Variable-line double-screw rotor structure

A rotor structure and twin-screw technology, applied in the direction of rotary piston pumps, rotary piston machines, rotary piston/swing piston pump components, etc., can solve the problem of the size of the leakage triangle, the difficulty of further improving the efficiency of the screw rotor, and the noise level Can not be further lowered and other problems, to achieve the effect of increased size, compact structure, and low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

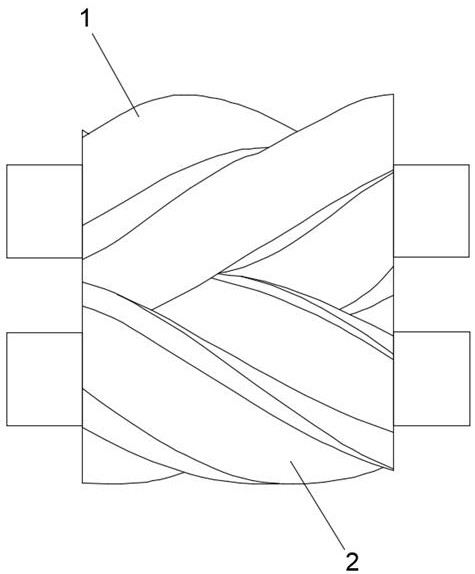

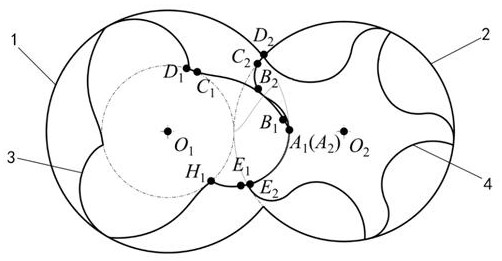

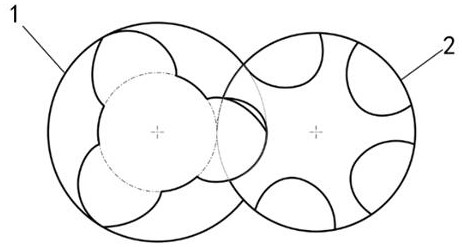

[0018] Such as Figure 1-5 As shown, a modified line twin-screw rotor structure, including a male rotor 1 and a female rotor 2, is characterized in that: the male rotor has 3 teeth, and the female rotor has 5 teeth, and the profile 3 of the male rotor 1 includes the sequence Connected: arc segments D 1 C 1 , arc envelope segment C 1 B 1 , arc segment B 1 A 1 , arc segment A 1 E 1 , point meshing cycloid segment E 1 H 1 ;

[0019] The profile 4 of the female rotor 2 includes sequentially connected: arc segments D 2 C 2 , arc segment C 2 B 2 , arc envelope segment B 2 A 2 , arc envelope segment A 2 E 2 ;

[0020] The arc segment D 1 C 1 is the shaft center of the male...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com