A design method of a variable-pitch internal meshing screw rotor and a twin-screw compressor rotor

A compressor rotor and internal meshing technology, which is applied in the field of compressors, can solve the problems of increasing leakage intensity, increasing leakage area, and large pressure difference in the working chamber, so as to improve thermal performance, avoid leakage area, and reduce vibration and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

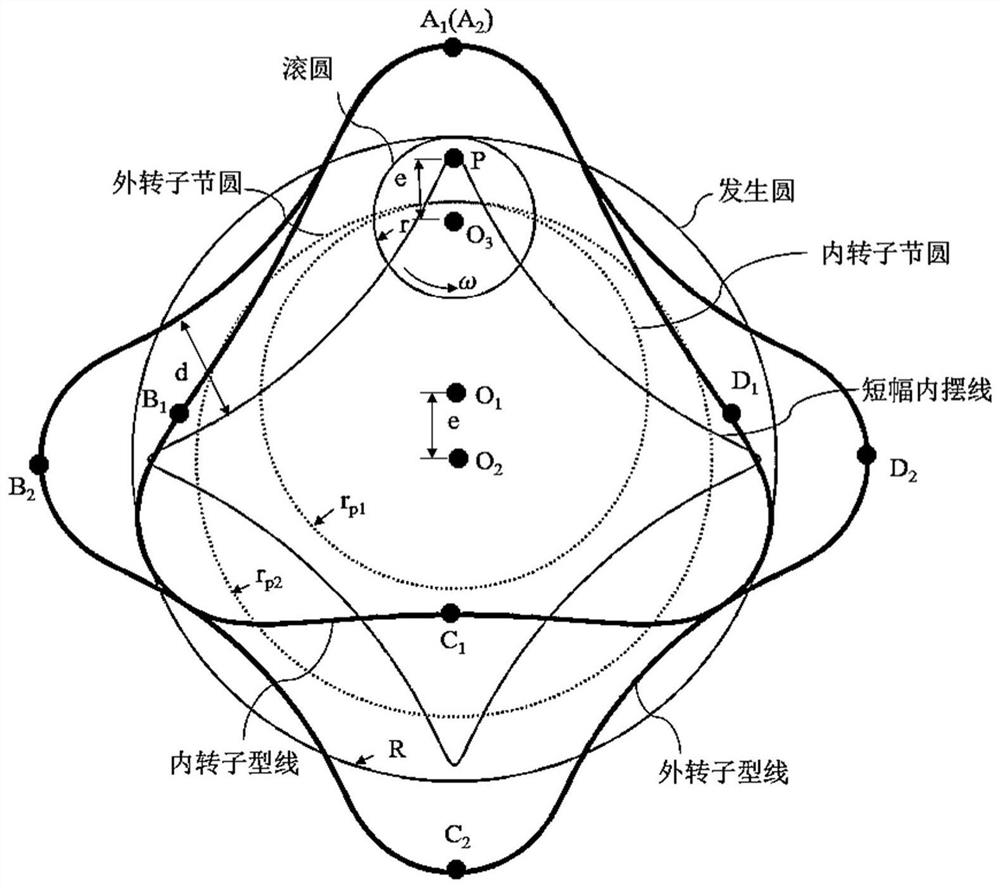

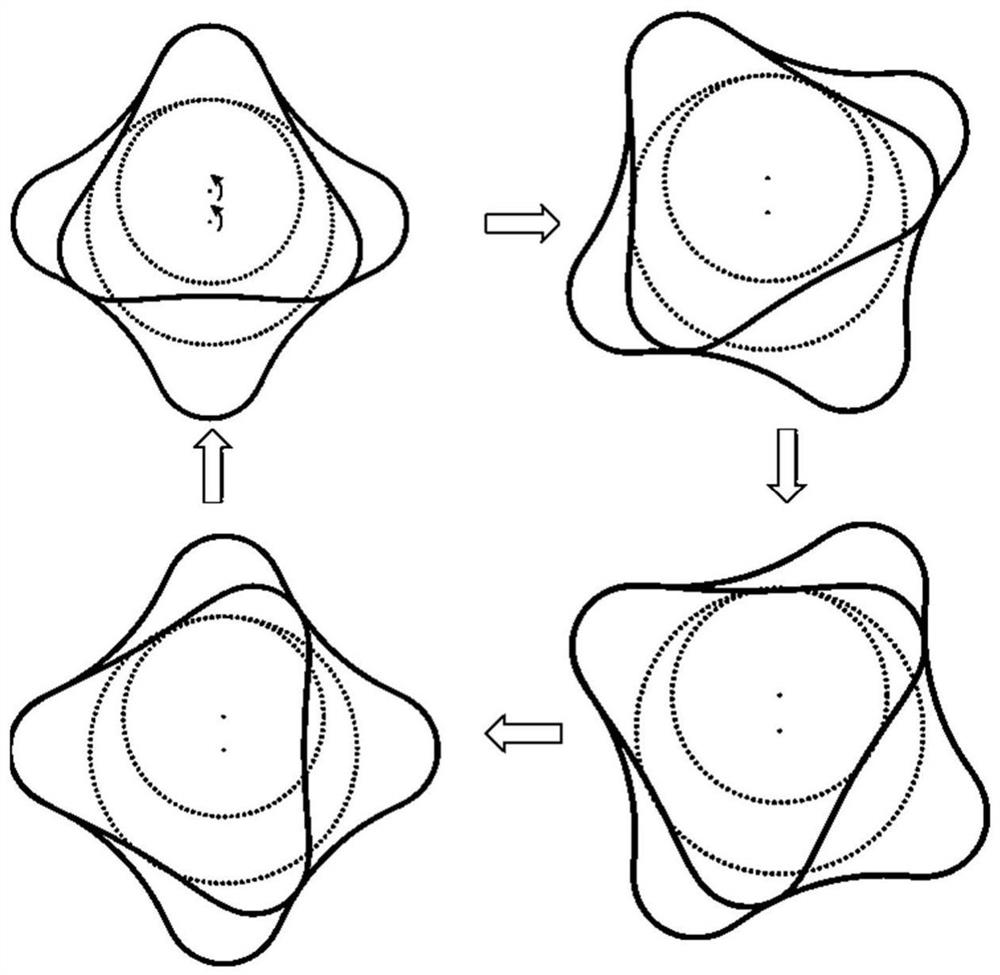

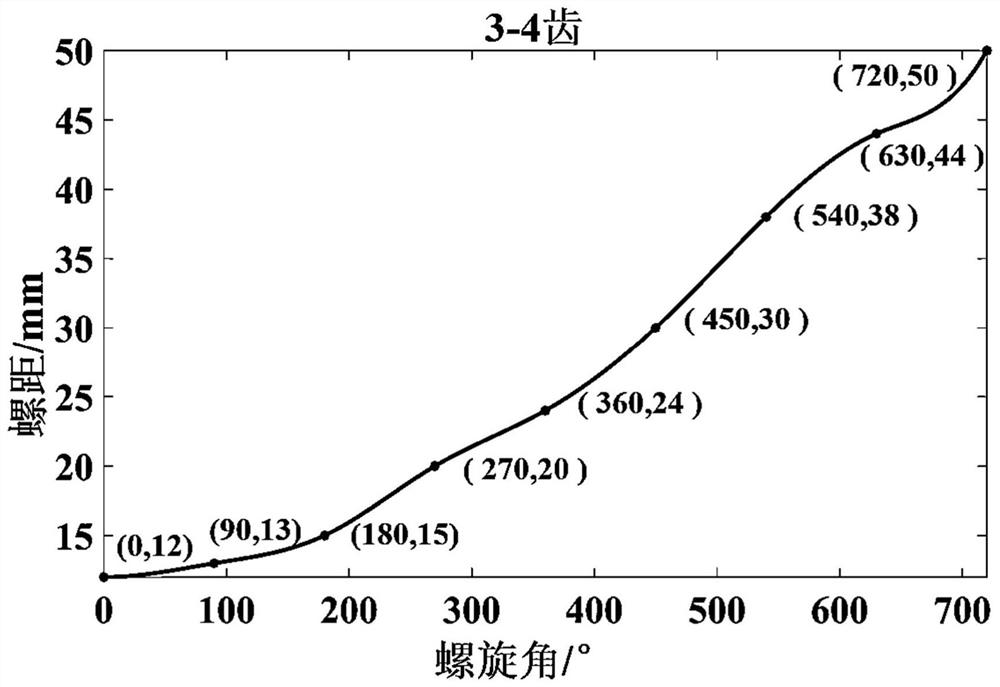

[0079] The profile line of the outer rotor of the variable pitch inner meshing twin-screw compressor rotor of the present invention is A 2 B 2 C 2 D 2 , the inner rotor profile is the conjugate curve A of the outer rotor profile 1 B 1 C 1 D 1 . The inner and outer rotors of the rotor of the twin-screw compressor of the present invention are formed by scanning along the guiding helix with variable pitch while the rotor profile rotates, and the independent parameter is the number of teeth Z of the outer rotor. 2 , spheroid radius r and eccentricity e, equidistant distance d, outer rotor leading helix discrete point lead P 1 -P n , the corner γ 2 . Its design process is as follows:

[0080] 1. The helix angle γ of the outer rotor is optimized according to the requirements of gas tightness and force performance. 2 is 2π (720°).

[0081] 2. The rotor center distance e, the spheroid radius r, the equidistant distance d, and the number of teeth of the outer rotor Z are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com