A toughness and strength testing device for toughened bulletproof materials

A strength detection and toughness technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve the problems of low applicability, inaccurate detection, low work efficiency, etc. Accurate and precise detection of material strength and the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

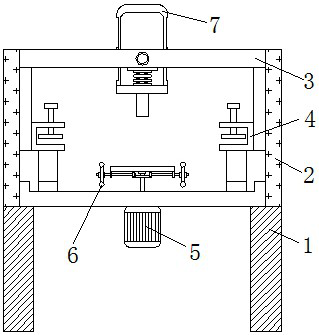

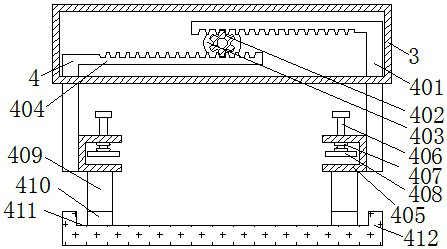

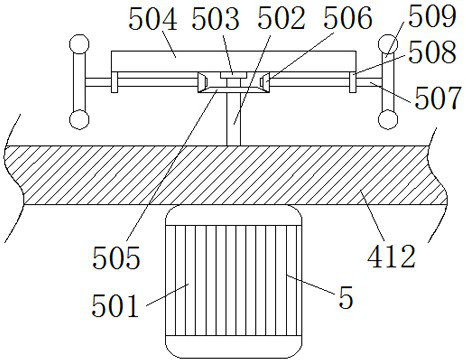

[0032] see Figure 1-5 , the present invention provides a technical solution: a toughness and strength detection device for toughened bulletproof materials, comprising:

[0033] Support column 1, vertical plate 2, top plate 3, toughness measuring component 4, upper toothed rod 401, toothed shaft 402, rotary block 403, lower toothed rod 404, C-shaped block 405, threaded rod 406, first spring 407 , pressing plate 408, vertical block 409, first slider 410, first chute 411, bottom plate 412, knocking assembly 5, motor 501, rotating rod 502, bearing 503, fixed plate 504, first pair of bevel gears 505, the first Two pairs of bevel gears 506, connecting rod 507, collar 508, movable rod 509, replacement assembly 6, inserting rod 601, first threaded block 602, second threaded block 603, gravity ball 604, impact assembly 7, connecting plate 701, The second spring 702, the mounting plate 703, the impact block 704, the pull plate 705, the second chute 706 and the second slide block 707, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com