Whole ellipse and ellipse envelope type double-screw rotor, compressor and expansion machine

A twin-screw and elliptical technology, applied in the direction of machines/engines, rotary piston machines, mechanical equipment, etc., can solve problems such as insufficient space for design parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in further detail below in conjunction with the accompanying drawings.

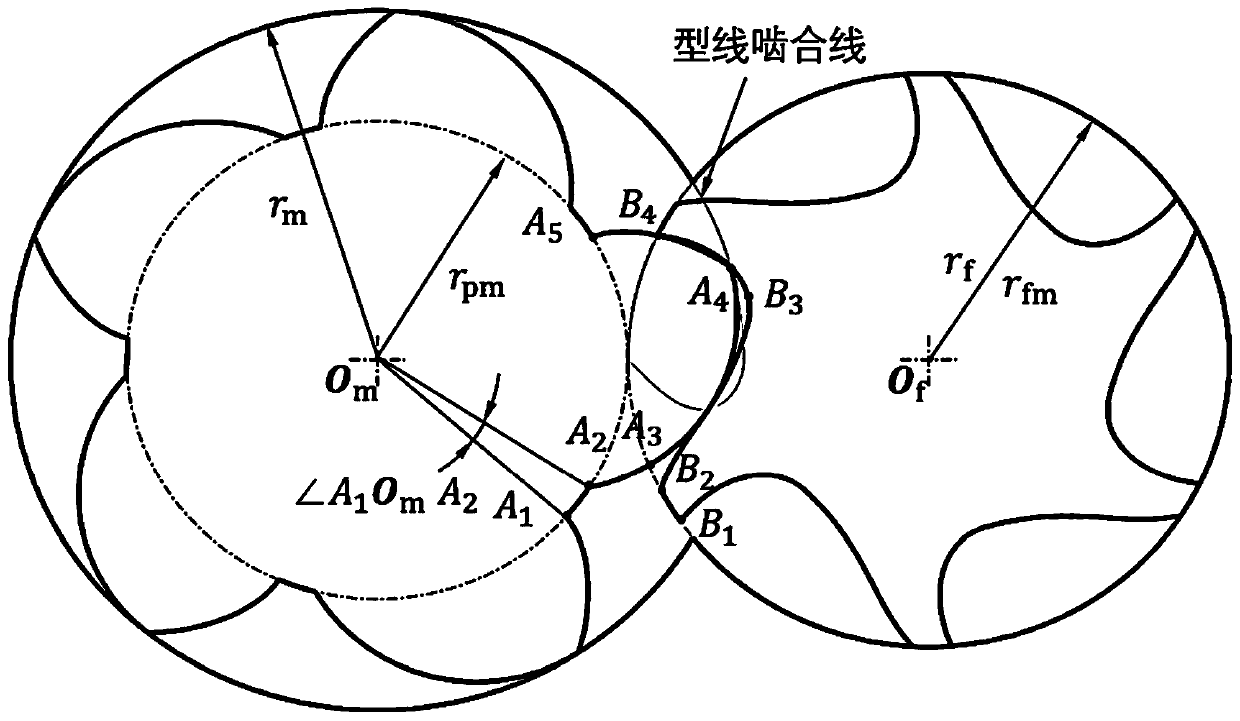

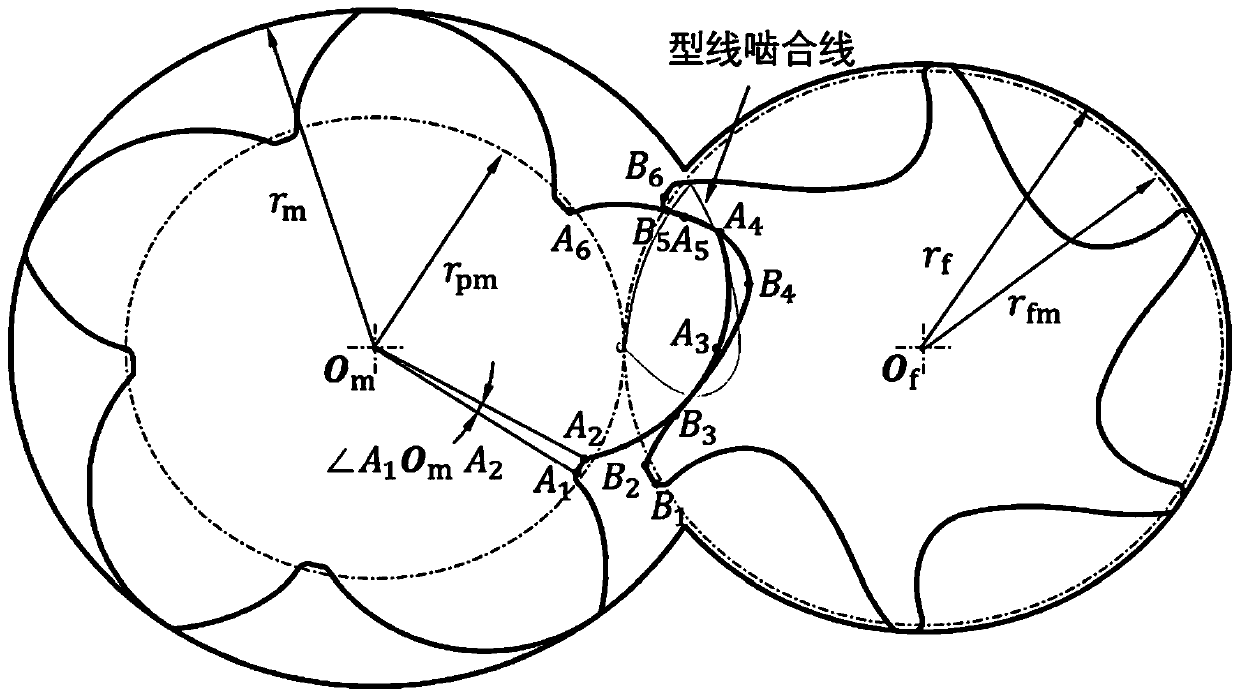

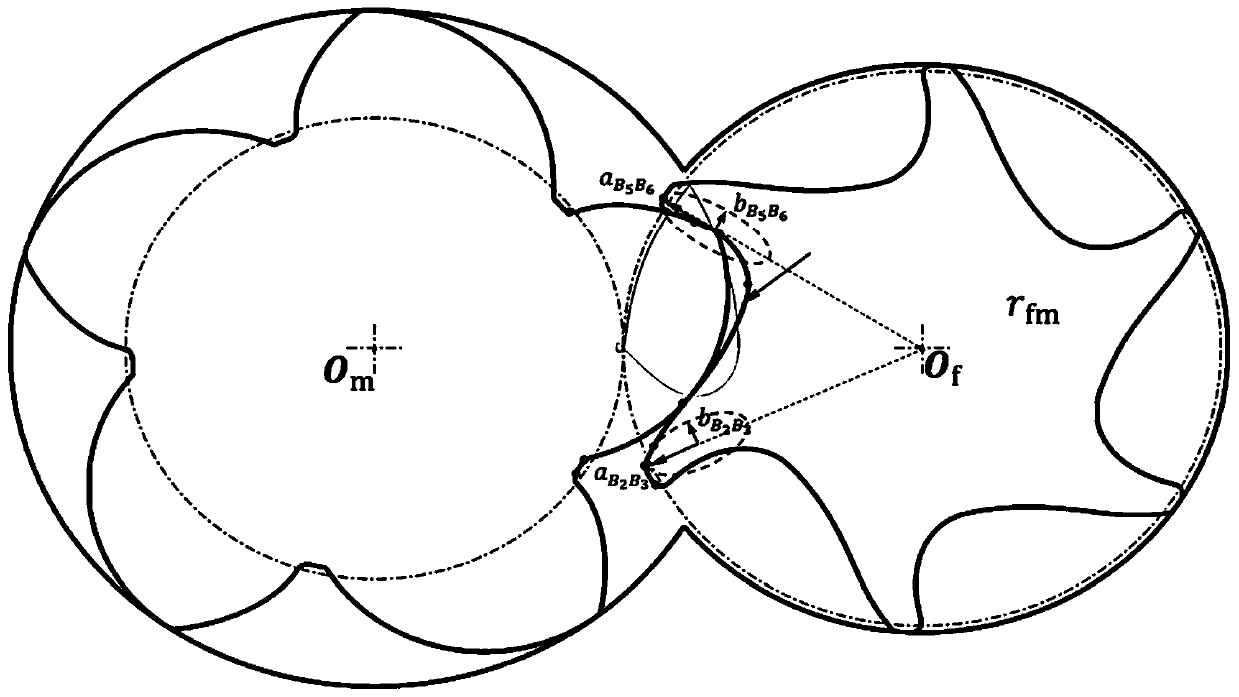

[0073] see figure 1 , in the original screw rotor profile, A in the left male rotor profile 1 A 2 A 3 A 4 A 5 It is single-tooth tooth shape, single-tooth tooth shape A 1 A 2 A 3 A 4 A 5 The origin of the profile line of the male rotor O m to rotate and tooth shape A 1 A 2 A 3 A 4 A 5 End to end, so repeat n 1 After the number of times, the left male rotor profile is formed, where n 1 Indicates the number of teeth, in figure 1 middle n 1 Take it as 5. Similarly, the profile line of the female rotor on the right is also formed by the single-tooth profile B 1 B 2 B 3 B 4 The only decision. In the original tooth shape, A 1 A 2 A 3 A 4 A 5 From arc segment A 1 A 2 , the point engages the epicycloid segment A 2 A 3 , arc segment A 3 A 4 , epicycloid segment A 4 A 5 Composition, B 1 B 2 B 3 B 4 from arc segment B 1 B 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com