Soft rock triaxial strength evaluation method and system

An evaluation system and strength technology, applied in the direction of strength characteristics, instruments, measuring devices, etc., can solve the problems of difficult to obtain parameters, include many parameters, and not suitable for soft rock, etc., achieve high degree of automation, high evaluation accuracy, and ensure objectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

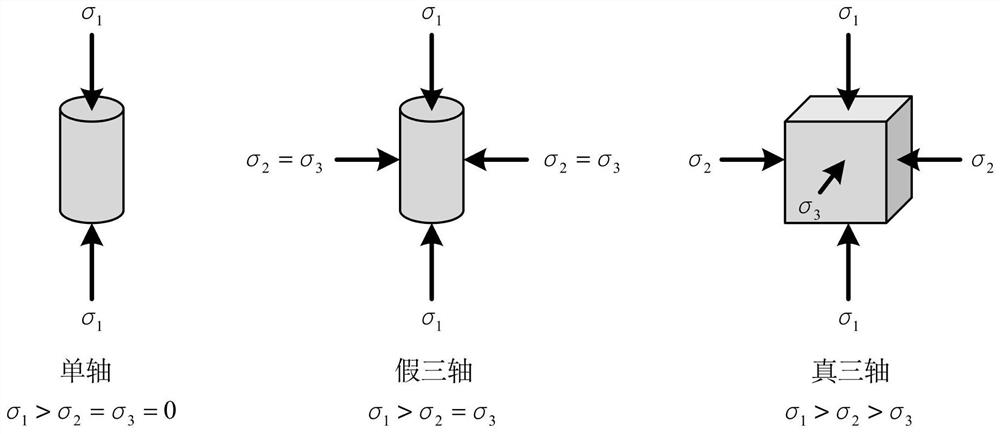

[0060] Engineering background: buried rocks (soft rock or hard rock) are usually in a complex triaxial stress state rather than a simple uniaxial stress state; in order to accurately predict the mechanical behavior of soft rock in a triaxial stress state , it is necessary to accurately evaluate the true triaxial strength of soft rock; to obtain the true triaxial strength of soft rock, the most direct way is to conduct a true triaxial test; however, performing a true triaxial test is extremely time-consuming, laborious, and expensive The direct reason is that less than 50 sets of rock true triaxial tests have been conducted in the world; for this reason, bypassing the complicated and cumbersome true triaxial tests and evaluating the true triaxial strength of soft rock through a simple method is very important for the safety and efficiency of soft rock engineering. The construction is of great significance; unfortunately, the existing methods cannot be applied to soft rocks becau...

