Isostatic pressing device, dry bag type isostatic press and isostatic pressing method

A technology of pressurizing device and isostatic press, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of dry bags or rubber mold thickness and hardness pressing products, pull-off, etc., to reduce The effect of randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

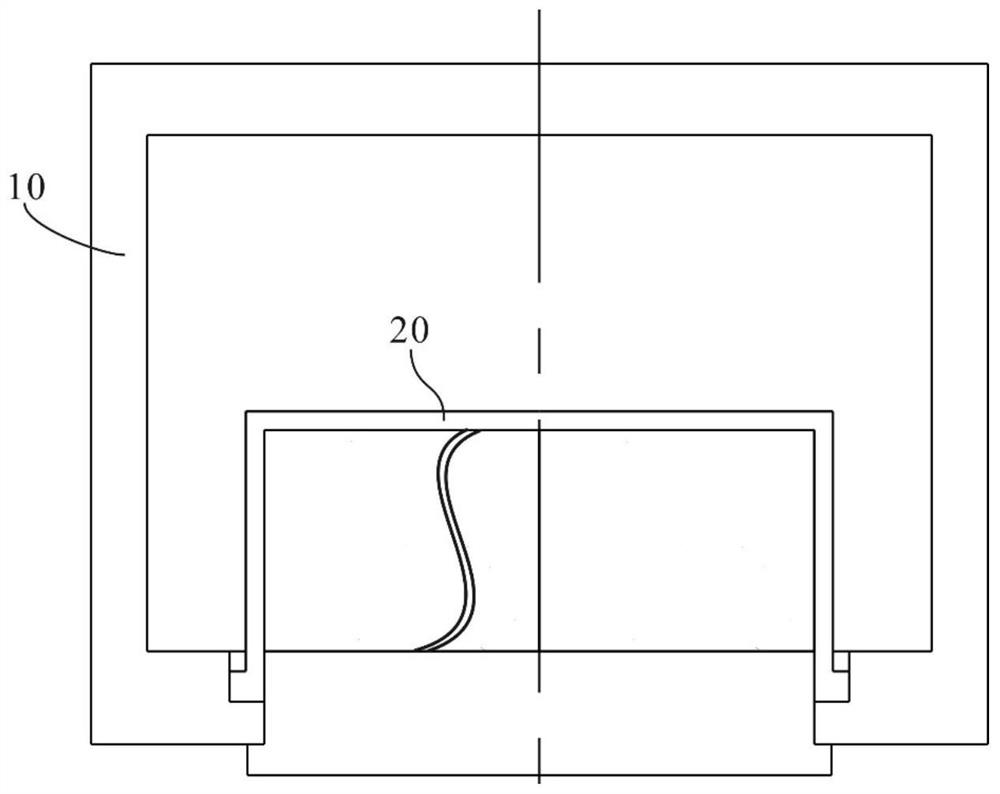

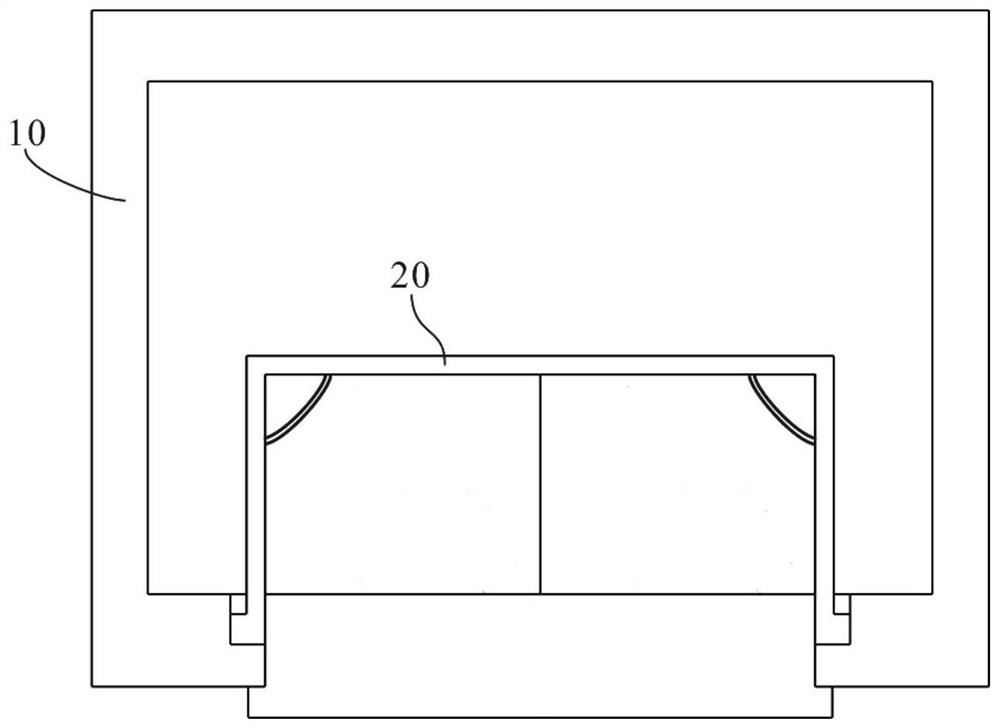

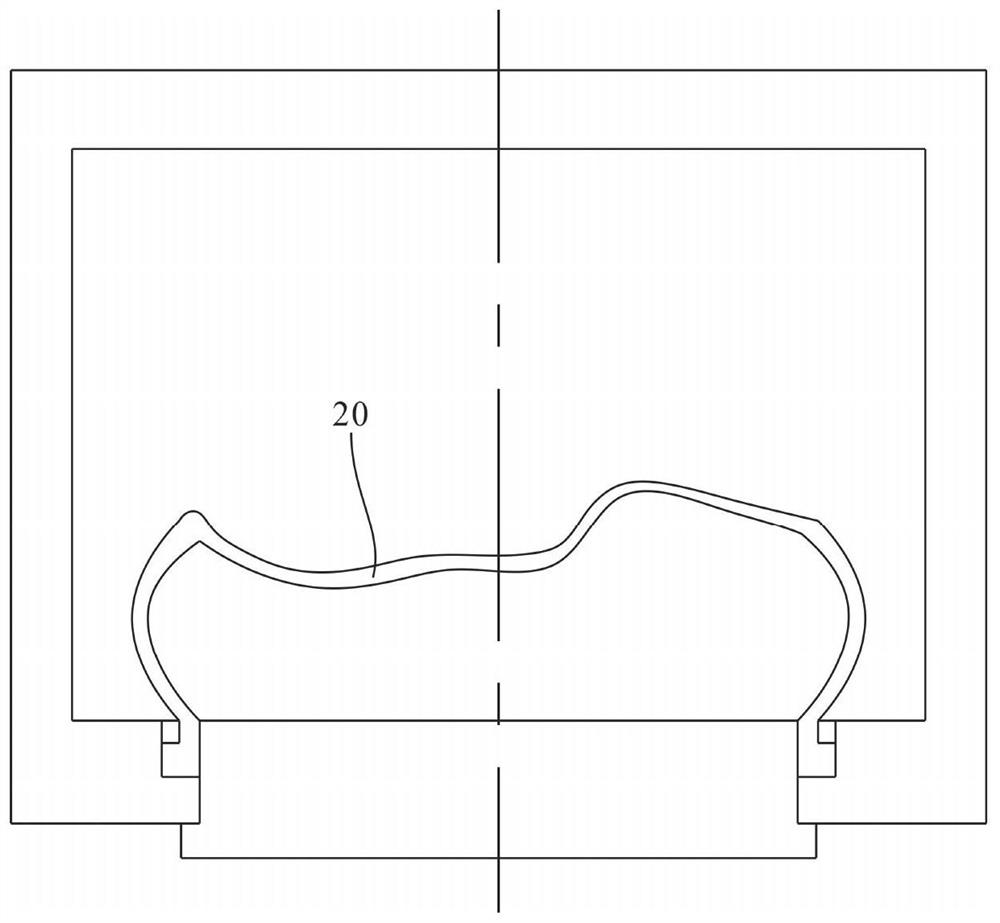

[0041] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0042] overview

[0043] The dry bag isostatic press usually includes a high-pressure chamber 10, a dry bag unit 20 is arranged in the high-pressure treatment chamber of the high-pressure chamber 10, and an isostatic pressure medium is installed between the dry bag unit and the high-pressure chamber. The static pressure medium can be a liquid medium or a gas medium. Then, the powder to be formed is directly loaded into the dry bag unit 20, or the powder to be formed is first loaded into the mold unit, and the mold unit is then loaded into the dry bag unit; The isostatic pressing medium is pressurized and the powder to be formed is formed in a dry bag or a mold unit, thereby completing the isostatic pressing.

[0044] However, it has been found i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com