Patents

Literature

49results about How to "Solve the problem of slagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

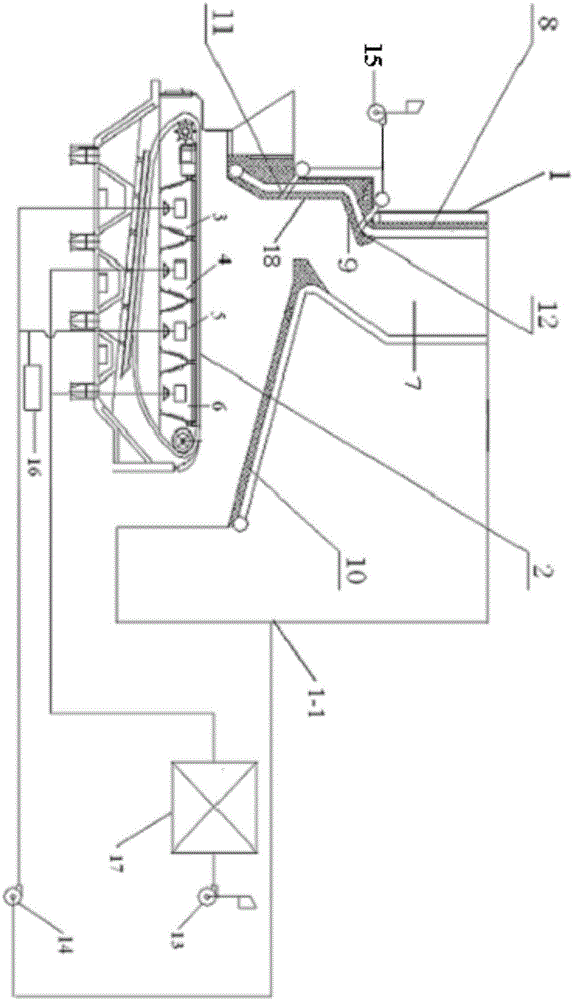

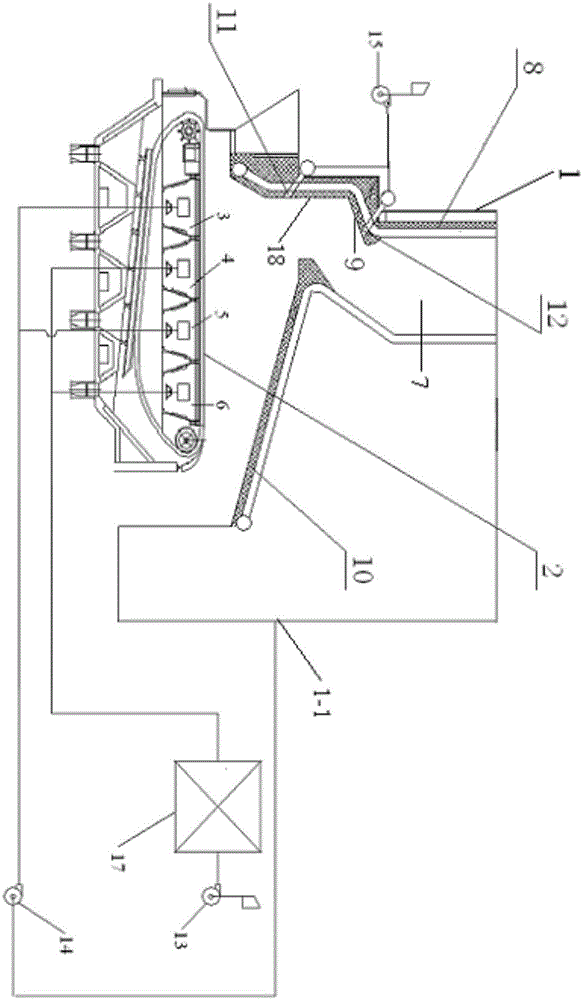

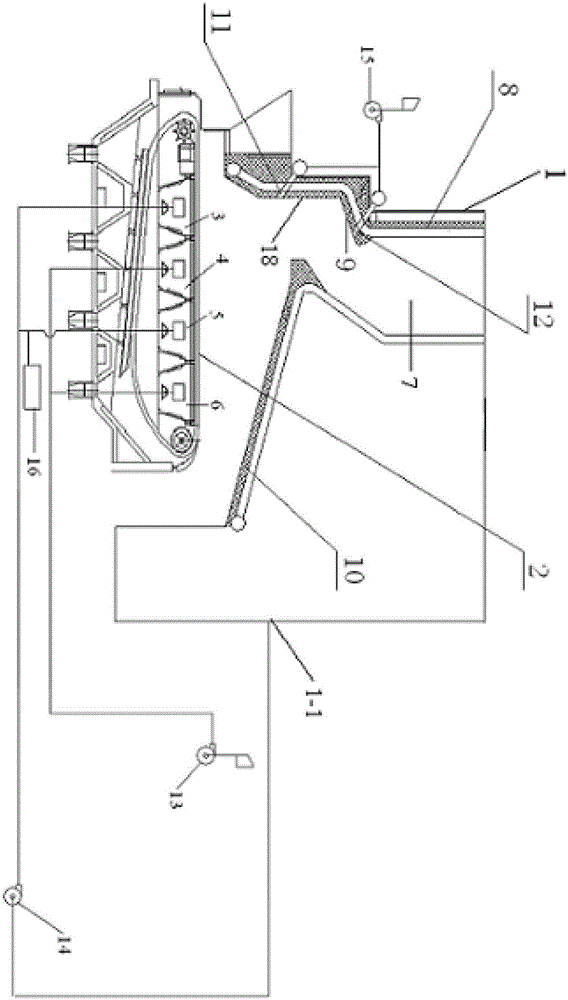

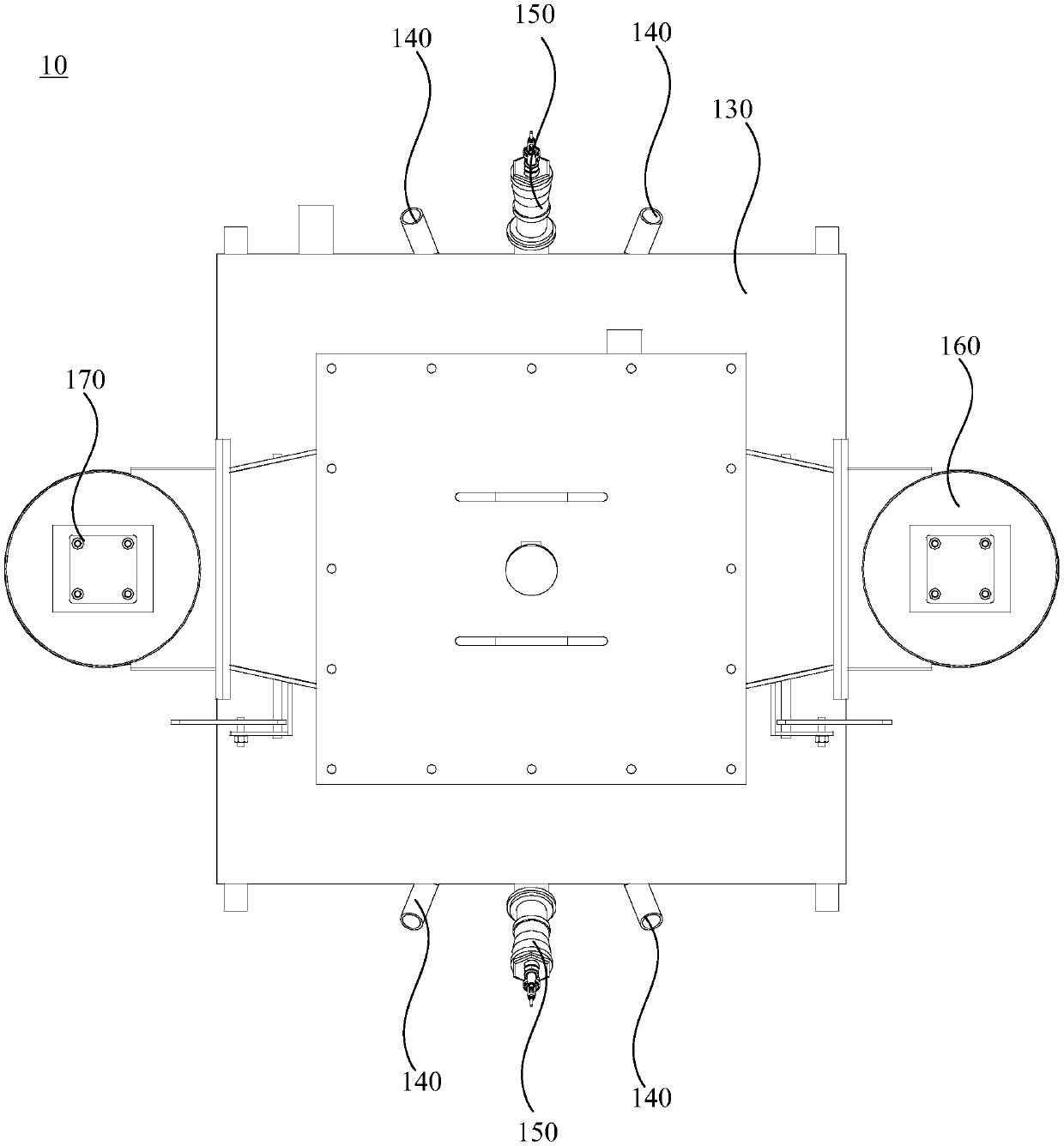

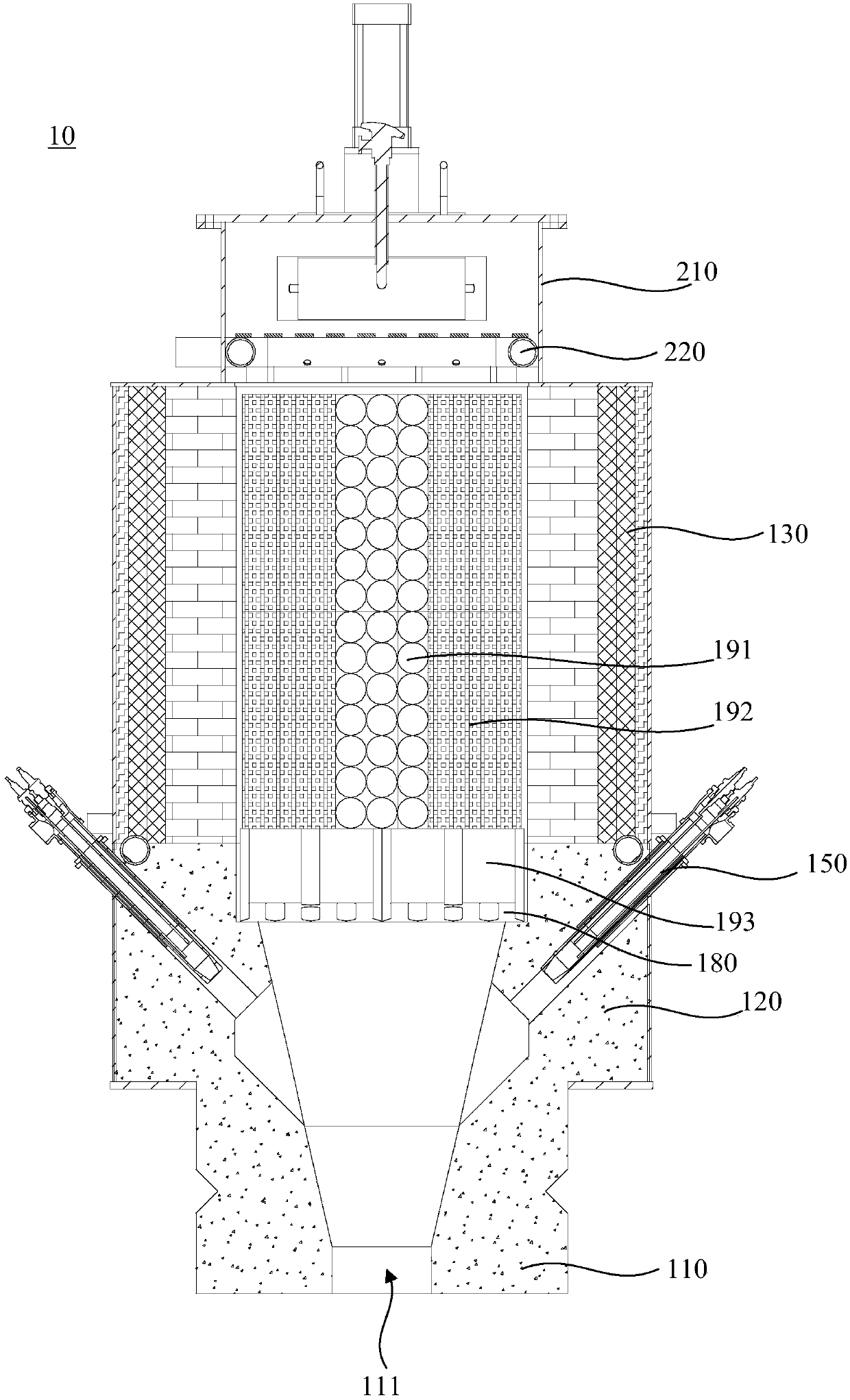

Circulating fluidized bed garbage incineration boiler and pollution control system with same

