Patents

Literature

142results about How to "Smooth slag discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

InactiveCN102213077AEasy to crackLarge range of pressure reliefDrill bitsConstructionsHydraulic pumpHigh pressure water

The invention relates to coalmine gas extraction and permeability enhancement equipment and technology, and discloses a coal seam reaming system using three-dimensional (3D) swirling water jet. The system is connected to a high-pressure rotary joint through a high-pressure hose provided with a stop valve by virtue of a high-pressure hydraulic pump station and is characterized by being connected to a high-pressure water jet drill stem through a drilling machine, wherein the front end of the high-pressure water jet drill stem is connected with a high-pressure water jet head with nozzle bases; and high-pressure swirling water jet nozzles are arranged on the nozzle bases. The invention further discloses a coal seam reaming and fracturing method for permeability enhancement using the 3D swirling water jet. In the coal seam reaming method using the 3D swirling water jet, coal is sheared so as to lower the hydraulic pressure loss, improve the cutting efficiency and increase the cracks and bore diameter of the coal; high-pressure water is injected so as to fracture the coal between a hydraulic reamed hole and control bored holes; and a coal seam is fully depressurized within a large range so as to shorten the pre-extraction time of the coal seam.

Owner:CCTEG SHENYANG RES INST +1

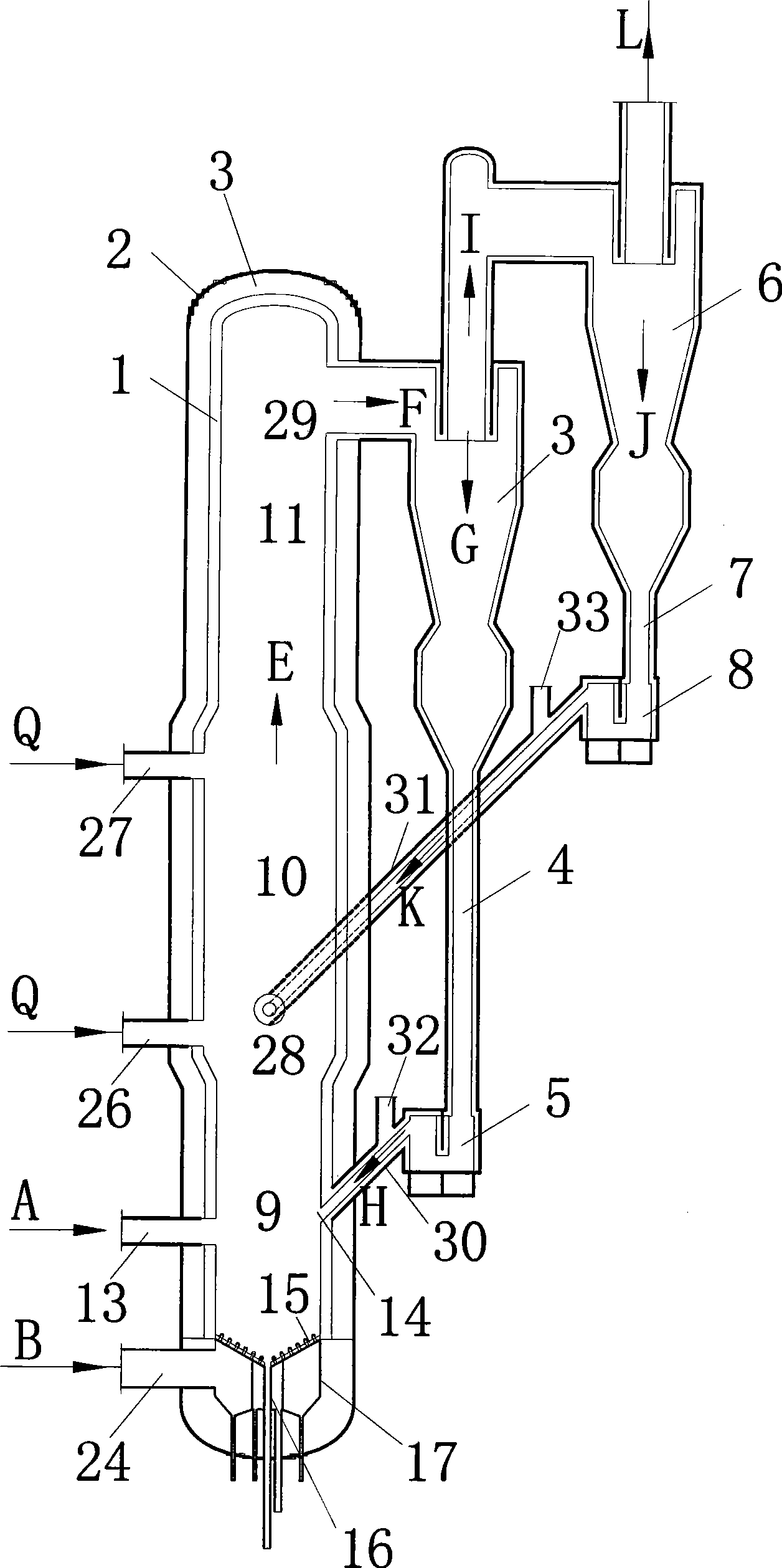

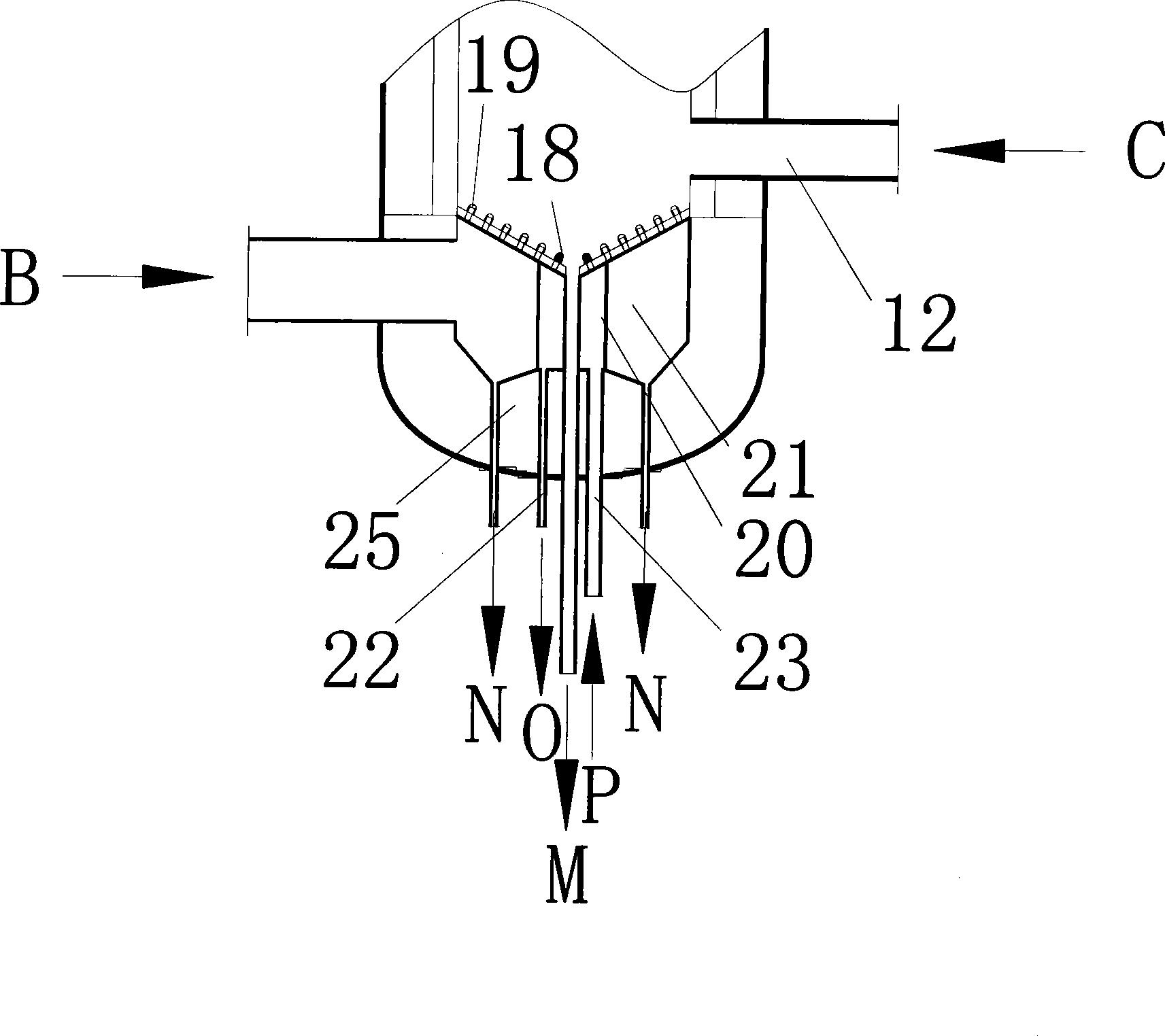

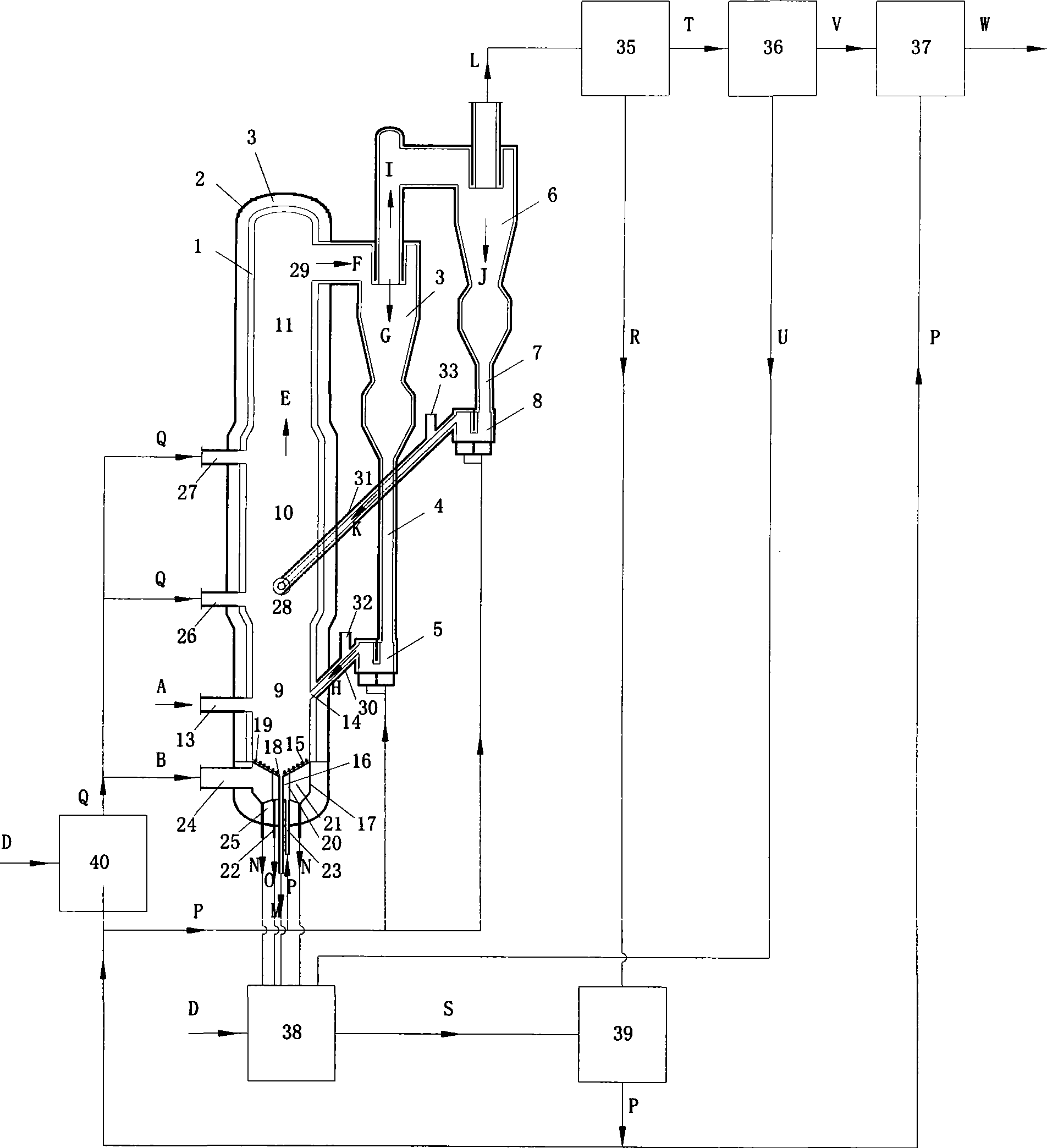

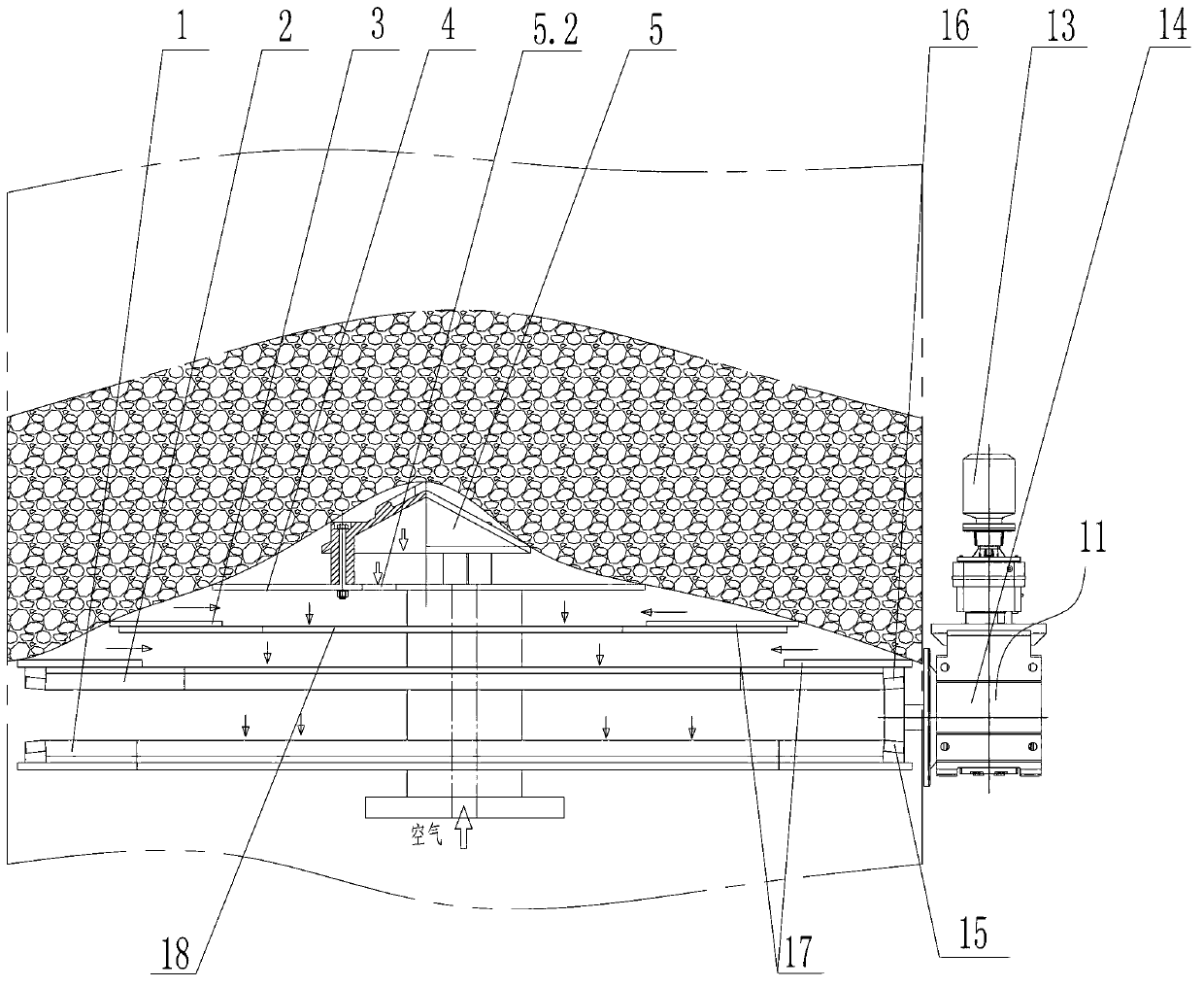

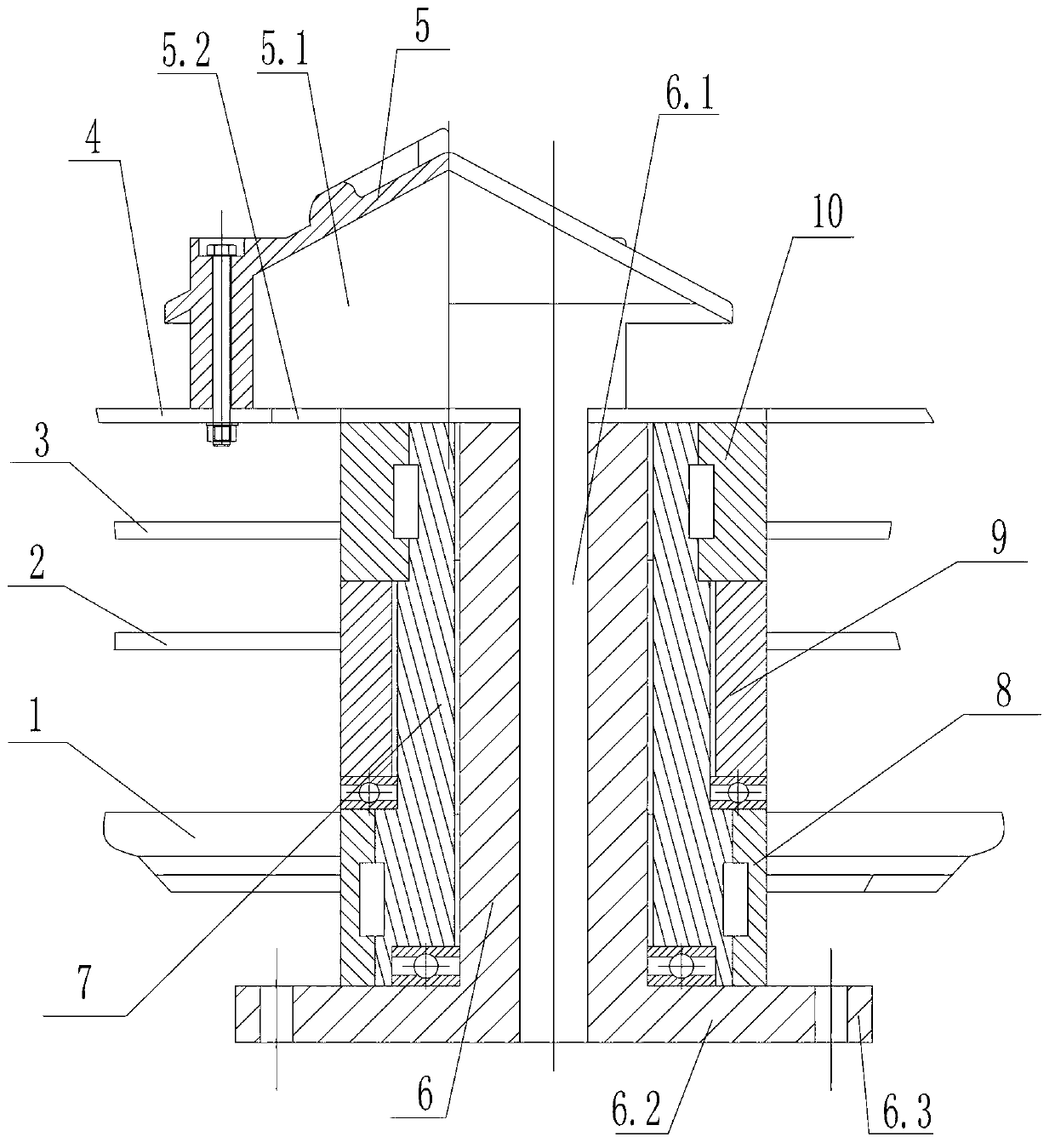

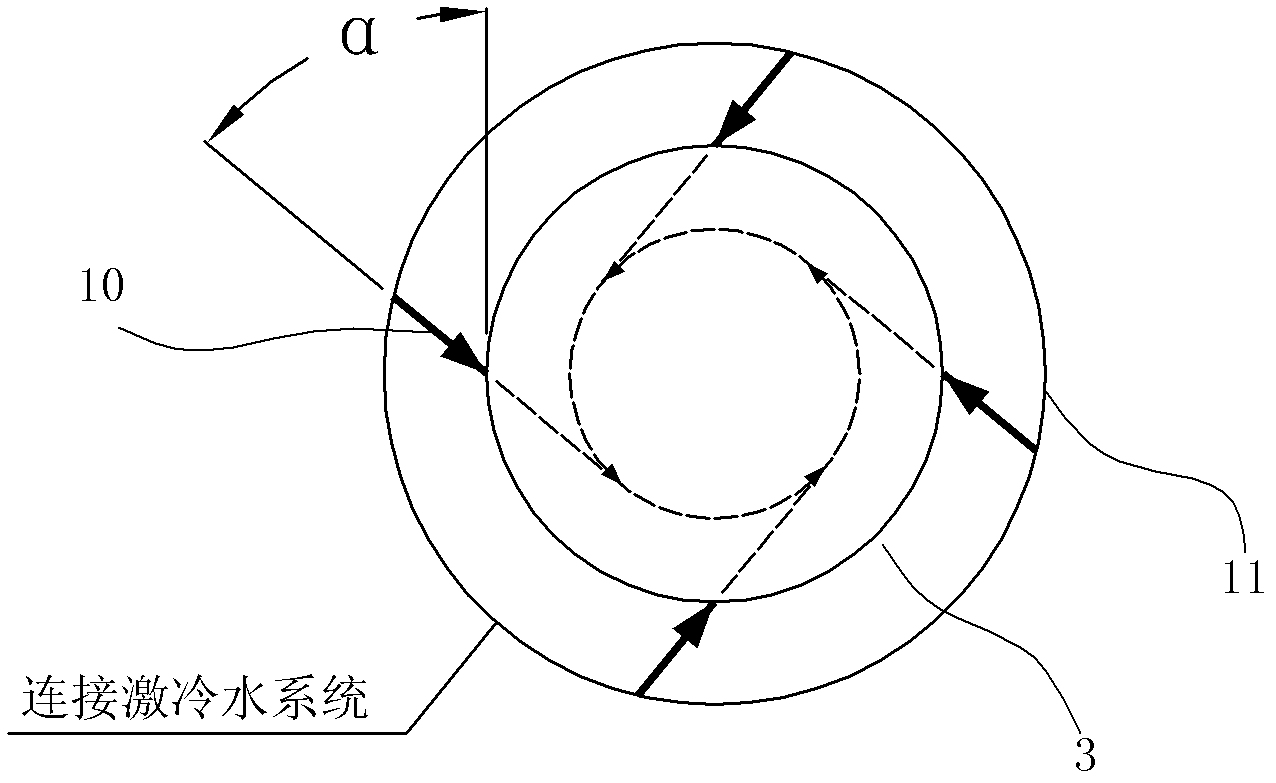

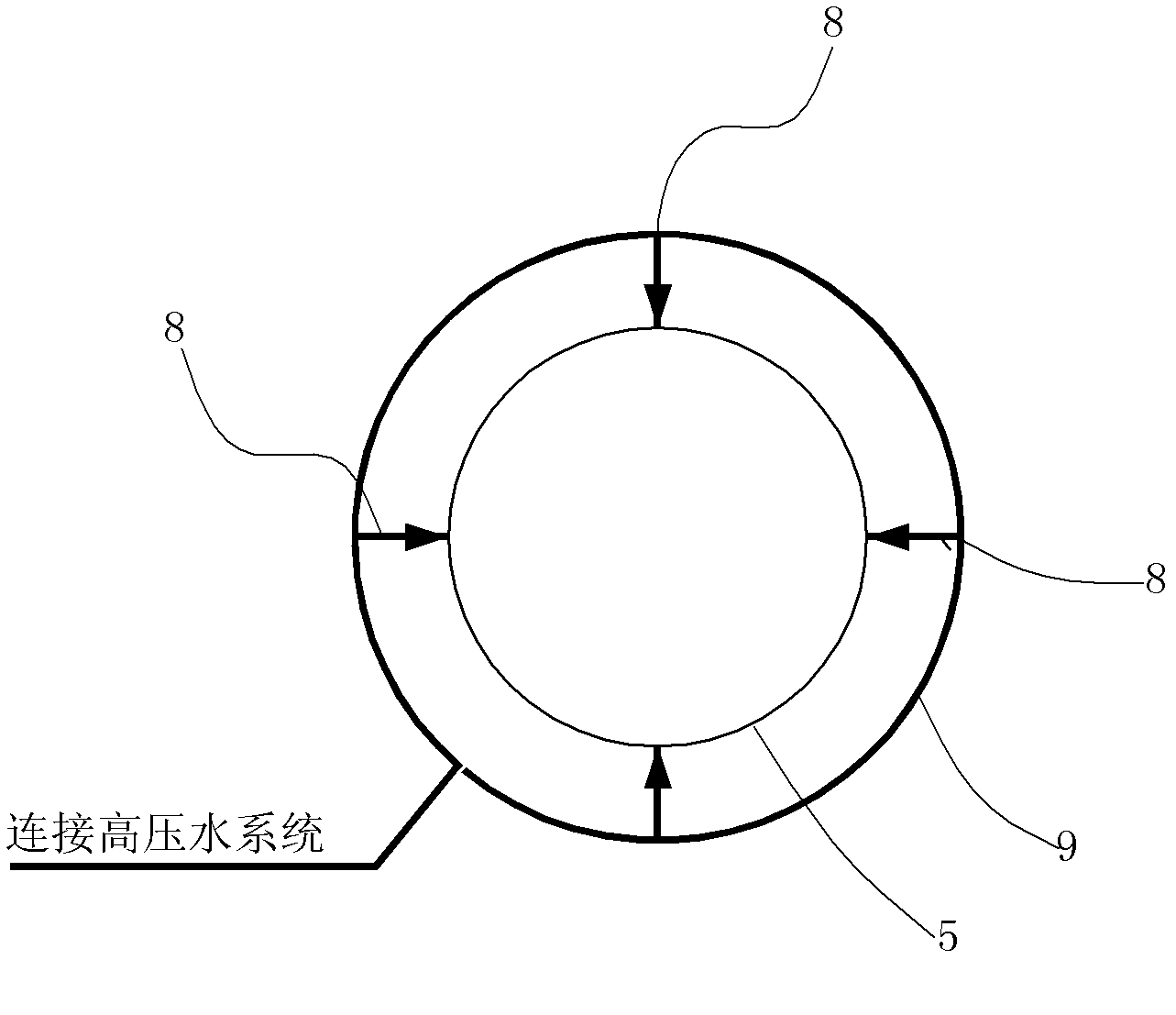

High-density pressurized fluidized bed coal gasification apparatus and method

ActiveCN101372635AGood amplification performance of flow dynamic characteristicsImprove carbon conversionCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringTransformation ratio

A high-density pressurized fluid bed coal gasification device and a method relate to a gasification device and a method which are especially suitable for the efficient treatment of the high-sulfur, high-ash and high ash fusion point coal with high reserve volume in China and have the advantages of broad coal type adaptability, high carbon transformation ratio in the gasification process, high heat value of coal gas, low investment and excellent environment-friendly performance. A gasification reactor (1) is arranged in a pressure shell (2) and is divided into a dense-phase turbulent flow fluidizing section (9), a high-density core-annulus flow section (10) and a density rapid flow section (11) from bottom to top, and according to the gasification character of the goal with high sulfur, high ash and high ash fusion point, flow states with different features are adopted for pressurizing and sectionalized gasification from bottom to top and the pressure for gasification is 1.0-2.5MPa.

