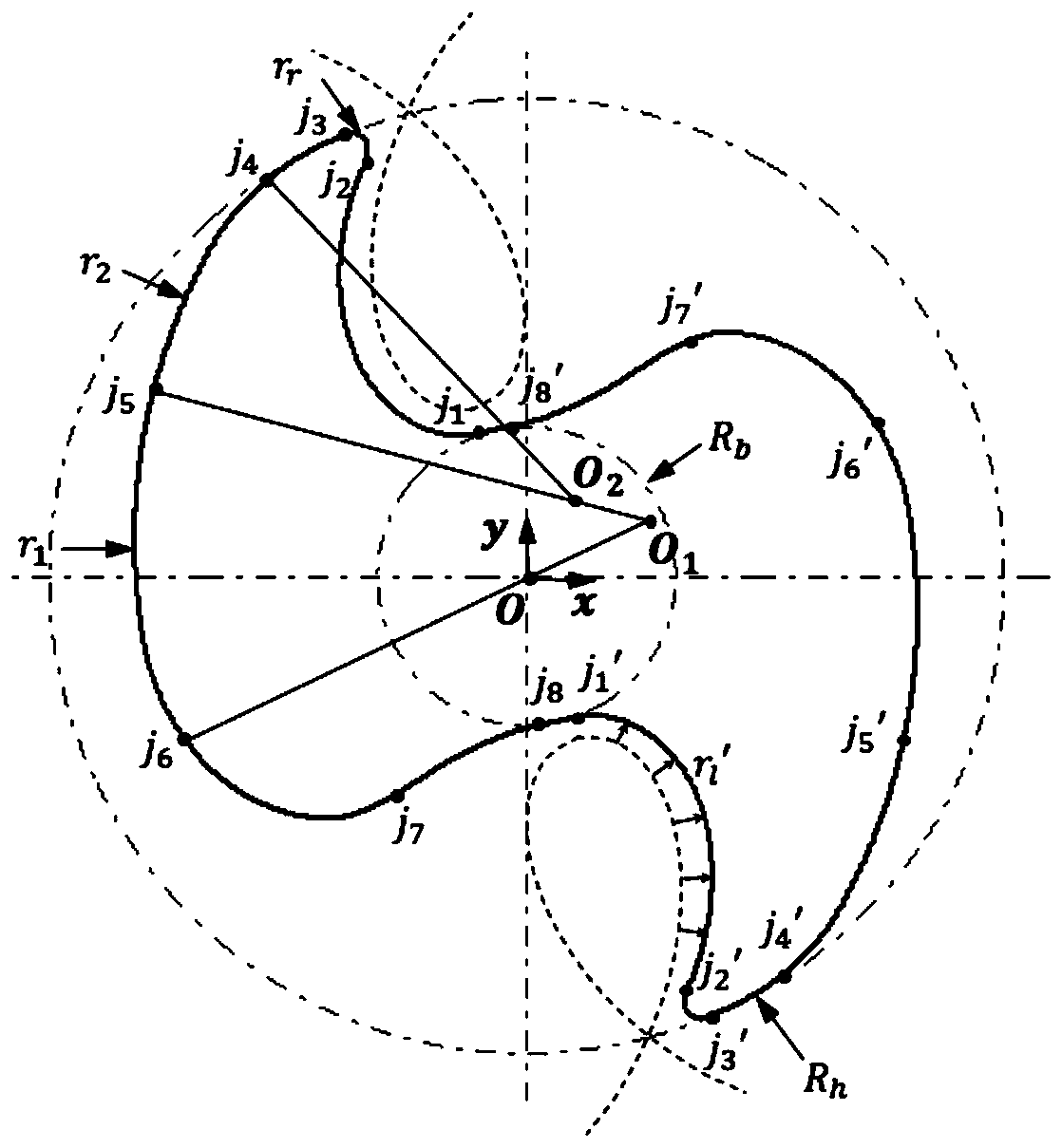

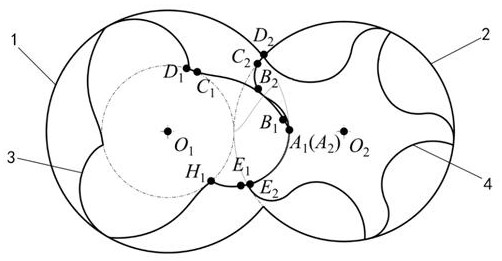

Double-screw vacuum pump rotor profile

ActiveCN107829931AEnsure consistencyImprove processing speedPump componentsRotary piston pumpsLine segmentEngineering

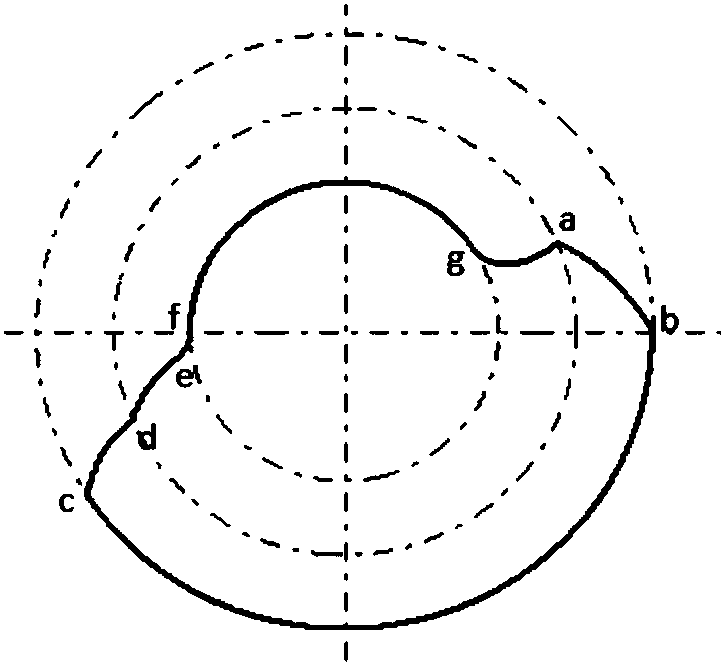

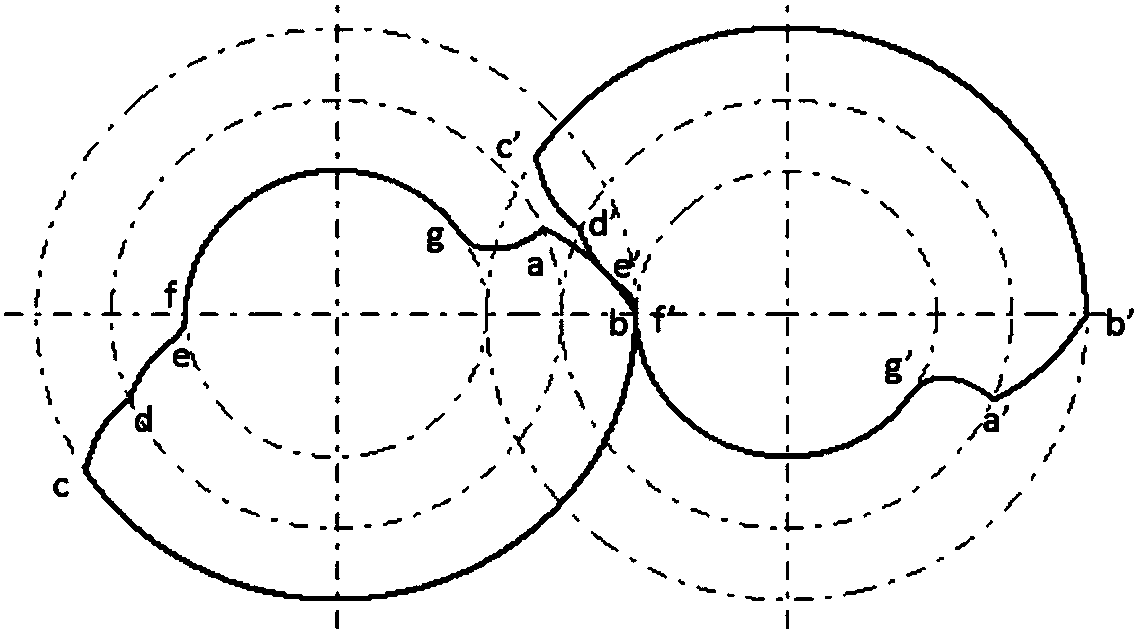

Disclosed is a double-screw vacuum pump rotor profile. One rotor comprises a first involute ab, an addendum circle arc action bc, a point engagement cycloid cd, a second involute de, a first point engagement epicycloid ef, a dedendum circle arc section fg and a second point engagement epicycloid ga which are sequentially connected in an end-to-end mode, and the other rotor has the same structure,wherein a point a is located on the pitch circle, during rotation, the point a is engaged with a cycloid section c'd', the involute ab is engaged with the involute d'e', a point b is engaged with an epicycloid section e'f', the addendum circle arc section bc is engaged with a dedendum circle arc section f'g', a point c is engaged with an epicycloid section g'a', the cycloid section cd is engaged with a point a', the involute de is engaged with an involute a'b', the epicycloid section ef is engaged with a point b', the dedendum circle arc section fg is engaged with the addendum circle arc section b'c', and the epicycloid section ga is engaged with a profile point c'. The structures of the two rotors are the same, and the machining cost is low.