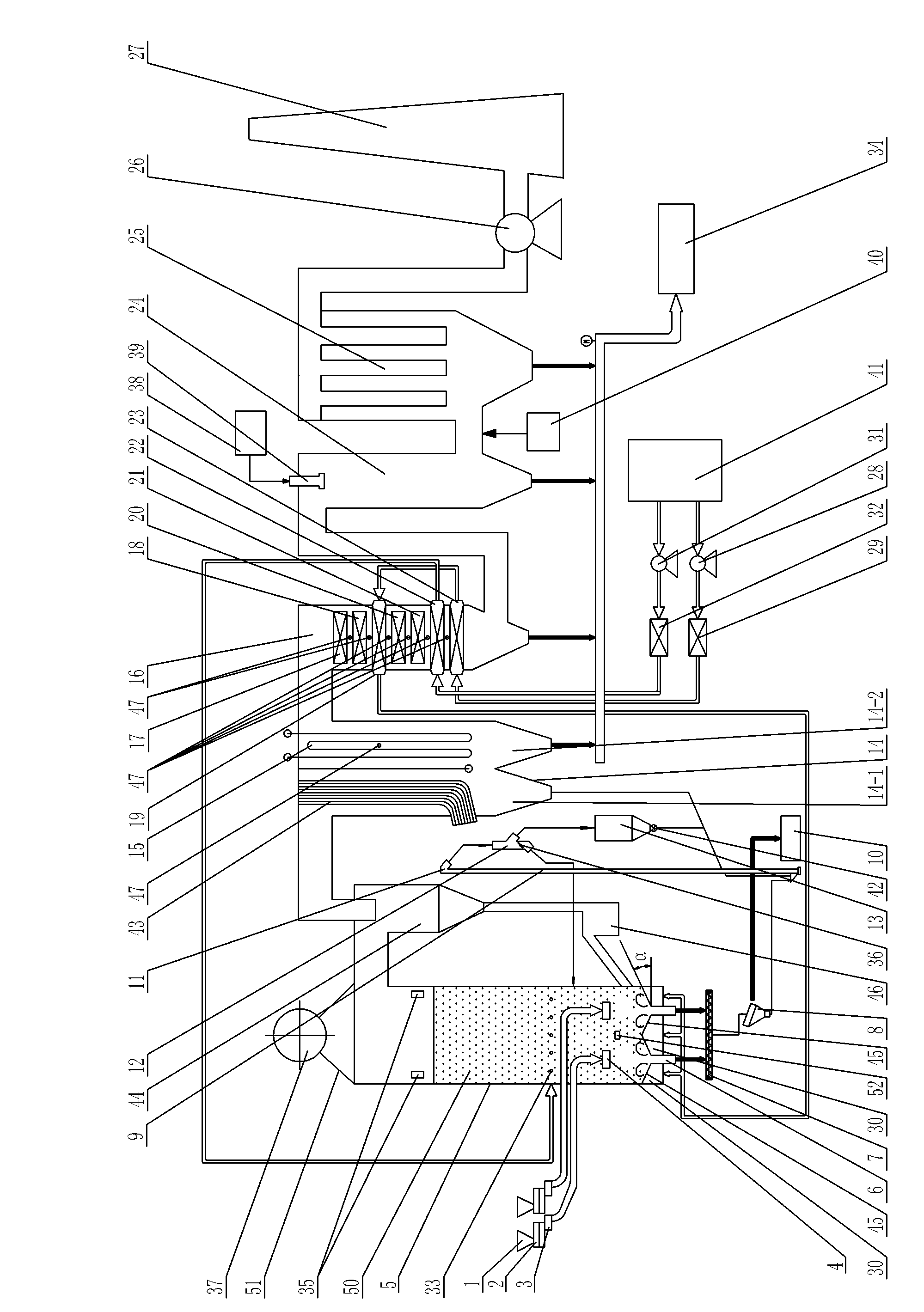

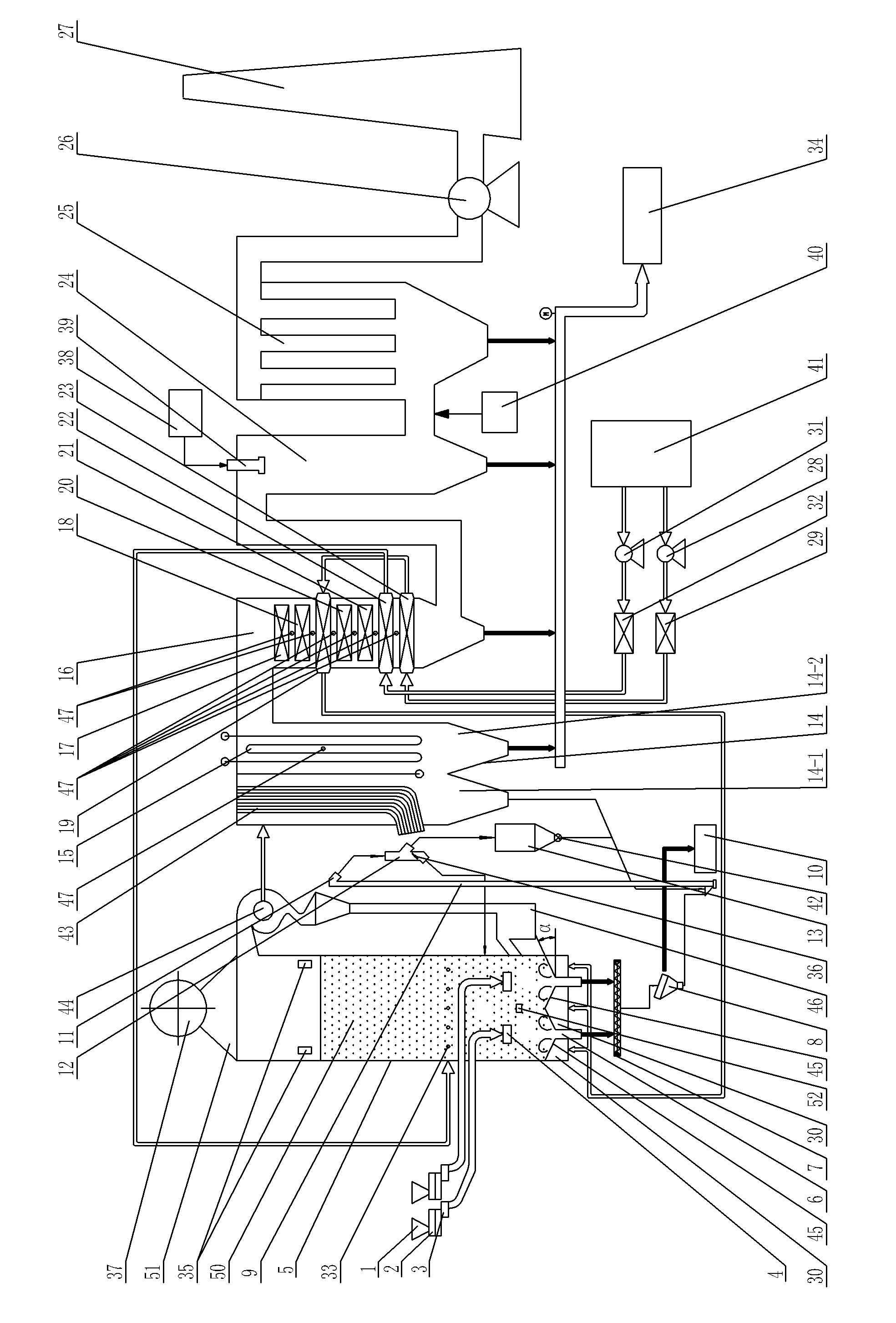

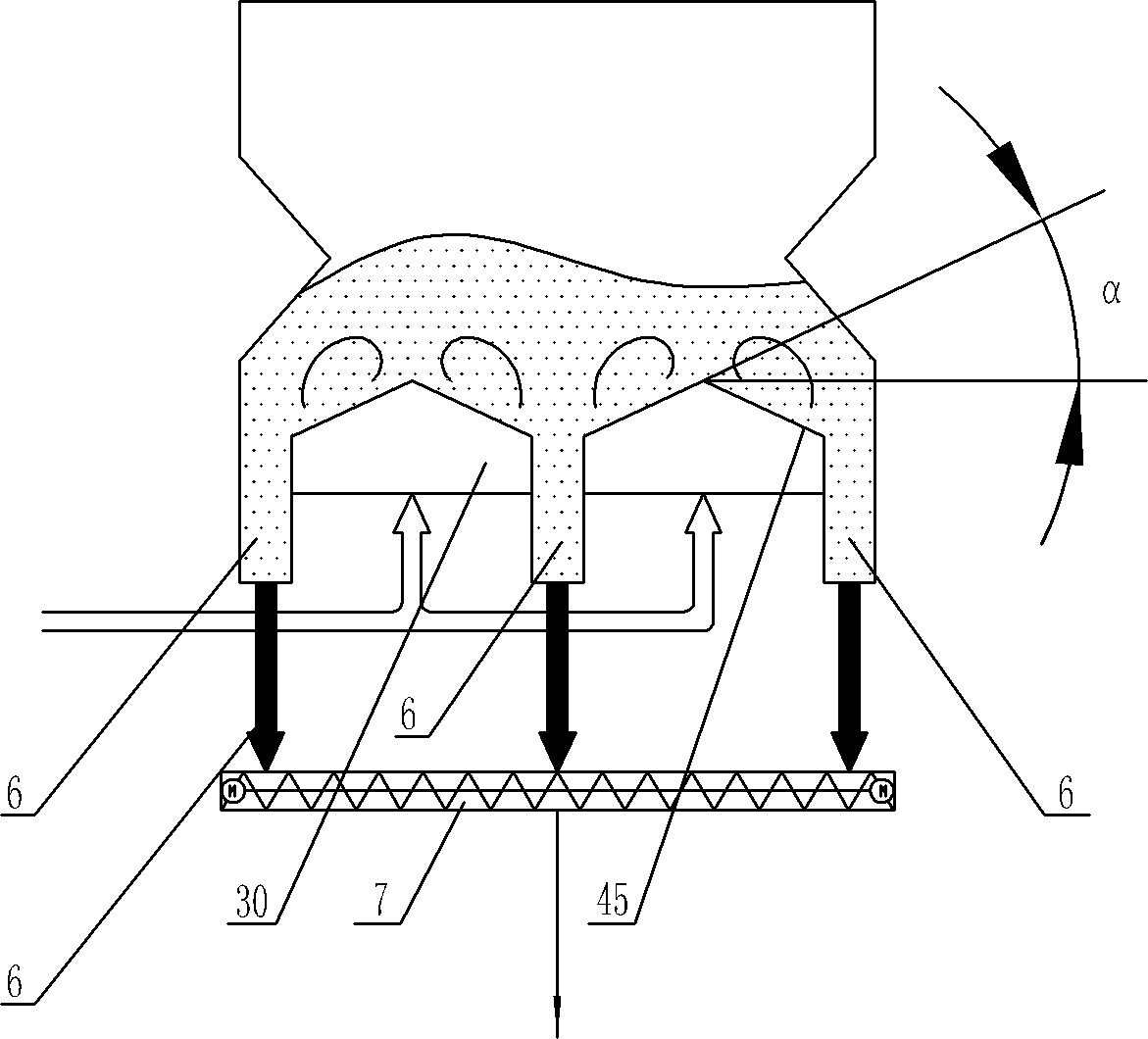

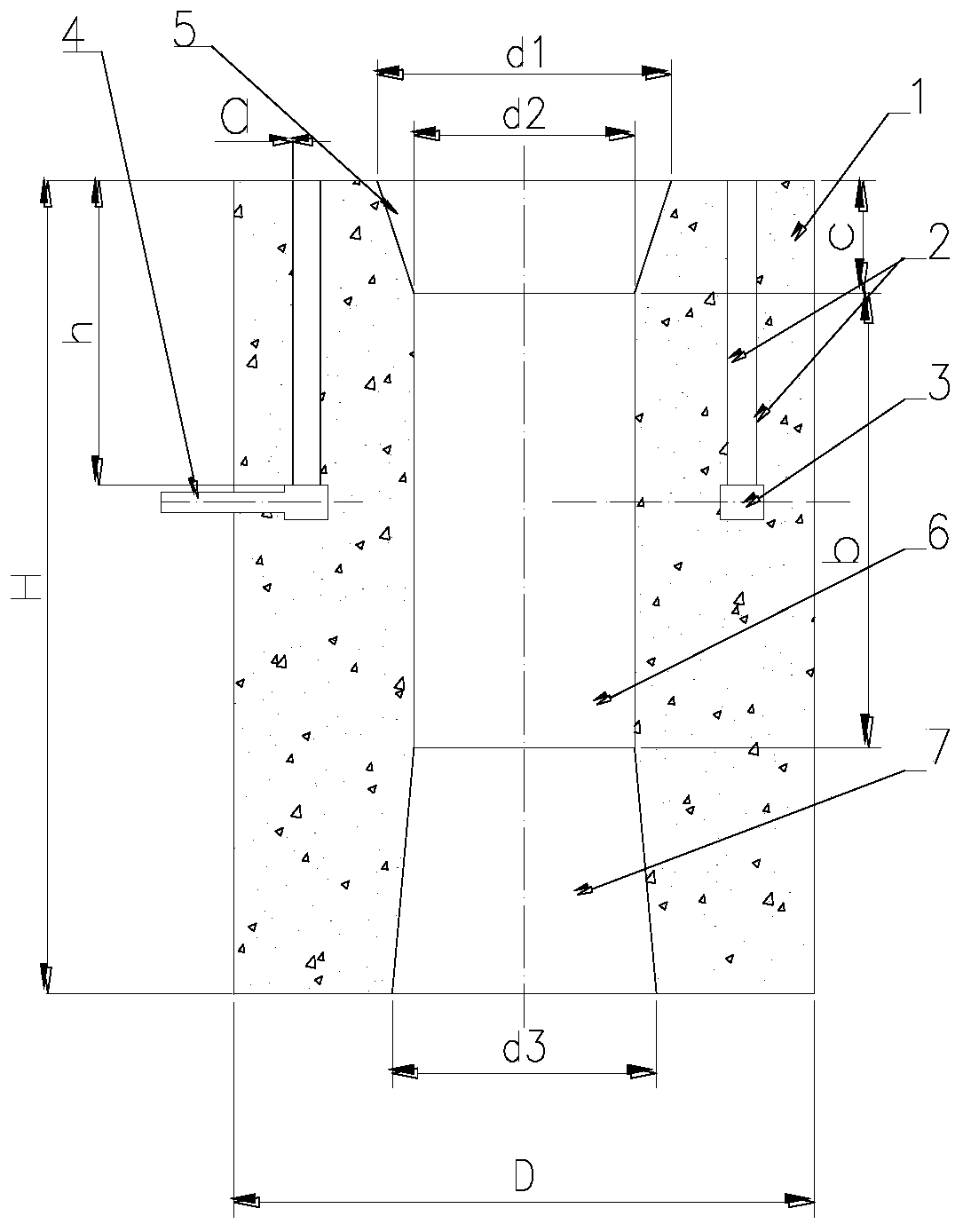

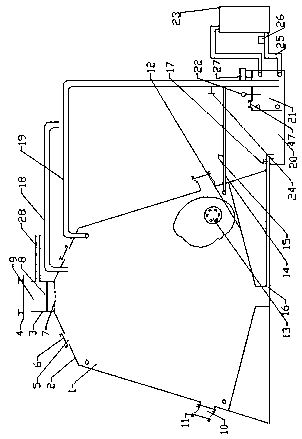

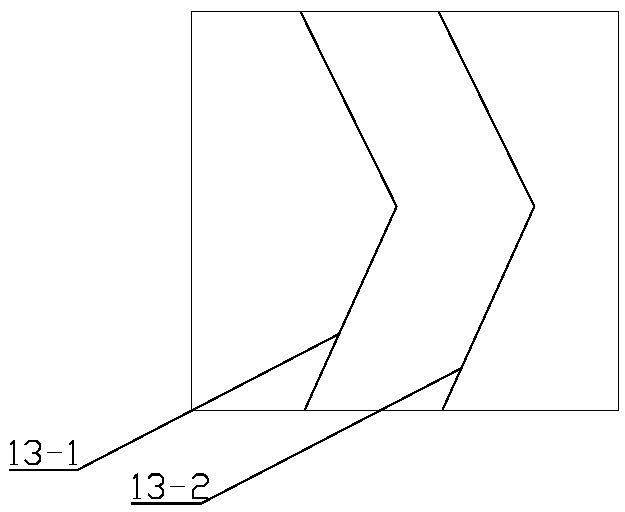

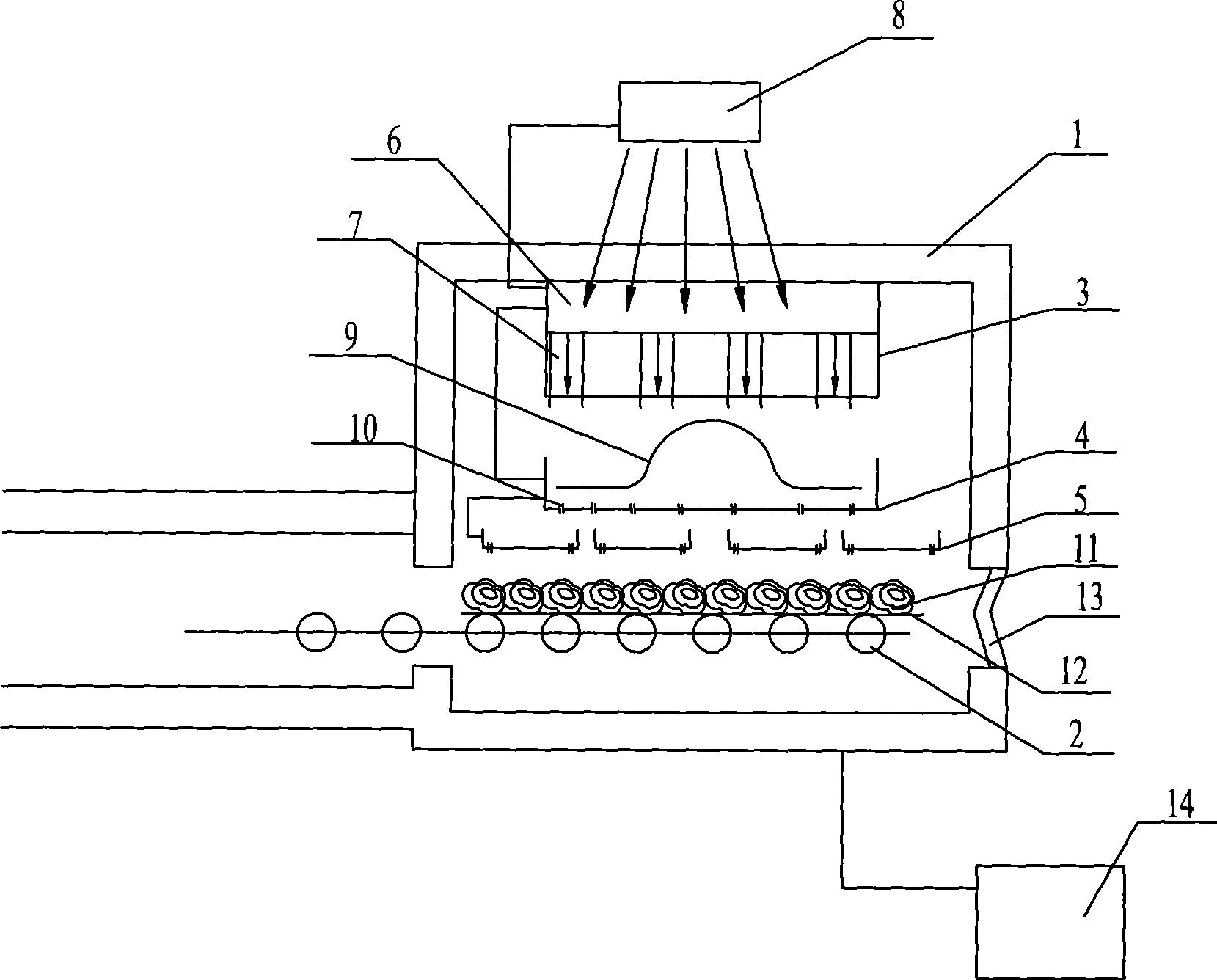

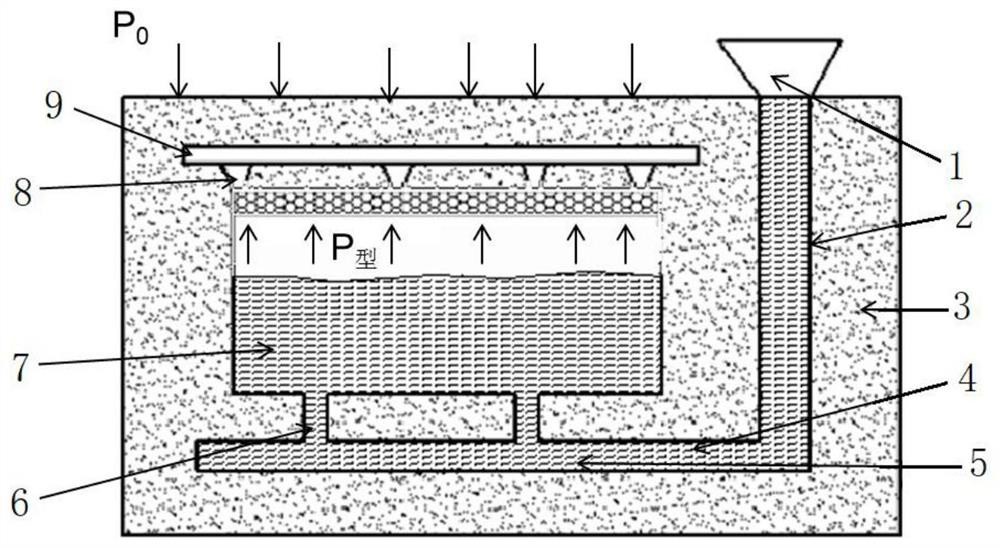

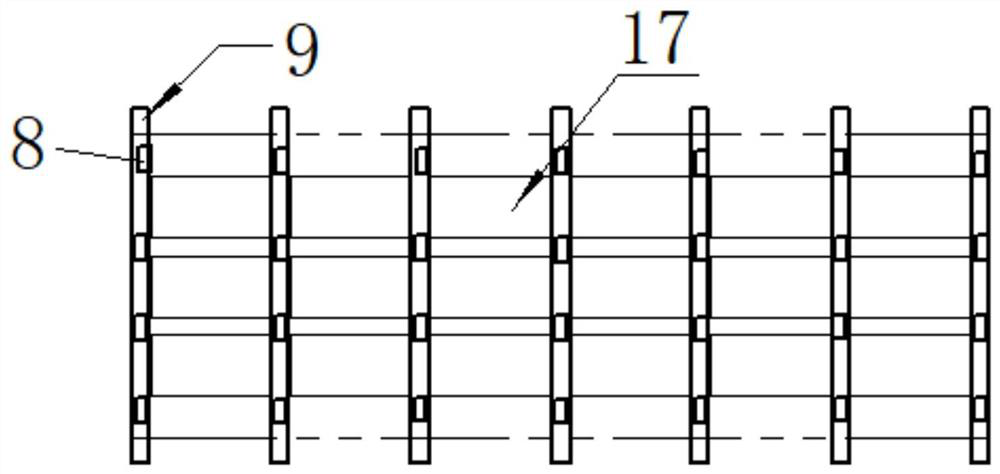

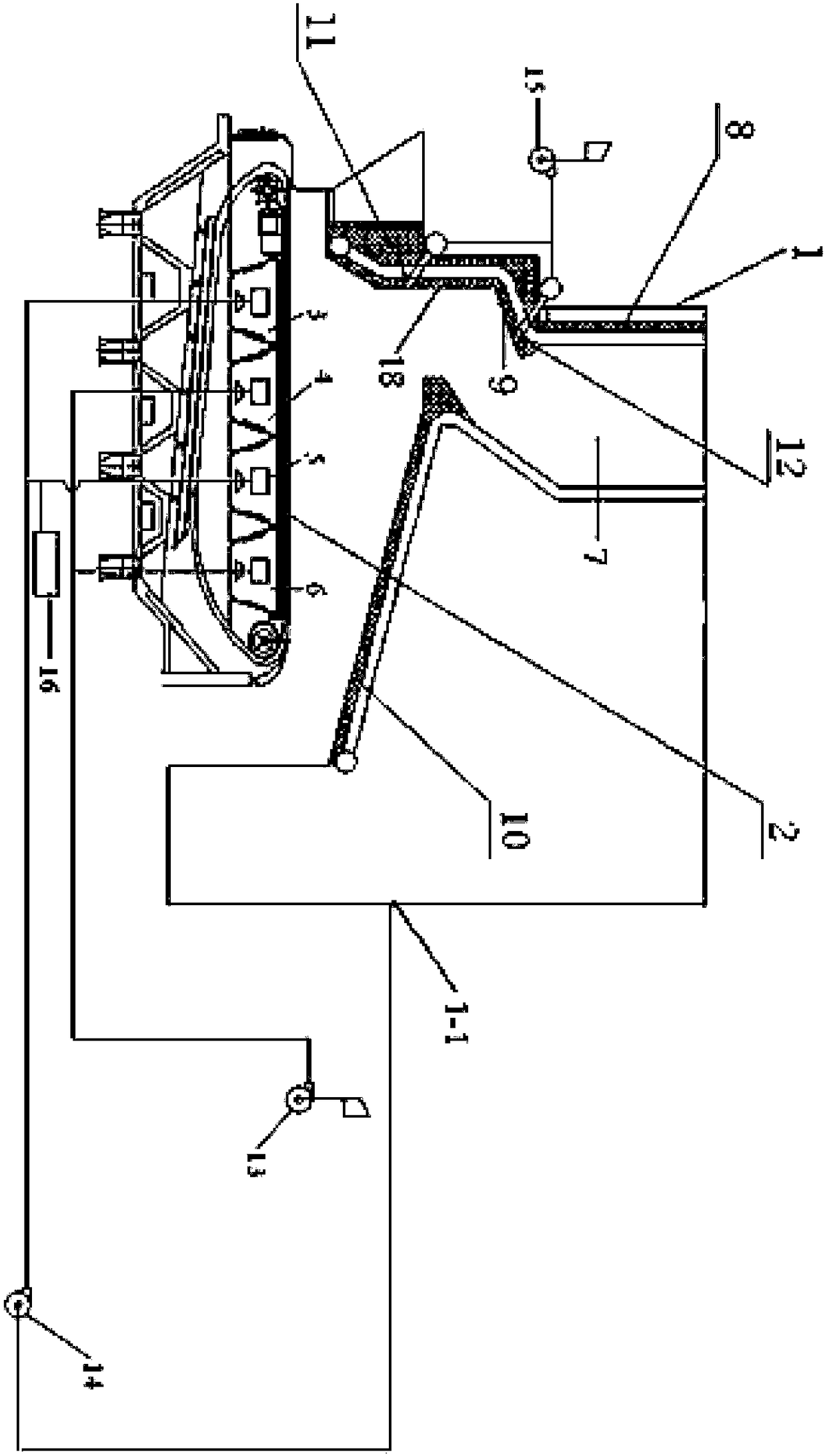

The invention discloses a circulating fluidized bed garbage incineration boiler and a pollution control system with the same, which relate to a garbage incineration boiler and a pollution control system with the same, and aim to solve the problems that the conventional circulating fluidized bed garbage incineration furnace difficultly discharges slag and is required to be stopped regularly to remove the slag and the economy of a garbage incineration plant is influenced. According to the scheme I, a circulating fluidized bed and double V-shaped wind distributing plates are arranged in a boiler body, the boiler body, a separator, a flue gas cooling chamber and a tail flue are communicated in sequence, an upper level low-temperature superheater, a lower level low-temperature superheater, a primary wind air preheater, a secondary wind air preheater, an upper level primary wind economizer, a lower level primary wind economizer, an upper level secondary wind economizer and a lower level secondary wind economizer are arranged in the tail flue, and the separator is communicated with the boiler body by a U-shaped valve; different from the scheme I, the scheme III is characterized in that: double inverted V-shaped wind distributing plates are adopted; different from the scheme III, the scheme V is characterized in that: an inverted V-shaped wind distributing plate is adopted; and according to the scheme II, the scheme IV and the scheme VI, a semidry reaction tower, a bag-type dust collector, an induced draft fan, a chimney, a fly ash cabin, a lime slurry preparation system, a rotary atomizer and an active carbon injecting device are added on the basis of the scheme I, the scheme III and the scheme V. The circulating fluidized bed garbage incineration boiler and the pollution control system with the same are used for incinerating garbage, and pollutant emission can be controlled.

