Narrow flow channel turbine

A narrow channel and turbine technology, applied in the field of narrow channel turbines, can solve problems such as prone to surge, high pressure ratio of centrifugal compressors, increased energy consumption, etc., to achieve the effects of broadening applications, improving efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

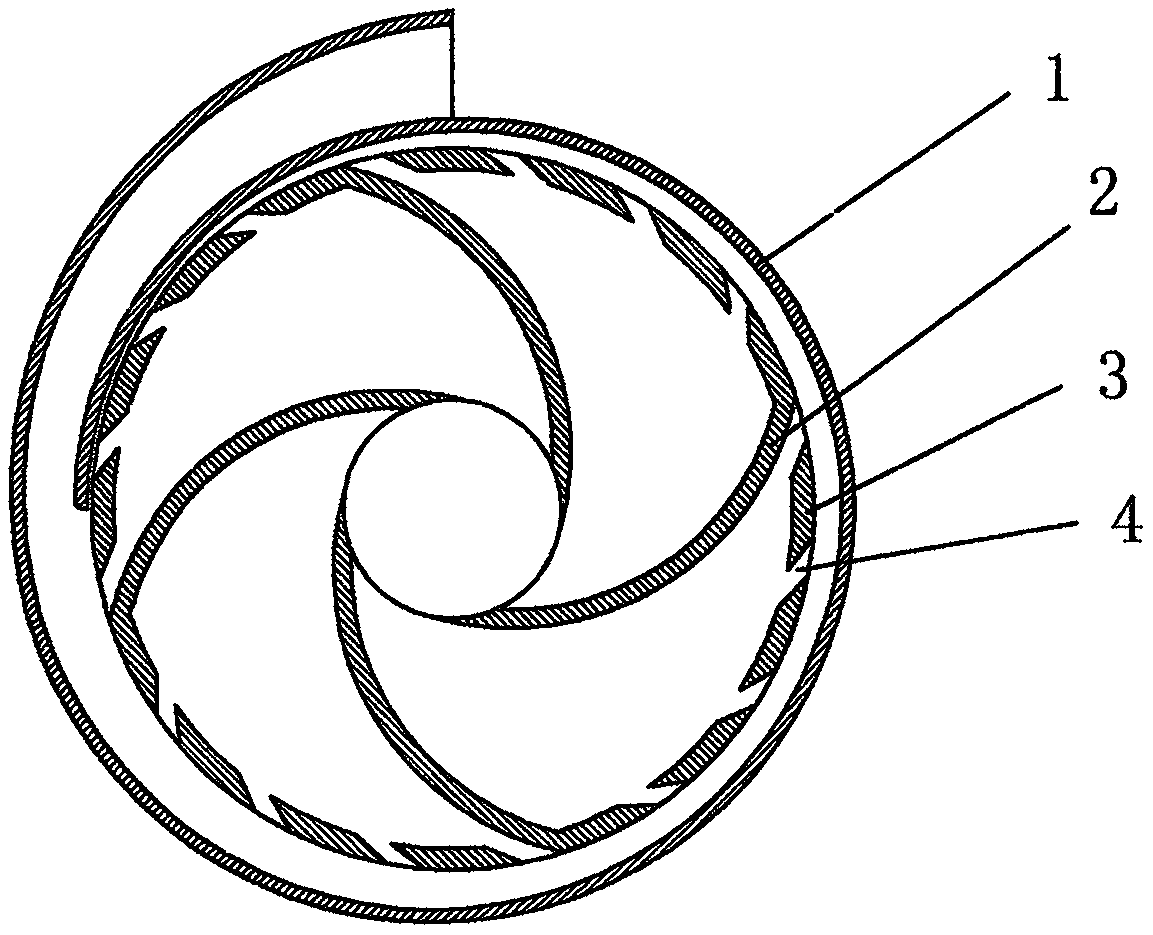

[0009] In the figure, there is a turbine rotor (2) inside the casing (1), and a closed retaining wall (3) is arranged on the circumference of the turbine rotor (2), and small holes (4) are distributed on the closed retaining wall (3).

[0010] When working, the turbine rotor (2) is driven by external force to rotate at a high speed, the fluid is sucked in from the middle of the turbine rotor (2), and then sprayed into the casing (1) through the small hole (4).

