Patents

Literature

30results about How to "Accurate tapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

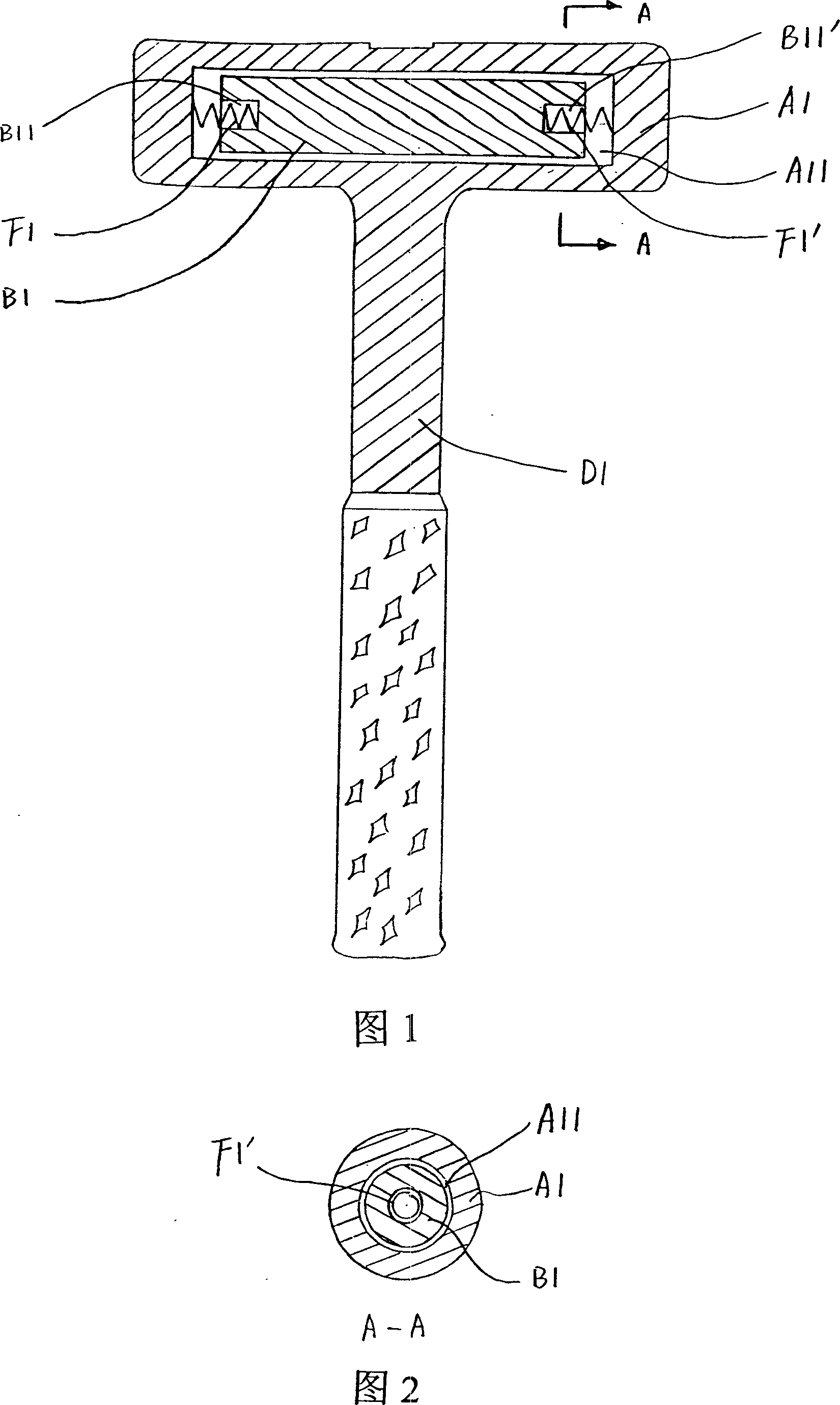

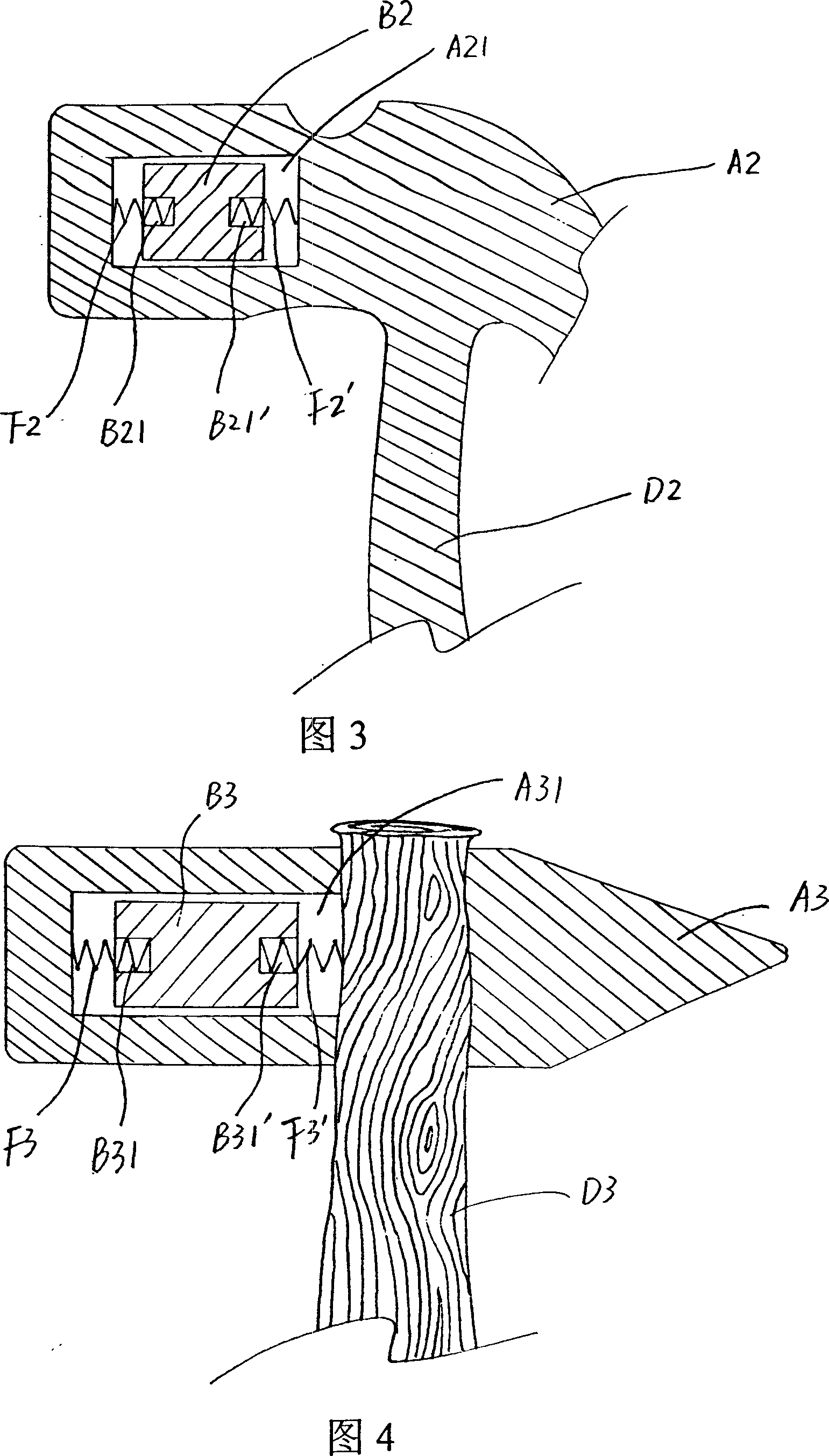

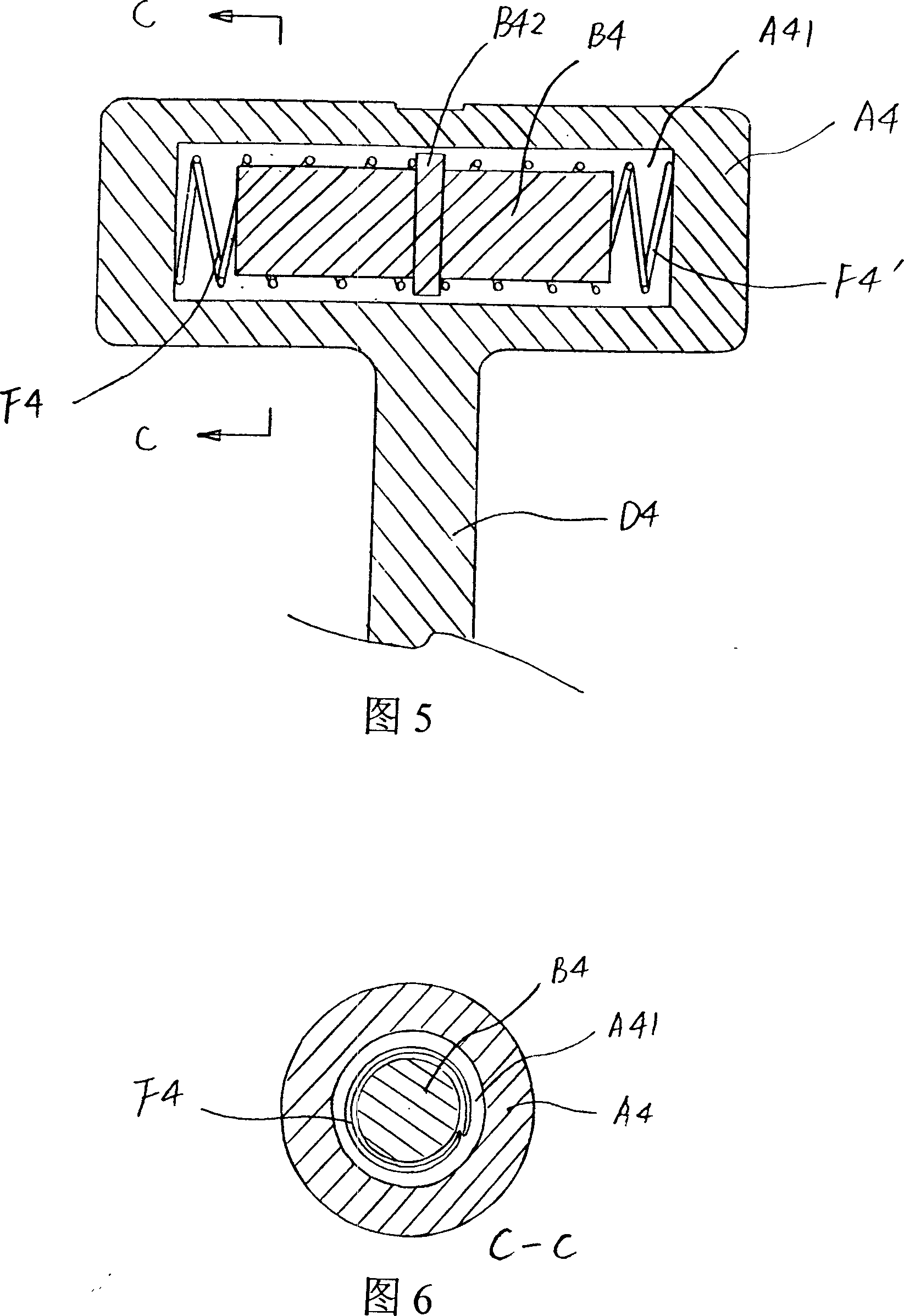

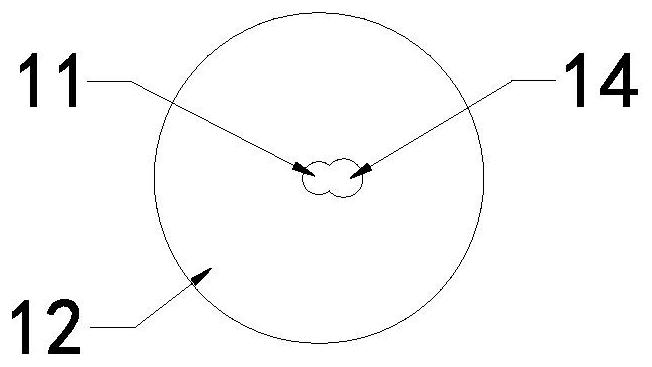

Double-beat hammer mechanism

InactiveCN1970238AImprove percussionReduce or eliminate elasticityHoesHand cultivatorsEngineeringGolf Ball

It relates to a dual acting hammer modified from ordinary hammers. It comprises the hammer head and hammer handle, with the head contained with sealed and movable blocks. It features in the once time for time hammering with improved hammering effect, being more accurate, reduced or illuminated vibration resulted from counteraction, simple structure, same shape with the ordinary hammer after quick resetting of blocks. It can be used for hammering tools like hack, handle axe, axe, tennis racket, and golf pole and so on.

Owner:弗兰克·当泰·埃多莱·克罗那

Electricity-coal process melting and reduction ironmaking technology

The invention relates to an electricity-coal process melting and reduction ironmaking technology. The electricity-coal process melting and reduction ironmaking technology comprises the following steps of: conveying metallized pellets produced by a gas / coal-based direct reduction device into a heat preservation storage silo of a melting and reduction furnace by utilizing a hot delivery device at the temperature of 900-1000 DEG C under non-oxidizing conditions, completing mixture making in the heat preservation storage silo, then conveying the mixture into a high-temperature area in the furnace, then heating by utilizing electric arc to melt the mixture, simultaneously spraying carbon powder to perform reduction, and then performing technological slagging off and electric arc heating melting in a circulating manner till the temperature and the ingredients of a sample achieve the standards, wherein the mixture making in the heat preservation storage silo is performed by mixing the metallized pellets, a reducing agent and slag charge according to the weight ratio of 85: 15: 5. The electricity-coal process melting and reduction ironmaking technology disclosed by the invention is designed against low-grade ores, refractory ores and complex ores, open-burning coal is used as energy, the carbon-containing metallized pellets are taken as raw materials, a final reduction technology for directly producing molten iron (or titanium refining slag and the like) is solved, and the electricity-coal process melting and reduction ironmaking technology is of a key technology for sustainable development of iron and steel industry in China, energy conservation, emission reduction and environment-friendly development.