Owner:NINGBO BAOSI ENERGY EQUIP

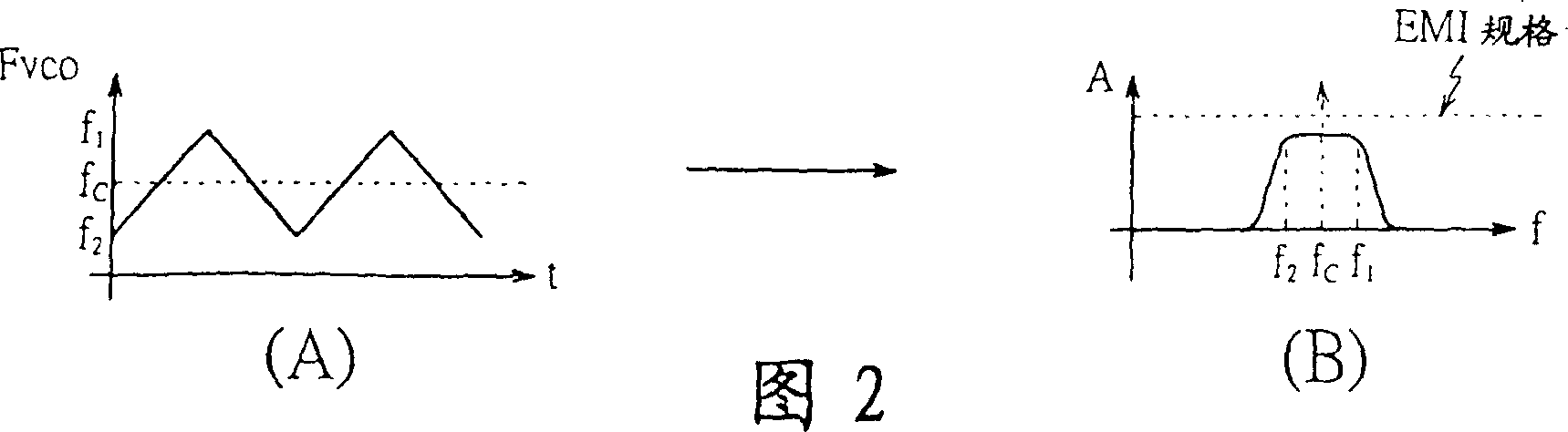

Spread spectrum phase locking circuit with adjustable spread spectrum range

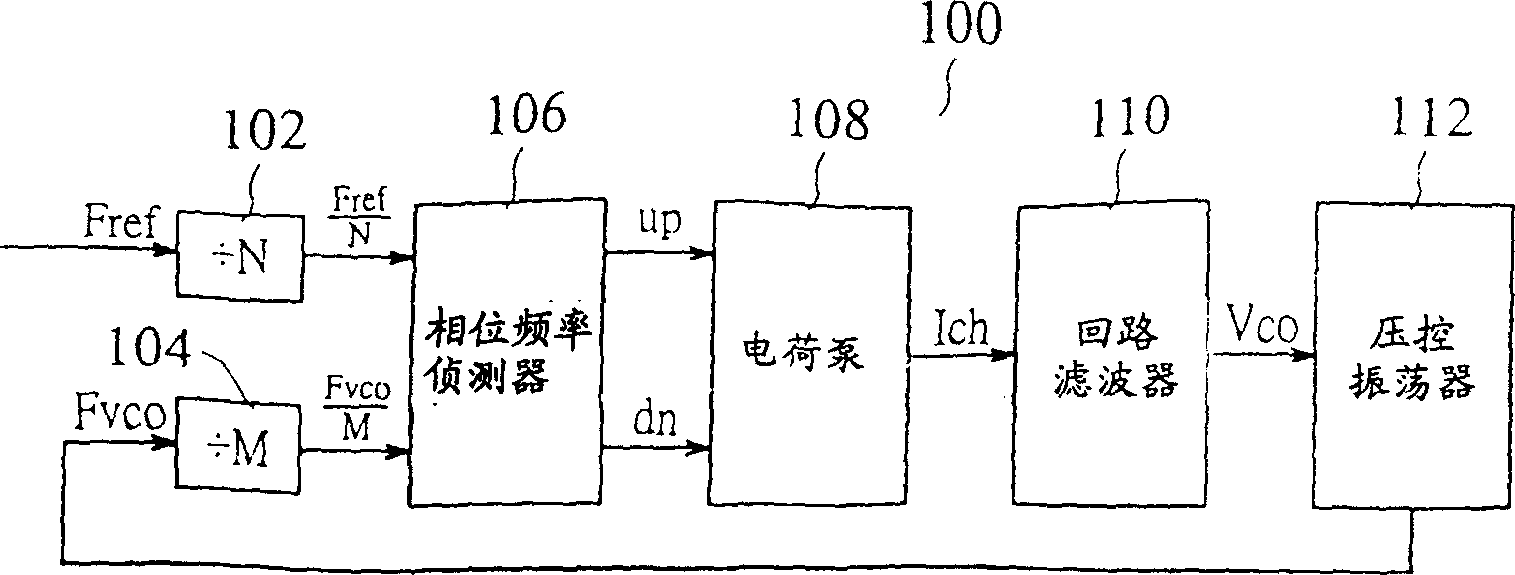

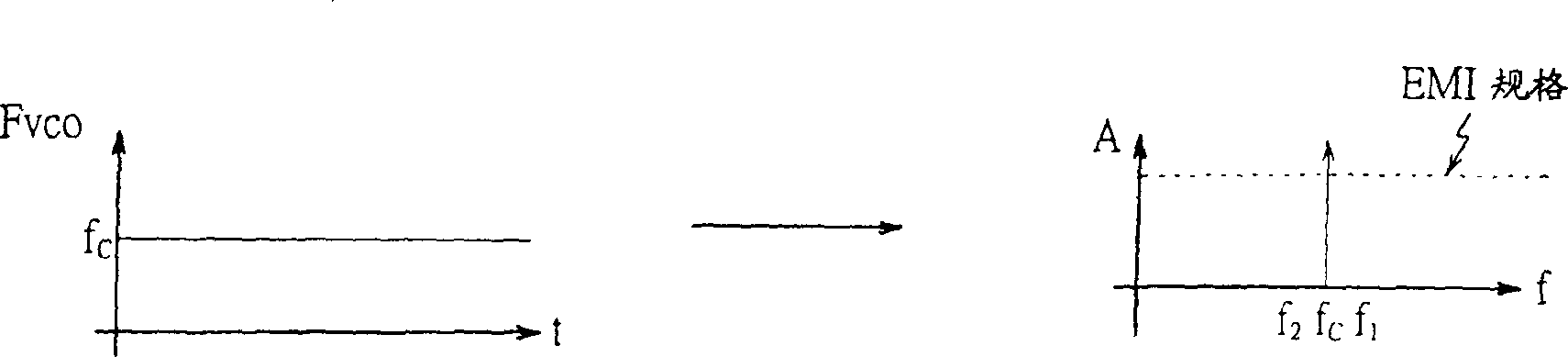

InactiveCN1288846CControl Spread Spectrum SizeNo surgePulse automatic controlLoop filterControl signal

A spread spectrum phase-locked loop includes a reference time pulse generator, a phase frequenct detector, a charge pump, a loop filter, a voltage variable module, a time sequence generation controller, a first and second voltage-controlled oscillators, the time sequence generation controller outputs periodical variance FM / AM control signal, and voltage variable module receives the voltage signal of loop filter, outputs the first voltage signal and outputs a second voltage signal according to the control signal of time sequence generation controller. The first voltage control oscillator receives the first voltage signal of the voltage variable module and outputs the feedback time sequence signal to phase frequency detector and the second receives the second voltage signal to output needed spread spectrum signal.