Owner:SOUTHEAST UNIV

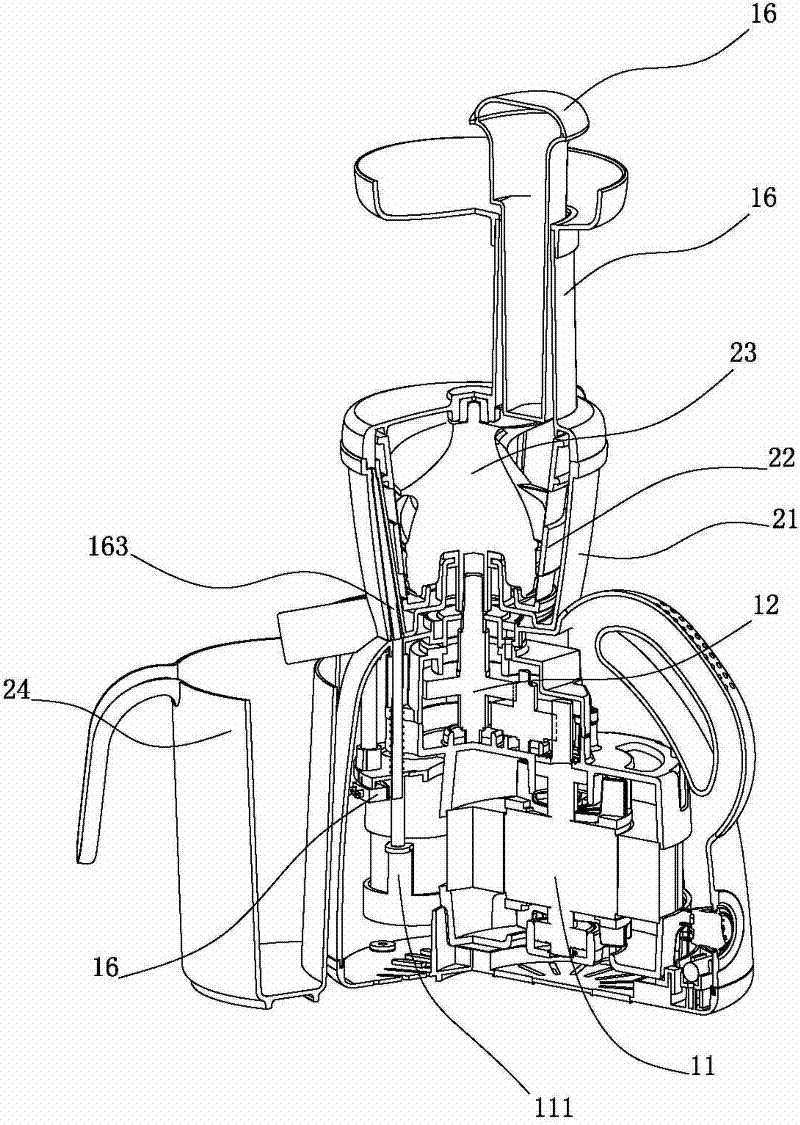

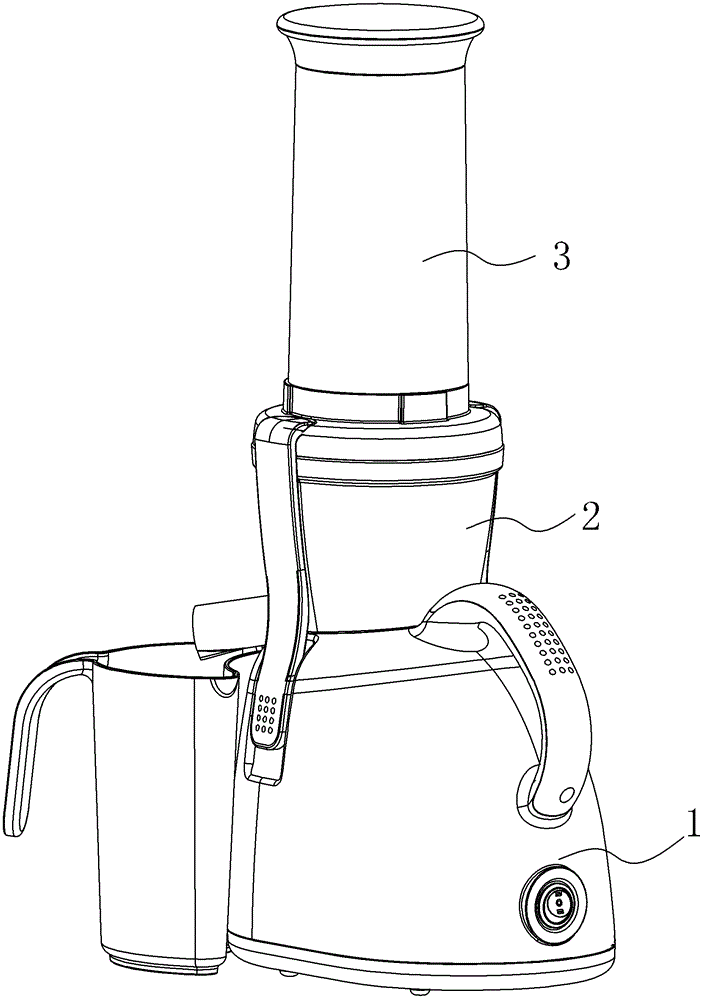

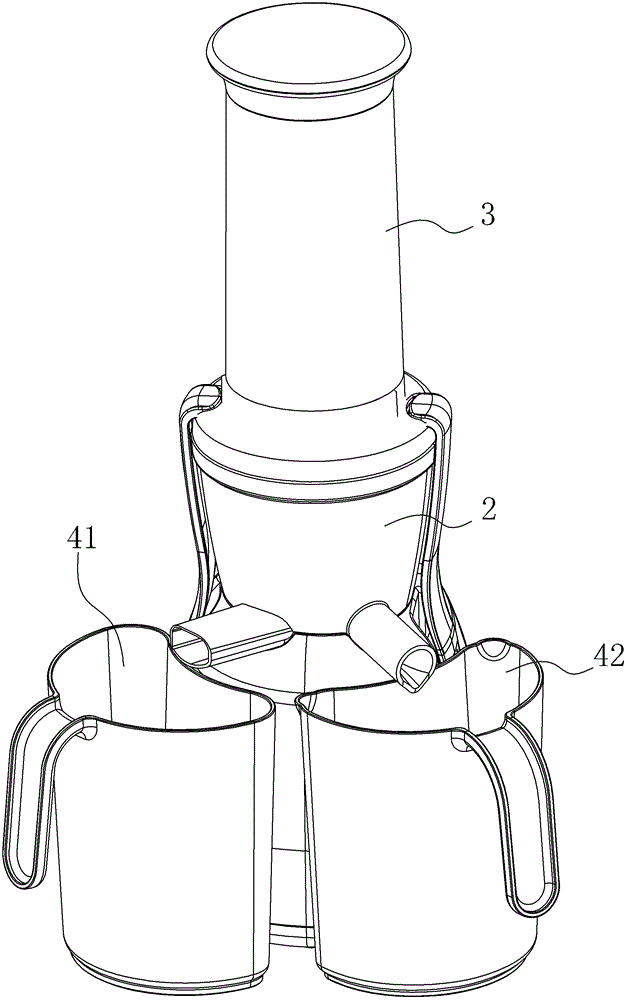

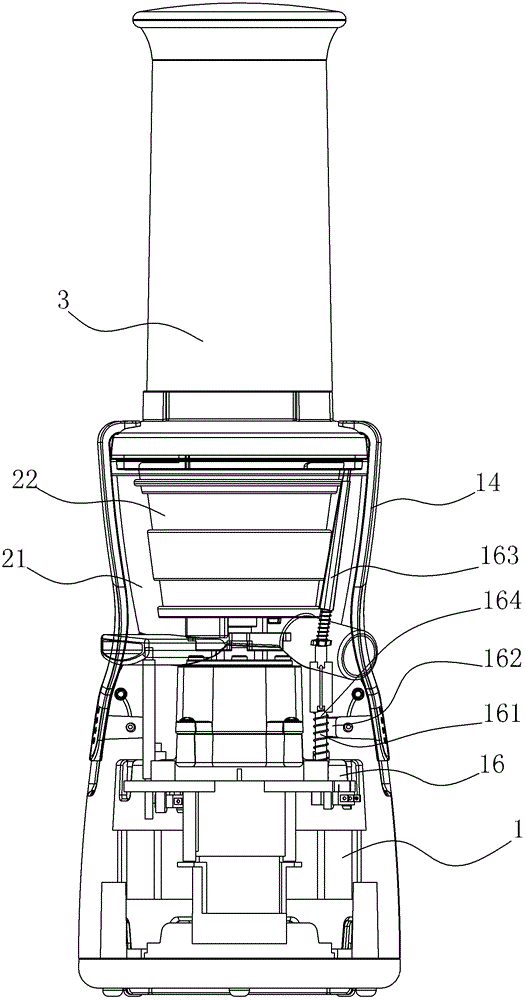

Squeezing type juicer

Owner:胡伟

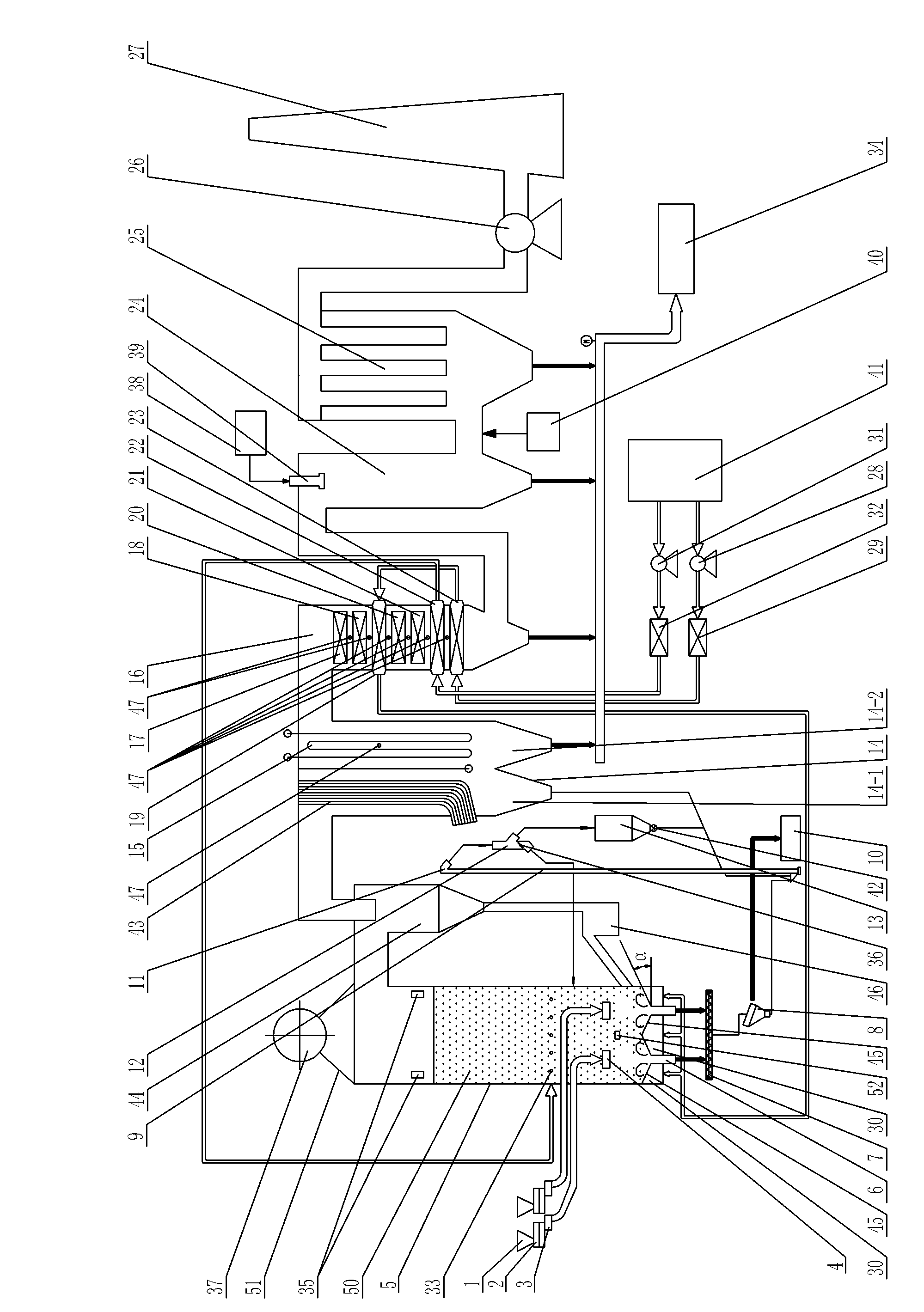

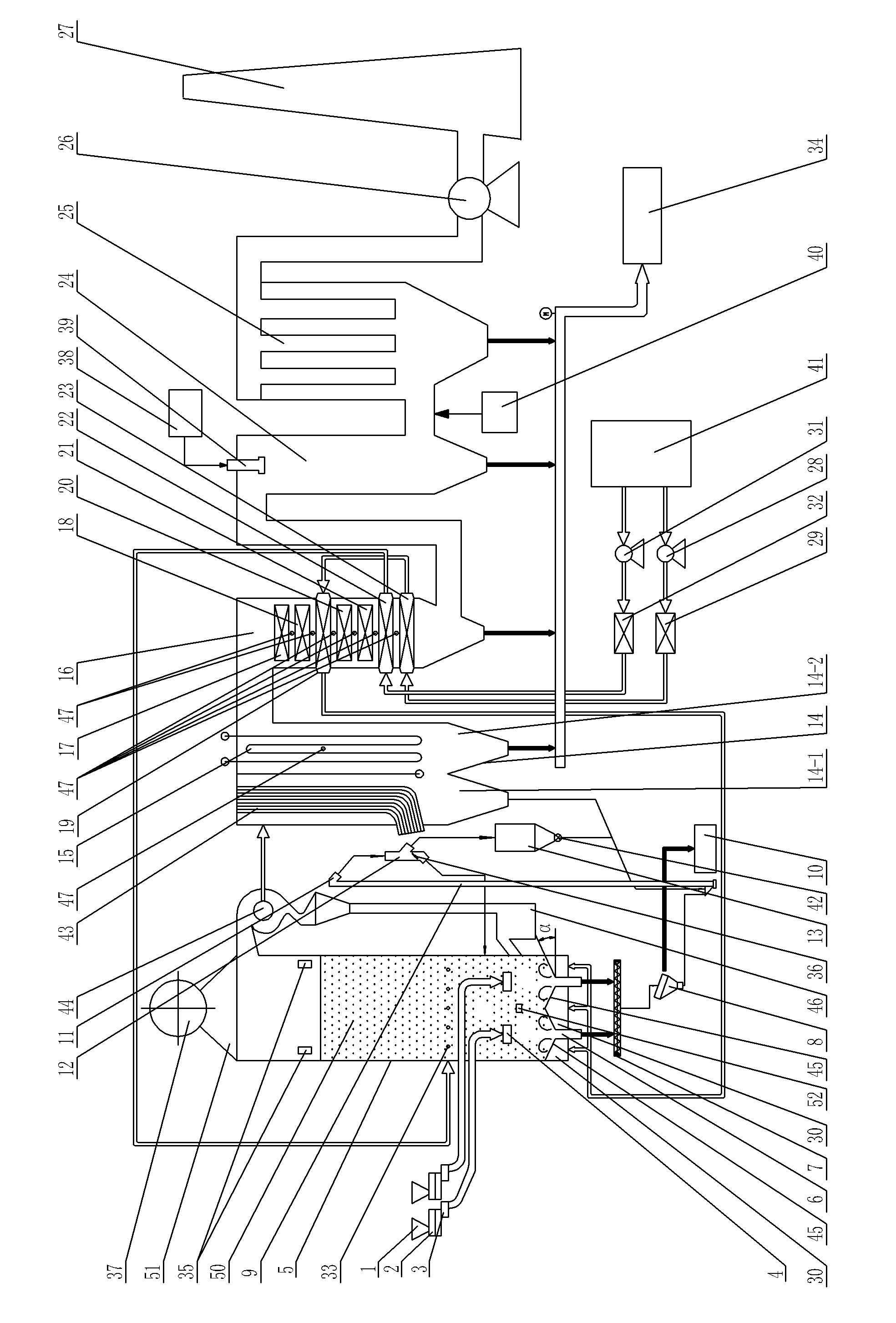

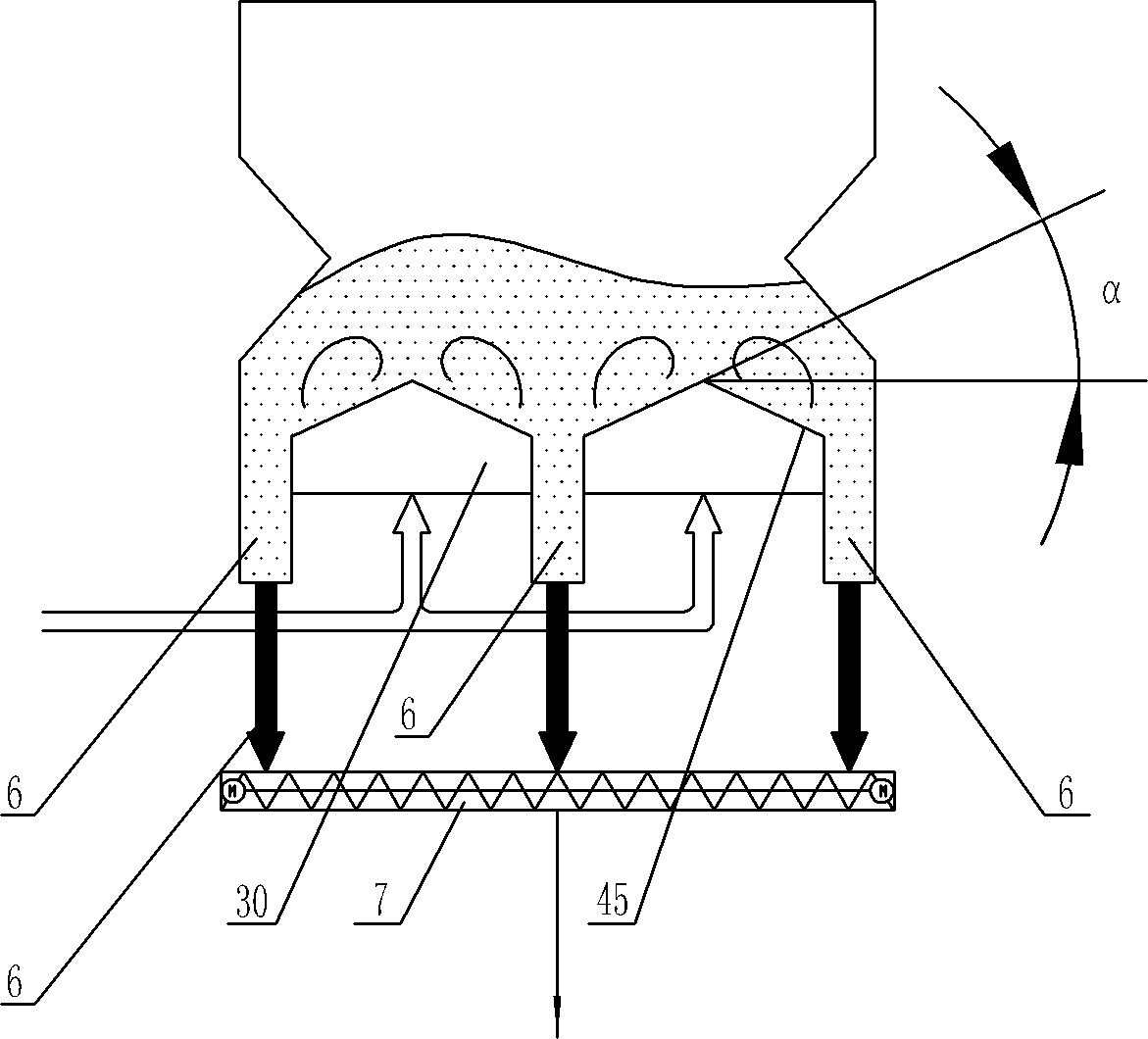

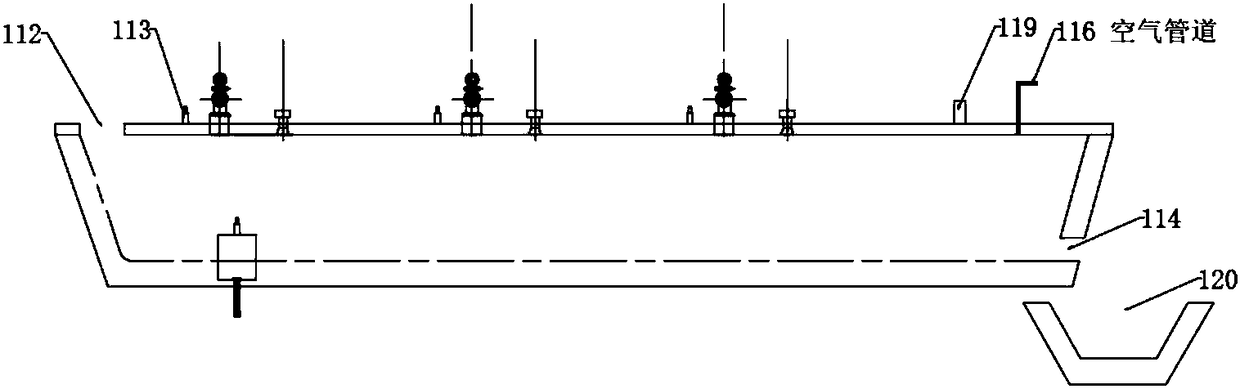

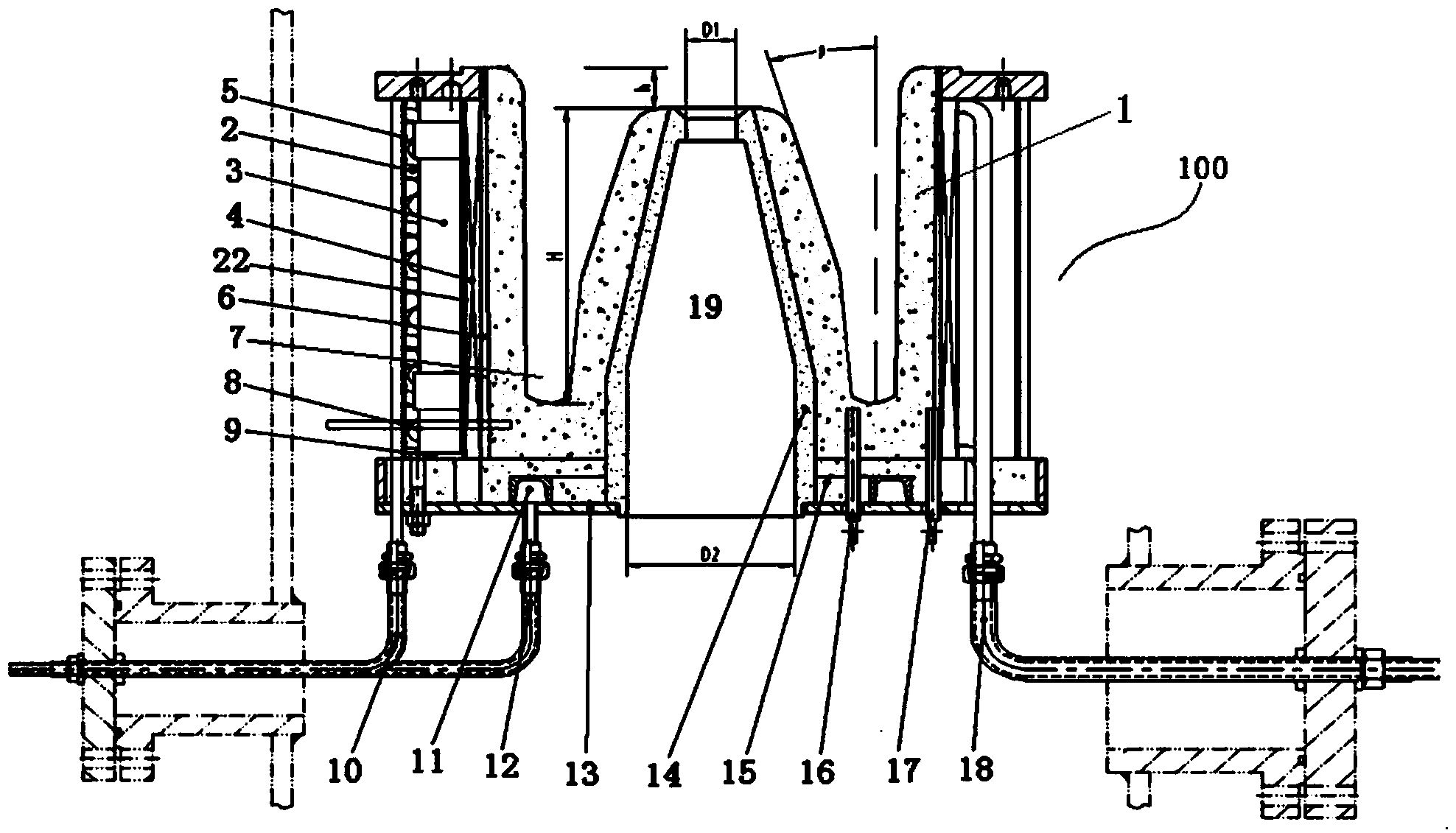

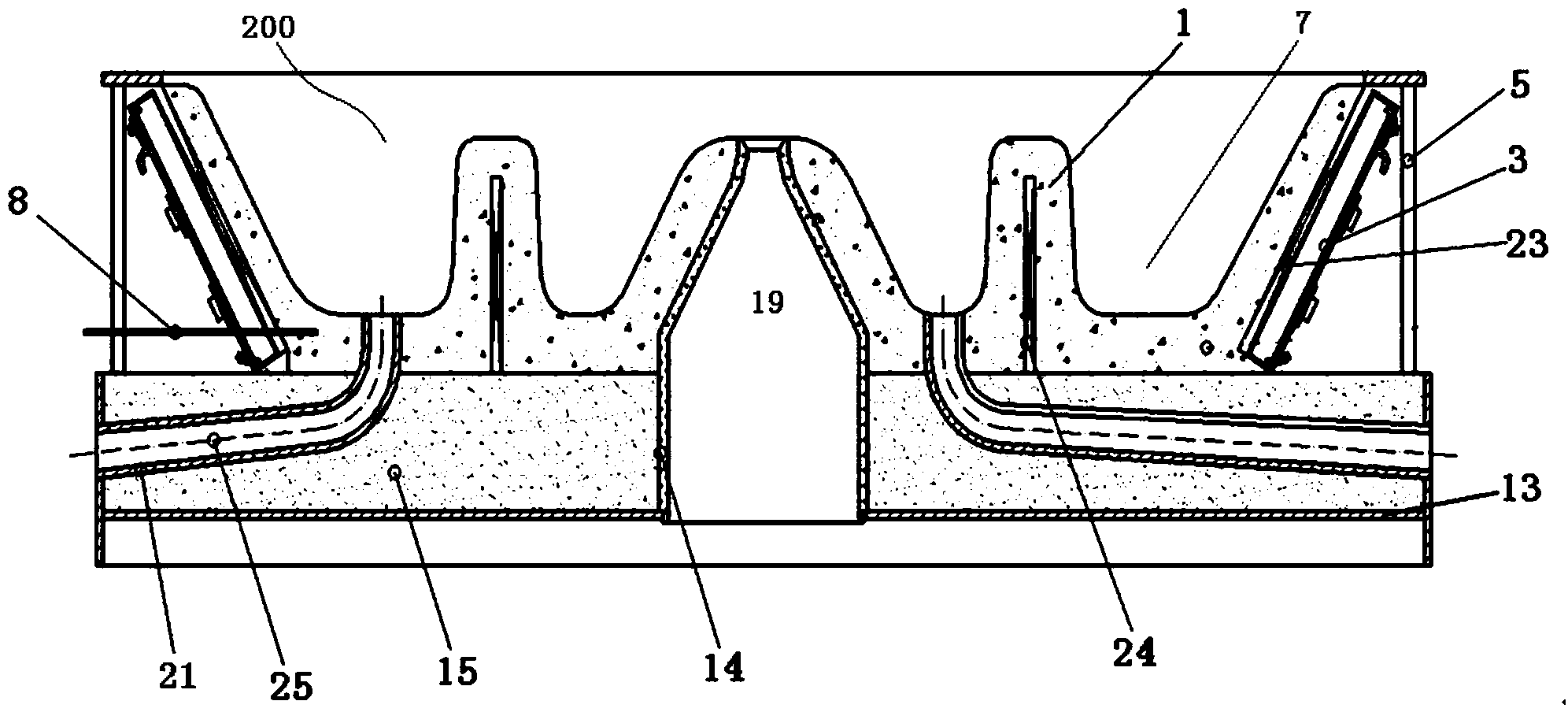

Circulating fluidized bed garbage incineration boiler and pollution control system with same

The invention discloses a circulating fluidized bed garbage incineration boiler and a pollution control system with the same, which relate to a garbage incineration boiler and a pollution control system with the same, and aim to solve the problems that the conventional circulating fluidized bed garbage incineration furnace difficultly discharges slag and is required to be stopped regularly to remove the slag and the economy of a garbage incineration plant is influenced. According to the scheme I, a circulating fluidized bed and double V-shaped wind distributing plates are arranged in a boiler body, the boiler body, a separator, a flue gas cooling chamber and a tail flue are communicated in sequence, an upper level low-temperature superheater, a lower level low-temperature superheater, a primary wind air preheater, a secondary wind air preheater, an upper level primary wind economizer, a lower level primary wind economizer, an upper level secondary wind economizer and a lower level secondary wind economizer are arranged in the tail flue, and the separator is communicated with the boiler body by a U-shaped valve; different from the scheme I, the scheme III is characterized in that: double inverted V-shaped wind distributing plates are adopted; different from the scheme III, the scheme V is characterized in that: an inverted V-shaped wind distributing plate is adopted; and according to the scheme II, the scheme IV and the scheme VI, a semidry reaction tower, a bag-type dust collector, an induced draft fan, a chimney, a fly ash cabin, a lime slurry preparation system, a rotary atomizer and an active carbon injecting device are added on the basis of the scheme I, the scheme III and the scheme V. The circulating fluidized bed garbage incineration boiler and the pollution control system with the same are used for incinerating garbage, and pollutant emission can be controlled.

Owner:无锡光核新能源建设有限公司

Pipe jacking construction technology through water-mud balance

The invention discloses a pipe jacking construction technology through water-mud balance. The pipe jacking construction technology comprises the steps of construction preparation, equipment mounting and debugging, pipe jacking machine out of a hole, pipe section jacking construction, intermediate jacking station jacking construction, main top jacking and the like, and circulation is conducted till jacking is finished. Through the construction technology, construction is conducted especially aiming at the specific soil texture of the pipe jacking construction technology, the operation difficulty is greatly reduced, the maximum amount of excavation is increased, the construction technology is easy, the construction progress is quick, the construction difficult problems such as ground subsidence are controlled within the range stipulated by standards, and the construction technology is suitable for being applied and popularized.

Owner:ZHEJIANG BAOTIAN ENVIRONMENT CONSTR CO LTD

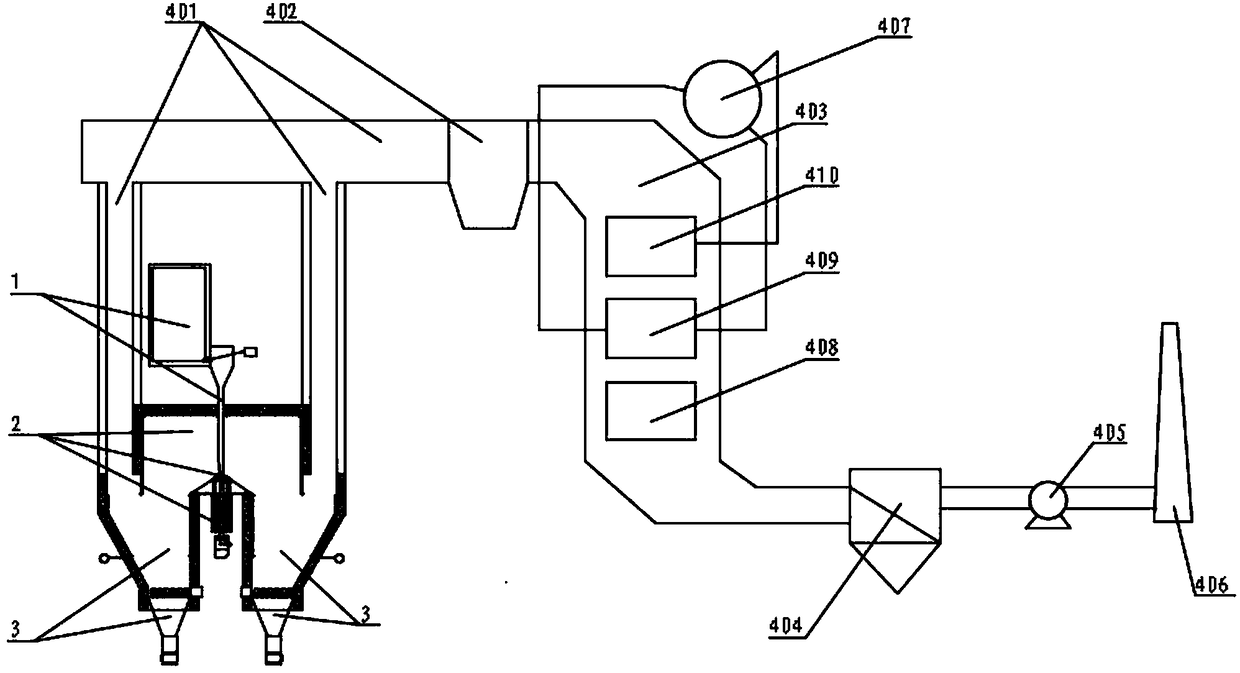

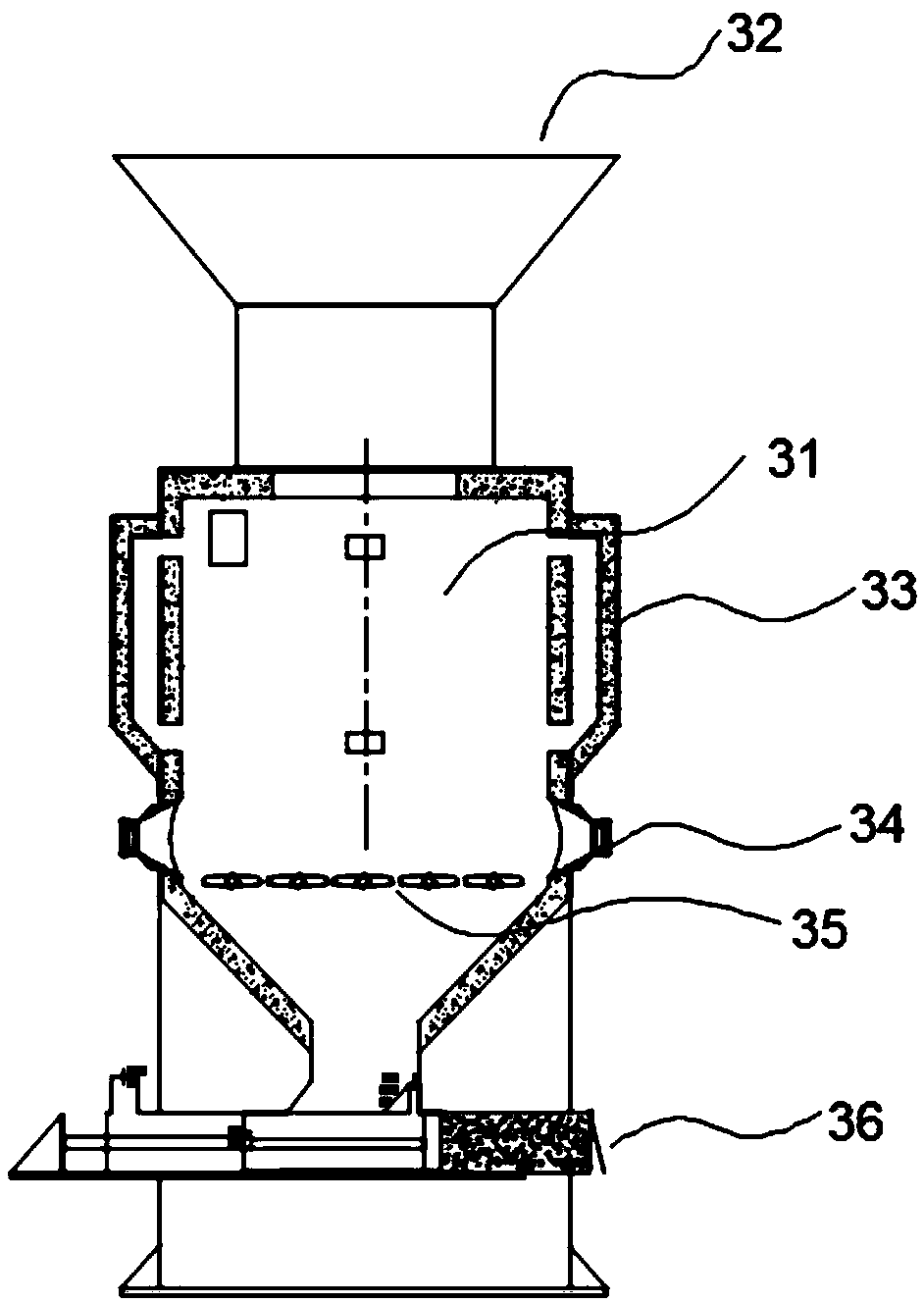

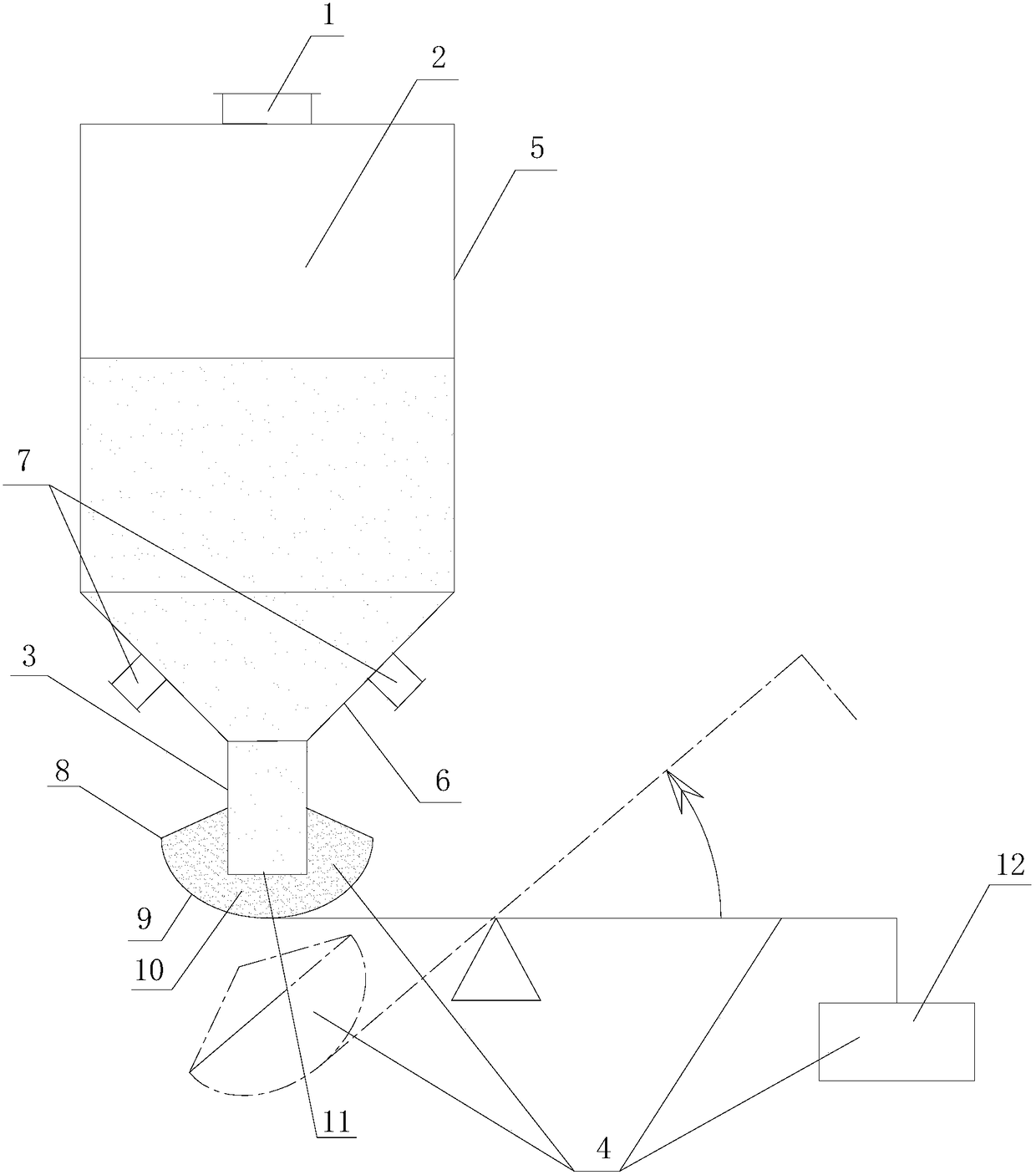

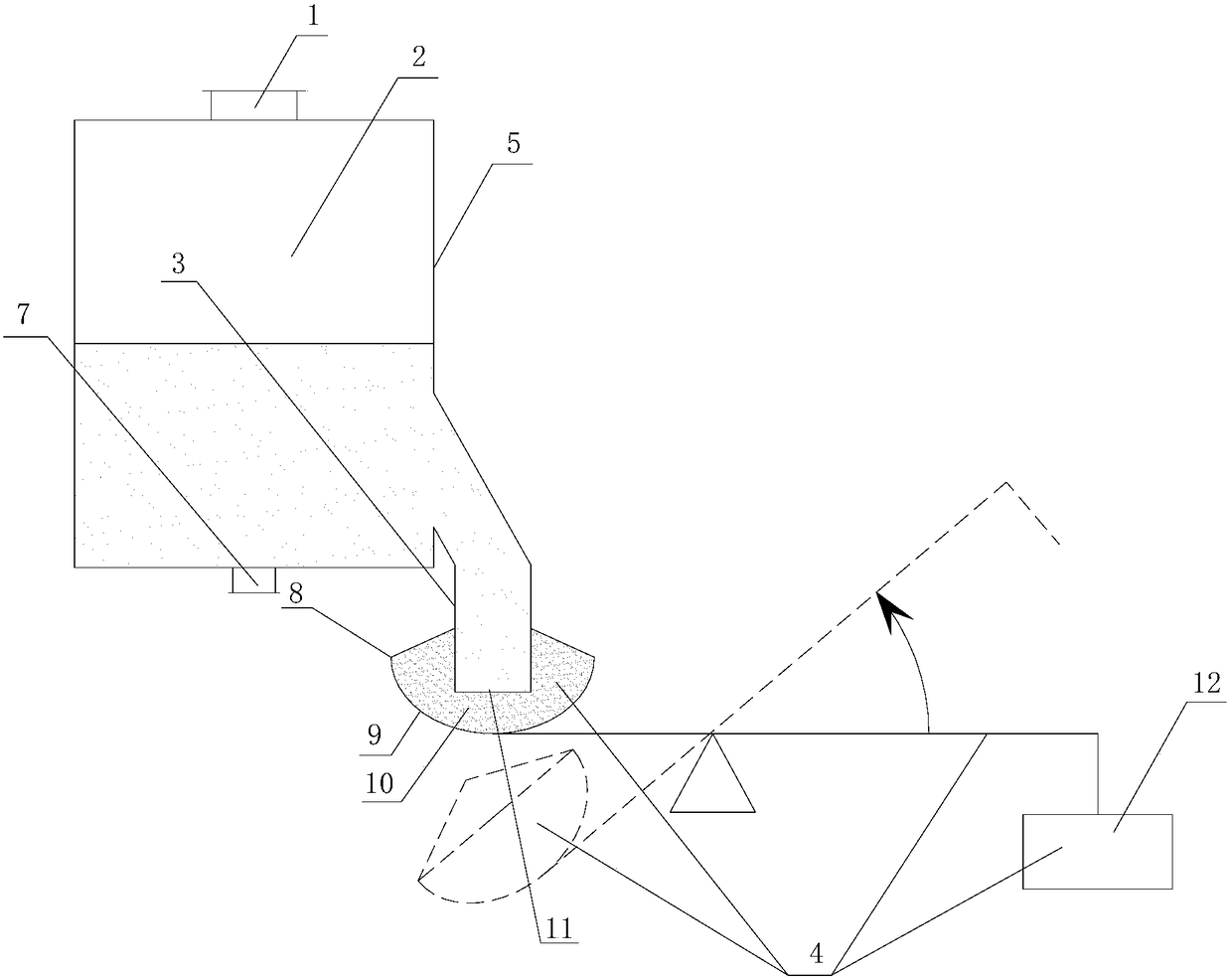

Liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions

ActiveCN108330233AEnsure structural stabilityGuaranteed operational safetyExhaust gas handlingRecycling and recovery technologiesMetallurgyIron industry

The invention discloses a liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions. The system comprises a molten slag buffer-storage and flow control unit, a granulation unit, a mobile bed unit and an afterheat utilization unit; the molten slag buffer-storage and flow control unit is arranged at the upper part ofthe granulation unit and is used for buffer-storage of the liquid molten slag and controlling the flow rate and speed of the liquid molten slag falling to the granulation unit; the granulation unit is used for granulating the falling liquid molten slag; the mobile bed unit is arranged at the lower part of the granulation unit and is used for cooling and temporarily storing the granulated molten slag; hot air inside the granulation unit and the mobile bed unit communicates with the afterheat utilization unit; and the afterheat utilization unit comprises a hot air flue, a primary dust collector, an afterheat boiler, a secondary dust collector, an exhaust fan and a chimney which are arranged in sequence. The system disclosed by the invention does not use water resources, is free of environmental pollution, can effectively recycle high-quality afterheat resources contained in the high-temperature liquid molten slag, and can meet the urgent requirements of energy conservation and emissionreduction of the present steel and iron industry.