Owner:XIAN TAOYUAN METALLURGY EQUIP ENG CO LTD

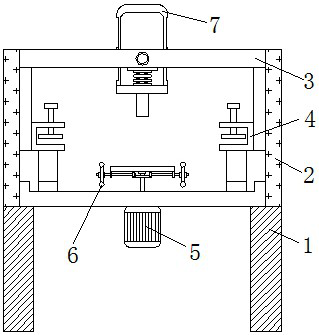

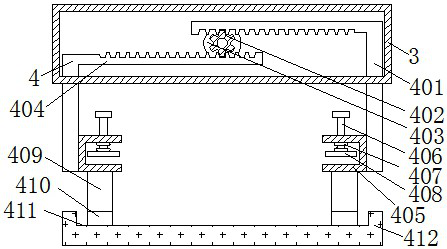

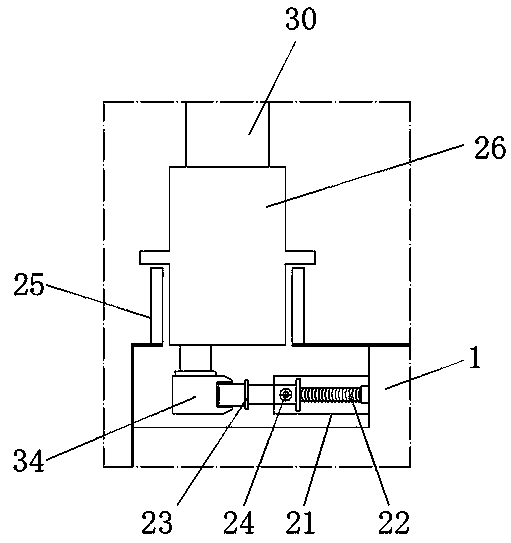

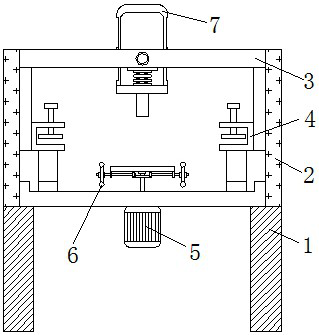

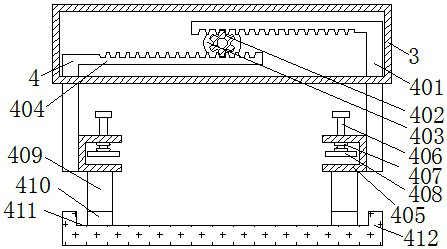

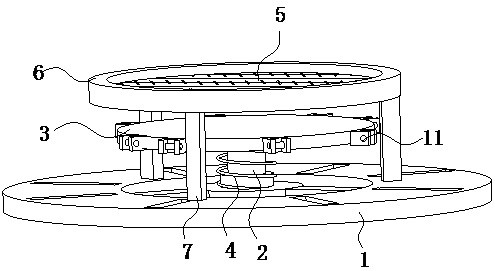

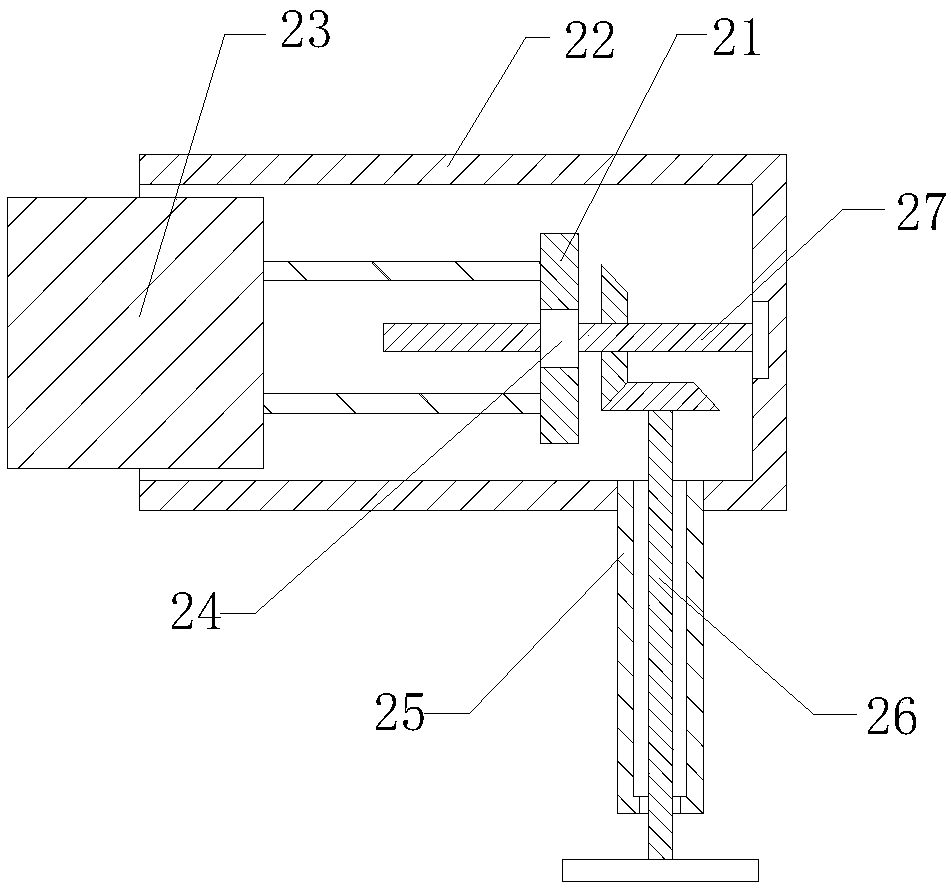

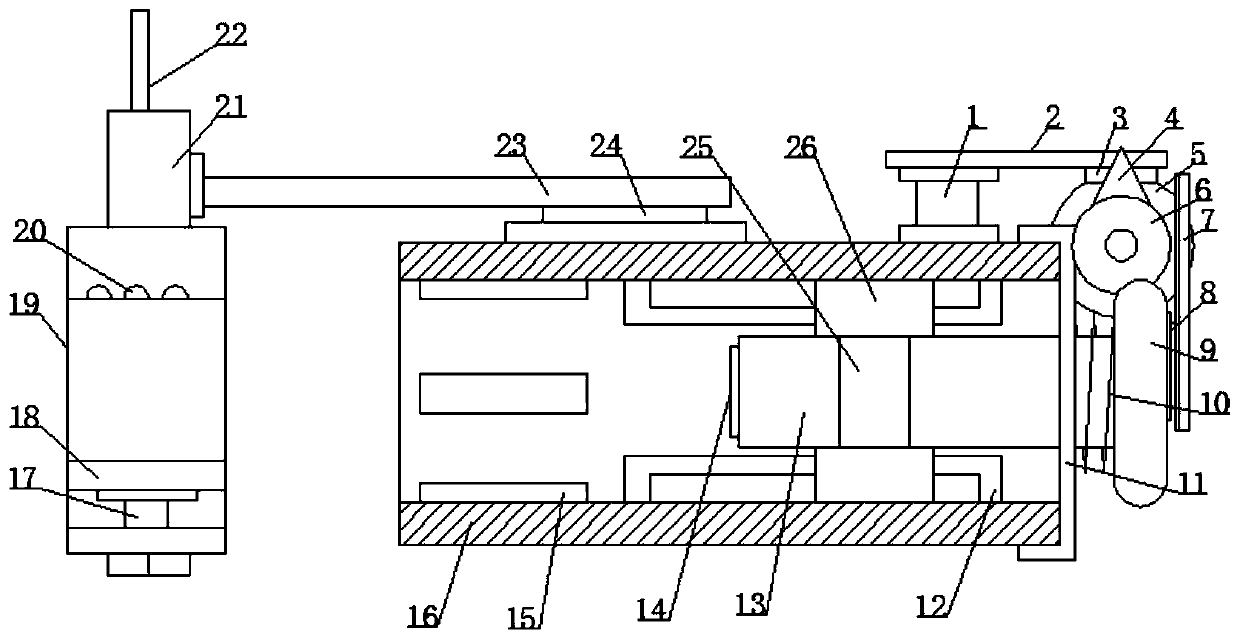

Toughness and strength detection device for toughened bulletproof material

ActiveCN111678816AFast and convenient toughness testingGuaranteed uniformityMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention relates to a toughness and strength detection device for a toughened bulletproof material. The device comprises a supporting column; the top end of the supporting column is provided witha vertical plate, and the top of the vertical plate is connected with a top plate; the bottom of the top plate is provided with a toughness measuring assembly; an upper insection rod is arranged in the toughness measuring assembly; an insection shaft is installed at the bottom end of the upper insection rod in an engaged mode, and a rotating block is connected with the rear end face of the insection shaft. According to the invention, the toughness measuring assembly is designed; a material is placed at the bottom of the pressing plate; the material is pressed by rotating the threaded rod, andthe detected material is fixed in a C-shaped block; the rotating block is rotated, and under the action of the insection shaft, the upper insection rod and a lower insection rod drive the C-shaped block to move, so that the C-shaped block stretches the two sides of the detected material; the toughness of the material is detected; and through the arrangement, toughness detection can be rapidly andconveniently conducted on the material, stress uniformity of the two sides of the detected material is guaranteed, and objectivity and accuracy of detection are guaranteed.

Owner:上海衡益特陶新材料有限公司

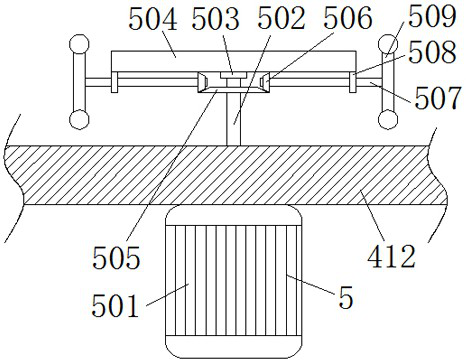

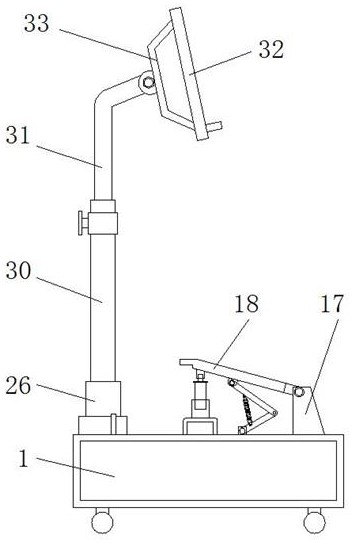

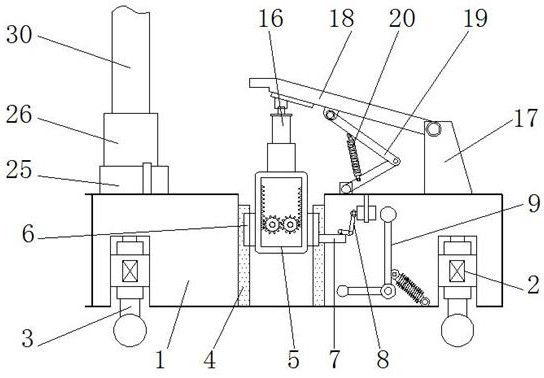

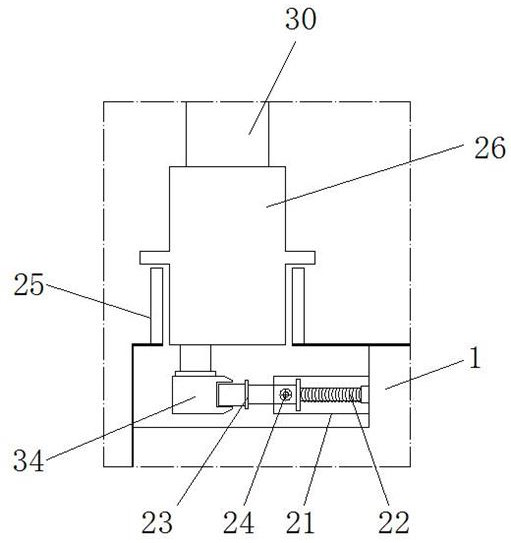

Foot-operated metronome for music teaching

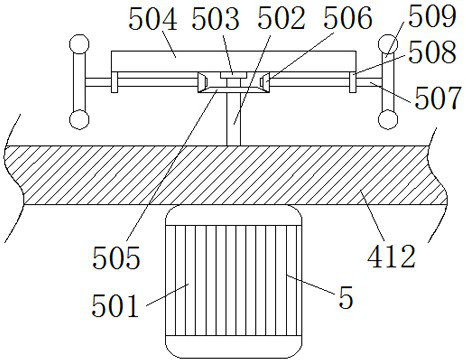

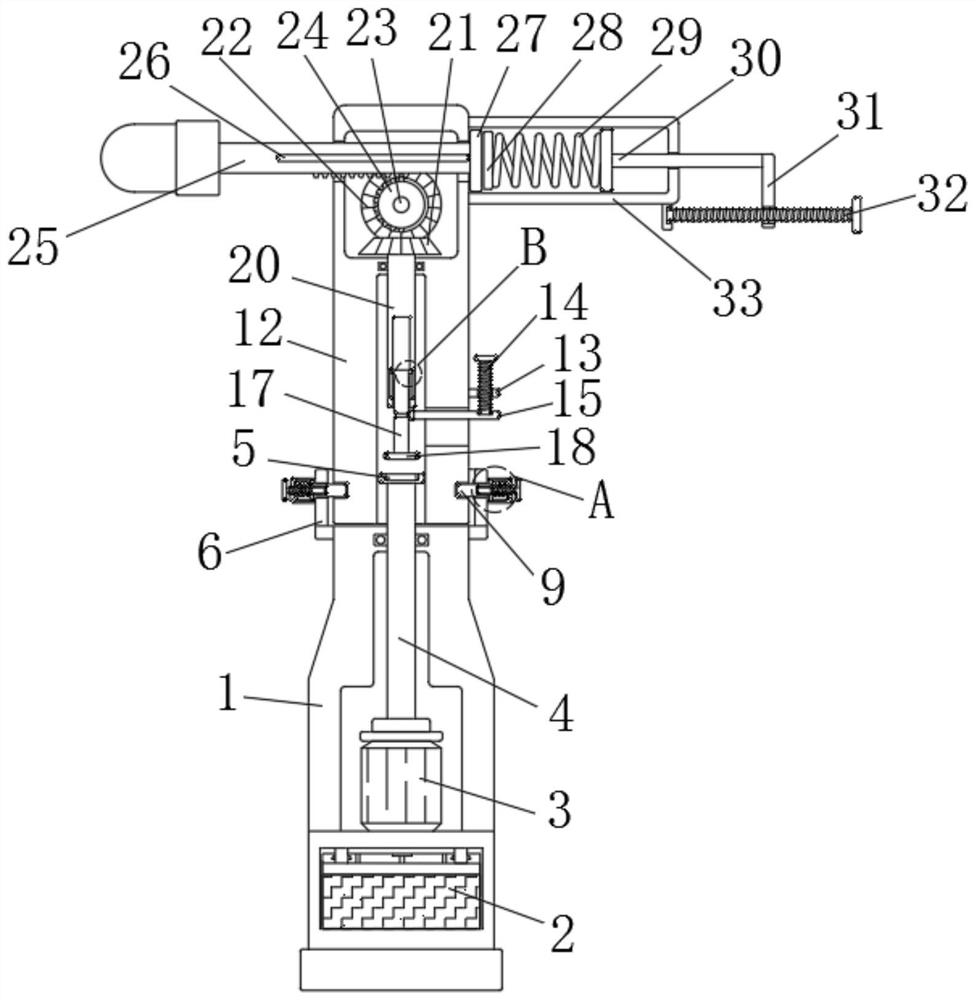

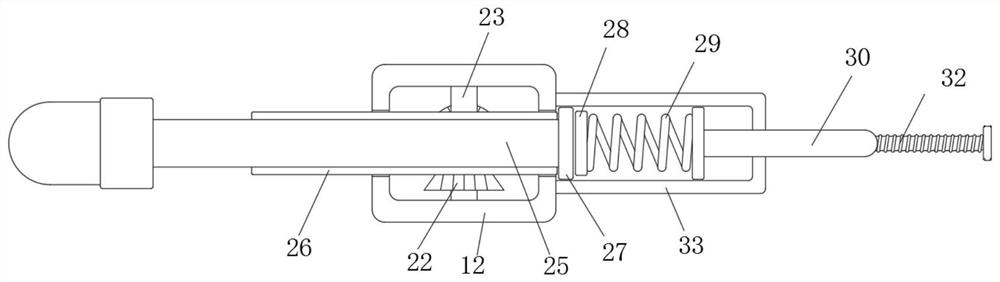

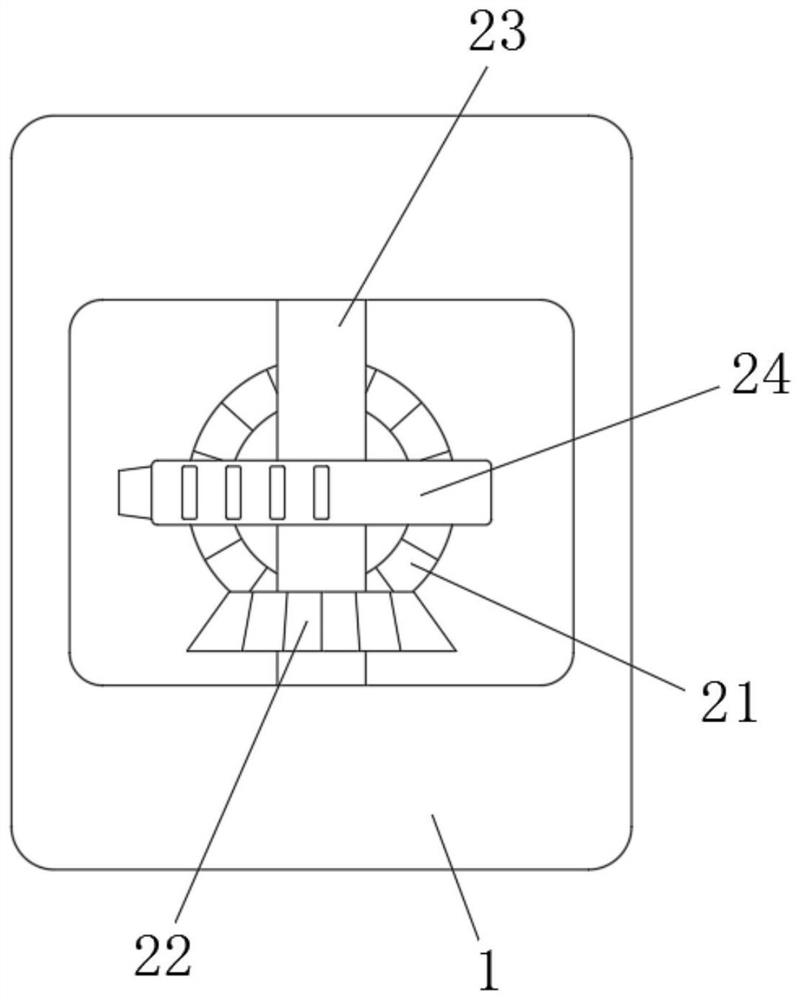

The invention discloses a foot-operated metronome for music teaching comprising a base, a fixed frame, a mounting sleeve, a battery pack, a servo motor, a music stand and a control panel. Hydraulic push rods are embedded and installed into the lower surface of the base, truckles are fixed to the lower sides of the hydraulic push rods, guide posts are installed in the base, tooth blocks are fixed on inner walls of the fixed frame, a folding rod is installed on the lower surface of a foot pedal, a pressure receiving cylinder is embedded and installed at the right side of the internal part of thebase, the surface of a safety pin is provided with a handle, a limiting block is fixedly installed under the mounting sleeve, and a sleeve rod is fixed above an inserting sleeve. According to the foot-operated metronome for music teaching, the fixed frame moves up and down, so footsteps of students are always regular inching, the students are helped to develop a stable beat, and so the students correctly tap on notes on a music score with the beat of a foot as an original beat.

Owner:HUAIHUA UNIV

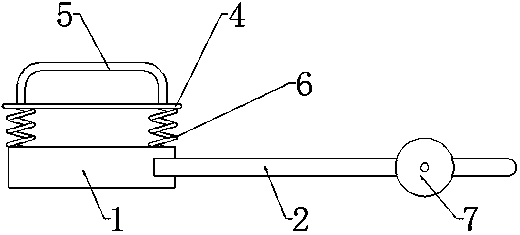

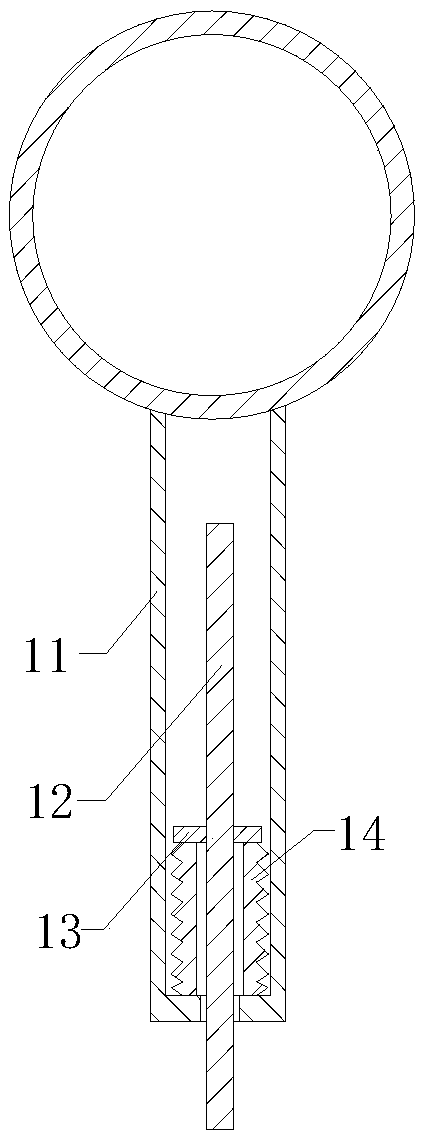

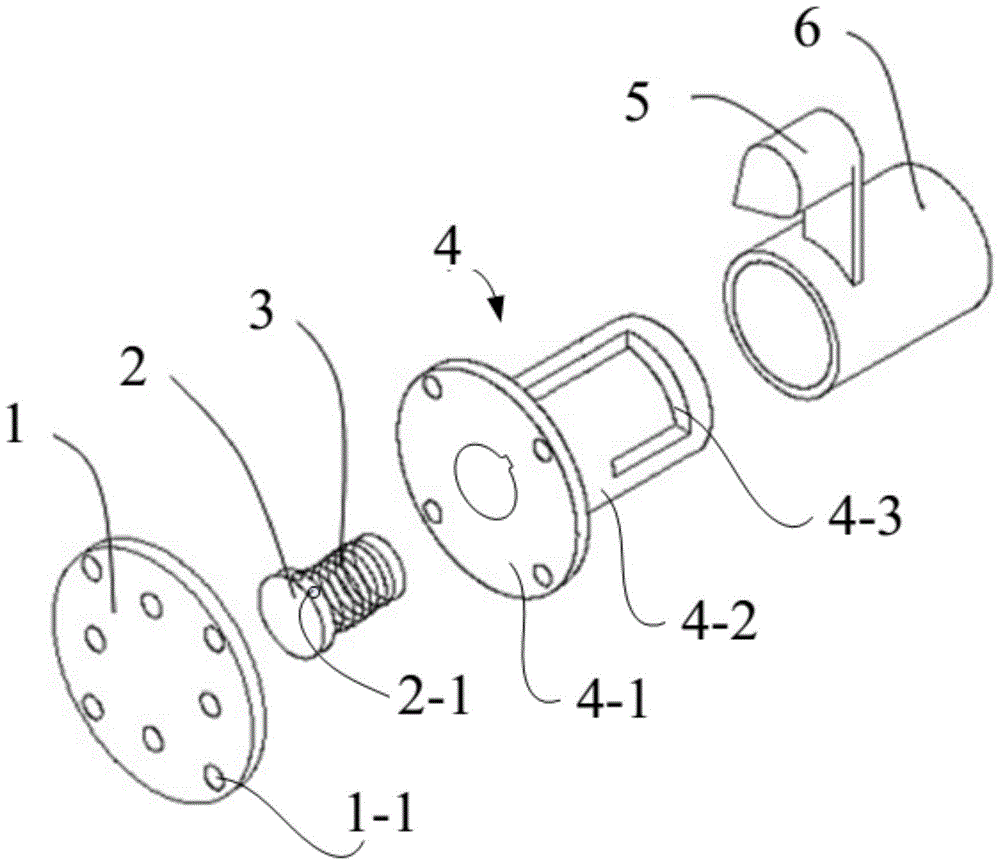

Safety hammer for bus

InactiveCN104648300AAccurate tappingPedestrian/occupant safety arrangementMechanical engineeringEngineering

A safety hammer for a bus comprises a sleeve. A push rod is arranged in the sleeve; one end of the push rod extends out of the sleeve, and a handle is arranged at the extended end; the other end of the push rod is a piercing part; a stop block is arranged at a position, close to the piercing part, of the push rod; a spring is arranged between the end, positioned at the sleeve, of the push rod and the stop block; and a suction disc is arranged at the other end of the sleeve. By using the safety hammer for the bus, the hitting point of glass can be hit accurately with slight effort.

