Concrete mixing system based on integrated operational amplifier processing technology design

A mixing system and technical design technology, applied in the field of concrete mixing systems, can solve the problems of backward teaching technology, many strokes, time-consuming, etc., and achieve the effects of scientific design, avoiding environmental pollution, and reasonable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

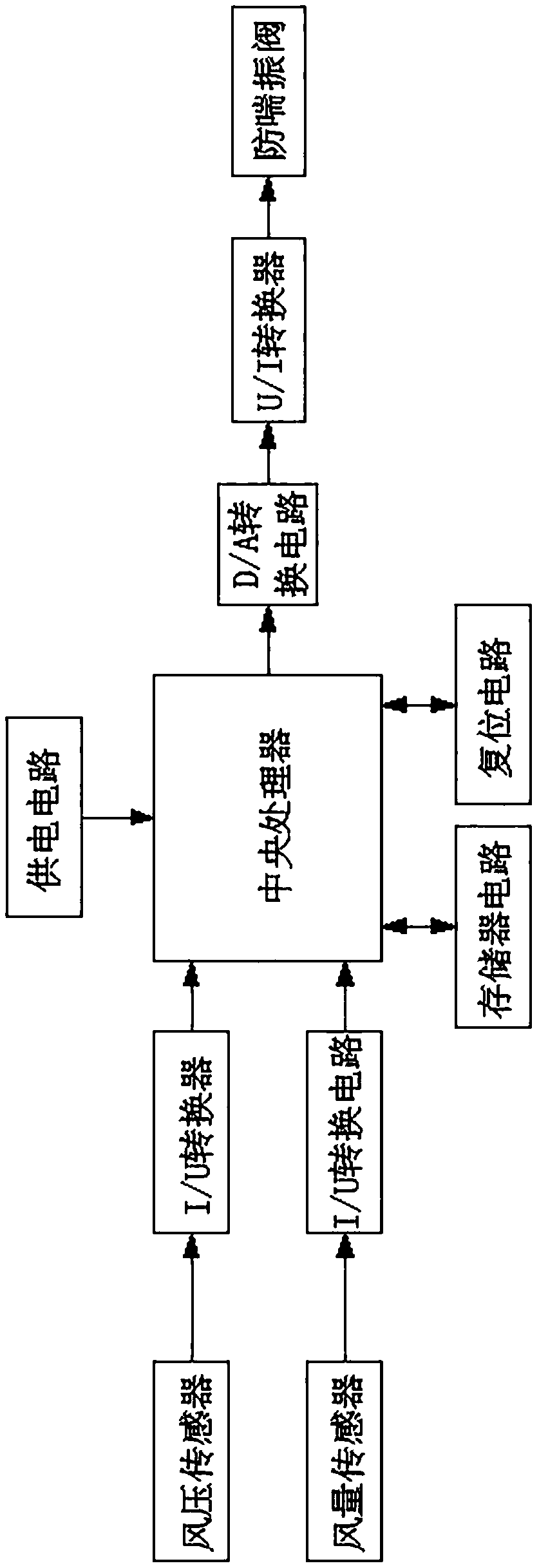

[0035] A concrete mixing system designed based on integrated operation and amplifier processing technology. During commercial concrete production, a current-voltage conversion circuit is jointly formed by a proportional operational amplifier circuit and a post-stage amplifier circuit, in order to realize the transformation from current signal to voltage signal. The collected air volume information is safely and reliably transmitted to the central processing unit for later safe and reliable processing. The designed I / U conversion circuit has higher efficiency and better stability during flow pressure conversion, avoiding systematic A fault occurs that affects the normal operation of the entire circuit, such as figure 1 , figure 2 As shown, the following arrangement structure is adopted in particular: a central processing unit, a wind pressure circuit, an air volume circuit and an anti-surge circuit are provided, the wind pressure circuit and the air volume circuit are both con...