Owner:XI AN JIAOTONG UNIV

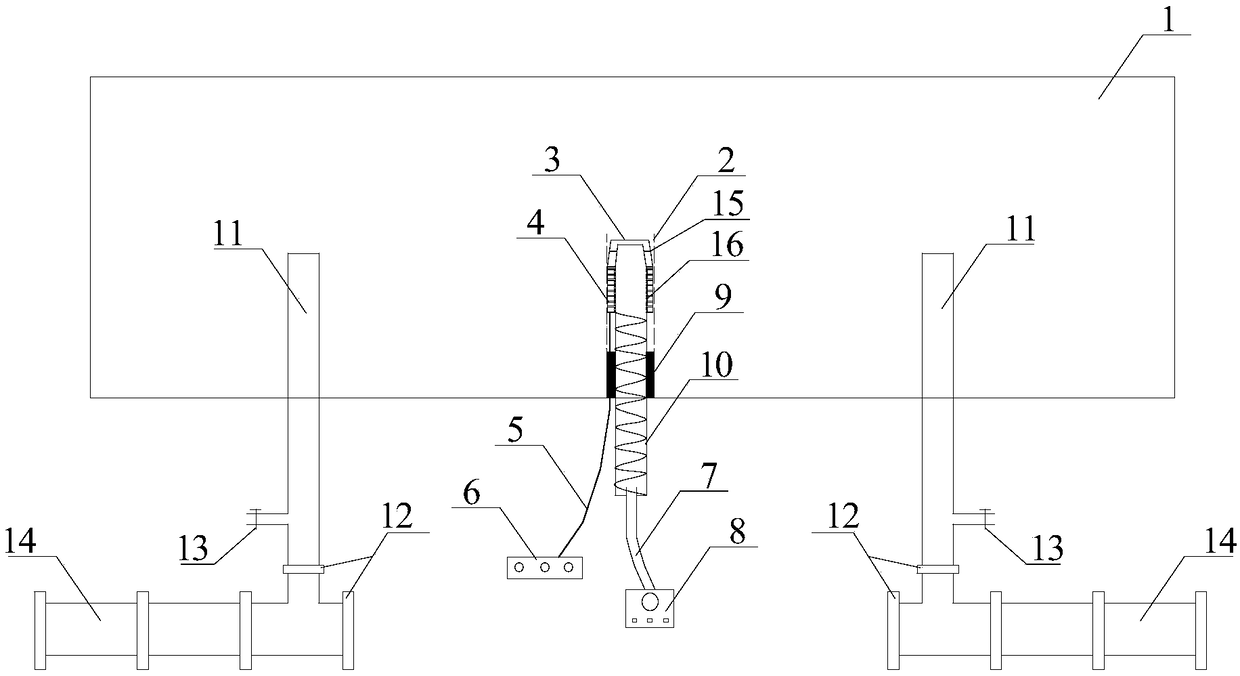

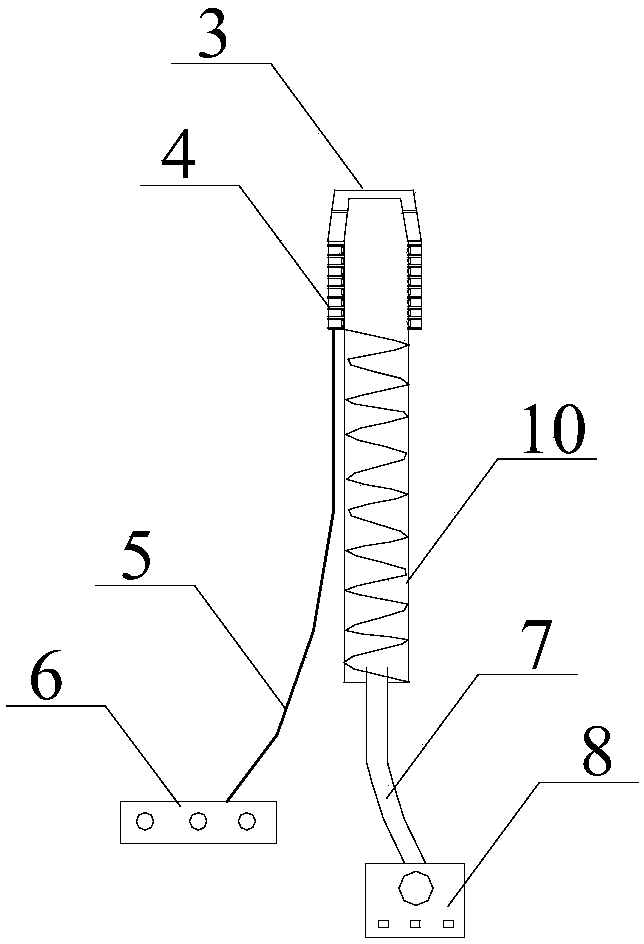

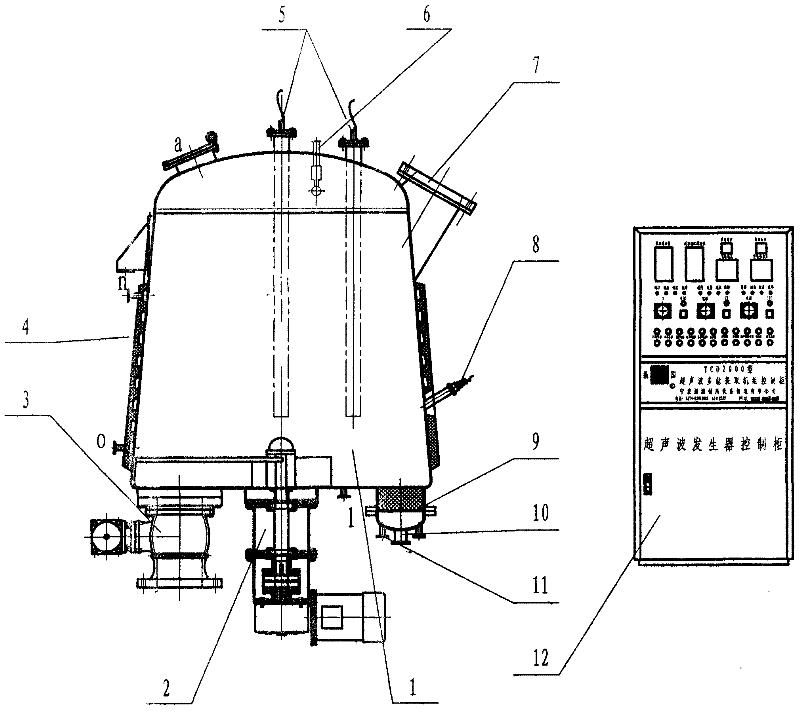

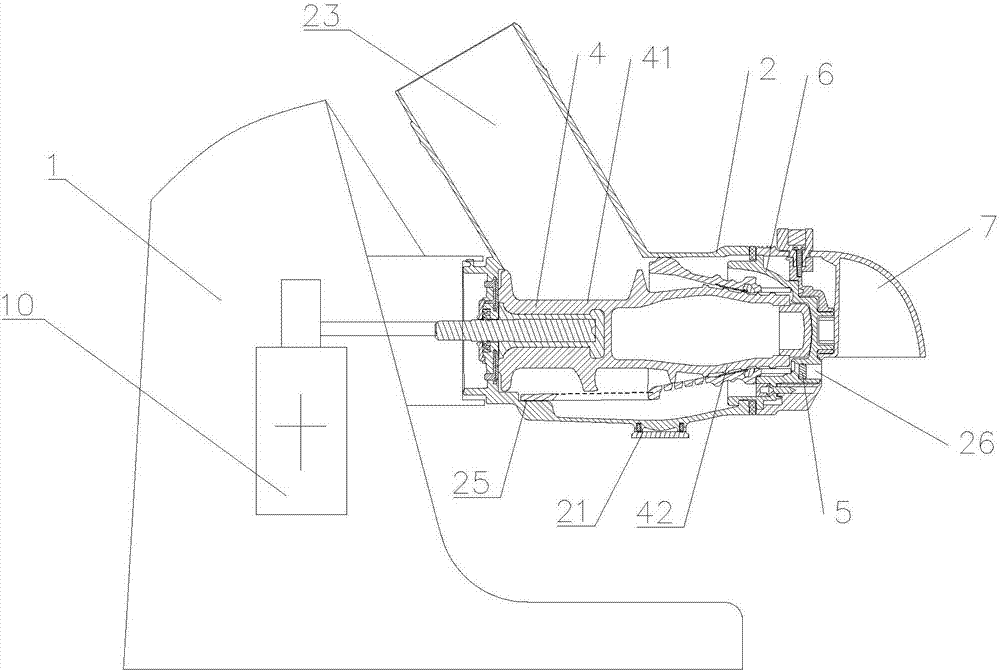

Ultrasonic excitation and hydraulic slotting integrated device, compound intensified gas extraction system and method

PendingCN108194070AFacilitate separation and even volatilizationImprove permeabilityLiquid/gas jet drillingFluid removalDesorptionEngineering

The invention discloses an ultrasonic excitation and hydraulic slotting integrated device, a compound intensified gas extraction system and method. The ultrasonic excitation and hydraulic slotting integrated device comprises a sleeve, a hydraulic slotting drill bit is fixed to the top of the sleeve, and a plurality of hydraulic slotting drill bit jet holes are formed in the circumferential direction of the hydraulic slotting drill bit; and the bottom of the sleeve is connected to a high pressure pump through a high-pressure hose, an ultrasonic transducer is arranged on the lower portion of thehydraulic slotting drill bit, the sleeve is sleeved with the ultrasonic transducer, and the ultrasonic transducer is connected to an ultrasonic generator through a cable. According to the ultrasonicexcitation and hydraulic slotting integrated device, advantage complementation of two single technologies is achieved through organic combination of ultrasonic excitation and hydraulic slotting, coalseam gas desorption is effectively promoted, the coal seam permeability is increased, the technical problem of mine gas extraction is solved, and the ultrasonic excitation and hydraulic slotting integrated device is applicable to various complicated geologic conditions, and has the wide application range.

Owner:SHAANXI COAL & CHEM TECH INST

Efficient smelting technology for producing low-phosphorous clean steel through converter

ActiveCN109897933AEfficient separationReduce lossManufacturing convertersProcess efficiency improvementSlagDolomite

The invention discloses an efficient smelting technology for producing low-phosphorous clean steel through a converter. According to the technology, furnace slag of last furnace is subjected to slag splashing treatment, final slag is totally or partially left in the furnace, raw materials are added for smelting, during the one-time gun going and blow beginning stage, the gun position and flow of an oxygen gun are controlled, after the gun goes down and is ignited, an iron oxide ball adding and mine returning begin, then lime and light calcined dolomite are added, after all is added, the gun position is gradually hoisted up, and slag is poured; and the gun position and flow of the oxygen gun are controlled secondly, after fire is on, the lime begins to be added, the slag is adjusted in time, the position and the oxygen supply amount of the oxygen gun are controlled, finally, furnace pouring is carried out, the gun is lifted, and finally, the furnace slag is totally left in the converterfor slag and phosphorous curing, and used for smelting in next furnace. According to the technology, the slag added when the converted smelts the low-phosphorous clean steel is adjusted in time, thegun position and the oxygen supply amount of the oxygen gun are controlled, the final point steel tapping condition can meet the high-cleanness low-phosphorous steel converter final point control condition with C larger or equal to 0.12% and P smaller than or equal to 0.006%.

Owner:ZENITH STEEL GROUP CORP

Method for preprocessing coal tar

ActiveCN101838550AReduce frequent switchingLess number of tanksTreatment with plural serial refining stagesPretreatment methodImpurity

The invention discloses a method for preprocessing coal tar. The method comprises the following steps of: mixing the coal tar and an extractant A in a mass ratio of 1:0.5-1:4, heating the mixture to the temperature of between 50 and 150 DEG C, and performing continuous centrifugal separation on the obtained mixed solution in a sedimentation type centrifuge to obtain soluble matters and impurity-containing extraction insoluble matters. The method has the advantages of good impurity-removing effect, high utilization ratio of the coal tar (over 96 percent), simple process, high automaticity, andlow labor intensity, and suitability for large-scale preprocessing of the coal tar and comprehensive utilization and deep processing of full-cut coal tar which is the byproduct in industries such as coal chemical industry, coal gasification industry and the like..