Owner:XIAN JIAOTONG UNIV JINGSHENG SCI & TECH DEV

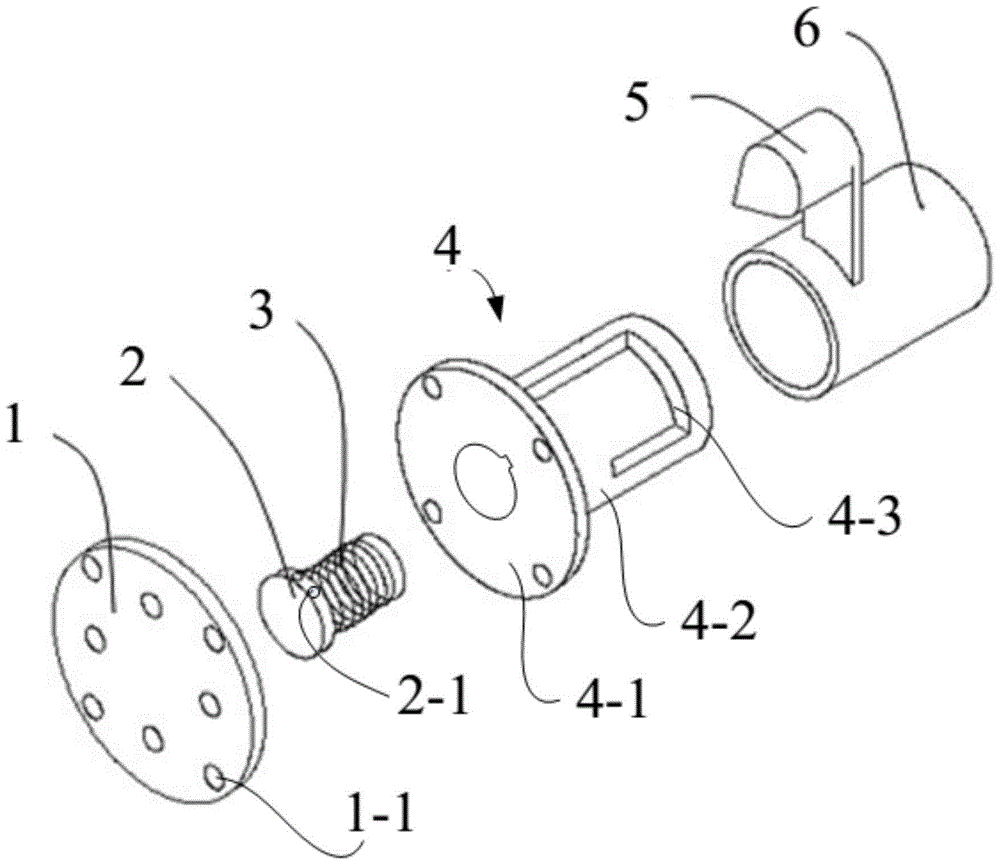

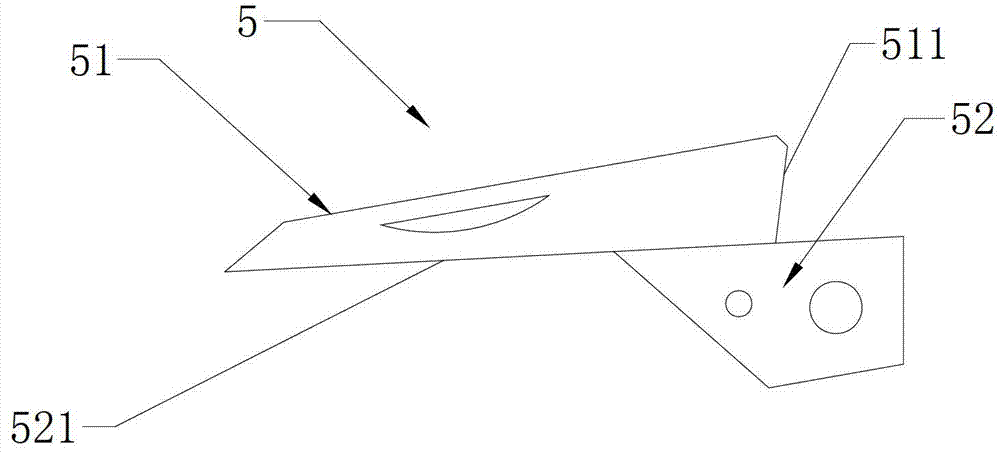

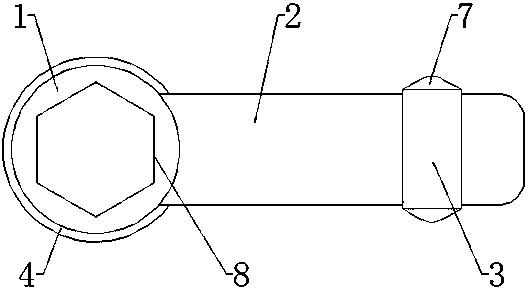

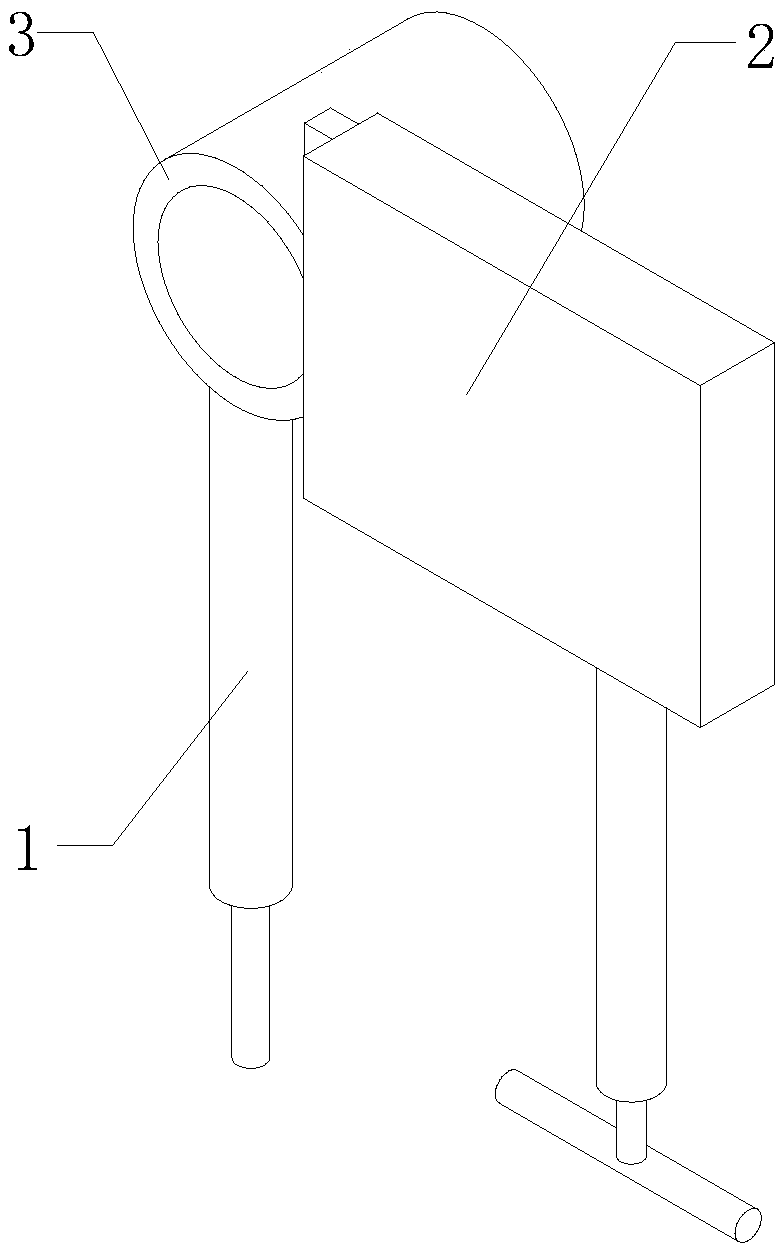

Escape hammer capable of positioning

InactiveCN104554116AAccurate tappingShorten the timePedestrian/occupant safety arrangementEngineeringMaterial resources

The invention discloses an escape hammer capable of positioning. The escape hammer comprises a flange guide rod for positioning, wherein the flange guiding rod consists of a flange part and a guiding rod part connected with the flange part, the guiding part is slidably provided with a sleeve, and the outer side of the sleeve is fixedly connected with a knocking hammer. The escape hammer is capable of realizing accurate positioning when knocking on a glass, the manpower and material resources are saved to the greatest extent, and the escape time is reduced. Furthermore, the escape hammer is simple in structure, convenient in operation, safe in use, and high in success rate of shredding glass.