Owner:无锡光核新能源建设有限公司

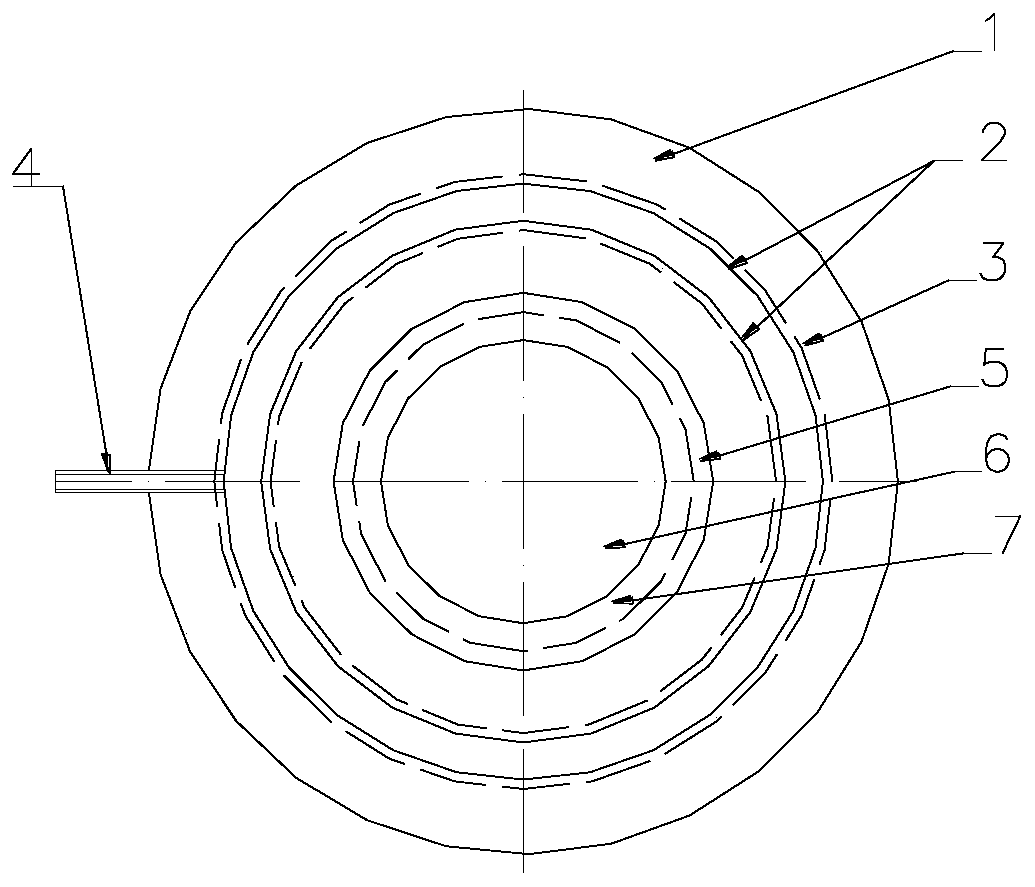

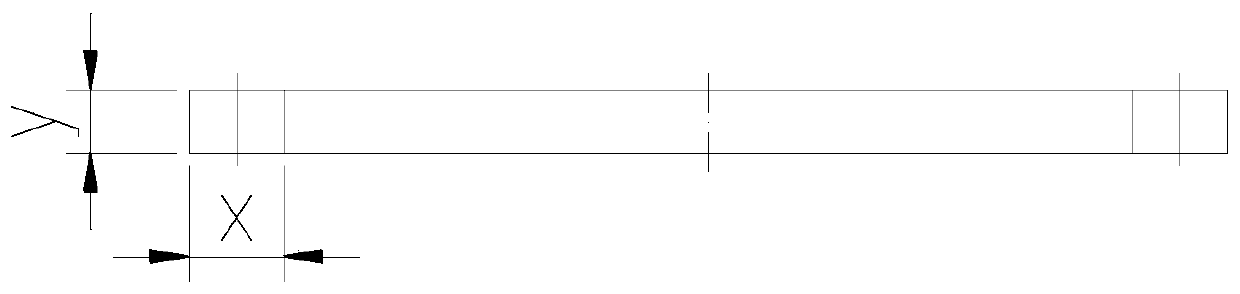

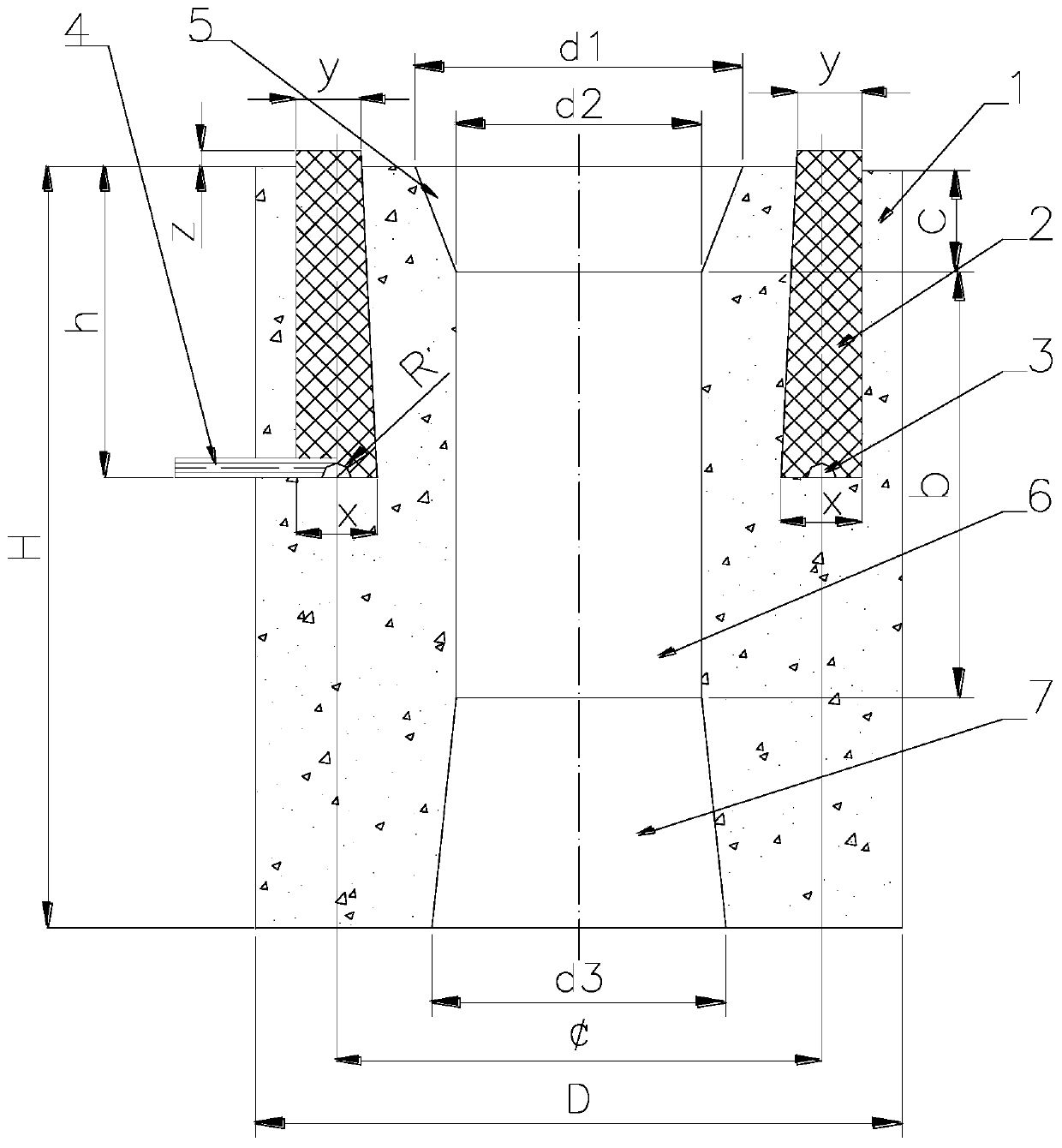

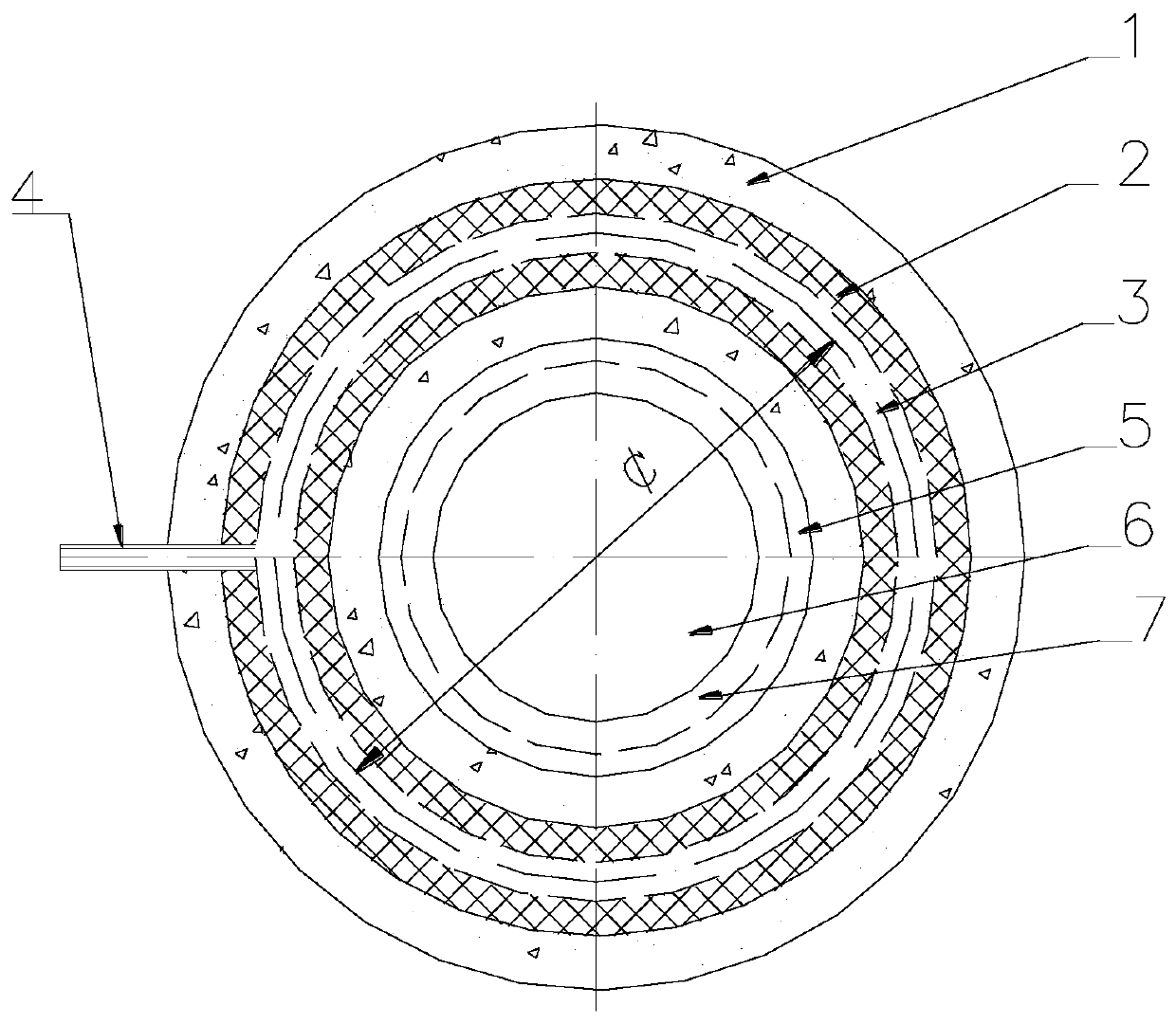

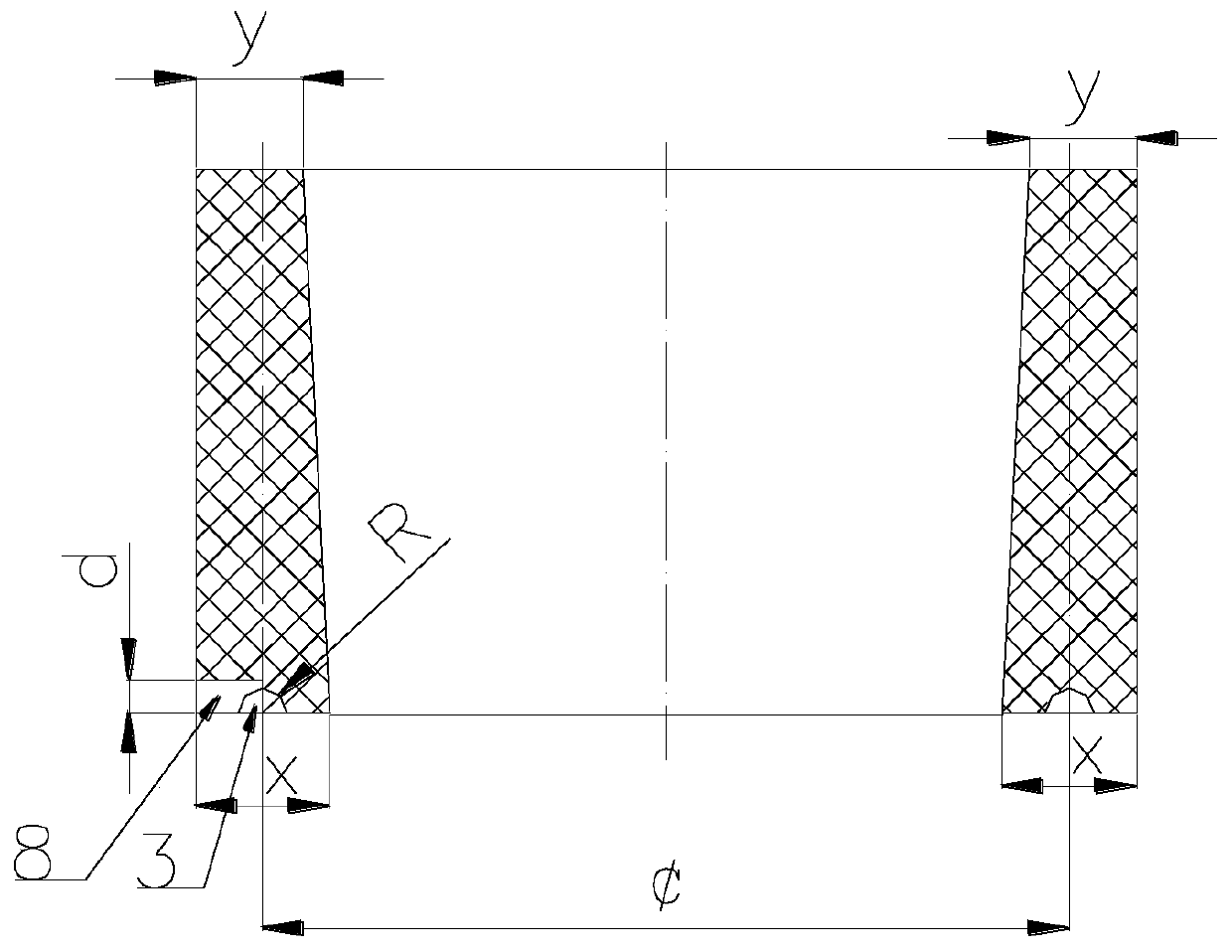

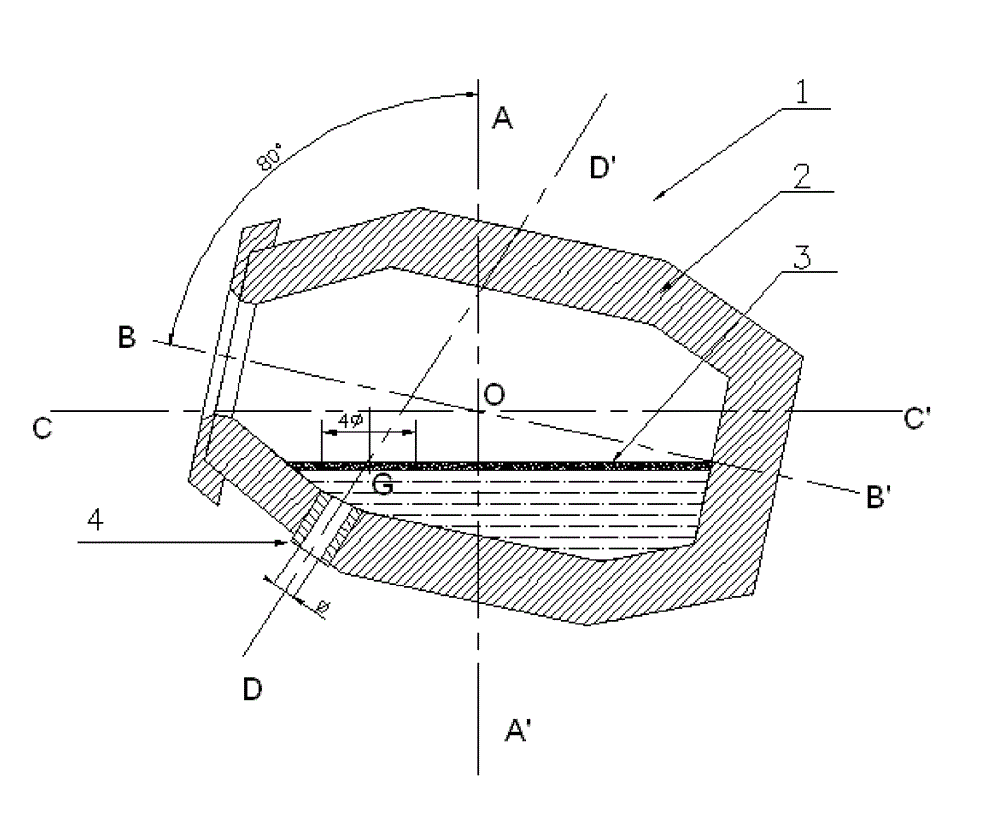

Steel ladle circumferential weld type ventilating water feeding opening seat block and argon blowing metallurgy method thereof

PendingCN109719290AInhibit slagSolve the slag problemMelt-holding vesselsProcess efficiency improvementSlagEngineering

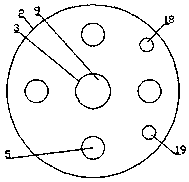

The invention relates to a steel ladle circumferential weld type ventilating water feeding opening seat block. The steel ladle circumferential weld type ventilating water feeding opening seat block comprises a steel ladle water feeding opening seat block body, circumferential welds, an air chamber box and an air inlet pipe, and a liquid steel hole, a connecting hole and a water feeding opening mounting hole which penetrate up and down are formed in the middle of the steel ladle water feeding opening seat block body. In the casting steel ladle pouring process, argon is blown in all the way, theargon flow is automatically adjusted according to changing of the net weight of steel ladle inner molten steel, the argon penetrates through the circumferential welds to form tiny argon bubbles, mostargon bubbles move upwards to form an annular air curtain screen on the periphery of a steel ladle water feeding opening, air purge is carried out on molten steel about to enter the steel ladle waterfeeding opening, stable and continuous annular air flow is formed in the water feeding opening, accretion of water feeding opening is restrained, and in the steel ladle pouring later period, steel ladle roughing slag caused by flow vortex and current drainage sunken pit is effectively restrained.