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

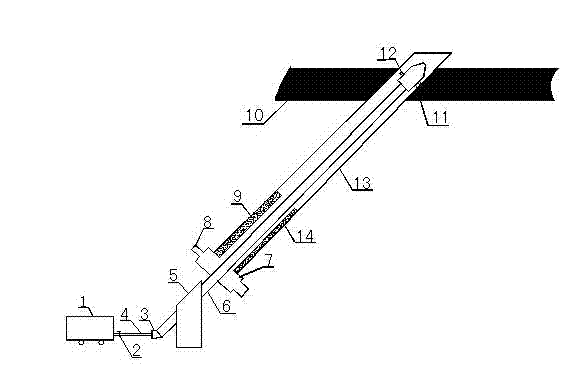

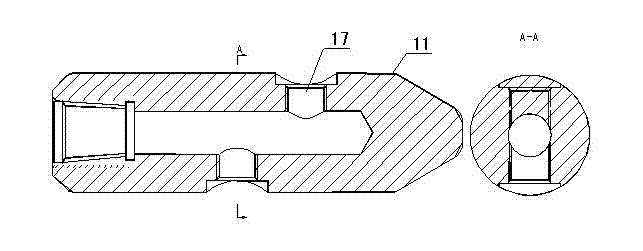

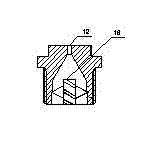

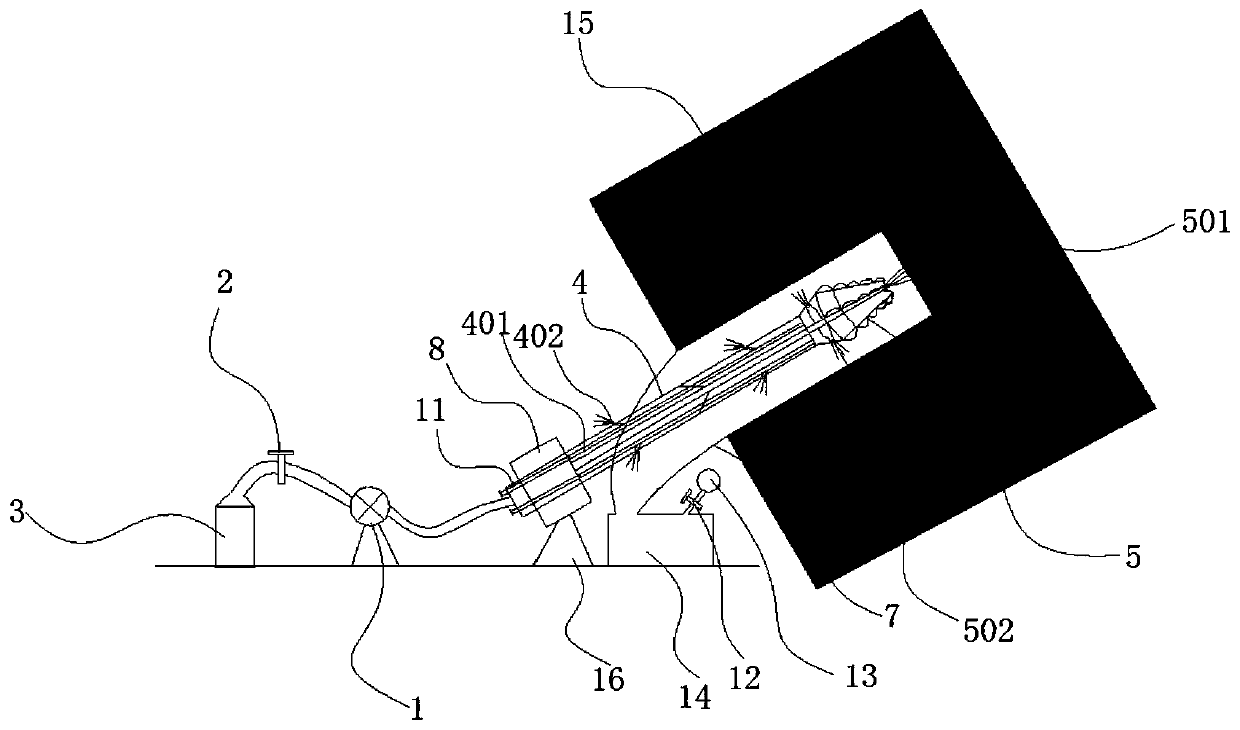

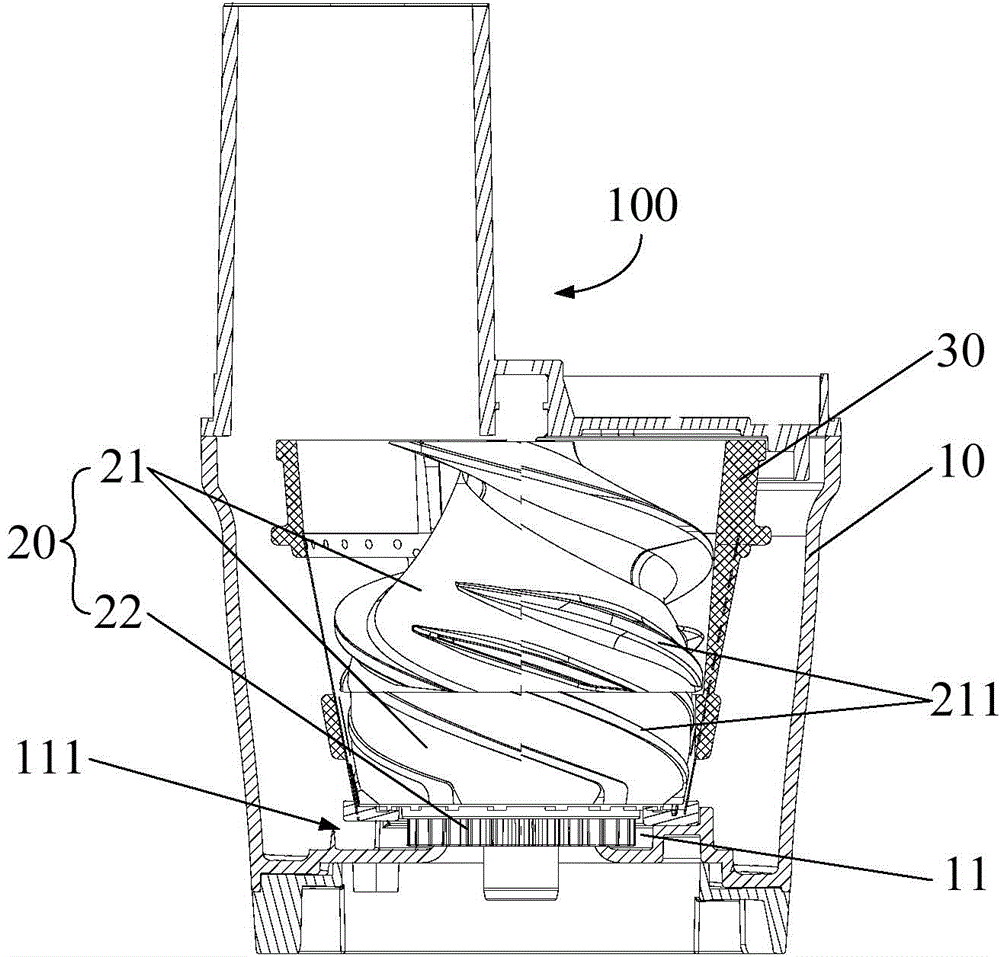

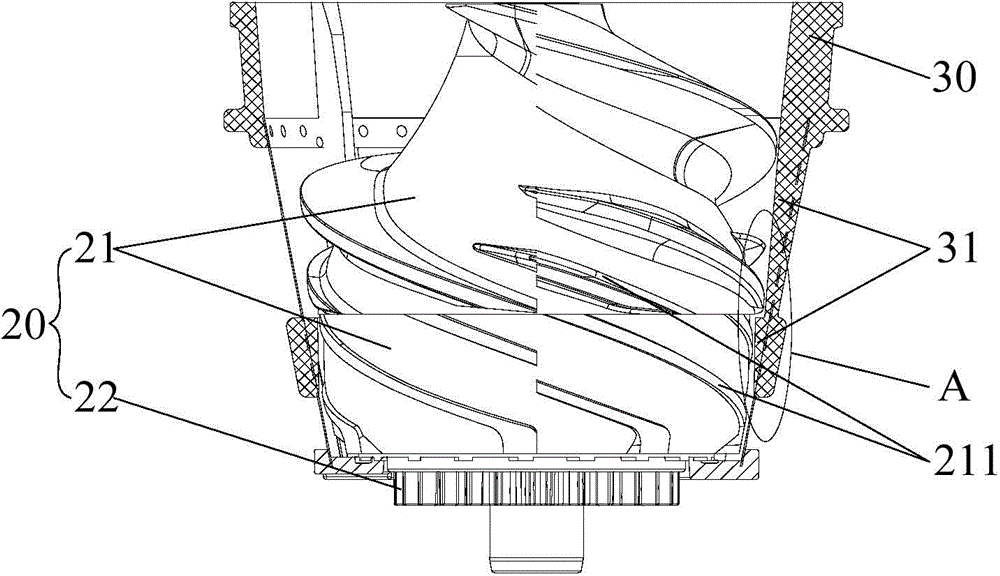

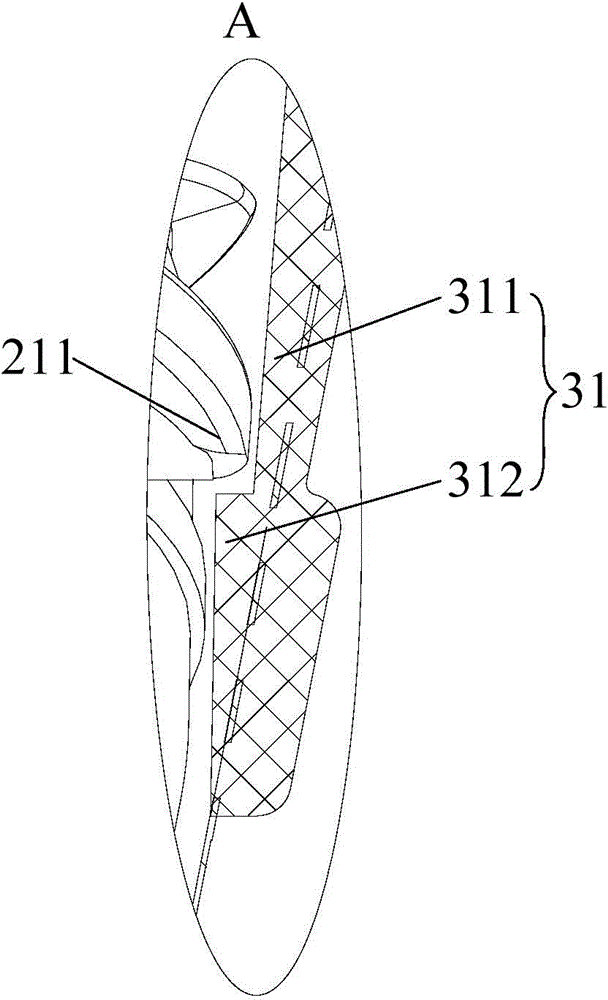

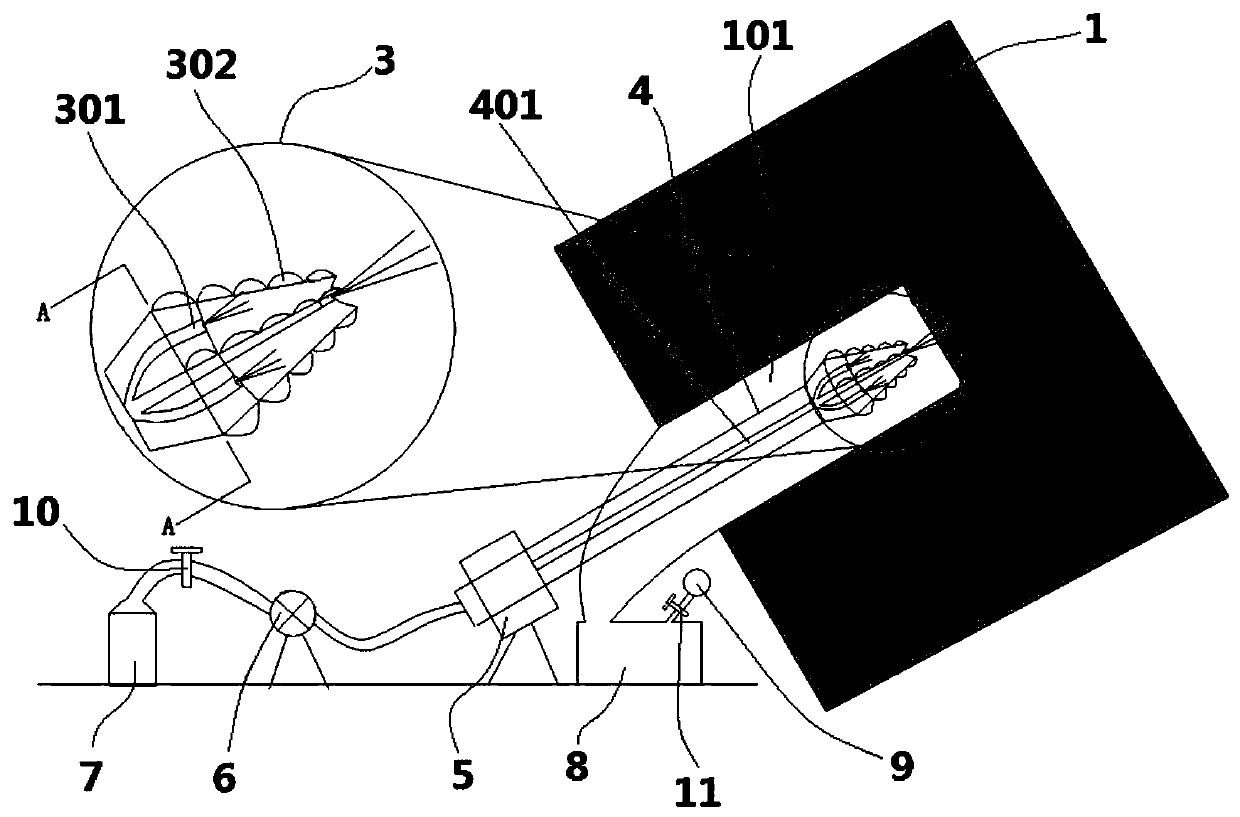

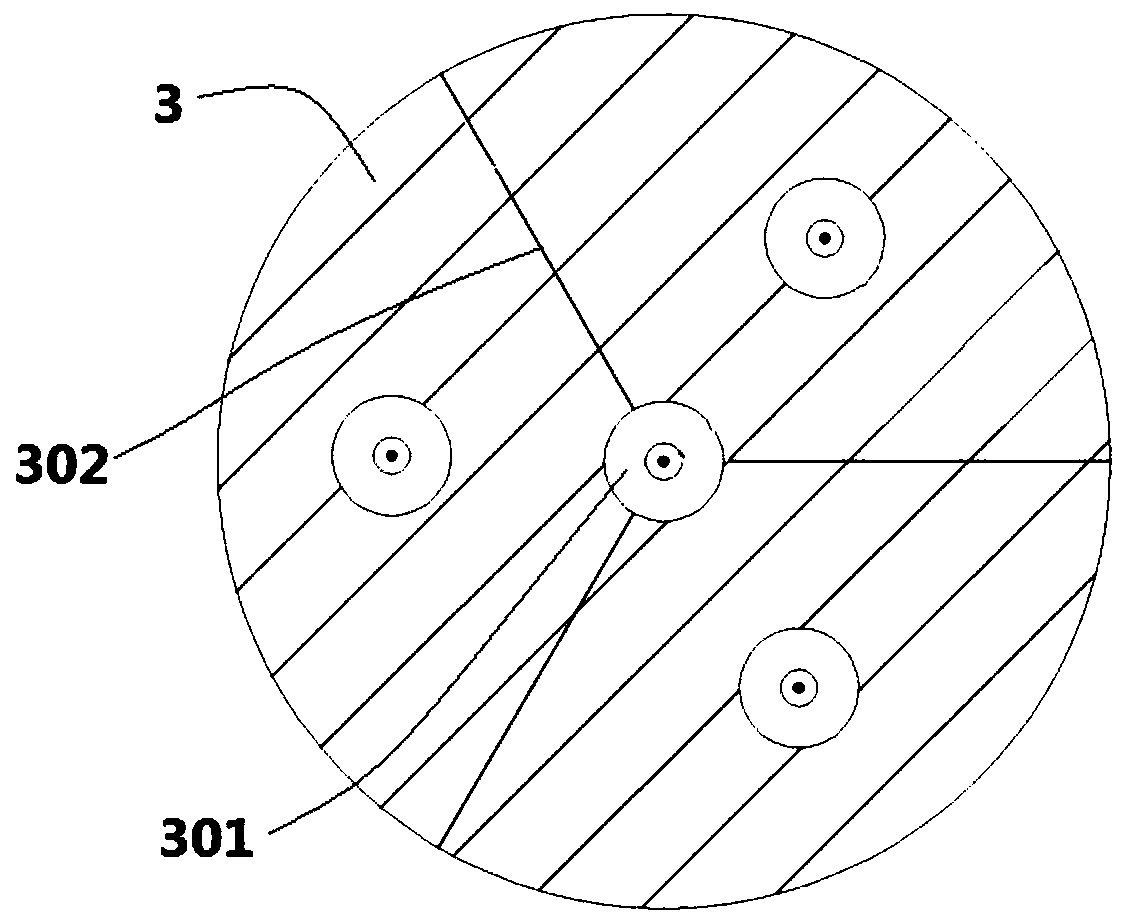

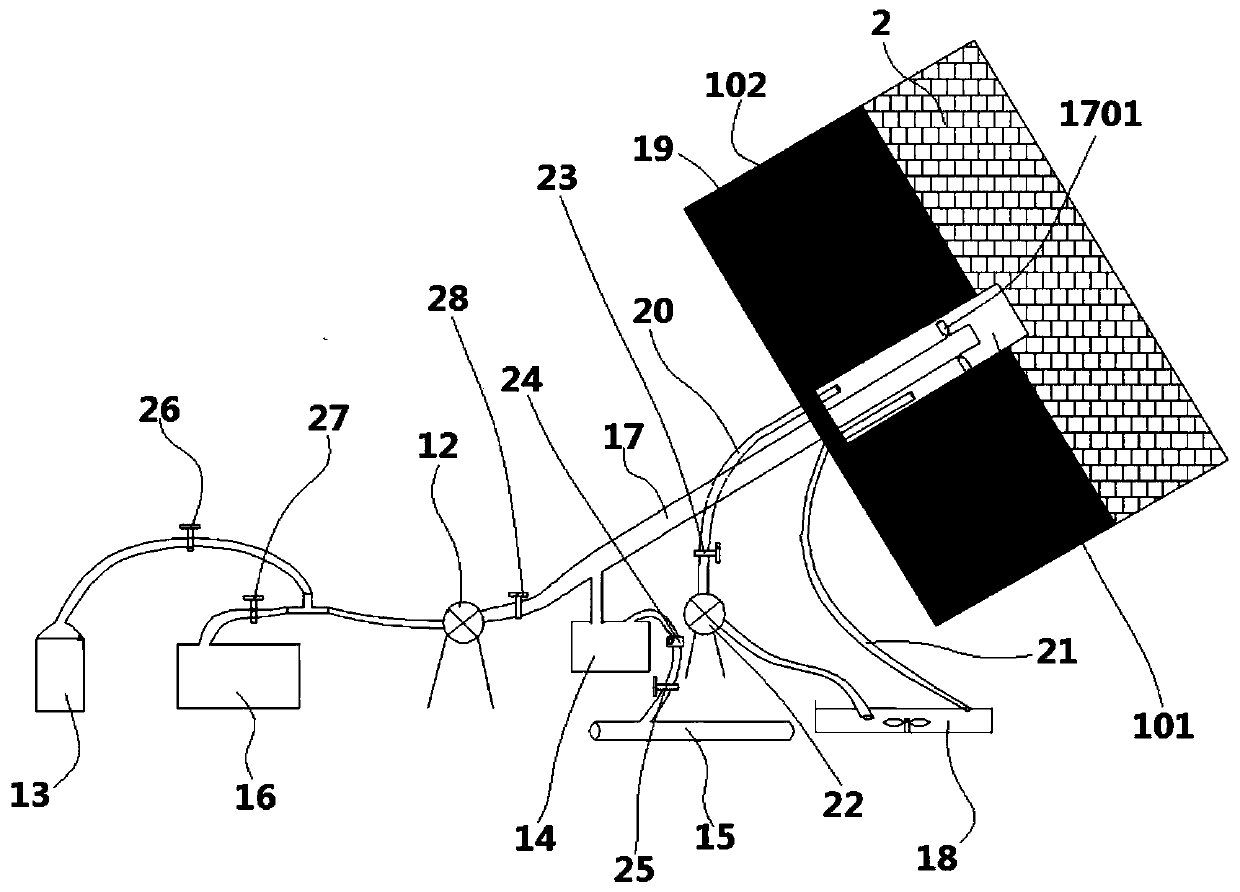

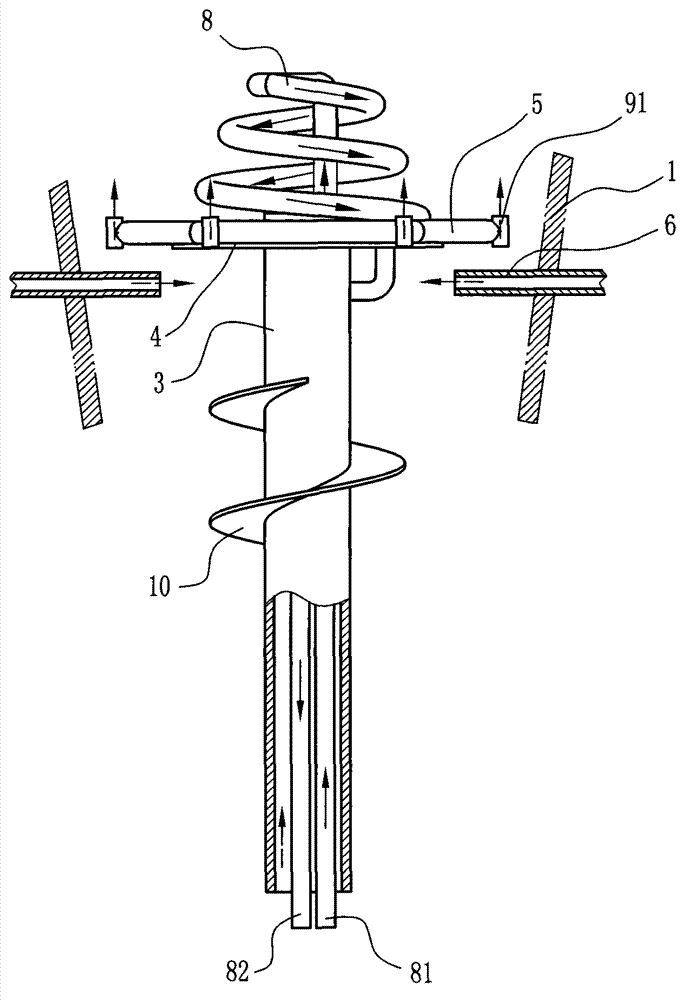

Ultra-high pressure water jet slotting system and using method thereof

ActiveCN110617044AImprove liquiditySmooth slag dischargeDrill bitsLiquid/gas jet drillingUltra high pressureSlag

The invention provides an ultra-high pressure water jet slotting system and a using method thereof. The ultra-high pressure water jet slotting system comprises an ultra-high pressure water jet generating system, a drill rod and drill tool system, an orifice sealing device, a gas-slag separator and a drilling machine. The drilling machine clamps the drill rod, drives the drill rod to rotate and drill into a coal and rock stratum. The drill bit rotates around the axis of the drill bit under the driving of the rotation of the drill rod. A nanofluid enters an inner cavity or a channel I of the drill rod through an ultrahigh pressure water pump and a water braid. The nanofluid is fed into the drill bit through the inner cavity or into a channel II through the channel I. A radial nozzle forms high-pressure water jet to impact a coal body in front. An axial nozzle forms a high-pressure water jet to impact surrounding coal bodies. The coal bodies are crushed by the impact of high-pressure water or grinded and crushed by the drill bit. The nanofluid impacts and wets coal dust through the channel II. The ultra-high pressure water jet slotting system can significantly improve the fluidity ofcoal and rock dust and provide power for smooth discharge of the coal and rock dust, and the problems that seriously affect the operation safety, such as hole spraying, hole plugging, drill sticking and the like caused by poor slag discharge are solved.