Owner:XIAN UNIV OF SCI & TECH

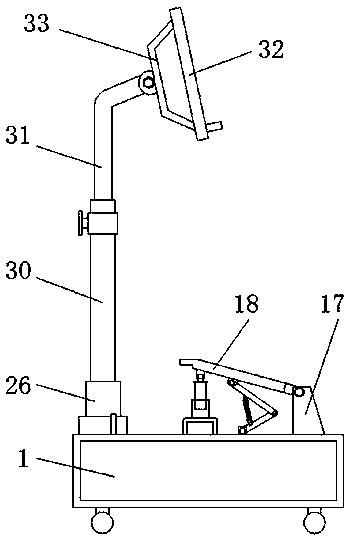

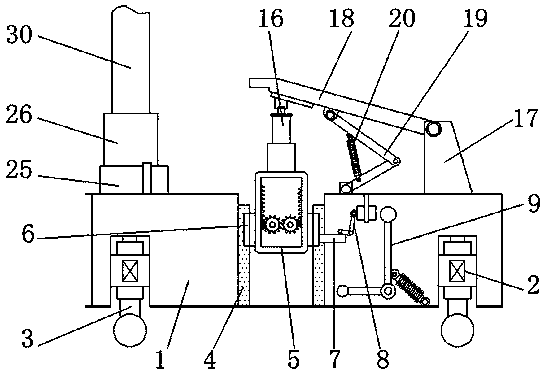

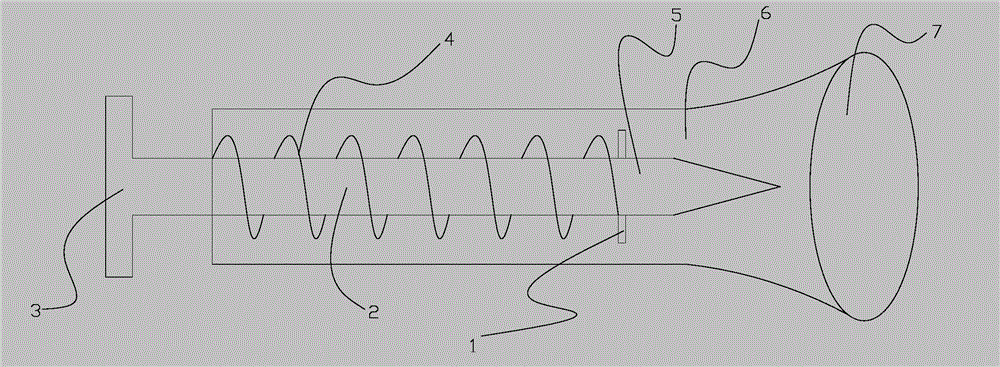

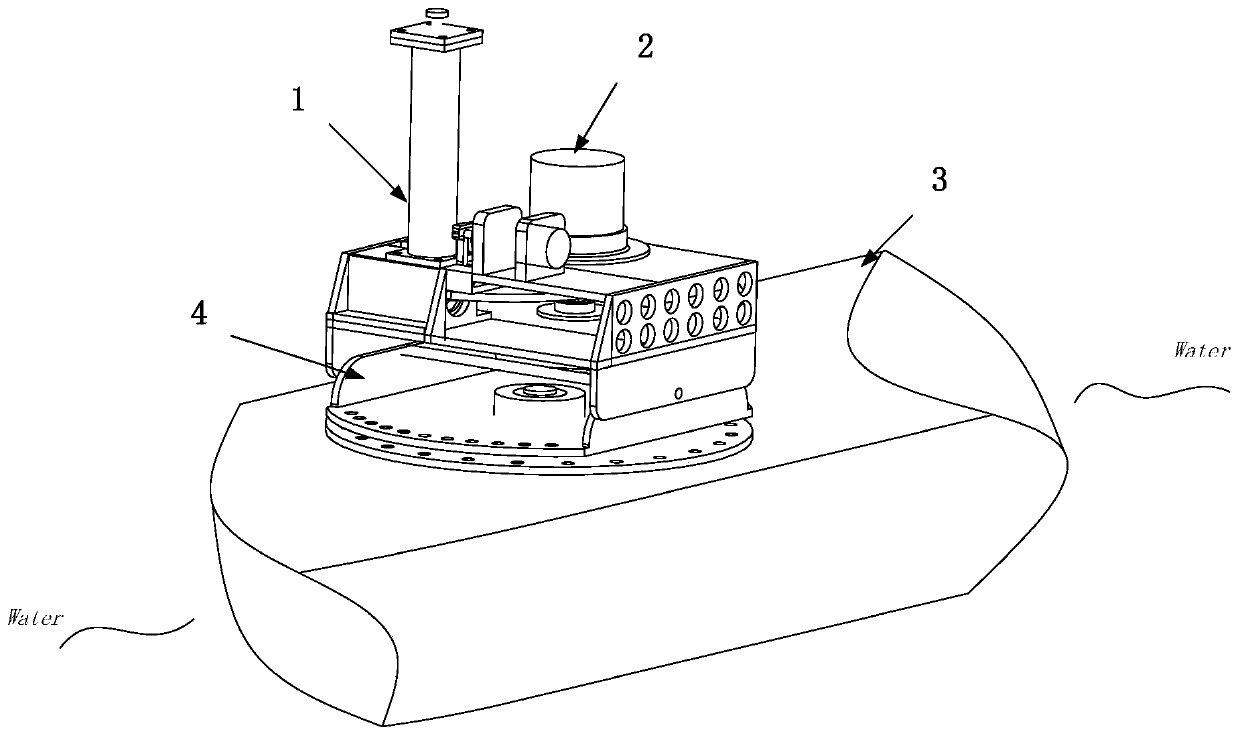

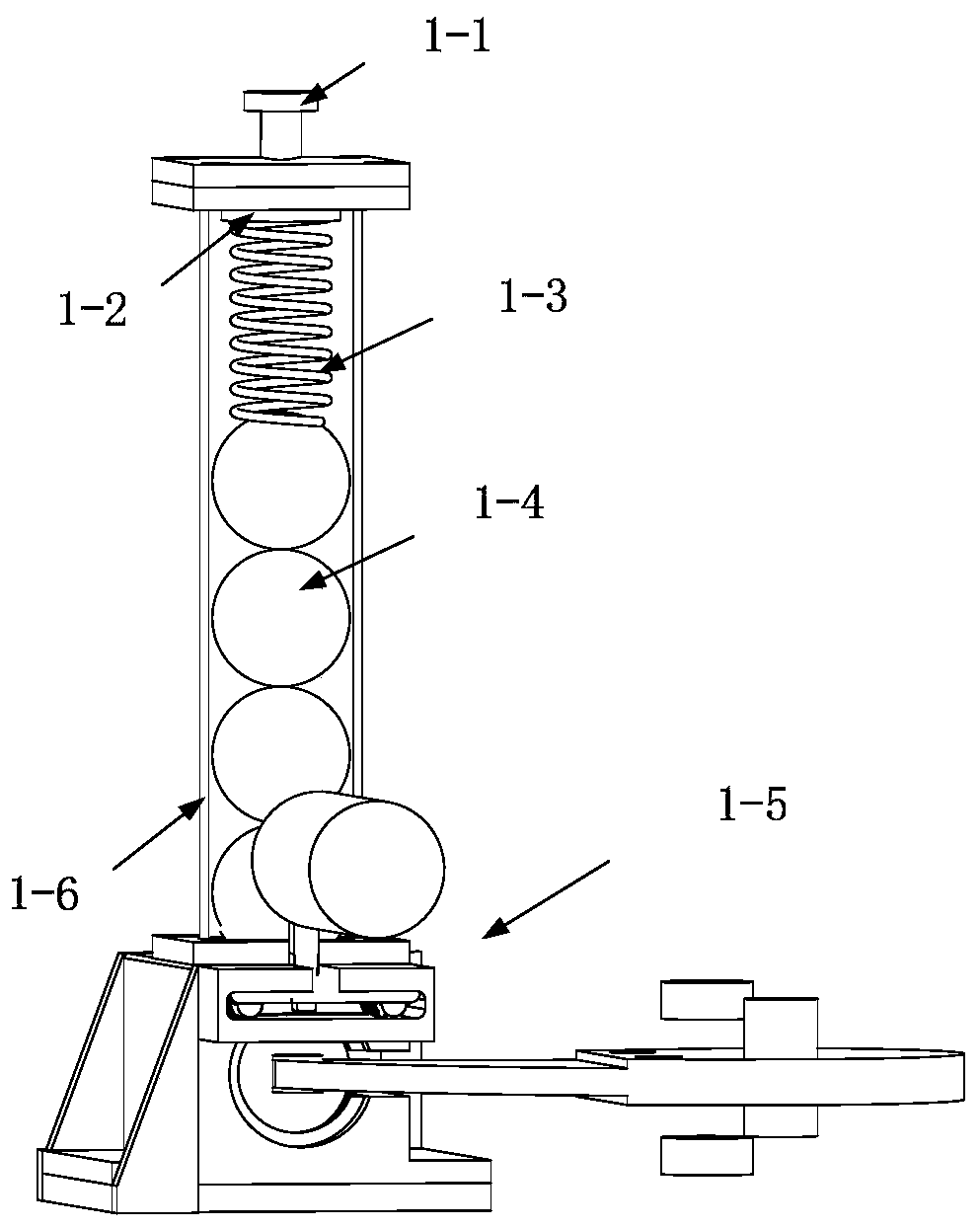

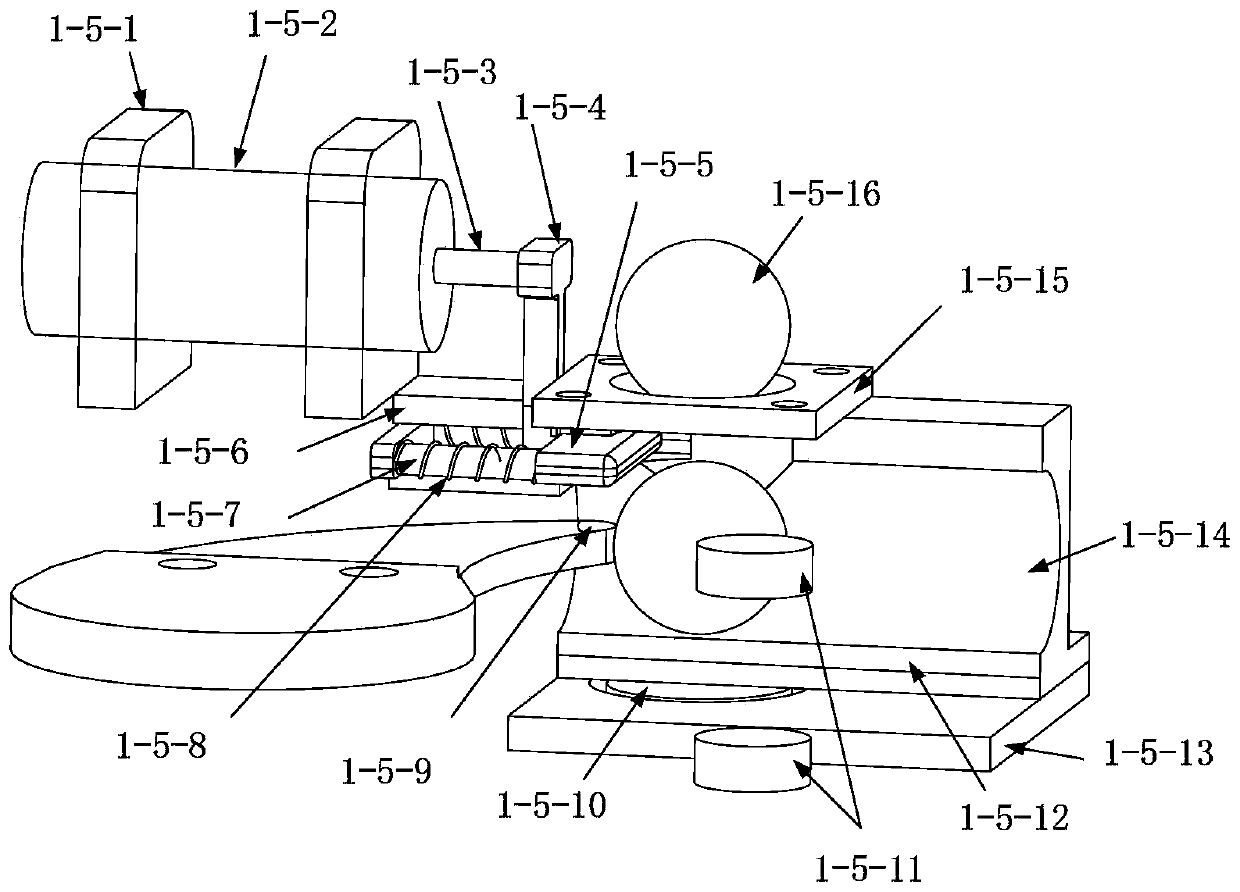

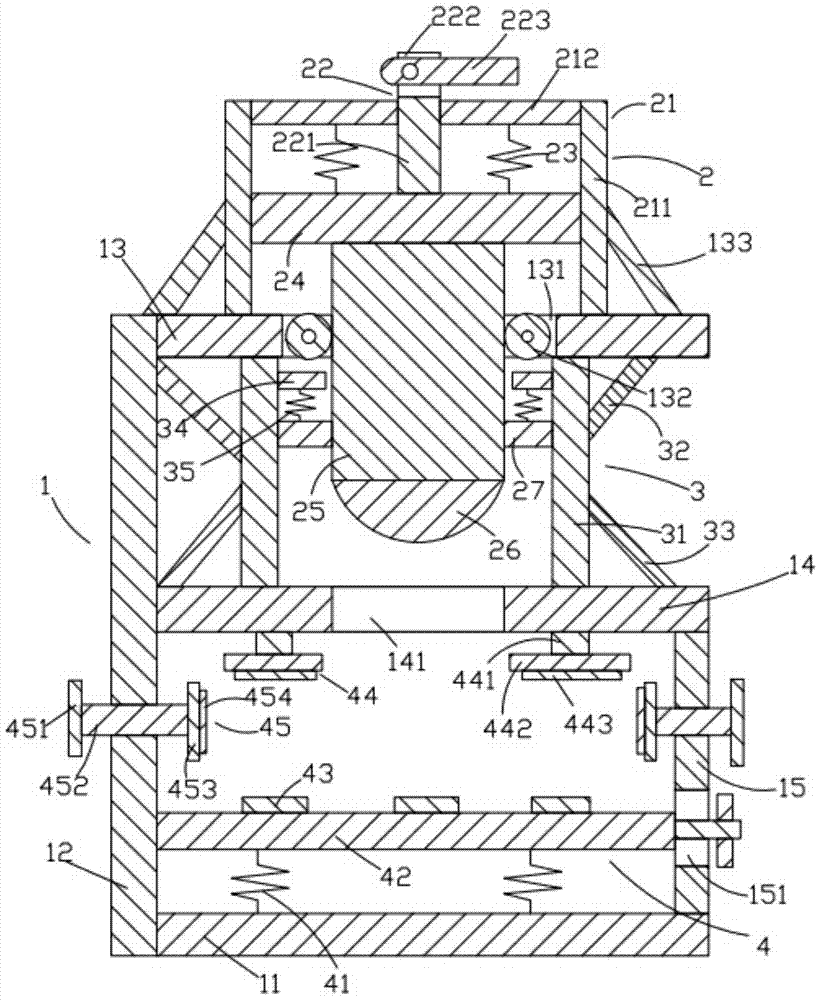

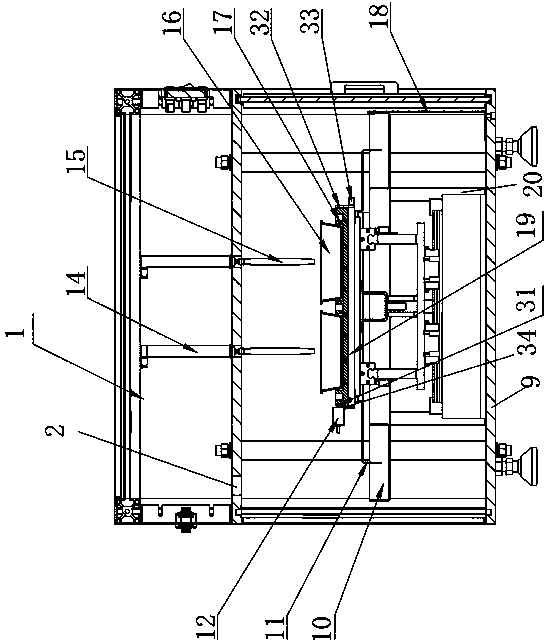

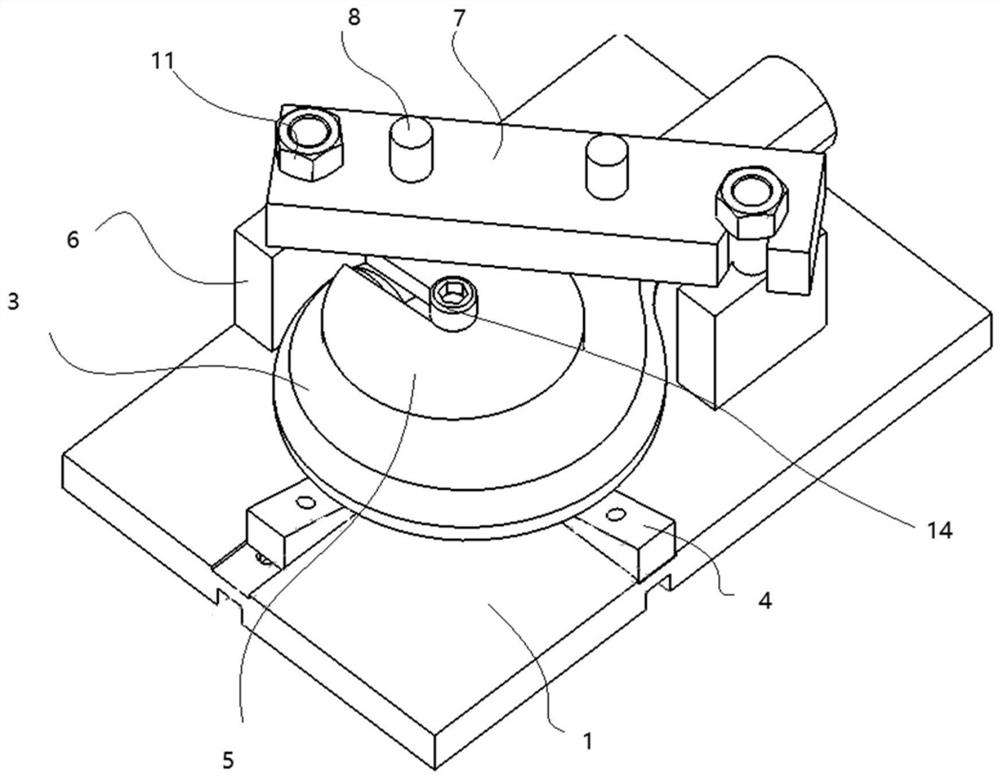

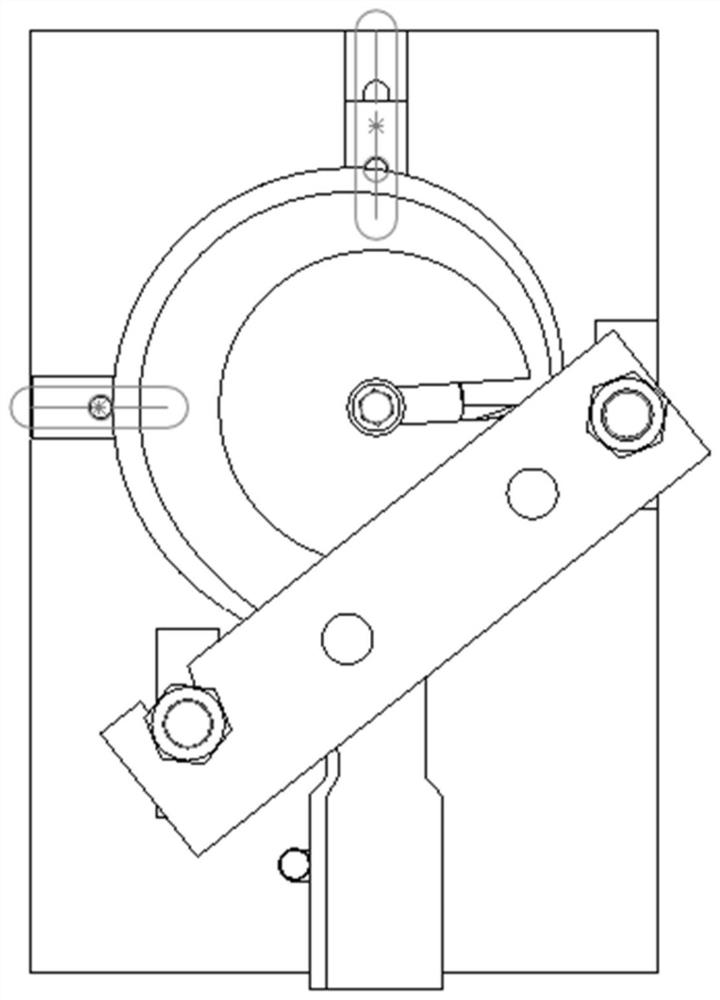

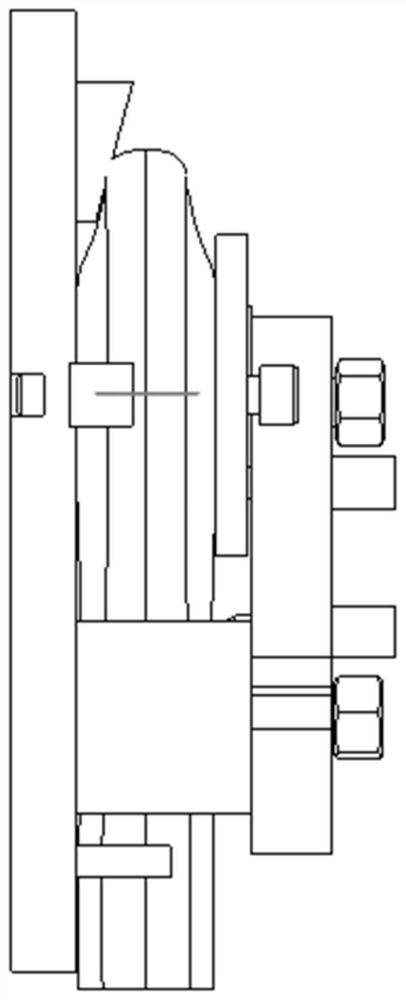

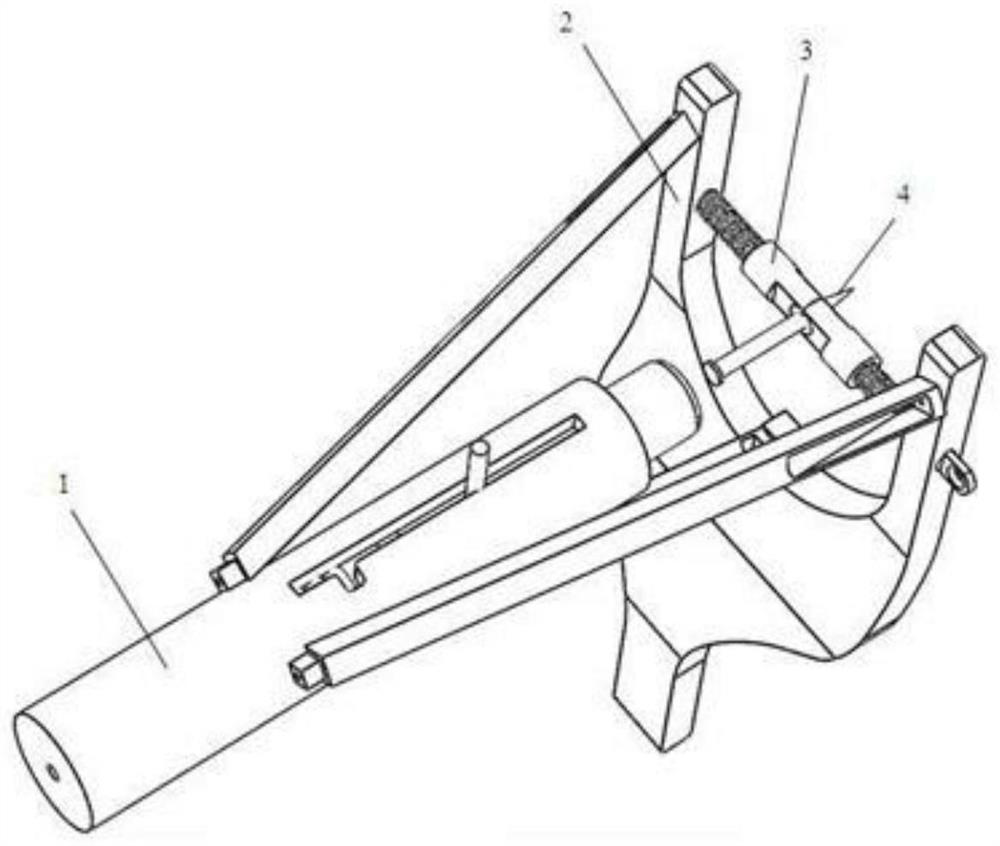

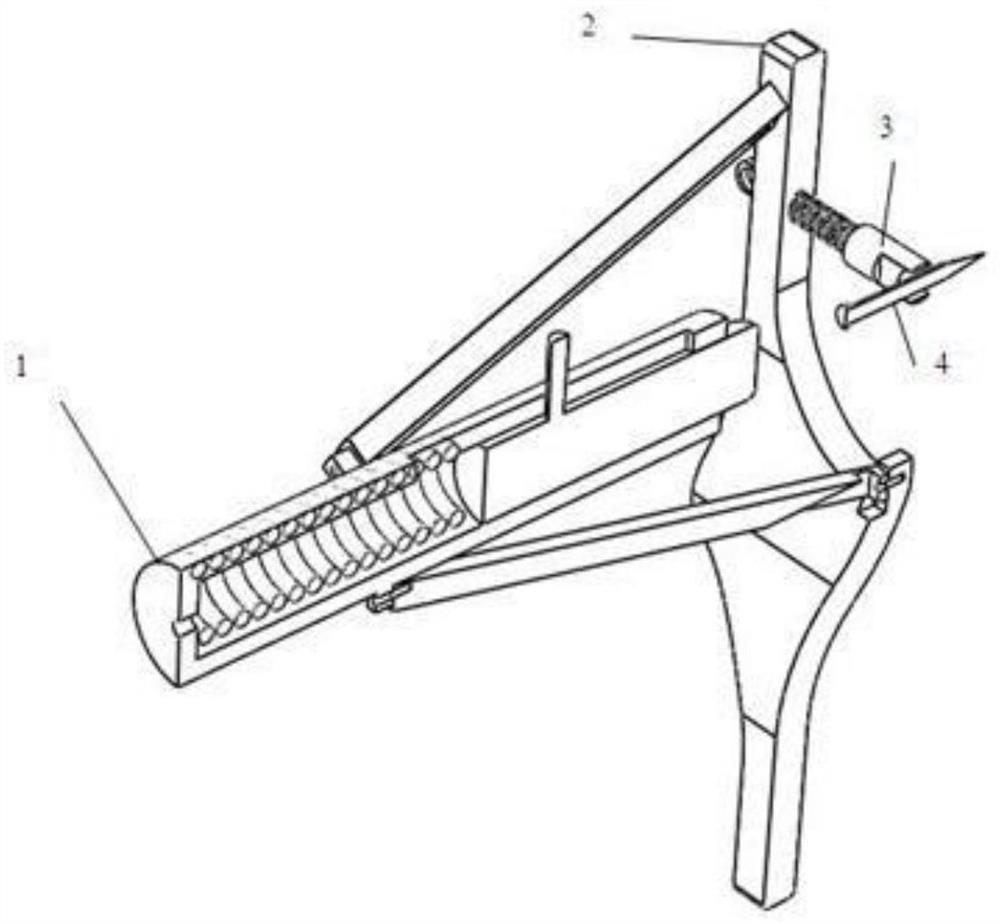

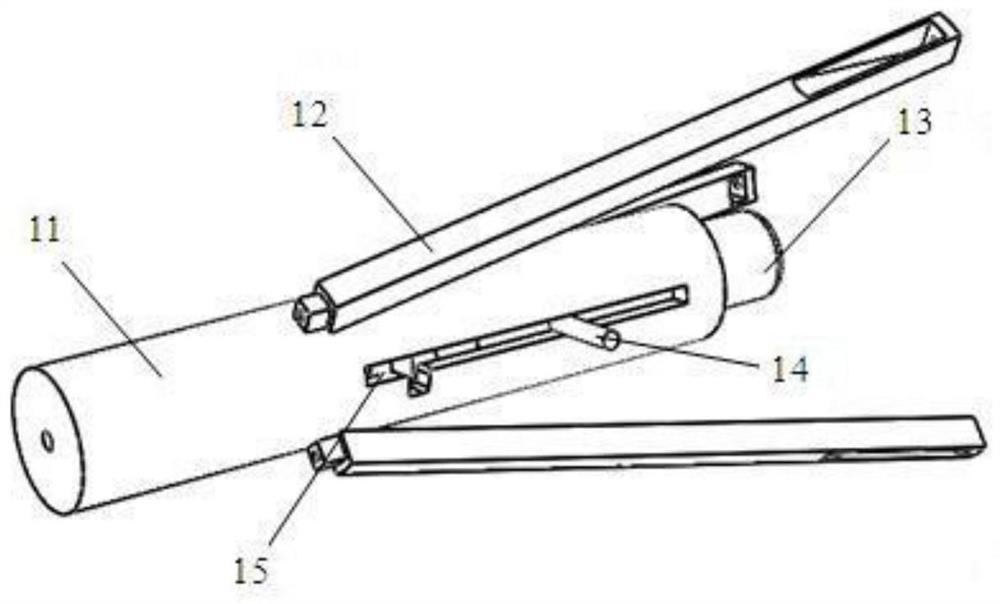

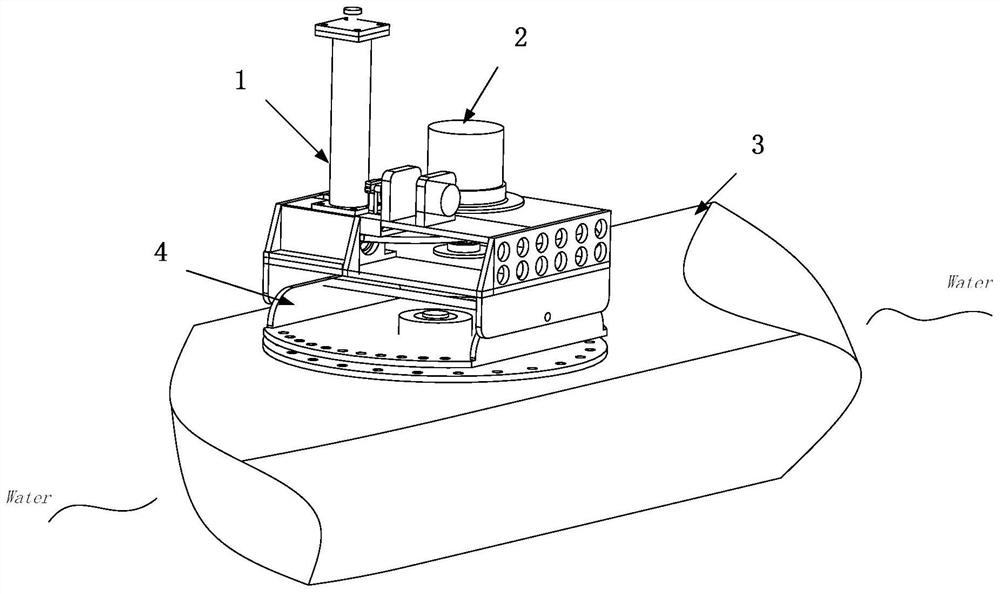

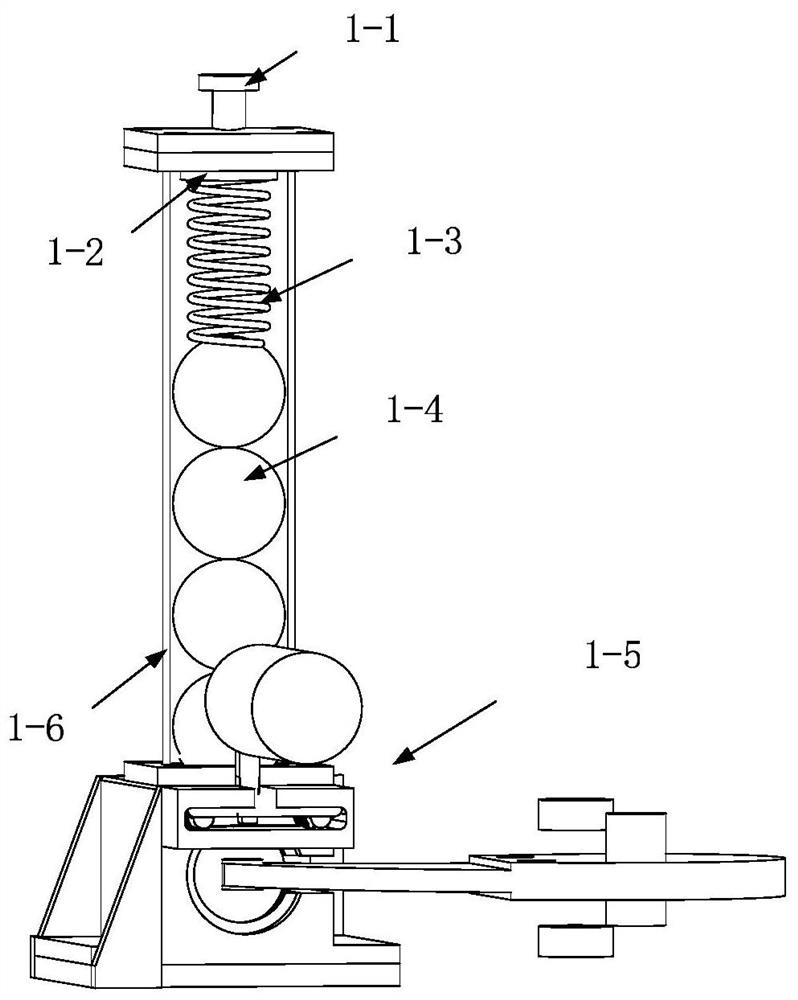

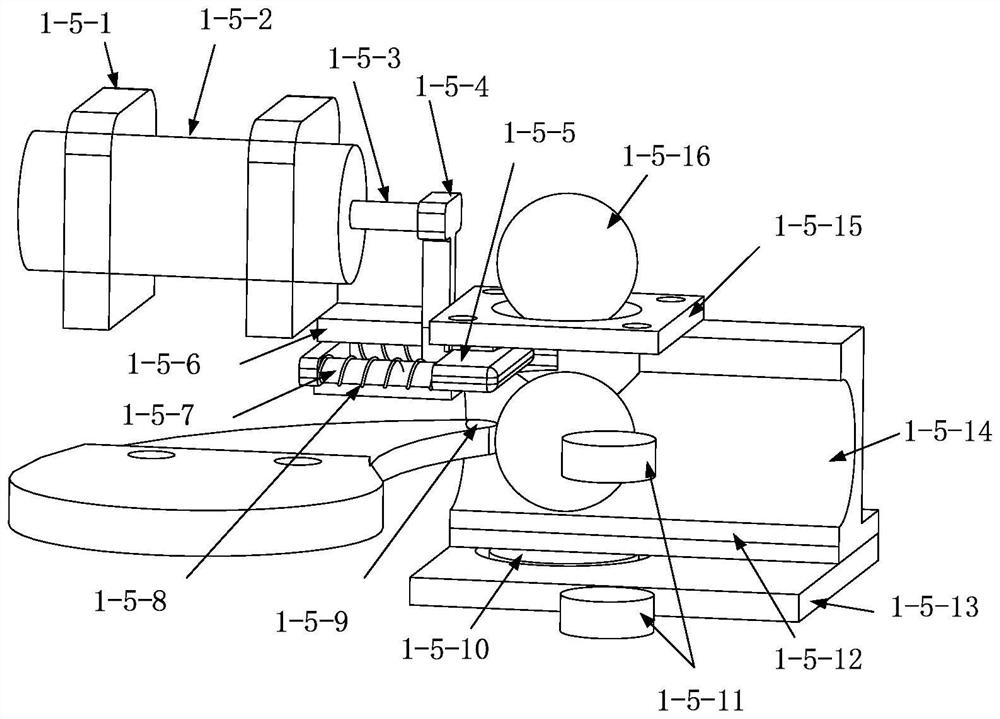

Novel hydrodynamic high-frequency cannonball launching reoil simulation test device

ActiveCN111336861ASimulate the realAvoid stabilityTraining adaptationEducational modelsScale modelClassical mechanics

The invention relates to a novel hydrodynamic high-frequency cannonball launching recoil simulation test device, and belongs to the technical field of hydrodynamic test simulation systems. In order tosolve the technical problems that the stability of a ship under a special operation condition is not considered in the existing ship body stability test, the defects exist in the test process, the influence of the continuous pulse type cannonball recoil on the ship body attitude angle in the high-frequency launching process of the ship cannonball is not studied and analyzed and the like, the invention designs a simulation test device comprising a cannonball positioning and