Positioning device for processing lifting hook detection points

A technology of positioning device and detection point, which is applied in positioning device, metal processing equipment, drill dies for workpieces, etc., can solve the problems of size deviation of detection point, affecting hook maintenance, etc., and achieve the effect of simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

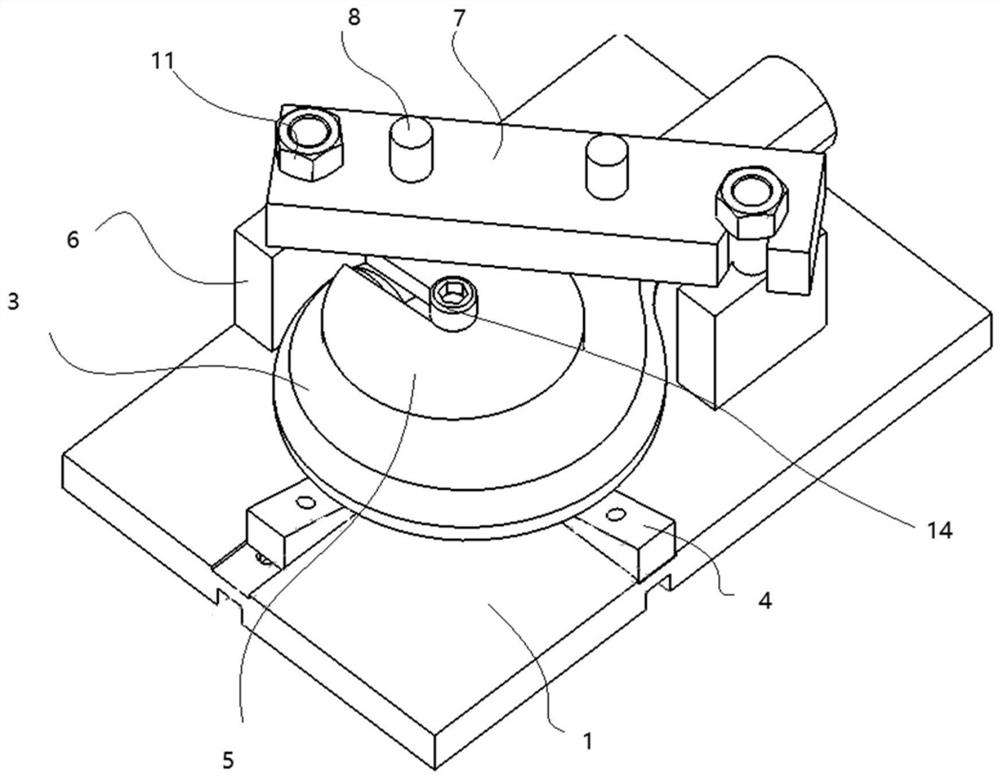

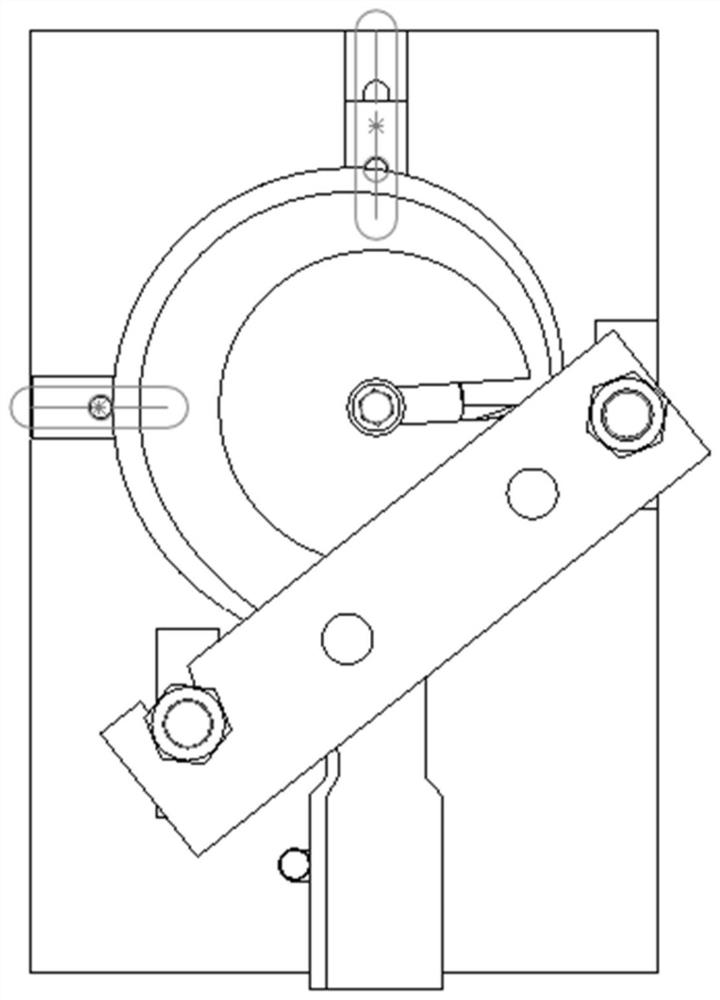

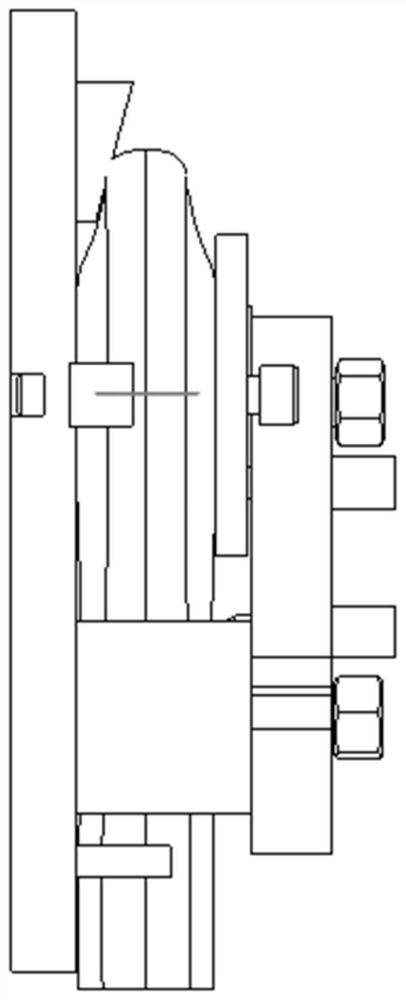

[0032] A positioning device for processing hook detection points, such as Figure 1 to Figure 6 shown, including:

[0033] bottom plate 1;

[0034] The central positioning column 2 and the first locking nut 14, the central positioning column 2 is vertically connected to the base plate 1, and its surface is matched with the inner edge of the hook 3. After the central positioning column 2 locates the hook 3, the first locking nut 14 lock;

[0035] There are a plurality of corner blocks 4, which are arranged on the waist-shaped holes opened on the bottom plate 1 and move in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com