Owner:CHONGQING UNIV +2

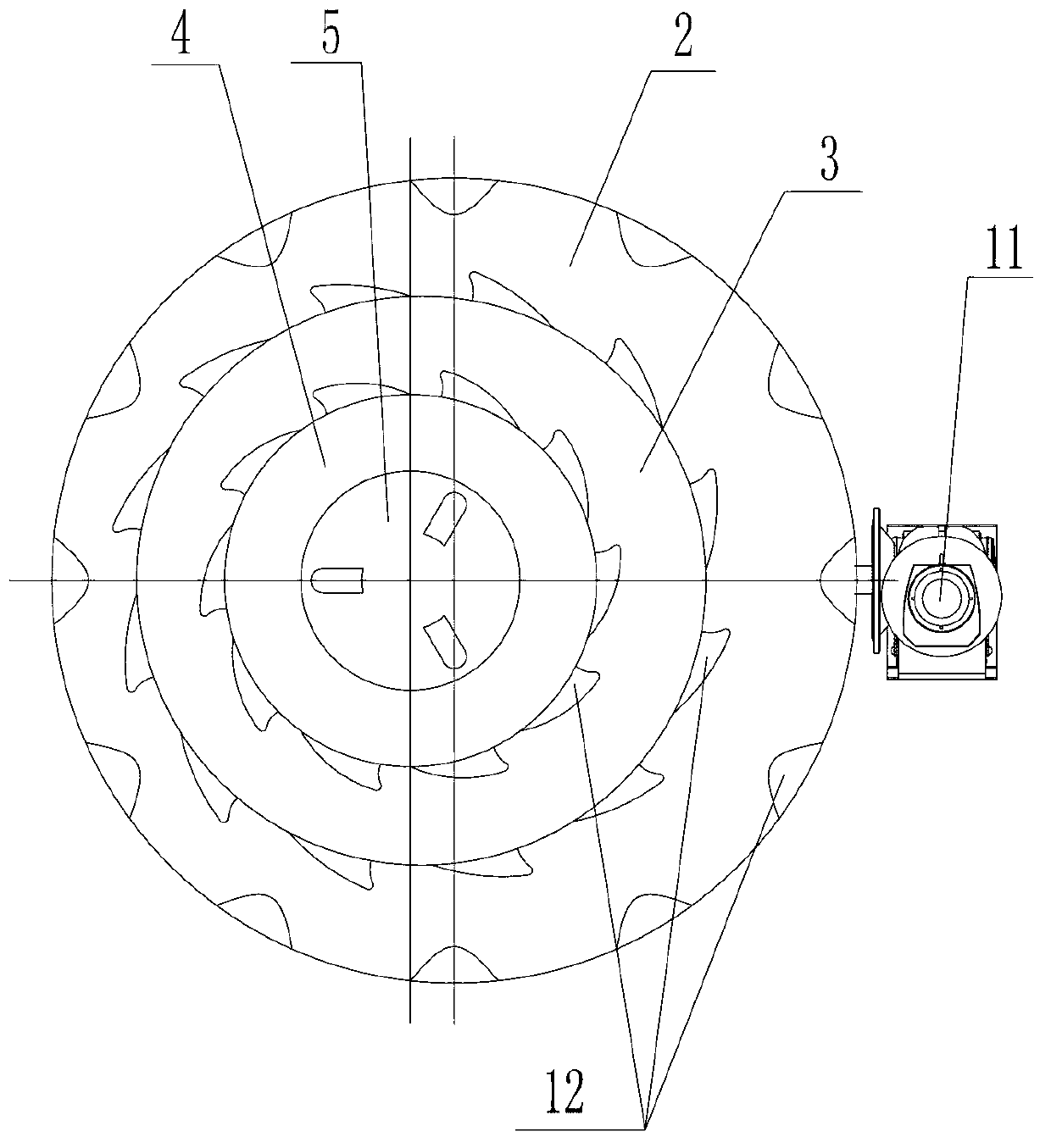

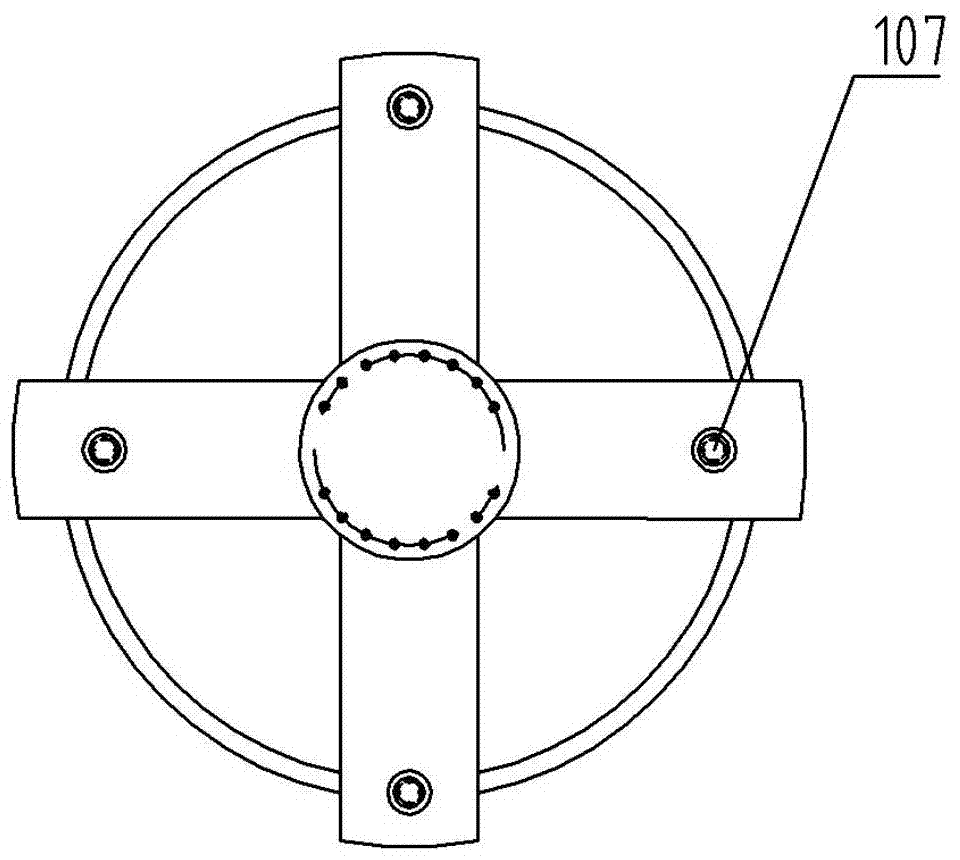

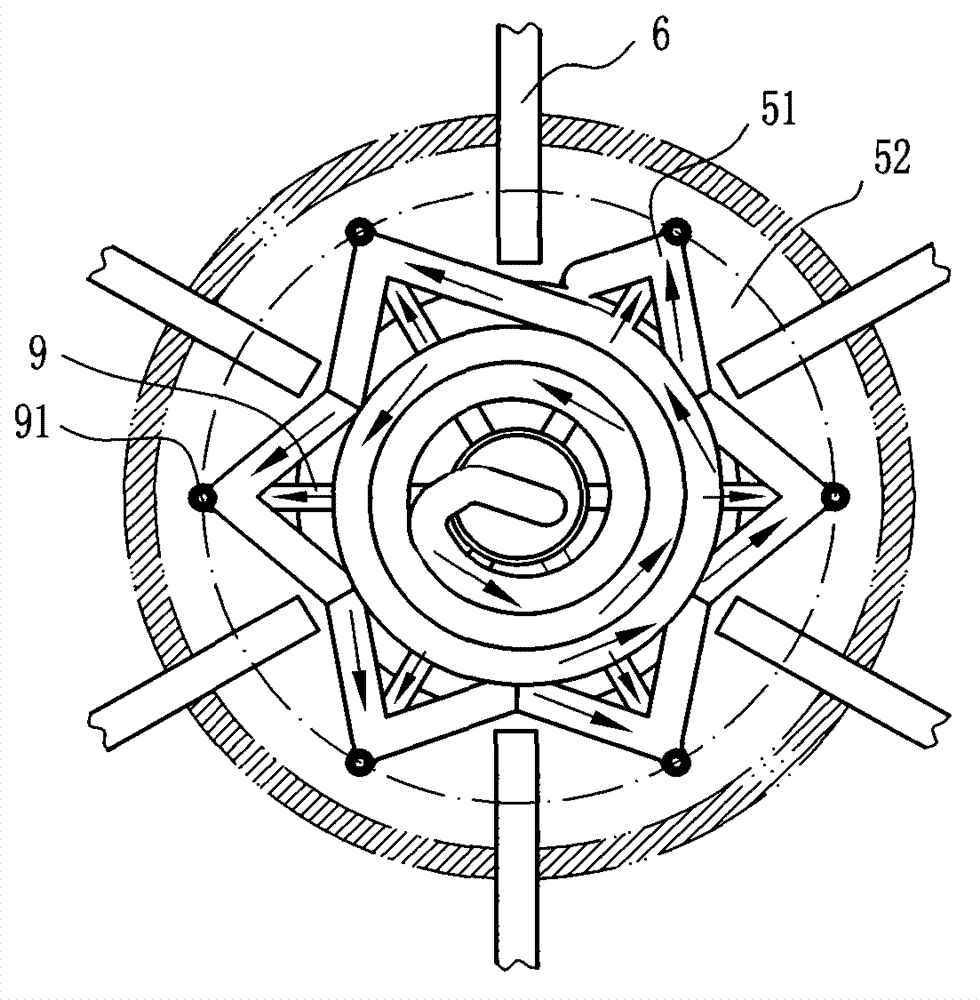

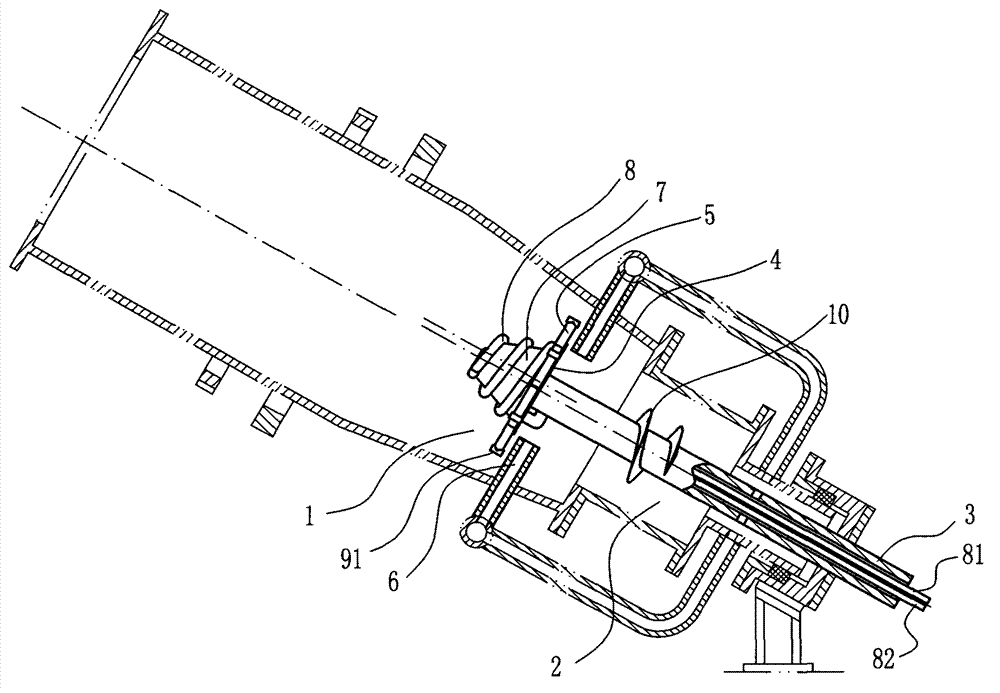

Rotary fire grate

The invention relates to a rotary fire grate which comprises a fixed shaft, a main shaft sleeve, a first forward driven fire grate, a second forward driven fire grate and a forward driving fire grate connected with a driving mechanism. The forward driving fire grate, the first forward driven fire grate and the second forward driven fire grate have slag removing holes. The forward driving fire grate, the first forward driven fire grate and the second forward driven fire grate are fixedly connected with the main shaft sleeve which is movably sleeved with the fixed shaft. The rotary fire grate further comprises a reverse driving fire grate. The forward driving fire grate, the reverse driving fire grate, the first forward driven fire grate and the second forward driven fire grate are arranged sequentially from bottom to top and distances are reserved between adjacent fire grates. The forward driving fire grate is connected with the driving mechanism, the reverse driving fire grate is movably sleeved with the main shaft sleeve, and the reverse driving fire grate has a slag removing hole. The rotary fire grate is good in slag breaking effect and smooth in slag discharge.

Owner:宁波泰来环保设备有限公司

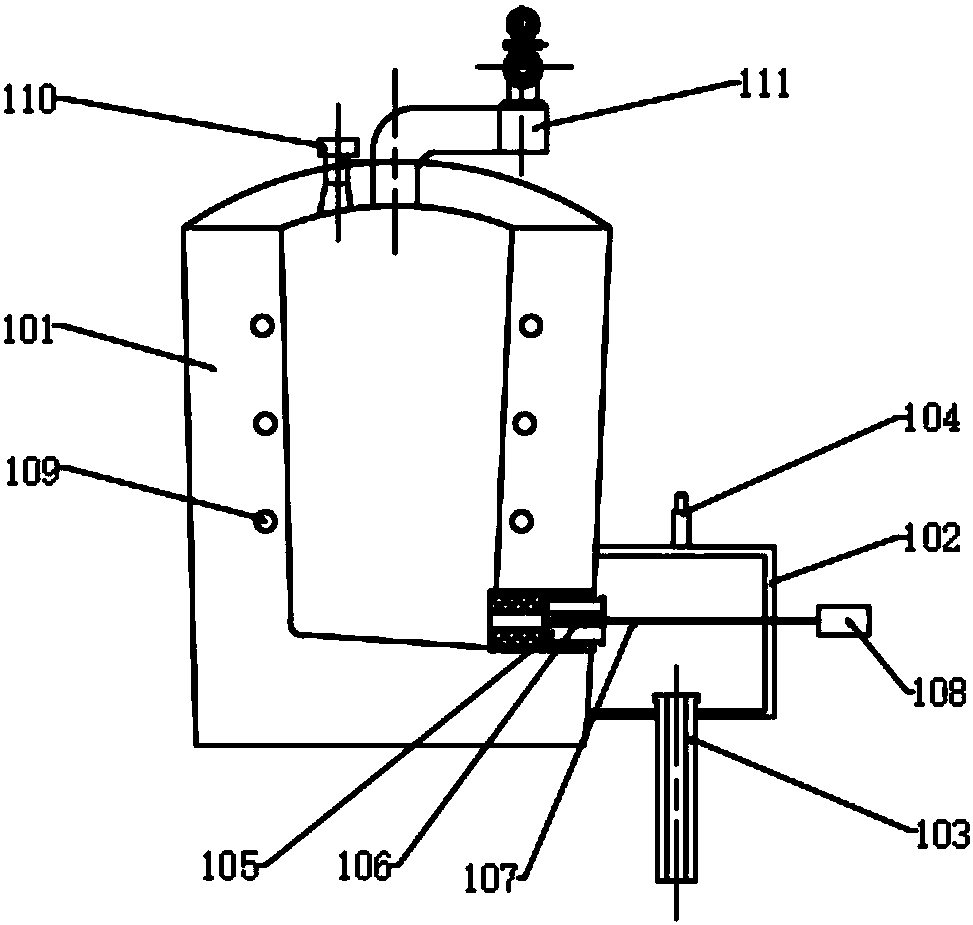

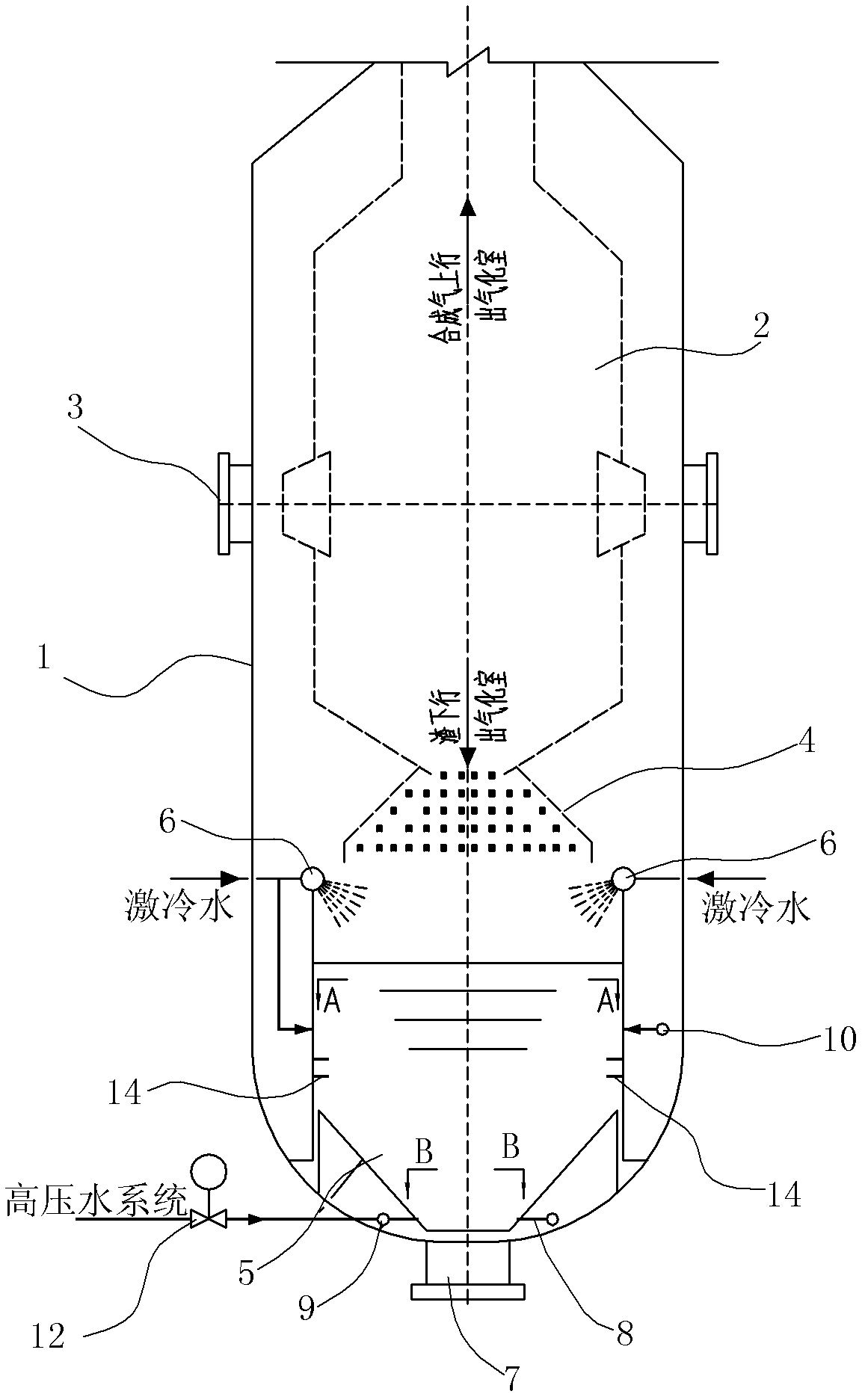

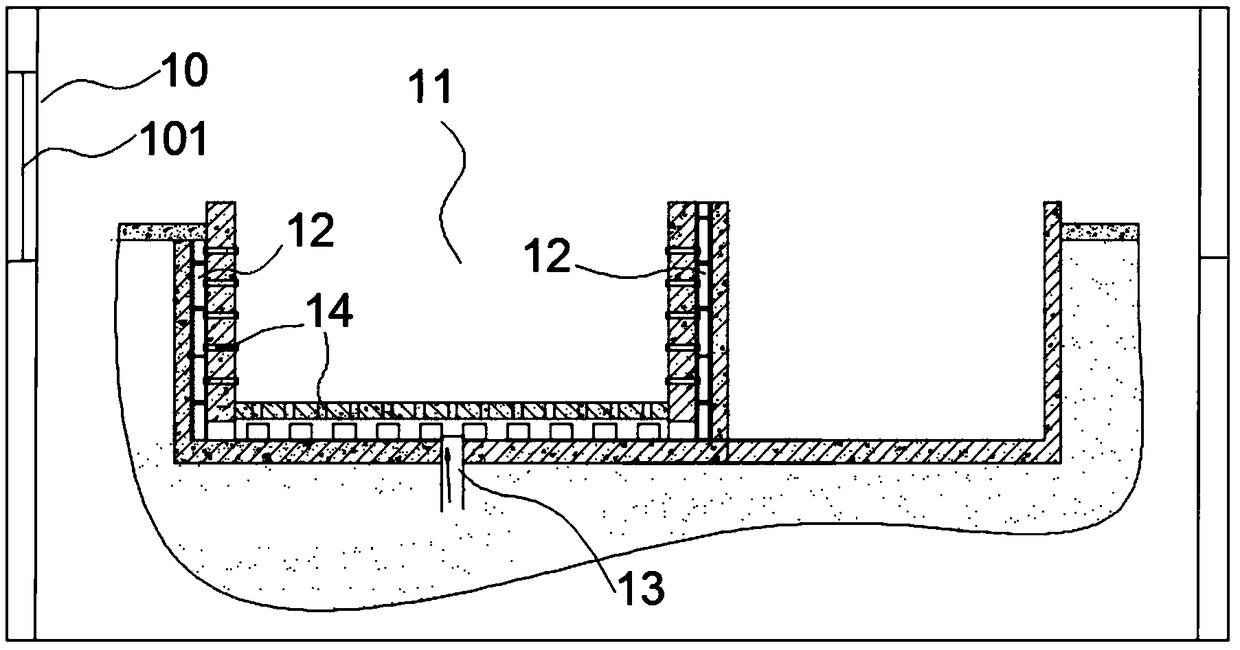

Slag-discharge system of pulverized coal gasification furnace

ActiveCN102634379ABroken GuaranteeImprove crushing effectGranular/pulverulent flues gasificationSlagChilled water