conveying device 1, a cam rotating high-frequency knocking structure 2, a ship model upper end face 3 and a cannonball direction adjusting structure 4, equivalent high-frequency cannonball launching impulse action conditions can be provided for a test model, and the test environment of a scaling model water surface shooting operation can be simulated more truly. The defect that a traditional stability test does not consider the influence condition of cannonball shooting on the ship body is overcome, so that the hydrodynamic stability of a naval vessel is simulated more truly, and the accuracy of the hydrodynamic test of the naval vessel is improved.

Owner:CHINA SPECIAL TYPE FLIER RES INST +1

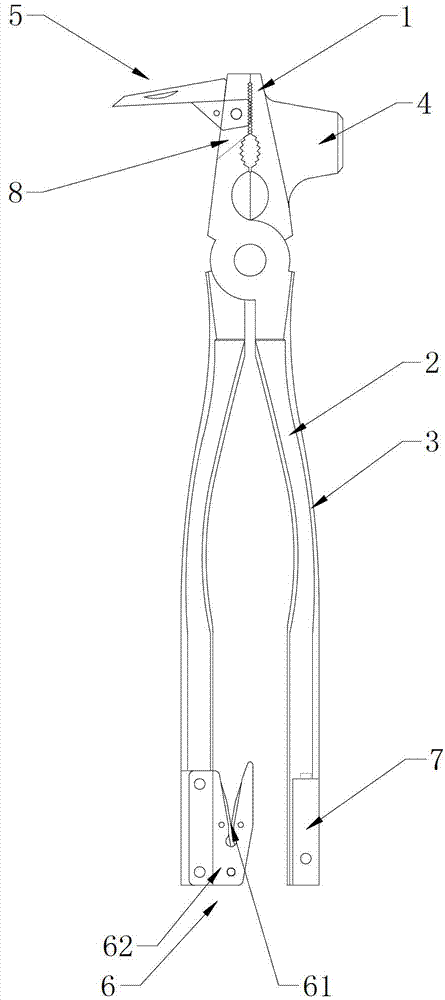

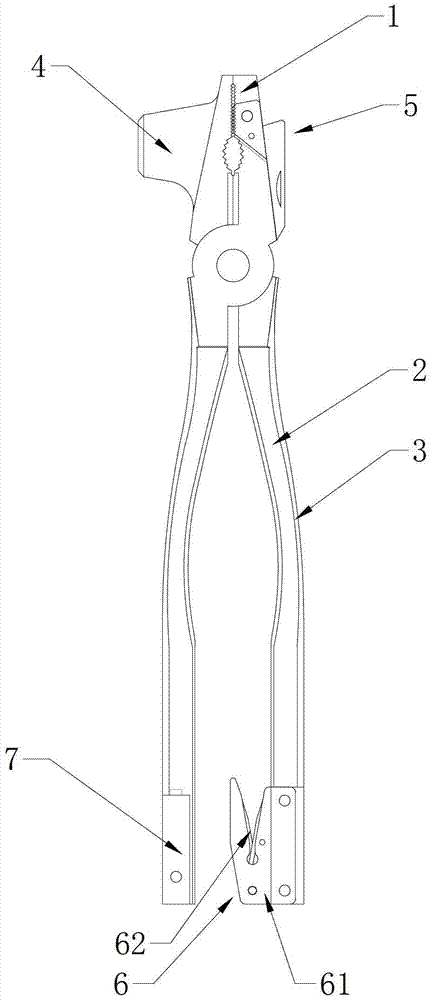

Clamp for escape

InactiveCN103084995ASmash quicklyAccurate tappingPliersPedestrian/occupant safety arrangementConductor CoilBiomedical engineering

The invention discloses a clamp for escape. The clamp for escape comprises two handles and two clamp mouths. The two handles are connected in a hinged mode with each other. The clamp mouths are arranged on the heads of the handles in a one-to-one corresponding mode. A hammer for knocking hard objects is arranged at the outside of one of the clamp mouths. The clamp for escape not only has functions of a common clamp which is capable of clamping and fixing a processing workpiece for escape, and twisting, winding, and cutting a metal silk thread, but also users can knock glass with the hammer when the car is in emergency, the glass is rapidly broken, and people is helped to escape.

