A triangular rotor engine combined cylinder molded line design method

A triangular rotor, combined technology, used in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problem of not considering the radial seal movement, accelerate the wear of the top of the radial seal and the cylinder profile, and increase engine friction. Power loss and other issues, to achieve the effect of improving flutter, increasing engine compression ratio, and improving wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

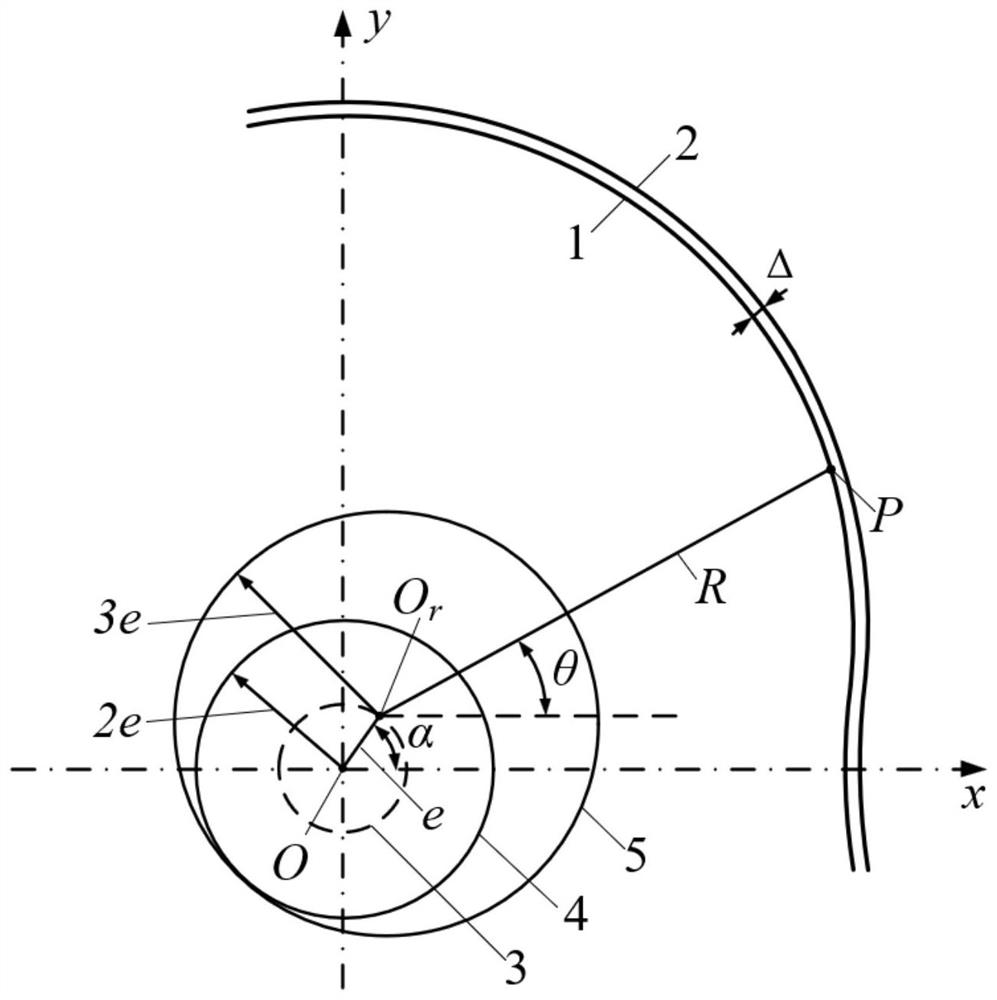

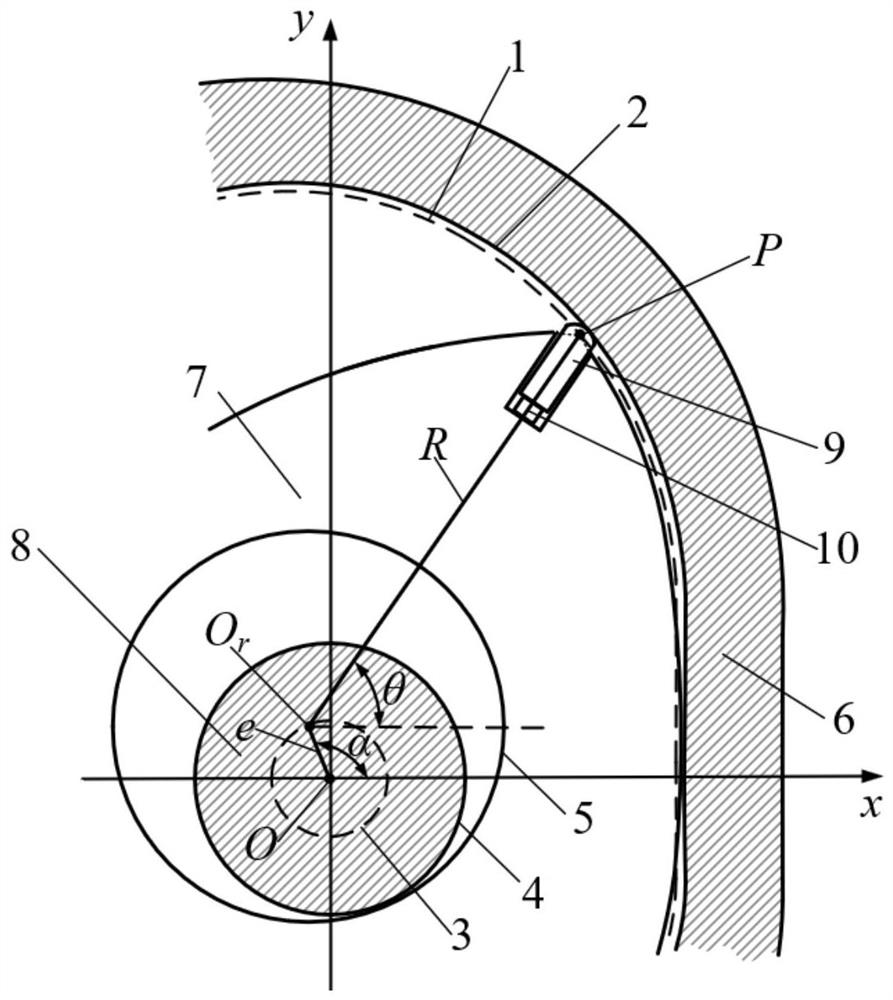

[0068] The theoretical cylinder profile of a rotary engine is geometrically called a double-arc short epitrochoid, with figure 1 Schematic showing the inscribed creation of the cylinder profile. When the center of the circle is O r 1. When the pitch circle 5 with a radius of 3e (equivalent to the internal gear of the rotor) rolls without slipping along the pitch circle 4 with the center of O and the radius of 2e (equivalent to the external gear of the eccentric shaft), there is a pitch circle outside the pitch circle 5 Circle 5 Center O r The connected point P (the apex of the rotor) also rolls together, so that the trajectory of point P is the cylinder theoretical profile, that is, the initial cylinder theoretical profile 1. The actual profile 2 of the initial cylinder can be obtained by offsetting the theoretical profile line 1 of the cylinder outward by a distance of δ. Among them, the equation of initial cylinder theoretical line 1 is:

[0069]

[0070] attached f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com