Owner:REALTEK SEMICON CORP

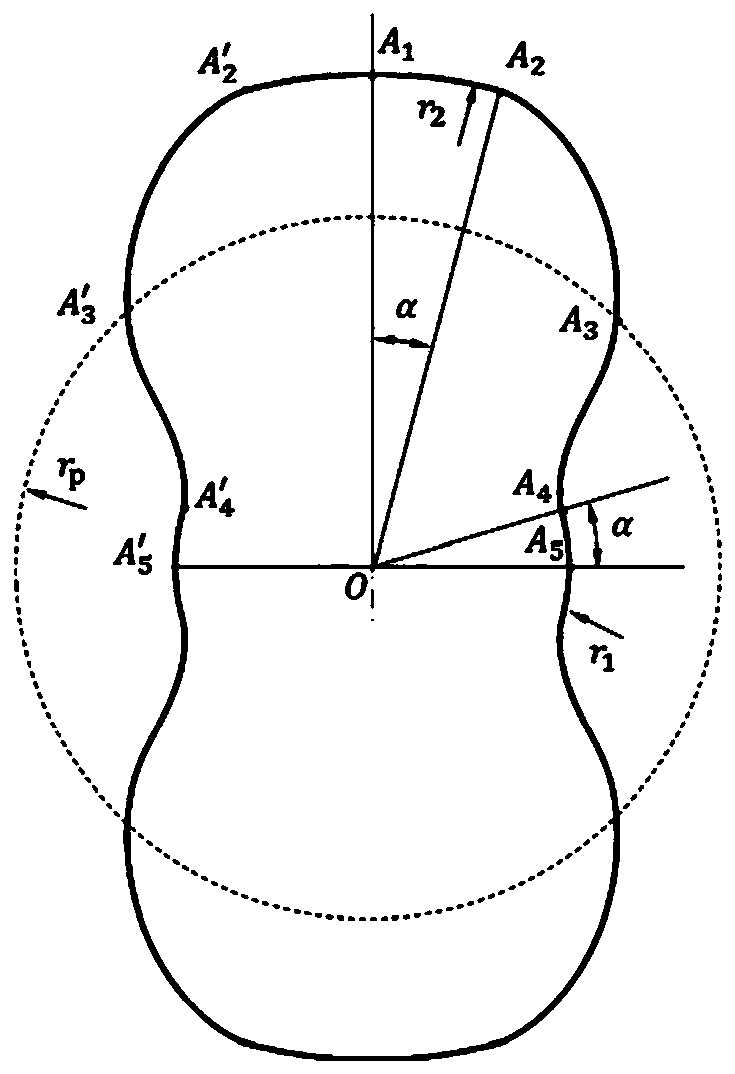

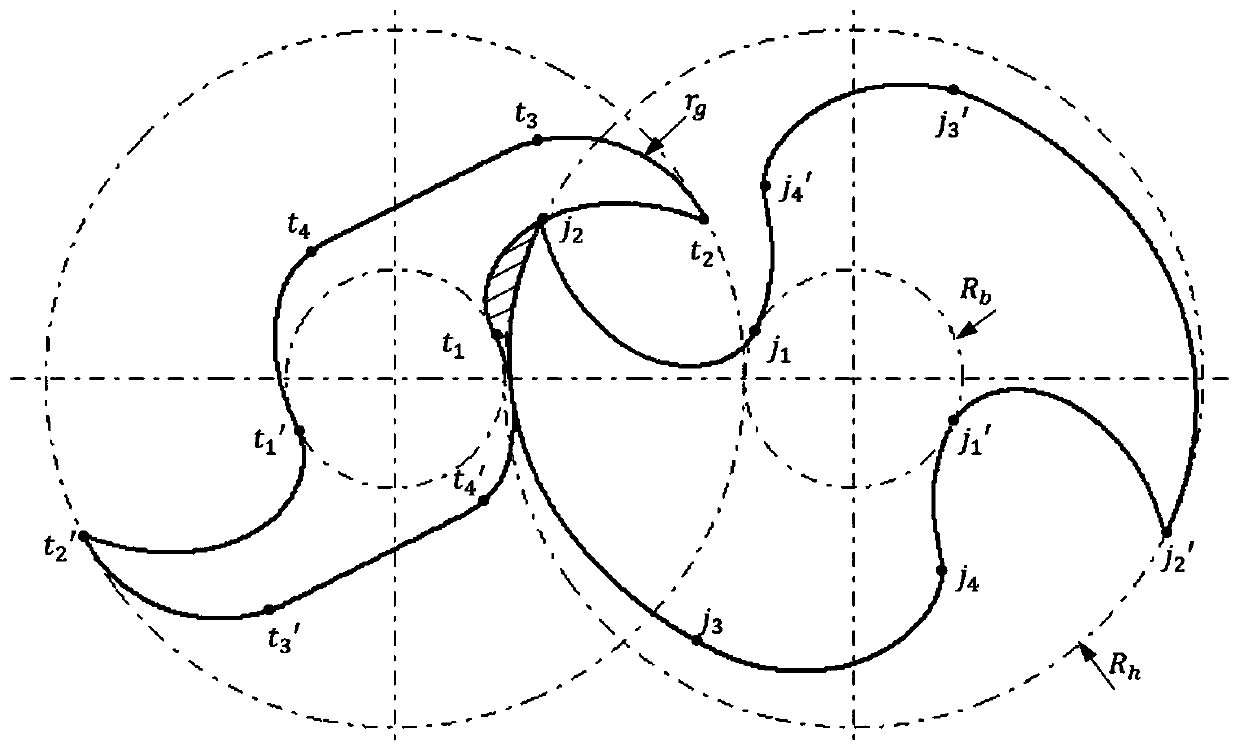

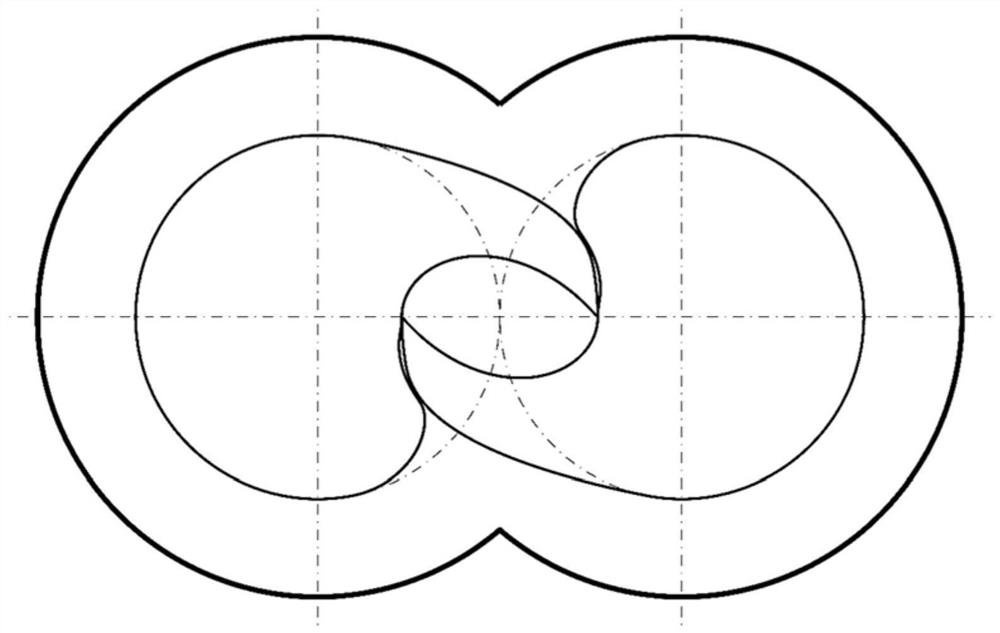

Whole ellipse and ellipse envelope type double-screw rotor, compressor and expansion machine

ActiveCN110685909AFlexible shape adjustmentImprove volumetric efficiencyPump componentsRotary piston pumpsRooted toothEngineering

The invention discloses a whole ellipse and ellipse envelope type double-screw rotor, a compressor and an expansion machine. The rotor comprises a male rotor and a female rotor capable of realizing mutual meshing during the rotating process; the tooth profile of the single tooth of a male rotor profile line is composed of a tooth root circular arc section, an ellipse envelope line segment, an ellipse arc segment, the ellipse arc segment and the ellipse envelope line segment sequentially connected end to end; the tooth profile of the single tooth of the male rotor profile line is composed of atooth tip circular arc segment, the ellipse arc segment, the ellipse envelope line segment, the ellipse envelope line segment and the ellipse segment sequentially connected end to end; the adjacent curve segments of the male rotor profile line and the female rotor profile line are continuous at the intersected point and are also continuous in slope; according to the teeth number of the male and female rotor profile lines, rotation is carried out to generate the tooth profile of the single tooth is generated, and the tooth profiles are sequentially connected end to end to generate a complete female and male rotor profile line. The rotor profile lines are composed of ellipses and envelope lines of the ellipses, cusps are eliminated, and according to the demand of the design working condition, the rotor shape is flexible and adjustable to improve the performance.

Owner:XI AN JIAOTONG UNIV

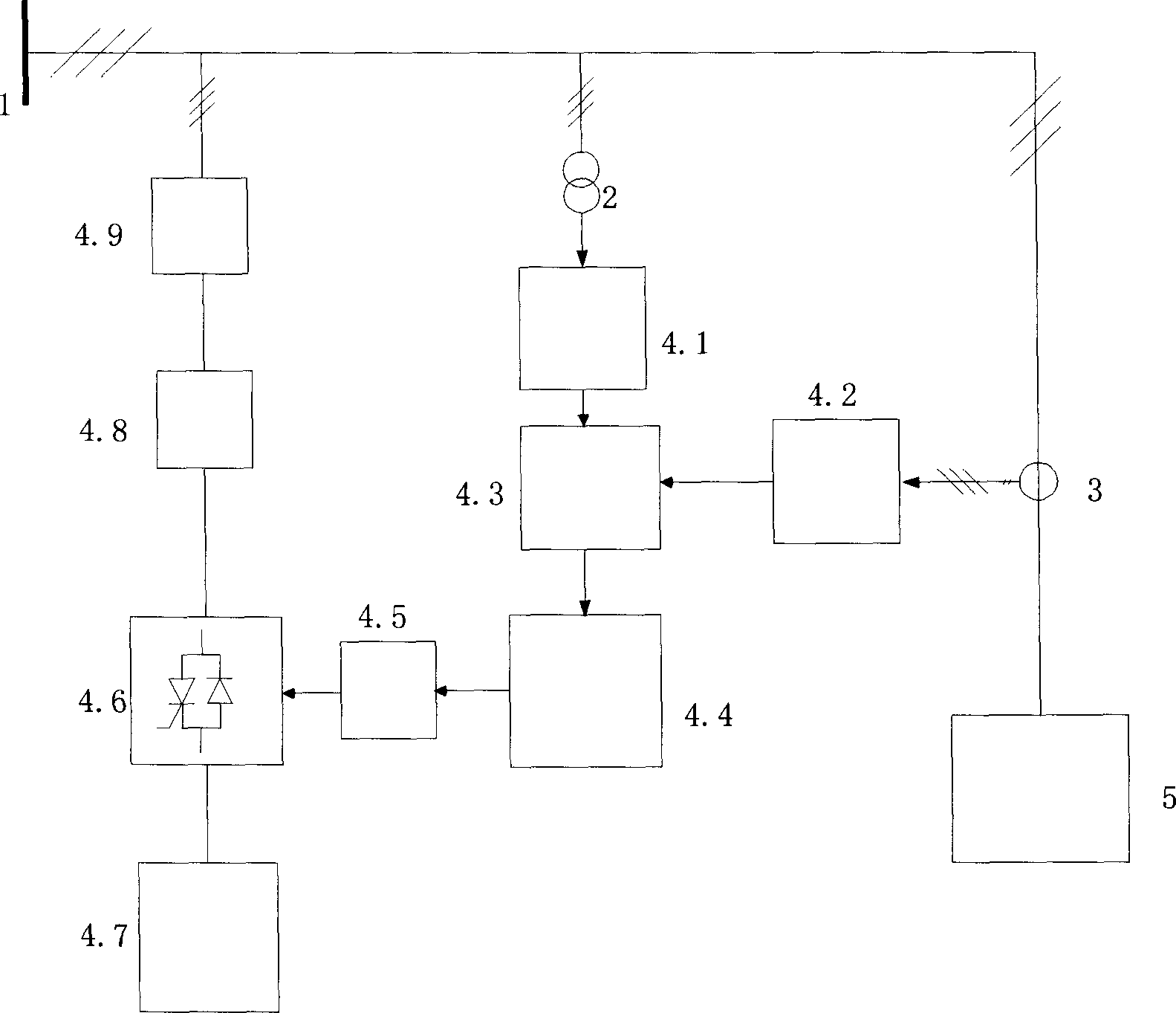

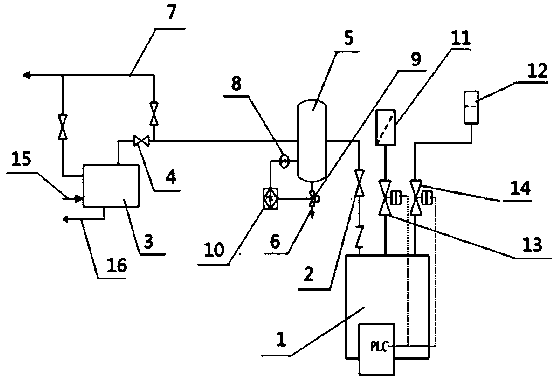

Protection control system of air compressor

PendingCN110821793ANo surgeReduce corrosionPositive displacement pump componentsPump controlLine tubingControl system