Owner:JIANGSU HONGBAO HARDWARE

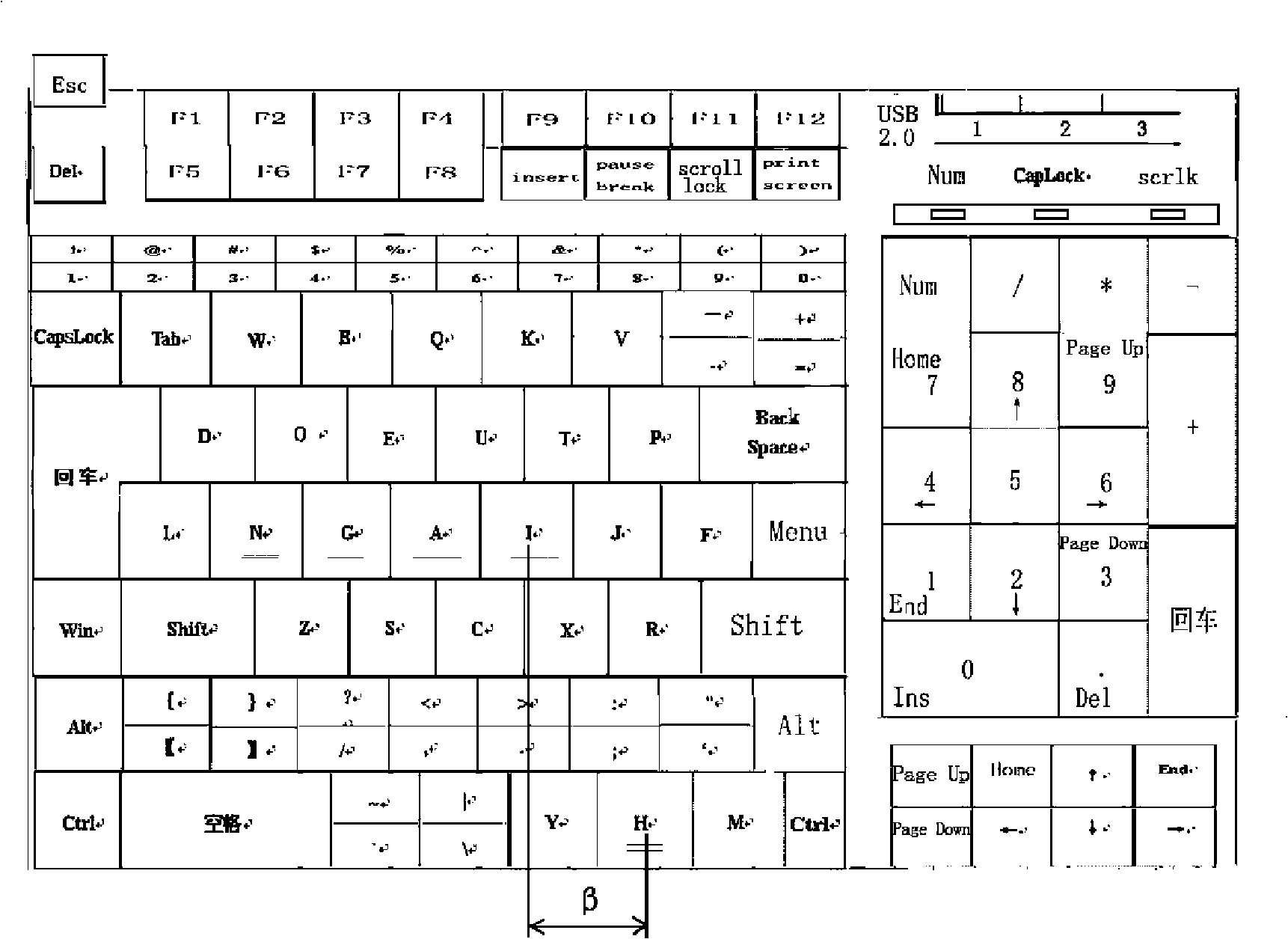

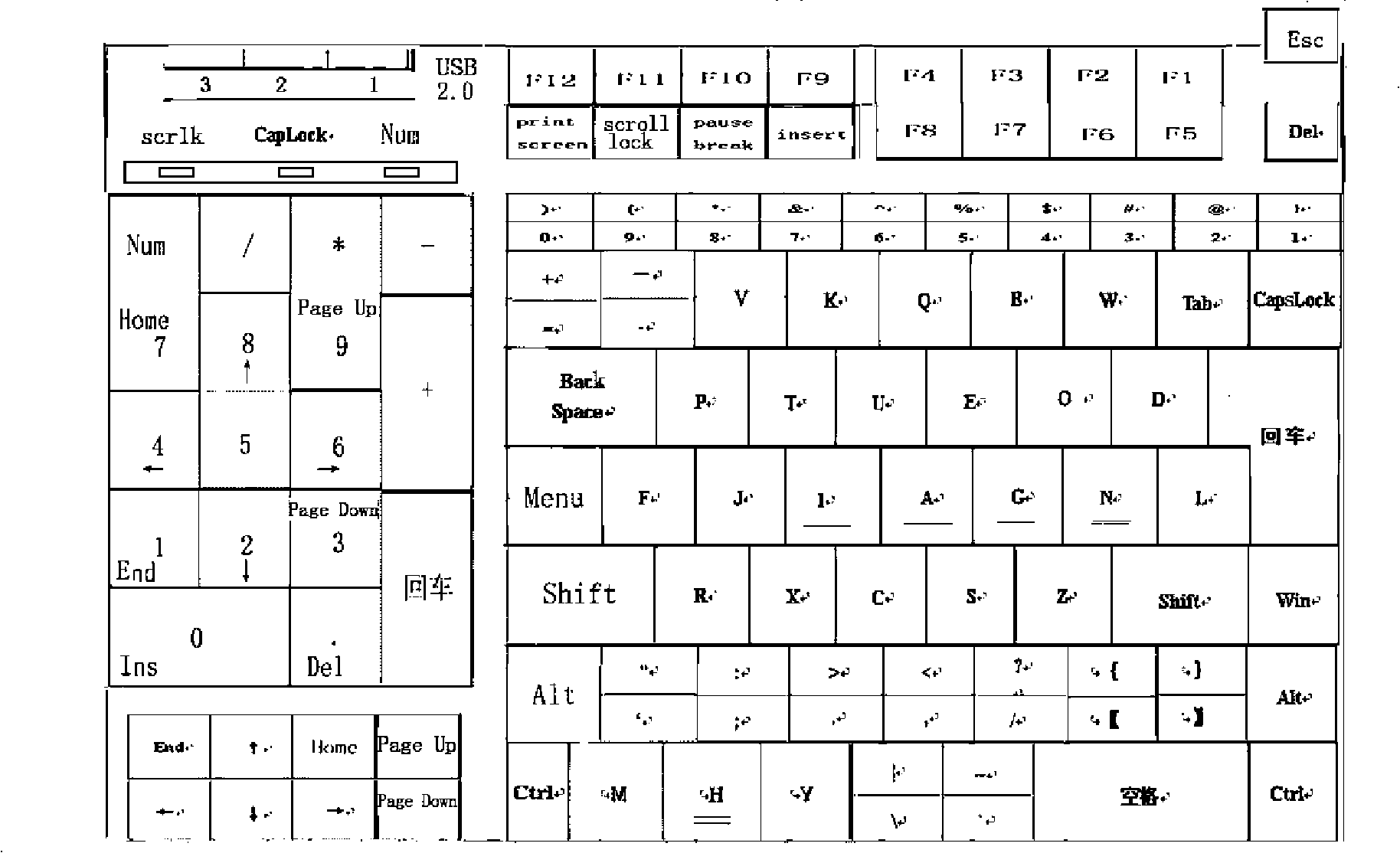

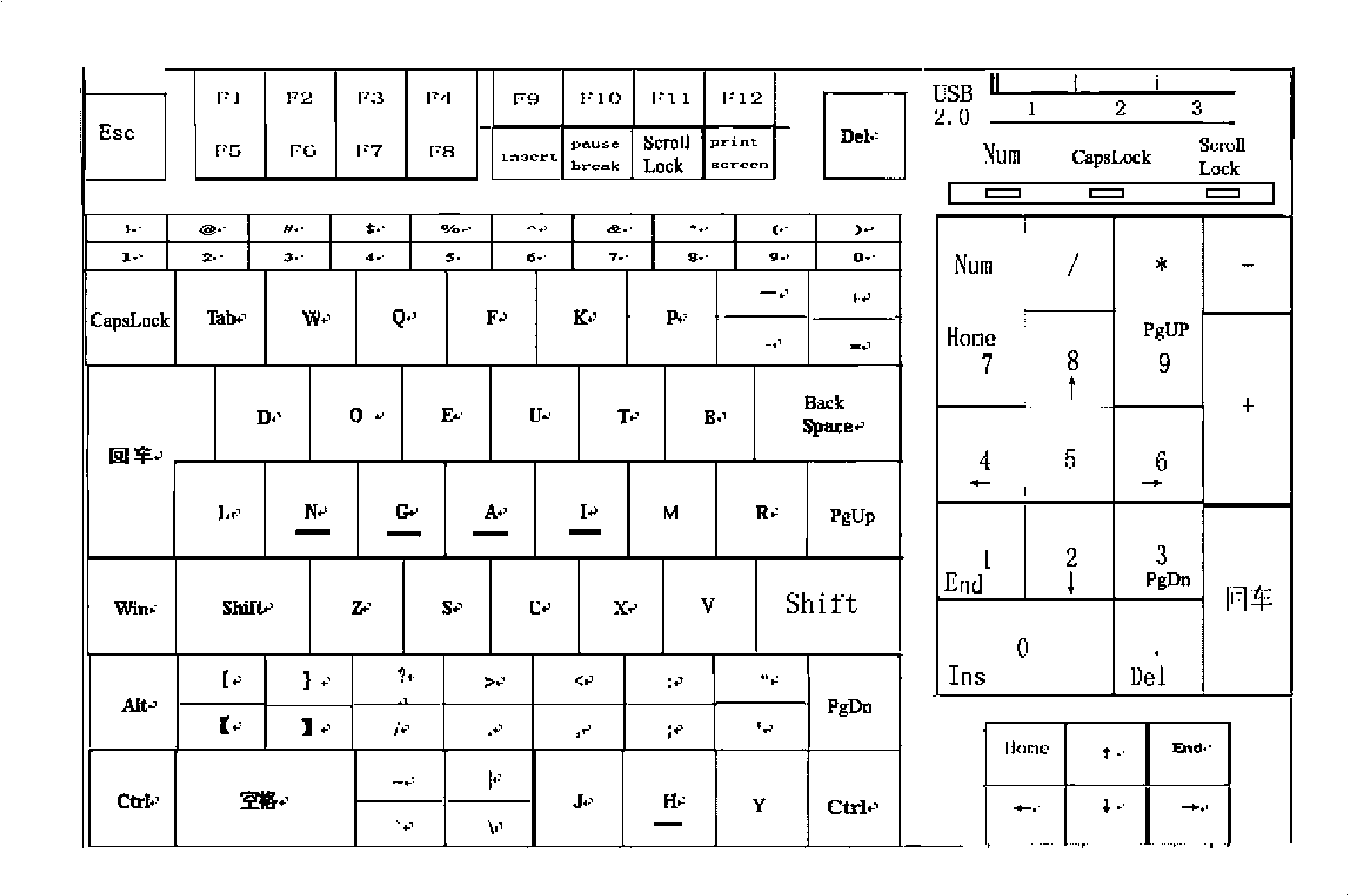

Universal single-hand keyboard

InactiveCN101526859AReasonable layoutPlay with flexibilityInput/output processes for data processingComputer scienceInput function

A universal single-hand keyboard comprises a letter key area consists of 26 English letters. The letter keys are not less than two rows and four columns, transversely looking, key N, key G, key A and key I are located in the same row, key G is located between key N and key A, key A is located between key G and key I; key H is located right or obliquely below key I, the horizontal distance Beta from the center line of key H to the center line of key I has a width of 0-3 keys, and the row where key I is located and the row where key H is located are adjacently arranged or has 1-3 rows of other keys between. The keyboard can be operated with a single hand, the letter key area has a reasonable arrangement, the work efficiency with five fingers is extremely high, and the arrangement of the keys is easy to be remembered. With complete input function of 101 / 104 keys on the keyboard and slightly higher design of the space bar as well as with no need of special input method, the keyboard is more easy for realizing rapid touch typing with single hand; in addition, the keyboard also has the advantages of small and exquisite structure, easy portability and convenient use, etc.

Owner:路磊

Glass touch keyboard

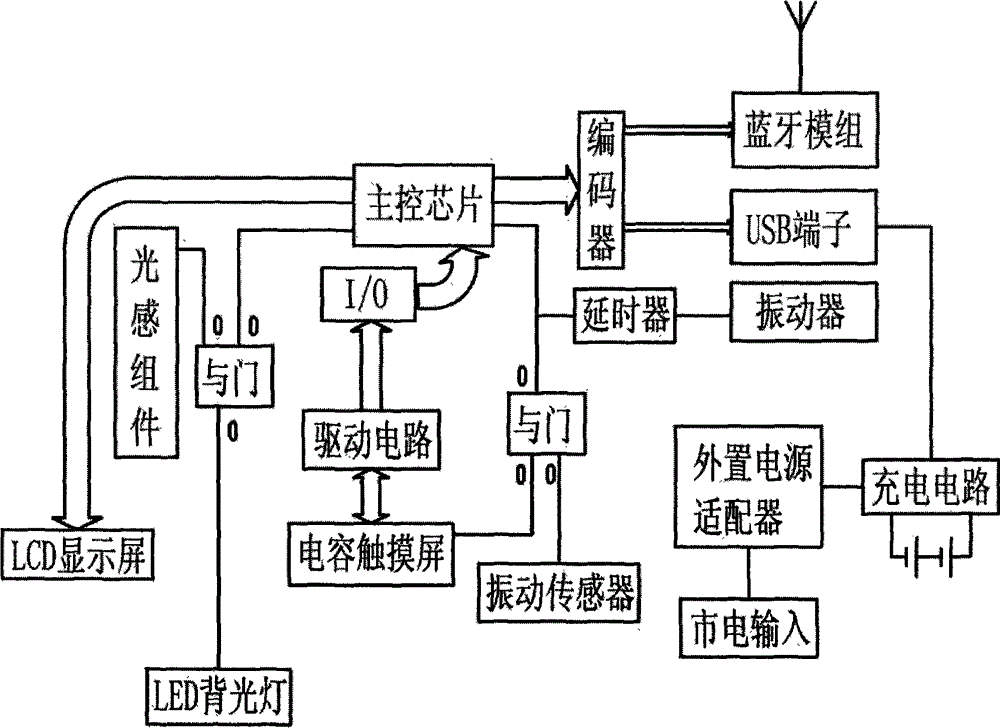

InactiveCN105302321AAccurate tappingReduce noiseInput/output for user-computer interactionEngineeringTouchscreen

The invention discloses a glass touch keyboard. The glass touch keyboard comprises a glass panel, an encoder, a main control chip, a bluetooth module, a USB terminal, a capacitive touch screen and a vibration sensor. The capacitive touch screen is connected with the main control chip by means of a driving circuit. An output end of the vibration sensor is connected with the main control chip. An output end of the main control chip is connected with an input end of the encoder. An output end of the encoder is connected with the bluetooth module and the USB terminal.The glass touch keyboard has following beneficial effects: the keyboard is made by adoption of a transparent or a translucent glass panel; floating key positions are arranged on the surface of the keyboard so that the overall keyboard is integrally designed; input operation by utilizing the keyboard is finished by the panel; no gap is kept between every two key positions; key markers are made by embossment or etching technology; the key positions are tapped with good hand feel and can be accurately tapped; noise is small in a collective office environment; water-proof and dust-proof functions are fulfilled; and the glass touch keyboard is convenient to clean and move and can be used alone.

Owner:SHENZHEN KEENEST TECH CO LTD

Brain injury examination percussion device for internal medicine of traditional Chinese medicine

The invention provides a traditional Chinese medicine internal medicine brain injury examination percussion device which comprises a handheld part, an L-shaped rod, a percussion part, a power spring, a percussion part locking structure and a percussion part releasing mechanism, the vertical section of the L-shaped rod is fixed to the handheld part, and an L-shaped channel is formed in the L-shaped rod in the moving direction of the L-shaped rod; the tapping part comprises a sliding column which is inserted into the horizontal section of the L-shaped channel and is in sliding connection with the horizontal section of the L-shaped channel; the hammer head is fixed at the front end of the sliding column; the power spring is arranged in the L-shaped channel along the trend of the L-shaped channel, one end of the power spring is connected with the sliding column, and the other end of the power spring is connected with the elasticity adjusting piece; the tapping part locking structure is arranged in the horizontal section of the L-shaped channel; the tapping part releasing mechanism is connected with the tapping part locking structure and used for unlocking the tapping part locking structure. According to the percussion device, the percussion force of the percussion device can be accurately adjusted, and percussion can be accurately conducted on the percussion part.

Owner:驻马店市中医院

Nondestructive testing accurate knocking device and method thereof

PendingCN113671029AAccurate tappingSave human effortAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationEvaluation resultClassical mechanics

The invention discloses a nondestructive testing accurate knocking device and a method thereof, and relates to the technical field of nondestructive testing. The problem that the evaluation result of internal defects of detected wood is affected due to the fact that the existing nondestructive testing technology is difficult to reflect the internal structure of the wood truly is solved. The nondestructive testing accurate knocking device comprises a cylindrical frame with one open end and the other closed end, a spring, a pull rod and a hammer head arranged in an inner cavity of the cylindrical frame, one end of the pull rod is hinged to the hammer head, the other end of the pull rod penetrates through an end plate of the cylindrical frame and extends out of a cylindrical, the pull rod is sleeved with the spring, and the two ends of the spring abut against the hammer head and the end plate respectively; the method comprises the steps that after the hammer head is aligned with a detected object, the pull rod is pulled to a certain scale or mark to determine the knocking force, the pull rod is loosened, and the hammer head is instantly accelerated under the action of the elastic force of the spring and automatically knocks the knocking point of the stress wave sensor on the detected object.

Owner:SHANGHAI CONSTRUCTION GROUP

A toughness and strength testing device for toughened bulletproof materials

ActiveCN111678816BFast and convenient toughness testingGuaranteed uniformityMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention relates to a toughness and strength detection device for a toughened bulletproof material. The device comprises a supporting column; the top end of the supporting column is provided witha vertical plate, and the top of the vertical plate is connected with a top plate; the bottom of the top plate is provided with a toughness measuring assembly; an upper insection rod is arranged in the toughness measuring assembly; an insection shaft is installed at the bottom end of the upper insection rod in an engaged mode, and a rotating block is connected with the rear end face of the insection shaft. According to the invention, the toughness measuring assembly is designed; a material is placed at the bottom of the pressing plate; the material is pressed by rotating the threaded rod, andthe detected material is fixed in a C-shaped block; the rotating block is rotated, and under the action of the insection shaft, the upper insection rod and a lower insection rod drive the C-shaped block to move, so that the C-shaped block stretches the two sides of the detected material; the toughness of the material is detected; and through the arrangement, toughness detection can be rapidly andconveniently conducted on the material, stress uniformity of the two sides of the detected material is guaranteed, and objectivity and accuracy of detection are guaranteed.

Owner:上海衡益特陶新材料有限公司

Percussion hammer device for departments of pediatrics

InactiveCN111643119AEasy to control the strength of tappingEasy to tapPleximetersEngineeringStructural engineering

The invention discloses a percussion hammer device for departments of pediatrics. The percussion hammer device includes a first handle, a storage battery and a motor; the storage battery is installedinside the bottom end of the first handle; the motor is installed in the center of the first handle, and the output end of the motor is connected to a first rotating shaft; and the end, away from themotor, of the first rotating shaft is fixedly connected to a first rotating disc. Through the arrangement of a fixing rotary wheel and a second moving rod and the rotating of the fixing rotary wheel,a percussion head can move in a second handle, so that the percussion head can conveniently and precisely percuss the limbs of patients; through the moving of the second moving rod, percussion strength can be conveniently controlled; and through the arrangement of limit rods and the inserting of the second handle in first fixing frames, the limit rods can be inserted in the second handle, so thatthe second handle can be limited in the first fixing frames, the first handle and the second handle can be effectively and conveniently assembled and disassembled.

Owner:宋丽

Stable impact spanner

InactiveCN109397160AImprove operational stabilityTighten firmlySpannersWrenchesEngineeringOperational stability

The invention discloses a stable impact spanner, and relates to the field of mechanical tools. When the stable impact spanner is used, the head of a bolt can be sleeved with a bolt sleeve hole of a sleeve, a user holds a pull handle with one hand to push and press a pressing plate, the sleeve is tightly attached to the head of the bolt by utilizing the compression pre-tightening force of springs,and the user holds a hammer with the other hand to aim at aiming conical faces on the end faces of a hammering column for hammering. The user can hammer the stable impact spanner more accurately, thena handle can bear more horizontal impact force, then the sleeve can stably rotate, the bolt can be quickly and stably screwed or unscrewed, and the operation stability of the spanner is improved.

Owner:赵粉弟

Calculus removing device for urinary surgery calculus treatment

The invention discloses a calculus removing device for urinary surgery calculus treatment, and belongs to the technical field of calculus treatment. The calculus removing device comprises a base, a telescopic rod is fixedly connected to a rotating shaft of the base, and a baffle is fixedly connected to the upper end of the telescopic rod; the baffle is fixedly connected with a first spring for resetting the baffle; an elastic net is arranged above the baffle, the outer side of the elastic net is fixedly connected with a fixing ring, the fixing ring is fixedly connected with the base through a fixing rod, a calculus removing assembly is arranged above the fixing ring, and a driving assembly is arranged on the side edge of the calculus removing assembly; by adjusting the heights of the L-shaped sliding rod and the fixed rod, the height of the limiting ring corresponds to the waist of the patient, and it is guaranteed that the knocking block can accurately knock the waist of the patient; and the shape of the knocking ring is matched with that of the waist of the human body, so that each knocking block can knock the waist of the patient.

Owner:孙镭

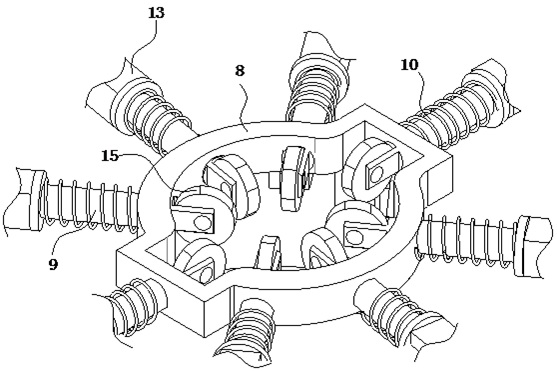

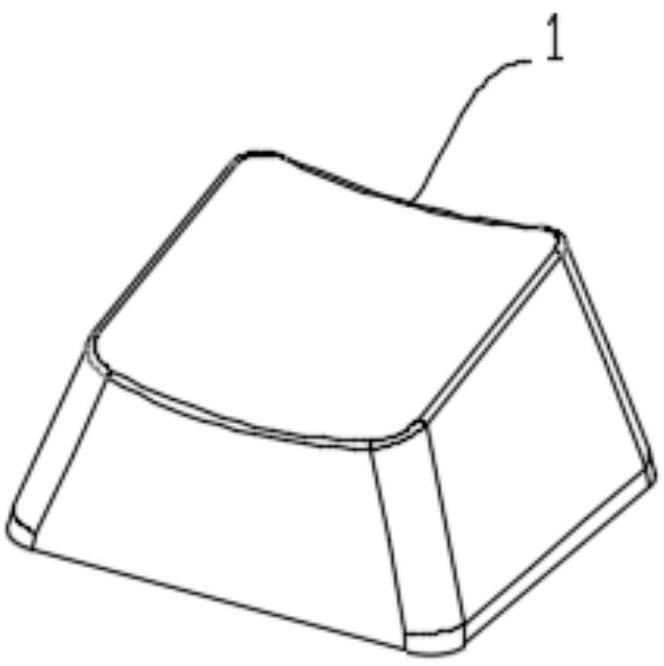

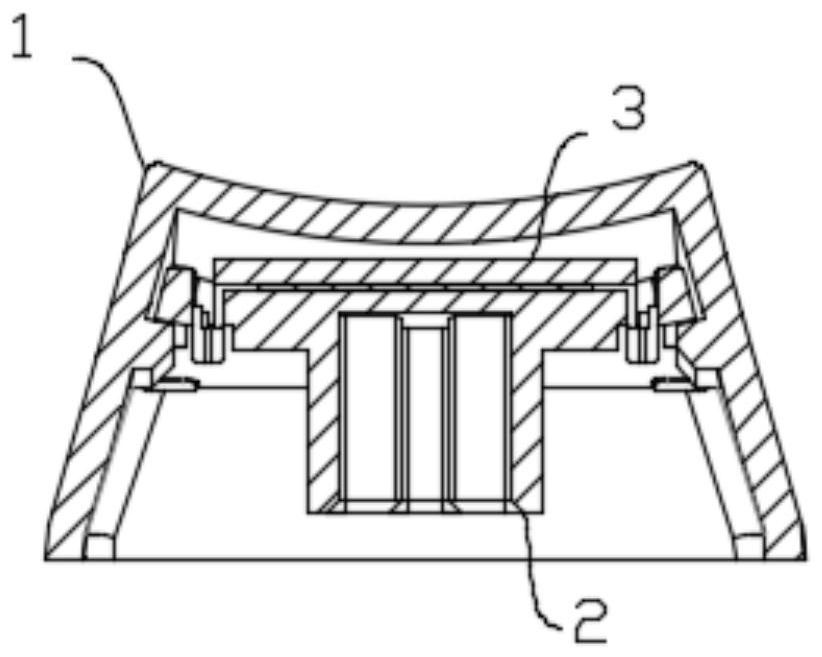

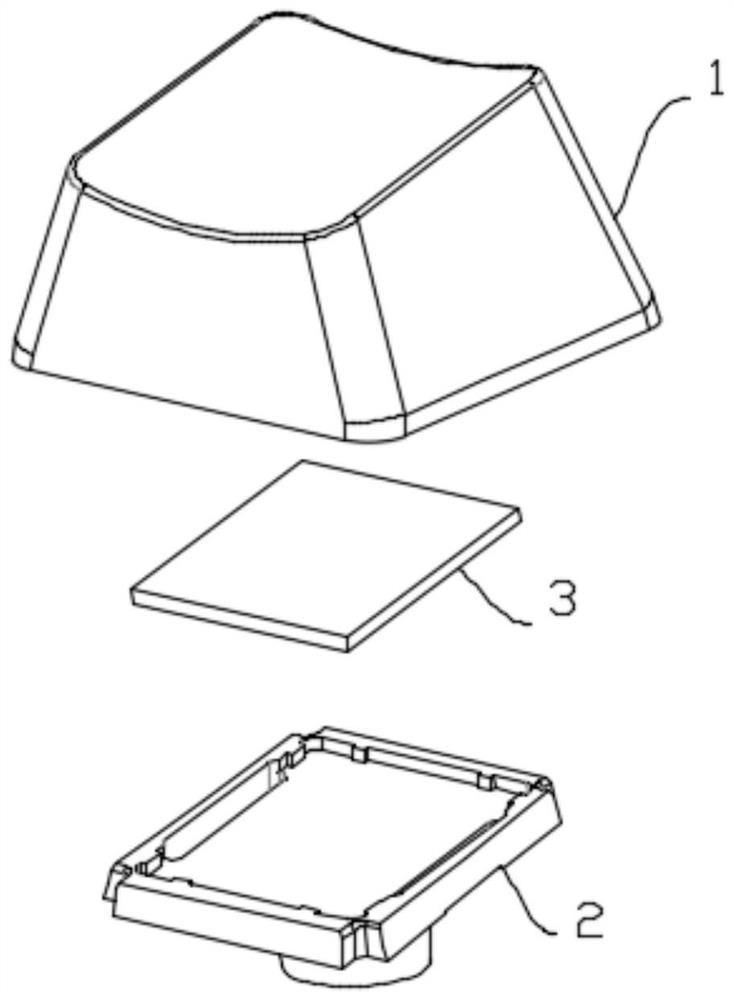

Novel keycap

PendingCN114093703AThere is no problem of insufficient brightnessAccurate tappingElectric switchesControl systemEngineering

The invention relates to the technical field of keyboard equipment, and discloses a novel keycap, which comprises a keycap shell provided with an accommodating cavity formed by being recessed inwards; a supporting component arranged in the accommodating cavity; and a light-emitting matrix arranged on the supporting component, wherein light-emitting units which are evenly distributed in an array mode are arranged on the light-emitting matrix, and the light-emitting units compile light-emitting characters through the control system. The light-emitting matrix is used for emitting the light-emitting characters, and the device is more suitable for being used under the condition of insufficient illumination at night.