Embodiment 2

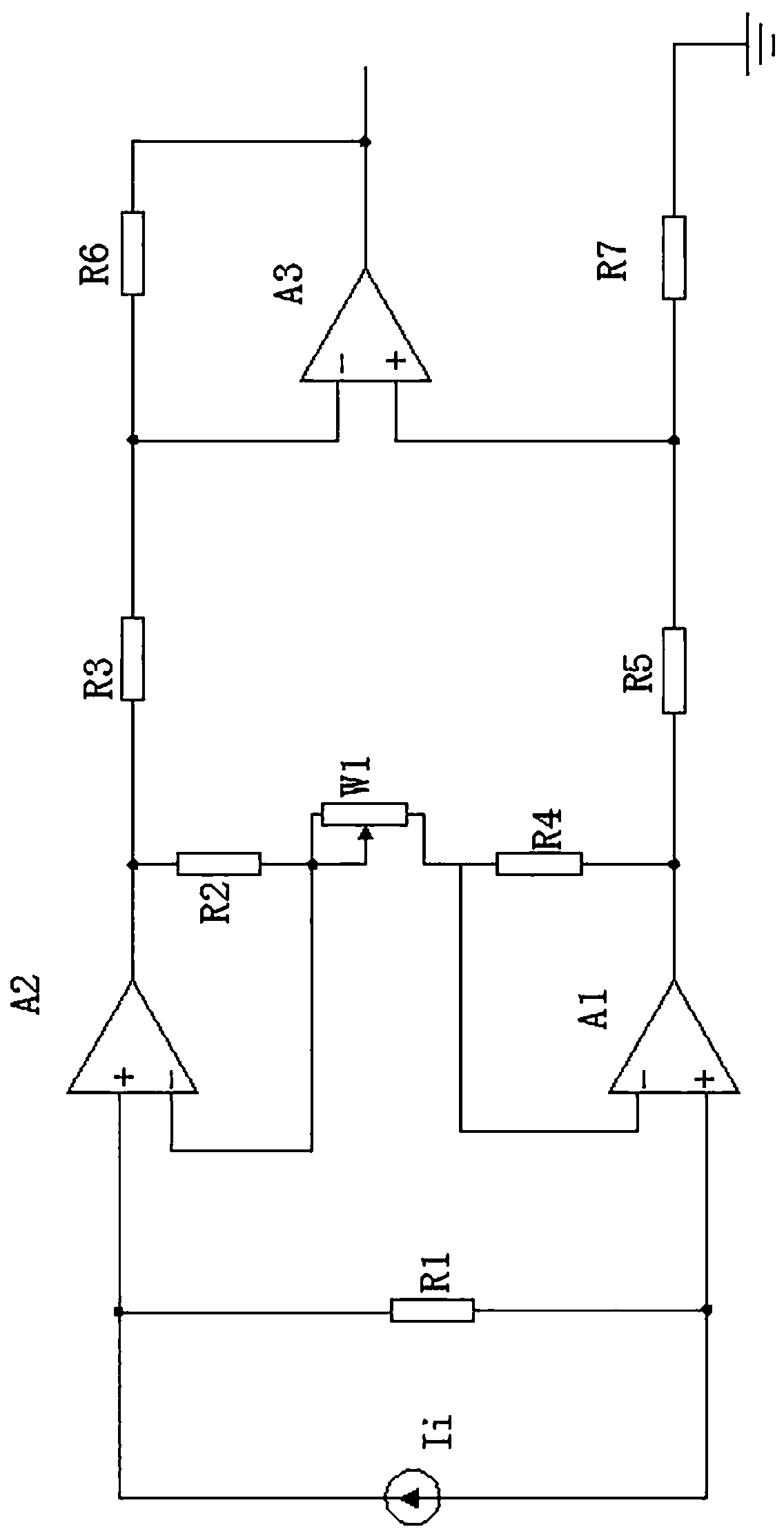

[0037] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as figure 1 , figure 2 As shown, the following arrangement structure is adopted in particular: a resistor R1, an op amp A2, an op amp A1, a resistor R2, a resistor R4 and a potentiometer W1 are arranged in the pre-stage proportional operational amplifier circuit, and the resistor R1 is used as the pre-proportional operational amplifier The input terminals of the circuit are respectively connected to the non-inverting input terminal of the operational amplifier A1 and the non-inverting input terminal of the operational amplifier A2, and the resistor R1 is connected to the output terminal of the air volume sensor, and the output terminal of the operational amplifier A2 is connected to the resistor R3, The resistor R3 is connected to the inverting input terminal of the operational amplifier A3; the output terminal of the operational a...

Embodiment 3

[0040] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 , figure 2 As shown, the following arrangement structure is particularly adopted: a wind pressure sensor for converting non-electrical wind pressure information into electric quantity information is arranged in the wind pressure circuit, and is used to convert the converted wind pressure current signal into a current An I / U converter for voltage conversion, the wind pressure sensor is connected to the I / U converter, and the I / U converter is connected to the central processing unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com