The invention relates to a protection control system of an air compressor. The protection control system of the air compressor comprises the air compressor; an air compressor outlet valve is arrangedon an outlet pipeline at the top end of the air compressor; the air compressor outlet valve is connected to a freezing dryer through a pipeline; a freezing dryer inlet valve is arranged on the pipeline and near the position of the freezing dryer; a buffer tank is arranged on the pipeline between the air compressor outlet valve and the freezing dryer inlet valve and near the position of the air compressor outlet valve; a water discharging pipeline is arranged at the bottom of the buffer tank; a leading-out pipeline is arranged on the pipeline between the freezing dryer inlet valve and the buffer tank and near the freezing dryer inlet valve; the leading-out pipeline is connected to an industrial air pipe network; an outlet pipeline of the freezing dryer is connected to the leading-out pipeline, and the outlet pipeline of the freezing dryer and the leading-out pipeline are jointly connected to the industrial air pipe network; the protection control system of the air compressor overcomes the defect of no buffer device when the compressed gas in the original air compressor system enters the industrial air pipe network through the freezing dryer; and the buffer tank is arranged at the compressor outlet, so the water of the gas can be discharged out of the buffer tank and the corrosion phenomenon of the outlet pipeline is reduced.

Owner:DALIAN FUJIA DAHUA GASOLINEEUM CHEM

Roots pump rotor and Roots pump

ActiveCN110685906BEliminates closed volume problemsFew independent parametersPump componentsRotary piston pumpsRooted toothMechanical engineering

The invention discloses a rotor of a roots pump and the roots pump. The basic forming curved section A1A2A3A4A5 of the molded line of the rotor is composed of a tooth crest arc section, a pseudo polynomial curved section, a conjugate curved section of a pseudo polynomial curve and a tooth root arc section, all of which are sequentially connected end to end. The pseudo polynomial curved section A2A3 is tangent to the tooth crest arc section A1AA1. The basic forming curved section A1A2A3A4A5 and a curved section A1A'2A'3A'4A'5A'6 symmetric with the basic forming curved section A1A2A3A4A5 are combined into a tooth molded line A'6A'5A'4A'3A'2A1A2A3A4A5 of a tooth. The tooth molded line A'6A'5A'4A'3A'2A1A2A3A4A5 is repeated according to the number n of teeth of the molded line of the rotor of the roots pump to generate n tooth molded lines, and the tooth molded lines are sequentially connected end to end to generate a complete rotor molded line. The two rotor molded lines are the same and can be engaged in the rotating process. By means of the rotor, part of points of original molded lines are eliminated, the design parameter space of the molded line of the rotor of the roots pump is expanded, and the performance of the roots pump is improved.

Owner:XI AN JIAOTONG UNIV

Narrow flow channel turbine

The invention provides a narrow flow channel turbine. The narrow flow channel turbine comprises a shell and a turbine rotor, wherein a sealing retaining wall is arranged on the circumference of the turbine rotor, and small holes are distributed in the sealing retaining wall, so that fluid sucked by the turbine rotor at high rotating speed is sealed in the rotor; and the fluid is compressed and filled in the radial direction under the action of centrifugal force, cavitation or surge is avoided, and the fluid is sprayed into the shell only through the small holes, so that high lift under small flow is achieved. The efficiency of a centrifugal pump can be improved under the working condition of the small flow and the high lift, and meanwhile, the cavitation is not generated at high speed so that the centrifugal compressor can reach the high pressure ratio at the small flow, and meanwhile, the surge is not generated at the high speed; and the application range of an impeller type fluid conveying mechanism is widened, and energy consumption is reduced.

