A twin-screw vacuum pump rotor profile

A technology of rotor profiles and vacuum pumps, applied in pumps, pump components, rotary piston pumps, etc., can solve the problems of increasing processing costs and achieve the effects of reducing processing costs, compact structure, and high pumping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

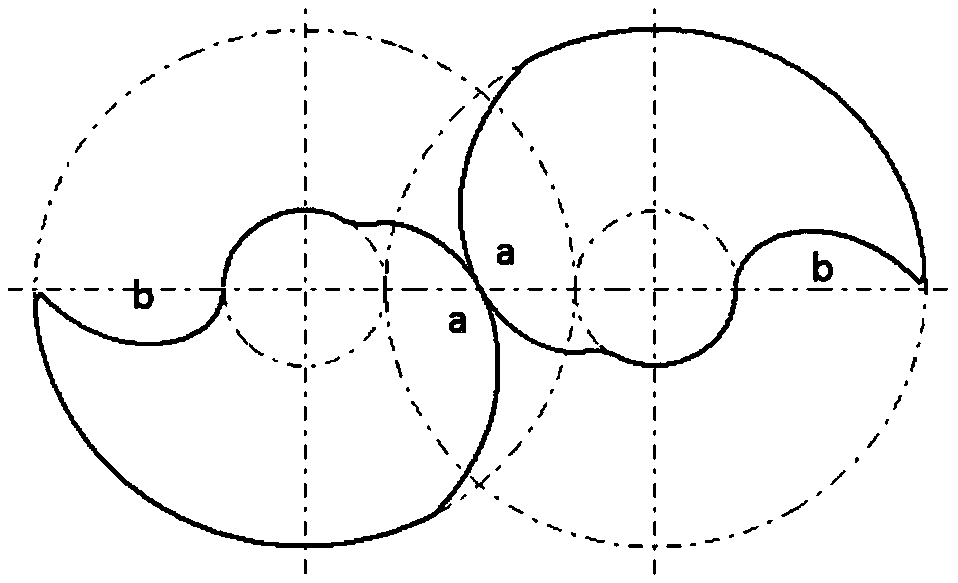

[0029] see figure 1 , the present invention adopts the original single-head twin-screw vacuum pump profile as the original shape and can be transformed. In the original profile, the a curve of the two circular arc connecting line is meshed with the other rotor a curve, and the b curve is meshed with the b curve. In order to ensure The similarity of the profiled lines of the two rotors, the profiled lines of the two rotors must be exactly the same, so that the structure of the male and female rotors has the opposite direction of rotation, and the profiled lines of the present invention mesh with the curve a and the curve b, thereby realizing the symmetry of the profiled lines and ensuring The consistency of the structure of the male and female rotors is ensured.

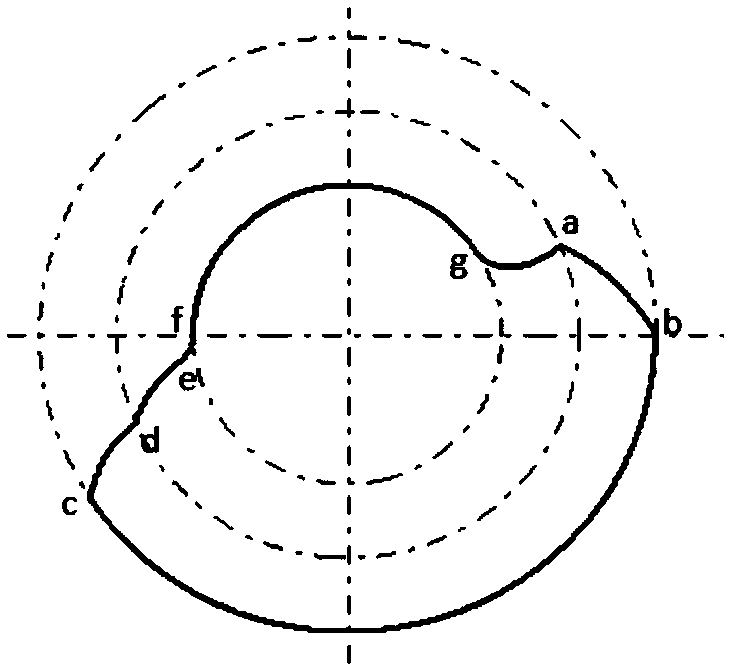

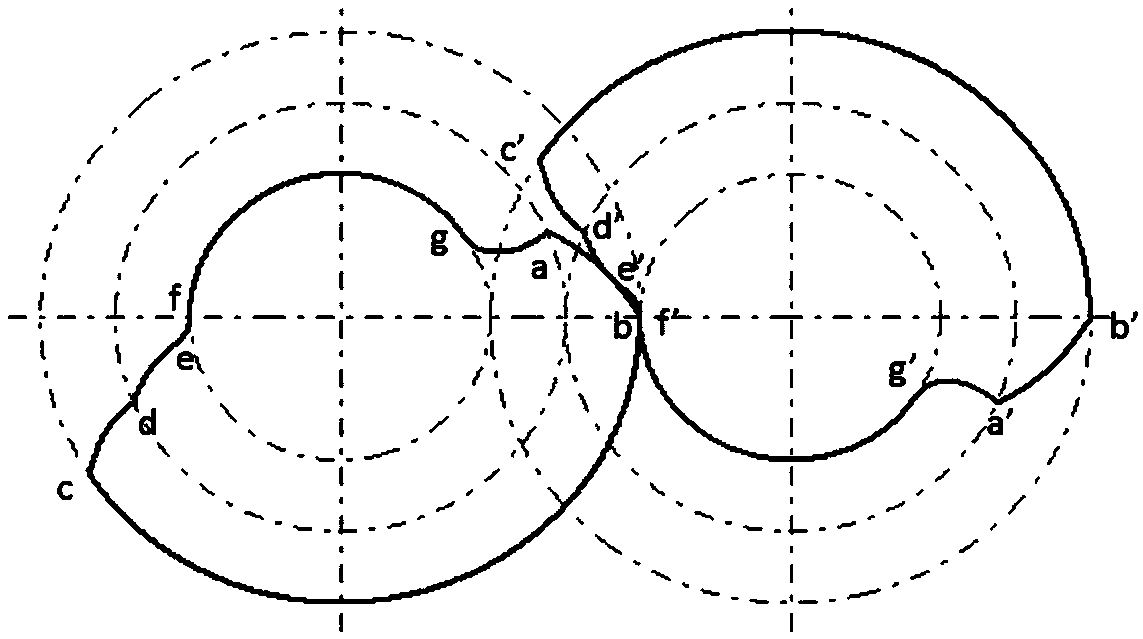

[0030] see Figure 2-3 and Figure 4 (a)- Figure 4 (h), the profile line of the rotor of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com