Protective equipment for wind power generation

A protective equipment, integrated technology, applied in the direction of wind energy power generation, wind turbines, mechanical equipment, etc., can solve the problem of generator heat is not easy to dissipate, affect the service life, reduce the use performance and other problems, to improve work efficiency and performance, not easy to block , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

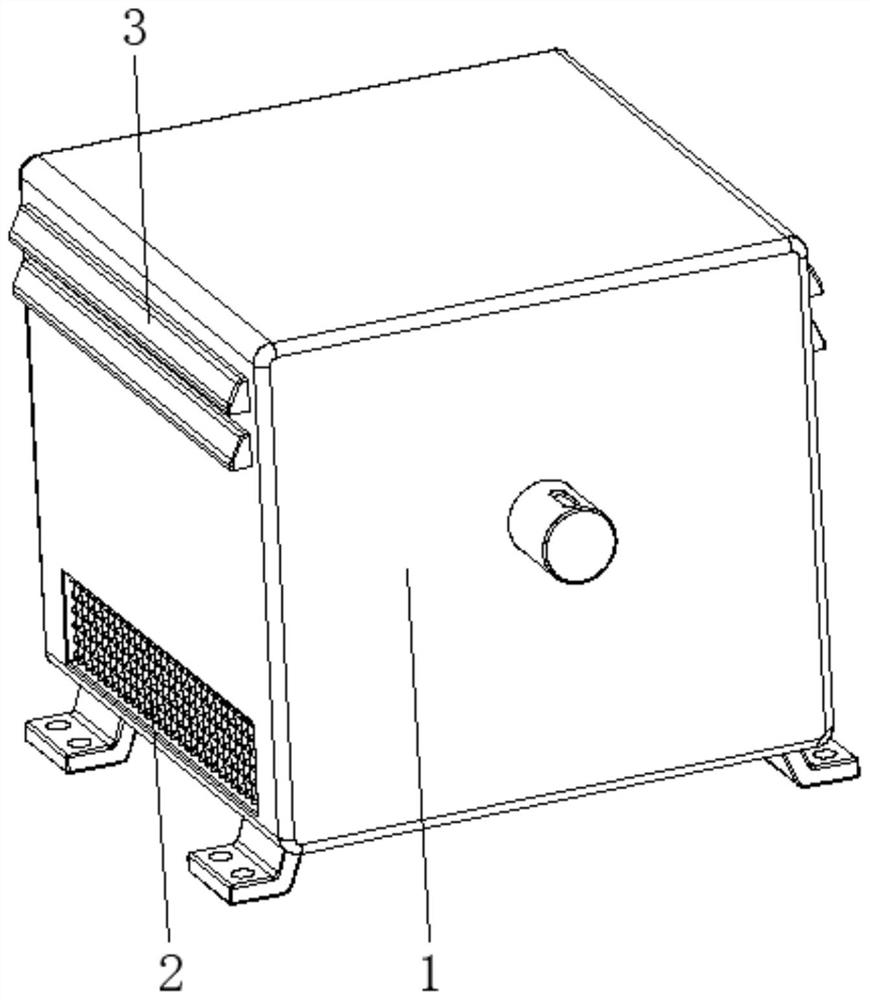

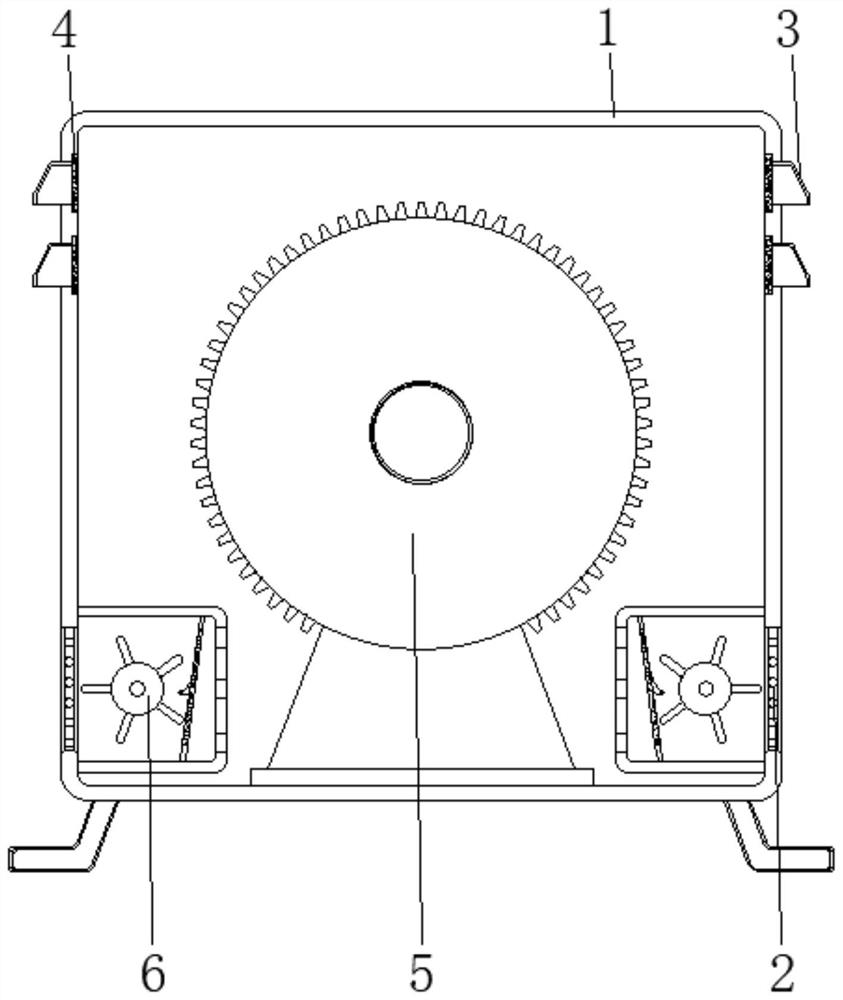

[0032] see Figure 1-7 , the present invention provides a technical solution: a protective device for wind power generation, including a box 1, a partition 2, and a cover 3, the partition 2 is fixed on the two sides corresponding to the bottom of the surface of the box 1, and the cover 3 is fixed On both sides corresponding to the top part of the surface of the box body 1, the cover plate 3 corresponds to the position of the partition net 2;

[0033] The interior of the box body 1 is provided with a dustproof filter screen 4, a wind power generator 5, and an integrated processing device 6. The dustproof filter screen 4 is fixed on the inner wall of the box body 1 and is located at the position of the cover plate 3, and the wind power generator 5 is fixed on the box body. The bottom of the inner wall of the body 1 is located in the center, and the integrated processing device 6 is arranged inside the box body 1 and located at the position of the partition net 2, which can dissi...

Embodiment example 2

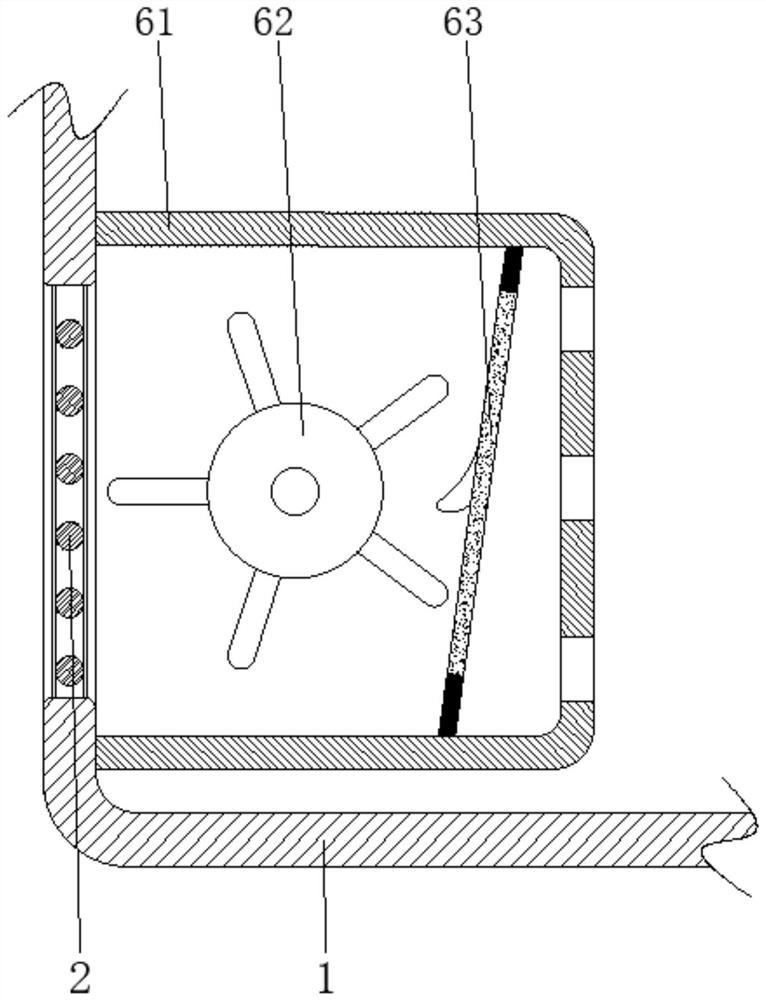