Owner:SHANDONG IRON & STEEL CO LTD

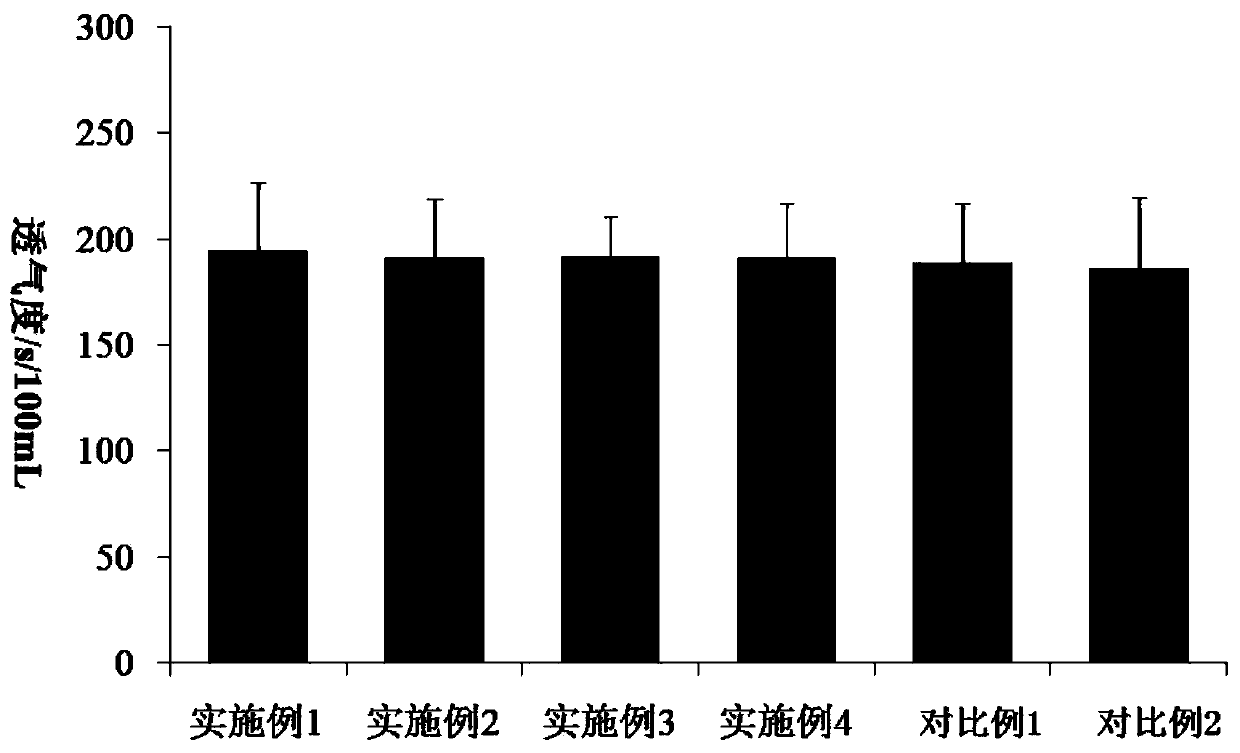

Infrared radiation coating and preparation method thereof

The invention discloses an infrared radiation coating. The infrared radiation coating is formed by mixing a solid material with a liquid material based on a weight ratio of 1:1, wherein grain sizes of the components of the coating are from 100 nanometers to 2 microns; the liquid material is an adhesion agent; and the solid material comprises the following components in percentage by weight: 45-75percent of blackening agent, 20-45 percent of zircon sand and 0-15 percent of aluminum oxide. The grains sizes of the principal components of the coating are from 100 nanometers to 2 microns, so thatthe radiation property of the coating is improved and the service life of the coating is prolonged. The radiance (Epsilon) of the coating is higher at a high temperature of 1,000-1,400 DEG C and can reach more than 0.9; and even at the temperature of 1500 DEG C, the stable radiation still can be maintained and the normal total emissivity of the coating still can reach 0.87; meanwhile, the infrared radiation coating can be applied to different heating types of kilns.

Owner:唐山晟科陶瓷制品有限公司

Steel-ladle diffusion ring gas-permeable upper nozzle seat brick and argon blowing metallurgy method thereof

PendingCN109732074ASolve the breathability problemSolve quality problemsMelt-holding vesselsProgramme control in sequence/logic controllersBrickSlag

The invention relates to a steel-ladle gas-permeable upper nozzle seat brick. The steel-ladle gas-permeable upper nozzle seat brick comprises an upper nozzle seat brick body, a diffusion type gas-permeable ring, a gas chamber box and a gas inlet pipe, wherein a steel flowing hole, a connecting hole and an upper nozzle installing hole which vertically penetrate are formed in the middle of the steel-ladle upper nozzle seat brick body. In the continuous-casting steel-ladle pouring process, argon is blown in the whole process, and the flow rate of argon is automatically adjusted according to changes of net weight of molten steel in a steel ladle; the argon permeates through the diffusion type gas-permeable ring to form tiny argon bubbles, most of the argon bubbles move upwards to form an annular gas curtain barrier around the steel-ladle upper nozzle, and the molten steel to be fed into the steel-ladle upper nozzle is subjected to gas washing; and a stable and continuous annular gas flow is formed in the upper nozzle for preventing nodulation of the upper nozzle, and at the later stage of the steel ladle pouring, the steel-ladle lower slag caused by a conflux vortex and a discharge pitcan be effectively inhibited. By means of the steel-ladle gas-permeable upper nozzle seat brick, compared with the prior art, the pouring margin of the molten steel in the steel ladle can be reducedby 36% or above, and the weight of electrolytic inclusions of a continuous casting blank sample is reduced by 35% or above.

Owner:SHANDONG IRON & STEEL CO LTD

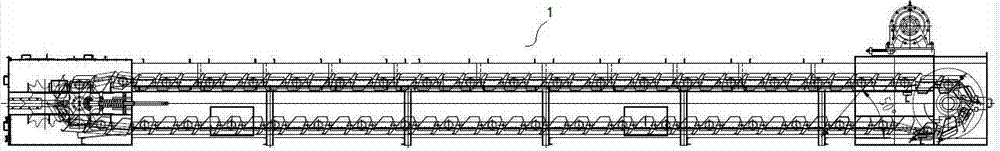

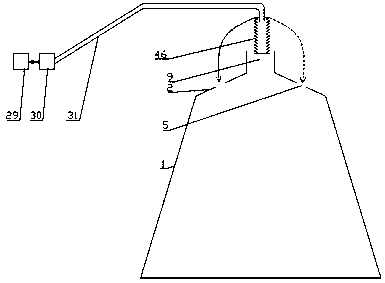

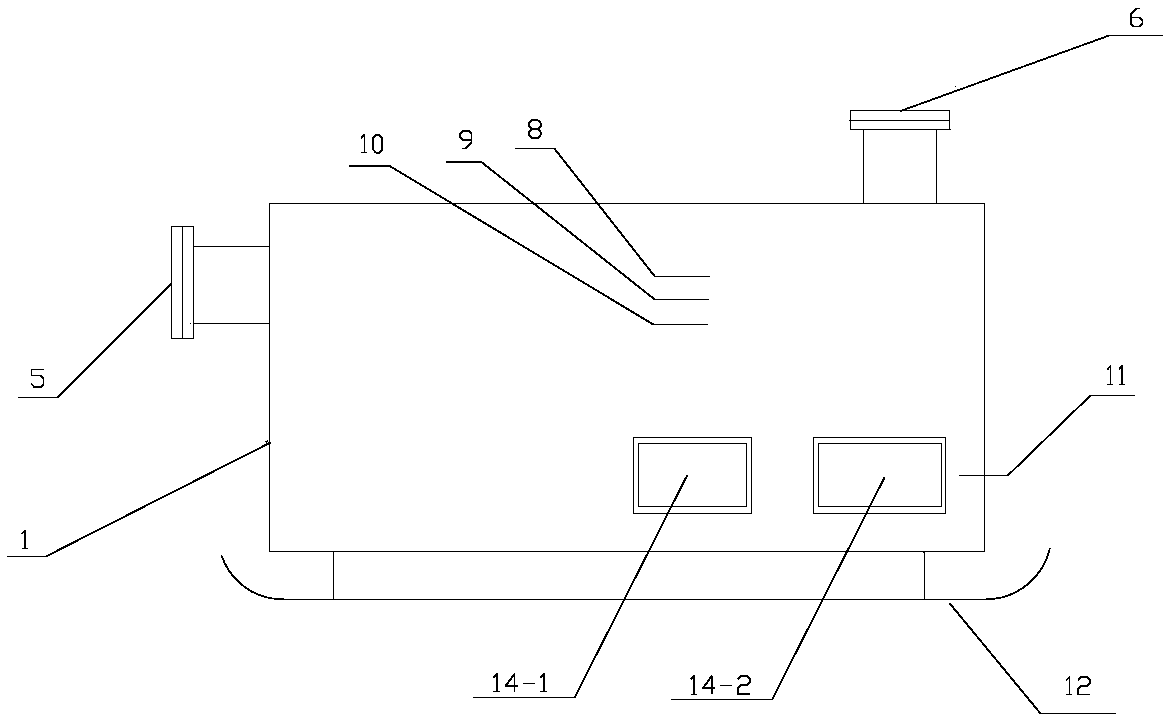

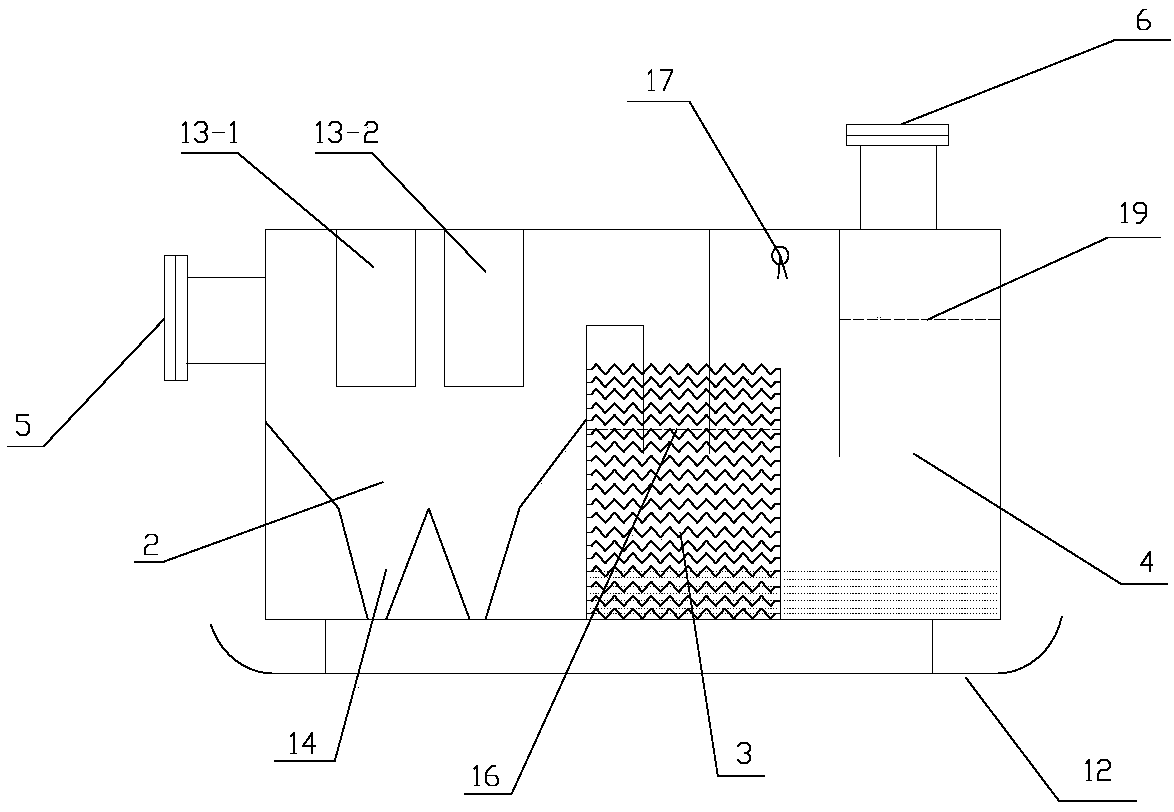

Anti-slagging biomass cascade conversion combustion device

ActiveCN106594713APrevent slaggingThermochemical conversion achievedSolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterWater vapor

The invention provides an anti-slagging biomass cascade conversion combustion device and relates to a biomass combustion device. The anti-slagging biomass cascade conversion combustion device aims at solving the technical problem that slagging happens easily when straw is combusted through an existing chain furnace. The anti-slagging biomass cascade conversion combustion device is composed of a chain furnace, a steam generator, an air blower, a high-temperature induced draft fan and an air preheater. A secondary air nozzle is arranged on the front wall below a front arch. An overfire air nozzle is arranged on the front arch. A circulating flue gas chamber communicates with a flue opening in the tail of the chain furnace through the high-temperature induced draft fan. A weak primary air chamber communicates with the air blower through the air preheater. A steam-circulating flue gas chamber communicates with the steam generator and the high-temperature induced draft fan. A strong primary air chamber communicates with the air blower through the air preheater. The secondary air nozzle communicates with the air blower. The overfire air nozzle communicates with the air blower. The anti-slagging biomass cascade conversion combustion device effectively solves the problem of slagging of biomass combustion chain grates.

Owner:HARBIN INST OF TECH

Production method of thick and large titanium alloy fired mold precision casting

InactiveCN106825409ASolve the problem of slaggingShorten the production cycleFoundry mouldsFoundry coresWaxDissolution

A production method of a thick and large titanium alloy fired mold precision casting comprises the following steps of wax mold preparation, two-time thick liquid adhering, titanium alloy fired mold casting preparation after mold shell back layer preparation, wax removing, high-temperature sintering, pouring, shell cleaning and pouring system removing in a constant-temperature constant-humidity workshop and titanium alloy fired mold precision casting obtaining through quality defect removing of a titanium alloy fired mold casting. According to the production method of the thick and large titanium alloy fired mold precision casting, an innovative technological design philosophy is adopted in the whole process, and the problems of wax-removing face layer re-dissolution, internal residue adding and surface cracking of the thick and large titanium alloy fired mold precision casting are solved through reasonable production technological scheme route formulating, mold shell face layer proportion selecting and pickling technology formulating; and meanwhile, production cost can be effectively reduced, the production period is shortened, the follow-up repairing time is reduced, and the surface quality of the casting is promoted.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Low-carbon free-cutting sulfur narrow strip steel and production method thereof

ActiveCN109055853AQuality improvementAvoid it happening againProcess efficiency improvementMetal rolling arrangementsSlagStrip steel

The invention belongs to the technical field of production of strip steel of plates, and particularly relates to low-carbon free-cutting sulfur narrow strip steel and a production method thereof. Thelow-carbon free-cutting sulfur narrow strip steel is characterized in that the carbon and oxygen equilibrium in molten steel is controlled to omega [C].omega[O]<=6.5*10<-4>. The invention further provides the production method of the low-carbon free-cutting sulfur narrow strip steel. Under the condition that the carbon and oxygen equilibrium in molten steel is controlled to omega [C].omega[O]<=6.5*10<-4>, subsurface bubbles of a cast blank can be avoided, and the surface quality of the cast blank is improved. In the refining process, the molten steel is deoxidized through a Ca feeding line, sothat CaO inclusions generated in the deoxidization process are small, spindle-shaped MnS can be formed, and thus, the cutability of the steel is improved. Meanwhile, scabbing of a continuous castingnozzle, slag entrapment of a crystallizer, steel leakage during continuous casting and cracks of rolled products are avoided, and the sulfur content and the oxygen content are controlled.

Owner:SHANDONG IRON & STEEL CO LTD

Environment-friendly building brick and preparation method thereof

InactiveCN107814557AGood physical propertiesHigh strengthCeramic materials productionClaywaresBrickMaterials science

The invention discloses an environment-friendly building brick and a preparation method thereof. The environment-friendly building brick is prepared from the following raw materials in parts by weight: 60 to 80 parts of construction waste, 10 to 18 parts of coal ash, 15 to 30 parts of mineral residue, 3 to 10 parts of marble, 1 to 2 parts of magnet, 1 to 3 parts of medical stone, 3 to 7 parts of fluorite, 1 to 2 parts of alundum powder, 15 to 30 parts of clay, 0.1 to 0.5 part of shell active carbon, 0.1 to 0.3 part of nanoscale aluminum oxide, 0.08 to 0.12 part of sodium rosinate, 0.05 to 0.1part of sodium tripolyphosphate, and 10 to 15 parts of water. The building brick has the advantages of high strength, good wear resistance, acid and alkali corrosion resistance, high compactness and the like, also has insecticidal and healthcare functions, and has a good visual effect.

Owner:QINGYANG DUNBO TECH DEV CO LTD

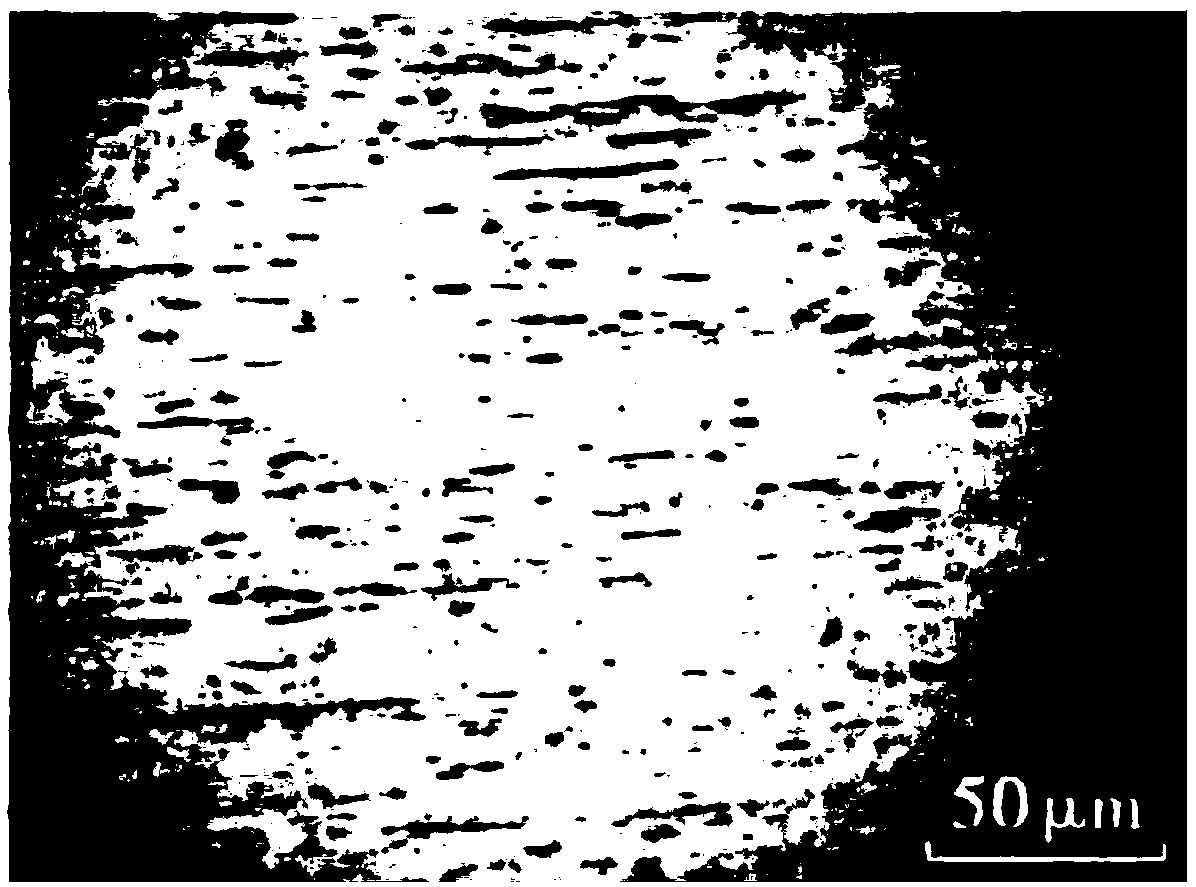

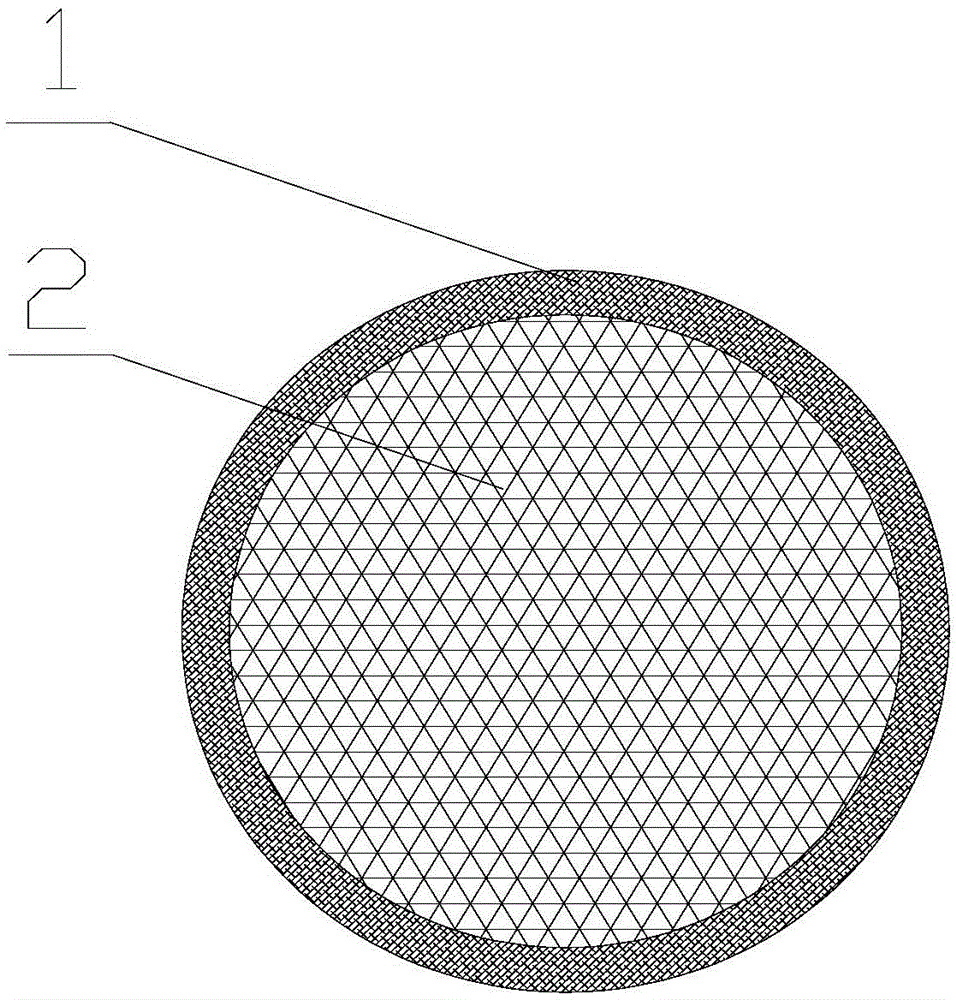

Carbon fiber composite ball and preparation method thereof

The invention discloses a carbon fiber composite ball and a preparation method thereof. The carbon fiber composite ball consists of a hard carbon fiber ball and a resin carbon layer covering the surface of the hard carbon fiber ball. The preparation method for the carbon fiber composite ball consists of the steps of fiber crushing and mixing; balling granulation; secondary balling granulation; solidification; carbonization and graphitization. The carbon fiber composite ball and the preparation method thereof have the characteristics that chopped carbon fibers or ground carbon fibers are sized, so that transportation and use are facilitated; due to high-carbon-fiber content balling, a well-developed porous structure is provided; the carbon fiber composite ball can be applied to the aspects of adsorption, heat preservation, a phase change energy storage carrier and the like; the field of application of the chopped carbon fibers is expanded; the preparation technology is relatively simple; and particularly compared with a hard carbon fiber heat preservation felt, the carbon fiber composite ball is suitable for large-scale continuous production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

