Double-beat hammer mechanism

A hammer and reset mechanism technology, applied in the field of striking tool mechanism and double-click hammer mechanism, can solve the problems of complex structure, increase the striking force, damage, etc., and achieve the effect of lifting effect, accurate striking and suppressing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

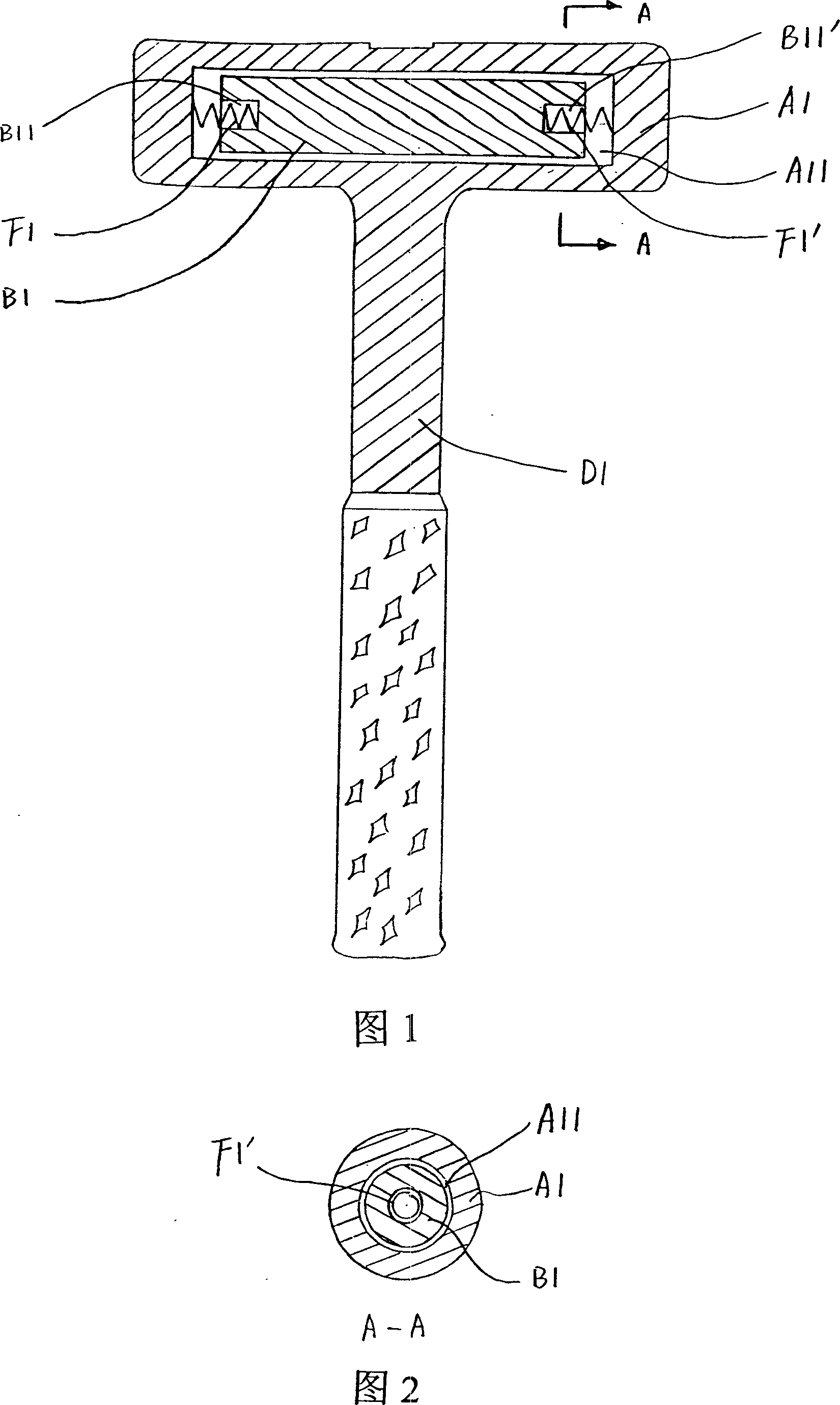

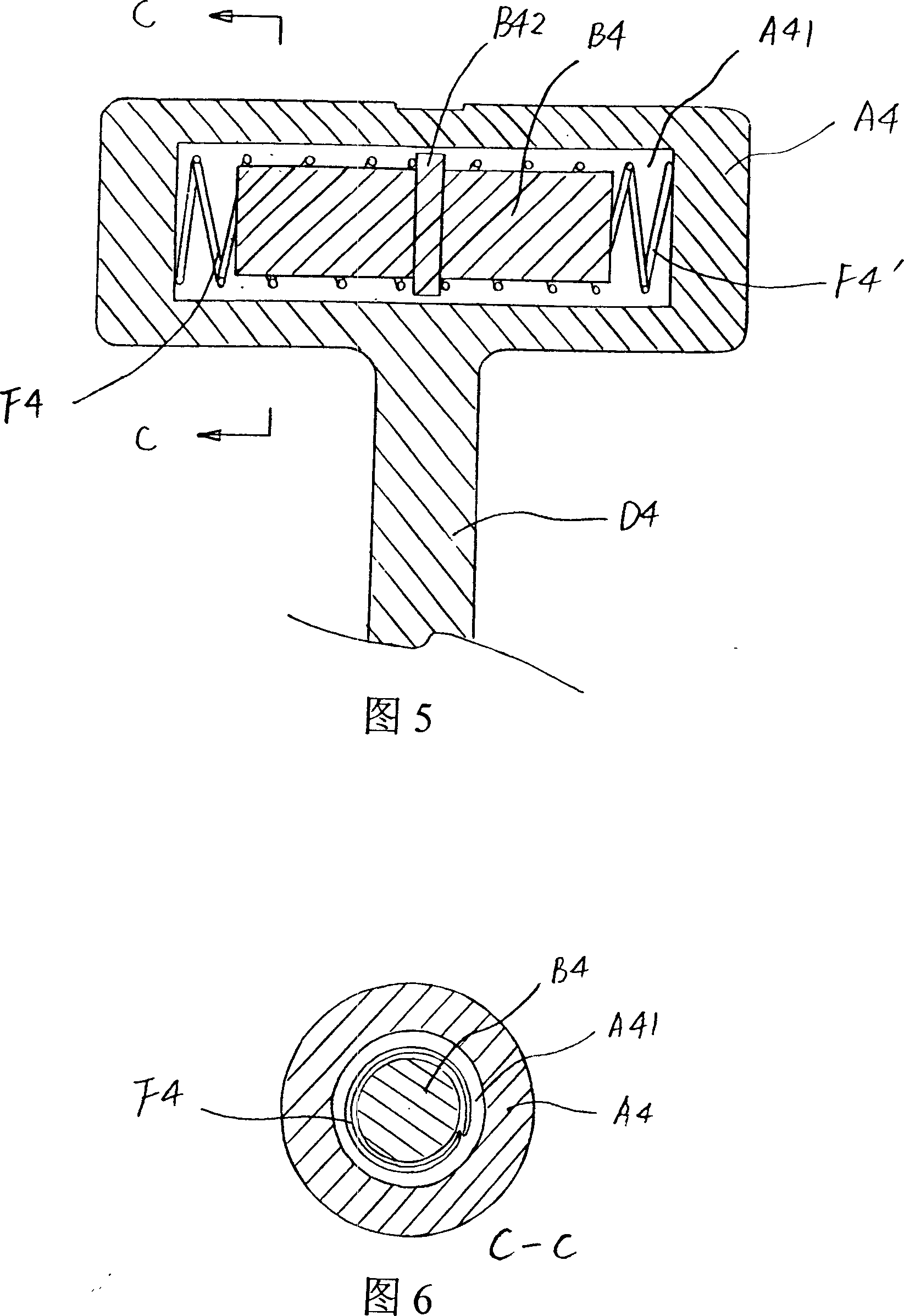

[0068] As shown in the cross-sectional structural schematic diagram of Figure 1 Embodiment 1 and the cross-sectional view of Figure 2A-A, a double-click hammer mechanism includes a hammer head A1 and a hammer handle D1, and the hammer head A1 has a sealed movable mass B1, which is sealed The structure of the mass block is not shown in the figure, and a cavity A11 is formed inside, and the mass block B1 can move along the direction of hammer strike and be positioned by the reset mechanism. Wherein, the reset mechanism is a pair of compression springs F1, F1'.

[0069] The mass B1 is a strip-shaped mass that matches the shape of the inner profile of the cavity A11, and has a certain gap with the cavity A11. The two ends are respectively provided with inner holes B11 and B11', and the parts of the compression springs F1 and F1' are respectively embedded in the two inner holes. In B11 and B11', the extension parts of the compression springs F1 and F1' respectively abut against the...

