Circulating fluidized bed garbage incineration boiler and pollution control system with same

A circulating fluidized bed and waste incineration technology, applied in incinerators, combustion methods, combustion types, etc., can solve the economic problems affecting waste incineration plants, slag discharge difficulties, pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

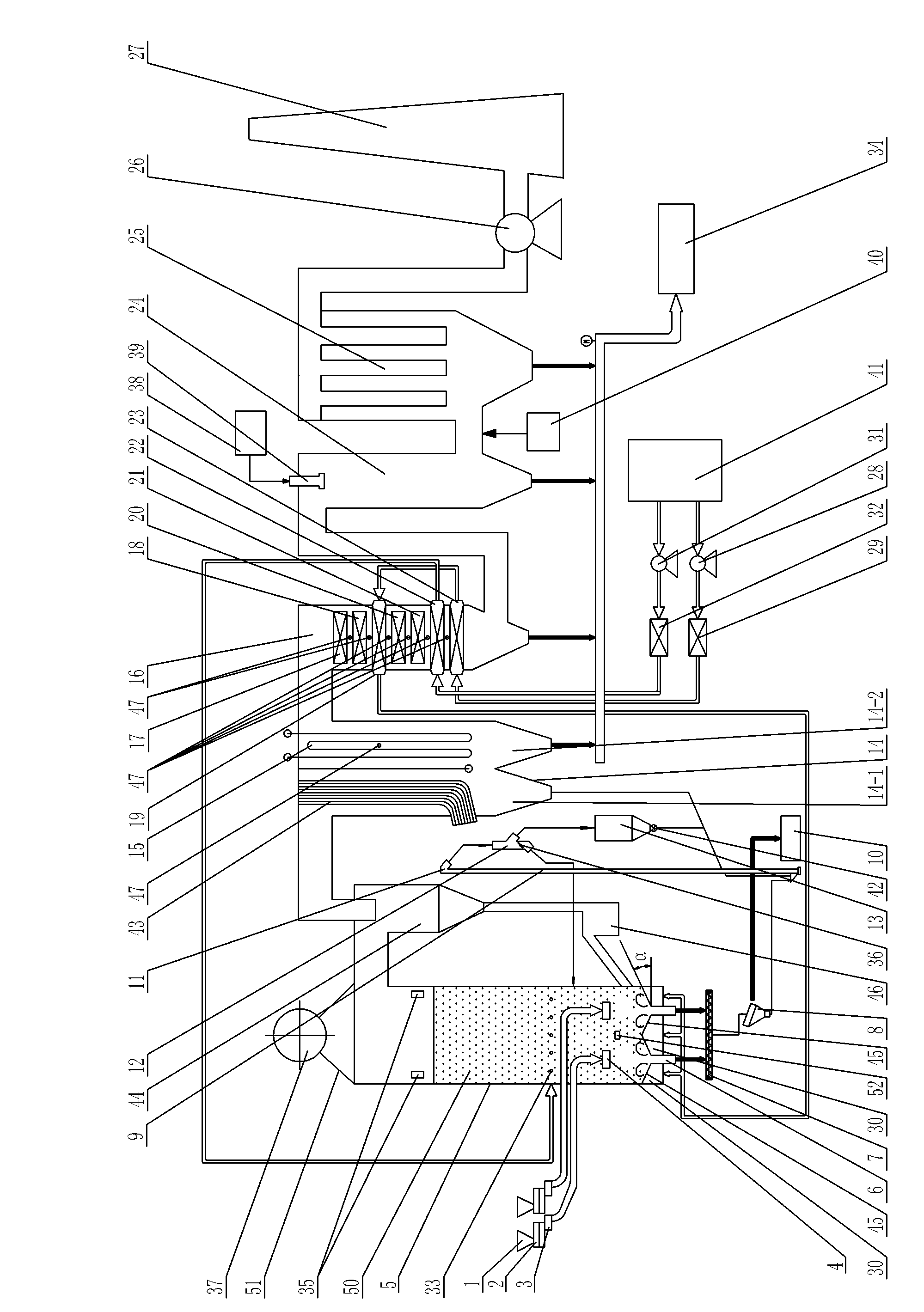

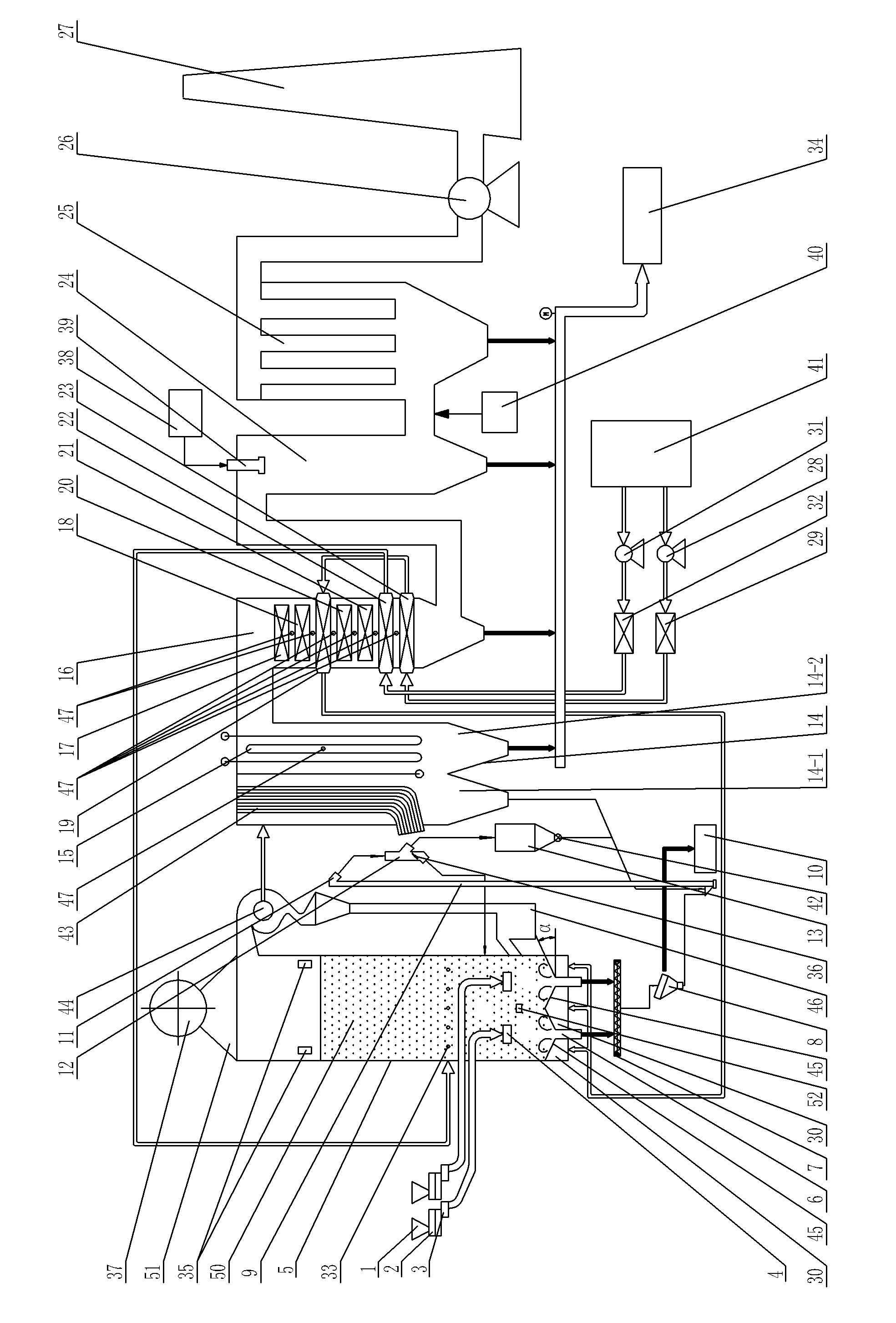

[0028] Specific implementation mode one: combine figure 1 and figure 2 Explain that the circulating fluidized bed waste incineration boiler of this embodiment includes a waste feeding port 4, a furnace body 5, a slag discharge port 6, a water-cooled double-helix auger 7, a vibrating screen 8, a lifting bucket 9, a non-combustible Material storage bin 10, distribution valve 12, bed material storage bin 13, flue gas cooling chamber 14, high temperature superheater 15, tail flue 16, upper low temperature superheater 17, lower low temperature superheater 18, primary air upper air preheater 19. Upper economizer 20, lower economizer 21, secondary air air preheater 22, primary air lower air preheater 23, primary fan 28, primary air steam air preheater 29, air chamber 30, secondary Secondary fan 31, secondary air steam air preheater 32, secondary air inlet 33, rotary valve 36, steam drum 37, star discharge valve 42, water cooling screen 43, separator 44, air distribution plate 45, U...

specific Embodiment approach 2

[0036] Specific implementation mode two: combination figure 1 and figure 2 Explain that the pollution control system of the circulating fluidized bed waste incineration boiler described in the first embodiment is installed in this embodiment, and the system includes a circulating fluidized bed waste incineration boiler 51; the system also includes a semi-dry reaction tower 24 , bag filter 25, induced draft fan 26, chimney 27, fly ash bin 34, lime slurry preparation system 38, rotary sprayer 39 and activated carbon injection device 40;

[0037] The lower rear side wall of the tail flue 16 of the circulating fluidized bed waste incineration boiler 51 communicates with the flue gas inlet of the semi-dry reaction tower 24 through the flue. The top of the semi-dry reaction tower 24 is provided with a rotary sprayer 39, which The sprayer 39 communicates with the lime slurry preparation system 38 through pipelines, the semi-dry reaction tower 24 communicates with the bag filter 25 ...