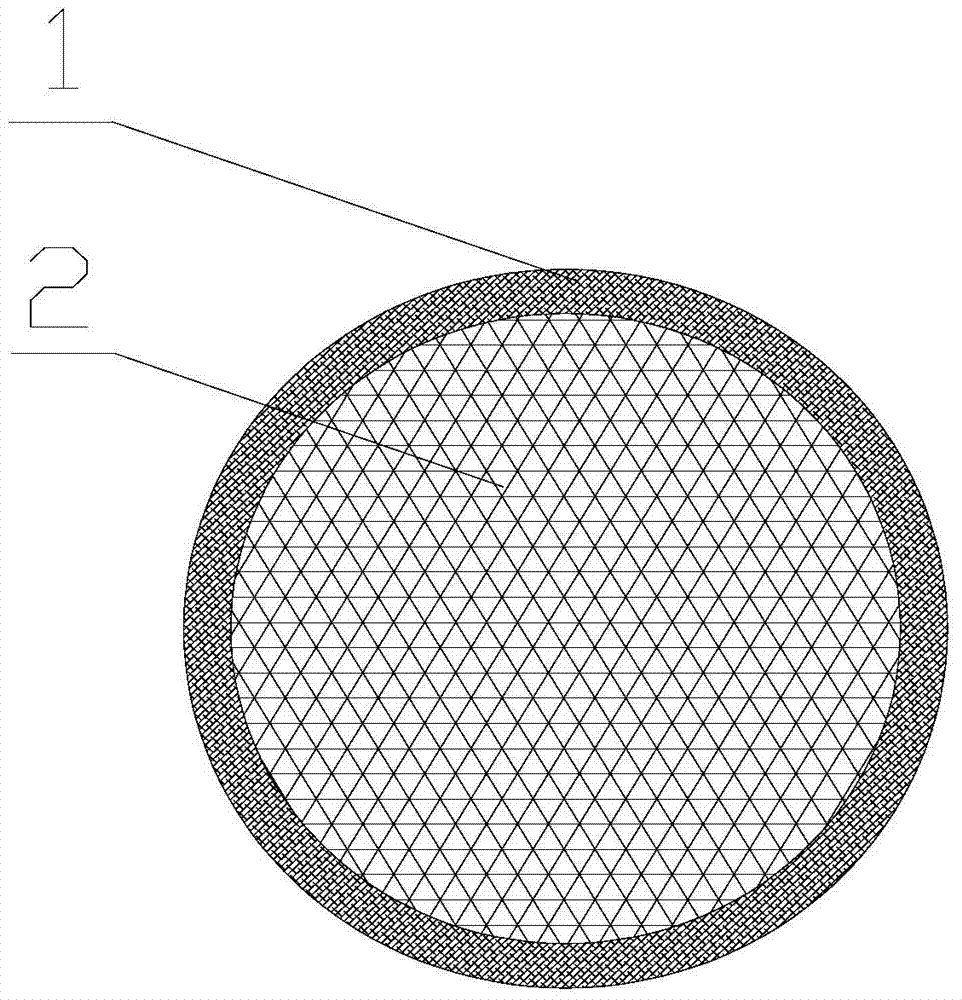

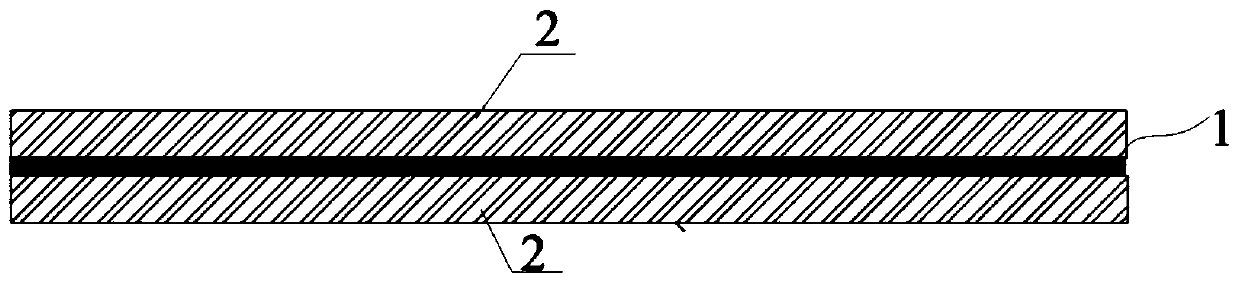

Composite isolating membrane of lithium ion battery and preparation method and application of composite isolating membrane

ActiveCN110416475AImprove heat resistanceSolve powder dropSecondary cellsCell component detailsFunctional monomerStructural formula

The invention discloses a composite isolating membrane of a lithium ion battery and a preparation method and application of the composite isolating membrane, and belongs to the technical field of lithium ion batteries. The composite isolating membrane comprises an organic / inorganic hybrid polymer bonding layer and porous base membranes positioned at the upper end and the lower end of the organic / inorganic hybrid polymer bonding layer, wherein the organic / inorganic hybrid polymer bonding layer is a copolymer of modified silicon dioxide and an organic functional monomer, the modified silicon dioxide is silicon dioxide of which the surface is modified by double bonds, and the structural formula of the organic functional monomer comprises at least one of unsaturated double bonds or triple bonds. The composite isolating membrane designed by the invention is good in thermal stability and excellent in air permeability, and the lithium ion battery prepared from the composite isolating membraneis relatively good in cycling stability.

Owner:湖北锂诺新能源科技有限公司

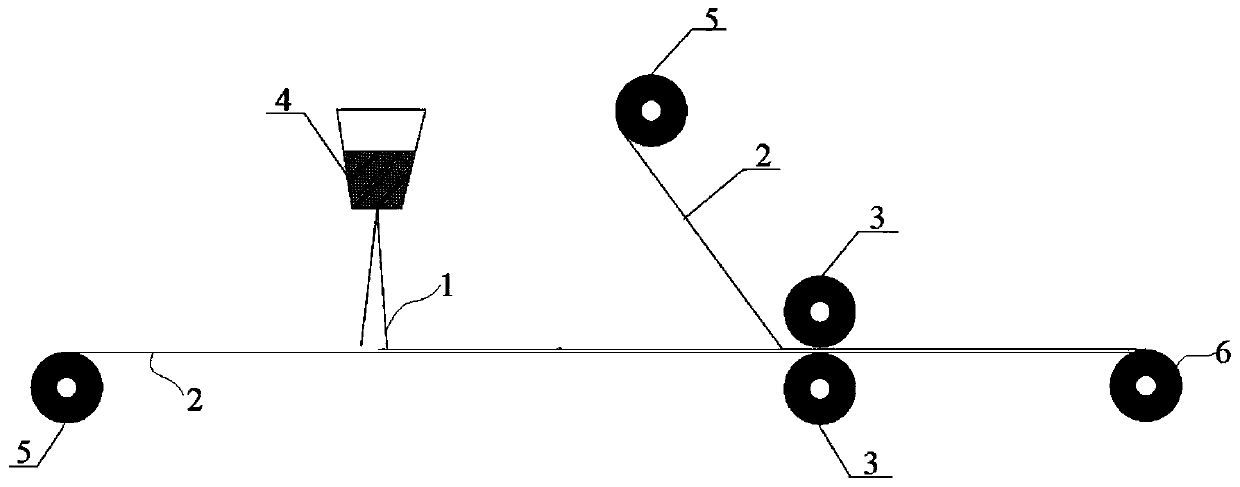

Chlorpyrifos microcapsule suspension seed coating agent for controlling underground pests and preparation method thereof

InactiveCN102197823AEffective protectionLong durationBiocideArthropodicidesChlorpyrifosFilm-forming agent

The invention discloses a chlorpyrifos microcapsule suspension seed coating agent for controlling underground pests and a preparation method thereof. The chlorpyrifos microcapsule suspension seed coating agent comprises chlorpyrifos technical, solvent oil No.500, a capsule wall material, an emulsifying agent, a film forming agent, a dispersant, an organic silicon defoaming agent and water. The chlorpyrifos microcapsule suspension seed coating agent can release active ingredients slowly, so that the duration of the pesticide effect is effectively prolonged, the safety of the pesticide agent is increased at the same time, and particularly, an obvious effect of controlling the underground pests is achieved. The chlorpyrifos microcapsule suspension seed coating agent has seed coating film-forming property, and can uniformly coat chlorpyrifos microcapsules on the surface of a seed so as to protect the seed effectively and prevent the seed from being damaged by the underground pests.

Owner:JIANGSU BAOLING CHEM

Dietary fiber instant rice grain noodle production process

The present invention provides a dietary fiber instant rice grain noodle production process, which comprises screening, mixing, constant temperature and constant humidity conditioning, extrusion granulation molding, drying, and cooling. According to the dietary fiber instant rice grain noodle production process, wheat dietary fibers are added to the formula so as to slow down formation of starch crystal and gluten network structure in flour during extrusion in the extrusion process, such that no gas hole is generated in the rice grain noodle, the obtained rice grain noodle has a compact structure, the dietary fiber content in the rice grain noodle is increased, and the taste of the rice grain noodle is ensured; and the appropriate proportion of propylene glycol alginate and sucrose fatty acid ester are added, such that the problem of easy dreg shedding or rough surface of the rice grain noodle prepared by adding the wheat dietary fibers is solved.

Owner:江苏江南上一道科技股份有限公司

Modification method of melamine foam

The invention provides a modification method of melamine foam, and relates to the technical field of foam material modification. Modified melamine foam is prepared from, by weight, 40-50 parts of melamine, 20-30 parts of formaldehyde, 4-5 parts of polyvinyl alcohol, 1-2 parts of copper sulfate, 1-2 parts of zinc chloride, 2-3 parts of aluminum stearate, 3-4 parts of a silane coupling agent, 2-4 parts of a stabilizer, 1-3 parts of an antioxidant, 3-5 parts of a plasticizer, 5-6 parts of a crosslinking agent and 6-8 parts of a foaming agent. The modification process of the melamine foam is optimized, and parts of additives are reasonably added, so the problems of high hardness, fragility, residue dropping and low strength of the melamine foam are effectively solved, and the performances of the melamine foam are obviously, thereby the quality of the melamine foam material is further improved.

Owner:徐州盛安化工科技有限公司

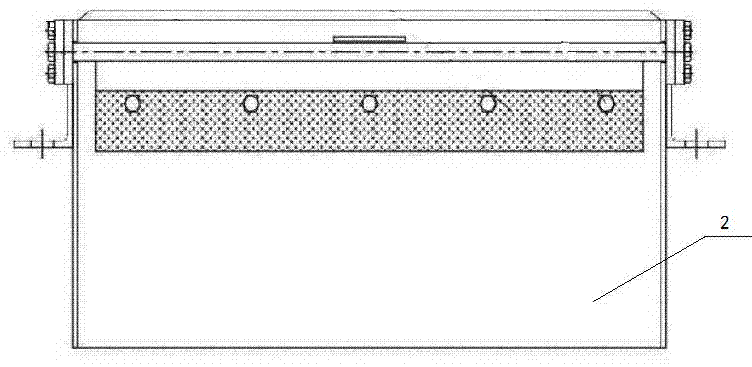

Automatic cleaning device of bucket chain conveyor

A bucket chain conveyor with a cleaning function comprises buckets which operate in a circulation and turnover mode. The bucket chain conveyor is characterized in that scraping plates are fixedly arranged on the discharging port sides of the buckets of the bucket chain conveyor, and part of the scraping plates are in a comb tooth shape, the other part of the scraping plates are in a toothless shape, and the scraping plates in the comb tooth shape and the scraping plates in the toothless shape are sequentially arranged at intervals on the buckets of the bucket chain conveyor, wherein the buckets operate in the circulation and turnover mode. The problem that slag is accumulated at the bottom of the bucket chain conveyor is solved, the accumulated slag at the bottom of a shell of the bucket chain conveyor can be fundamentally cleared, stability of equipment operation is improved, cost for equipment maintaining is reduced, and the utilization efficiency of the equipment is improved.

Owner:QINGDAO SONGLING POWER ENVIRONMENTAL EQUIP

High-temperature biogas production device in agricultural waste straw mixed raw materials

InactiveCN110628602ACompact structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsWater dischargeSlag

The invention discloses a device for preparing biogas from agricultural waste straw mixed raw materials at a medium-high temperature. The device comprises a double-cone fermentation tank and an automatic deslagging system, the double-cone fermentation tank and the automatic deslagging system comprise a fermentation tank body, the top of the fermentation tank body is provided with a tank top, the top of the tank top is connected to a gas storage tank, the gas storage tank is provided with a gas storage tank cover, the side wall of the gas storage tank is connected to a gas guide pipe, the conical tank top is provided with a peripheral feeding port, the conical tank top is provided with an overflow pipe and a backflow pipe, the lower end of the backflow pipe extends into a biogas slurry pool, and a heating circulating pipe is arranged in a biogas slurry heating chamber and is communicated with a boiler; inspection windows are arranged at the lower part of the fermentation tank and are matched with and connected to covers; and the bottom of the fermentation tank is provided with a slag discharging channel and a water discharging pipe which are communicated with the biogas slurry pool.The device has the advantages that the structure is compact, the design is reasonable, the straw biogas mixed raw material is subjected to stack retting in the fermentation tank by adopting a full-dry fermentation process, the stack retting temperature is as high as 60-70 DEG C, after the old biogas slurry returns, the straw mixed raw material can be subjected to medium-high temperature fermentation, the fermentation period is short, the gas production rate is high, and a large amount of crop straw can be consumed.

Owner:ANHUI WANEN BIOGAS TECH CO LTD

Slag stopping material, slag stopping method and combined technology method of slag stopping and slag splashing protection

InactiveCN102943143ASolve the problem of slaggingReduce thicknessManufacturing convertersMaterial consumptionSlag

The invention relates to a slag stopping material, a slag stopping method and a combined technology method of slag stopping and slag splashing protection. The sum of mass percentages of CaO, MgO and C in the slag stopping material accounts for over 40% of the total mass of the slag stopping material, igloss is smaller than 47% of the total mass of the slag stopping material, and the mass percent of C is not more than 25% of the total mass of the slag stopping material. The slag stopping method comprises the step of putting a certain amount of slag stopping material on the liquid level area over a steel tapping hole in a converter. The slag stopping material, the slag stopping method and the combined technology method of slag stopping and slag splashing protection have the following beneficial effects: roughing slag amount is reduced, the thickness of the slag blanket in a ladle is thinned obviously, the tasks of deoxidation of molten steel in the ladle and modification of top slag are relieved, the consumption of deoxidizer is lessened, the phenomena of rephosphorization and silicon pick up in the refining process of the molten steel are reduced, the consumption of slag regulating materials is lowered, the time of molten steel refining is shortened and the smelting cost is decreased; and after steel tapping is finished, the slag stopping material can be directly used as a slag splashing protection material, the use amount of the slag splashing protection material is reduced, the time of slag splashing protection is shortened and the working efficiency of the converter is enhanced.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

