Upright coke-oven transition purification receiving and extinguishing technique and equipment

A coking oven and vertical technology, which is applied in coking ovens, petroleum industry, coke cooling, etc., can solve the problems of air pollution in coking plants, which have not been completely solved, and achieve obvious environmental protection benefits, low transformation costs, and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

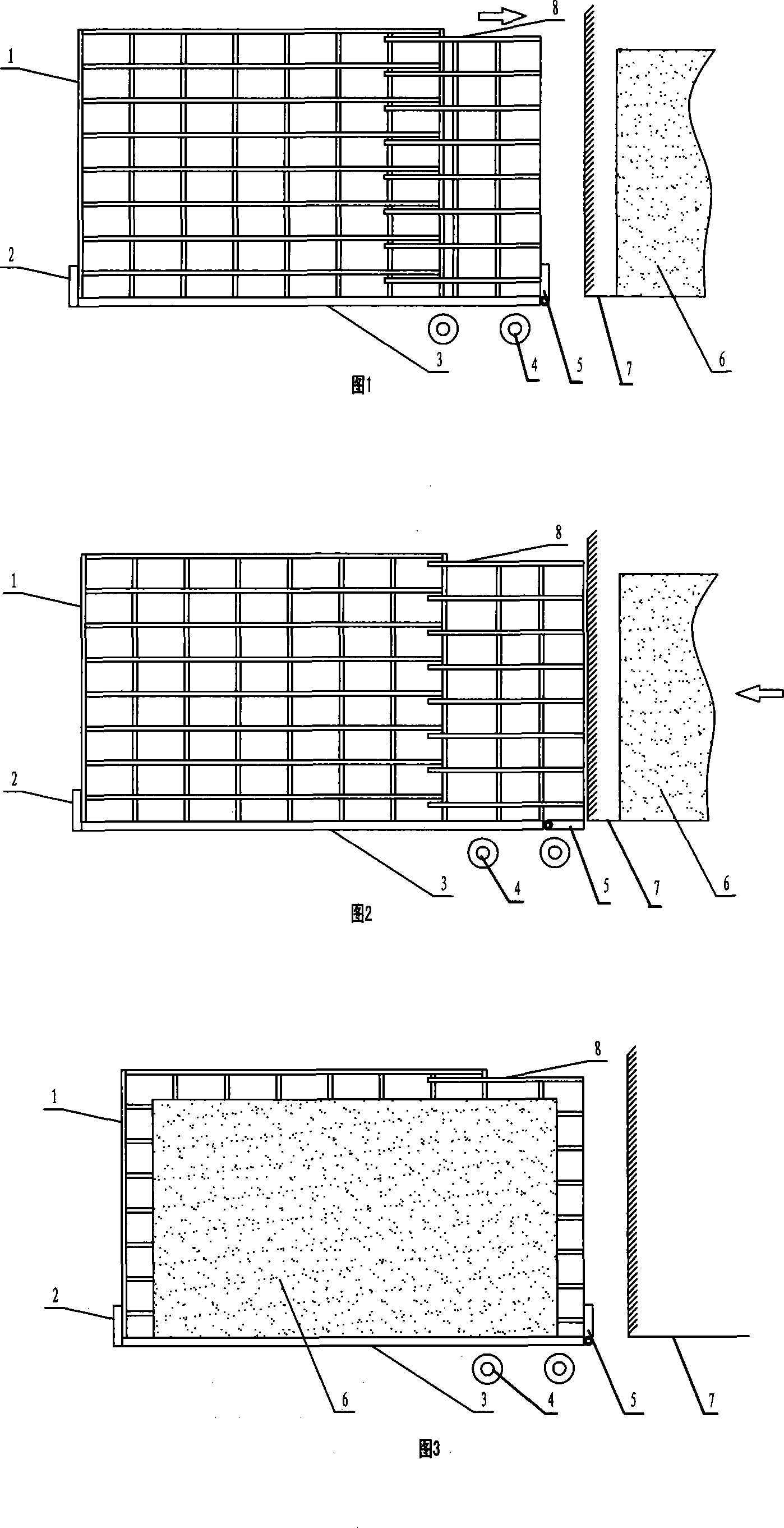

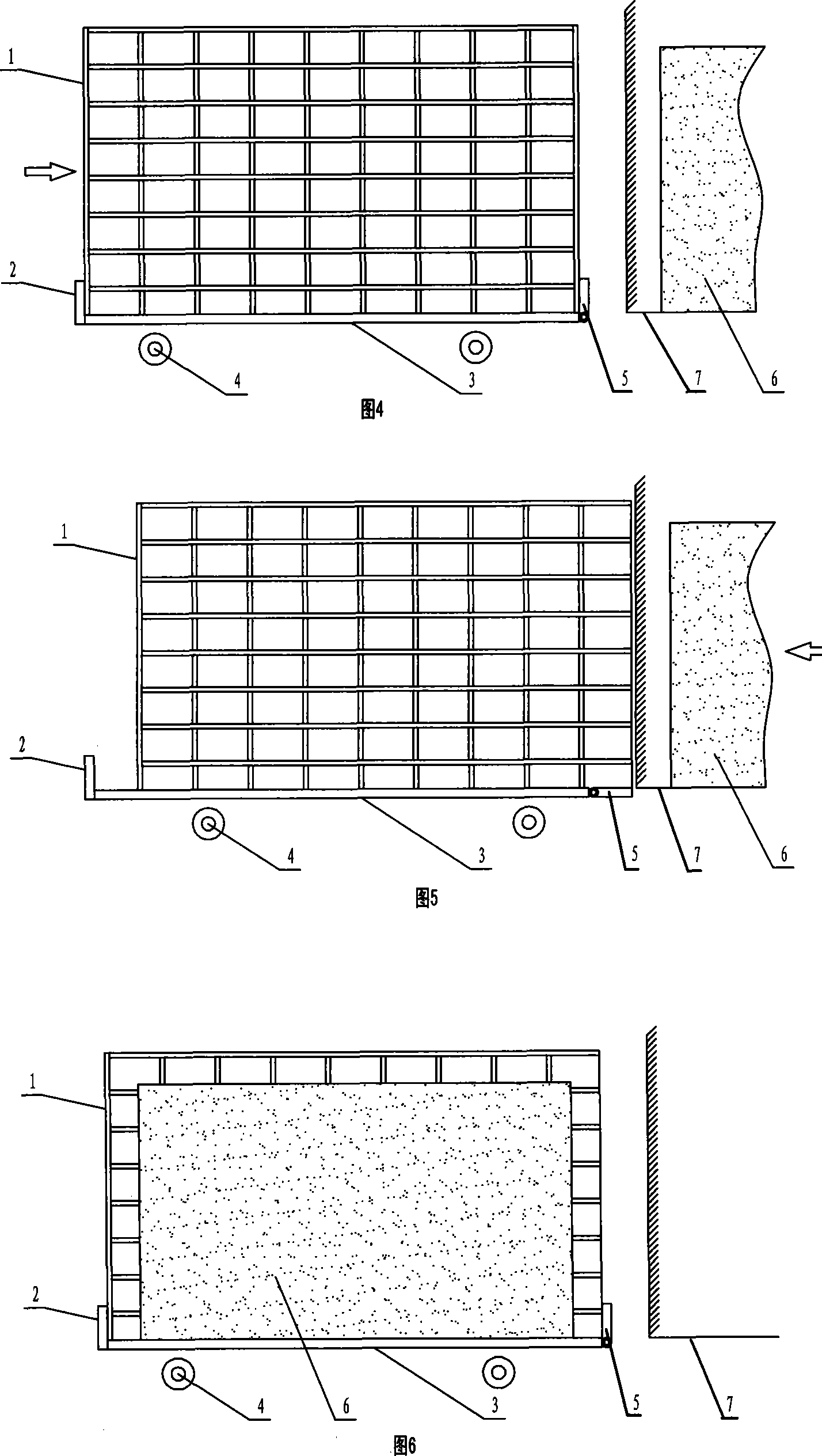

