Polycrystalline silicon thin film transistors with bridged-grain structures

A thin film transistor and transistor technology, applied in transistors, electric solid state devices, semiconductor devices, etc., can solve the problems of increased threshold voltage, total mobility loss, etc., and achieve the effect of reducing threshold voltage and leakage current, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The many innovative teachings of the present application will be described with particular reference to presently preferred embodiments, by way of example, and not limitation.

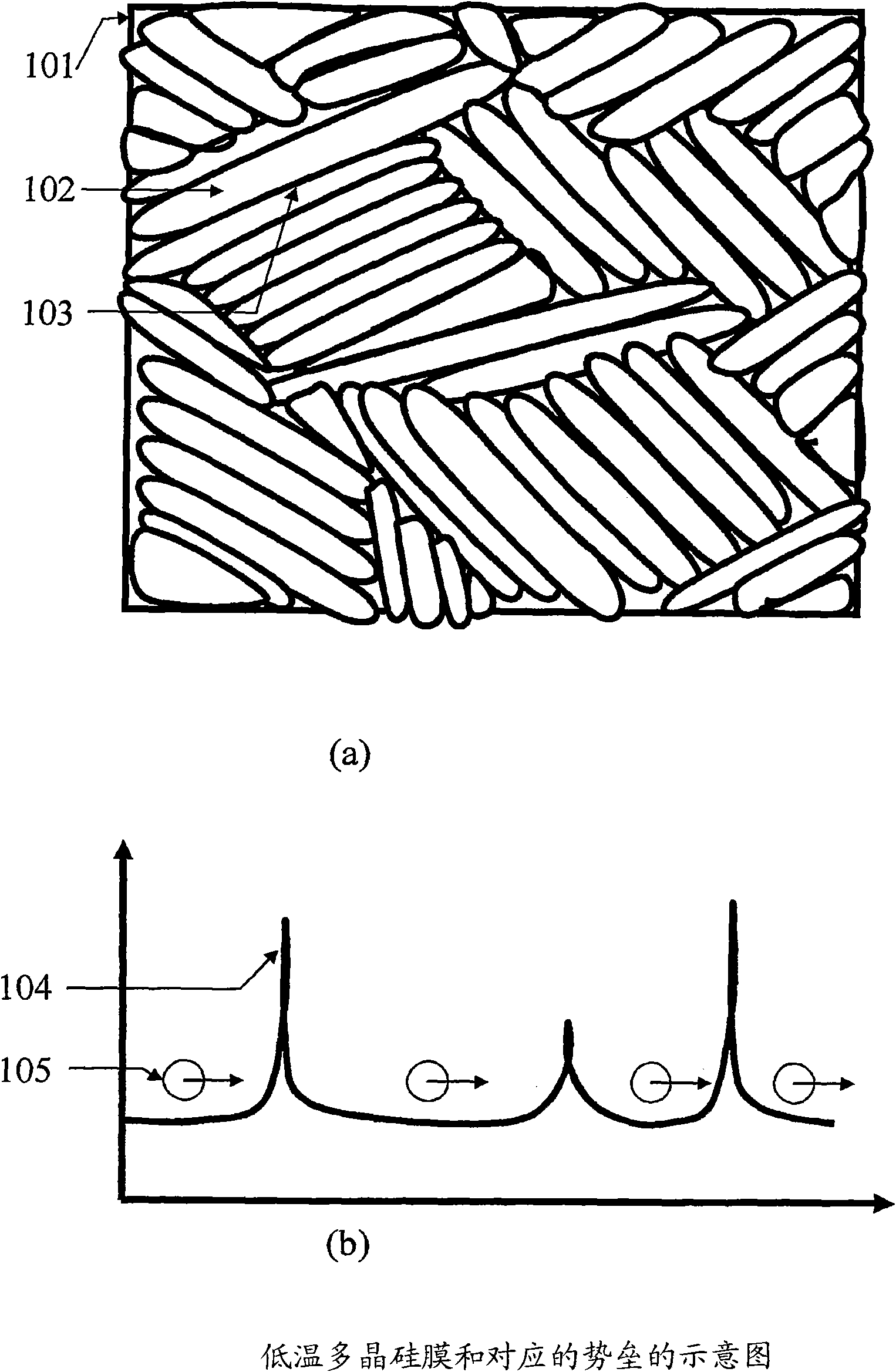

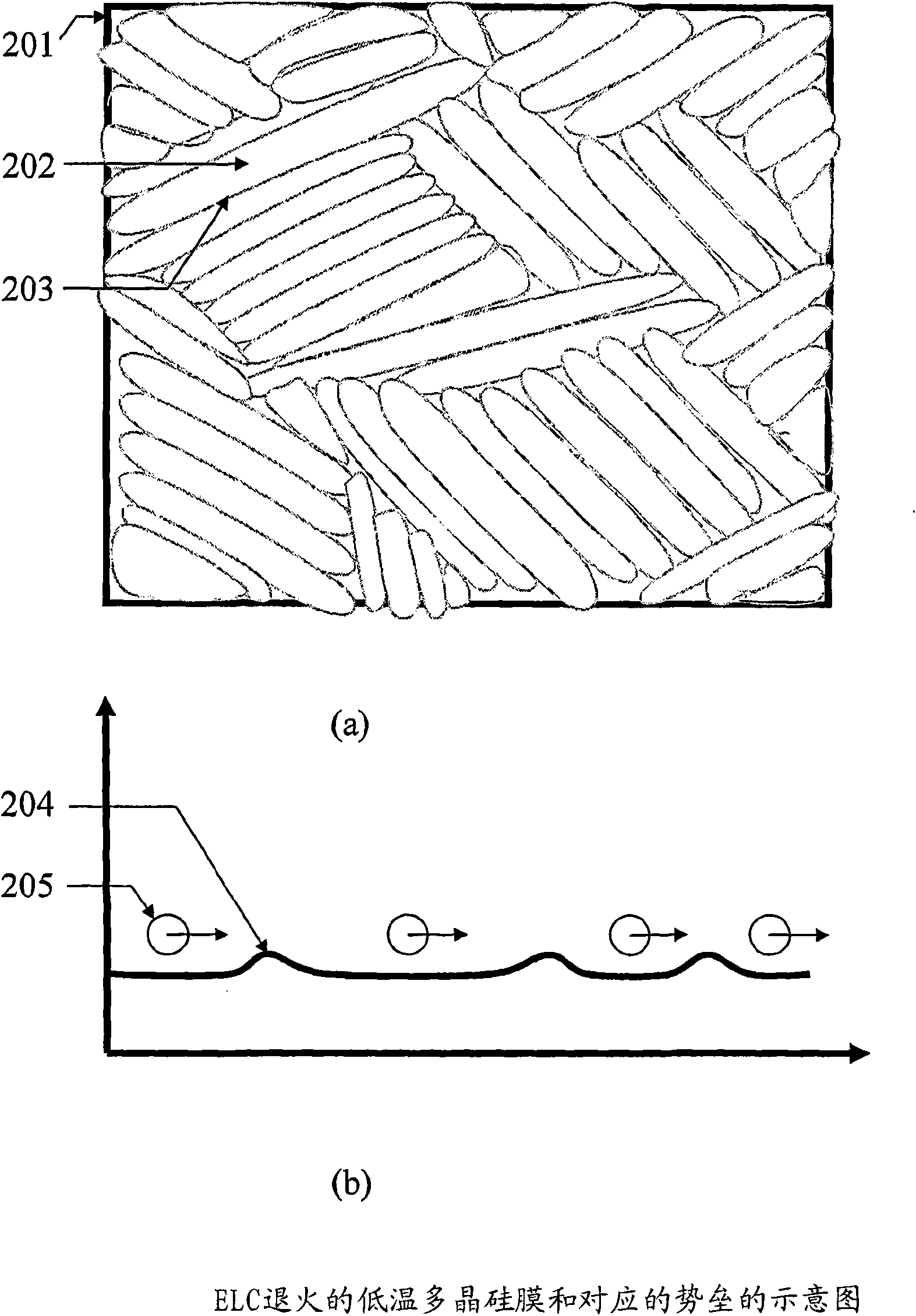

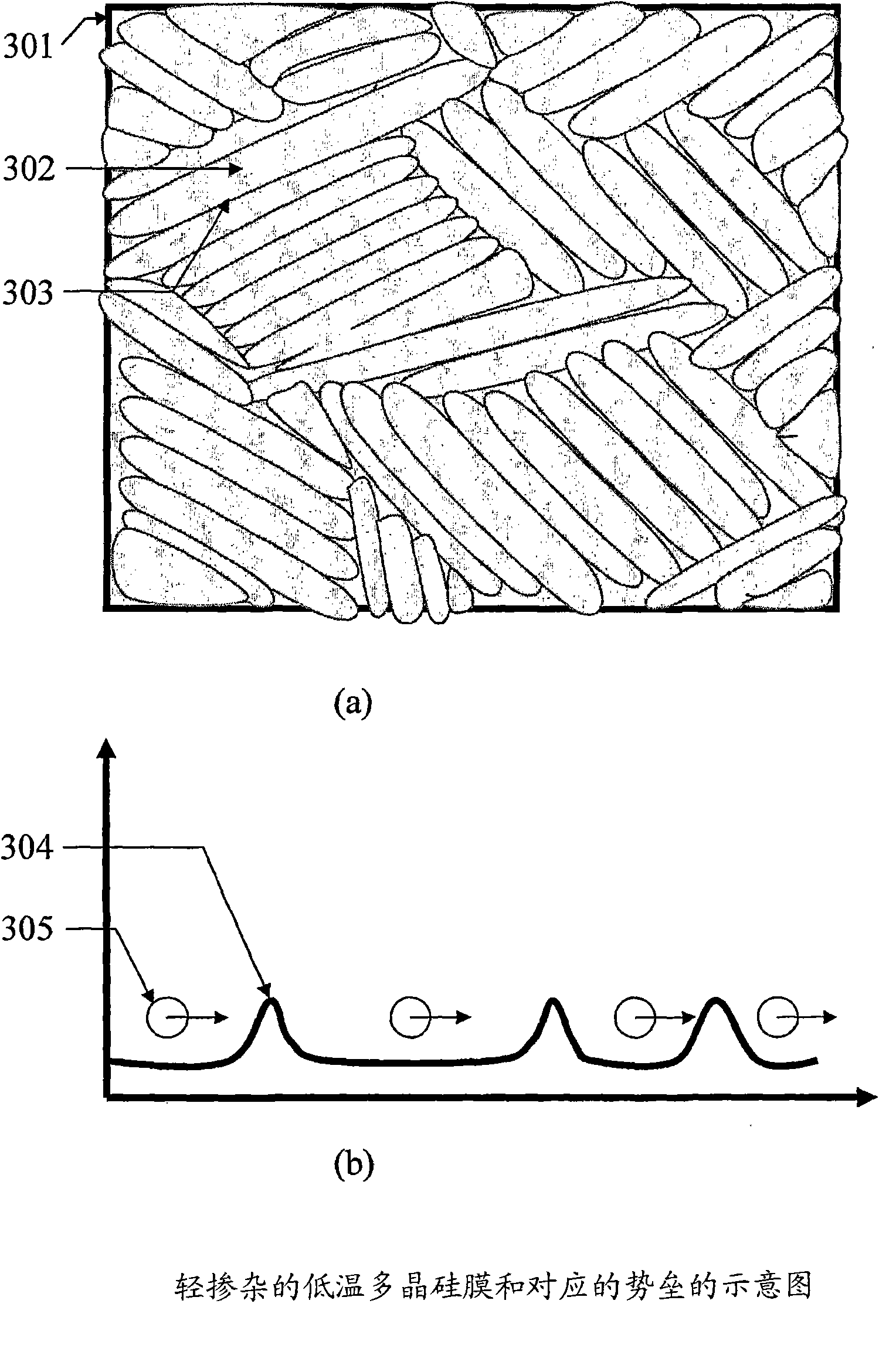

[0053] One of the disclosed inventions is to use conductive strips or bridges to connect the die inside the active channel of a TFT. The crystal grains are randomly distributed inside the channel, as shown in Figs. 1-3. The performance of the TFT can be greatly improved by forming conductive bands or lines between the crystal grains perpendicular to the direction of current movement. Basically the two-dimensional network is turned into a pseudo-one-dimensional network. Referring briefly to Figure 4a, the conductive wires facilitate the flow of current in a direction perpendicular to the current flow. The influence of grain boundaries is reduced by these conductive lines, which can be considered as bridges across the grains. This structure is defined as a bridge grain (BG) structure. However,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com