Owner:时剑

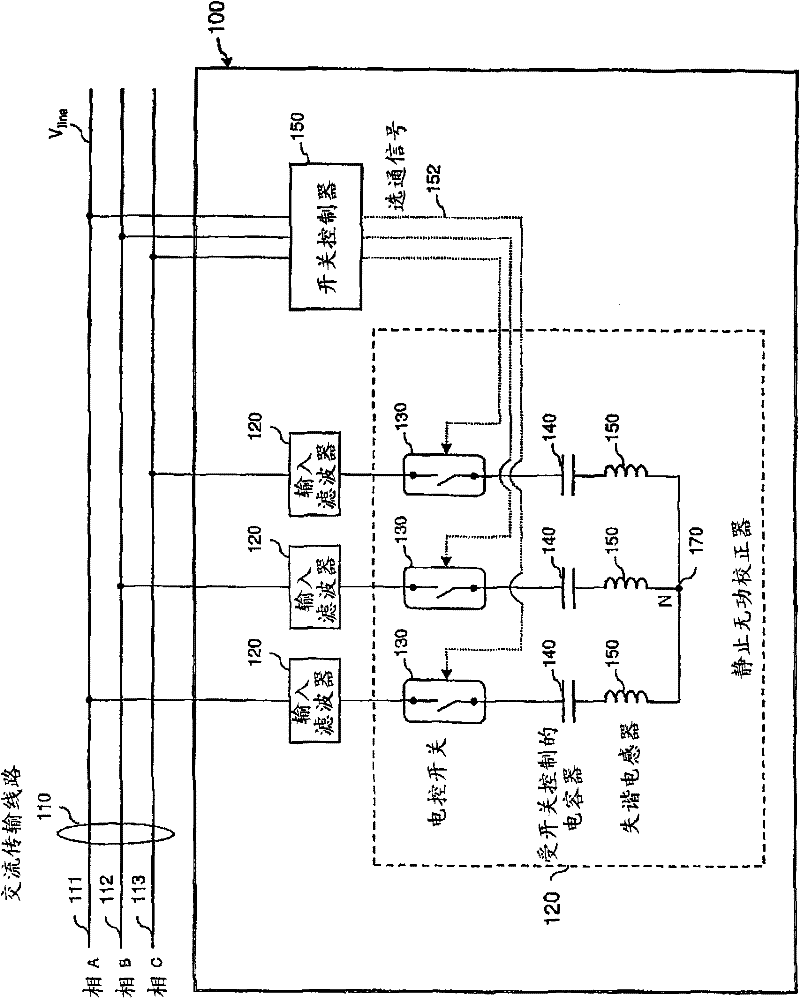

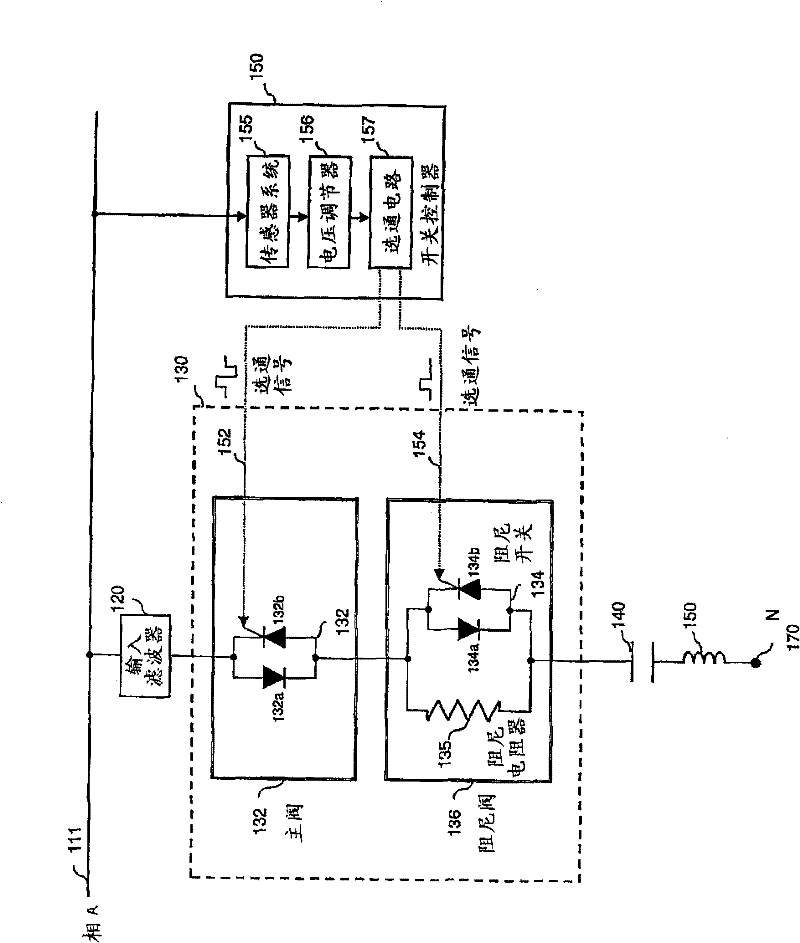

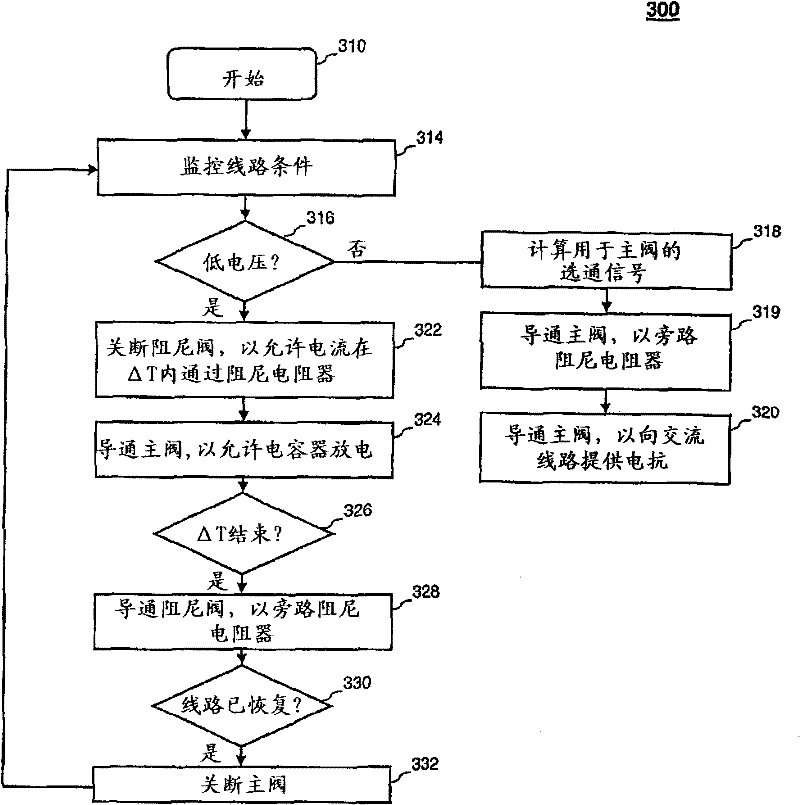

Static var corrector

InactiveCN101621203BAdjust and correct power factorImprove performanceFlexible AC transmissionReactive power adjustment/elimination/compensationPower compensationControl theory

Disclosed is a static VAR corrector. A system for providing reactive power compensation to a utility power network includes a switch coupled to the utility power network, and a capacitor coupled with the switch for providing a controlled amount of reactive current based on conditions of the utility power network. The system also includes a switchable power dissipation device coupled in series to the capacitor and configured to provide a preselected amount of impedance to the reactive current for a predetermined duration when a line voltage on the utility power network drops below a threshold.

Owner:AMERICAN SUPERCONDUCTOR

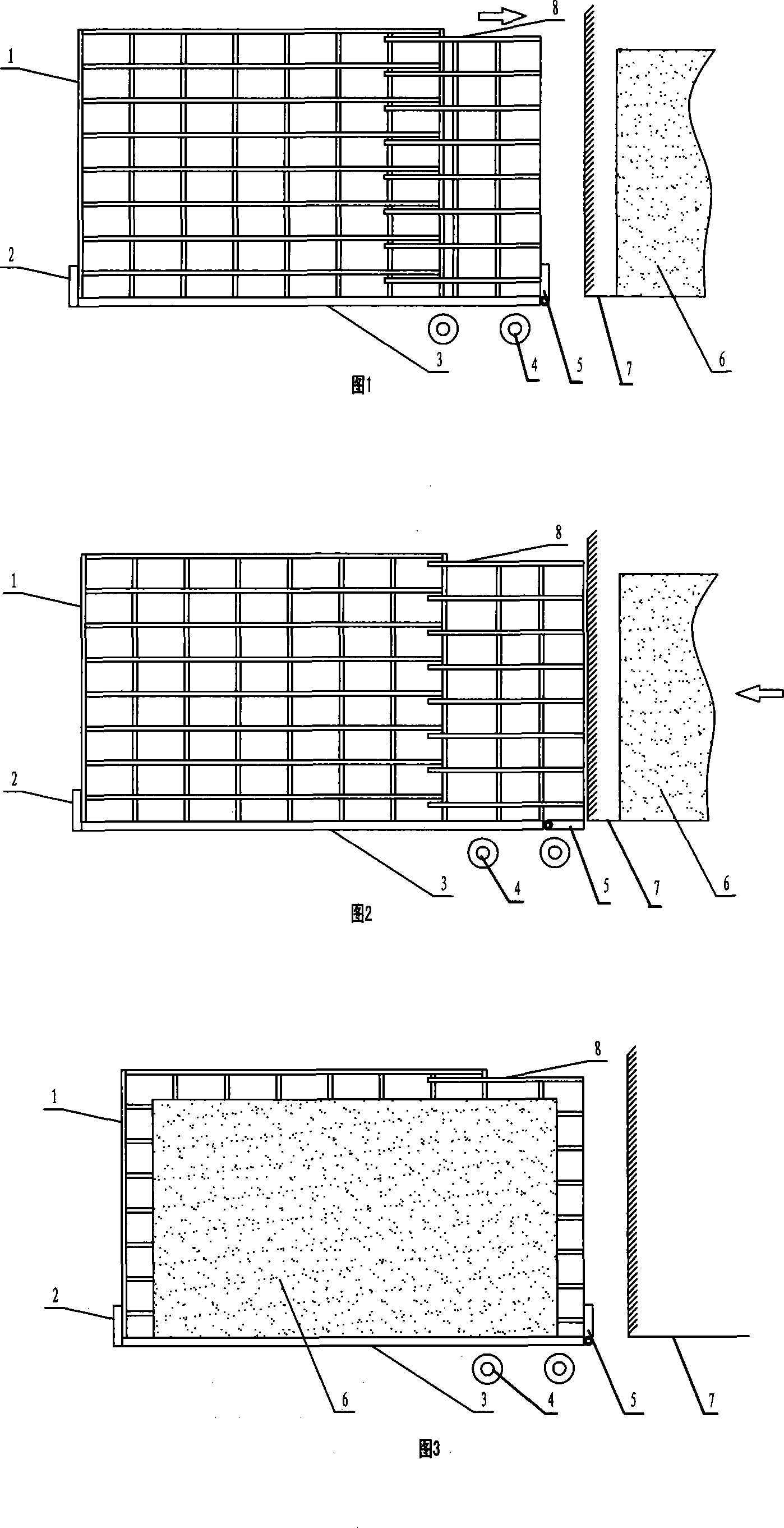

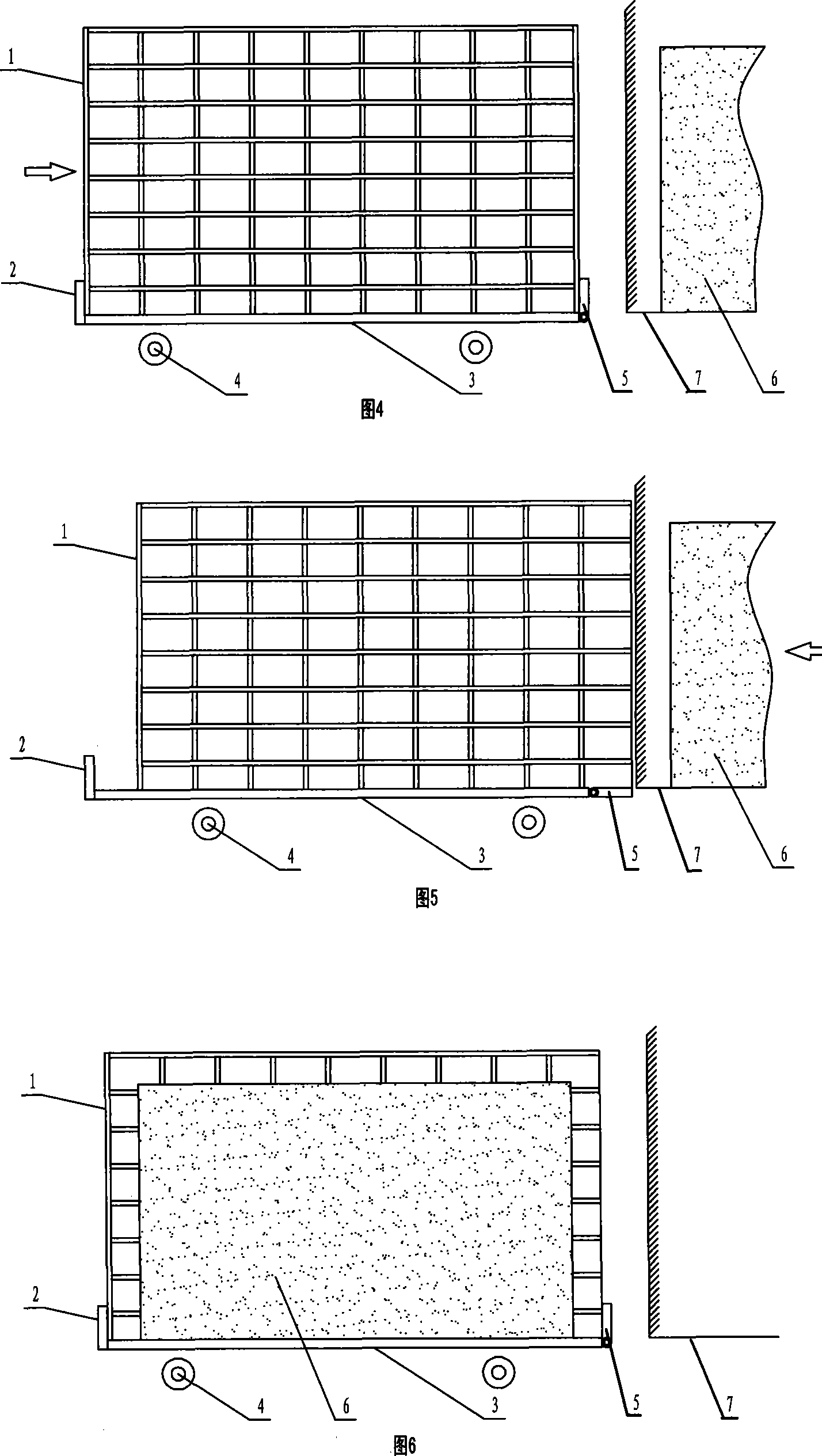

Upright coke-oven transition purification receiving and extinguishing technique and equipment

The invention provides a vertical device which has the technology of coke receiving and quenching by translation and purification of a coke oven. The equipment consists of a horizontal car for coke receiving and a drum for coke quenching. The horizontal car for coke receiving consists of systems of coke receiving and coke discharging while the drum for coke quenching consists of a tower body, a water pump station, and a spray system of three directions. The invention is characterized in that the system of coke receiving consists of a storehouse for coke receiving and a horizontal moving device. The storehouse for coke receiving has the structure of a box with grids, and the structure consists of two-side walls, a motherboard, and plates on the two sides. The motherboard is not integrated with the two-side walls, and a gradient is in front and back. The plate of the storehouse for coke receiving which is close to the coke oven is rotatable and is not integrated with the two-side walls.The invention can greatly reduce or avoid the dust pollution resulted from the process of the coking discharging in the coking plant and is applied to the coking discharging system which has a new coke oven as well as the reconstruction of a old coking discharging system. The reconstruction expense is low and the environment protection benefit is distinct.

