Variable-line double-screw rotor and design method thereof

A twin-screw and rotor technology, applied in design optimization/simulation, mechanical equipment, rotary piston pumps, etc., can solve problems such as high operating noise and insufficient rotor efficiency of twin-screw compressors, and achieve low vibration and noise, compact structure, Effect of reducing drag loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

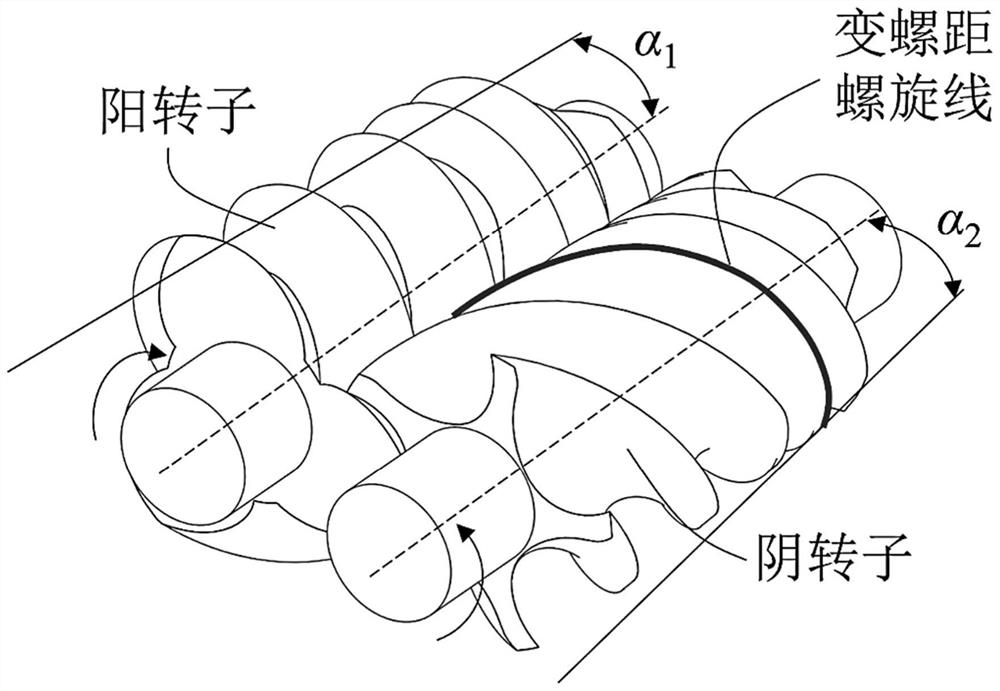

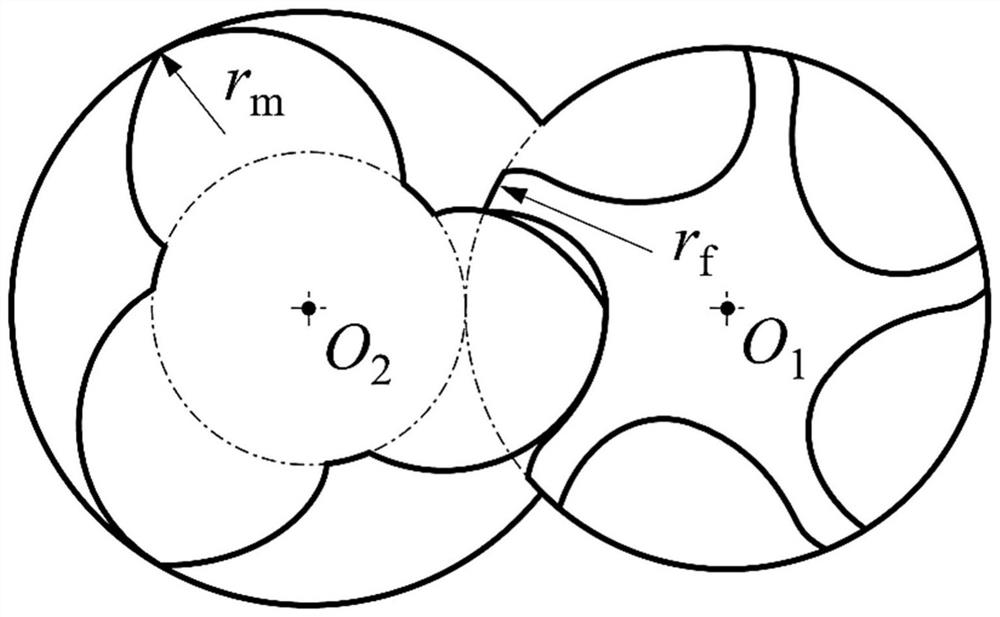

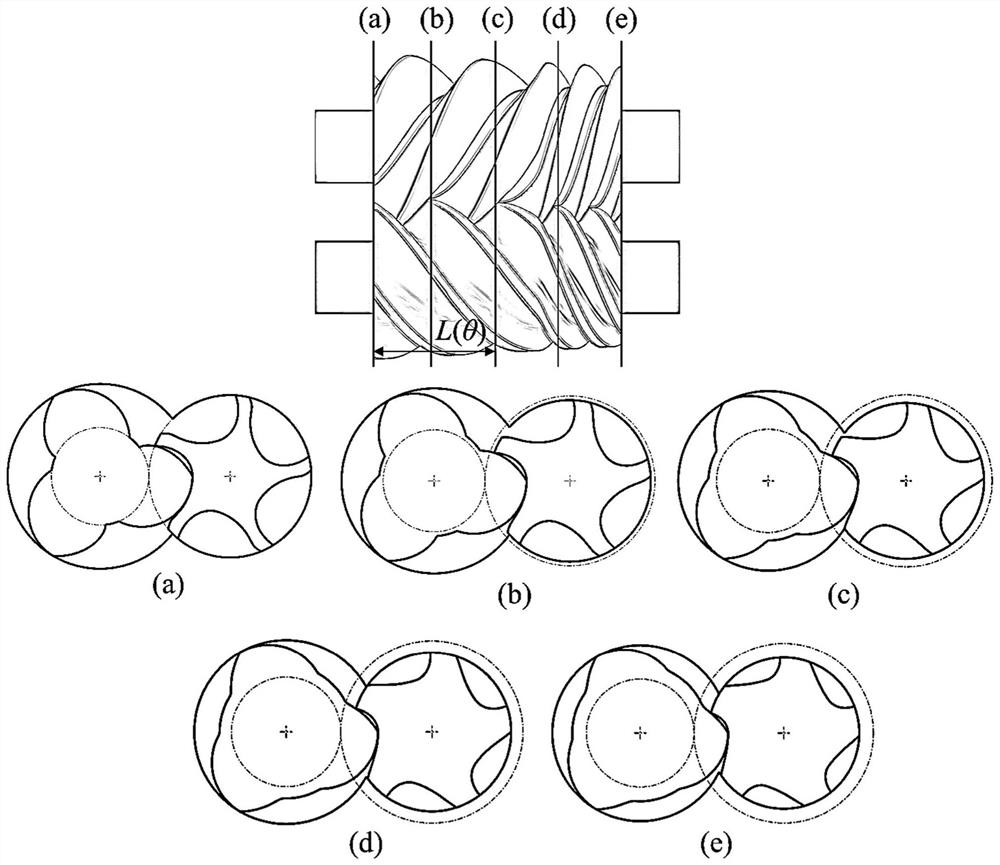

[0039] Such as figure 1 As shown, the outer contour of the male and female screw rotors of the modified twin-screw rotor of the present invention is a tapered structure, and the rotor guiding helix adopts a variable pitch method. Its conical structure relies on changes such as figure 2 Addendum radius r of the male and female rotor profiles shown m with r f to realise. Such as image 3 As shown, as the axial distance of the rotor increases, the addendum radius r m with r f Decrease linearly, so as to achieve the female screw rotor cone angle α shown in Figure 4 2 Cone angle α with male screw rotor 1 . The rotor guiding helix adopts two equal-pitch helixes, and the relationship between the rotor pitch and the rotation angle is as follows: Figure 5 As shown in the figure, the rotation angle at which the pitch change starts can be adjusted arbitraril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com