Owner:DONGGUAN HEATMOVING ELECTRONIC TECH CO LTD

A neurological detection device

The invention discloses a detecting device used for a neurology department. The detecting device comprises a frame body, a knocking device, supporting devices and a fixing device; the frame body comprises a first horizontal part, a first vertical part, a second horizontal part, a third horizontal part and a second vertical part, and the second horizontal part is provided with a first through hole, a rolling wheel and a first inclined plate; the knocking device comprises a fixing frame, a positioning rod, a cross beam, a first spring, a knocking column, a knocking head and first fixing rods; the supporting devices comprise supporting columns, second inclined plates, third inclined plates, second fixing rods and second springs; the fixing device comprises third springs, a supporting plate located on the third springs, first sponge cushions located on the supporting plate, first fixing structures located on the lower portion of the third horizontal part and second fixing structures arranged on the left side and the right side of the third horizontal part. A portion needed to be detected of a patient can be fixed, accurately knocking can be carried out on the portion needed to be detected, and the detecting effect is accurate.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Dust removal and ventilation device for wear-resisting material production workshop

InactiveCN109028428AReduce workloadAvoid climbing workLighting and heating apparatusSpace heating and ventilation detailsEngineeringProtection mechanism

The invention provides a dust removal and ventilation device for a wear-resisting material production workshop. The dust removal and ventilation device for the wear-resisting material production workshop comprises a knocking mechanism, a protection mechanism and a ventilation fan. The knocking mechanism comprises a limiting cylinder, a knocking rod, a clamping plate and reset springs. The limitingcylinder is assembled on the lower side of the annular side face of the ventilation fan, the knocking rod is assembled in the limiting cylinder, the lower end of the knocking rod extends to the lowerside of the limiting cylinder, the clamping plate is installed on the annular side face of the knocking rod, the clamping plate is arranged in the limiting cylinder, the reset springs are assembled at the lower end of the clamping plate, and the clamping plate is connected with the limiting cylinder through the reset springs. According to the dust removal and ventilation device for the wear-resisting material production workshop, dust is knocked advantageously, protection is facilitated, the functions are complete, and safety and reliability are achieved.

Owner:NINGGUO HAOSHENG WEAR RESISTANT MATERIALS

A foot-operated metronome for music teaching

ActiveCN109377817BIncrease heightPlay the role of footingMetronomesMusicPhysical medicine and rehabilitationFixed frame

Owner:HUAIHUA UNIV

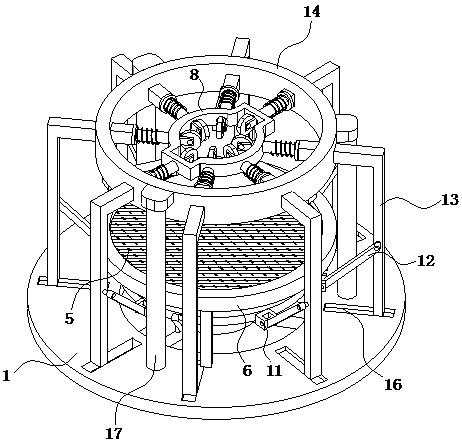

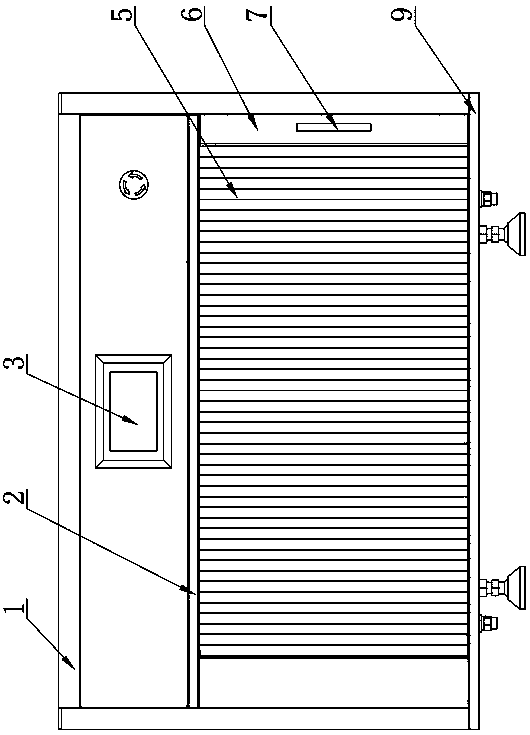

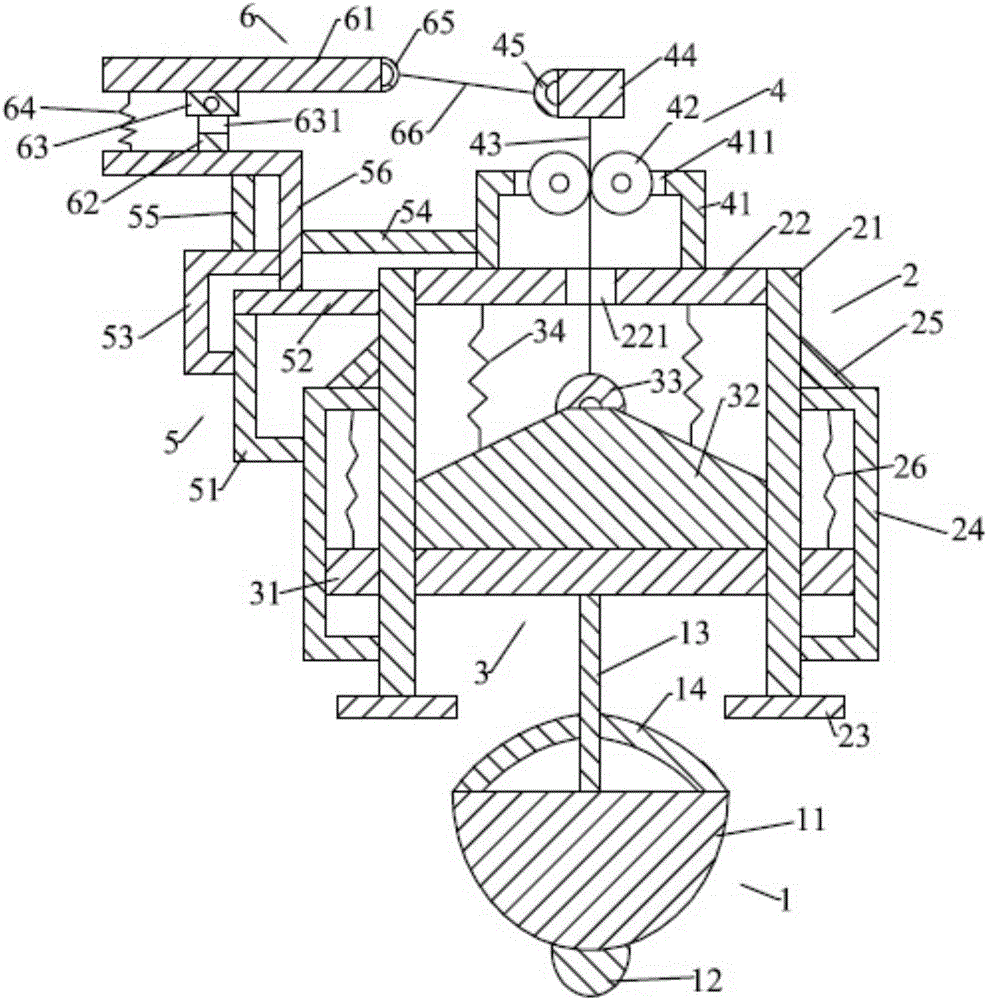

Infiltration tester for color fastness to perspiration, water and sea water of textiles

ActiveCN105527143BReduce work intensityAccurate tappingPreparing sample for investigationPerspirationEngineering

The invention relates to an infiltrating instrument for textile samples for testing color fastness to perspiration, water and sea water. The infiltrating instrument comprises a plurality of air cylinder knocking devices, a plurality of sample boxes for accommodating textile samples and solutions, a sample box putting tray, an X-Y direction moving platform device and a controller. Each of the air cylinder knocking devices comprises a small air cylinder and a knocking part which are connected, one end of each knocking part is connected to a piston rod of the corresponding air cylinder, and the other end of each knocking part faces a corresponding sample box. The X-Y direction moving platform device comprises an upper moving unit and a lower moving unit moving directions of which are perpendicular to each other. Each moving unit comprises a linear guide rail, a driving mechanism and a platform. The platforms are driven to move on the guide rails through the driving mechanisms. The tray is fixed on the X-Y direction moving platform device. After the controller controls the driving mechanisms to move the tray to a proper position, the controller controls the knocking parts of the air cylinder knocking devices to penetrate into the sample boxes and to knock. The infiltrating instrument is advantaged by being fully automatic, efficient and convenient and having a function of protecting safety.

Owner:NINGBO TEXTILE INSTR FACTORY +2

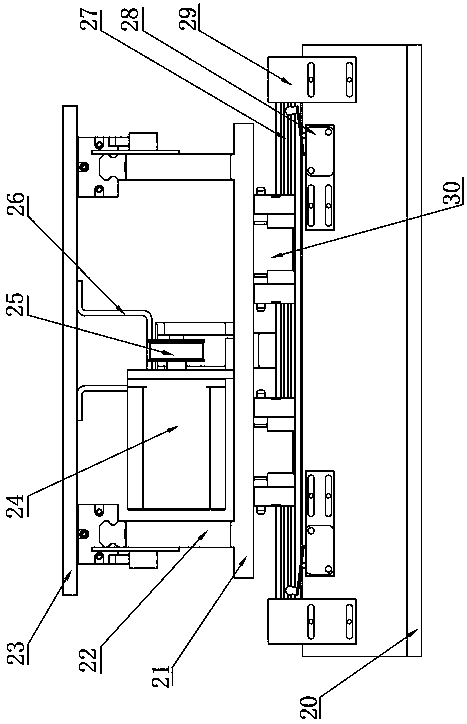

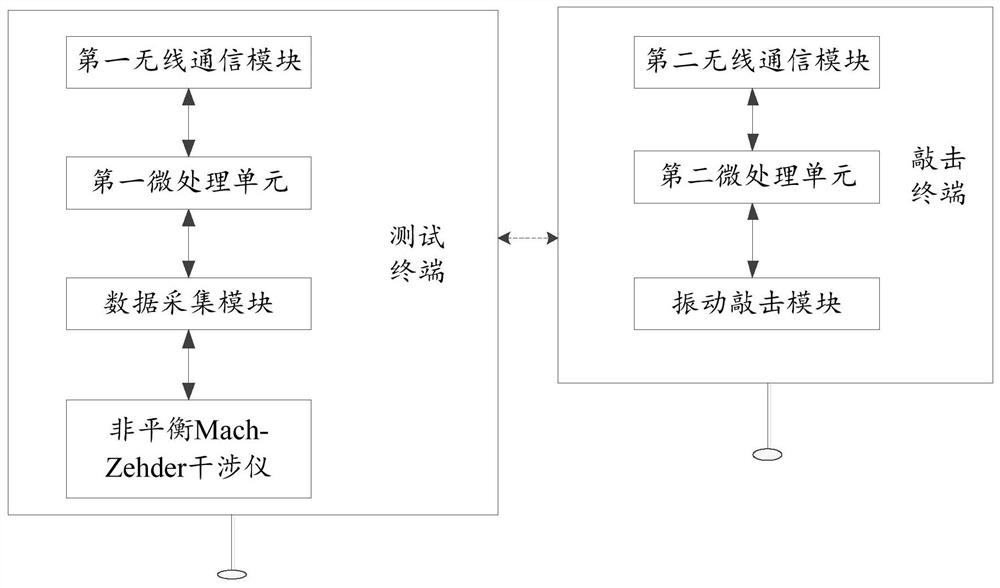

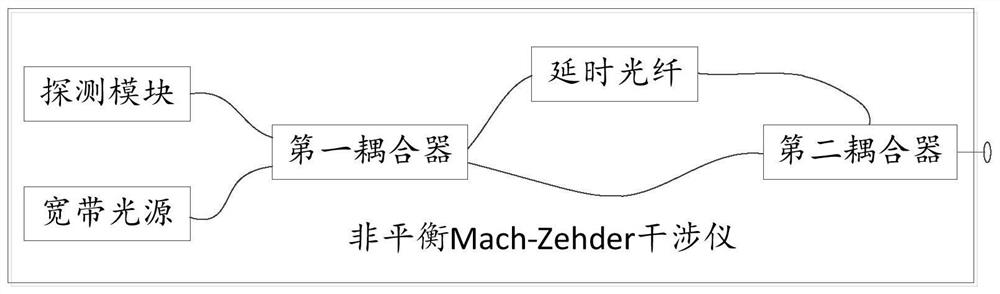

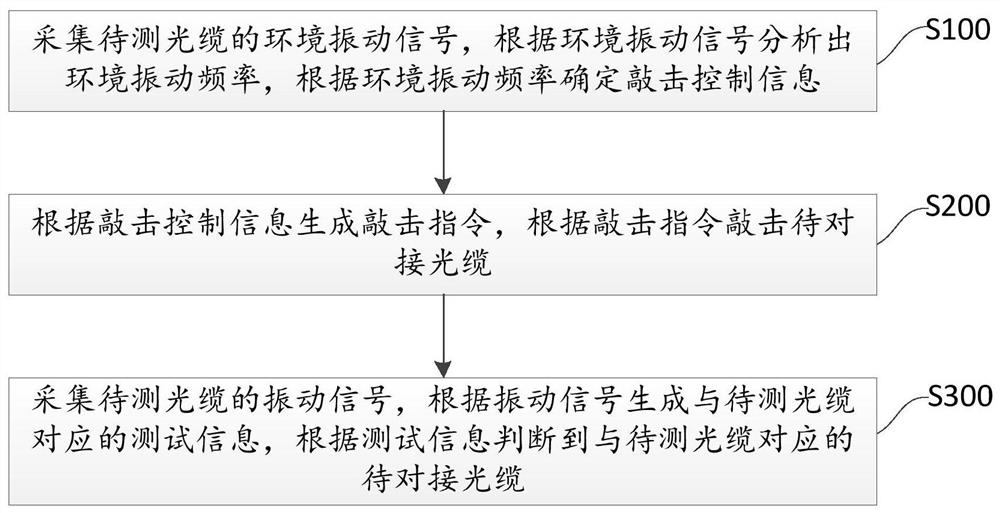

Optical cable identification device and identification method

ActiveCN109813525BAccurate tappingImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementTelecommunicationsInterference (communication)

The invention relates to an optical cable identification device, comprising a test terminal and a knocking terminal; the test terminal comprises a first wireless communication module, a first micro control unit and an unbalanced Mach-Zehder interferometer; the unbalanced Mach-Zehder interferometer The instrument is used to convert the vibration signal collected from the optical cable to be tested into an electrical signal, the first micro-control unit is used to process the electrical signal and generate knocking control information and test information according to the electrical signal, the first The wireless communication module is used to transmit tapping control information and matching result information; the tapping terminal includes a second wireless communication module, a second micro control unit and a vibration tapping module. The present invention is based on optical fiber interference vibration sensing technology, adopts a vibration generator, and combines wireless communication technology to realize precise tapping on optical cables and accurate identification of tapping frequency, build a synchronous feedback mechanism, effectively select frequencies, and avoid interference frequency bands. The accuracy and efficiency of optical cable identification are improved.

Owner:WUHAN OVLINK TECH

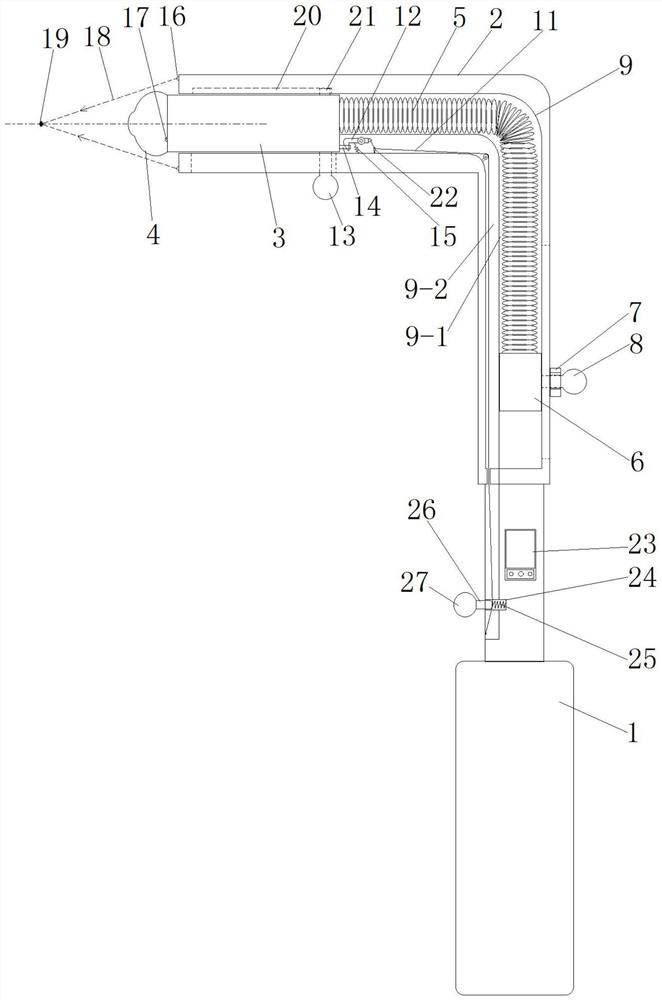

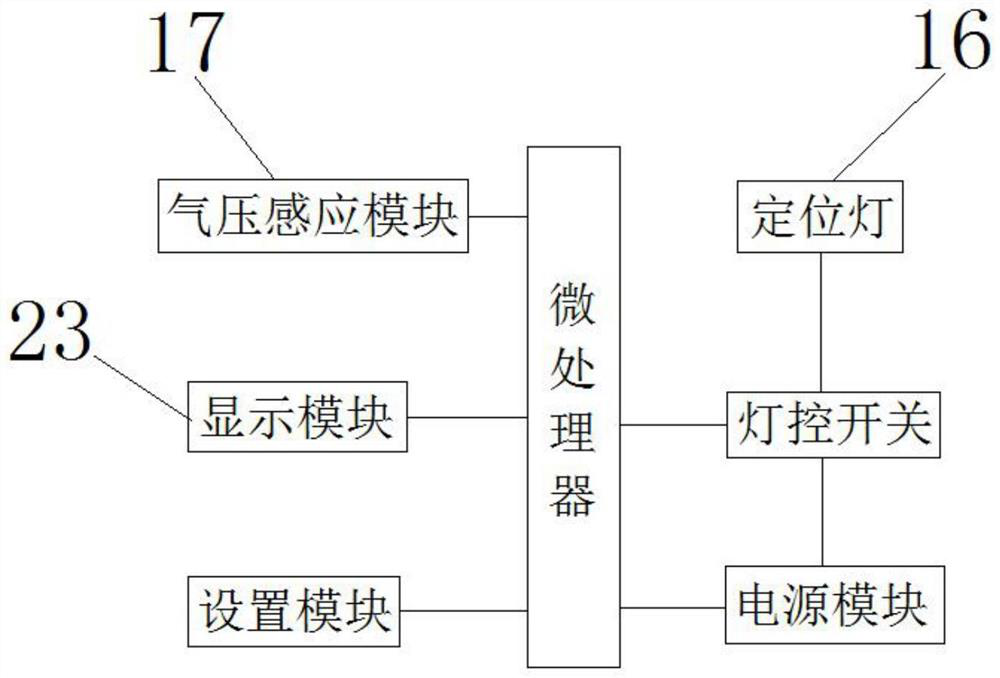

A positionable escape hammer

InactiveCN104554116BAccurate tappingShorten the timePedestrian/occupant safety arrangementEngineeringMaterial resources

The invention discloses a positionable escape hammer, comprising a flange guide rod for positioning, the flange guide rod is composed of a flange part and a guide rod part connected with the flange part, and the guide rod part slides A sleeve is provided, and an impact hammer is fixedly connected to the outside of the sleeve. The present invention can achieve precise positioning when striking glass, save manpower and material resources to the greatest extent, and reduce escape time; in addition, the present invention has simple structure, convenient operation, safe use, and high success rate of breaking glass.

