Adjustable damping damping device and vibration reduction method in the milling process of thin-walled parts

A technology for thin-walled parts and damping adjustment, which is applied in the direction of milling machine equipment, milling machine equipment details, maintenance and safety accessories, etc., can solve the problems of large machining allowance, easy to generate flutter, thin wall and poor rigidity of thin-walled parts, etc., to achieve Effect of large structural loss factor, suppression of blade flutter, and multiple vibration energies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

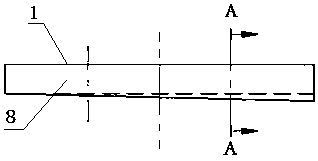

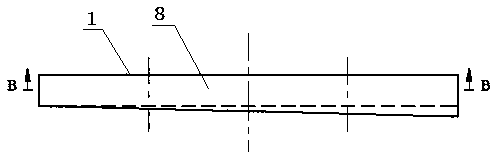

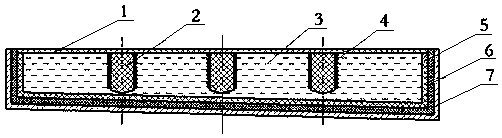

[0033] An adjustable damping type vibration damping and vibration suppression device in the process of milling thin-walled parts, which is composed of: a vibration damping and vibration suppression device 9, the vibration damping and vibration suppression device comprises a sealing cavity 8, and the sealing cavity The top plate 1 is installed on the upper plane, the outer layer of the sealed cavity is a constraining layer 7, a damping layer 6 is installed inside the constraining layer, a damping layer substrate 5 is installed inside the damping layer, and the damping layer substrate A magnetorheological fluid 3 is installed inside, six permanent magnets 2 are installed in the magnetorheological fluid, and a coil 4 is wound around the outside of the permanent magnet.

Embodiment 2

[0035] According to the adjustable damping type vibration damping and anti-vibration suppression device during the milling of thin-walled parts according to Embodiment 1, the permanent magnets are divided into two rows and arranged in parallel with three in each row, and the upper plane of the permanent magnets is the same as that of the permanent magnets. top plate fit.

Embodiment 3

[0037] According to the adjustable damping vibration damping and vibration suppression device during the milling process of thin-walled parts according to Embodiment 1 or 2, the vibration damping and vibration suppression device is bonded to one side of the blade 10 by strongly adsorbing the double-sided tape, so The other side of the blade mentioned above is the surface to be machined (machined with a ball end mill).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com