Anchor bolt recycling device

A technology for recovering device and bolt, which is applied in the installation of bolt, mining equipment, earth-moving drilling, etc., and can solve the problems of increase in height, waste of material production cost, and inability to take out smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

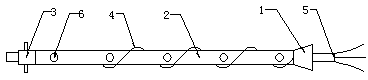

[0011] The anchor rod recovery device of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] As shown in the figure, the anchor rod recovery device of the present invention includes a drill bit 1 of a hollow conical structure and an auger rod 2 of a tubular structure connected to the upper end of the drill bit. The top end of the auger rod 2 is provided with a connector 3, and the auger rod 2 The outer surface is provided with a raised helix 4; the auger rod 2 is provided with a core rod 5 whose outer diameter is smaller than the inner diameter of the anchor rod, the upper end of the core rod 5 is fixedly connected in the connector 3, and the lower end of the core rod 5 The elastic bifurcation structure is set to expand outwards, and the elastic bifurcation structure is closed to form a tapered structure with steps.

[0013] Further, the surface of the pipe body of the auger rod 2 also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com