Owner:贺建红 +1

A design method of a variable-pitch internal meshing screw rotor and a twin-screw compressor rotor

ActiveCN113153741BImprove work performanceImprove volumetric efficiencyRotary piston pumpsDesign optimisation/simulationClassical mechanicsEngineering

Owner:XI AN JIAOTONG UNIV

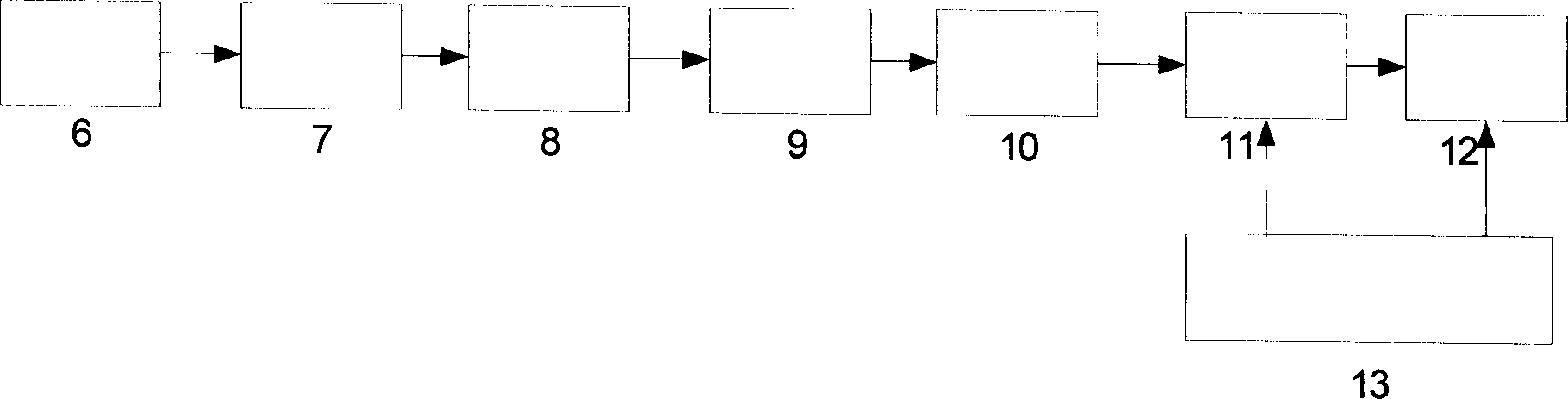

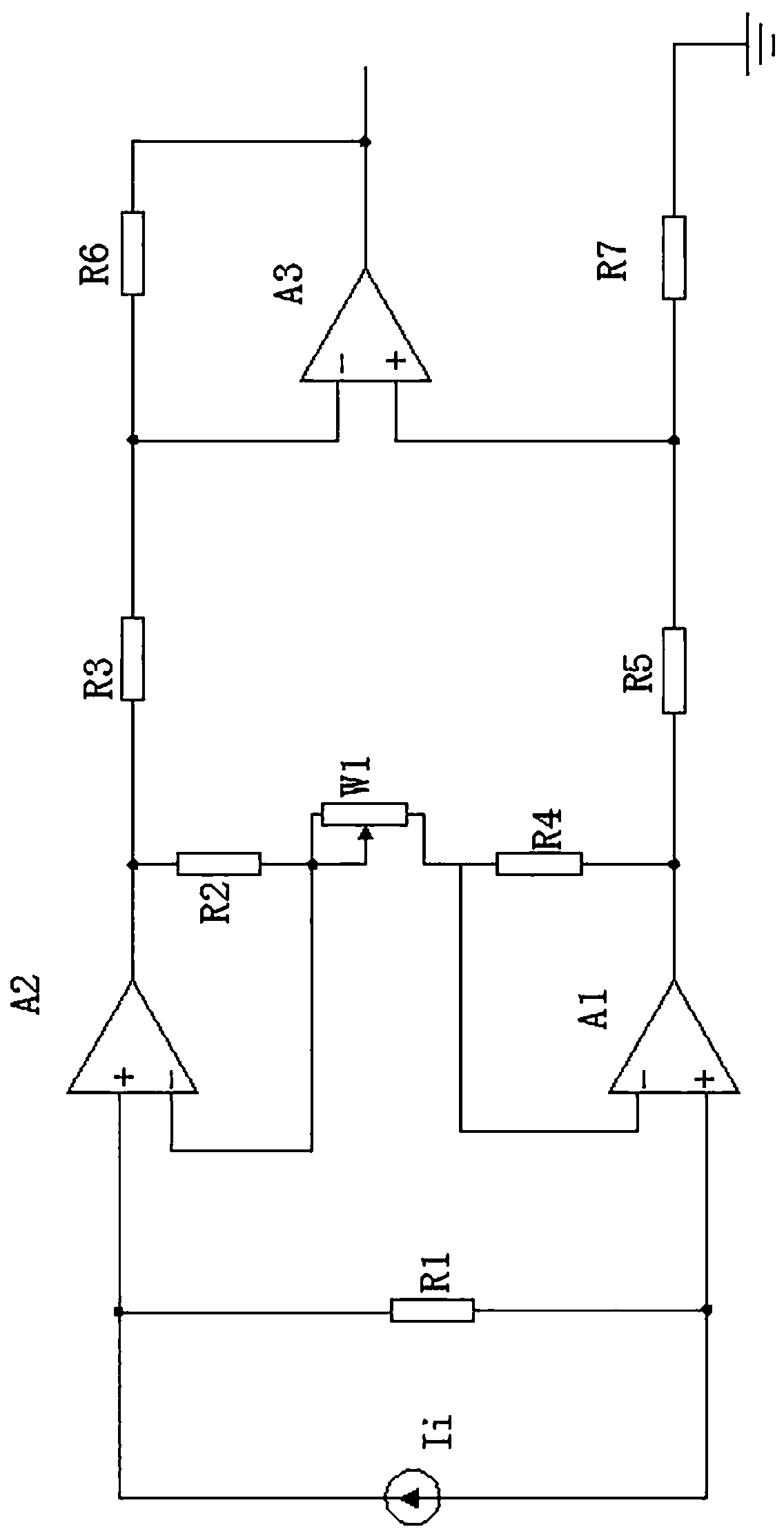

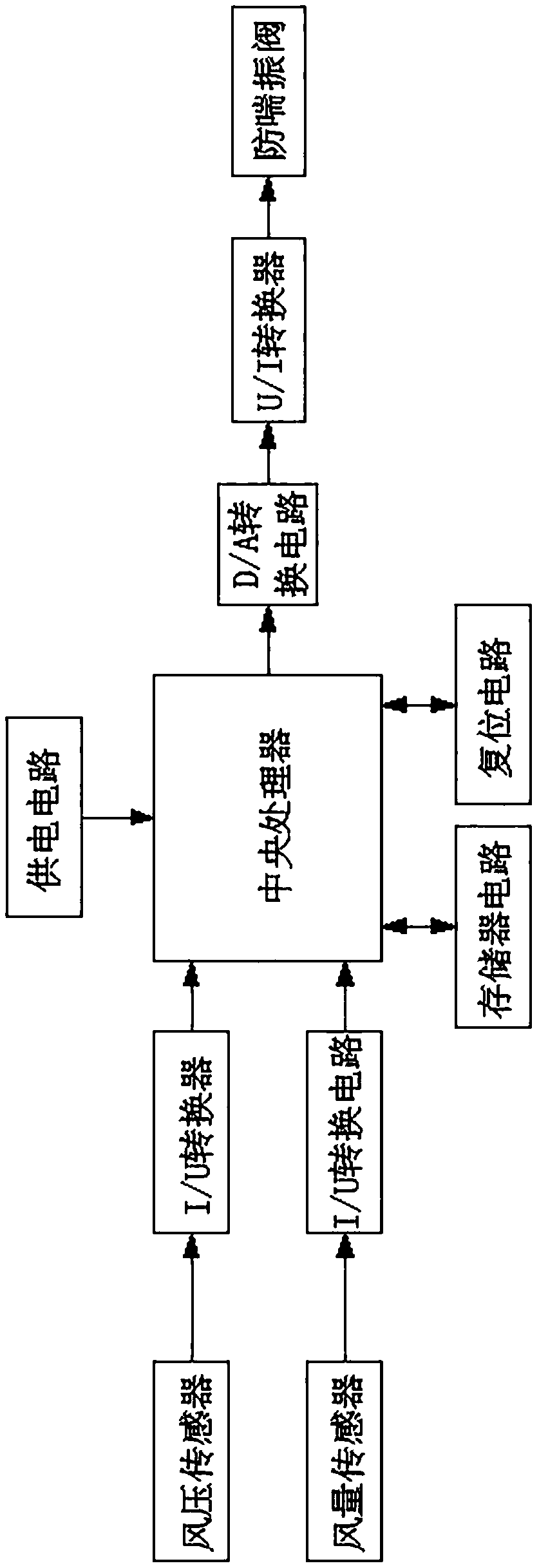

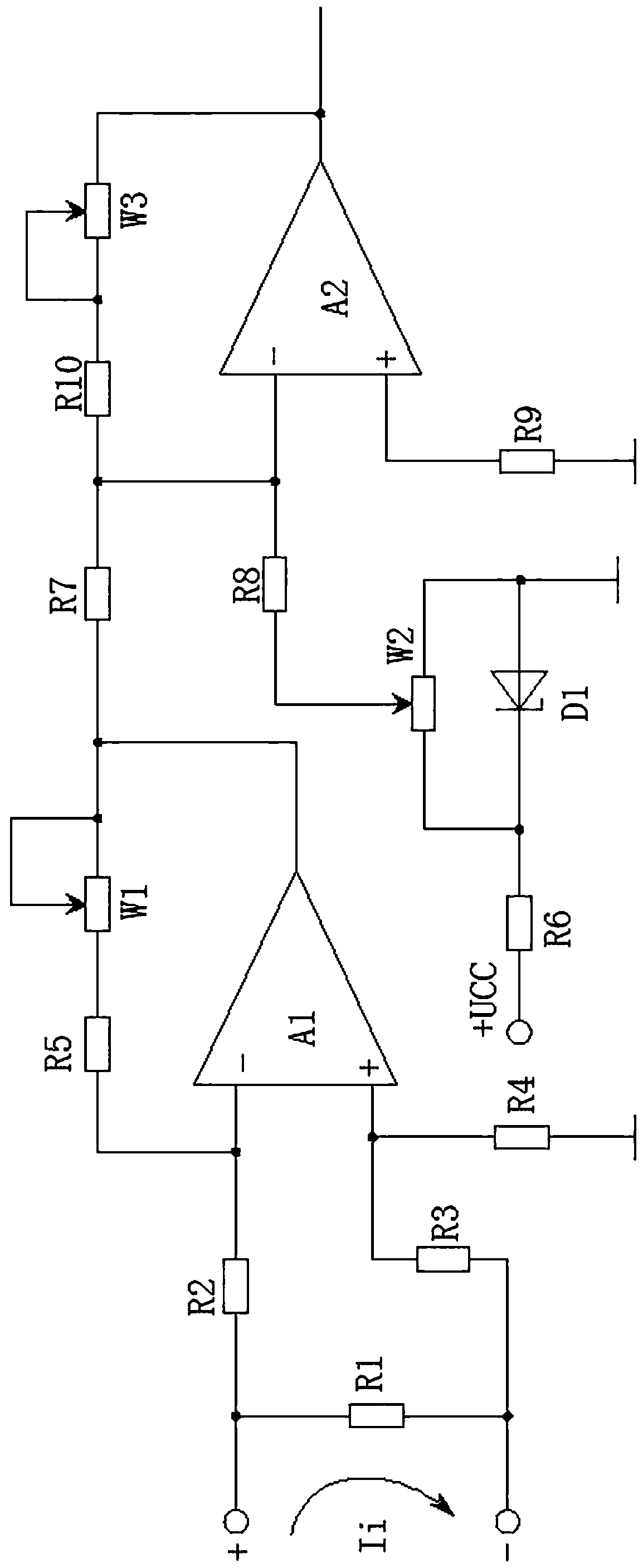

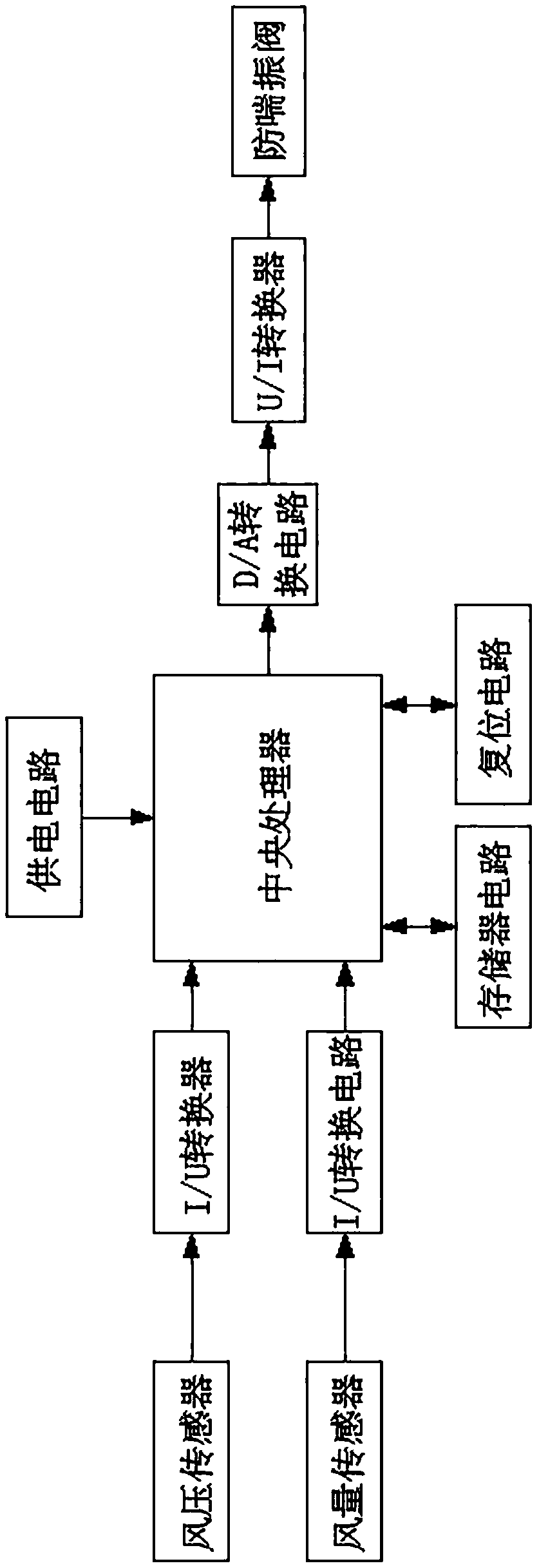

Concrete mixing system based on integrated operational amplifier processing technology design

InactiveCN108089505AAffect normal operationSecure transmissionProgramme controlComputer controlElectrical resistance and conductanceReliable transmission

The invention discloses a concrete mixing system based on an integrated operational amplifier processing technology design. The system comprises a central processing unit, a wind pressure circuit, anair quantity circuit and a surge-preventing circuit; an air volume sensor and an I / U conversion circuit are arranged in the air quantity circuit; a preceding stage scaling operation amplification circuit and a post amplification circuit which are connected with each other are arranged in the I / U conversion circuit, an operational amplifier A3, a resistor R3, a resistor R5, a resistor R6 and a resistor R7 are arranged in the post amplification circuit, input ends of the operational amplifier A3 are connected with an output end of the preceding stage scaling operation amplification circuit through the resistor R3 and the resistor R5 respectively, an out put end of the operational amplifier A3 is connected with a first input end of the operational amplifier A3 through the resistor R6, and a second input end of the operational amplifier A3 is connected with the ground through the resistor R7. According to the system, a flowing pressure conversion circuit is cooperatively formed by the scaling operation amplification circuit and the post amplification circuit to achieve conversion from an electric current signal to a voltage signal, so that collected air volume information is safely andreliably transmitted to the central processing unit.

Owner:成都优诺美企业管理咨询有限公司

A twin-screw vacuum pump rotor profile

ActiveCN107829931BGuaranteed tightnessEnsure consistencyPump componentsRotary piston pumpsVacuum pumpEpicycloid

