Asymmetric elliptic twisted blade roots rotor, compressor and expander

An asymmetric and elliptical technology, applied in expanders, asymmetric elliptical twisted-lobe Roots rotors and compressors, can solve problems such as insufficient parameter space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings.

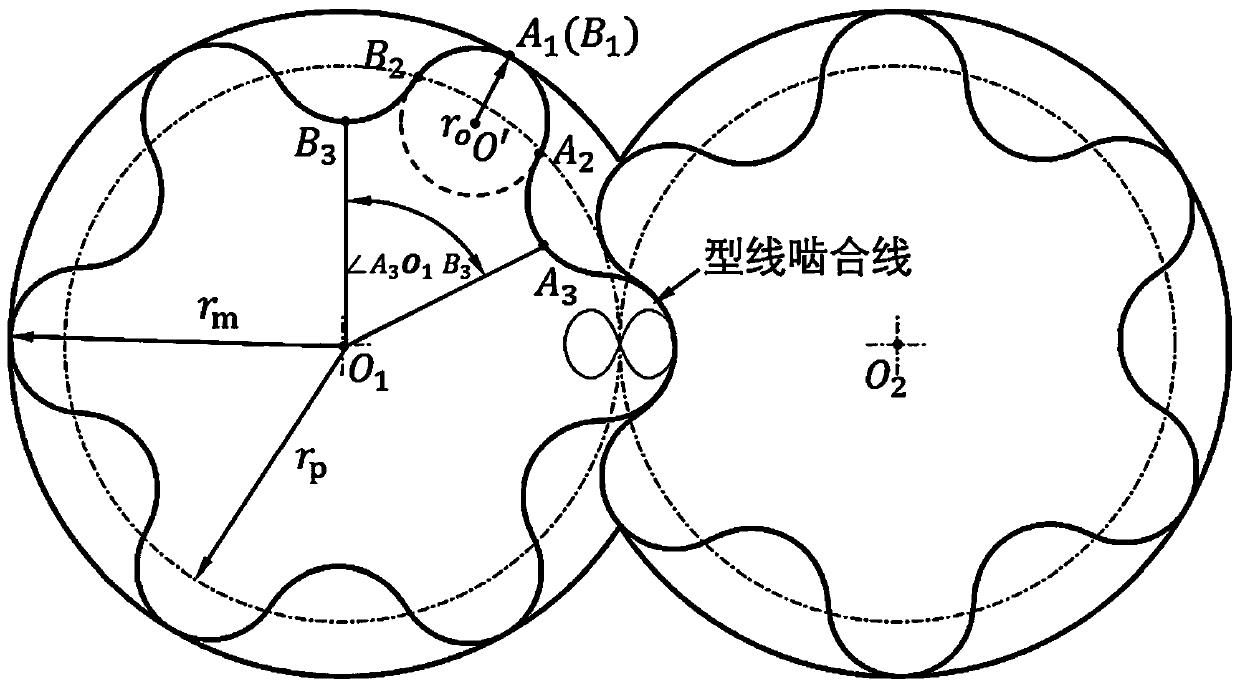

[0062] see figure 1 , in the original rotor profile, the arc segment A 1 A 2 , arc segment B 1 B 2 , arc envelope line segment B 2 B 3 , arc envelope segment A 2 A 3 The curve segment consisting of B 3 B 2 A 1 A 2 A 3 The single-tooth profile that constitutes the original rotor profile, the single-tooth profile B 3 B 2 A 1 A 2 A 3 Around the origin of the rotor profile O 1 to rotate and tooth shape B 3 B 2 A 1 A 2 A 3 connected end to end, and after repeating this n times, the original rotor profile is formed, where n represents the number of teeth of the profile, in figure 1 The n is taken as 6, and the arc segment A 1 A 2 with arc segment B 1 B 2 about 1 A 1 Symmetrical, arc envelope segment B 2 B 3 with arc envelope line segment A 2 A 3 about 1 A 1 Symmetry, arc segment A 1 A 2 with arc envelope line segment A 2 A 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com