specific Embodiment approach 3

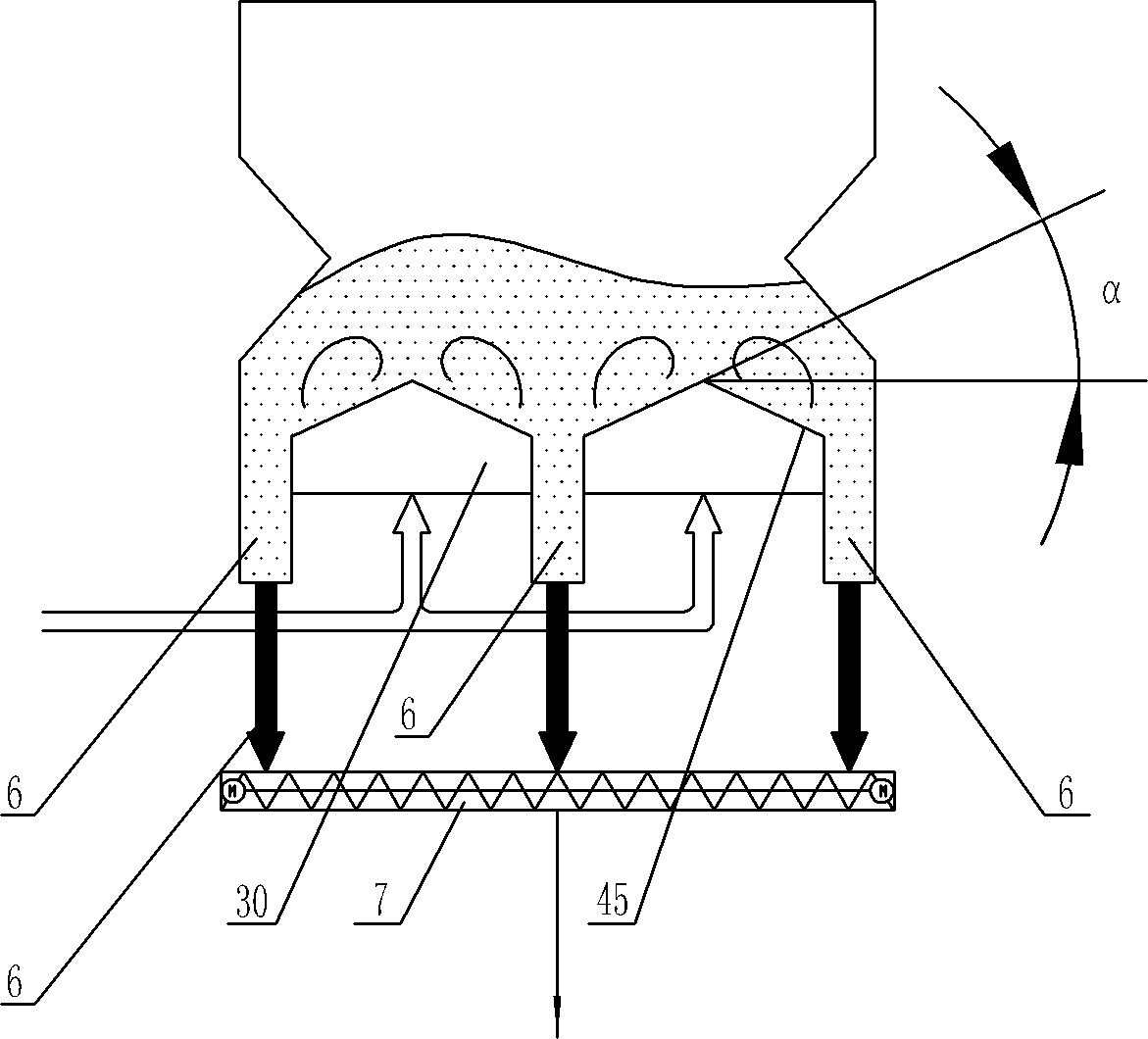

[0038] Specific implementation mode three: combination Figure 1 ~ Figure 3 Note, in this embodiment, the figure 1 and figure 2 The double "V" shaped air distribution panels in the image 3 The double inverted "V" shaped air distribution board in the middle is enough;

[0039] The circulating fluidized bed garbage incineration boiler of this embodiment, the boiler includes a garbage feeding port 4, a furnace body 5, a slag discharge port 6, a water-cooled double-helix auger 7, a vibrating screen 8, a lifting bucket 9, a non-combustible storage Bin 10, distribution valve 12, bed material storage bin 13, flue gas cooling chamber 14, high temperature superheater 15, tail flue 16, upper low temperature superheater 17, lower low temperature superheater 18, primary air upper air preheater 19, Upper economizer 20, lower economizer 21, secondary air air preheater 22, primary air lower air preheater 23, primary fan 28, primary air steam air preheater 29, air chamber 30, secondary f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com