[0035] The integrated processing device 6 is provided with a U-shaped housing 61, a heat dissipation device 62, and a dust removal device 63. The open end of the U-shaped housing 61 faces the partition net 2 and is fixedly connected with the inner wall of the box body 1. The heat dissipation device 62 is arranged on the U-shaped housing. The inside of the body 61 is close to the central position, and the dust removal device 63 is arranged on the inner side of the U-shaped housing 61. The cooling device 62 is connected with the dust removal device 63, which makes full use of its own rotation during heat dissipation and reduces the impact on power. Use, combined with the mutual cooperation between the heat dissipation device 62 and the dust removal device 63, has played the effect of heat dissipation and dust removal at the same time, and achieved multiple functions.

Embodiment example 3

[0037]The cooling device 62 is provided with a drive roller 621, a fan blade device 622, and a ball 623. The end of the drive roller 621 is rotatably connected to the inner wall of the U-shaped housing 61. The fan blade device 622 is arranged inside the drive roller 621 and is located on the surface. The ball 623 is set on the surface of the fan blade device 622 and away from the end of the driving roller 621. When the driving roller 621 drives the fan blade device 622 to rotate, it can drive the air in the box 1 in time and discharge it from the dustproof filter 4 , and the external space enters the box body 1, so that the air circulation is used to quickly dissipate heat from the wind turbine 5, and at the same time, the rotating fan blade device 622 uses the ball 623 to roll on the arc surface gradual protrusion 633 to reduce friction , and press the frame 631 and shake it to make the whole rotation process smoother, and use the action force and reaction force to make the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com