Embodiment 2

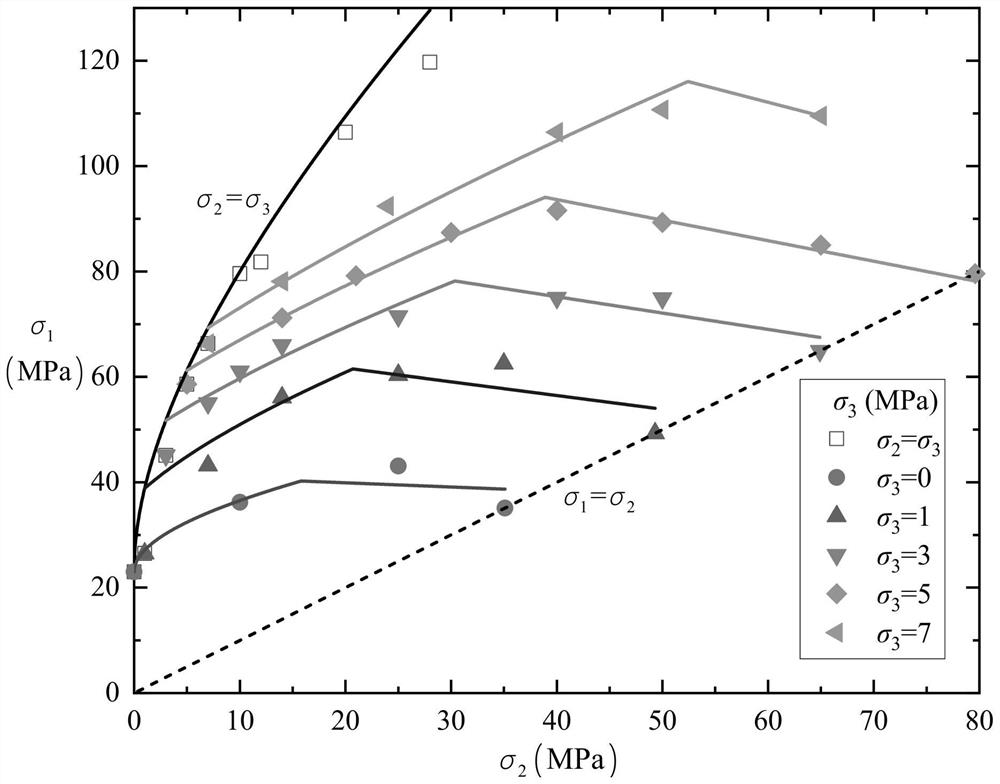

[0093] Test background: due to the very few rock true triaxial test data (less than 50 groups in the world), the true triaxial test data about soft rock is even less, so it is intended to verify the evaluation effect of the present invention through a large amount of soft rock true triaxial test data This road is impossible; for this reason, it is a good choice to further verify the evaluation effect of the present invention through a large amount of false triaxial test data (soft rock database, see Table 2); in fact, as before As mentioned above, when the dimensionless parameter B=0, the true triaxial degenerates into a false triaxial; in other words, the false triaxial is a special case of the true triaxial.

[0094] The soft rock database for verifying the evaluation effect is shown in Table 2 below.

[0095] Table 2 Soft rock database information

[0096]

[0097]

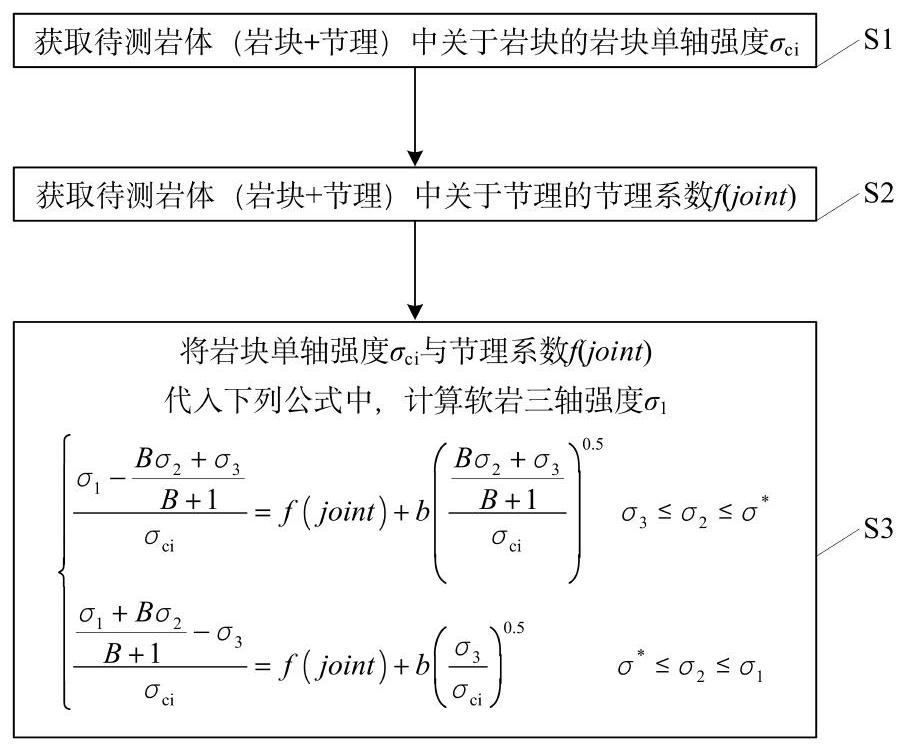

[0098] Specifically, such as figure 2 As shown, the soft rock triaxial strength evaluation method p...

Embodiment 3

[0122] The third embodiment provides a soft rock triaxial strength evaluation system, which can automatically realize the soft rock triaxial strength evaluation method described in the first and second embodiments. Specifically, the soft rock triaxial strength evaluation system includes: a uniaxial strength acquisition unit, a joint coefficient acquisition unit, a stress acquisition unit, a soft rock triaxial strength calculation unit, an input display unit and a control unit.

[0123] The uniaxial strength acquisition part can acquire the uniaxial strength σ of the rock block in the soft rock mass to be measured ci , which includes a uniaxial strength tester and a uniaxial strength data processor. The uniaxial strength tester can perform uniaxial strength test on the soft rock mass to be tested to obtain uniaxial strength test data, and the uniaxial strength data processor processes the uniaxial strength test data to obtain the uniaxial strength σ of the rock block ci .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com