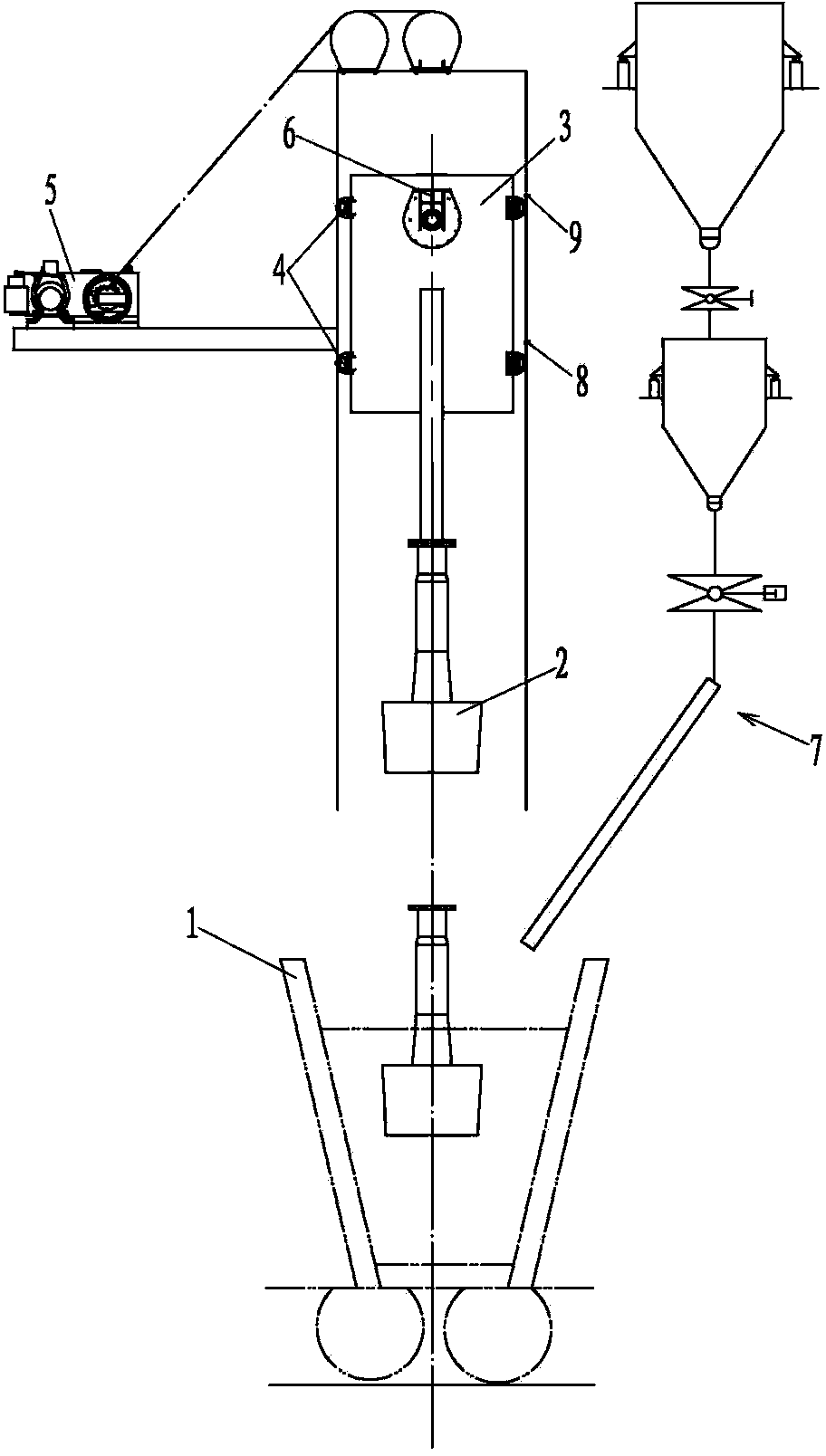

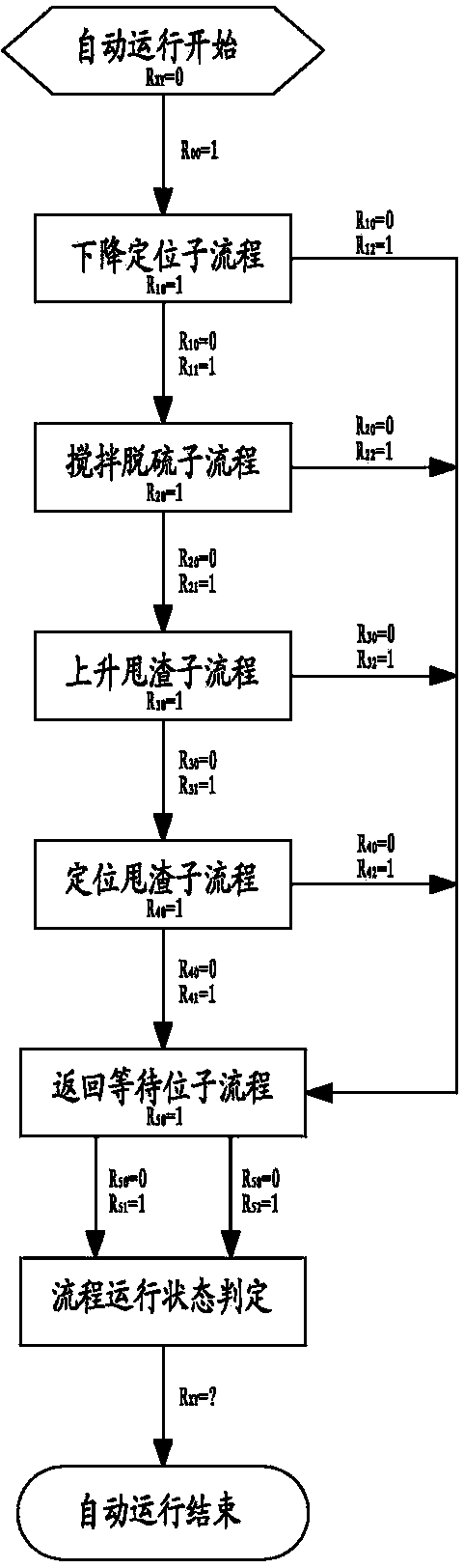

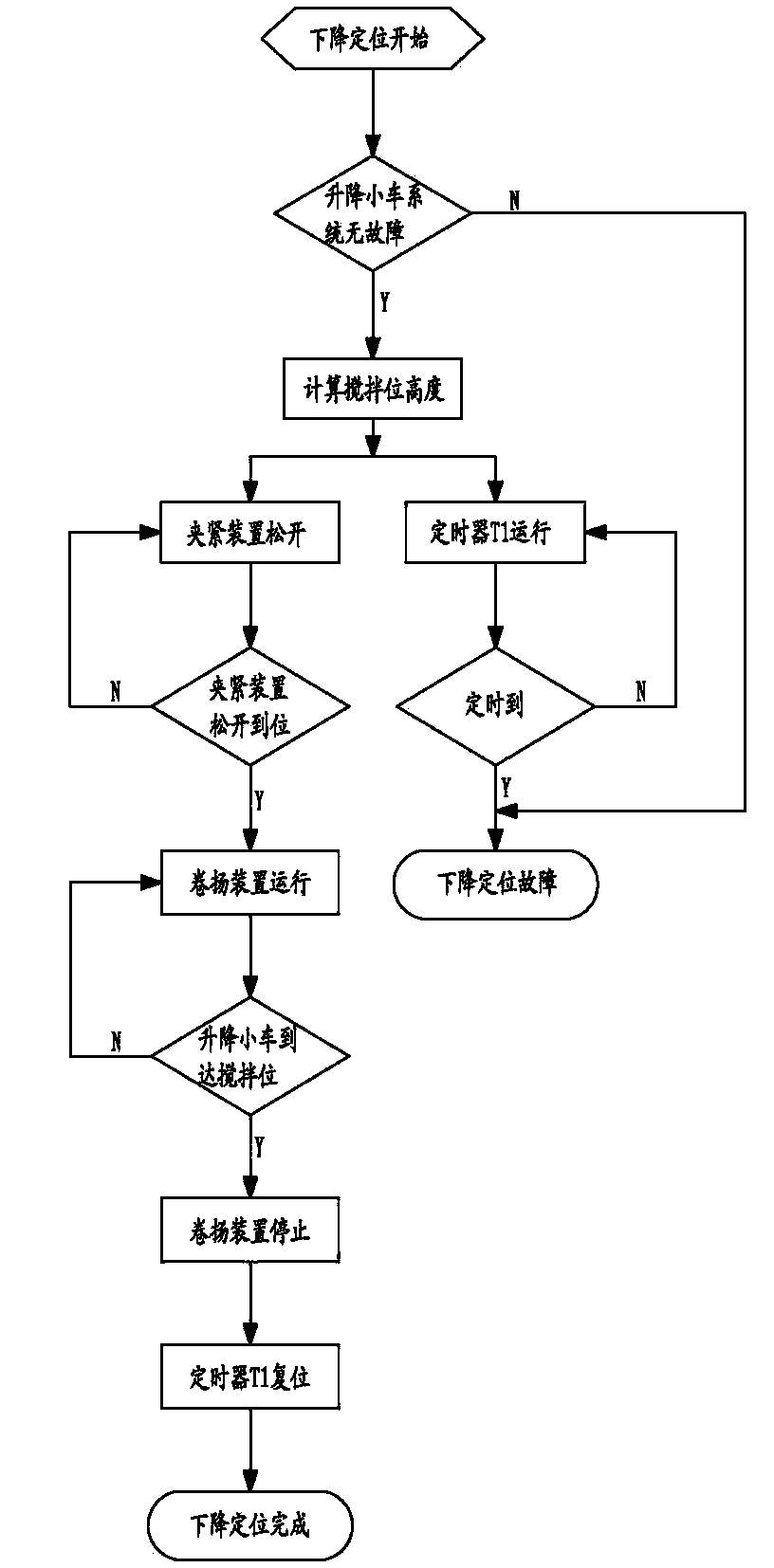

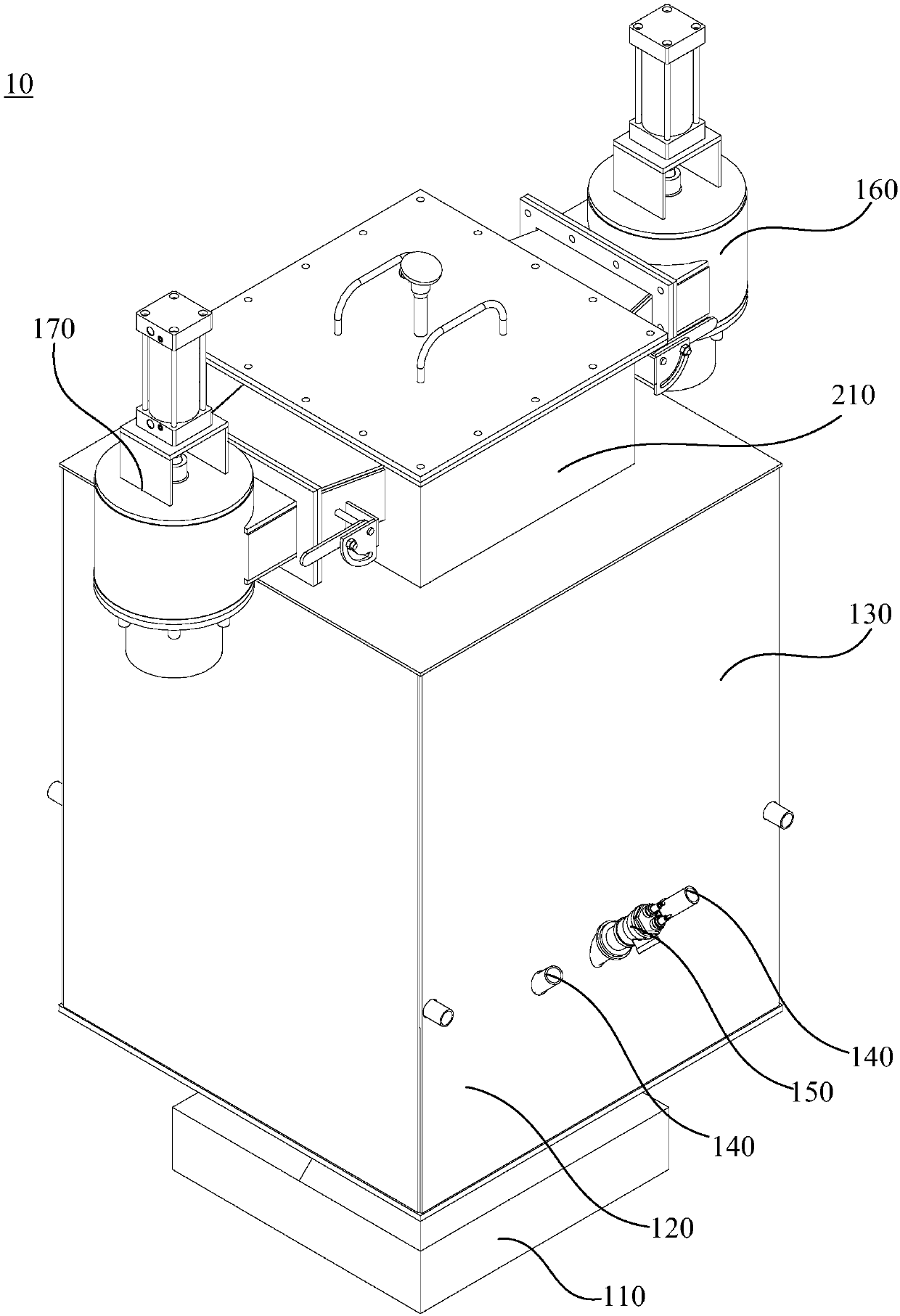

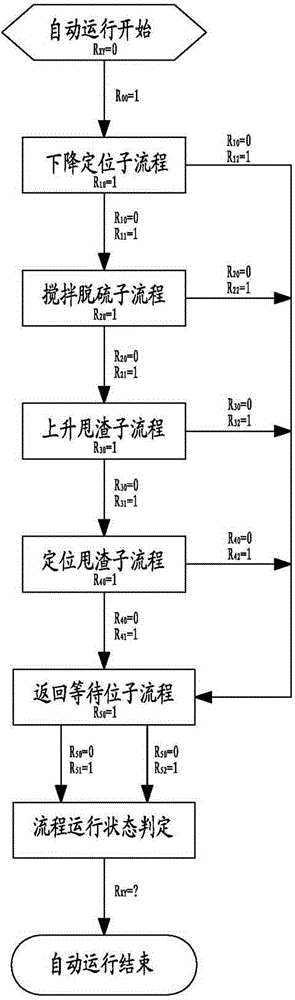

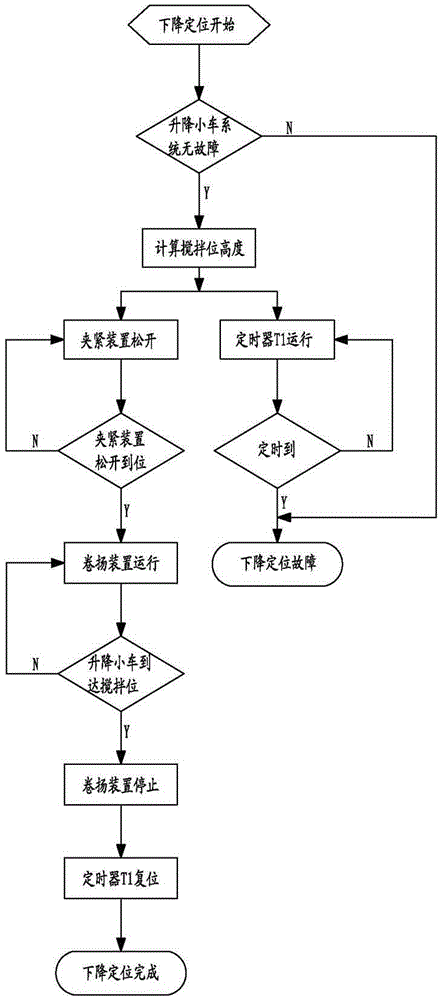

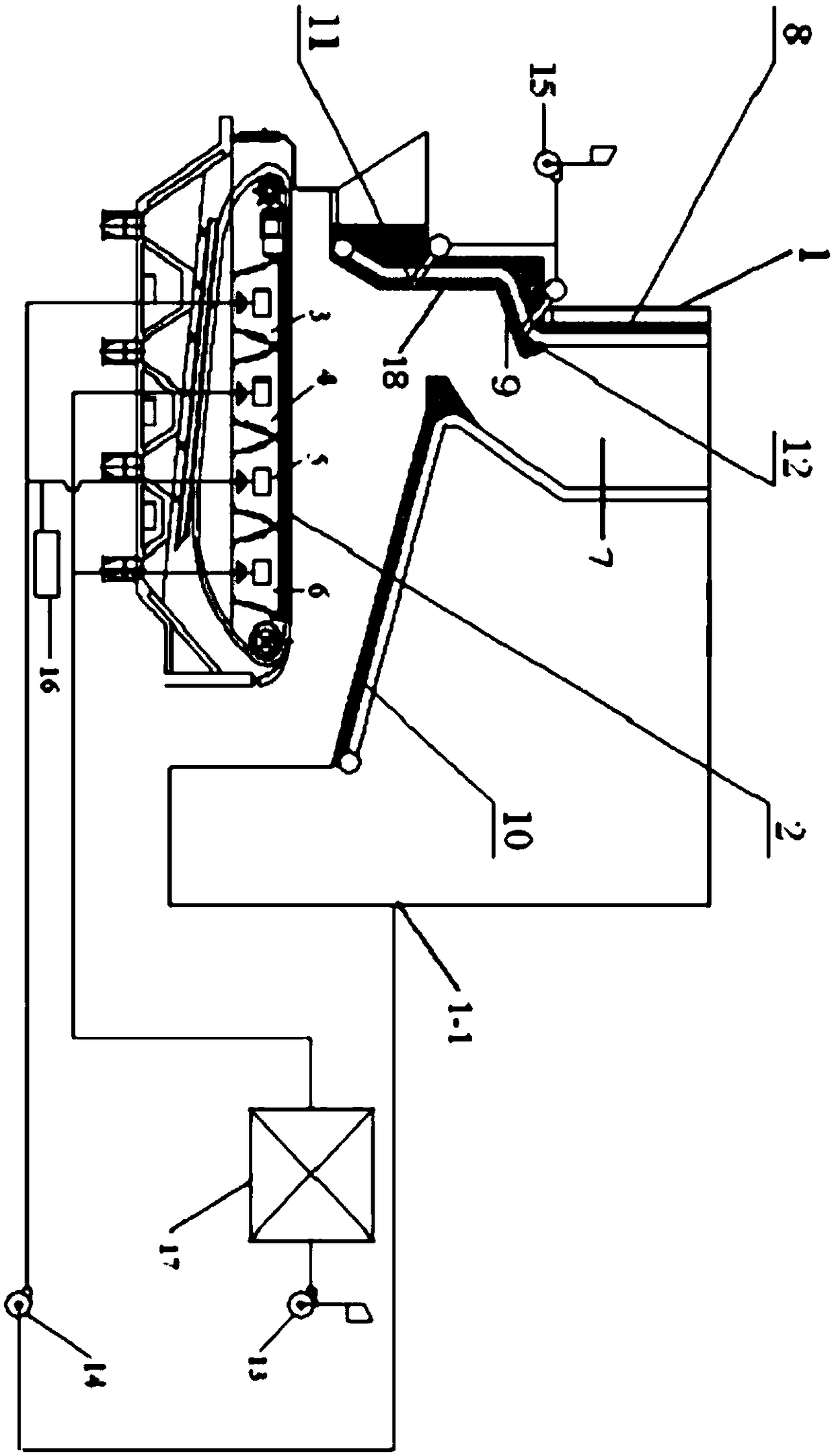

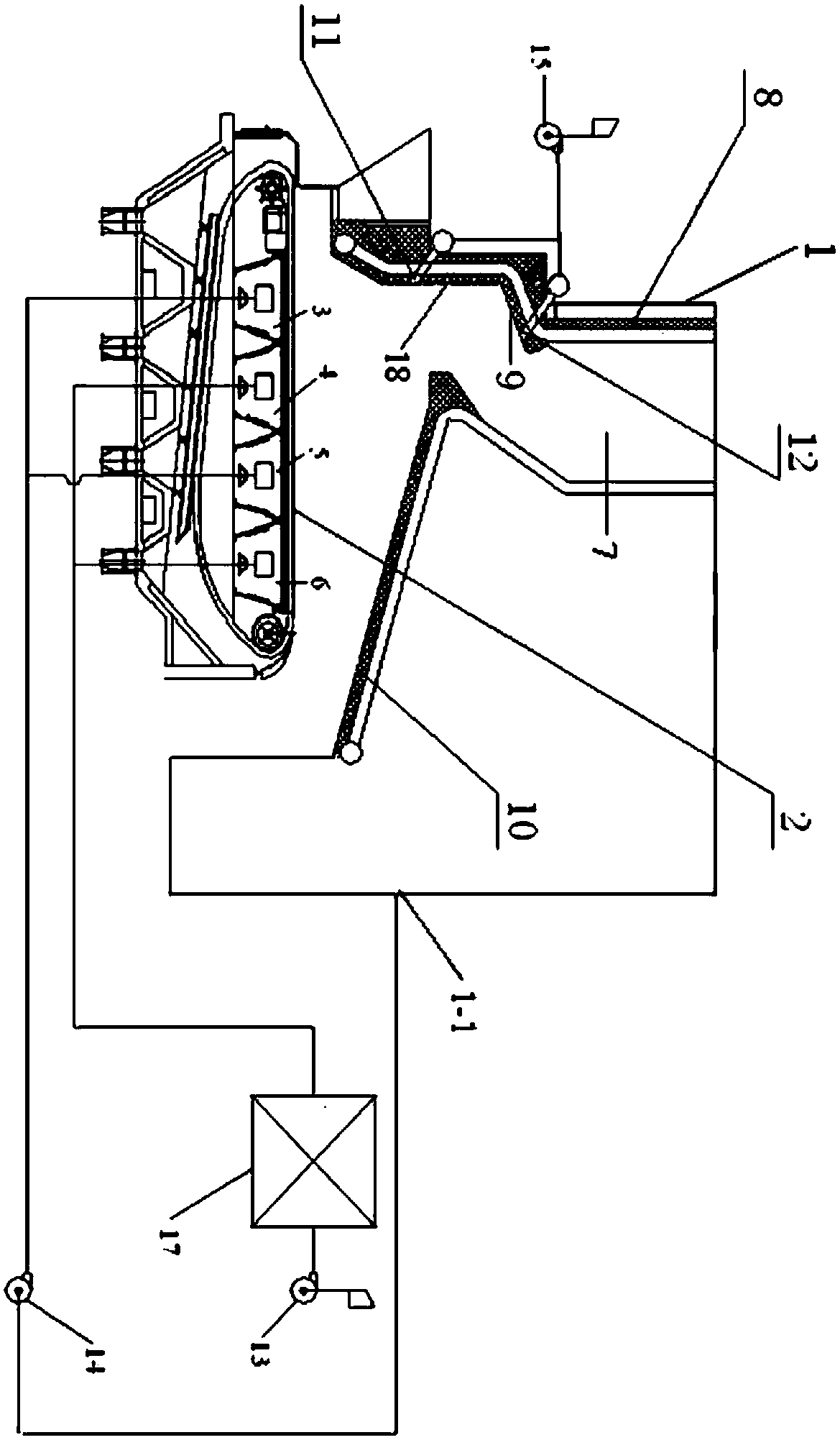

Intelligent control method of lifting trolley system of knotted reactor (KR) desulfurization

ActiveCN103421926ASolve the slag problemRealize fully automatic controlProcess efficiency improvementControl systemSlag

The invention discloses an intelligent control method of a lifting trolley system of knotted reactor (KR) desulfurization. The intelligent control method comprises the following steps: controlling the lifting trolley system by using a KR desulfurization control system to descend to a stirring position; controlling a clamping device to press a guide rail tightly to fix a lifting trolley, rotating a stirrer, adding a desulfurizing agent and gradually increasing the rotating speed of the stirrer to reach a set working speed value; after the stirring time reaches the set value, reducing the rotating speed of the stirrer to be two thirds of the working speed, loosening the clamping device and starting a winding plant so as to enable the lifting trolley to ascend to a slag throwing position; fixing the lifting trolley by using the KR desulfurization control system, rotating the stirrer until the set upper limit speed is reached and maintaining for a period of time; and after the rotating time reaches the set value, stopping a stirring device, loosening the clamping device and lifting the lifting trolley to a standby position. By the intelligent control method, fully-automatic control of the lifting trolley system can be realized, blades of the stirrer carries few slags, even no slag during normal production, production continuity is guaranteed, and production period is shortened.

