Autonomous network distribution hot-line operation robot, system and method

A live work and robot technology, which is applied in the direction of manipulators, overhead line/cable equipment, disassembly/armored cable equipment, etc., can solve the problem that the research on the actual live work site environment is not thorough enough, the research is not deep enough, and there is no product suitable for robots. Work process planning and other issues to achieve the effect of light weight, heavy weight, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

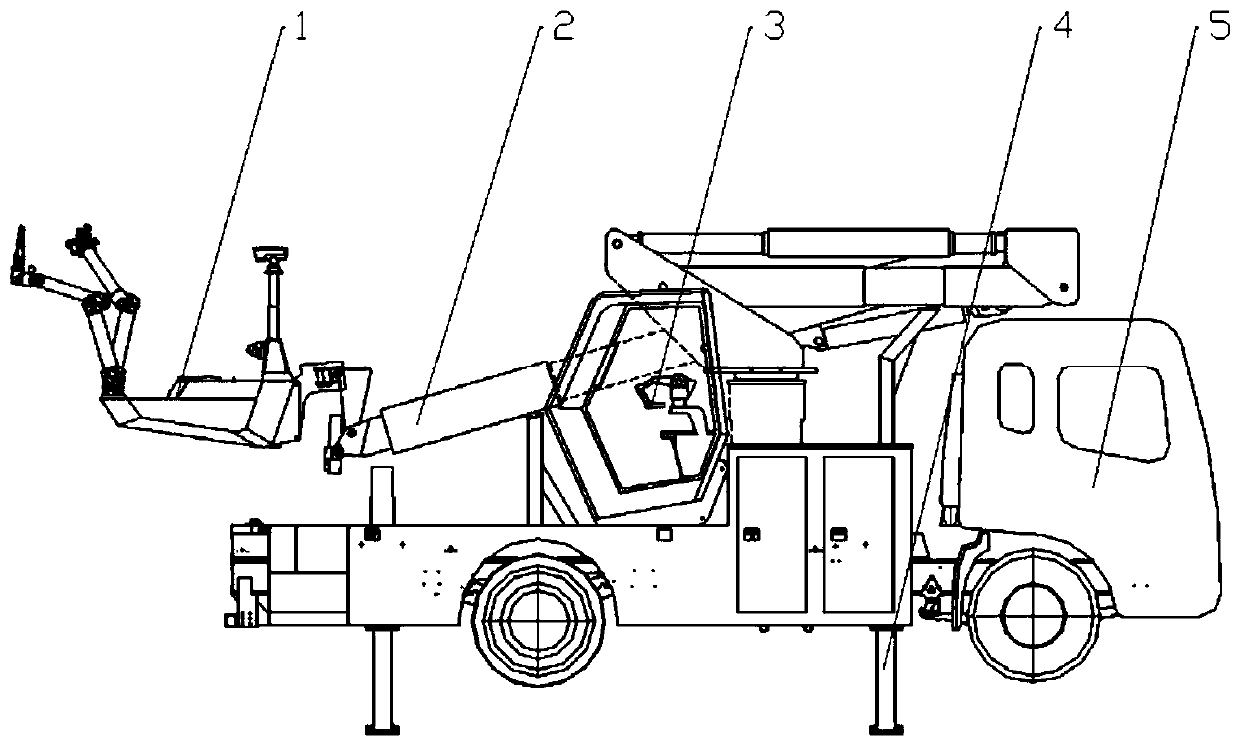

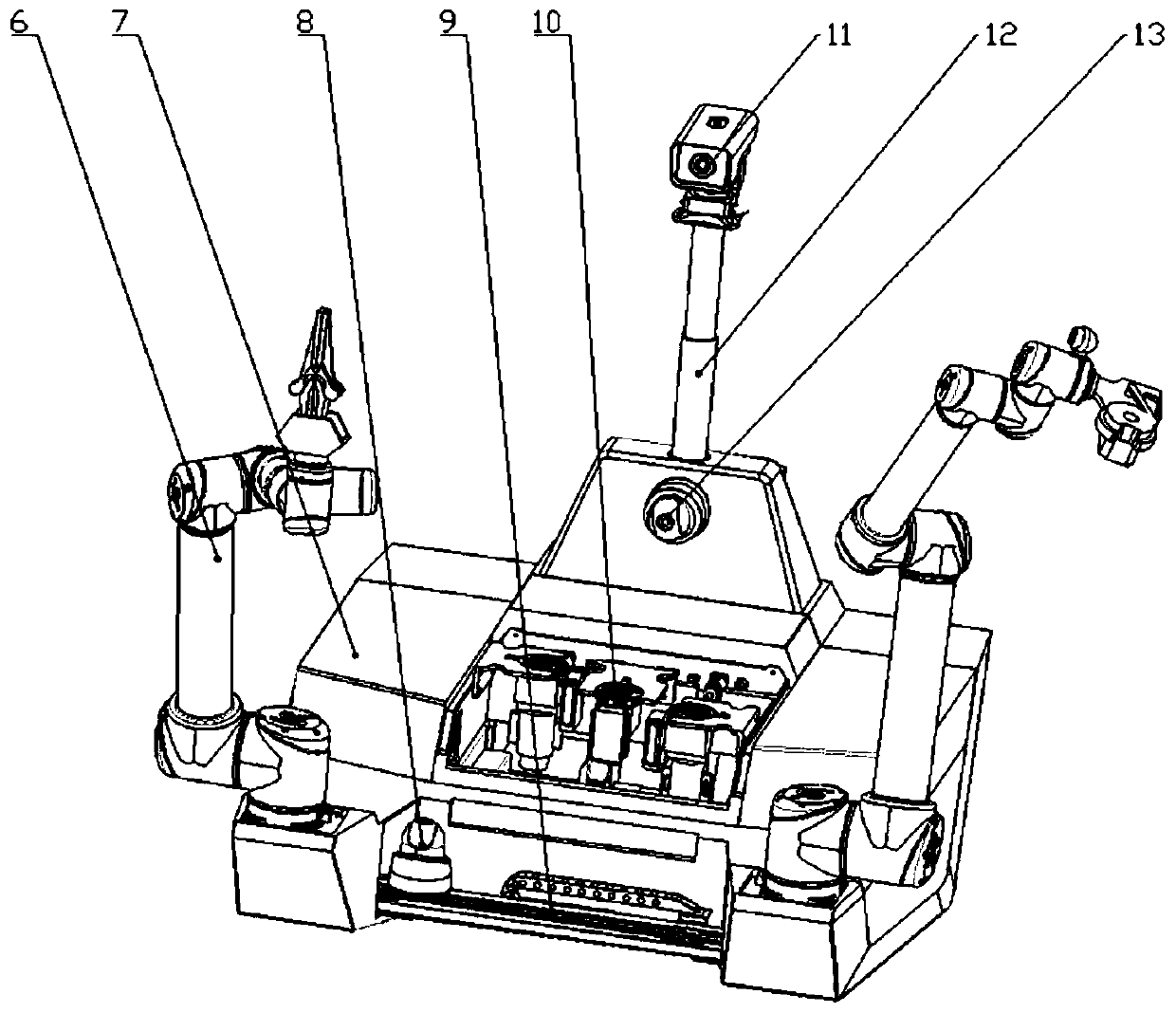

[0028] In one or more embodiments, an autonomous distribution network live working robot is disclosed, referring to figure 1 , including: a mobile body 5 and an insulating lifting arm 2 arranged on the moving body 5; a robot aerial work platform 1 is arranged at the end of the insulating lifting arm 2, and a first control module and a first control module are respectively arranged on the aerial work platform. A control module is connected to the operating robot arm 6 and the visual feedback module; the mobile body 5 is provided with a control part, and the control part can communicate with the aerial work platform to realize the master-slave control of the operating robot arm 6 or realize the operation mechanism Master-slave / programmed mode switching for arm 6.

[0029] Specifically, in the master-slave mode, the movement control of the working manipulator 6 can be realized by manipulating the master hand; in the program control mode, the movement of the manipulator body in th...

Embodiment 2

[0051] In one or more embodiments, a working method of a live working robot system for an autonomous power distribution network is disclosed, including:

[0052] The autonomous distribution network live working robot can work in the master-slave mode or the program-controlled mode; and through the control terminal in the vehicle-mounted control room 3, the two working modes can be switched arbitrarily.

[0053] In the master-slave mode, the control action of the main hand controlled on the ground is transmitted to the operating robot arm 6 in real time, and the operation information of the operating robot arm 6 is fed back in real time through the visual feedback module, so as to realize the movement of the operating robot arm 6 and the control of the main hand controlled on the ground Action synchronization;

[0054] In the program control mode, the operating manipulator 6 is controlled to perform live work according to the set program instructions, including: the operating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com