Owner:XIAN UNIV OF SCI & TECH

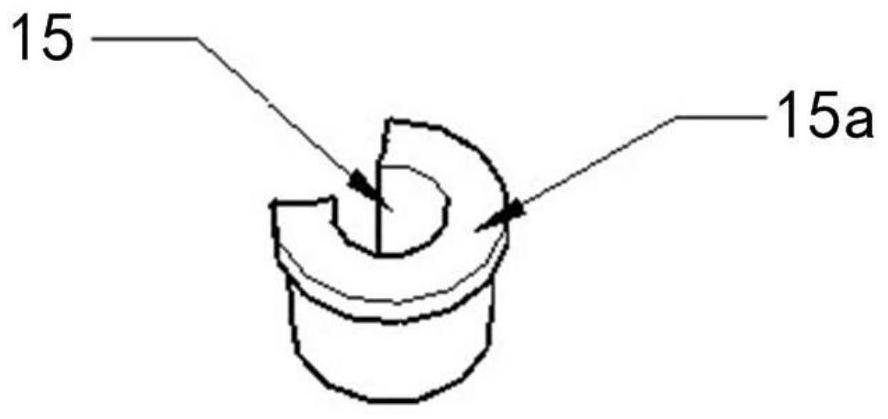

A clamping device for bearing assembly

To solve the existing problem of laborious assembly of bearings, the invention discloses a clamping device for bearing assembly, comprising a connecting rod, a connecting plate, a mounting rod, a pushing block, an electric motor, a rotary table, a pushing plate, a positioning rod, a baffle plate, a coil spring, an end cap, a guide frame, an adsorption layer, a sliding tube, a heating rod, a holding cylinder, a screw, a clamping rod, a snap ring, a through hole, a pump, a water guide pipe, a positioning plate, a rotating rod, a lantern ring and a sliding block. The clamping device has the advantages of reasonable design, convenient operation, reasonable structure and simple principle of thermal expansion and cold contraction the adopted, so that the bearing is convenient to be assemble andaccords with the social demand, and is worth popularizing and using in the mechanical field.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

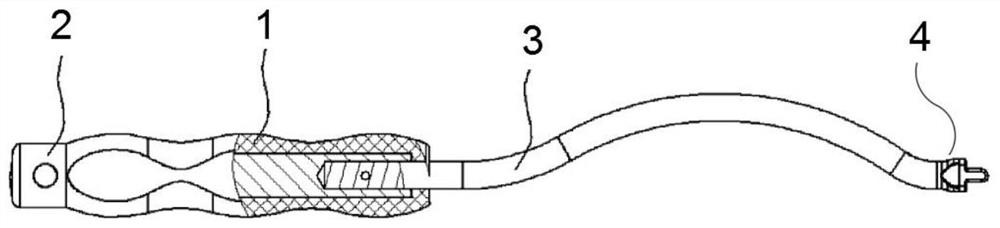

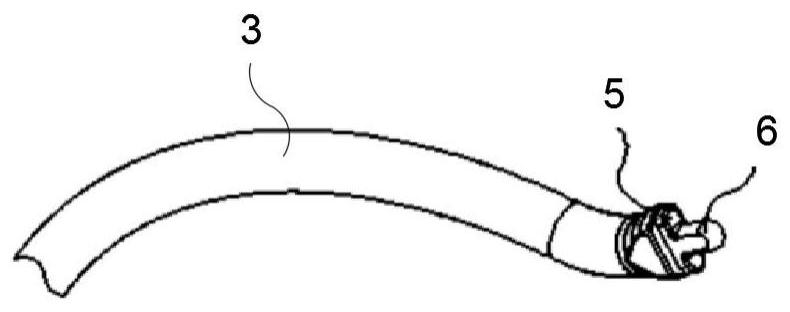

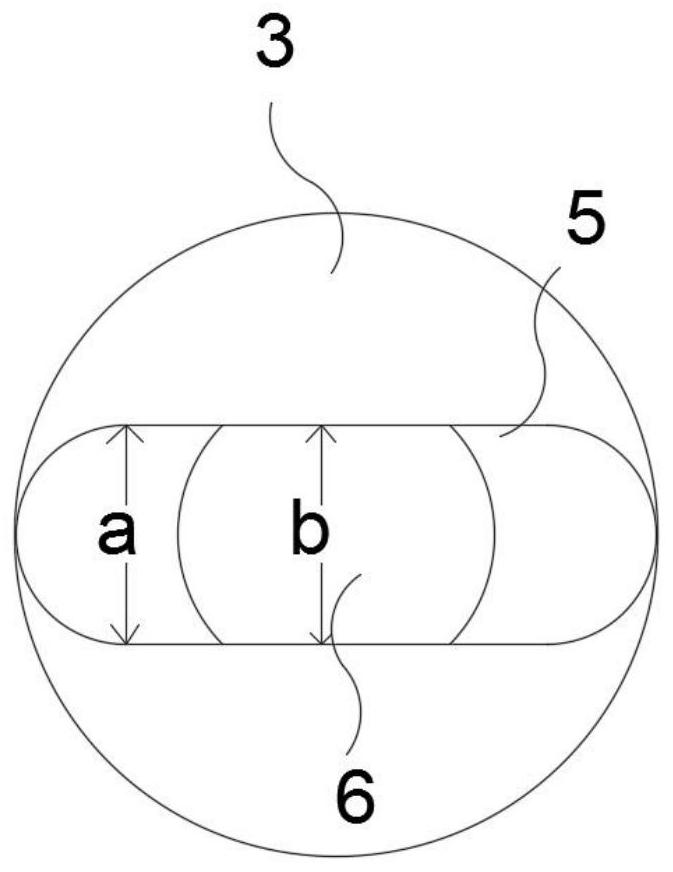

Eccentric femoral stem impactor

The invention discloses an eccentric femoral stem impactor. The eccentric femoral stem impactor comprises a rubber-coated handle; an impactor handle core is arranged on one side of the rubber-coated handle; an eccentric rod is arranged on the side, away from the impactor handle core, of the rubber-coated handle; a femoral stem butt joint mechanism is arranged on the side, away from the rubber-coated handle, of the eccentric rod; the femoral stem butt joint mechanism comprises a kidney-shaped boss and a guide column; the kidney-shaped boss is located at the end, away from the rubber-coated handle, of the eccentric rod; and the guide column is located at the end, away from the eccentric rod, of the kidney-shaped boss. According to the eccentric femoral stem impactor disclosed by the invention, the position of a femoral stem prosthesis in the femoral marrow cavity can be adjusted, namely the inclination angle of the femoral stem prosthesis is accurately adjusted, so that the femoral stemprosthesis can be accurately placed at a proper position, looseness of the femoral stem prosthesis in an implantation process due to inaccurate position is prevented, and the femoral stem prosthesis is accurately impacted into the marrow cavity and compacted; and meanwhile, the arranged eccentric rod can effectively avoid subcutaneous fat, so that the femoral stem prosthesis is simpler, more convenient and more controllable to install.

Owner:AFFILIATED HOSPITAL OF ZUNYI UNIV

Efficient examining system for neurology department

The invention relates to an efficient examining system for a neurology department. The efficient examining system comprises a knocking device, a bracket device, a moving device, a positioning device, a fixed device and a rotating device, wherein the knocking device comprises a knocking head, a knocking block, a first fixed rod and a first bending rod; the bracket device comprises a first positioning rod, a second fixed rod, a first limiting rod, a first positioning frame, a first oblique rod and a first spring; the moving device comprises a moving rod, a moving block, a first fixed ring and a second ring; the positioning device comprises a first bracket, a first rolling wheel, a first stay wire, a first fixed block and a second fixed ring; the fixed device comprises a second bracket, a third fixed rod, a third bracket, a fourth fixed rod, a fourth bracket and a fifth fixed rod; and the rotating device comprises a sixth fixed rod, a rotating rod, a second fixed block, a third spring, a third fixed ring and a second stay wire. The efficient examining system can be used for conveniently examining patients and is simple and convenient to operate, and the knocking is relatively accurate.

Owner:深圳市中科智诚科技有限公司

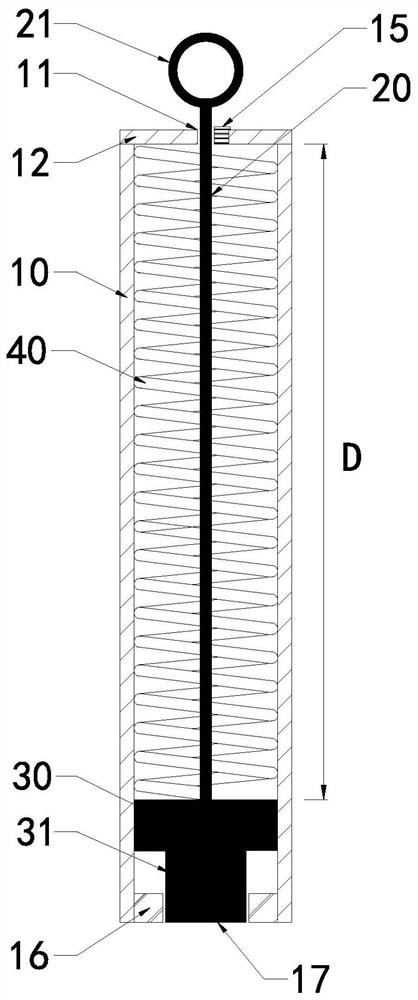

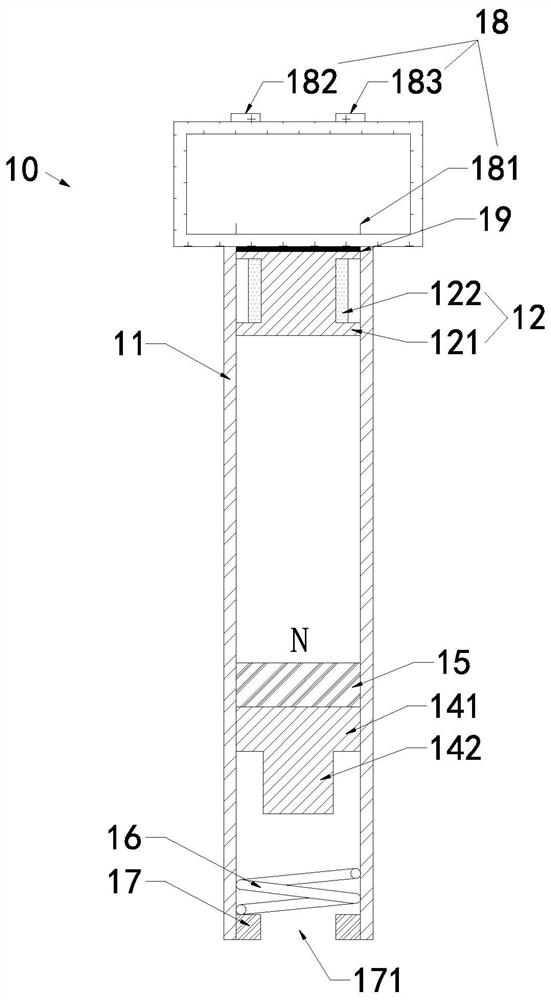

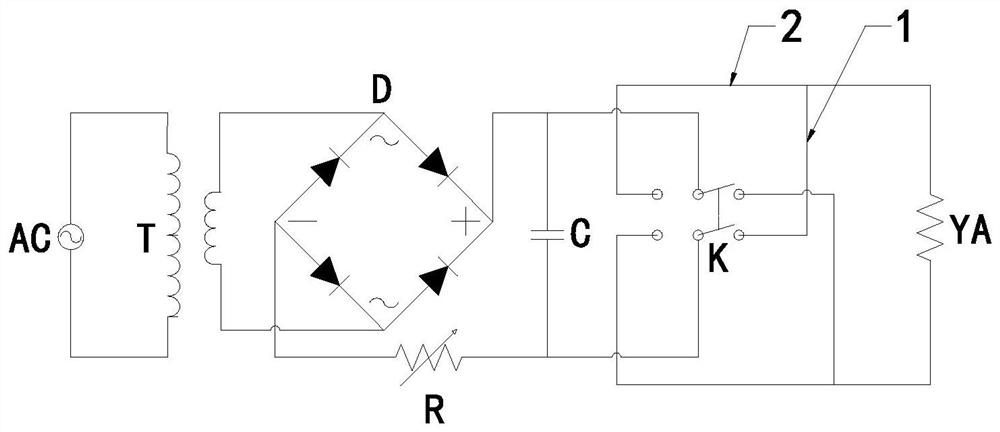

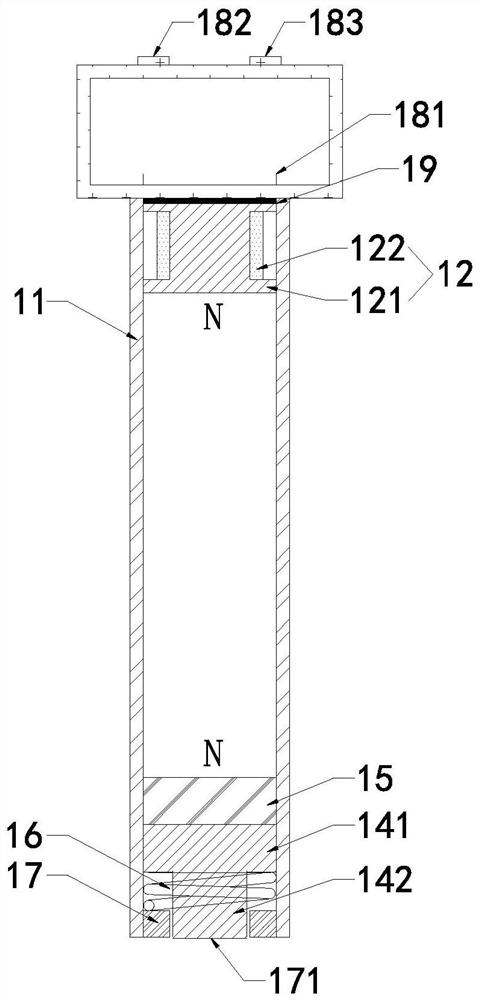

Automatic knocking device and method for nondestructive testing

PendingCN113655120AReduce measurement errorAccurate tappingAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationEvaluation resultSuction force

The invention discloses an automatic knocking device and method for nondestructive testing, and relates to the technical field of nondestructive testing. The problem that an existing nondestructive testing technology is inaccurate in evaluation result is solved. The device comprises a barrel-shaped frame, an electromagnet and a knocking assembly which are arranged in an inner cavity of the barrel-shaped frame, and a main controller which is connected with the electromagnet, wherein the electromagnet is fixed to the closed end of the barrel-shaped frame, a hammer head and a magnetic block of the knocking assembly can slide along the axis of the barrel-shaped frame, the magnetic block is fixedly connected to one end of the hammer head, and the other end of the hammer head can be in contact with a detected object positioned at the open end of the cylindrical frame. The method comprises the following steps: aligning the hammerhead of the automatic knocking device for nondestructive testing to a knocking point, adjusting the magnetic pole of the electromagnet by using the control circuit, generating repulsive force when the magnetic poles of the electromagnet and the magnetic block are the same, sliding the knocking assembly towards a detected object and knocking, and generating suction force when the magnetic poles of the electromagnet and the magnetic block are opposite, wherein the knocking assembly slides towards the direction of the electromagnet and is attached to the electromagnet for resetting, so that different detected objects are knocked and detected repeatedly.

Owner:SHANGHAI CONSTRUCTION GROUP

Positioning device for processing lifting hook detection points

InactiveCN114682829AAchieve fixationAccurate tappingPositioning apparatusDrill jigsEngineeringStructural engineering

The invention relates to a positioning device for processing lifting hook detection points. The positioning device comprises a bottom plate; the center positioning column is vertically connected to the bottom plate, the surface of the center positioning column is matched with the inner edge of the lifting hook, and after the center positioning column positions the lifting hook, the center positioning column is locked by the first locking nut; the angle blocks are arranged on kidney-shaped holes formed in the bottom plate and move in the direction from the principle to the direction close to the center positioning column; the supporting block is used for installing the drill plate on the bottom plate, a plurality of through holes are formed in the drill plate, and the two tips are inserted into two of the through holes respectively. Compared with the prior art, the lifting hook is fixed through the angle block and the central positioning column, and a knocking point is fixed by adopting the drill plate, so that accurate knocking of the detection point is realized.

Owner:SHANGHAI GUOSHANG ELECTROMECHANICAL TECH

Handheld nailing tool and use method thereof

PendingCN112936188AAchieving Median PositioningClamp tightlyStapling toolsNailing toolsSimulationHand held

The invention discloses a handheld nailing tool and a using method thereof. The handheld nailing tool comprises an impact mechanism, a handheld frame and two oppositely arranged clamping mechanisms, wherein the impact mechanism and the clamping mechanisms are connected with the handheld frame, so that nails clamped by the impact mechanism and the clamping mechanisms are located on the same axis, and the impact force generated by the impact mechanism is used for driving the nails clamped in the clamping mechanisms into target positions. Middle position positioning and tight and stable clamping of a nail are achieved through the two oppositely arranged clamping mechanisms, and manual clamping is not needed any more; through the integrated design of the impact mechanism, the clamping mechanisms and the handheld frame, it is guaranteed that the impact force generated by the impact mechanism accurately knocks and nails a nail clamped in the clamping mechanisms into a target position without deviation.

Owner:NANJING COLLEGE OF INFORMATION TECH

A simulation test device for the recoil force of hydrodynamic high-frequency projectiles

ActiveCN111336861BSimulate the realImprove accuracyTraining adaptationEducational modelsScale modelWater Movements

Owner:CHINA SPECIAL TYPE FLIER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com