Owner:WISDRI ENG & RES INC LTD

Combustion system and overhead regenerative burner

PendingCN109519920ARelease fullyTake advantage ofGaseous fuel burnerCombustion systemCombustion chamber

The invention relates to a combustion system and an overhead regenerative burner. The overhead regenerative burner comprises a nozzle, a combustion chamber, a heat accumulation chamber, a main fuel burner, an ignition burner, combustion-supporting air valves and smoke exhaust valves. According to the combustion system and the overhead regenerative burner, the nozzle downwards extends in the direction vertical to the top of a stove, so that flames sprayed from a fire spraying opening are downwards sprayed into a hearth in the direction vertical to the top of the stove, a flame channel does notneed to be reserved, hearth feeding is not limited, and the hearth space can be fully relieved and is fully utilized; molten aluminum and aluminum slags are not gathered at the fire spraying opening,the fire spraying opening is always clean and smooth, the problem that the slags are accumulated at the fire spraying hole is solved; and accumulated dust in heat accumulators can be automatically cleared without external power, and the function of prolonging the service life and maintenance period of the heat accumulators is achieved.

Owner:广州龙鑫蓄热工业炉有限公司

Multi-stage totally-enclosed mining drilling and dust removal device

The invention relates to a multi-stage totally-enclosed mining drilling and dust removal device, which comprises a box body, a gravity dust removal chamber, a water bath dust removal chamber and a spray dust removal chamber. In the coal mine drilling process, the generated dust-containing gas enters a gravity settling chamber through an air inlet, and larger granular dust is firstly removed, and discharged from a slag discharge hopper at the bottom under the action of the gravity and a baffle plate. And then the gas sequentially enters the water bath dust removal chamber and the spray dust removal chamber to realize the separation of gas and dust, and the discharge of water vapor is reduced through a gas-water separator at an air outlet. The clean gas in the gas-water separator enters an extraction pipeline, dust particles are deposited at the bottom of the container, and the dust particles are collected and discharged from a slag digging port. The multi-stage totally-enclosed mining drilling and dust removal device can effectively reduce the dust content of the construction roadway and avoid dust blocking the extraction pipeline, and has the advantages of low cost, easy operationand convenient movement.

Owner:ANHUI UNIV OF SCI & TECH

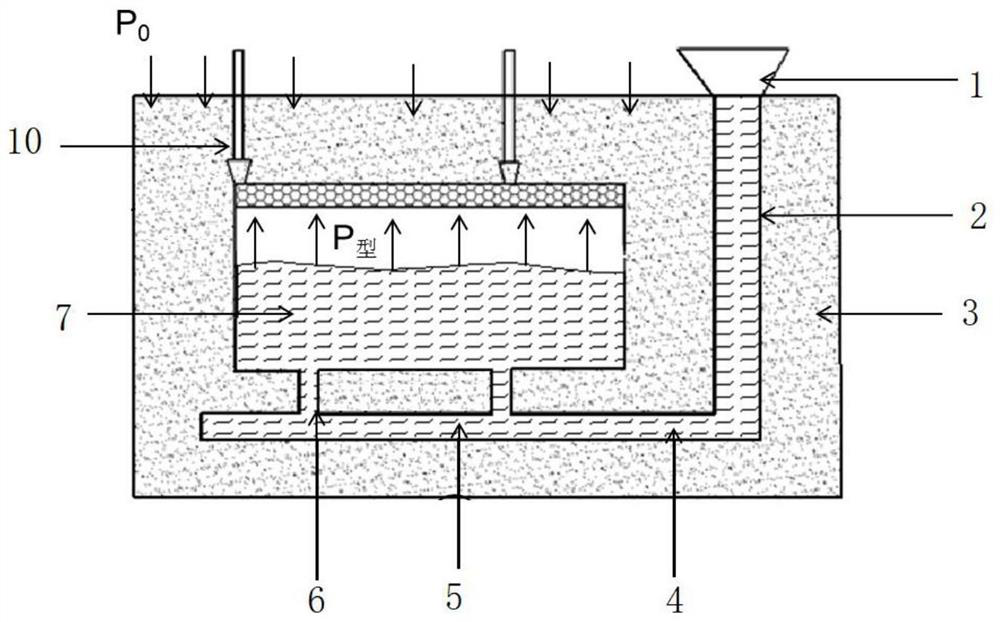

High pressure membrane anchor double uniform stream chilled glass furnace

InactiveCN101423325ASolve the slag problemPollution realizedGlass tempering apparatusSlagGlass furnace

The invention belongs to the technical field of glass tempered equipment, and particularly discloses a high-pressure transmembrane double uniform flow tempered glass furnace. The furnace comprises a furnace body and a roller path formed by rotating rollers, wherein the roller path is positioned at a furnace door of an inner cavity of the furnace body, and a high-pressure transmembrane double uniform flow system is arranged above the roller path; and the high-pressure transmembrane double uniform flow system consists of a special level convection equation device, a first level convection equation device and a second level convection equation device which are orderly arranged in the inner cavity of the furnace body from top to bottom and connected with one another by circuits. The high-pressure transmembrane double uniform flow tempered glass furnace with novel heating mode provided by the invention has the advantages of high efficiency, energy conservation and environmental protection, and successfully meets the requirement of quick heating when the Low-E glass is tempered under the U value of between 0.02 and 0.08; and more importantly, the furnace eliminates the phenomena of falling slag and flying ash of heat insulation cotton for puzzling the industry for multiple years.

Owner:江宜桥

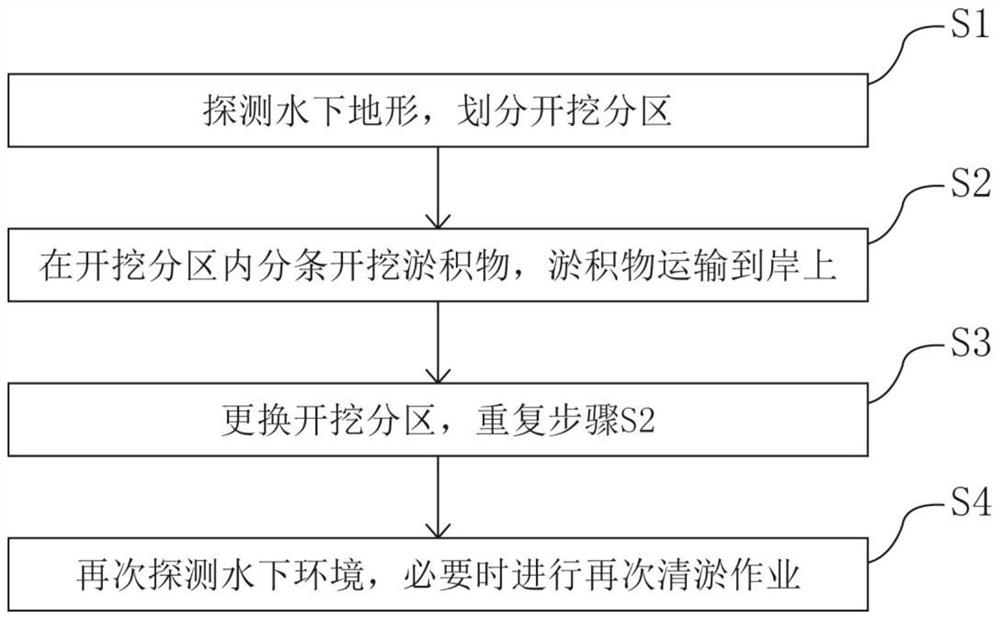

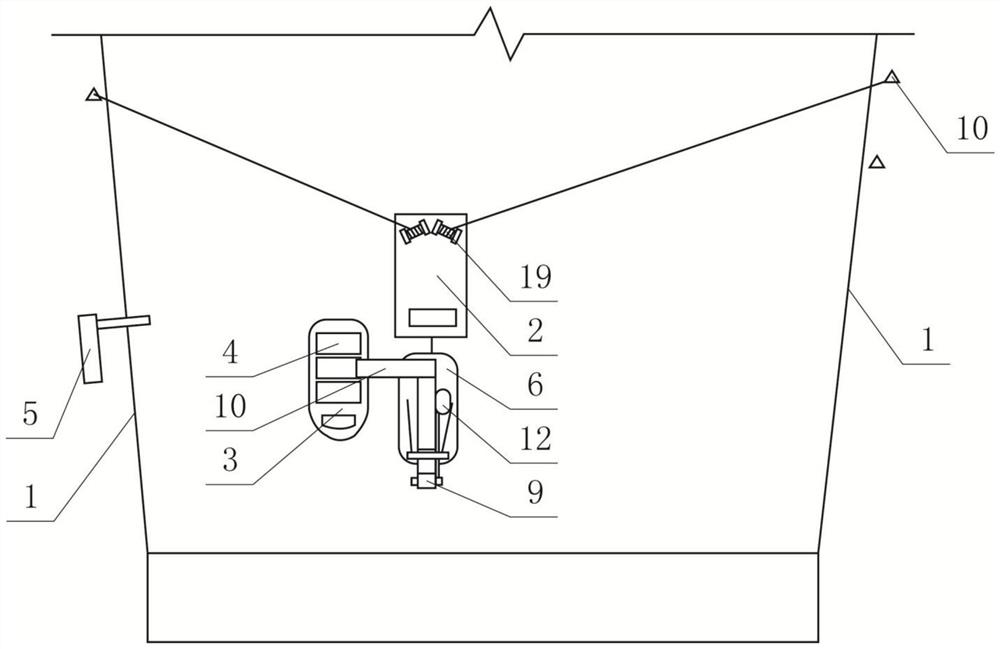

Reservoir deepwater sediment cleaning method

InactiveCN112376641ADoes not affect normal power generationDoes not affect runnabilityMechanical machines/dredgersShoreHydropower

Owner:SINOHYDRO HARBOR CO LTD

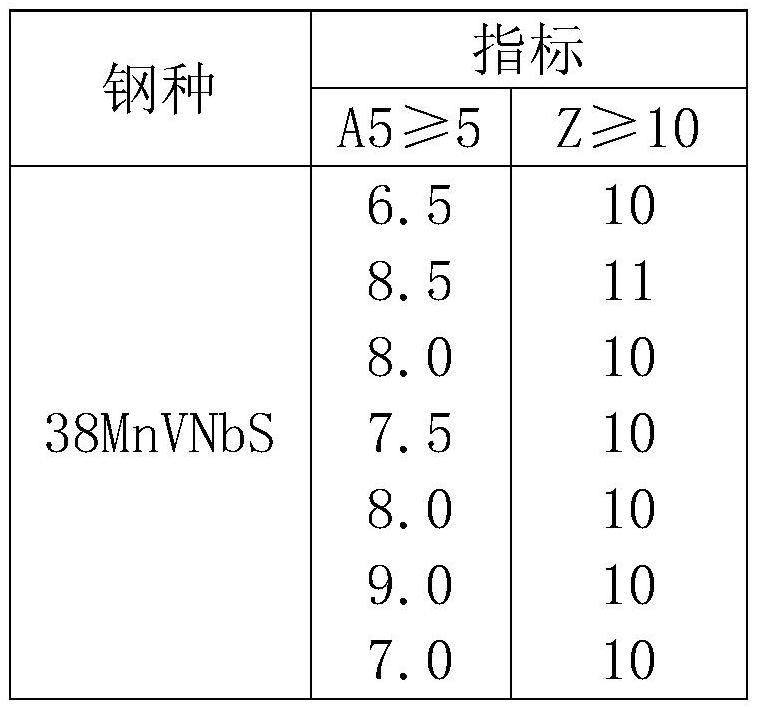

High-strength non-quenched and tempered steel connecting rod for heavy-duty car and manufacturing method thereof

InactiveCN111876682ARaise the brittle transition temperatureGrain refinementEngine componentsUltimate tensile strengthMaterials science

The invention discloses a high-strength non-quenched and tempered steel connecting rod for a heavy-duty car and a manufacturing method thereof, and mainly relates to the field of manufacturing of non-quenched and tempered steel connecting rods. The steel comprises the following components in percentage by weight: 0.30-0.50% of C, 0.40-0.70% of Si, 1.10-1.50% of Mn, less than or equal to 0.035% ofP, 0.030-0.050% of S, 0.10-0.30% of Cr, 0.05-0.15% of V and 0.015-0.040% of Nb, and the plasticity indexes are as follows: the transverse sample A5 is more than or equal to 5%, Z is more than or equalto 10%, the C segregation content is less than or equal to 15%, and the S segregation content is less than or equal to 25%. The manufacturing method has the beneficial effects that the manufacturingprocess of the connecting rod can be greatly simplified, the strength of the produced connecting rod is higher, and correction is more convenient.

Owner:SINO TRUK JINAN POWER

A kind of carbon fiber composite ball and preparation method thereof

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

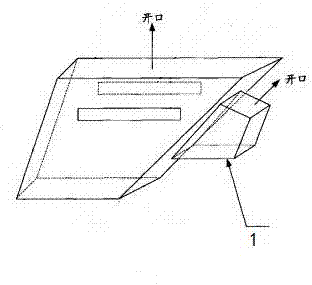

Hidden exhaust structure, gating system and casting method of large casting

The invention discloses a hidden exhaust structure of a large casting. The hidden exhaust structure of the large casting comprises a sand box; a runner and a mold cavity which communicate with each other are formed in the sand box; an exhaust component is further embedded in the sand box; the exhaust component is arranged above the mold cavity; the exhaust component comprises a plurality of sublimable air outlet strips which are arranged in parallel at intervals; a plurality of sublimable air outlet blocks are arranged on each air outlet strip at intervals; and the air outlet blocks communicate with the mold cavity. According to the hidden exhaust structure of the large casting, by means of a gating system and a technology of controlling the pressure of the mold cavity through molded surface hidden exhaust, the overall pressure value in the mold cavity is adjusted, uniform distribution of pressure is guaranteed, stable release of the pressure of the mold cavity is achieved, and later molten iron turbulence slag entrapment is avoided.

Owner:东风汽车零部件集团有限公司通用铸锻分公司

Machining method for magnetic steel precision part

The invention provides a machining method for a magnetic steel precision part. The machining method comprises the following steps that a, an adhesive for part clamping is selected and prepared; b, the part is clamped in an adhesive method; and c, grinding parameters are optimized, and the part is flatly ground and machined. According to the machining method for the magnetic steel precision part, the part clamping and locating manner is improved, the machining parameters are optimized, so that the problems of edge breakage and scaling-off during magnetic steel part machining are effectively solved, and the machining precision and surface quality of the part are improved.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

Intelligent control method of kr desulfurization lifting trolley system

ActiveCN103421926BSolve the problem of slaggingRealize fully automatic controlProcess efficiency improvementSlagControl system

The invention discloses an intelligent control method of a lifting trolley system of knotted reactor (KR) desulfurization. The intelligent control method comprises the following steps: controlling the lifting trolley system by using a KR desulfurization control system to descend to a stirring position; controlling a clamping device to press a guide rail tightly to fix a lifting trolley, rotating a stirrer, adding a desulfurizing agent and gradually increasing the rotating speed of the stirrer to reach a set working speed value; after the stirring time reaches the set value, reducing the rotating speed of the stirrer to be two thirds of the working speed, loosening the clamping device and starting a winding plant so as to enable the lifting trolley to ascend to a slag throwing position; fixing the lifting trolley by using the KR desulfurization control system, rotating the stirrer until the set upper limit speed is reached and maintaining for a period of time; and after the rotating time reaches the set value, stopping a stirring device, loosening the clamping device and lifting the lifting trolley to a standby position. By the intelligent control method, fully-automatic control of the lifting trolley system can be realized, blades of the stirrer carries few slags, even no slag during normal production, production continuity is guaranteed, and production period is shortened.

Owner:WISDRI ENG & RES INC LTD

An anti-slagging biomass cascade conversion combustion device

ActiveCN106594713BPrevent slaggingThermochemical conversion achievedSolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterWater vapor

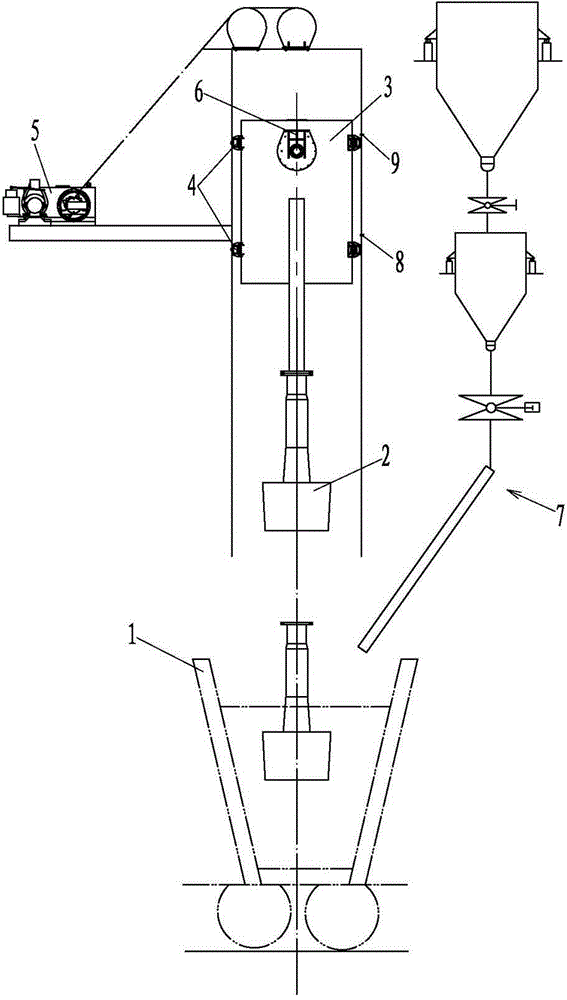

The invention provides an anti-slagging biomass cascade conversion combustion device and relates to a biomass combustion device. The anti-slagging biomass cascade conversion combustion device aims at solving the technical problem that slagging happens easily when straw is combusted through an existing chain furnace. The anti-slagging biomass cascade conversion combustion device is composed of a chain furnace, a steam generator, an air blower, a high-temperature induced draft fan and an air preheater. A secondary air nozzle is arranged on the front wall below a front arch. An overfire air nozzle is arranged on the front arch. A circulating flue gas chamber communicates with a flue opening in the tail of the chain furnace through the high-temperature induced draft fan. A weak primary air chamber communicates with the air blower through the air preheater. A steam-circulating flue gas chamber communicates with the steam generator and the high-temperature induced draft fan. A strong primary air chamber communicates with the air blower through the air preheater. The secondary air nozzle communicates with the air blower. The overfire air nozzle communicates with the air blower. The anti-slagging biomass cascade conversion combustion device effectively solves the problem of slagging of biomass combustion chain grates.