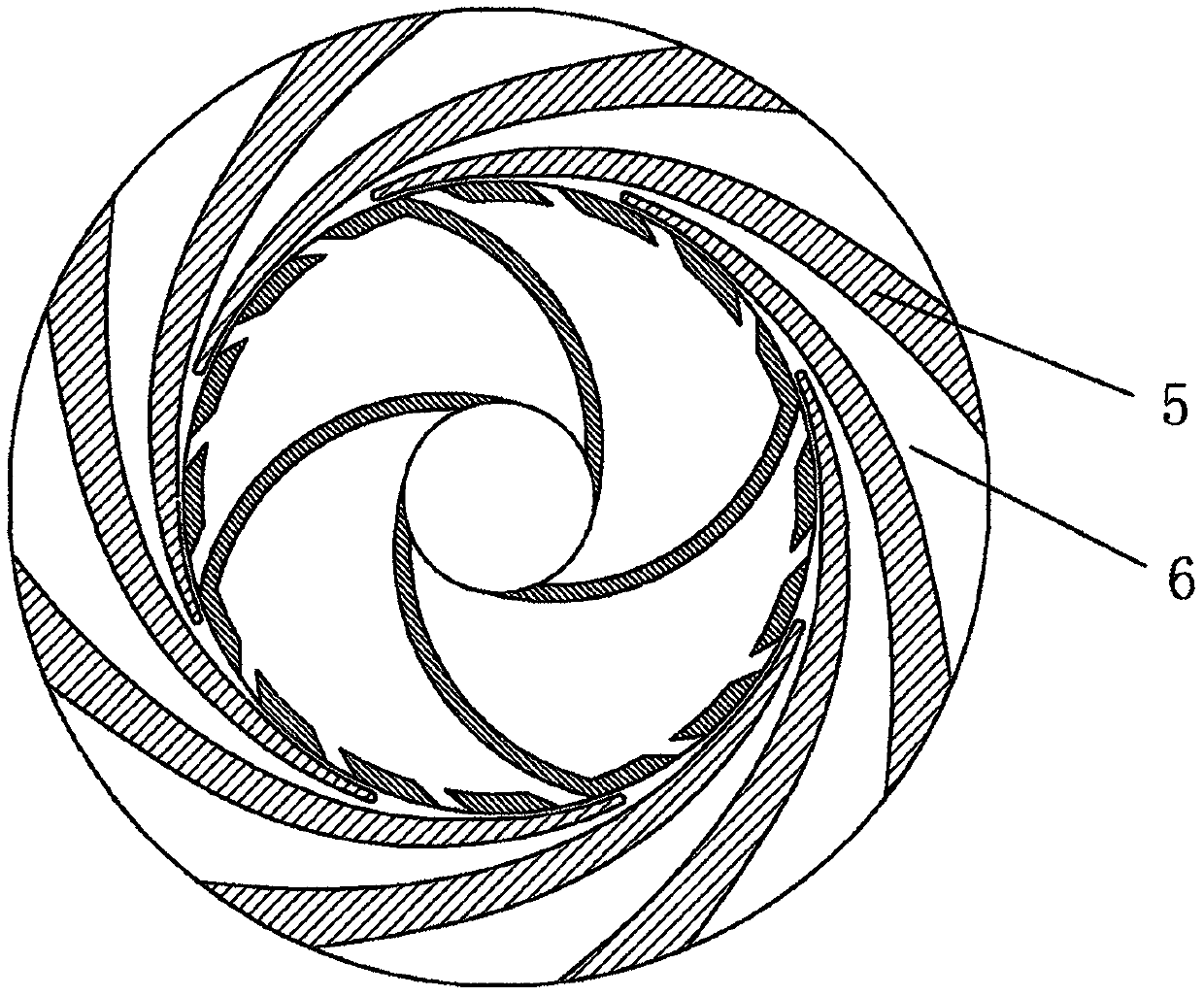

[0011] attached figure 2 It is a schematic diagram of a narrow-channel turbine rotor coupled with a narrow-channel diffuser mechanism. The diffuser (5) is provided with a plurality of curved narrow-channel diffuser slots (6). Due to the bending, the flow becomes longer, so the diffuser is more efficient. full.

[0012] The present invention does not limit the shape of the casing (1), which may be a volute, a pipeline or a pressure vessel, etc., all of which are within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com