Disclosed is a double-screw vacuum pump rotor profile. One rotor comprises a first involute ab, an addendum circle arc action bc, a point engagement cycloid cd, a second involute de, a first point engagement epicycloid ef, a dedendum circle arc section fg and a second point engagement epicycloid ga which are sequentially connected in an end-to-end mode, and the other rotor has the same structure,wherein a point a is located on the pitch circle, during rotation, the point a is engaged with a cycloid section c'd', the involute ab is engaged with the involute d'e', a point b is engaged with an epicycloid section e'f', the addendum circle arc section bc is engaged with a dedendum circle arc section f'g', a point c is engaged with an epicycloid section g'a', the cycloid section cd is engaged with a point a', the involute de is engaged with an involute a'b', the epicycloid section ef is engaged with a point b', the dedendum circle arc section fg is engaged with the addendum circle arc section b'c', and the epicycloid section ga is engaged with a profile point c'. The structures of the two rotors are the same, and the machining cost is low.

Owner:NINGBO BAOSI ENERGY EQUIP

A modified line twin-screw rotor and its design method

ActiveCN113153742BIncrease the areaImprove efficiencyGeometric CADInternal combustion piston enginesEngineeringAxial distance

A modified-line twin-screw rotor and a design method thereof. The rotor structure includes a male-female screw rotor whose outer contours are both conical structures. The guide helix of the male-female screw rotor adopts a variable pitch method, and the guide helix is divided into two parts. When the rotation angle is less than the set value, a larger rotor pitch is used. When the rotor rotation angle is greater than the set value, a smaller rotor pitch is used to realize the increase of the rotor axial exhaust port; with the increase of the rotor axial distance , the tooth tip radius of the yin and yang screw rotors decreases linearly, forming the conical angle of the yin and yang screw rotors; the volume of the working chamber of the twin-screw rotor decreases with the opening angle of the exhaust orifice, so as to realize that under the same internal volume ratio, the opening angle of the exhaust orifice decreases. Open earlier to increase the area of the exhaust port. The invention realizes the effective expansion of the exhaust port area of the screw compressor, which is beneficial to reduce the resistance loss at the exhaust and reduce the pressure pulsation at the exhaust side, thereby achieving the effects of improving the efficiency of the screw rotor and reducing the noise.