Embodiment 2

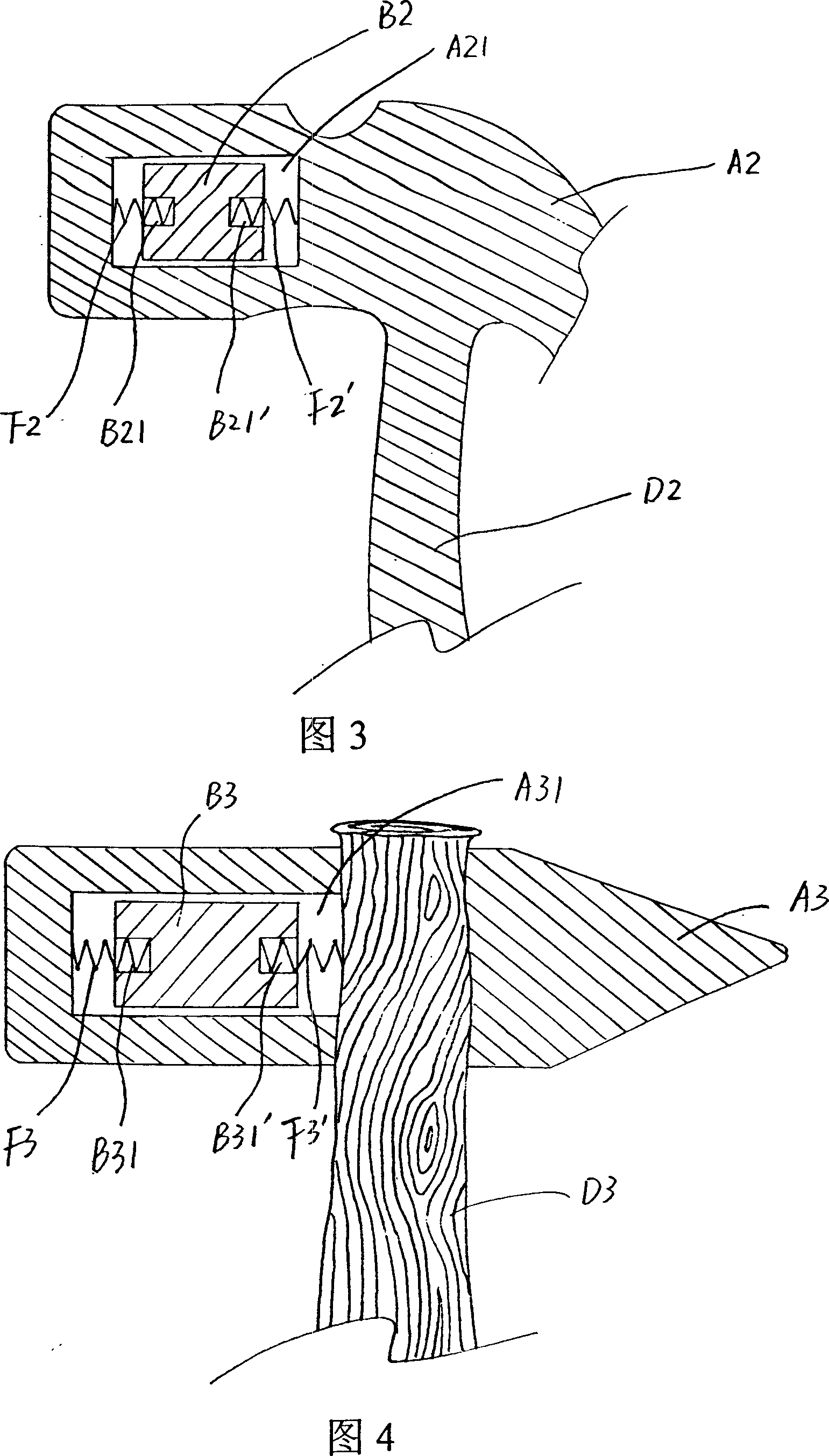

[0071]As shown in the schematic cross-sectional structure of Figure 3 Embodiment 2, a double-click hammer mechanism includes a hammer head A2 and a hammer handle D2, the hammer head A2 is a claw hammer head, and there is a sealed movable mass B2 in the hammer head A2. The structure of the sealed mass block is not shown in the figure, and a cavity A21 is formed inside. The said mass block B2 can move along the direction of hammer strike and be positioned by the reset mechanism. Wherein, the reset mechanism is a pair of compression springs F2, F2'.

[0072] The quality block B2 is a bar-shaped mass block that matches the shape of the inner profile of the cavity A21, and has a certain gap with the cavity A21. The two ends are respectively equipped with inner holes B21 and B21', and the parts of the compression springs F2 and F2' are respectively embedded in the two inner holes. In B21 and B21', the extension parts of the compression springs F2 and F2' respectively abut against th...

Embodiment 3

[0074] As shown in the cross-sectional structure schematic diagram of Figure 4 Embodiment 3, a double-click hammer mechanism includes a hammer head A3 and a hammer handle D3. The hammer head A3 is a hammer head provided with a through hole for the hammer handle to pass through. In the hammer head A3 There is a sealed movable mass B3, the structure of the sealed mass is not shown in the figure, and a cavity A31 is formed inside, the mass B3 can move along the direction of the hammer, and is positioned by the reset mechanism. Wherein, the reset mechanism is a pair of compression springs F3, F3'.

[0075] The quality block B3 is a bar-shaped mass block that matches the shape of the inner profile of the cavity A31, and has a certain gap with the cavity A31. The two ends are respectively equipped with inner holes B31 and B31', and the parts of the compression springs F3 and F3' are respectively embedded in the two inner holes. In B31 and B31', the extension of the compression sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com