Automatic knocking device and method for nondestructive testing

A non-destructive testing and automatic technology, applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, generation of ultrasonic/sonic/infrasonic waves, etc., can solve problems affecting the accuracy of evaluation results and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

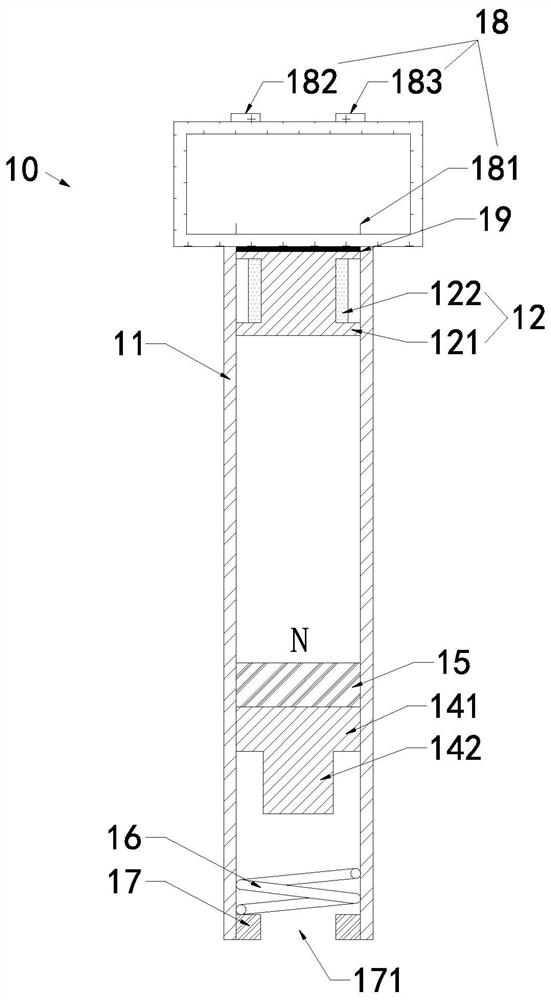

[0036] combine figure 1 with figure 2 Illustrate the non-destructive testing automatic knocking device 10 of the present invention, it comprises:

[0037]A cylindrical frame 11, which is a hollow cylindrical shell with one end closed, one end of the cylindrical frame 11 close to the detected object (not shown in the figure) is an open end, and the other end is provided with a closed end plate;

[0038] The electromagnet 12 is arranged in the inner cavity of the cylindrical frame 11 and fixed at one end close to the end plate;

[0039] The knocking assembly is arranged in the inner cavity of the cylindrical frame 11 and can slide along its axis. It includes a hammer head 141 and a magnetic block 15 arranged and connected in sequence along the axial direction. The hammer head 141 and the magnetic block 15 are connected to the cylindrical frame 11. The inner chamber of the magnetic block 15 is arranged opposite to the electromagnet 12 and fixedly connected to one end of the ha...

Embodiment 2

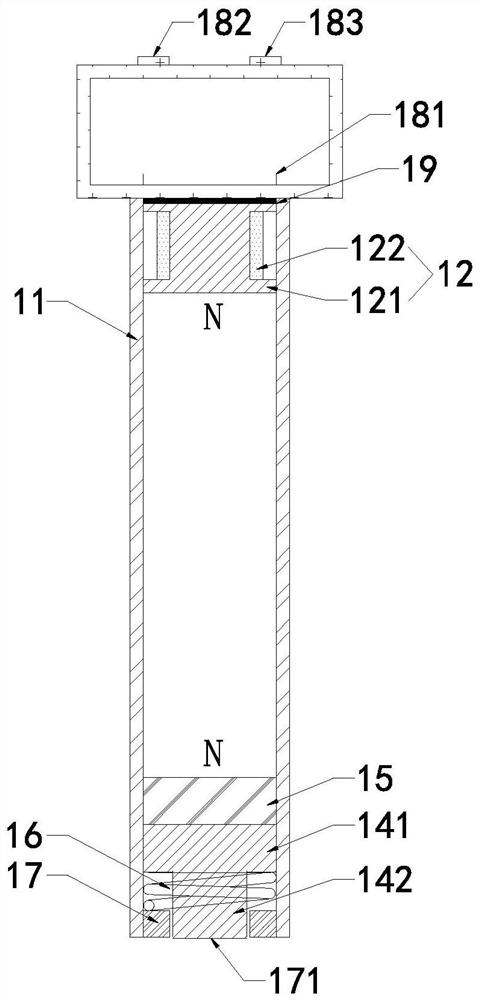

[0056] combine Figure 3 to Figure 6 Illustrate the non-destructive testing automatic tapping method of the present invention, concrete steps are as follows:

[0057] S1: Place the stress wave sensor on the top of the object to be detected and determine the knocking point, and vertically set the automatic knocking device 10 for non-destructive testing described in Embodiment 1 on the top of the knocking point, so that the hammer head 141 of the knocking assembly is quasi-tap point;

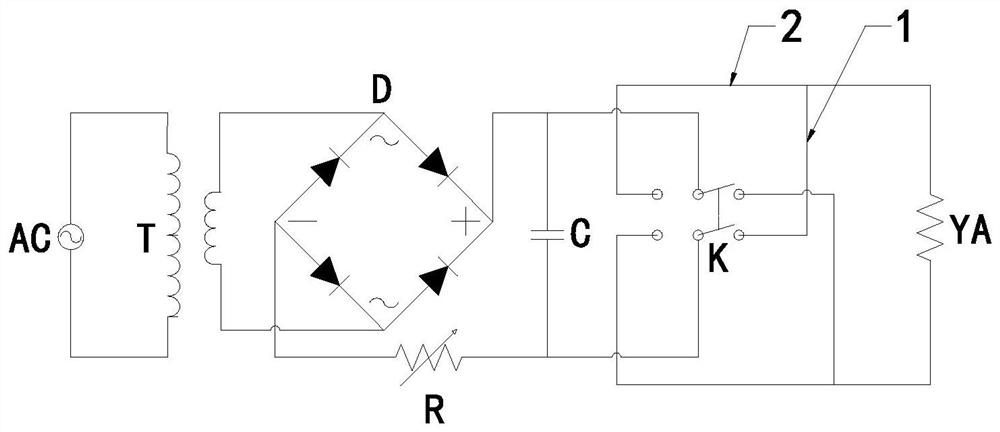

[0058] S2: if image 3 with Figure 4 As shown, adjust the control switch 182 of the main controller 18 to "off", the electromagnet 12 is non-magnetic, and the percussion assembly is attracted to the electromagnet 12 due to the magnetism of the magnet block 15 itself, and the control switch 182 is adjusted to "percussion". ”, the output terminal and input terminal of the double-pole double-throw switch in the control circuit are respectively connected to the interface of the first branch circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com