Owner:XI AN JIAOTONG UNIV

A double-headed claw pump rotor and its profile

ActiveCN108930650BAvoid severe wear and tearIncrease design parameter spaceRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

Owner:宝风压缩机科技(浙江)有限公司

Frequency conversion centrifuge and control method of hot gas bypass valve therein

ActiveCN108131871BImprove reliabilityNo surgeMechanical apparatusFluid circulation arrangementFrequency conversionMechanical engineering

The invention discloses a frequency conversion centrifuge and a method for controlling a hot gas bypass valve therein. The frequency conversion centrifuge includes a compressor, and the hot gas bypass valve is arranged between a suction pipe and an exhaust pipe of the compressor. The method includes the following steps: when the frequency conversion centrifuge is in the running state, the guide vane opening, the operating pressure ratio and the upper limit of the operating frequency of the compressor are obtained, wherein the operating pressure ratio is the absolute pressure of the exhaust gas of the compressor and the absolute pressure of the suction air. Ratio; calculate the critical frequency of the frequency conversion centrifuge according to the opening of the guide vane and the operating pressure ratio; control the opening of the hot gas bypass valve according to the critical frequency and the upper limit of the operating frequency. By controlling the opening of the hot gas bypass valve, the method can make the frequency conversion centrifuge run safely with a small load under high ambient temperature and high pressure ratio, and at the same time, there will be no compressor surge phenomenon under small load operation , Improve the reliability of frequency conversion centrifuge operation.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

Boiler energy-saving blowing-out system and method

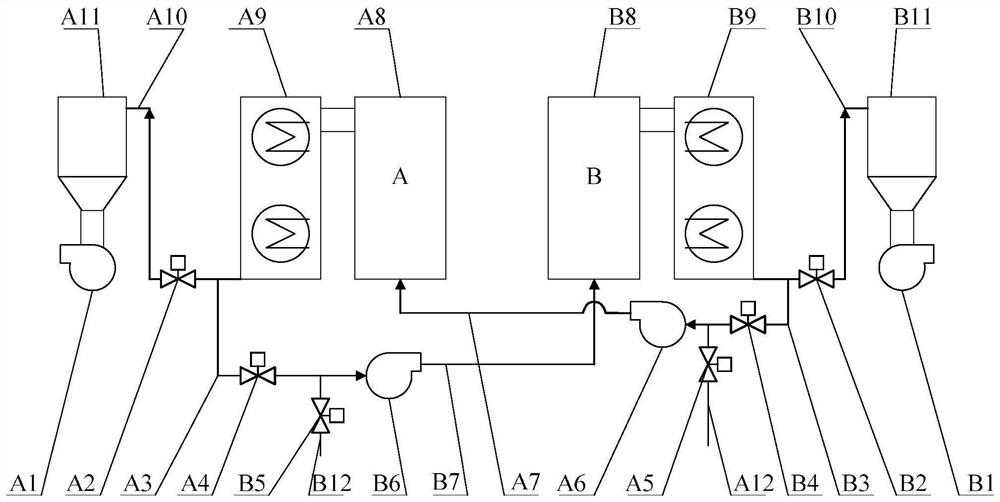

PendingCN111895440ASolve the problem of non-compliance with emission standardsSave electricityBlast-producing apparatusChimneysThermodynamicsCombustion

The invention discloses a boiler energy-saving blowing-out system and method. The system comprises a boiler A and a boiler B. Two channels are arranged at an air inlet of an air blower of the boiler A, one channel communicates with an inlet flue of a flue gas cleaning facility of the boiler B through a bypass flue of the boiler B, and the other channel communicates with the atmosphere through an inlet air duct of the air blower of the boiler A. Two channels are arranged at an air inlet of an air blower of the boiler B, one channel communicates with an inlet flue of a flue gas cleaning facilityof the boiler A through a bypass flue of the boiler A, and the other channel communicates with the atmosphere through an inlet air duct of the air blower of the boiler B. When one boiler blows out, discharged flue gas passes through the other boiler, is subjected to dust removal through another boiler operating normally and then is discharged. The problem that flue gas emission does not reach thestandard after blowing-out is solved. After one boiler blows out, an induced draft fan does not operate in a stalling zone of the induced draft fan without surging and harm, the safety is improved, and the service life is prolonged. Hot air going into the boiler blowing out is introduced into the other boiler operating normally for combustion, and utilization of waste heat is realized.

Owner:庆元琦丰新能源有限公司

A kind of screw vacuum pump rotor and screw vacuum pump

ActiveCN110645172BIncrease design parameter spaceImprove volumetric efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringVacuum pump

Owner:XI AN JIAOTONG UNIV

Variable-line double-screw rotor structure

ActiveCN113530819AReduce sizeReduce leakageInternal combustion piston enginesRotary piston pumpsEngineeringMechanical engineering

The invention provides a variable-line double-screw rotor structure. The variable-line double-screw rotor structure comprises a male rotor and a female rotor, the male rotor is provided with three teeth, the female rotor is provided with five teeth, and a molded line of the male rotor comprises an arc section D1C1, an arc envelope line section C1B1, an arc section B1A1, an arc section A1E1 and a point meshing cycloid section E1H1 which are connected in sequence; a molded line of the female rotor comprises an arc section D2C2, an arc section C2B2, an arc envelope section B2A2 and an arc envelope section A2E2 which are connected in sequence; the radius of the arc section B1A1 is rAB, the radius of the arc section C2B2 is rBC, and the values of the rAB and the rBC are linearly increased along with the increase of the axial position of the rotor from the air suction side to the air exhaust side. The defects in the prior art are overcome, the sizes of leakage triangles on the air suction side and the air exhaust side are reasonably configured by controlling the sizes of the leakage triangles on the air suction side and the air exhaust side of the double-screw rotor structure, the effects of reducing air exhaust pressure pulsation and reducing leakage on the air suction side and the air exhaust side are achieved, the thermodynamic efficiency of the rotor is improved, and the operation noise of the rotors is reduced.

Owner:爱景节能科技(上海)有限公司 +1

Current-to-voltage conversion circuit applied to commercial concrete production management system

InactiveCN108111137AHigh efficiency in flow pressure conversionImprove efficiencyAmplifier combinationsPump controlElectrical resistance and conductanceAir volume

The invention discloses a current-to-voltage conversion circuit applied to a commercial concrete production management system. The current-to-voltage conversion circuit applied to the commercial concrete production management system is provided with a central processing unit, an air pressure circuit, an air volume circuit and an anti-surge circuit; an air pressure sensor and an I / U converter are arranged in the air pressure circuit; the I / U converter comprises a front-stage current-to-voltage conversion circuit and a rear-stage current-to-voltage conversion circuit, which are connected with each other; a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, a potentiometer W1 and an integrated operational amplifier A1 are arranged in the front-stage current-to-voltage conversion circuit; the resistor R1 is connected with the input end of the integrated operational amplifier A1 through the resistor R2 and the resistor R3 separately; one input end of the integrated operational amplifier A1 is connected with the output end of the integrated operational amplifier A1 through the resistor R5 and the potentiometer W1, which are mutually connected in series; another input end of the integrated operational amplifier A1 is grounded through the resistor R4; the output end of the integrated operational amplifier A1 is connected with the input end of the rear-stage current-to-voltage conversion circuit; and conversion from current to voltage is carried out by utilization of the I / U converter, which is composed of two-stage current-to-voltage conversion circuits.

Owner:成都优诺美企业管理咨询有限公司

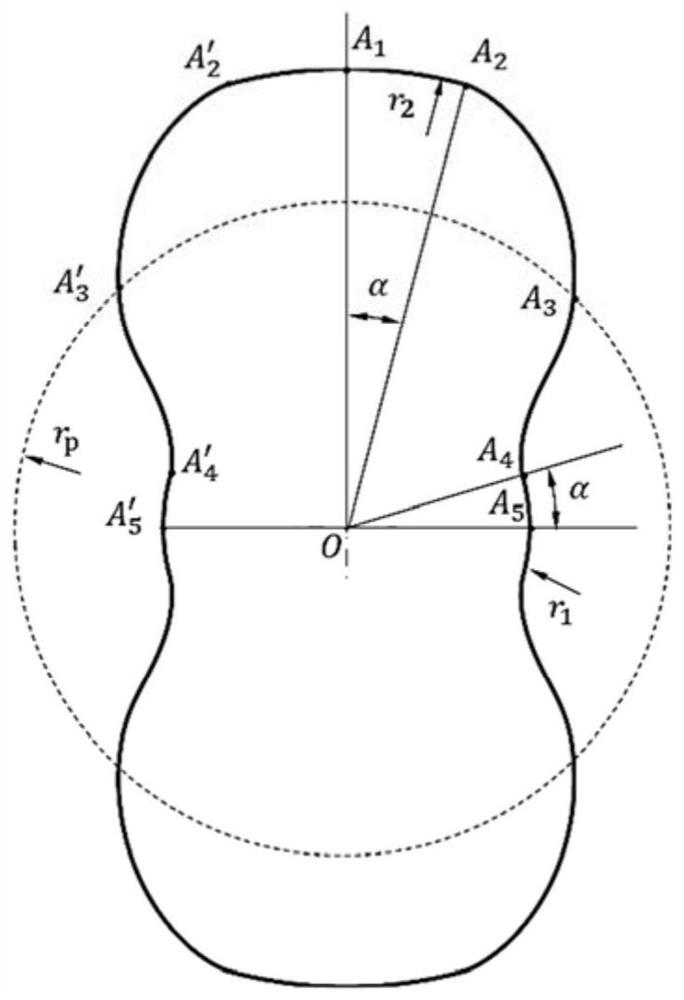

Claw pump rotor and claw pump

ActiveCN110762011BIncrease design parameter spaceImprove volumetric efficiencyRotary piston pumpsRotary piston liquid enginesEpicycloidVolumetric efficiency

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com