The invention relates to a slag-discharging system of a pulverized coal gasification furnace. A gasification chamber communicated with a feed port is arranged in the shell of the pulverized coal gasification furnace. A slag chamber is positioned below the gasification chamber and is communicated with the gasification chamber through a slag screen. The upper end of the slag chamber is provided with a chilling circular pipe for spraying chilling water towards coal slag entering the slag chamber, and the lower end of the slag chamber is communicated with a slag hole arranged at the bottom of the shell through a tapered slag hopper. The slagging system of the pulverized coal gasification furnace is characterized in that the peripheral wall of the slag chamber is provided with a plurality of water injection nozzles connected with a chilling water system. Compared with the prior art, the slagging system of the pulverized coal gasification furnace can effectively avoid slag blockage in the slag chamber, therefore, the gasification furnace can stably operate for a long term, the maintenance cost is saved, and the production efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

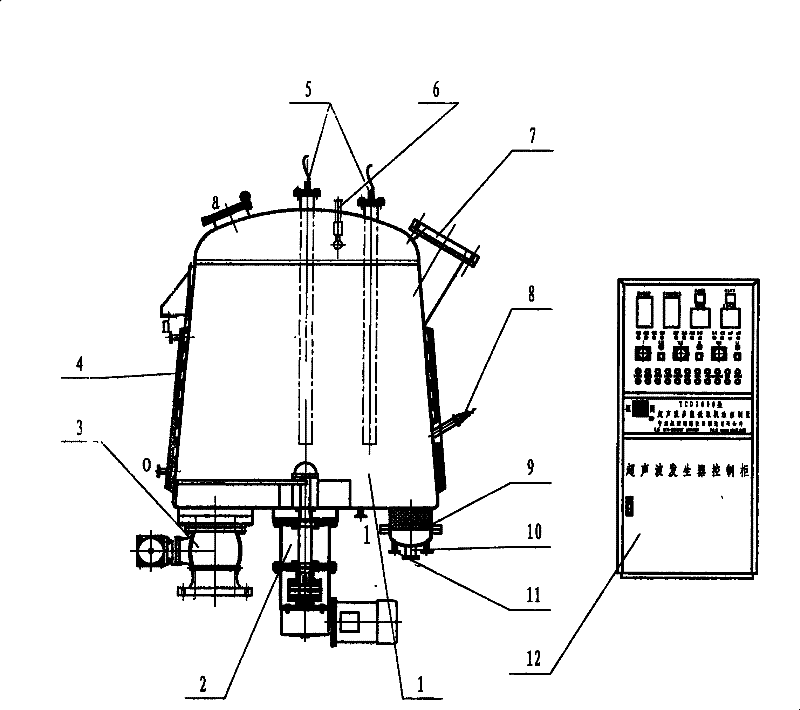

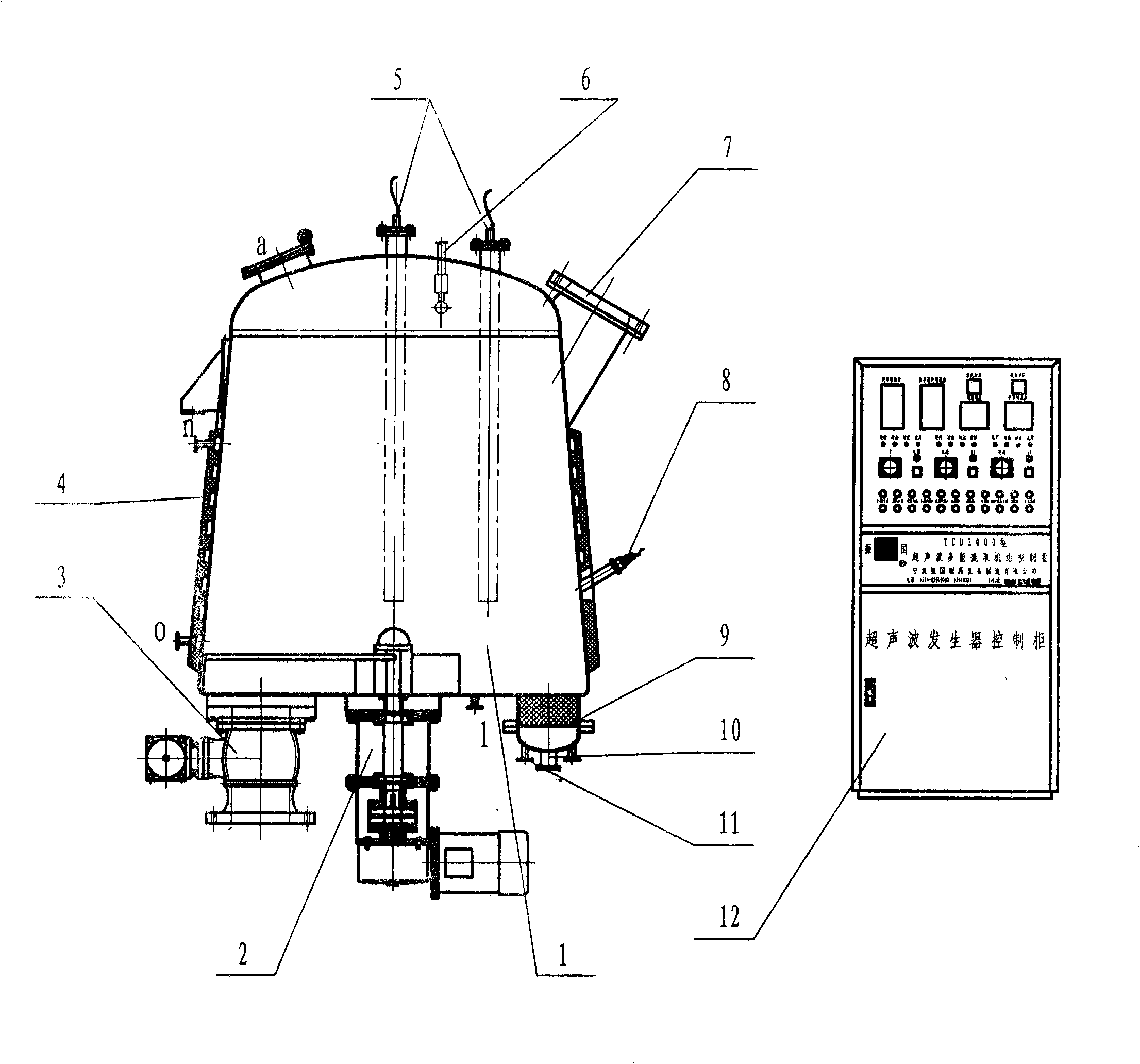

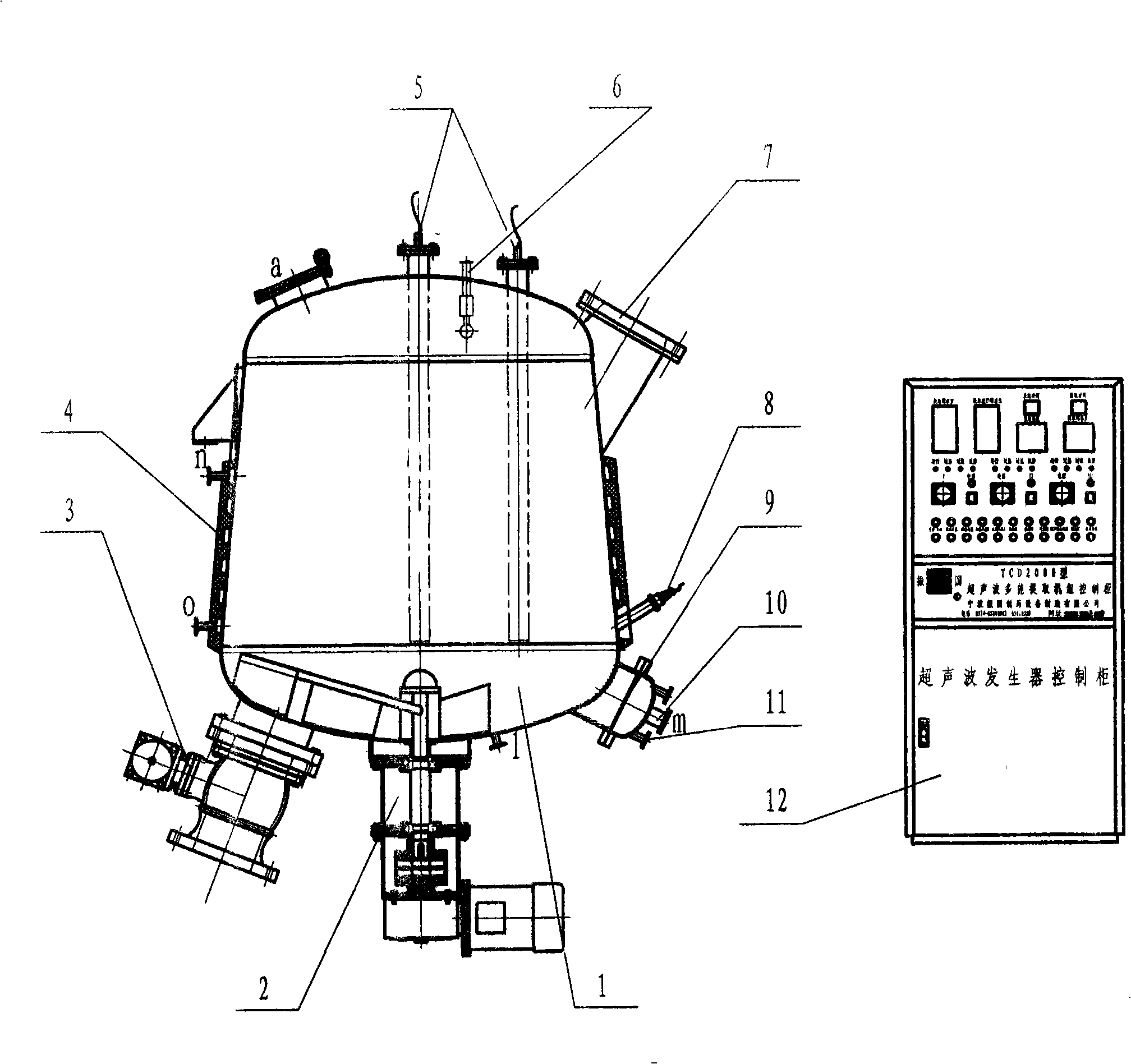

Ultrasonic conical triple slag extraction tank

InactiveCN101327381BReasonable structureSmooth slag dischargeEnergy based chemical/physical/physico-chemical processesSolid solvent extractionUltrasonic sensorSlag

The utility model relates to an ultrasonic conical three-part slag extraction tank, which is used for extracting active ingredients of traditional Chinese medicine. There is a conical tank with a small top and a large bottom, with a built-in cylindrical high-power ultrasonic transducer. The upper end of the ultrasonic transducer protrudes from the tank roof and is fixed with the tank roof; The automatic cleaning device passes through the top of the tank and is fixed to the top of the tank, and the upper part is connected to the water supply pipe; the bottom of the tank is equipped with a sewage outlet and a solid-liquid separation and slag discharge device. Rotary blade scraping and slag removal mechanism; the bottom of the tank is also equipped with a slag discharge port and a solid-liquid separation device; the slag discharge port is equipped with a pneumatic ball valve and an air flushing port; a filter screen is provided in the solid-liquid separation device, and a liquid outlet Mouth and breath. Compared with the prior art, the present invention has a more reasonable structure, integrates extraction and solid-liquid separation, and especially uses the three-blade rotary scraping and slag removal mechanism and the pneumatic slag flushing device to make the slag discharge smooth, and the drug residue is not Bridge, not blockage.

Owner:XIANGSHAN MEDICAL PRECISION INSTR

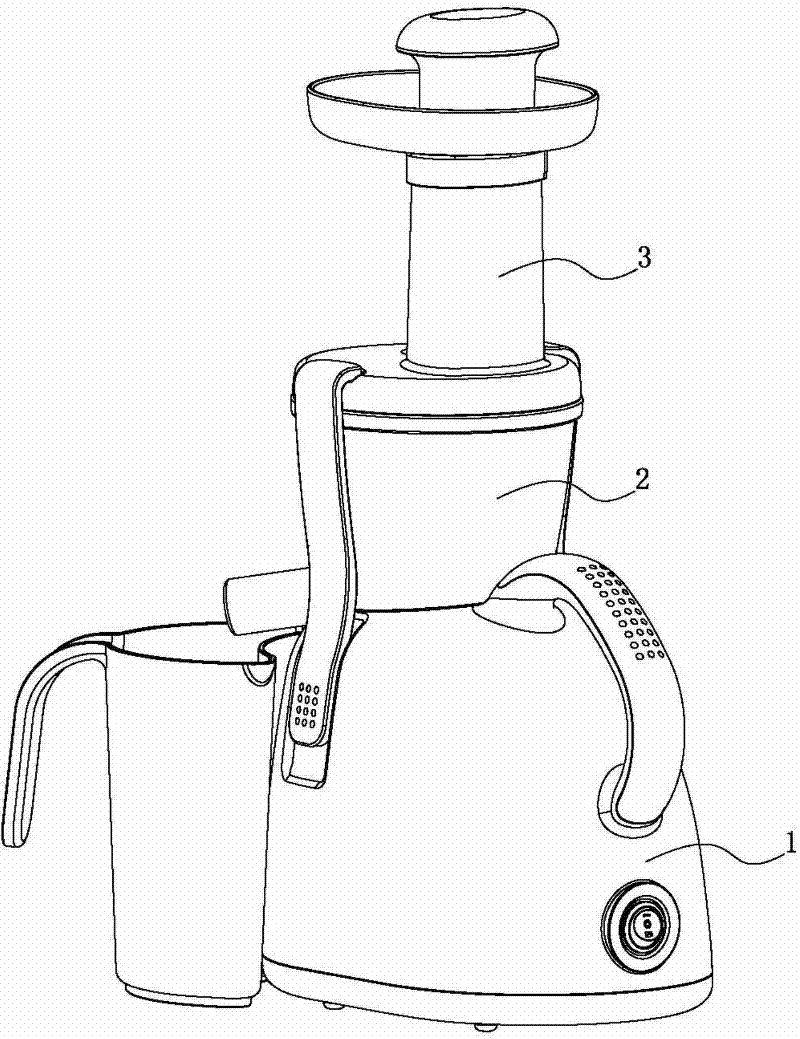

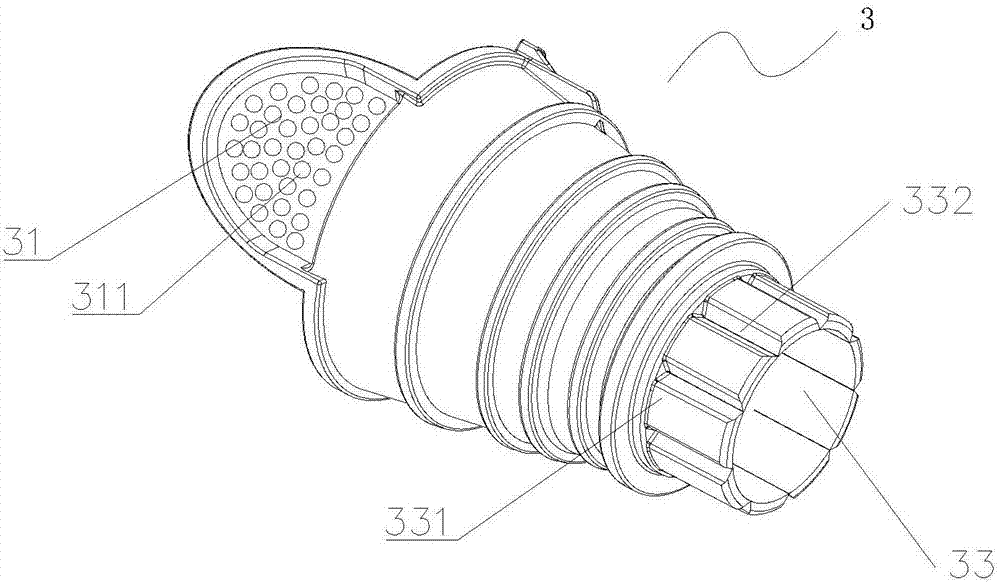

Method for making fruit juice with pulp by using juicer

The invention provides a method for making fruit juice with pulp by using a juicer. The juicer comprises an engine base, a juice collection cavity which is connected with the engine base and a threaded rod and a squeezing container which are horizontally arranged in the juice collection cavity, wherein the threaded rod comprises a material conveying segment and an squeezing grinding segment, the squeezing container is arranged on the outer portion of the squeezing grinding segment of the threaded rod in a sleeving mode, and a juice outlet and a residue outlet are formed in the juice collection cavity; the squeezing container comprises a smashing portion and a filtering portion, a residue discharge adjustment device is arranged in the residue outlet, and the filtering portion comprises a front filtering portion which is arranged at the front end of the squeezing container and a back filtering portion which is arranged at the back end of the squeezing container. According to the method for making the fruit juice with the pulp, through the steps such as regulating steps, squeezing juicing steps and front and back filtering steps, the fruit juice with the content-controllable pulp can be made, so that the fruit juice is rich in nutrition and more diversified in mouthfeel, and the user experiment is improved.

Owner:JOYOUNG CO LTD

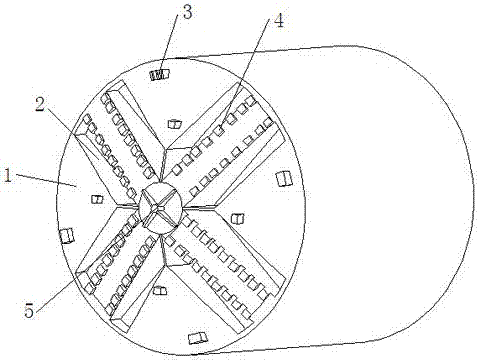

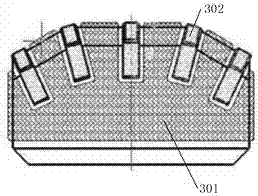

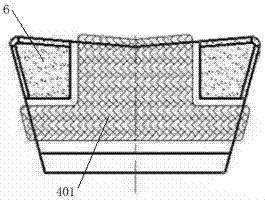

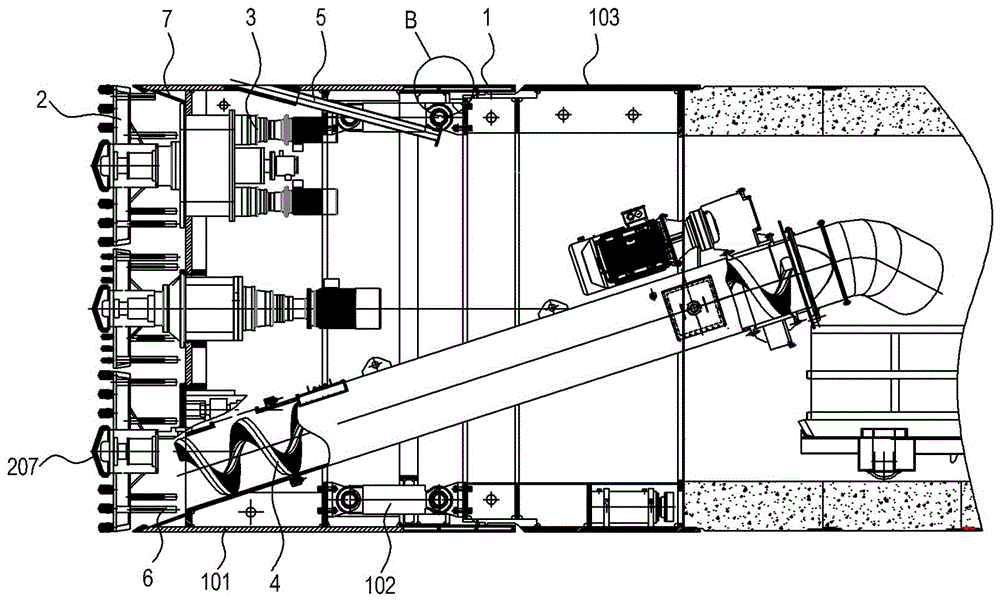

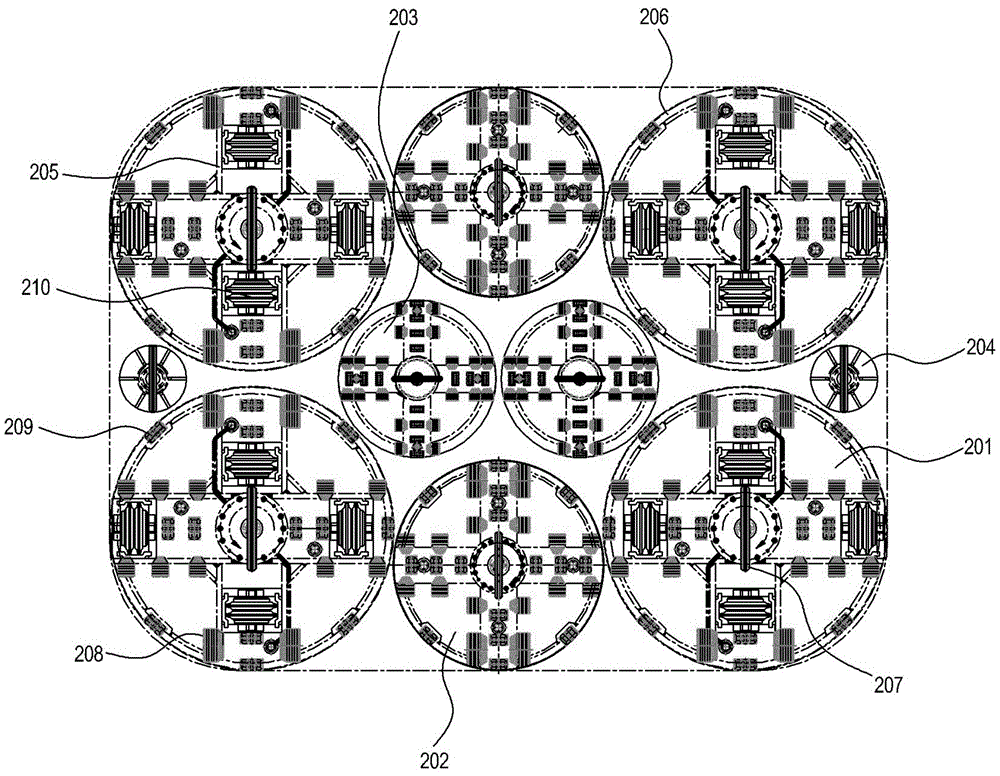

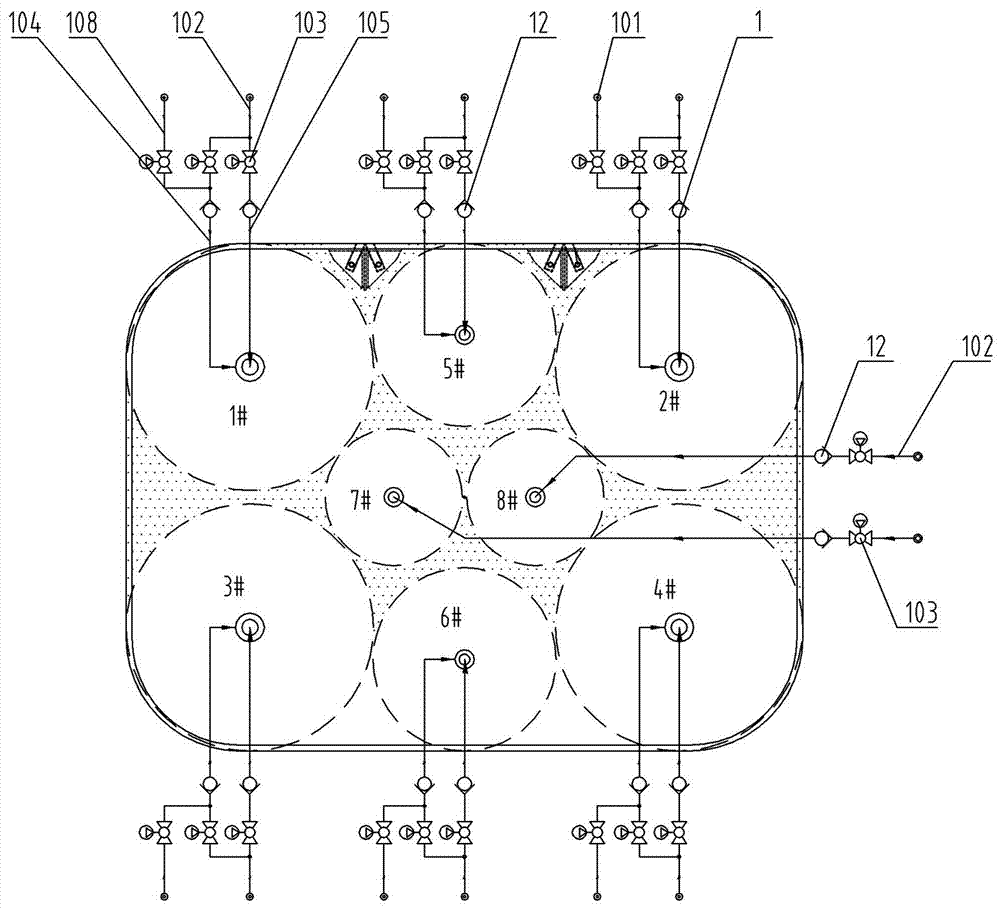

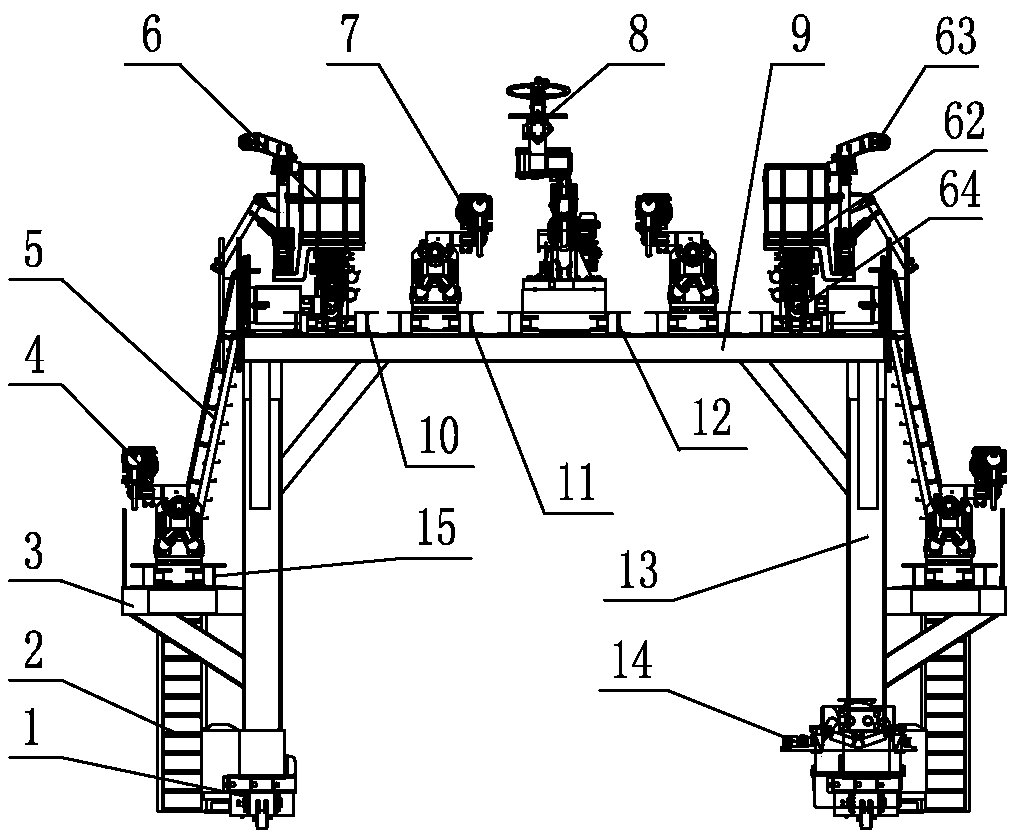

Same-plane multi-cutter-disc rectangular tunneling machine used in water-rich pebble stratum