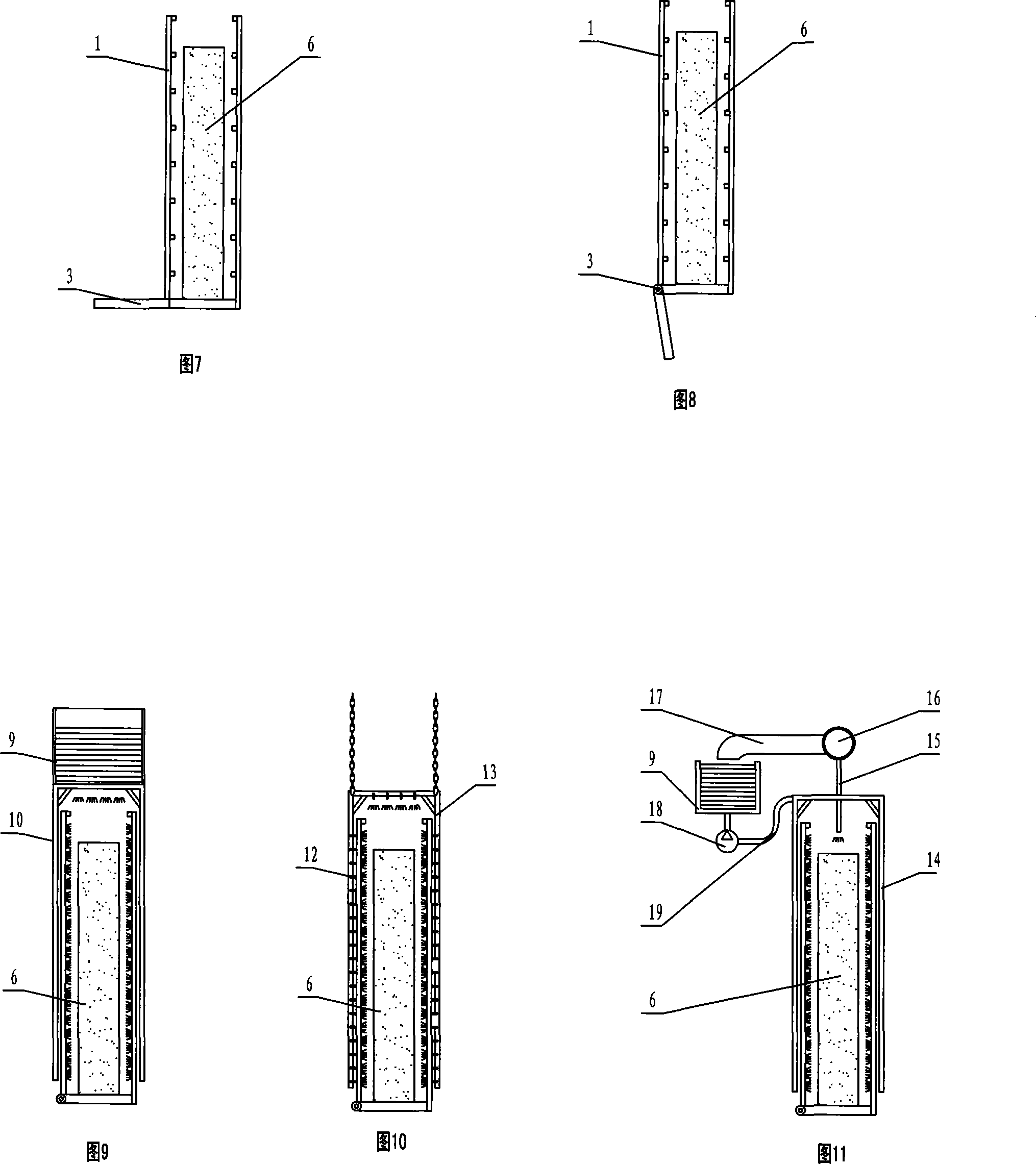

[0035] The equipment required for this set of technological process includes two parts, the translational coke receiving car and the coke quenching tower, which are used in conjunction with each other.

[0036] (1), translational coke receiving car

[0037] The translational coke receiving car is a special equipment for this technology, including coke receiving system, coke placing system, cart running system, furnace door picking and installing system, and dust collection system. Among them, the focus system and the focus system are the key core systems of the translational focus vehicle.

[0038] (1) Focus system

[0039] The function of the coke receiving system is to smoothly and smoothly receive mature coke 6 (coke cake) from the coke oven to the translational coke receiving car. The system consists of two parts, the coke bin and the traverse device 4 . The traverse device 4 runs along the direction of the coke oven carbonization chamber 7 . The coke receiving bin is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com