Owner:HARBIN INST OF TECH

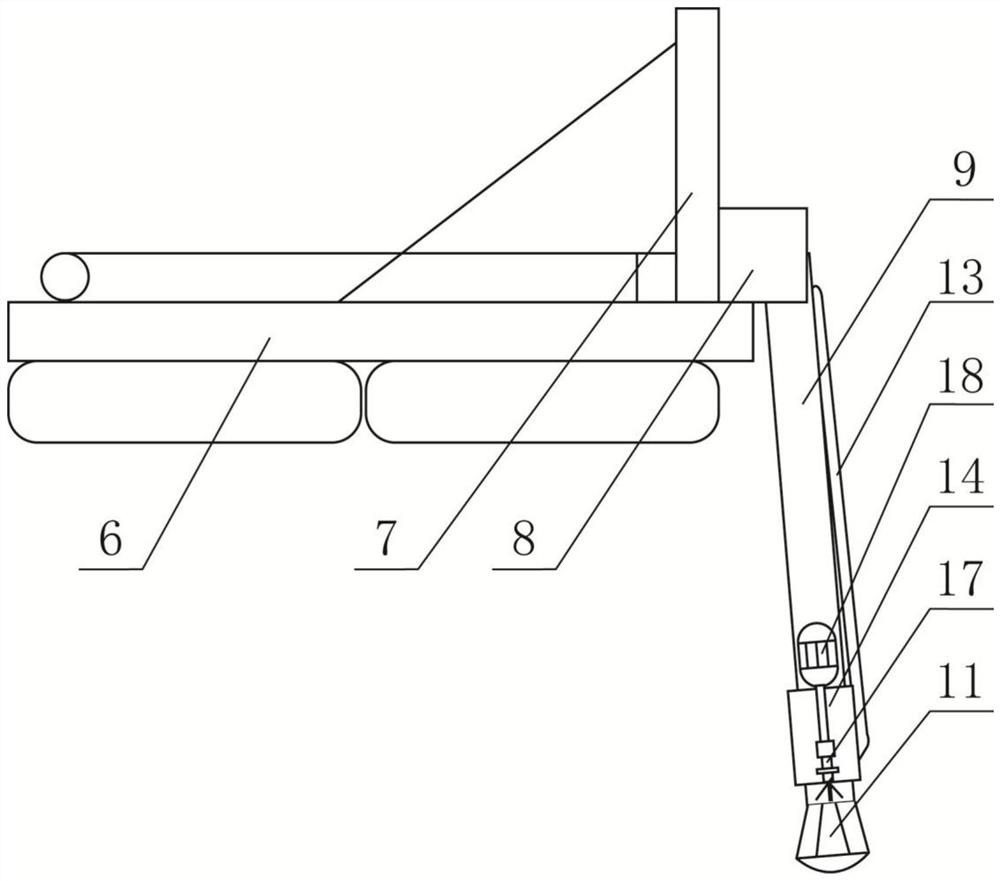

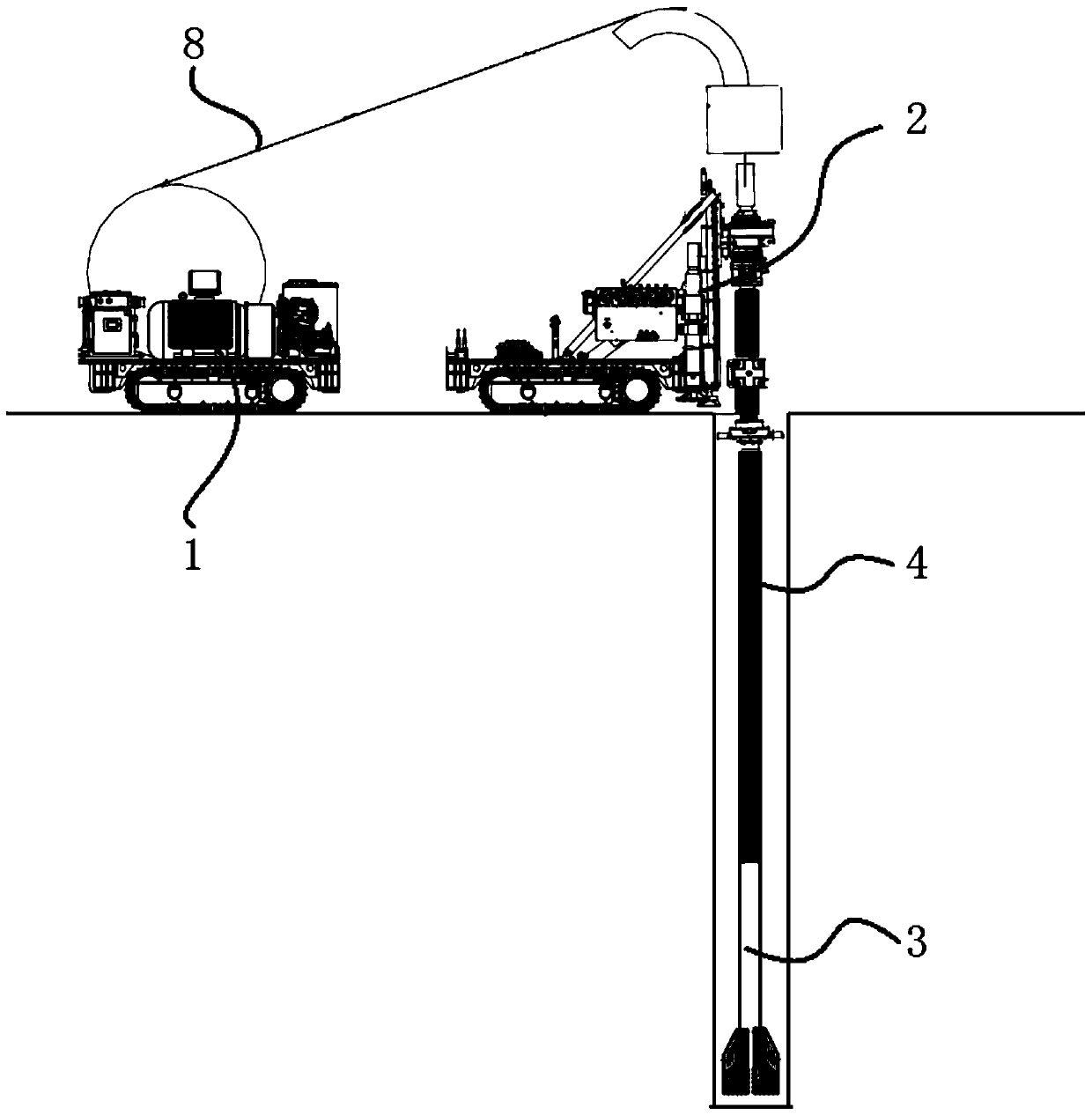

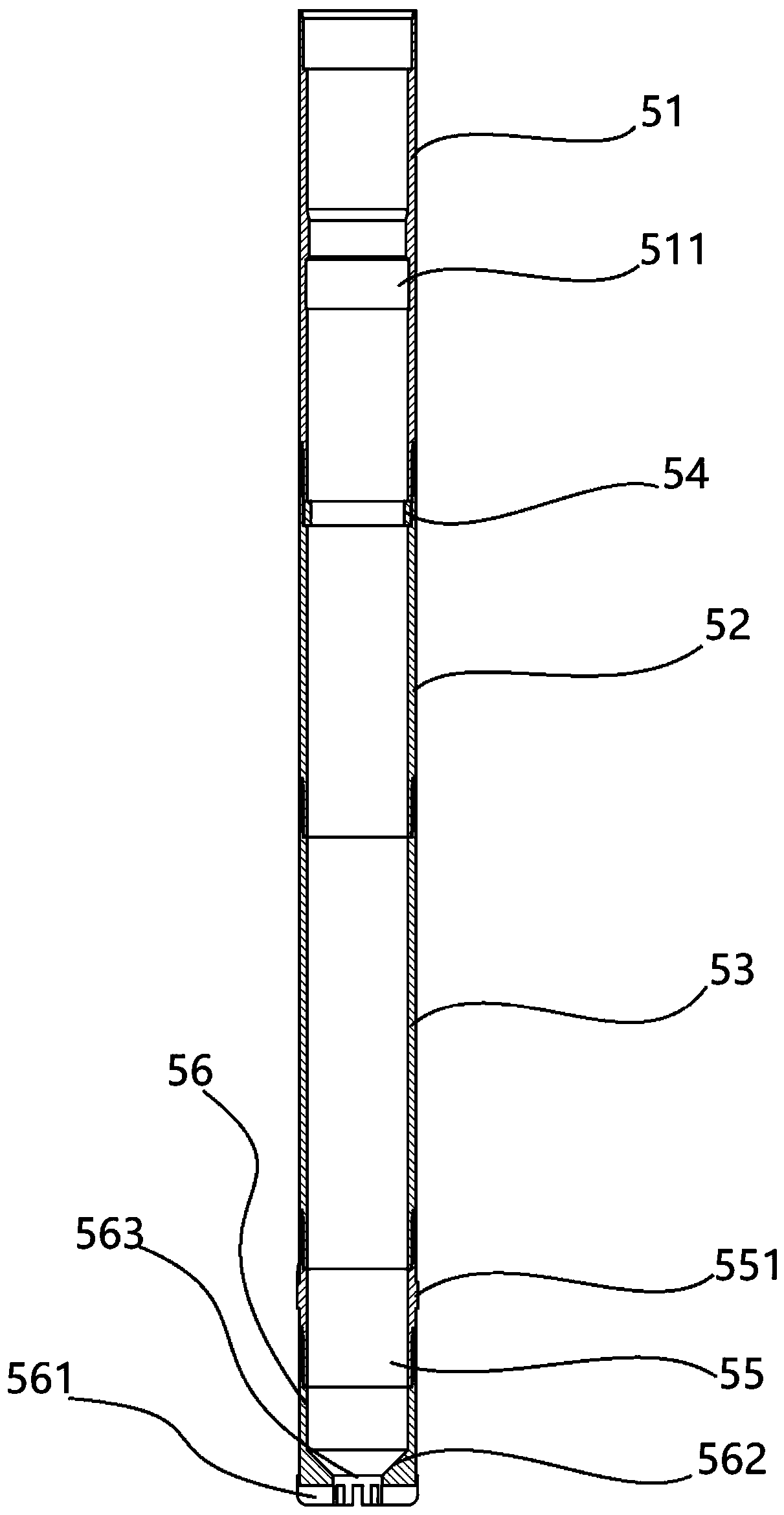

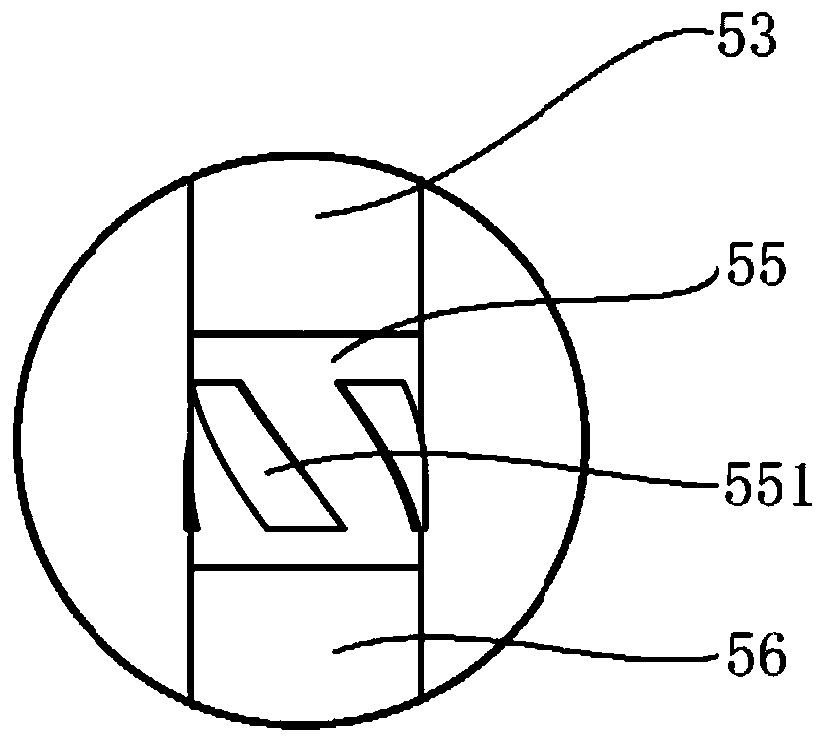

Dry drilling slag salvaging operation device and use method thereof

ActiveCN111502581ASolve the problem of slaggingProcess stabilityDrilling rodsDrilling casingsSlagStructural engineering

The invention discloses a dry drilling slag salvaging operation device and a use method thereof. The dry drilling slag salvaging operation device comprises continuous guide pipe operation equipment and a slag salvaging device. The continuous guide pipe operation equipment comprises a transmission device, and the transmission device comprises an injection head and an underground drill rig. The slagsalvaging device comprises an inner pipe assembly and an outer pipe assembly, the outer pipe assembly is connected with the underground drill rig through a drill rod, the inner pipe assembly is connected with a continuous guide pipe, the inner pipe assembly is connected with the outer pipe assembly in a clamping mode, the inner pipe assembly comprises an inner pipe assembly and a central assembly, and a self-gravity valve is arranged at the bottom of the inner pipe assembly. According to the dry drilling slag salvaging operation device and the use method thereof, the slag salvaging problem ofdry drilling coring operation is solved, and smooth operation of the dry drilling coring operation is ensured.

Owner:SHENZHEN UNIV

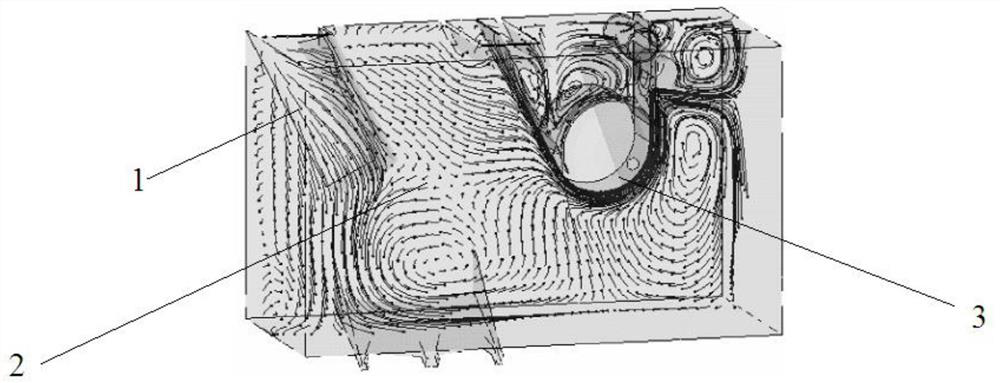

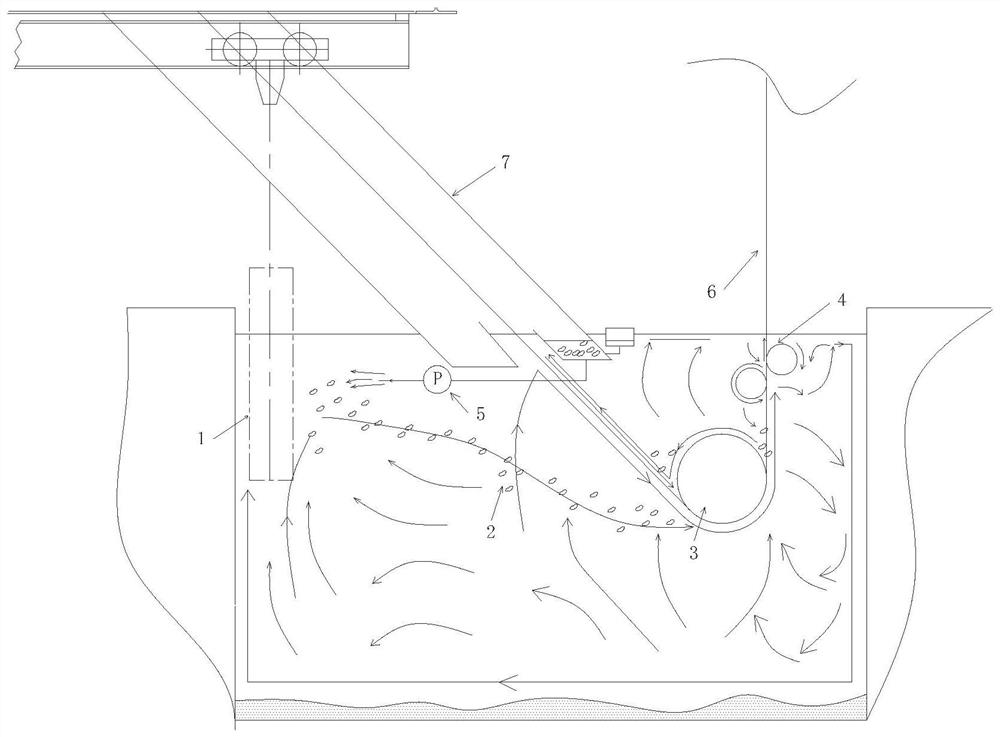

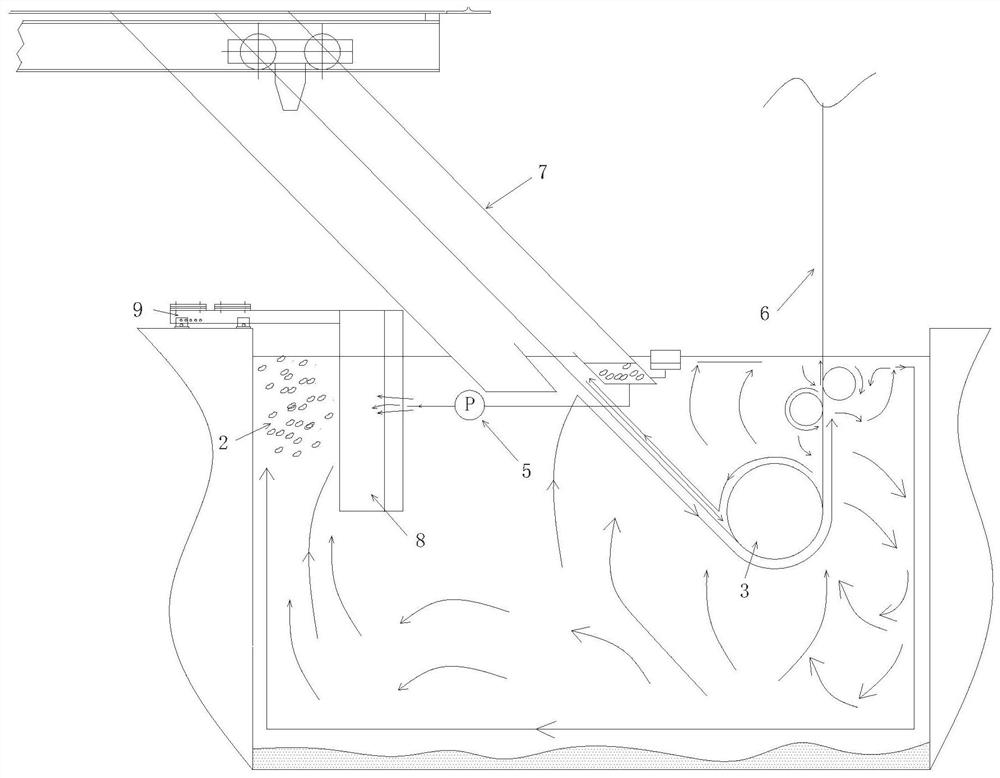

A system for reducing slag accumulation and steady flow in zinc pot rolls

ActiveCN109423589BReduce slag accumulation and stabilize flowSolve the problem of slaggingHot-dipping/immersion processesSlagIngot

The invention discloses a system for reducing zinc pot roller accumulated slag and stabilizing flow. The system comprises a separating plate arranged in a zinc pot, the separating plate is arranged between the rear side surface of a furnace nose and the inner wall of the zinc pot, the separating plate comprises a first slab part, a second slab part and a third slab part, the first slab part extends in the width direction of the zinc pot, the two ends of the first slab part in the width direction of the zinc pot are the first end and the second end, and the first slab part is provided with a first side surface facing the rear side surface of the furnace nose and a second side surface facing the inner wall of the zinc pot; at the first end, the second slab part obliquely extends from the first side surface of the first slab part to the rear side surface of the furnace nose; and at the second end, the third slab part extends from the second side surface of the first slab part to the innerwall of the zinc pot. According to the system for reducing the zinc pot roller accumulated slag and stabilizing flow, through arrangement of the separating plate, the influence of a zinc slag flow field in the zinc pot on an alloy layer in a sinking roller ditch groove is eliminated, and thus the problem of separation of suspending slag and zinc slag discharged by a liquid zinc pump due to the temperature difference of zinc ingots is solved, and the growth of a sinking roller surface alloy layer is accelerated.

Owner:宝钢日铁汽车板有限公司

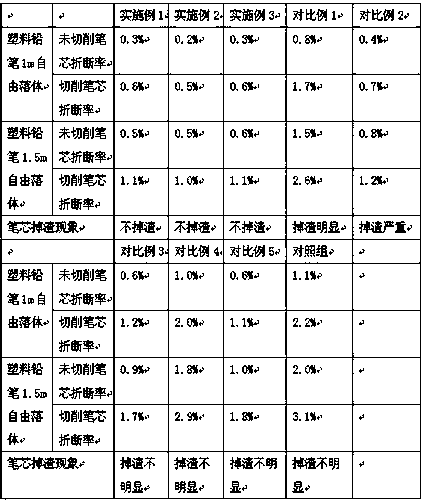

Modified plastic particle for graphite pencil lead of plastic pencil

The invention discloses a modified plastic particle for a graphite pencil lead of a plastic pencil. A preparation method is as follows: 1) performing micro-foaming treatment on a polymer plastic particle to obtain a micro-foamed polymer plastic particle; 2) adding a cellulose aqueous solution into a prepared alumina sol, and performing uniform stirring to obtain a composite sol solution; 3) dropwise adding ammonia water into the composite sol solution, performing mixing and stirring, and then adding the micro-foamed polymer plastic particle into the composite sol solution for vacuum impregnation treatment to obtain a composite gel / micro-foamed polymer composite plastic particle; and 4) performing solvent replacement and freeze-drying on the obtained composite plastic particle. The modifiedplastic particle prepared by the invention can be widely used in a formula of a graphite pencil lead of plastic pencils, can effectively solve the problems of easy breakage and slag dropping of the pencil lead, can also improve the writing comfort of pencils, and has good market application prospects.

Owner:安徽得亿文教用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com