The invention relates to the technical field of tunnel construction equipment, in particular to a same-plane multi-cutter-disc rectangular tunneling machine used in a water-rich pebble stratum. The same-plane multi-cutter-disc rectangular tunneling machine comprises a shield body, a cutter disc mechanism, a cutter disc driving mechanism and a residue soil delivery mechanism, wherein the cutter disc mechanism comprises 10 cutter discs symmetrically arranged on the same plane and comprises large cutter discs, middle cutter discs, small cutter discs and miniature cutter discs, the 10 cutter discs perform cooperative rotation on the same plane and do not interfere mutually. An advanced grouting pipe is obliquely arranged at the upper portion of the shield body. The excavation cutter discs of the same-plane multi-cutter-disc rectangular tunneling machine used in the water-rich pebble stratum are located on the same plane, unique structures of the cutter discs make the adaptability of the tunneling machine to the water-rich pebble stratum improved greatly, meanwhile an excavating face is effectively supported, soil body collapse is avoided, soil body sedimentation can be effectively controlled, and accordingly the life safety of workers is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

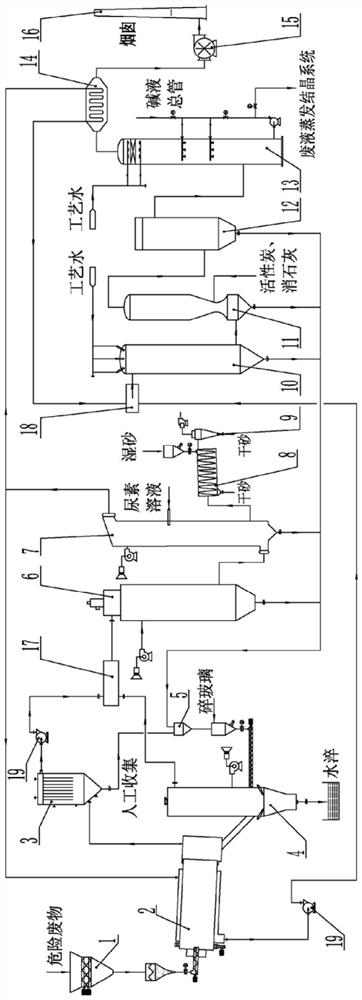

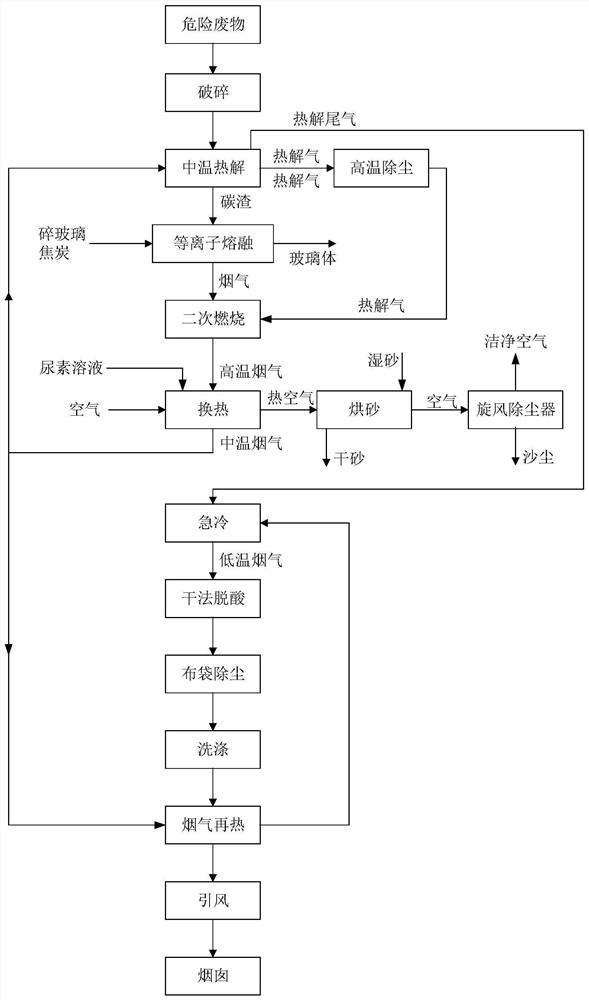

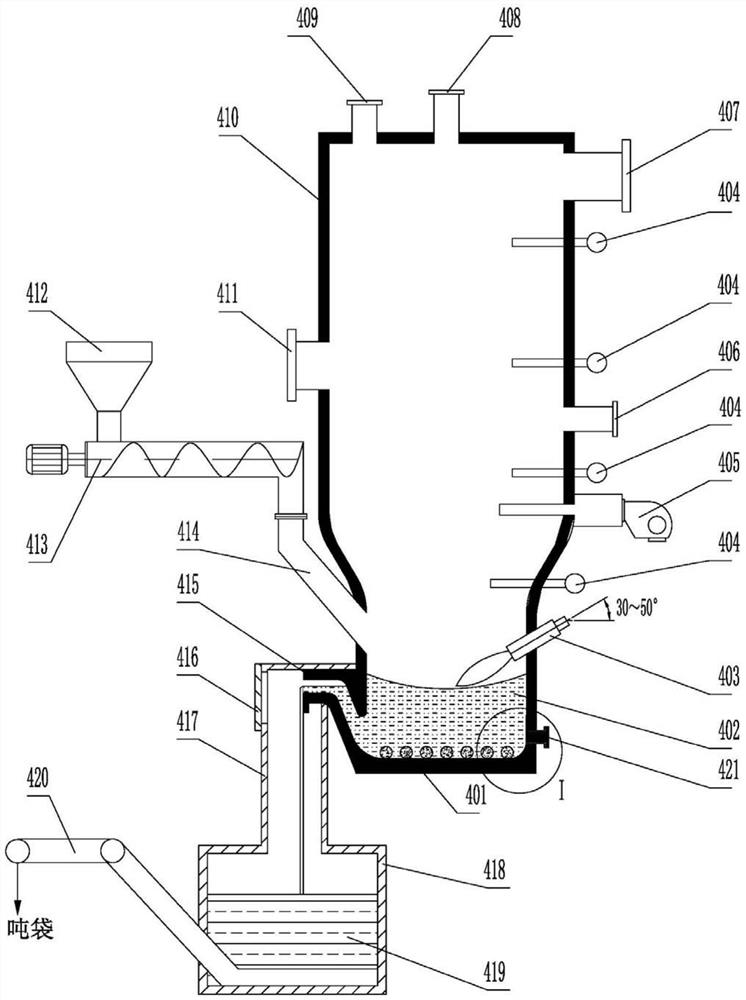

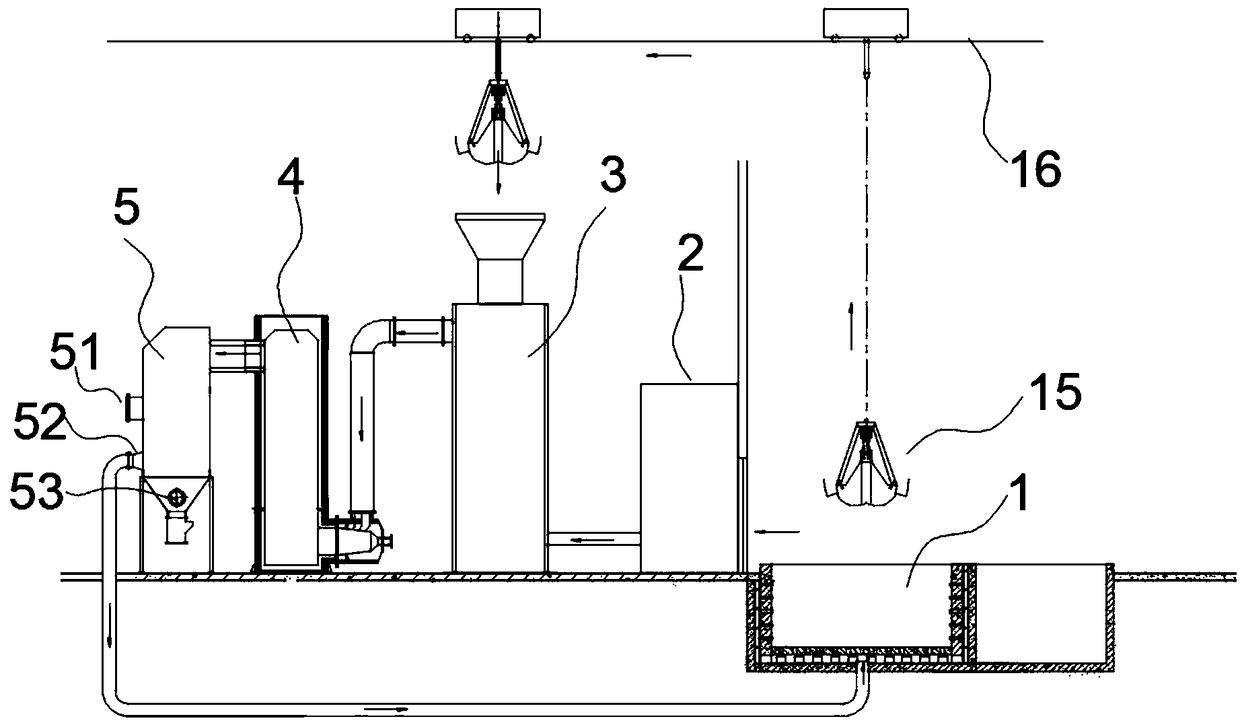

Hazardous waste treatment system and method based on medium-temperature pyrolysis and plasma high-temperature melting

ActiveCN113182311AHigh degree of harmlessnessHarmlessSolid waste disposalTransportation and packagingCombustion chamberDust control

The invention provides a hazardous waste treatment system and method based on medium-temperature pyrolysis and plasma high-temperature melting. The problems that existing hazardous waste incineration treatment is low in harmless degree, pyrolysis treatment is not thorough, and plasma melting treatment cost is high are solved. According to the system and method, hazardous waste is broken and then subjected to medium-temperature pyrolysis in an oxygen-deficient environment, pyrolytic carbon residues form harmless glass bodies through a plasma melting furnace, pyrolysis gas and smoke generated by plasma melting enter a combustion chamber to be subjected to secondary combustion, high-temperature smoke obtained after secondary combustion exchanges heat with air and then is cooled into medium-temperature smoke, the medium-temperature smoke is divided into two parts, one path enters a pyrolyzing furnace to heat materials, the other path enters a flue gas reheater to exchange heat, pyrolysis tail gas obtained after the materials in the pyrolyzing furnace are heated is mixed with flue gas obtained after heat exchange of the flue gas reheater, and after mixing, quenching cooling, dry-process deacidification, cloth bag dust removal, washing and reheating are conducted in sequence, and then a mixture is sent to a chimney to be discharged through an induced draft fan; and air is heated after heat exchange, is used as a heat source of a sand dryer, and is discharged after sand drying and cyclone dust removal.

Owner:ACADEMY OF AEROSPACE PROPULSION TECH +1

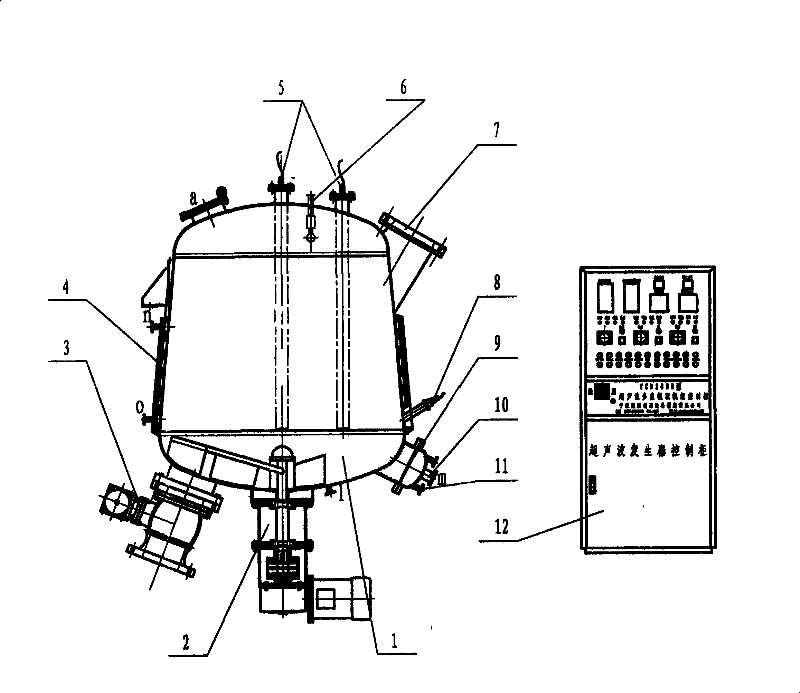

Ultrasonic conical ploughshare type residue-discharging extracting pot

InactiveCN101327381AReasonable structureSmooth slag dischargeEnergy based chemical/physical/physico-chemical processesSolid solvent extractionSlagSewage

The present invention relates to an ultrasonic conical three-share slag-off refining tank that is used for refining the active ingredients of the Chinese traditional medicine, which is provided with a conical tank body with an small upper part and a large lower part; a cylindrical large-power ultrasonic transducer is built in the conical tank body; the upper end of the ultrasonic transducer extends out of the tank top and is fixed to the tank top; the top of the tank is provided with an automatic cleaning device with a 360-degree rotation nozzle; the automatic cleaning device passes through the top of the tank and is fixed to the top of the tank, and the upper part of the automatic cleaning device is connected with a water-supply pipe; the bottom of the tank is provided with a sewage drainage port and a solid-liquid separation slag-off device; the main body of the solid-liquid separation slag-off device is a three-share with different lengths rotation-typed scraping slag-off mechanism; a filtering screen is arranged inside the solid-liquid separation device; a discharging port and a gas-charging port are arranged below the filtering screen. Compared with the prior art, the ultrasonic conical three-share slag-off refining tank has more reasonable structure, and integrates the extraction and the separation of the solid substance and the liquid; moreover, the ultrasonic conical three-share slag-off refining tank is provided with a three-share rotation-typed scraping slag-off mechanism and a pneumatic slag-washing device, so that the slag discharging is smooth, and the slag is free from building bridges and blocking.

Owner:XIANGSHAN MEDICAL PRECISION INSTR

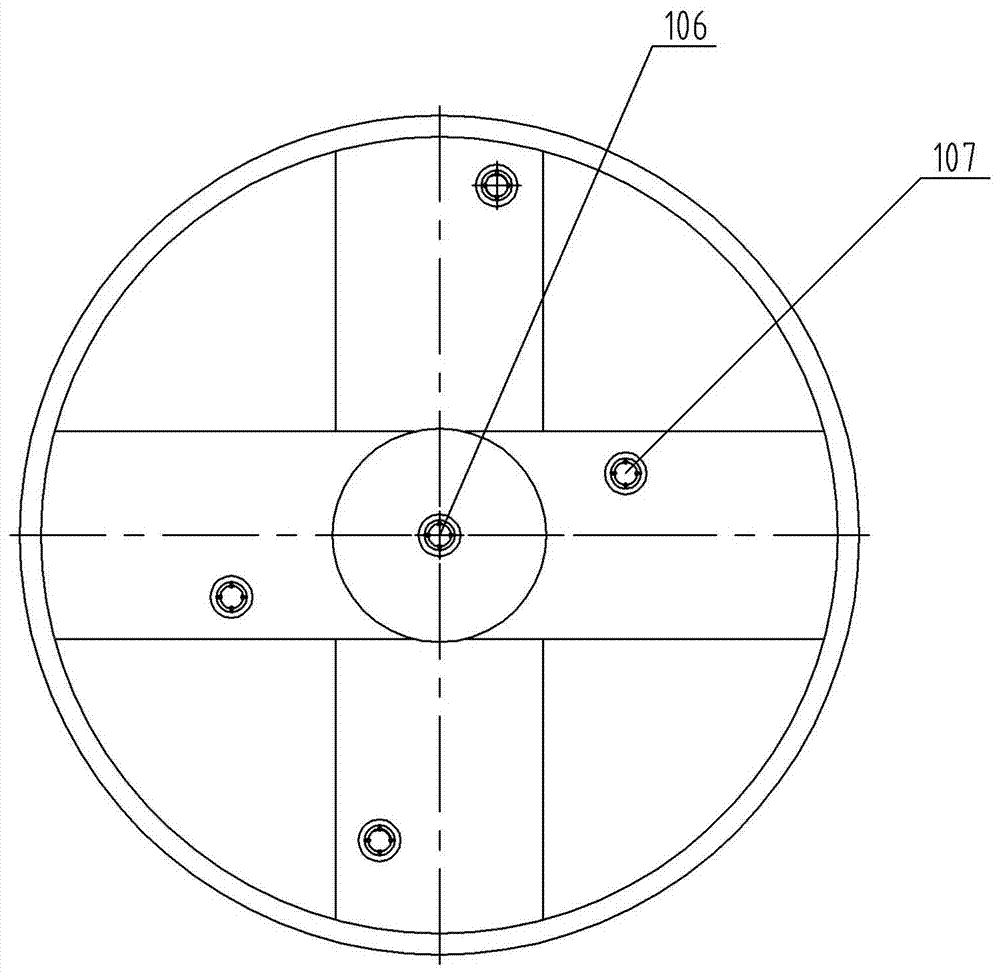

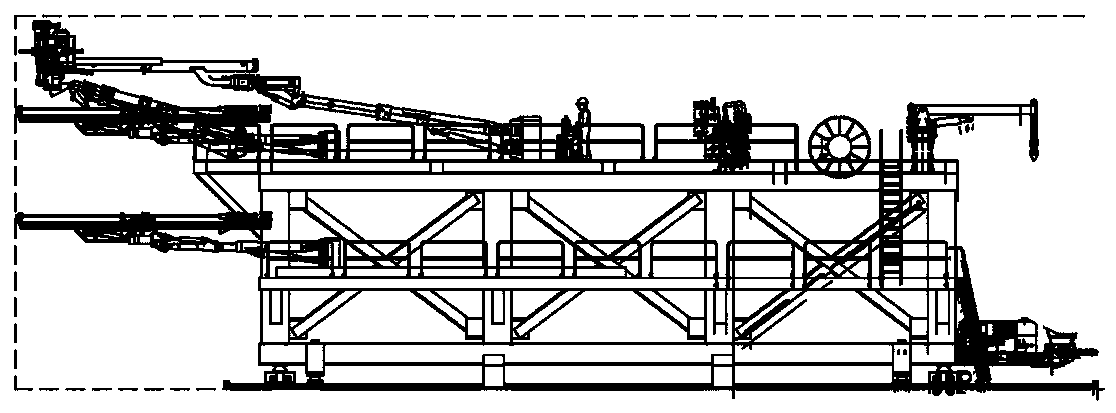

Muck improving system of multi-cutter tunnel boring machine

The invention belongs to the technical field of tunnel engineering construction equipment, and particularly relates to a muck improving system of a multi-cutter tunnel boring machine. The muck improving system comprises a cutter improving system, a clay injecting system, an excavation dead zone scouring system and a general control mechanism, collaborative or independent working of the cutter improving system, the clay injecting system and the excavation dead zone scouring system is controlled by the general control system, the cutter improving system can realize injection of muck improvers for multiple cutters, the cutters are independent from each other, and different improvers can be selectively injected to the cutters; the clay injection system can inject clay to the top of a clay bin, the upper portion of a residue discharging port and areas prone to residue accumulation on two sides of the bottom of an anterior shield partition to respectively realize functions of supporting an arch crown, reducing jacking friction force and wrapping large-particle muck; the excavation dead zone scouring system realizes muck cutting of excavation dead zones and assists in muck improving through high-pressure water.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Screw extrusion-type juice extractor

The invention provides a screw extrusion-type juice extractor which comprises a juice collecting cup, a screw and a filter screen support. A residue collecting groove is formed in the bottom face of the juice collecting cup, the cross sectional area of the residue collecting groove is smaller than the bottom face area of the juice collecting cup, a residue discharging opening is formed in the lateral wall of the residue collecting groove, the screw is arranged in the juice collecting cup in the axial direction of the juice collecting cup, a residue scraping part is arranged at the lower end of the screw and located in the residue collecting groove, the screw is provided with a plurality of working sections, a plurality of spiral ribs are arranged on the outer surface of each working section, the filter screen support is in a taper-shaped tube shape, a plurality of convex ribs are arranged at the position, corresponding to each working section, of the inner surface of the filter screen support, gaps are reserved between each convex rib and the multiple spiral ribs of the working section corresponding to the convex rib, the gaps are larger than or equal to 0.1 mm and smaller than or equal to 1 mm, and each convex rib is divided into two sections or multiple sections. The screw extrusion-type juice extractor has the advantages of being smooth in residue outlet, easy to wash, high in juice outlet rate and the like.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

