Eccentric femoral stem impactor

A technology of driver and femoral stem, which is applied in the field of eccentric femoral stem driver, can solve the problems of easy damage to the screw thread, high price, inconvenient use, etc., and achieve the effects of easy installation, time saving and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

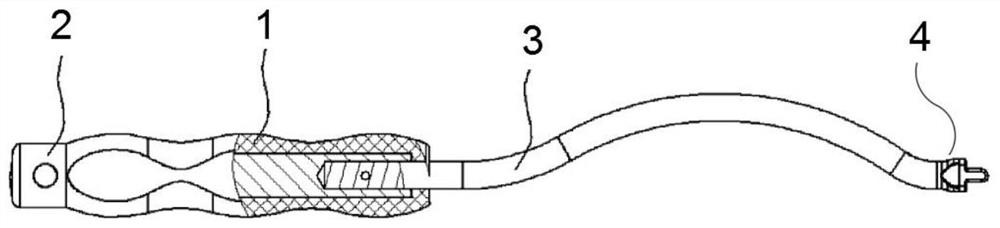

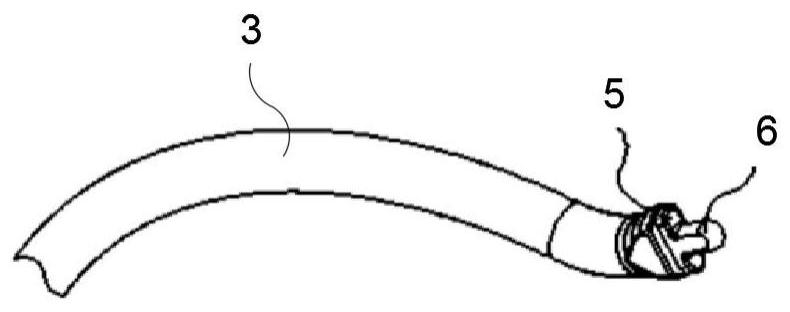

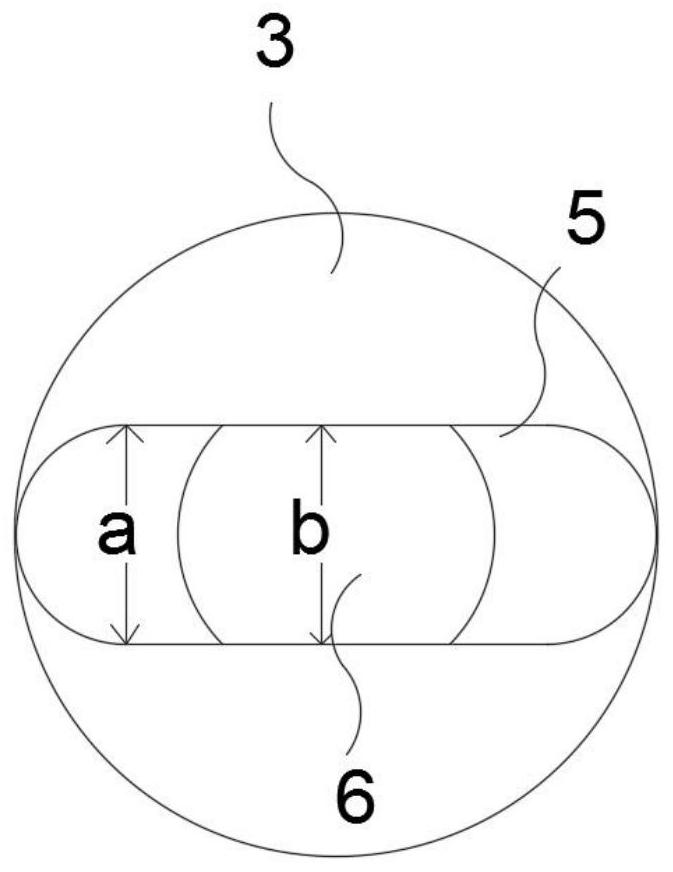

[0033] Embodiment: the present invention provides technical scheme, as figure 1 , 4, the eccentric femoral stem driver, including the rubberized handle 1, the outer wall of the rubberized handle 1 is wavy, which is easy to grasp by hand, the inner wall of the rubberized handle 1 is hollow, and is used to connect the eccentric rod 3, the outer wall of the rubberized handle 1 There is a flat pin surface on the top, which is used to increase friction and prevent the eccentric femoral stem driver from falling from the hand. One side of the rubberized handle 1 is provided with a driver handle 2. The driver handle 2 is a cylindrical structure. Its one end plane is fixedly connected with the rubber-coated handle 1, and the other end plane is used to correspond to the bone hammer 8, which is the force-bearing surface. The side of the rubber-coated handle 1 away from the driver core 2 is provided with an eccentric rod 3, and the eccentric rod 3 One end is inserted into the rubberized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com