Roots pump rotor and Roots pump

A rotor and rotor profile technology, applied in pumps, pump components, rotary piston pumps, etc., can solve problems such as inability to adapt to application performance requirements, increase space for variable shape parameters, insufficient space for variable shape parameters, etc., to achieve structural The effect of compactness, low vibration and noise, and high pumping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

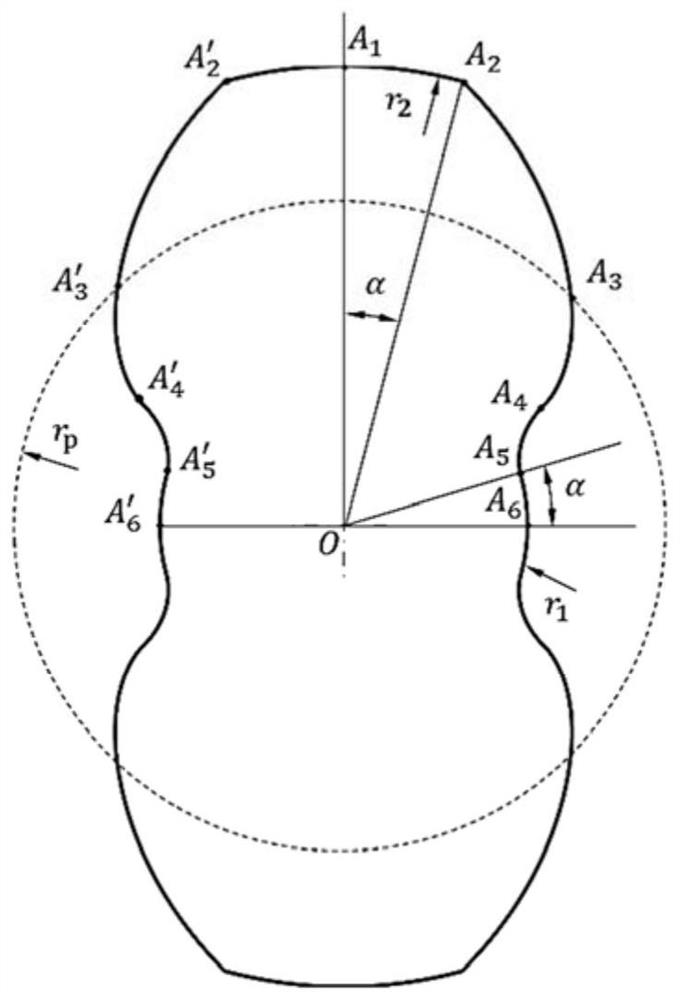

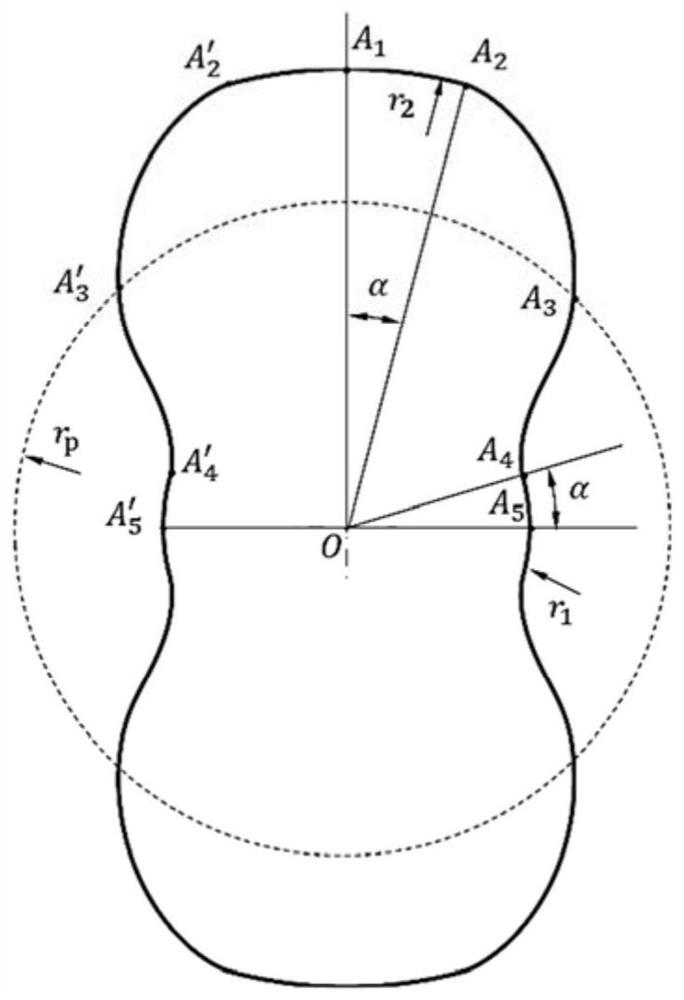

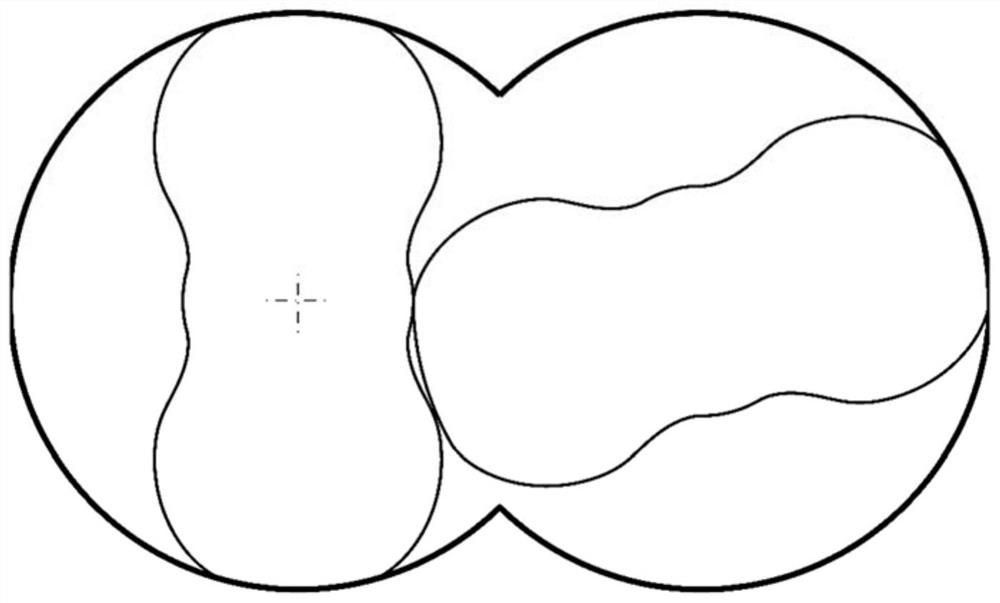

[0031] see figure 1 , in the profile line of the original Roots pump, the profile line A on the left side of the rotor 1 A' 2 A' 3 A' 4 A' 5 A' 6 with right side profile A 1 A 2 A 3 A 4 A 5 A 6 The left and right sides are symmetrical, and the lower profile and the upper profile are vertically symmetrical, so that the rotor profile is defined by the curve segment A 1 A 2 A 3 A 4 A 5 A 6 Uniquely determined, the curve segment consists of the arc segment A 1 A 2 , the involute segment A 2 A 3 , the involute segment A 3 A 4 , epicycloid segment A 4 A 5 , and arc segment A 5 A 6 composed of It can be seen from the figure that this type of line is determined by the parameter r 1 , r 2 With α uniquely determined, there are fewer independent parameters. and since the cusp A 2 The existence of , making the involute segment A 2 A 3 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com