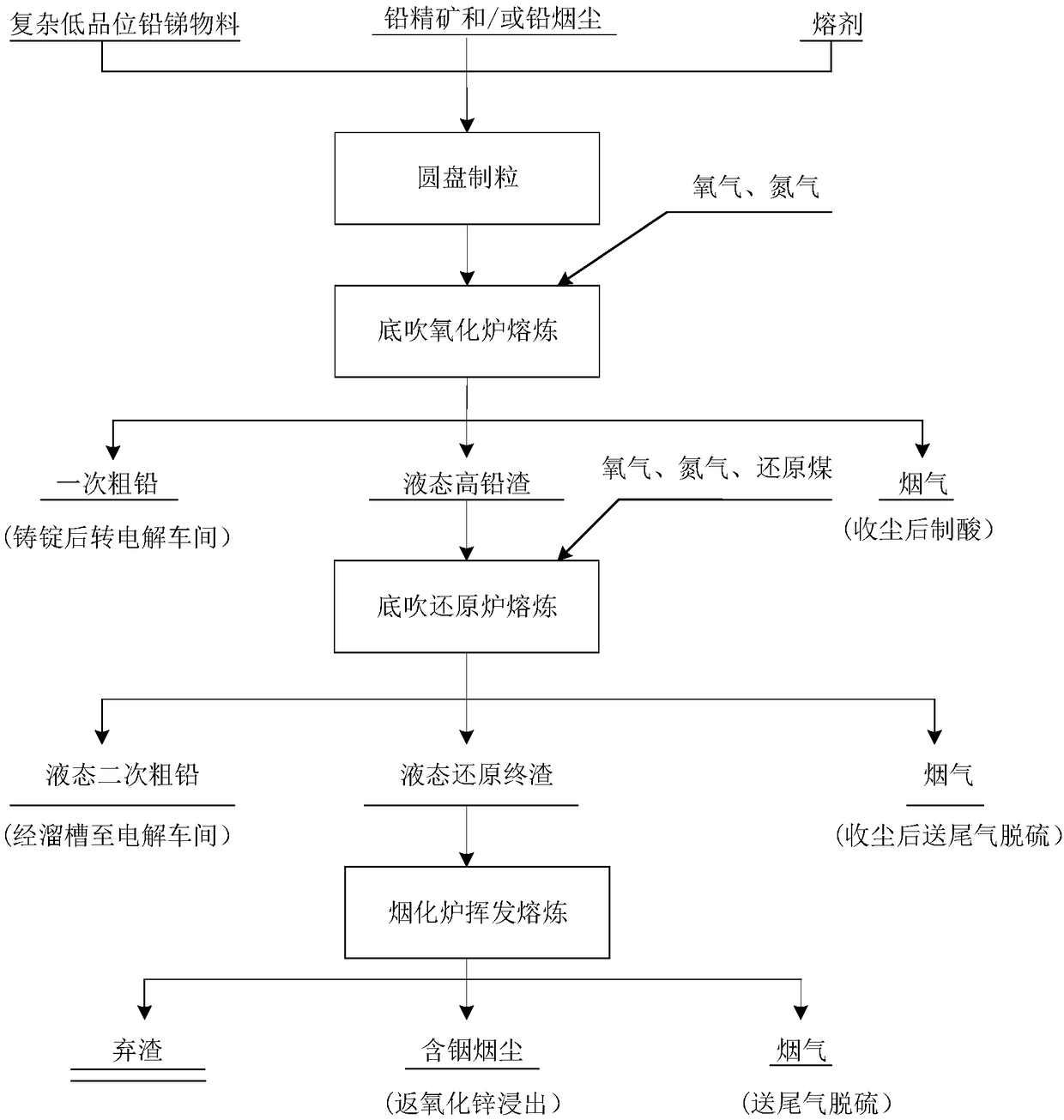

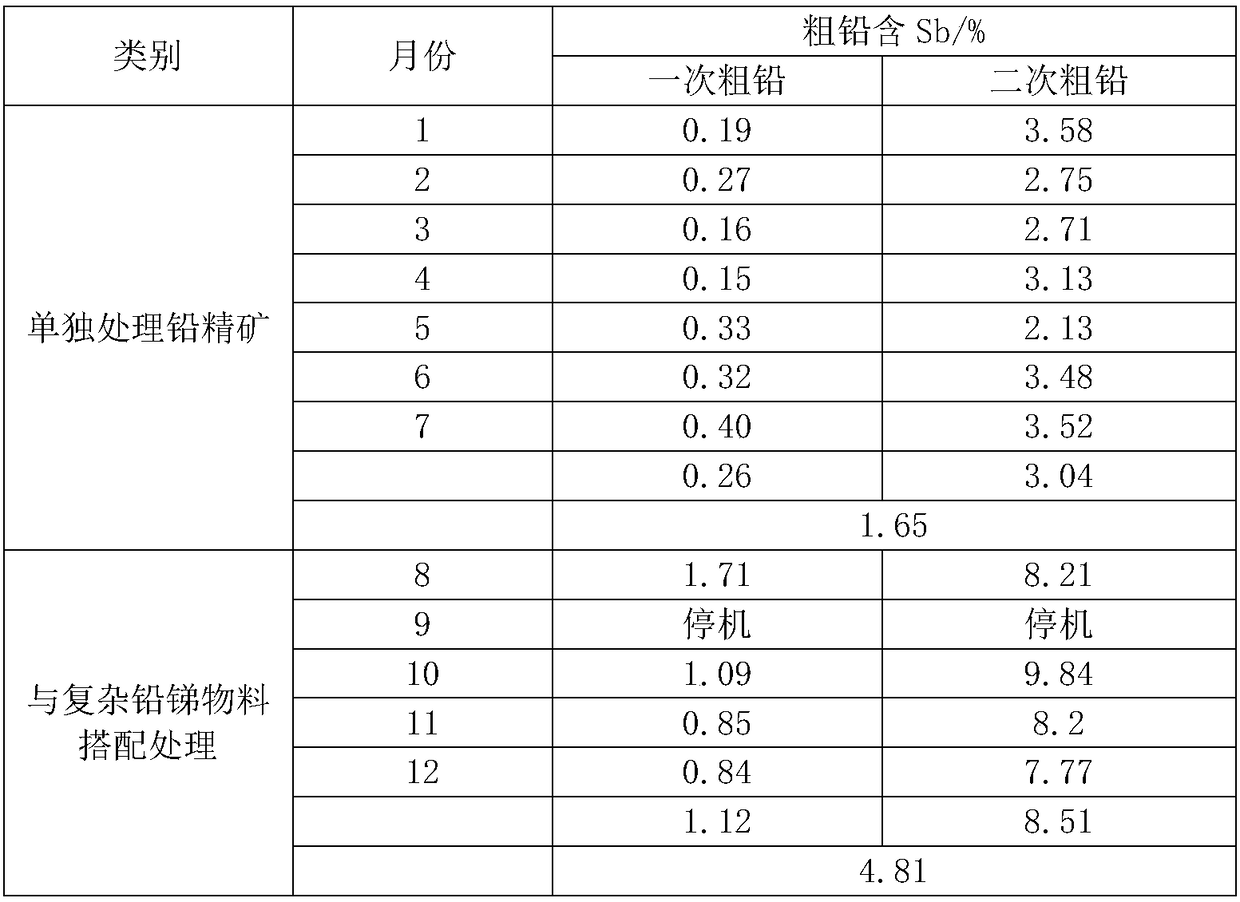

Method for treating complex low-grade lead-antimony material by matching dual bottom-blowing furnaces

InactiveCN108411123ASmooth slag dischargeImprove processing powerProcess efficiency improvementSmelting processLow graded

The invention discloses a method for treating a complex low-grade lead-antimony material by matching dual bottom-blowing furnaces. The method comprises the following steps of: (1) proportioning of complex low-grade lead-antimony material, lead concentrate and / or lead smoke dust and flux to be pelletized; (2) smelting in the bottom-blowing oxidizing furnace; (3) reducing in the bottom-blowing reducing furnace; and (4) volatilizing and smelting in a fuming furnace, specifically, a mixture obtained by proportioning comprises, by mass, greater than 40% of Pb and 1%-5% of Sb, a mass ratio of Fe toSiO2 is (1.2-1.6):1, and a mass ratio of CaO to SiO2 is (0.3-0.7):1. The method is used for treating the complex low-grade lead-antimony material by matching the dual bottom-blowing furnaces, and thethree continuous furnaces continuously and stably operate in the whole production and smelting process by strengthening batching, so that treatment capacity of the complex low-grade lead-antimony material is improved, and adaptability to raw materials is strong; and moreover, the yield of refined antimony can be increased, other valuable metal in the lead-antimony material is recycled more, comprehensive recycling profits are increased, and great significance is achieved for survival and development of enterprises.

Owner:蒙自矿冶科技开发有限责任公司

Anchor bolt recycling device

The invention discloses an anchor bolt recycling device used for recycling mine tunnel support anchor bolts. The anchor bolt recycling device comprises a drill bit of a hollow cone structure and a spiral drill pipe, the spiral drill pipe of a tubular structure is connected to the upper end of the drill bit, a connector is arranged at the top end of the spiral drill pipe, and a convex spiral line is arranged on the outer surface of the spiral drill pipe. A mandrel with the outer diameter smaller than the bore diameter of an anchor bolt is arranged in the spiral drill pipe, the upper end of the mandrel is fixedly connected in the connector, the lower end of the mandrel is arranged to be a flared elastic forky structure, and the elastic forky structure is enabled to be combined to form a stepped tapered structure. By the structure, the anchor bolts can be removed by means of arranging the lower end of the mandrel to be the flared elastic forky structure and enabling the elastic forky structure to be combined to form the stepped tapered structure; the anchor bolt recycling device is simple in design structure, convenient to operate and use and smooth in slag tapping; meanwhile, the anchor bolts can be recycled completely, material reuse rate is increased, production cost is lowered, and raw materials are saved.

Owner:ZHENJIANG ANDA COAL MINE SPECIAL EQUIP

Electricity-coal process melting and reduction ironmaking technology

The invention relates to an electricity-coal process melting and reduction ironmaking technology. The electricity-coal process melting and reduction ironmaking technology comprises the following steps of: conveying metallized pellets produced by a gas / coal-based direct reduction device into a heat preservation storage silo of a melting and reduction furnace by utilizing a hot delivery device at the temperature of 900-1000 DEG C under non-oxidizing conditions, completing mixture making in the heat preservation storage silo, then conveying the mixture into a high-temperature area in the furnace, then heating by utilizing electric arc to melt the mixture, simultaneously spraying carbon powder to perform reduction, and then performing technological slagging off and electric arc heating melting in a circulating manner till the temperature and the ingredients of a sample achieve the standards, wherein the mixture making in the heat preservation storage silo is performed by mixing the metallized pellets, a reducing agent and slag charge according to the weight ratio of 85: 15: 5. The electricity-coal process melting and reduction ironmaking technology disclosed by the invention is designed against low-grade ores, refractory ores and complex ores, open-burning coal is used as energy, the carbon-containing metallized pellets are taken as raw materials, a final reduction technology for directly producing molten iron (or titanium refining slag and the like) is solved, and the electricity-coal process melting and reduction ironmaking technology is of a key technology for sustainable development of iron and steel industry in China, energy conservation, emission reduction and environment-friendly development.

Owner:XIAN TAOYUAN METALLURGY EQUIP ENG CO LTD

Slag discharge device for pyrolysis and gasification furnace of household waste

InactiveCN108895458AAvoid enteringGuaranteed air volume supplyIncinerator apparatusAir preheaterLoss rate

The invention discloses a slag discharge device for a pyrolysis and gasification furnace of household waste. The slag discharge device for the pyrolysis and gasification furnace of the household wastecomprises the pyrolysis and gasification furnace and a slag discharge device body arranged at the bottom of the pyrolysis and gasification furnace; the slag discharge device body comprises a slag discharge pipe, a hydraulic oil cylinder and a push rod piston, a slag hopper is arranged below the interior of the pyrolysis and gasification furnace, a slag falling port is formed below the slag hopperand communicated with the slag discharge pipe, the hydraulic oil cylinder is connected with the push rod piston, a slag outlet is formed in one end of the slag discharge pipe, and the length of the push rod piston is larger than that of the slag falling port. The slag discharge device can achieve the effect of an air preheater, the temperature is guaranteed, and the energy consumption is reduced;the problems are solved that a traditional slag discharge system is huge and complicated, too much auxiliary equipment is arranged, the energy consumption is large, and the operation and maintenancecost is high; the problems of slag blockage and secondary pollution are solved, and the device has the advantages that the device is easy and reliable, the operation and maintenance cost is low, slagdischarge is smooth with a fixed quantity, incineration is thorough, and the ignition loss rate is low.

Owner:上海古蓝环境工程有限公司

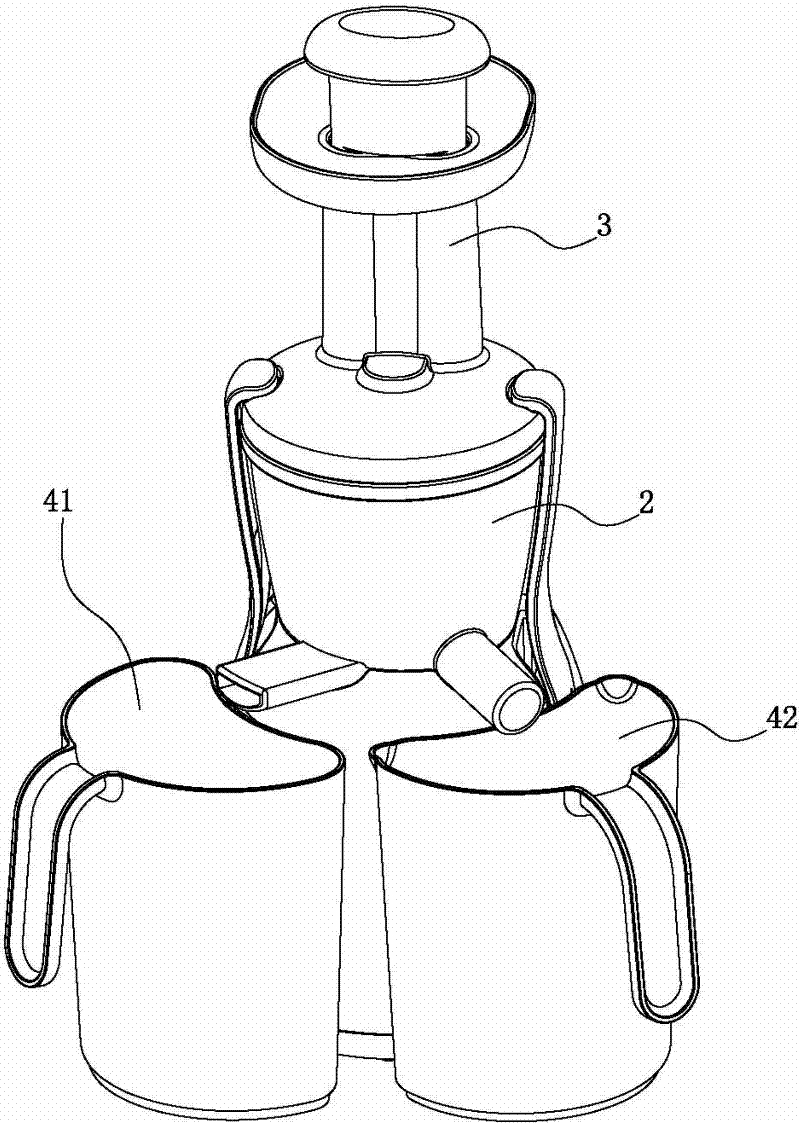

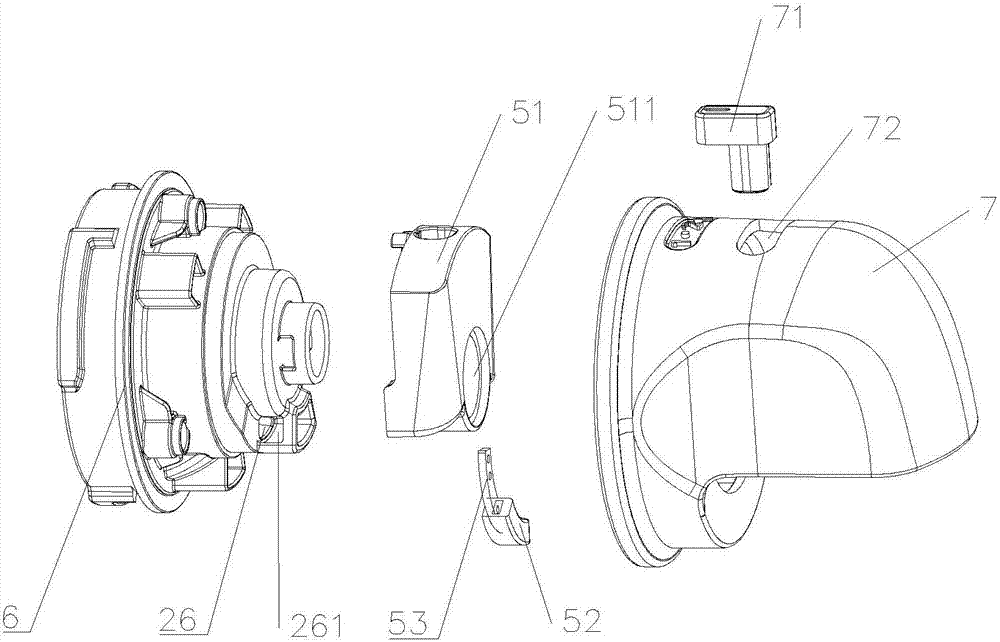

Squeezing type juicer

The invention discloses a squeezing type juicer. The squeezing type juicer comprises a base, a squeezing assembly mounted on the base, and a feeding assembly buckled on the squeezing assembly. A drive component is disposed inside the base, and a drive shaft is arranged at the top of the base. The squeezing assembly comprises a cup body, a meshed barrel fixedly mounted in the cup body and a screw rod located in the meshed barrel. The cup body is provided with a juice outlet and a pomace draining channel. A juice collection annular groove is formed at the bottom of the cup body and is communicated with the juice outlet. A pomace collecting annular groove is formed at the bottom of the meshed barrel and is communicated with the pomace draining channel. According to the invention, a rotating brush, a transmission mechanism of the rotating brush and a transmission gear located at the bottom of the screw rod in the prior art are omitted, so that the juicer is simpler in structure, is lower in failure rate, is prolonged in service lifetime, is more stable in operation, and is more convenient to wash.

Owner:NINGBO KEDLY APPLIANCE IND

Overflow type iron bath slag melting pool and slag removal method thereof

ActiveCN104293396AImprove operational efficiencyImprove operational safetyGasifier mechanical detailsCombustible gas productionLiquid slagFixed bed

The invention relates to an overflow type iron bath slag melting pool and a slag removal method thereof. The overflow type iron bath slag melting pool is characterized by comprising an annular furnace lining, wherein a hollow slag opening with the shape of cone frustum is formed in the middle of the furnace lining; an overflow port in the upper end of the slag opening is slightly lower than the upper edge of the outer wall of the furnace lining in the height direction; an annular slag pool is formed between the outer wall of the furnace lining and the slag opening; an inductor is arranged on the outer part of the furnace lining; a magnet yoke is arranged on the outer part of the inductor; a water cooled jacket is arranged on the outer part of the magnet yoke; an annular tray shaped furnace bottom is arranged below the furnace lining; a through hole which corresponds to the slag opening is formed in the middle of the furnace bottom; and a furnace charge layer is arranged between the furnace bottom and the furnace lining. With the adoption of an electromagnetic induction heating and melting principle, metal iron is added into the bottom of the slag pool in advance and is molten into molten iron through induction heating so as to continuously supply heat to liquid slag in the slag pool, and the liquid slag can preserve the flowing temperature to flow out of the overflow port of the slag pool. The slag is removed by adopting an overflow mode, a phenomenon that the slag removal is unsmooth due to small slag opening is avoided, and the operating efficiency and operating safety of a fixed bed slag gasifier are improved.

Owner:CCTEG CHINA COAL RES INST

Low-temperature chlorination furnace

The invention discloses a low-temperature chlorination furnace, and belongs to the technical field of metallurgical production equipment design and manufacturing. The low-temperature chlorination furnace which makes slag removing convenient and smooth and cannot cause TiCl4 product gas loss due to a slag removing structure is provided. The low-temperature chlorination furnace comprises a low-temperature chlorination furnace body with a smoke outlet formed in the top, and the low-temperature chlorination furnace further comprises an open type slag discharging structure and a disengaging plugging device; the open type slag discharging structure arranged on the lower portion of the low-temperature chlorination furnace body is opened and closed through the disengaging plugging device.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

System and method for enhancing gas extraction through drilling slag discharge and hydraulic oscillation fracturing based on nanofluids

The invention discloses a system and method for enhancing gas extraction through drilling slag discharge and hydraulic oscillation fracturing based on nanofluids. A coal rock body and broken rock at the front portion of a drill bit are wetted by the hydrophilic nanofluid in the coal body drilling process, the flowability of the coal rock body is increased, and the slag discharge smoothness in thedrilling process is ensured. Then, the hydrophobic nanofluid is injected into a coal seam to be attached to the surface of the coal body, high-pressure water is prevented from leaking off, the depth of cracks is better increased, and therefore the coal body can be efficiently cracked under the same water injection pressure, the rapid desorption of gas of the coal seam is promoted on a large scale,and the good synergistic effect of the nanofluids and the hydraulic fracturing is realized. The effect of integrating efficient drilling operation, efficient coal seam permeability improvement and efficient gas extraction is realized, the coal seam gas is scientifically and efficiently extracted, and the aim of effectively preventing high gas and low-permeability coal seam gas disasters is realized.

Owner:CHONGQING UNIV +1

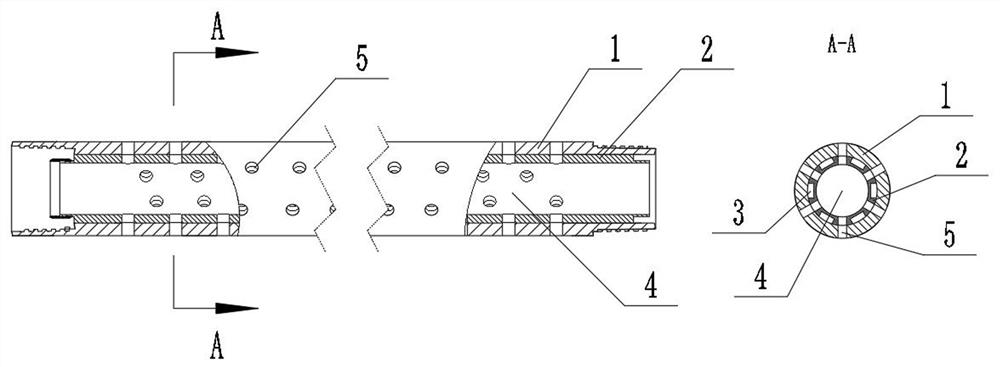

Outburst coal seam circumferential flow supply hole protection and pressure relief sieve pore drill rod

The invention discloses an outburst coal seam circumferential flow supply hole protection and pressure relief sieve pore drill rod. A drill rod body is formed by combining an outer pipe and an inner pipe, a plurality of axial flow supply channels are formed in the circumference of the drill rod body, and a circular-diameter inner slag discharging channel is formed in the center of the drill rod body; and a spiral groove or an axial groove or a plane is formed in the outer surface of the outer pipe of the drill rod body, and slag discharging sieve pores which are communicated with the inner slag discharging channel and avoid the flow supply channels are formed in the spiral groove, the axial groove and the plane. The drill rod is an inner slag discharging channel drill rod with circumferential flow supply, the diameter of the drill rod can be close to the diameter of a drill bit, the drill rod has the hole protection and pressure relief functions and can be used for conventional drilling and cableless directional drilling of an outburst coal seam, and if a cable passing pipe and a built-in communication cable thereof are installed in the axis of the inner pipe of the drill rod, the drill rod can also be used for cable passing directional drilling.

Owner:HENAN POLYTECHNIC UNIV

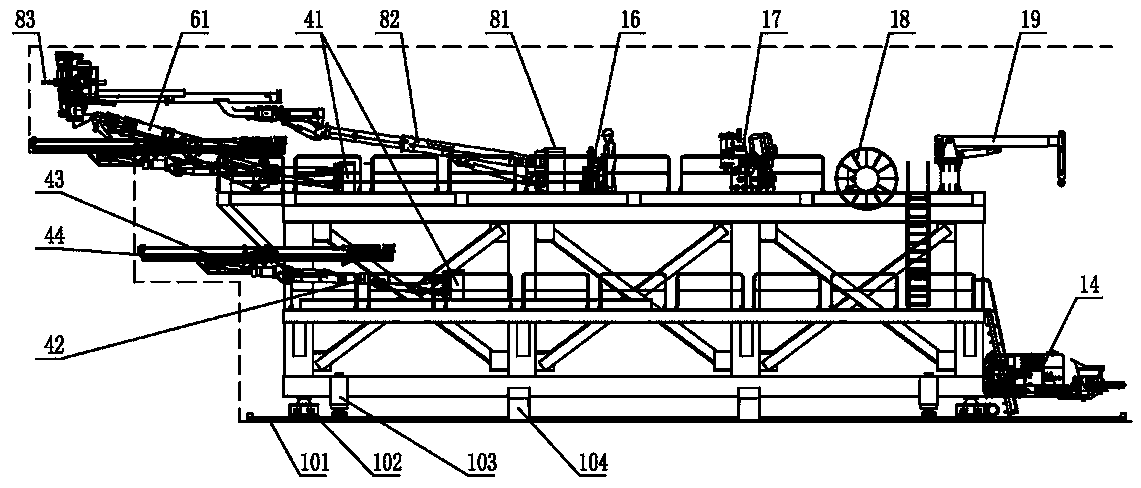

Tunnel construction unit workstation

PendingCN109779660AReduce in quantityShorten cycle timeUnderground chambersDerricks/mastsWork periodWorking environment

The invention discloses a tunnel construction unit workstation, and relates to the technical field of tunnel construction machinery. The tunnel construction unit workstation comprises a portal assembly and an automatic walking assembly driving the portal assembly to move front and back along a tunnel, the portal assembly comprises a portal and auxiliary platforms correspondingly arranged on two sides of the portal, a main platform is arranged at the top of the portal, and an arch frame mechanical arm, a wet spraying mechanical arm and a drilling assembly are fixedly installed on the front portion of the main platform side by side. The arch frame mechanical arm, the wet spraying mechanical arm and the drilling assembly are integrated, vehicle exchange in the working period does not need towait, the circulation time can be shortened, and efficient construction is achieved. By reducing the number of trolleys, the working space can be tidied and reduced, the improvement of the working environment and the improvement of the safety are realized, and the work of deslagging and the like can be smoothly carried out. Drilling assemblies are arranged on the main platform and the auxiliary platforms, the construction requirements of full-section excavation and step-method excavation can be met, the structure is novel, and operation is convenient.

Owner:中铁工程装备集团隧道设备制造有限公司

Disintegrating slag breaker of gasification furnace

ActiveCN102863990AAvoid furnace blockageSmooth slag dischargeGranular/pulverulent flues gasificationSlag

The invention discloses a disintegrating slag breaker of a gasification furnace. The disintegrating slag breaker comprises a spindle rotating relative to a furnace body. A slag breaking seat is fixedly mounted at the upper end of the spindle, inner slag breaking claws are uniformly fixed on the upper circumference of the slag breaking seat, slag collection gaps are reserved among the inner slag breaking claws, outer slag breaking claws arranged above or below the inner slag breaking claws are fixed on the inner wall of the furnace body, and ends of the outer slag breaking claws extend into slag collection passages corresponding to the slag collection gaps. The disintegrating slag breaker of the gasification furnace has the advantages that since the spindle rotates relative to the furnace body, the inner slag breaking claws are driven to rotate relative to the outer slag breaking claws, slags of the furnace can be cut and broken by the inner slag breaking claws and the outer slag breaking claws, blockage of the gasification furnace due to adhesion of ash slags is avoided, smooth slag discharge is realized and the gasification process is stable and continuous.

Owner:潍坊金丝达环境工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com